Patents

Literature

114results about How to "Reduce overgrinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reverse/direct flotation technology of collophanite

The invention discloses a reverse / direct flotation technology of collophanite. The technology comprises the following steps of: performing ore reduction, ore grinding and size mixing on the silicon calcium type collophanite; adding a carbonate gangue mineral flotation regulator and fatty-acid soap respectively to perform size mixing; performing reverse flotation on the material after the size mixing, wherein the product in the tank is reverse flotation concentrate; dehydrating the reverse flotation concentrate and adding sodium carbonate so as to adjust the pH value to 8-10; performing closed-loop ore grinding and grading on the base flow; enabling the grading overflow to enter a direct flotation stirring tank, and adding water glass and fatty acid soap into the tank respectively to perform size mixing; performing direct flotation on the material subjected to the size mixing, wherein the direct flotation foam product is direct flotation concentrate; and performing concentration, filtration and drying to obtain the finished product of phosphate concentrate. After dehydration (reagent removal), the technology disclosed by the invention can be used for remarkably reducing the amount of sodium carbonate for neutralizing acid water; the sodium carbonate has a dispersion and grinding aid function, and the over-grinding of the material of direct flotation can be reduced; and the fresh surface and proper size composition generated by the ore grinding are favorable for improving the sorted behavior of the direct flotation and improving the sorting efficiency.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

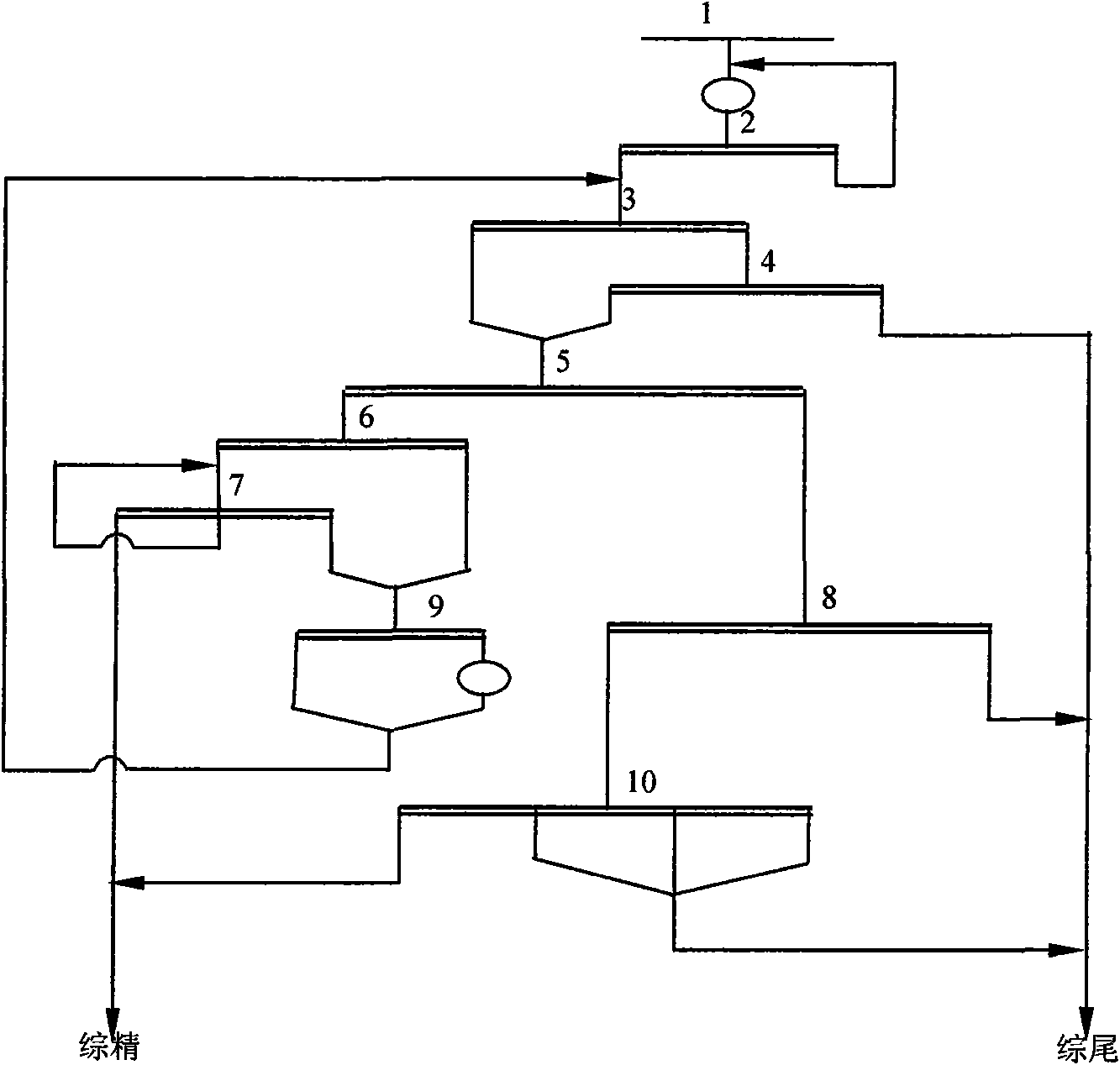

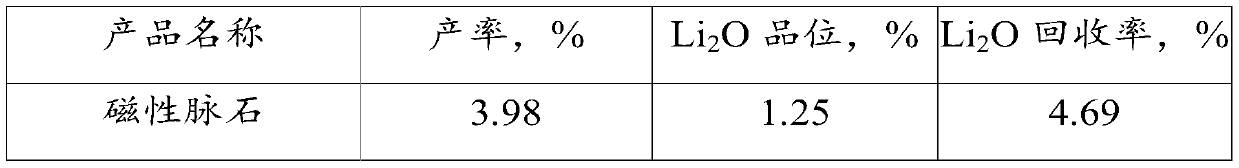

Benefication technology of extra poor hematite

ActiveCN101927209AReduce the amount of regrindReduce overgrindingWet separationOre concentrateBall mill

The invention relates to a benefication technology of extra poor hematite, which is characterized by comprising the following steps: feeding a raw ore in a closed circuit grinding system composed of a primary ball mill and a spiral classifying mechanism, feeding in a weak magnetic machine for benefication after primary classification and overflow, feeding the weak magnetic tailing in a strong magnetic machine, feeding a mixed magnetic concentrate composed of a weak magnetic concentrate and a strong magnetic concentrate in a spiral chute, obtaining a selected spiral concentrate as a coarse grain concentrate after the coarse grains are subjected to two-stage spiral chute benefication, performing self-circulation on the middling in the selected spiral chute, forming the middling by a roughly selected spiral tailing and a selected spiral tailing, feeding the middling in an open circuit grinding system composed of secondary classifying and secondary grinding for re-grinding, returning to the weak magnetic machine after re-grinding, feeding the overflow of a swirler after benefication of a centrifuge into a table for benefication, merging a table middling, table slurry and a table tailing into a table tailing, merging the strong magnetic tailing, a centrifugal tailing and a table tailing as a final tailing, and merging the selected spiral chute concentrate and the table concentrate into a final concentrate. The invention can improve the milling grade of follow-up operations of the extra poor hematite, reduce the re-grinding amount of the middlings, and is favor of acquiring better beneficiation indexes.

Owner:鞍钢集团矿业设计研究院有限公司

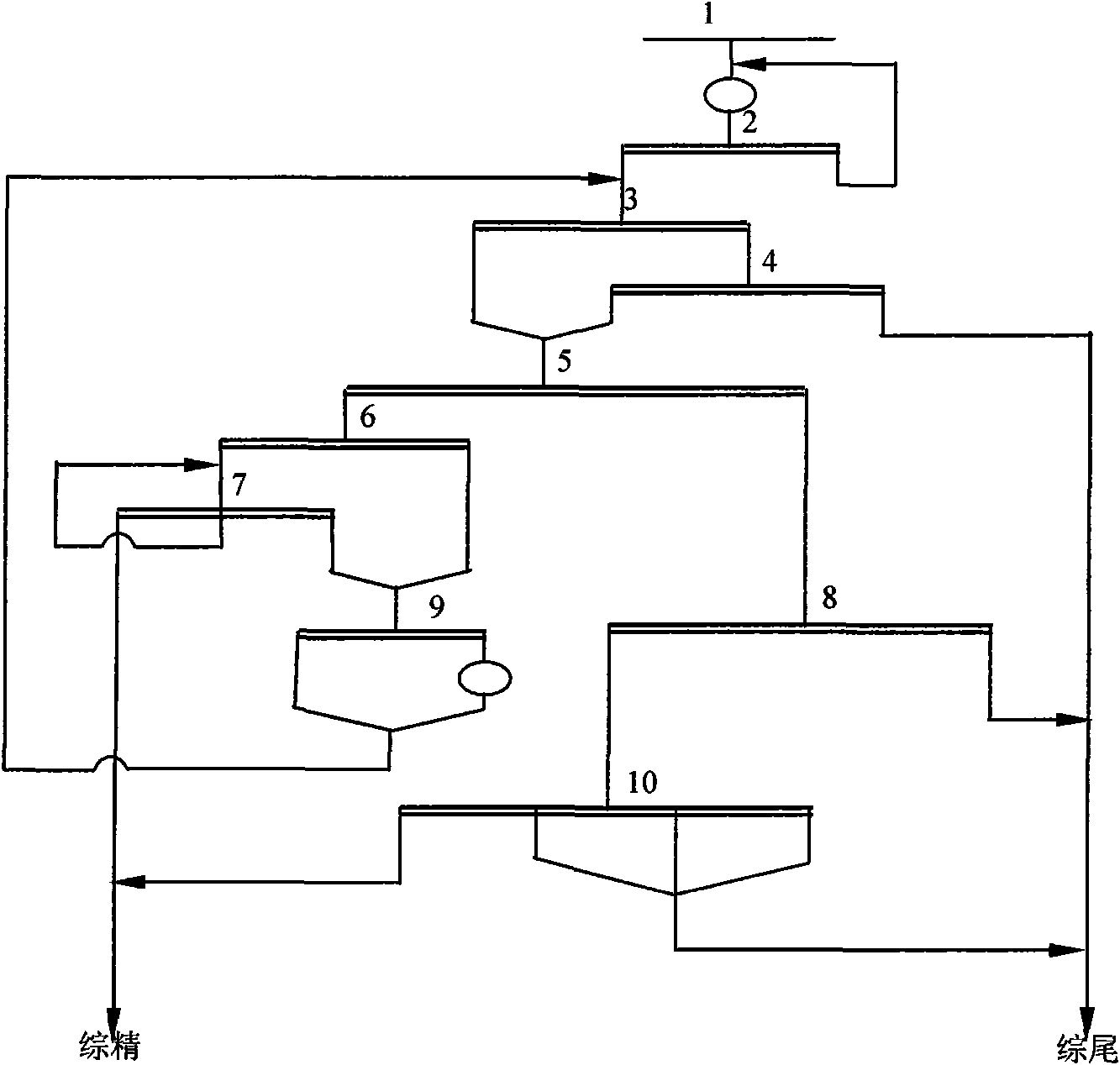

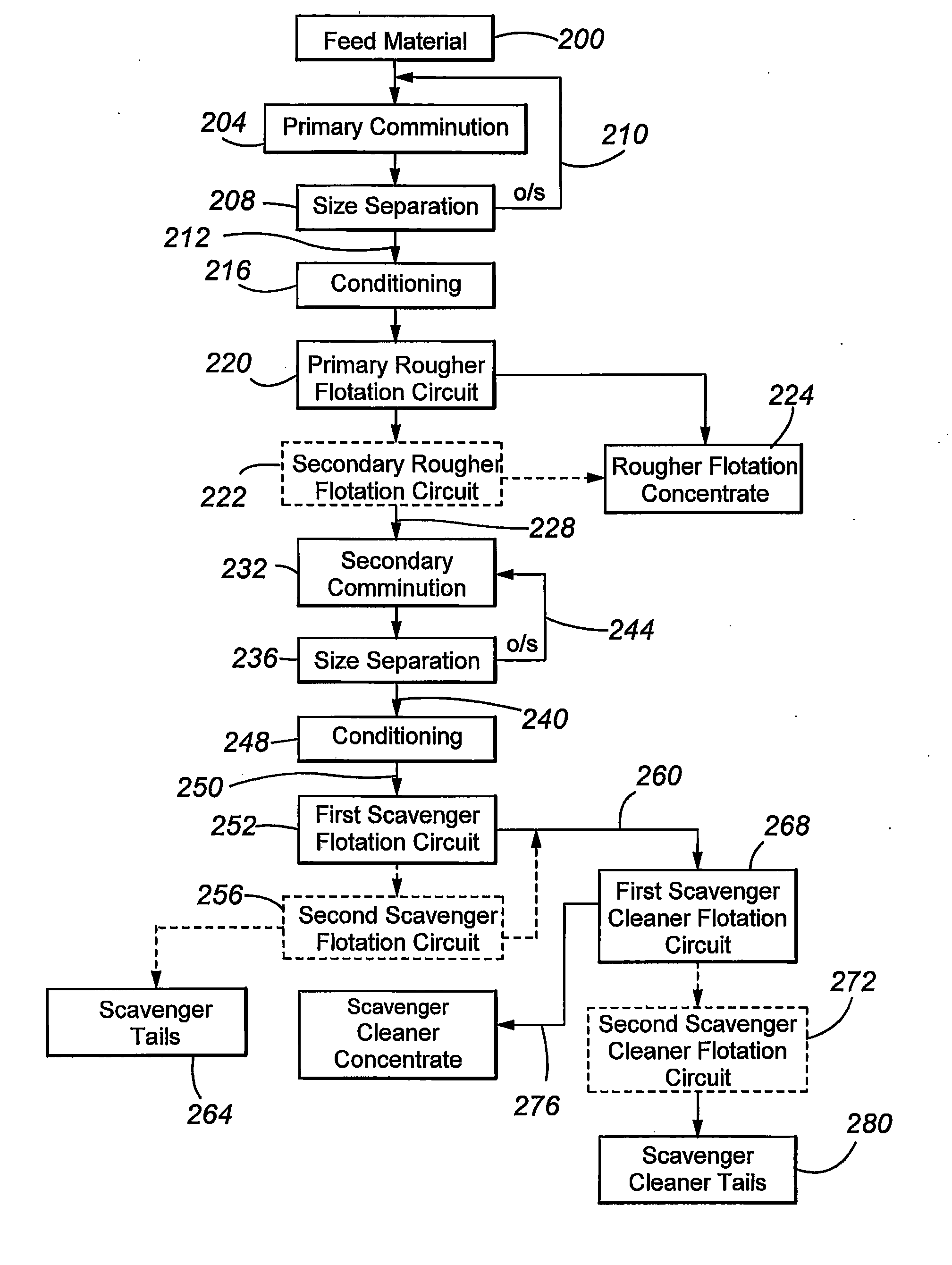

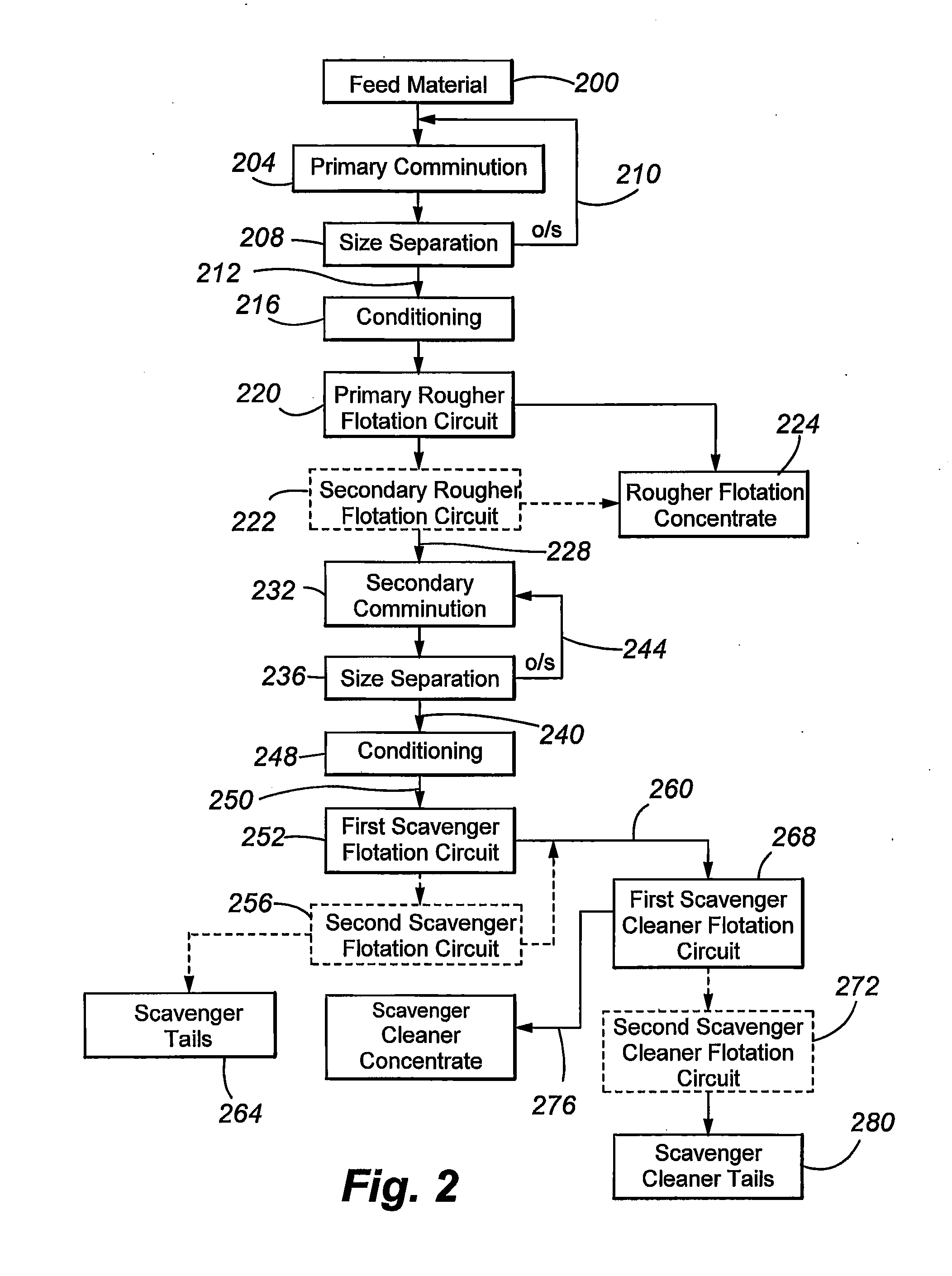

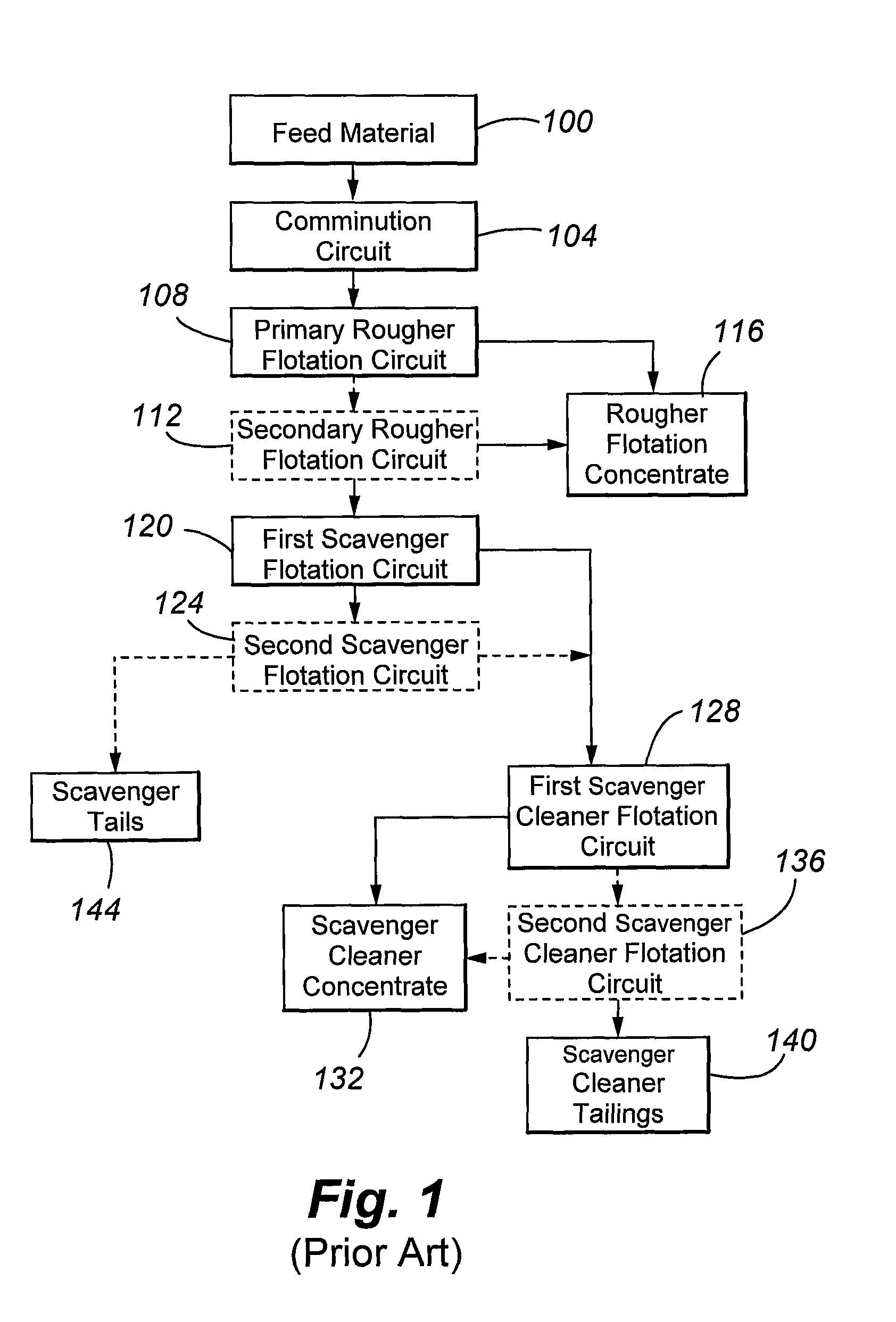

Process for recovering gold and silver from refractory ores

ActiveUS20090074607A1High goldHigh silver recoveryPhotography auxillary processesGold compoundsSulfideMaterials science

The present invention is directed to flotation of refractory gold sulfide ores in which the ore is ground, floated, the tailings reground, and refloated to produce gold-bearing concentrates.

Owner:BARRICK GOLD

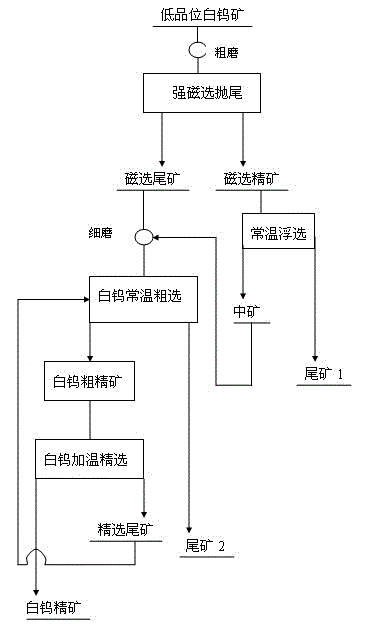

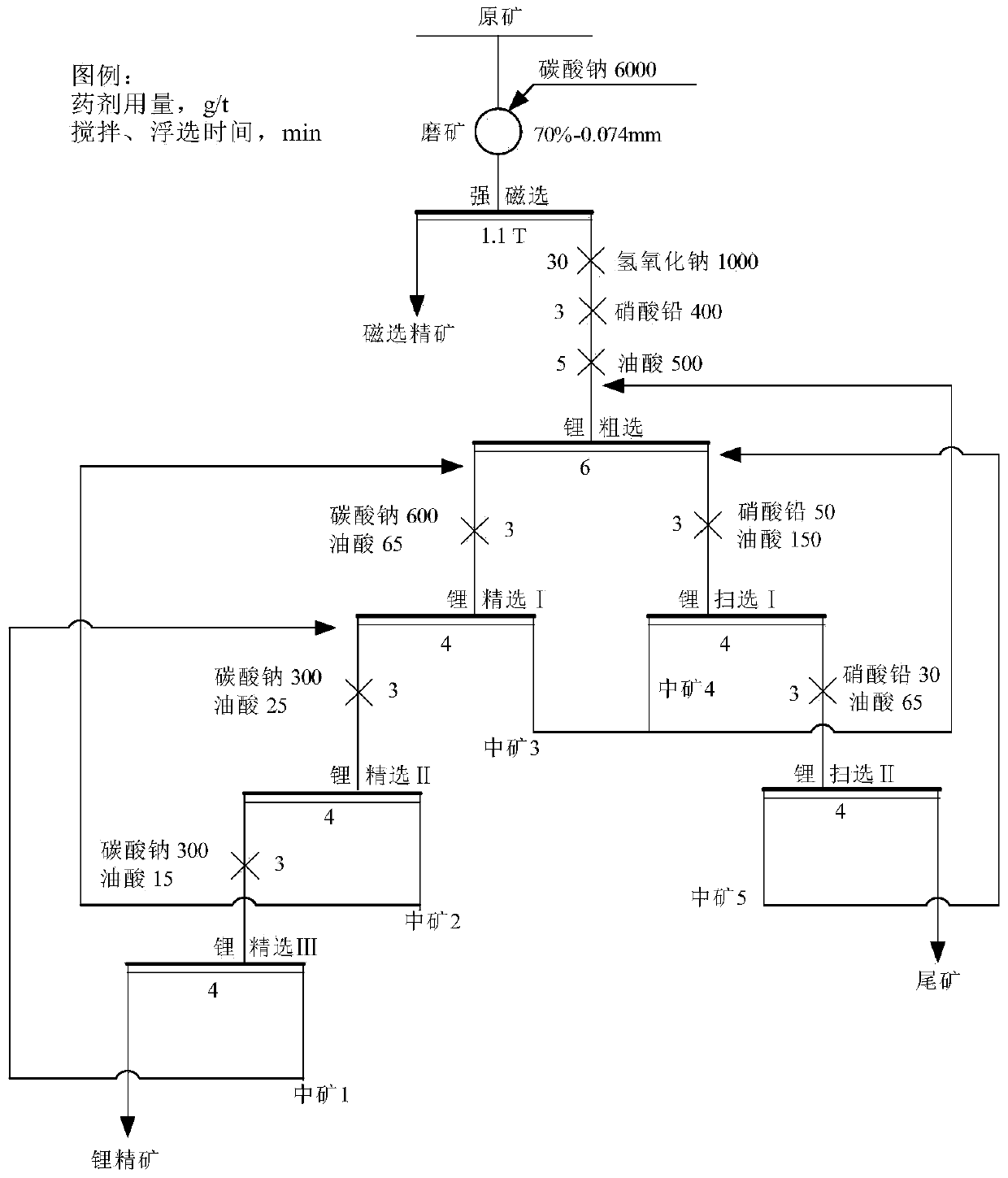

Scheelite beneficiation method

ActiveCN102909130AWith weak magneticEfficient separationFlotationMagnetic separationTotal recoveryMaterials science

The invention discloses a scheelite beneficiation method. The scheelite beneficiation method comprises the steps of: roughly grinding raw mineral with no need of desliming; screening the raw mineral in a sieve with 200-250mu m, roughly grinding the material on the sieve again, carrying out strong magnetic separation and discarding on the mineral under the sieve, wherein mainly magnetic garnets and other magenetic minerals are mainly discarded; carrying out scheelite normal temperature flotation on the nonmagnetic mineral after the nonmagnetic mineral is finely ground; carrying out scheelite warming flotation on concentrate obtained after the rough flotation to obtain scheelite concentrate; and carrying out normal temperature floatation on discarded magnetic concentrate, adding flotation middlings into the nonmagnetic scheelite concentrate to be finely ground. The scheelite beneficiation method aims at the mineral characteristics of the scheelite, the raw mineral contains a large amount of weak magnetism calcium and iron garnet gangue, so the recovery rate can be influenced due to the argillization caused by excessive grinding. The scheelite beneficiation method utilizes a ferromagnetic beneficiation method to effectively separate the magnetic ores, so that the excessive grinding condition is lowered, and the scheelite is preliminarily separated and beneficiated. The scheelite beneficiation method can enhance the mineral grinding efficiency, reduces the mineral grinding energy consumption, enhance the selection grade of the scheelite, reduces the beneficiation amount of the flotation, lowers the dosage of flotation reagents, and enhances the total recovery rate of the scheelite. The scheelite beneficiation method is especially suitable for medium grade and low grade scheelite beneficiation.

Owner:ZHONGXIANG TUNGSTEN IND

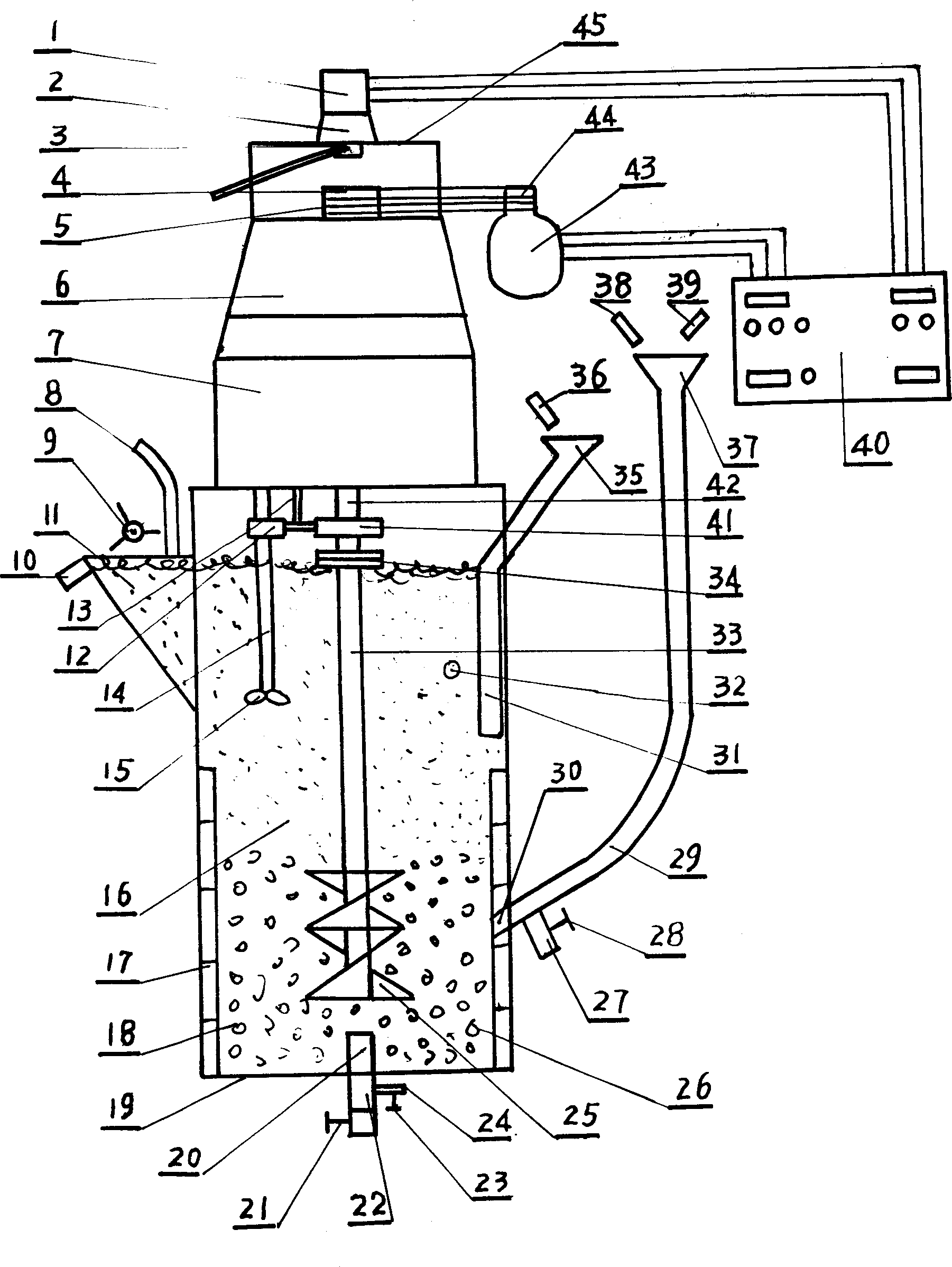

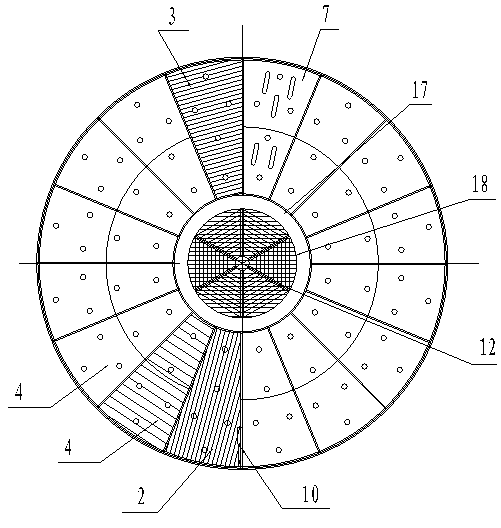

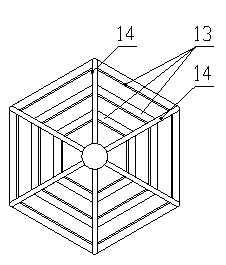

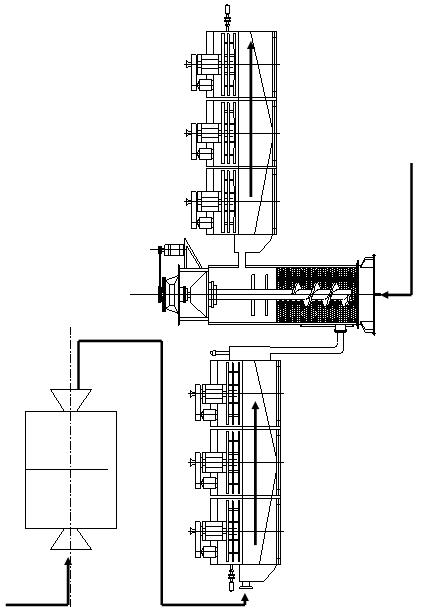

Tower type grinding flotation machine capable of carrying out grinding while flotation separation

A tower-type grinding floatation machine for grinding and hydrosizing ore at same time is composed of tower-type main body divided into upper floatation regino and lower grinding-hydrosizing region, screw stirrer, and drive mechanism. Said lower grindnig-hydrosizing region contains screw stirrer and grinding medium. Its advantages are multiple function, simple structure, and high recovery yield.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

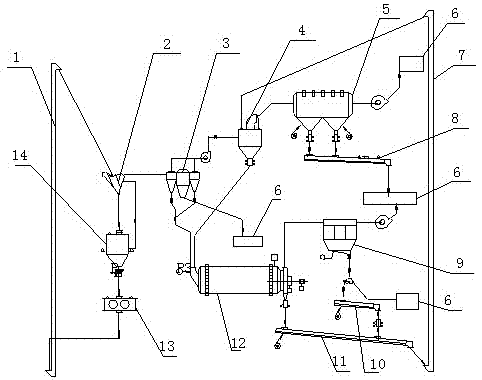

Combination cement grinding system

ActiveCN102950056AReduce overgrindingProne to overgrindingCement productionGrain treatmentsProcess engineeringCement grinding

The invention provides a combination cement grinding system. The combination cement grinding system mainly comprises a hoister, a roll squeezer, a first powder concentrator, a third powder concentrator, a ball grinder and a bag type dust collector; the combination cement grinding system mainly comprises two circulating systems, the first circulating system comprises a steady flow bin, a hoister, a roll squeezer, the first powder concentrator and a second powder concentrator; and the second circulating system comprises the second powder concentrator, the ball grinder, the third powder concentrator, two conveyors and the hoister. The finished cement contained in materials extruded by the roll squeezer through the system are separated out, the powder grinding phenomenon of the ball grinder can be reduced, the system yield can be improved, and proved by production, the production of the system can be increased by more than 10%, and electricity consumption is reduced.

Owner:阿克苏天山多浪水泥有限责任公司

Method for producing calcined kaolin with high covering power

ActiveCN104556078AGood storage stabilityGood dispersionAluminium silicatesKaoliniteParticle-size distribution

The invention discloses a method for producing calcined kaolin with high covering power and belongs to the technical field of calcined kaolin. The invention provides a method for producing calcined kaolin which is high in whiteness, superfine in grain size and centralized in particle size distribution and has the advantages of high oil absorption amount and high covering power. The method for producing calcined kaolin with high covering power provided by the invention comprises the following steps: performing dosing, coarse crushing, milling, pulping, horizontal screwing, disc treatment, filter pressing and spray drying on coal gangue or kaolinite rock, crushing and reducing the aggregated spray, calcining for performing decarbonizing and whitening, crystal water removal and forming a gap structure, and finally, aggregating the depolymerized and calcined materials, thereby obtaining the finished product. The method disclosed by the invention is mainly applied to the aspect of kaolin.

Owner:山西金宇科林科技有限公司

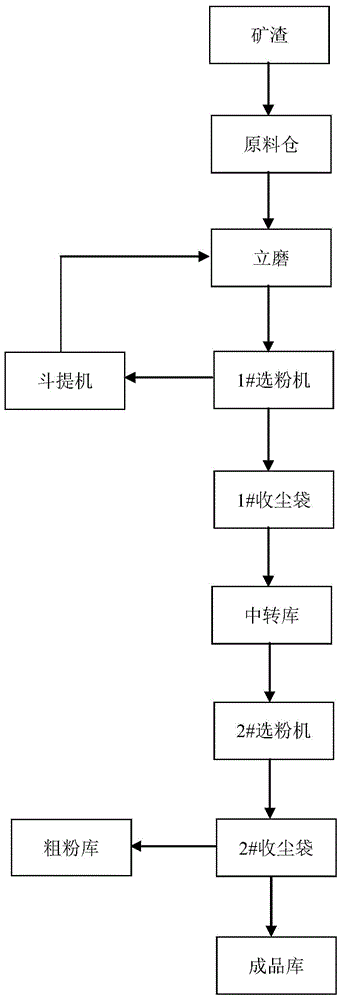

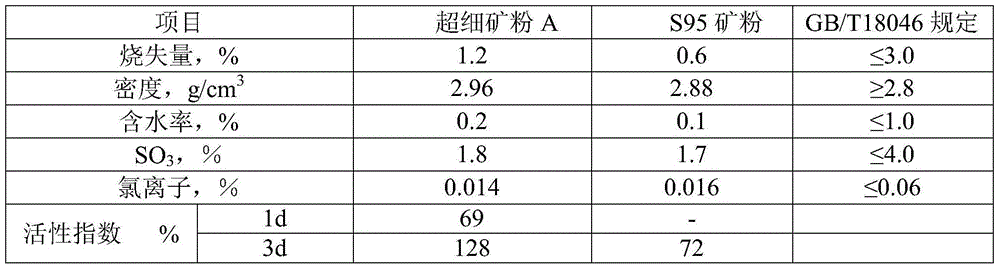

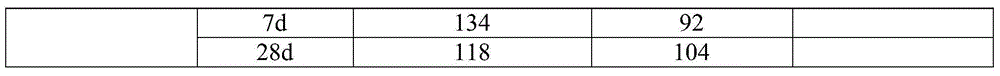

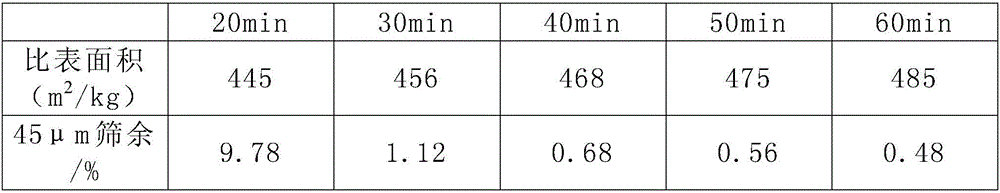

Ultrafine slag powder, and preparation method and application thereof

InactiveCN104478269AImprove finenessHigh activitySolid waste managementSlagUltimate tensile strength

The invention belongs to the field of comprehensive utilization of solid waste resource, and especially relates to an ultrafine slag powder, and a preparation method and application thereof. Vertical-milling grinding and two stages of sorting technologies are combined, a slag pre-grinded material subjected to vertical milling is subjected to a first stage of grading processing, so that a mineral powder with the specific surface area according with a requirement is sorted out, and unqualified slag crude powder falls into a vertical mill for grinding. The slag powder according with the requirement is subjected to a second stage of grading processing, so that a slag powder with the particle size of 20 mu m or less is sorted out, overly grinding phenomenon is avoided, and energy consumption and cost are reduced. The prepared slag powder has relatively high activity, can be applied to concrete as a mineral doping material, is capable of reducing the cost of concrete and concrete products, increasing the strength of concrete and improving the endurance of concrete, and also is applicable to production of pipe sheets and pipe piles. After the concrete is doped with the ultrafine slag powder, the doping amount of a cementing material can be properly reduced, and thus the purpose of saving energy and reducing cost and improving effect are realized.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

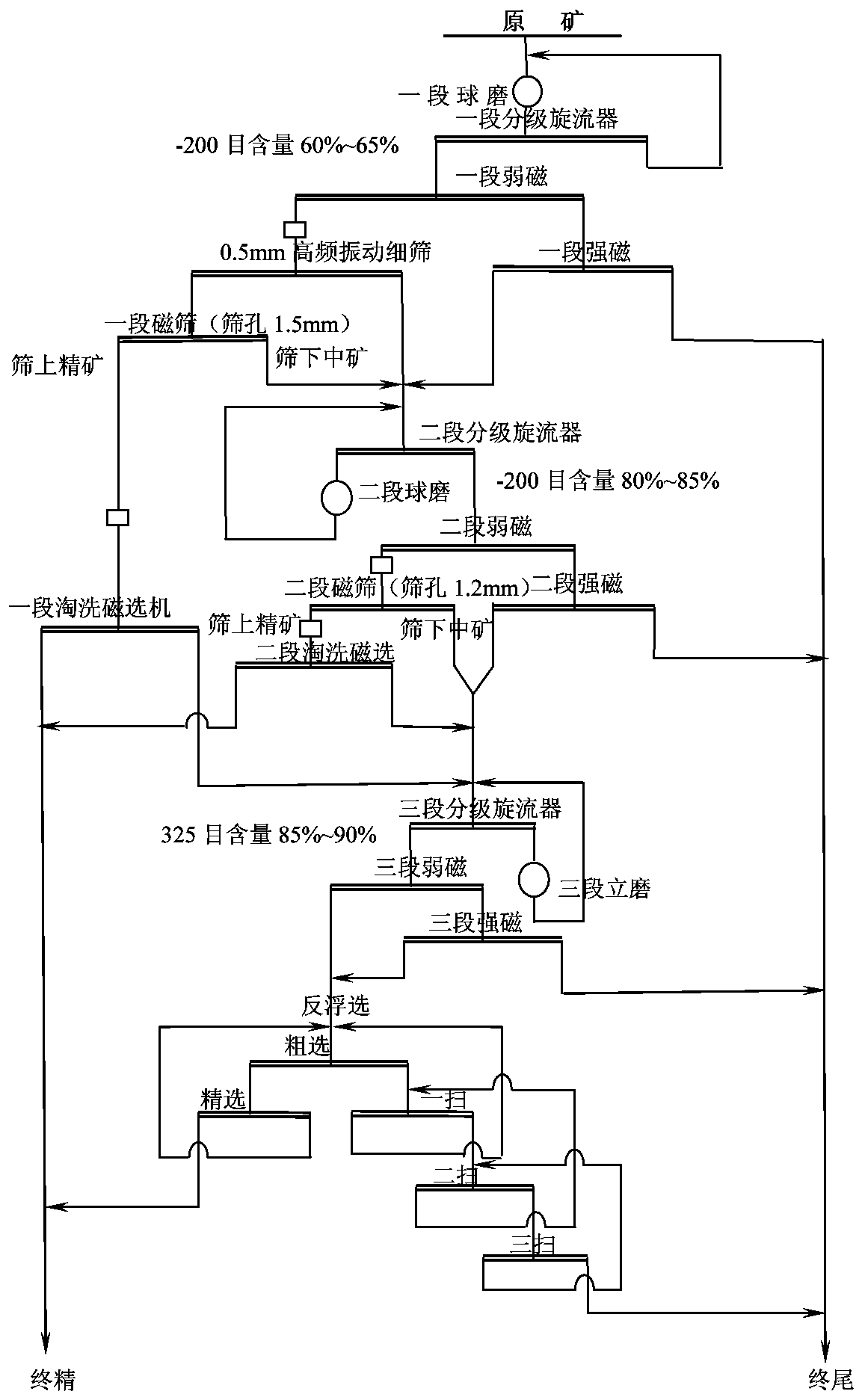

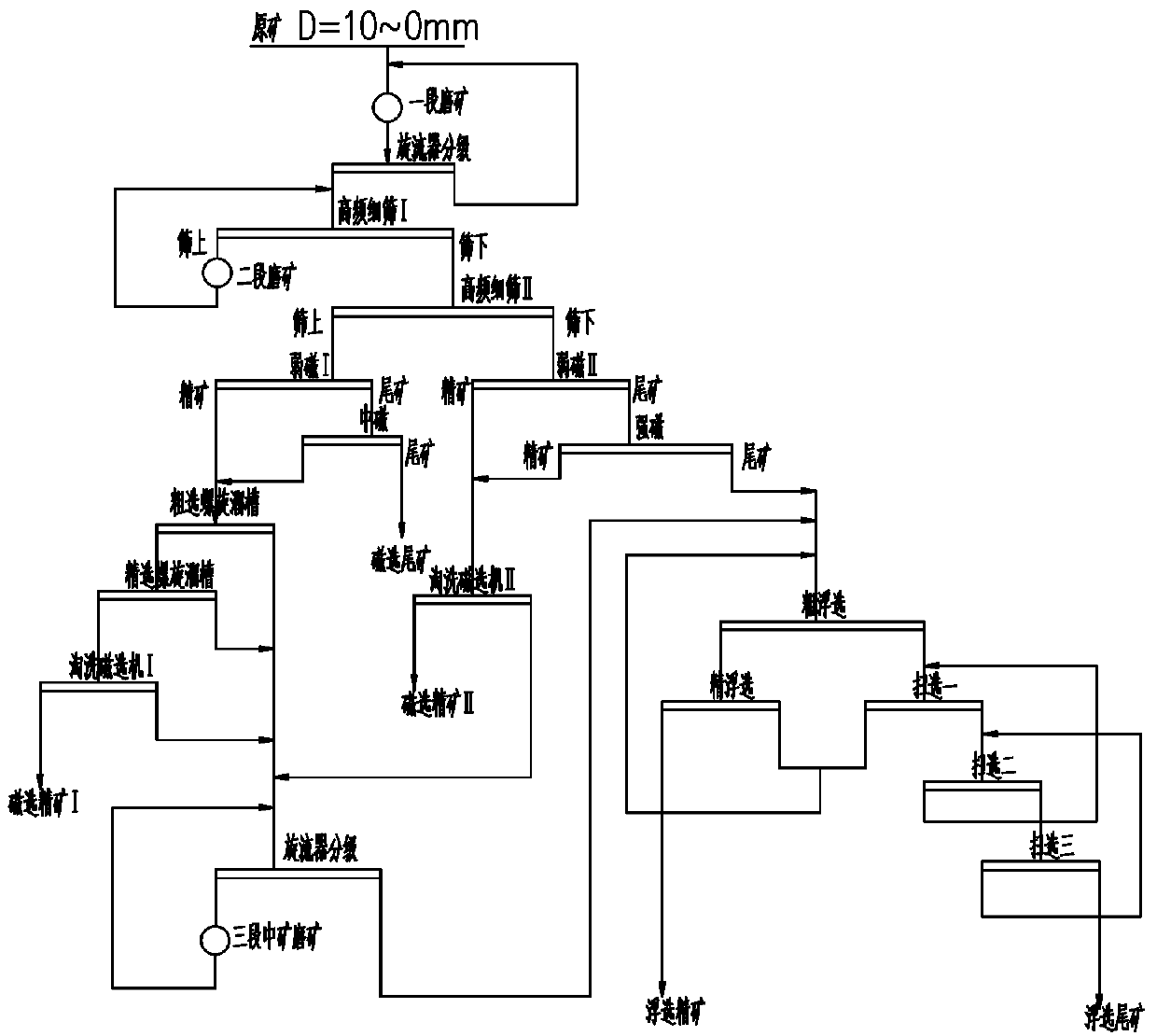

Separation process for magnetic red mixed ore based on iron material disseminated particle size treatment

ActiveCN109351467AReduce grinding energy consumptionReduce overgrindingSolid separationOre concentrateSeparation process

The invention relates to a separation process for magnetic red mixed ore based on iron material disseminated particle size treatment. The process comprises the operation of feeding the mixed ore withthe grade of 27%-29% and with magnetite as a main raw material into first-section closed circuit ore grinding operation to obtain a primary grading overflow product, and is characterized by further comprising first-section weak magnetic and strong magnetic operation, fine screening operation, first-section magnetic separation and first-section washing magnetic separation operation, second-sectionclosed circuits ore grinding operation, second-section weak magnetic strong magnetic operation, second-section magnetic separation and washing magnetic separation operation, third-section closed circuit ore grinding, third-section weak magnetic strong magnetic operation and reverse flotation operation. The final concentrate with the grade of 66%-66.5% is obtained through the operation. Compared with the prior art, the separation process has the advantages that 1) an efficient separation process which is characterized in that the concentrate can be obtained once dissociation is achieved and segmented ore grinding, segmented concentrate taking and segmented tailings discharging are achieved is provided for the magnetic red mixed ore with the non-uniform iron material disseminated particle sizes, so that overgrinding is reduced, and energy conservation and consumption reduction are achieved; 2) magnetic separation equipment is adopted for upgrading, and three sections of ore grinding is carried out by adopting vertical mills; and 3) the process is simple in structure, free of middling circulation, easy to implement on site and easy to produce and manage.

Owner:ANSTEEL GRP MINING CO LTD

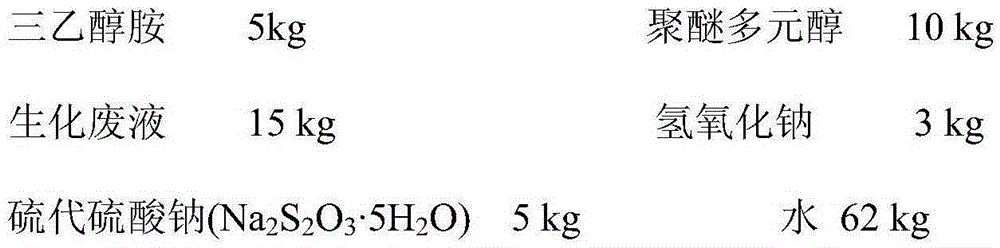

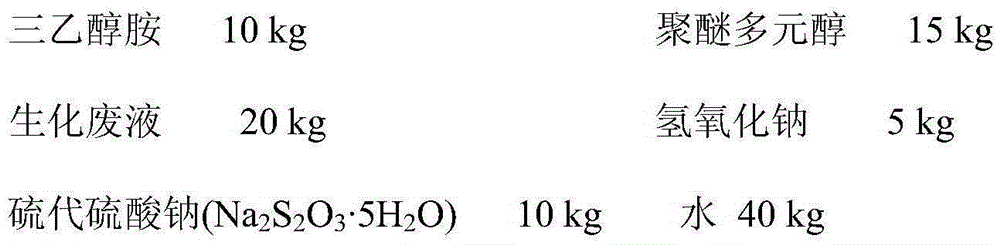

Cement grinding aid

The invention provides a cement grinding aid. The cement grinding aid comprises raw materials as follows: triethanolamine, polyether polyol, sodium hydroxide, sodium thiosulfate and a biochemical waste liquid, wherein the biochemical waste liquid is one of or a mixture of a waste liquid produced during production of industrial sodium gluconate and a waste liquid produced during production of an industrial itaconic acid product. The cement grinding aid can optimize the cement grain composition, activate the early strength of cement, improve the powder grinding efficiency of the cement and reduce energy consumption.

Owner:ZHANGQIU HUAMING CEMENT

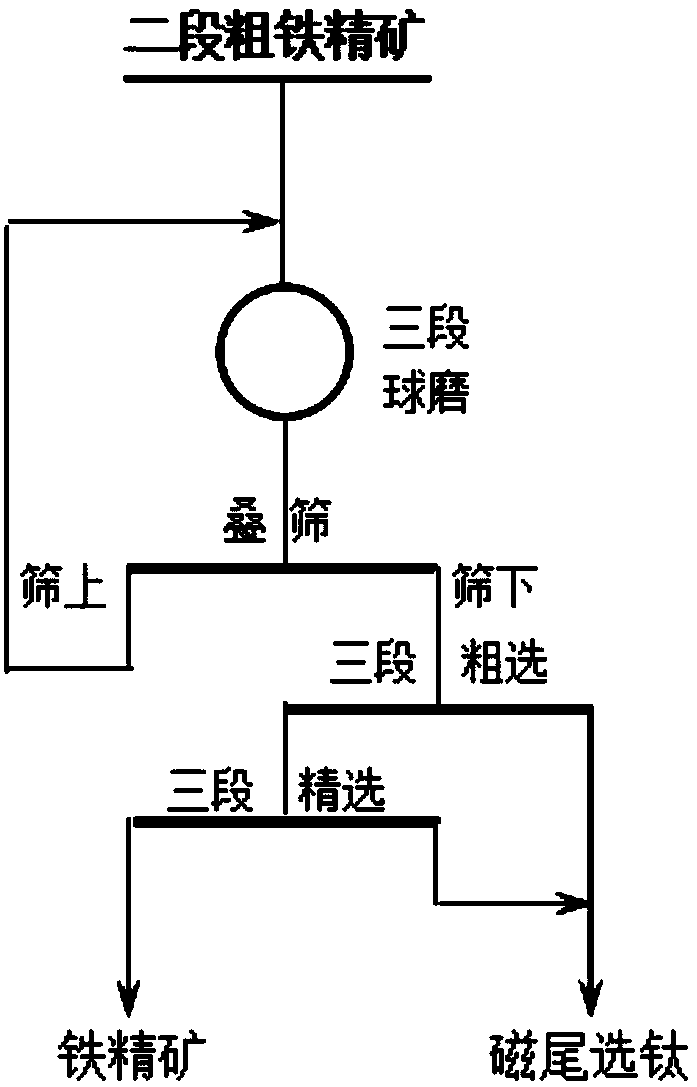

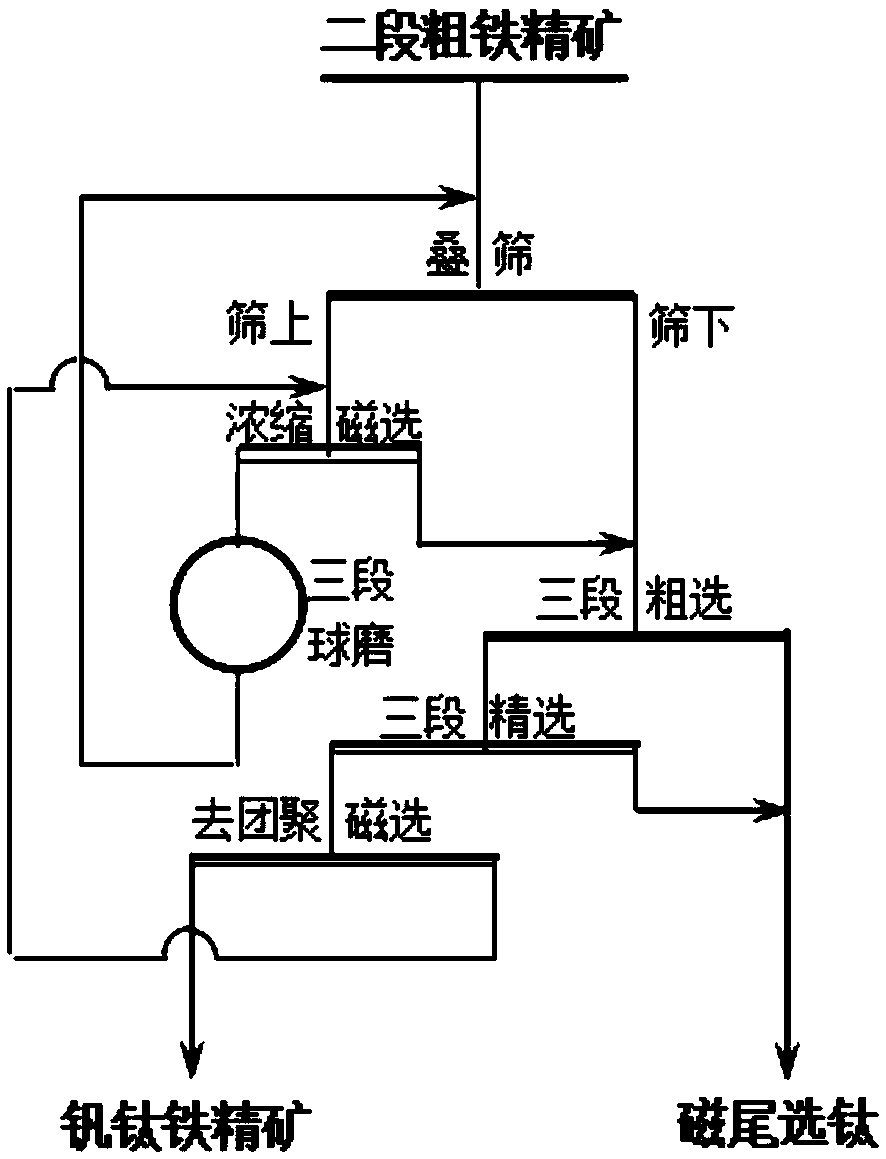

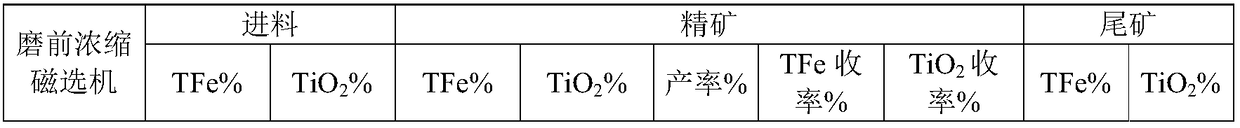

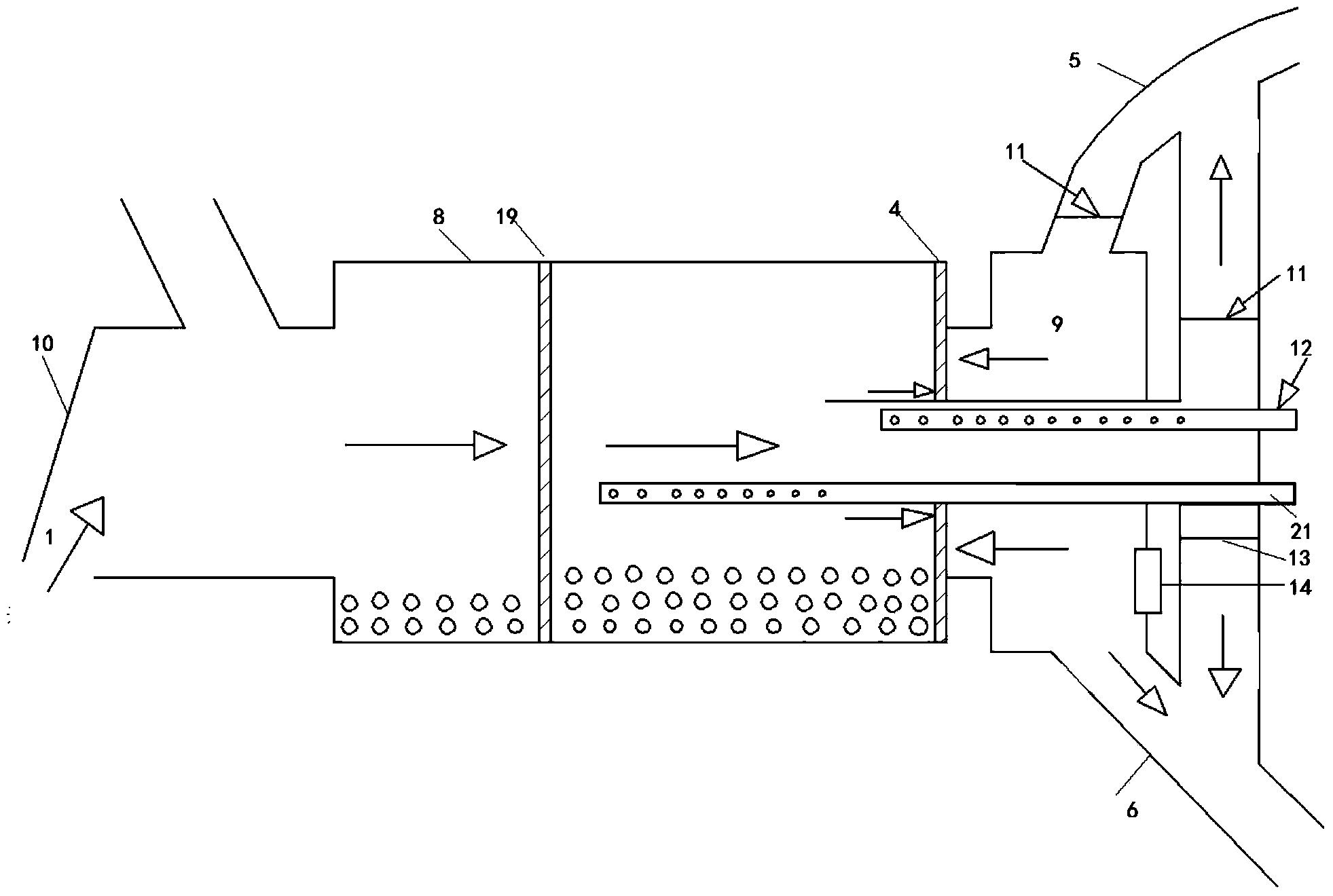

Technological method for improving quality of vanadium-titanium iron concentrates

InactiveCN109395873AReduce overgrindingImprove processing powerGrain treatmentsWet separationTitaniumMaceral

The invention relates to a technological method for improving the quality of vanadium-titanium iron concentrates. Various techniques are integrated. The technological method includes preliminary classification, fine screening classification, three-section ore grinding, concentration magnetic separation and stair magnetic separation. In preliminary classification, a qualified fraction part good indissociation in rough iron concentrates can be effectively classified out, the treatment capability of a mill is improved, and energy consumption of the product is lowered. In fine screening classification, a fine screening closed loop is adopted for cyclic ore grinding, compared with common rotational flow classification, classification is conducted strictly according to the particle size, meanwhile, the classification efficiency reaches up to 70% or higher, the qualified fraction is better classified out in time, excessive grinding is reduced, and cyclic loads are reduced. In concentration magnetic separation, concentration magnetic section is adopted before ore grinding, part of weak magnetic titanium ore and gangue can be removed out, excessive grinding of the titanium ore is reduced,and the titanium iron ore recycling rate is increased; and meanwhile, the ground ore grade is improved, the yield is increased, and the product cost is reduced. In stair magnetic separation, iron andtitanium separation is well achieved, and the iron concentrate grade is improved step by step.

Owner:SICHUAN LOMON MINING & METALLURGY

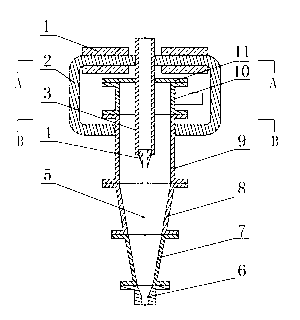

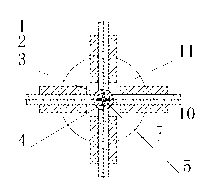

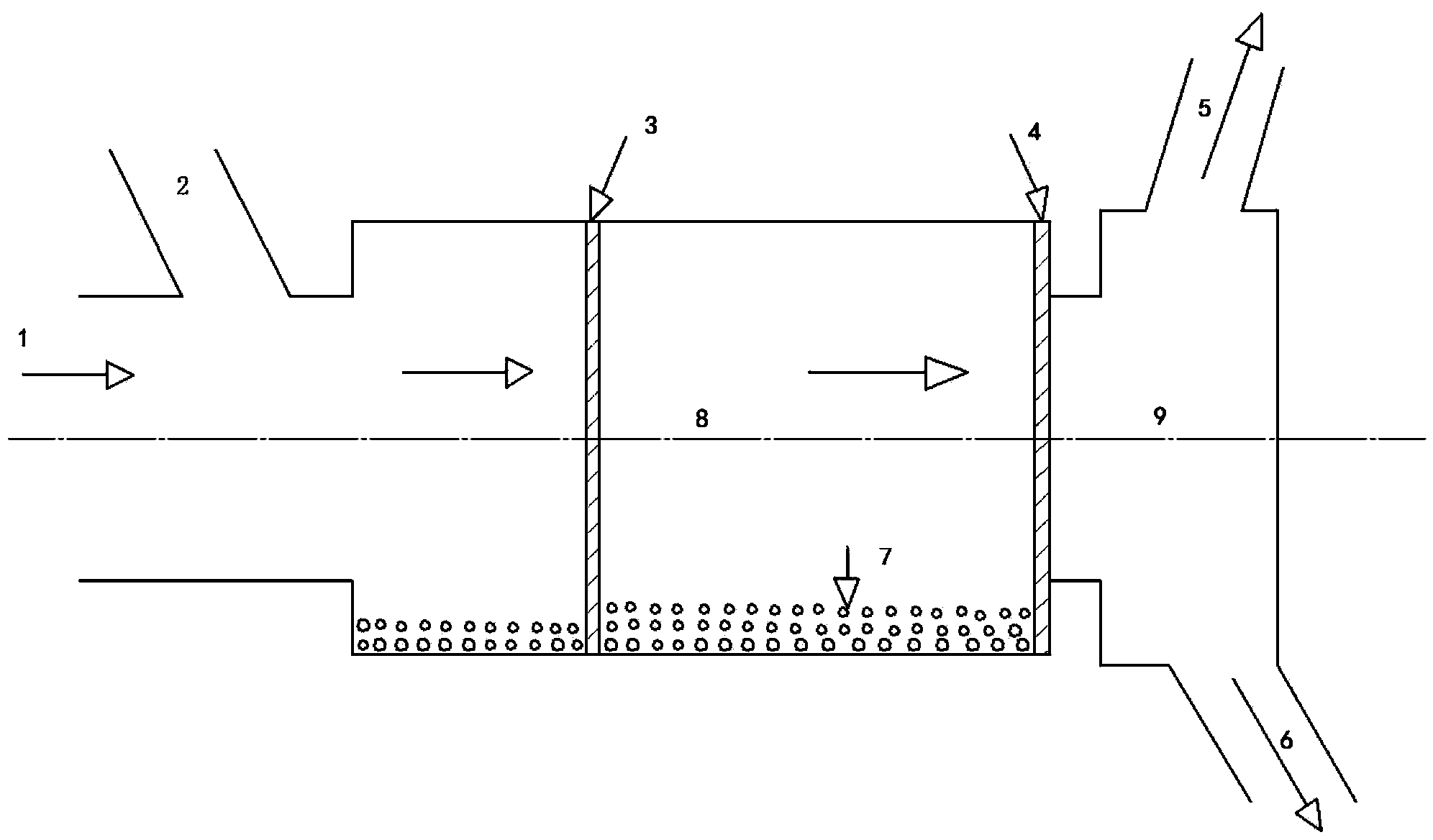

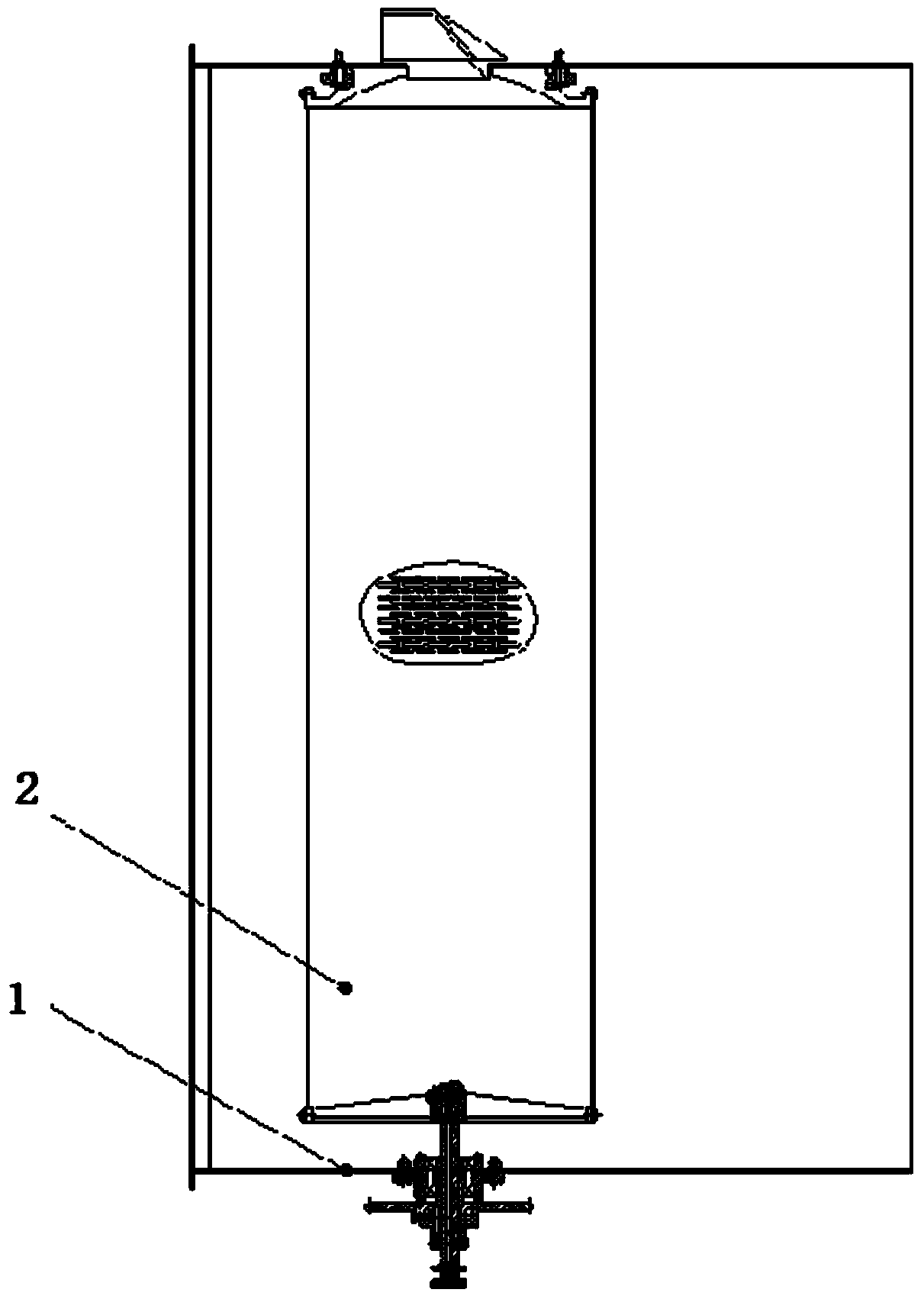

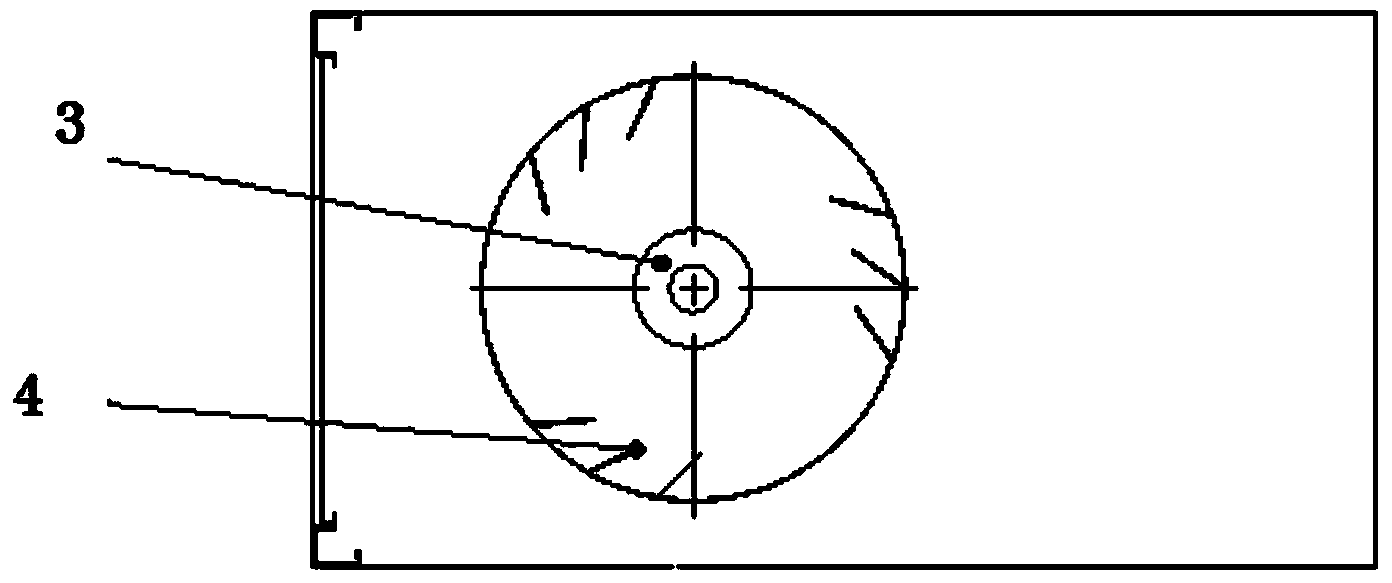

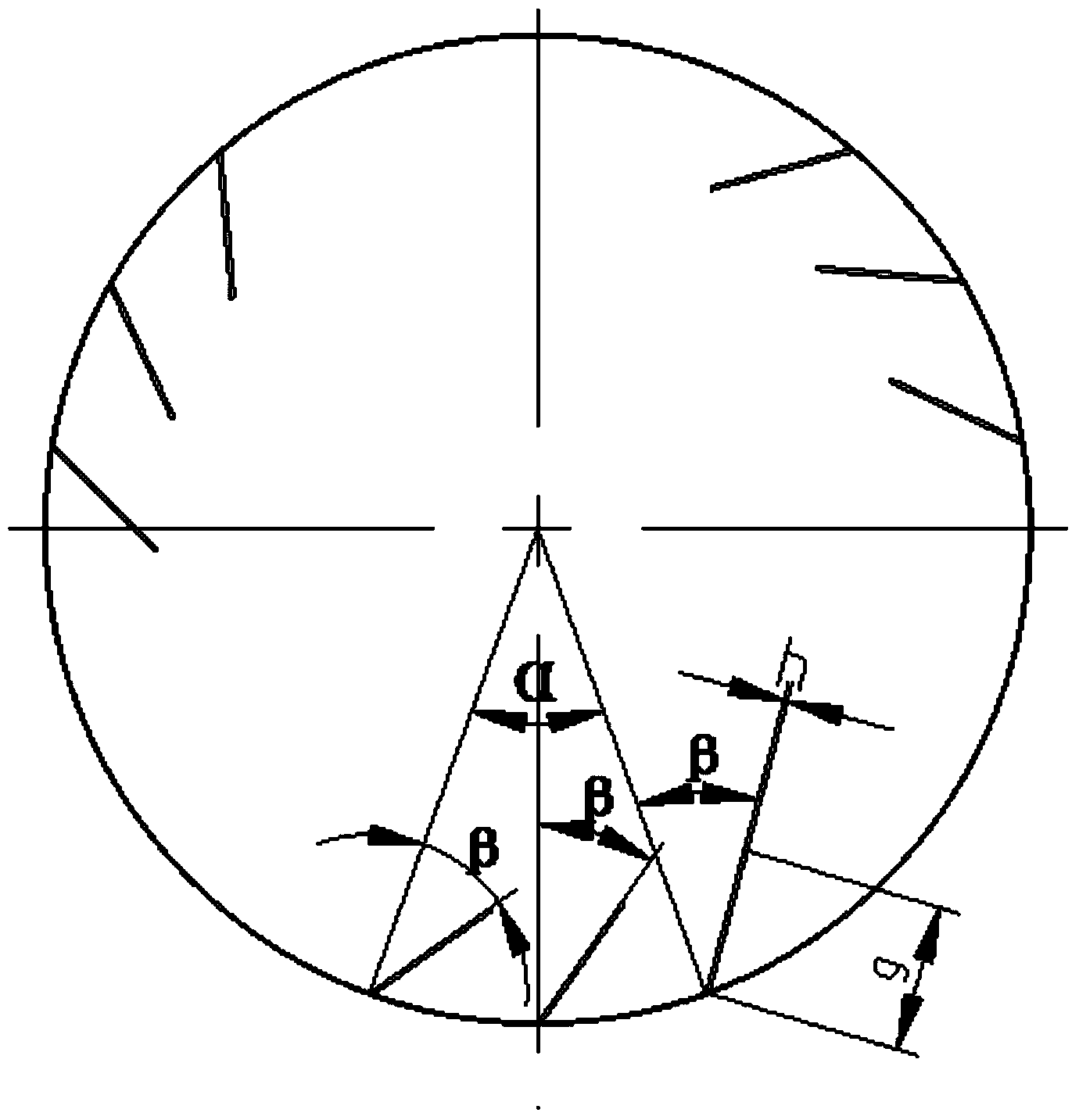

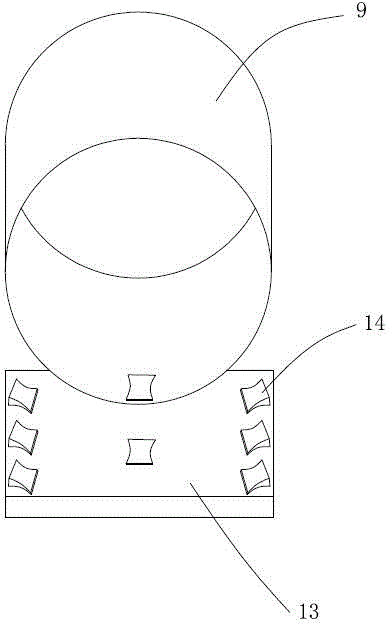

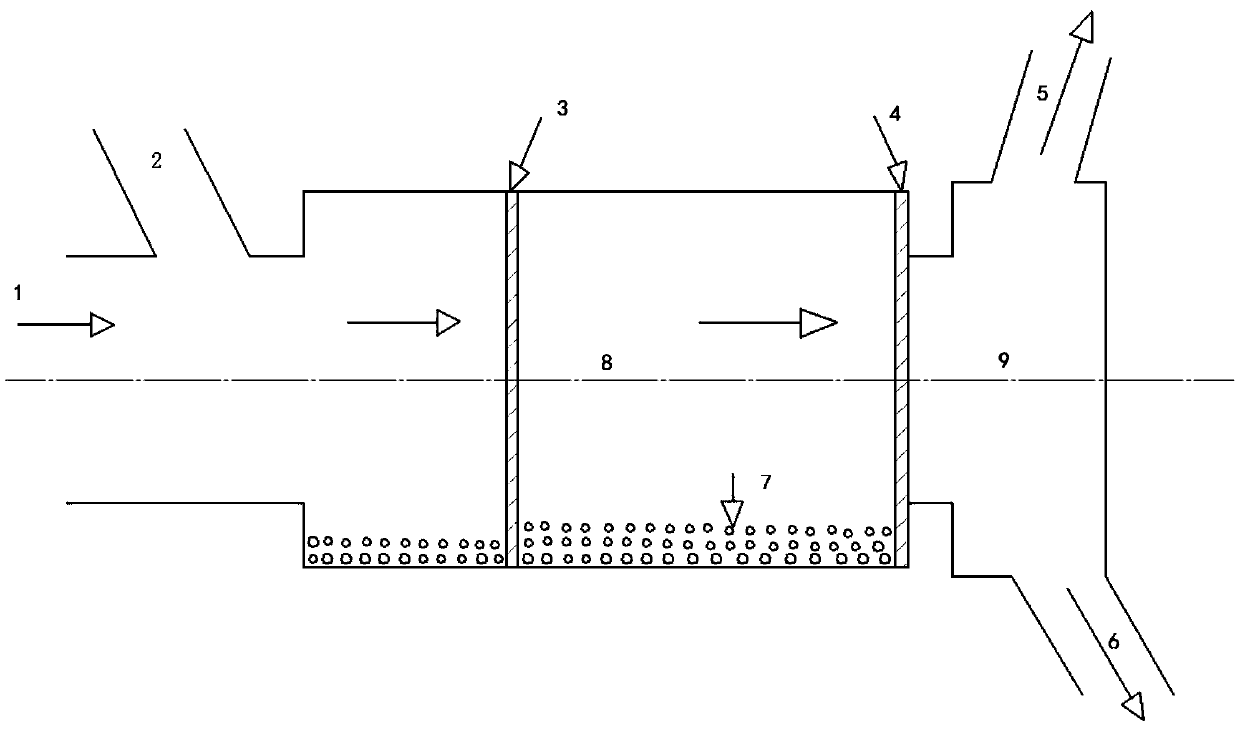

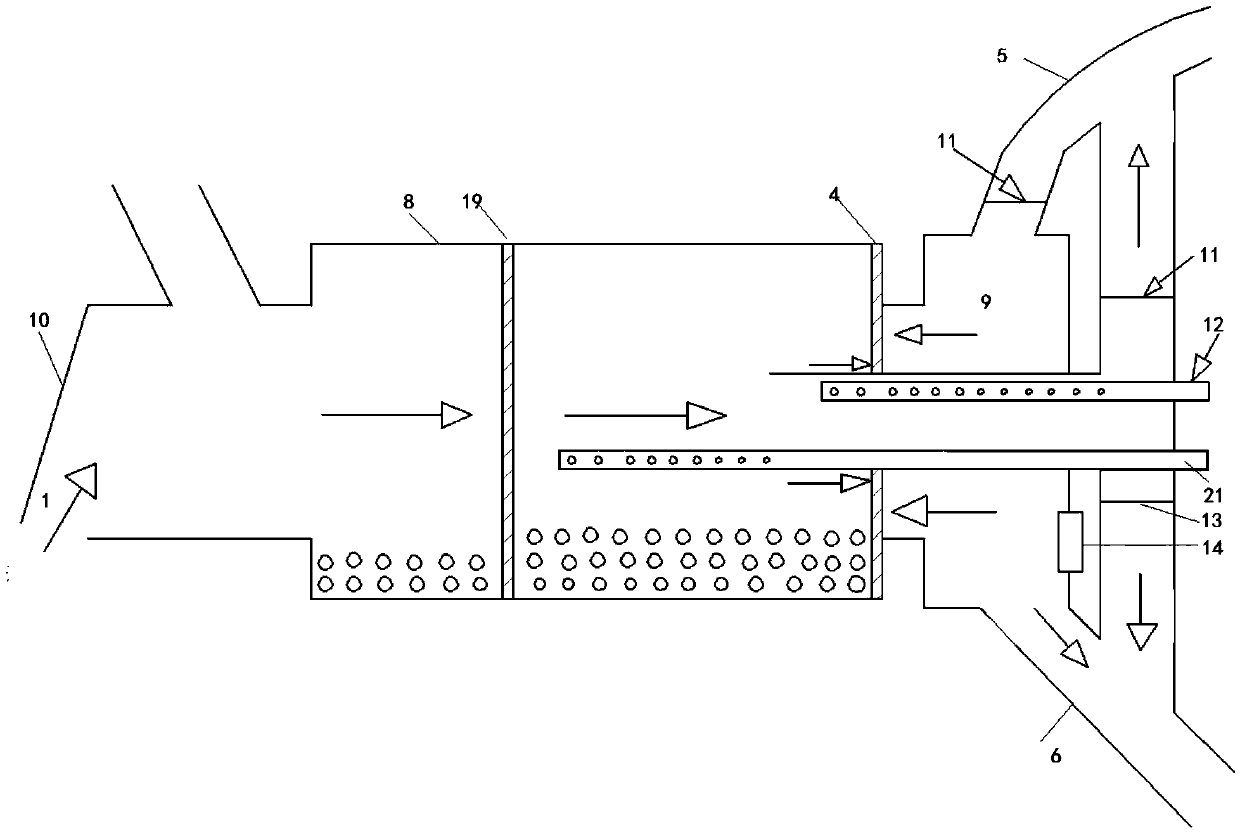

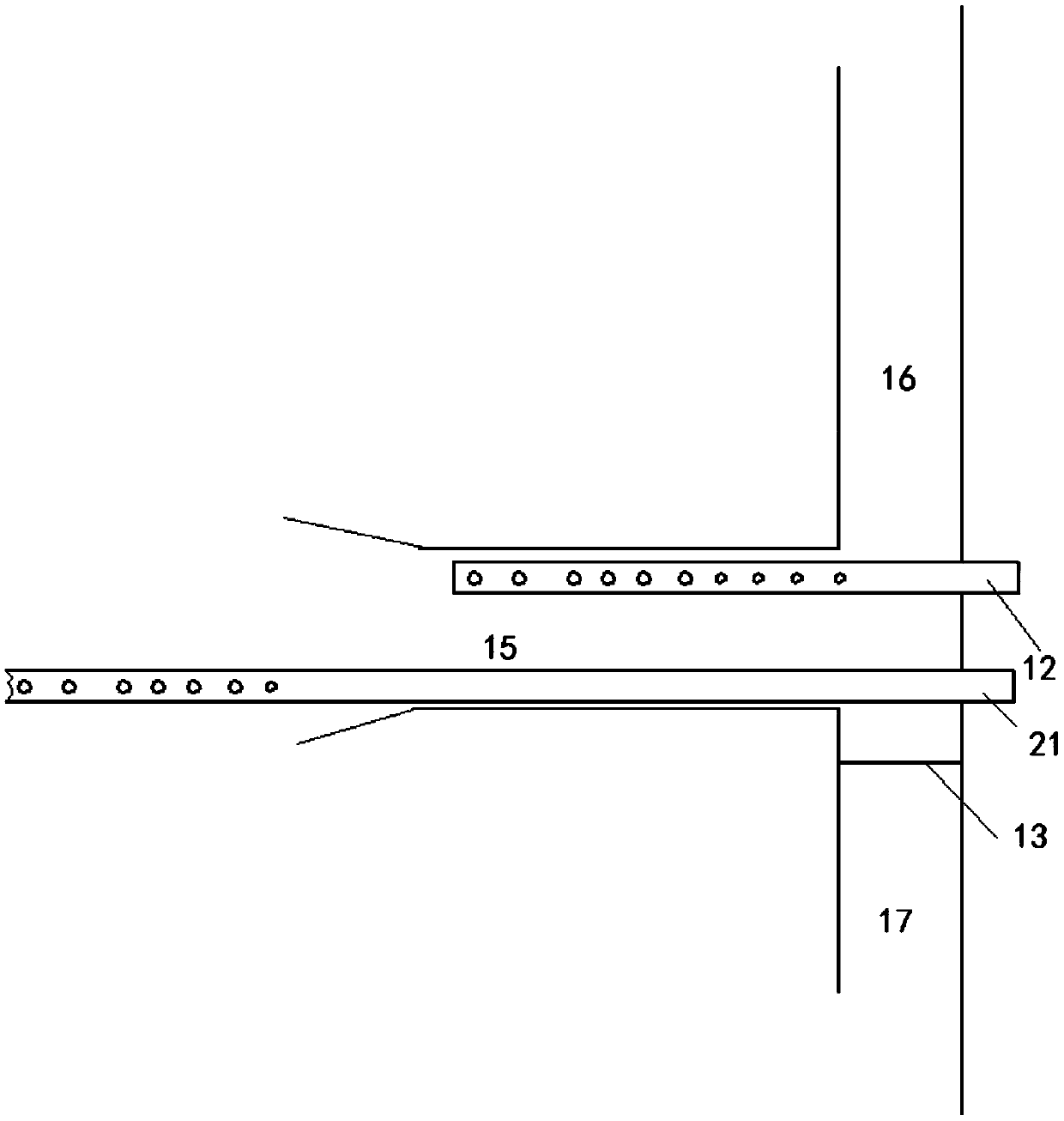

Overflow-discharge-type magnetic hydrocyclone

InactiveCN103056049ALow costSolution to short lifeReversed direction vortexEngineeringEnergy consumption

The invention relates to an overflow-discharge-type magnetic hydrocyclone. The technical scheme is that the lower end of an overflow tube (3) is positioned on the middle part or the lower part of a cylinder body (9); the upper end of a central magnetic bar (5) is welded on a port at the lower end of the overflow tube (3) through 2-4 connecting fins (4); the lower end of the central magnetic bar (5) is in flush with the lower end of an upper conical body (8), and the diameter of the central magnetic bar (5) is 0.2-0.3 times of the inner diameter of the overflow tube (3); the overflow tube (3), the connecting fins (4), the central magnetic bar (5), the upper conical body (8) and the cylinder body (9) all adopt magnetic materials; a top cover (11), an ore feeding block (10) and a lower conical body (7) all adopt nonmagnetic materials; one ends of four U-shaped iron cores wound with coils (1) are respectively welded on the outer wall of the overflow tube (3) extending out of the top cover (11), and the other ends of the four U-shaped iron cores wound with coils (1) are respectively welded on the outer wall of the cylinder body (9); and the U-shaped iron covers (2) wound with the coils are arranged in a 'cross-shaped' central symmetrical mode. The overflow-discharge-type magnetic hydrocyclone provided by the invention has the advantages of low cost, energy consumption conservation, long service life, convenience in operation, high classification efficiency and adaptability to industrial application.

Owner:WUHAN UNIV OF SCI & TECH

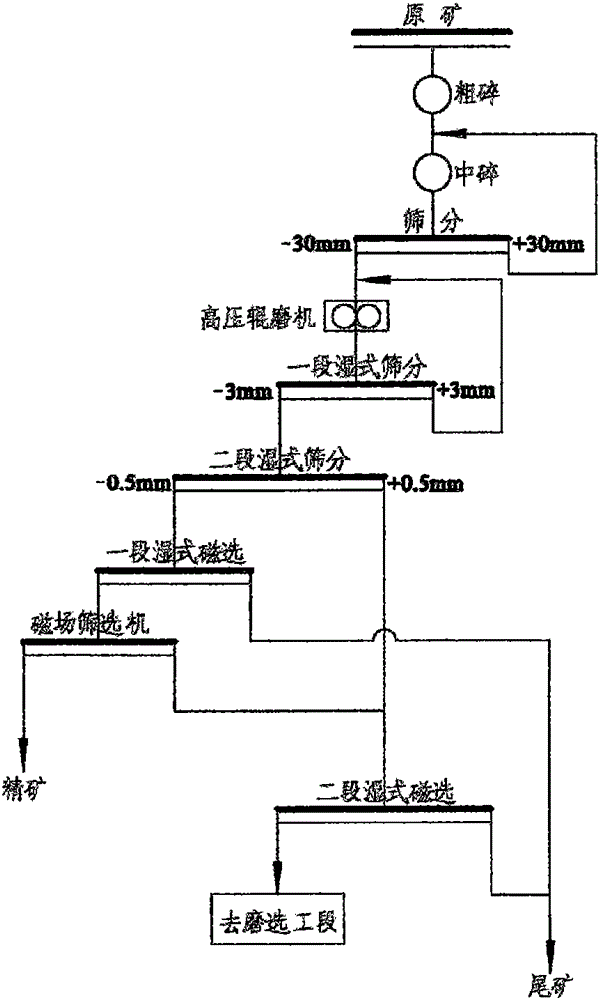

Efficient mineral processing technology achieved through cooperation of high-pressure grinding roller and magnetic field screening machine

InactiveCN105032582AEasy to handleFully dissociatedSolid separationGrain treatmentsOperational costsEconomic benefits

The invention discloses an efficient mineral processing technology achieved through cooperation of a high-pressure grinding roller and a magnetic field screening machine. The efficient mineral processing technology is scientific and simple in technological process and low in operating cost. The high-pressure grinding roller is high in reduction ration and small in product particle size, and therefore the iron mineral monomer separation degree is effectively improved during crushing operation, and the processing capacity of the grinding roller is greatly improved. For high-pressure roller fine fraction products, part of qualified iron core concentration where monomer separation is conducted is selected through the magnetic field screening machine, and therefore the excessive grinding amount and the grinding and separating operation ore quantity are effectively decreased, energy conservation and consumption reduction are achieved, and economic benefits are obvious.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Preparation method of cement grinding aid

The invention relates to the field of cement production, in particular to a method for preparing a cement grinding aid; (1) raw material preparation: weigh the raw materials according to the parts by mass: 10-15 parts of propylene glycol, 3-5 parts of unsaturated polyester resin, 6-12 parts of sodium thiosulfate, 2-8 parts of calcium formate, 0.6-0.8 parts of Tween-80, 6-12 parts of alkyl polyglycosides, 10-30 parts of maleic anhydride, 2-6 parts of nano silicon dioxide , 2.4-5.6 parts of sodium hexametaphosphate, 2-6 parts of allyl polyoxyethylene ether, 1.8-4.8 parts of water-retaining cellulose; (2) preparation of modified triethanolamine; (3) preparation of grinding aid: step Take 5-25 parts of modified triethanolamine prepared in (2) and add it to the stirrer, then add the raw materials except calcium formate and sodium thiosulfate, mix and stir evenly, carry out a polymerization reaction at 75°C for 5h, add calcium formate, sulfur Substitute sodium sulfate, after stirring evenly, drying to obtain the grinding aid; the method of the invention is simple and the production cost is low; the prepared cement grinding aid has the advantages of good water retention, and can improve the specific surface area and appearance of cement.

Owner:汤海涛

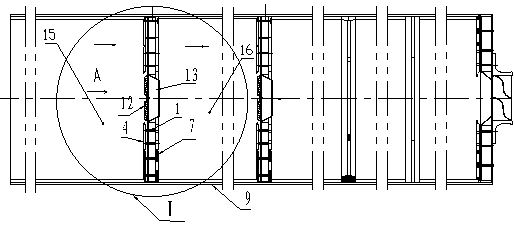

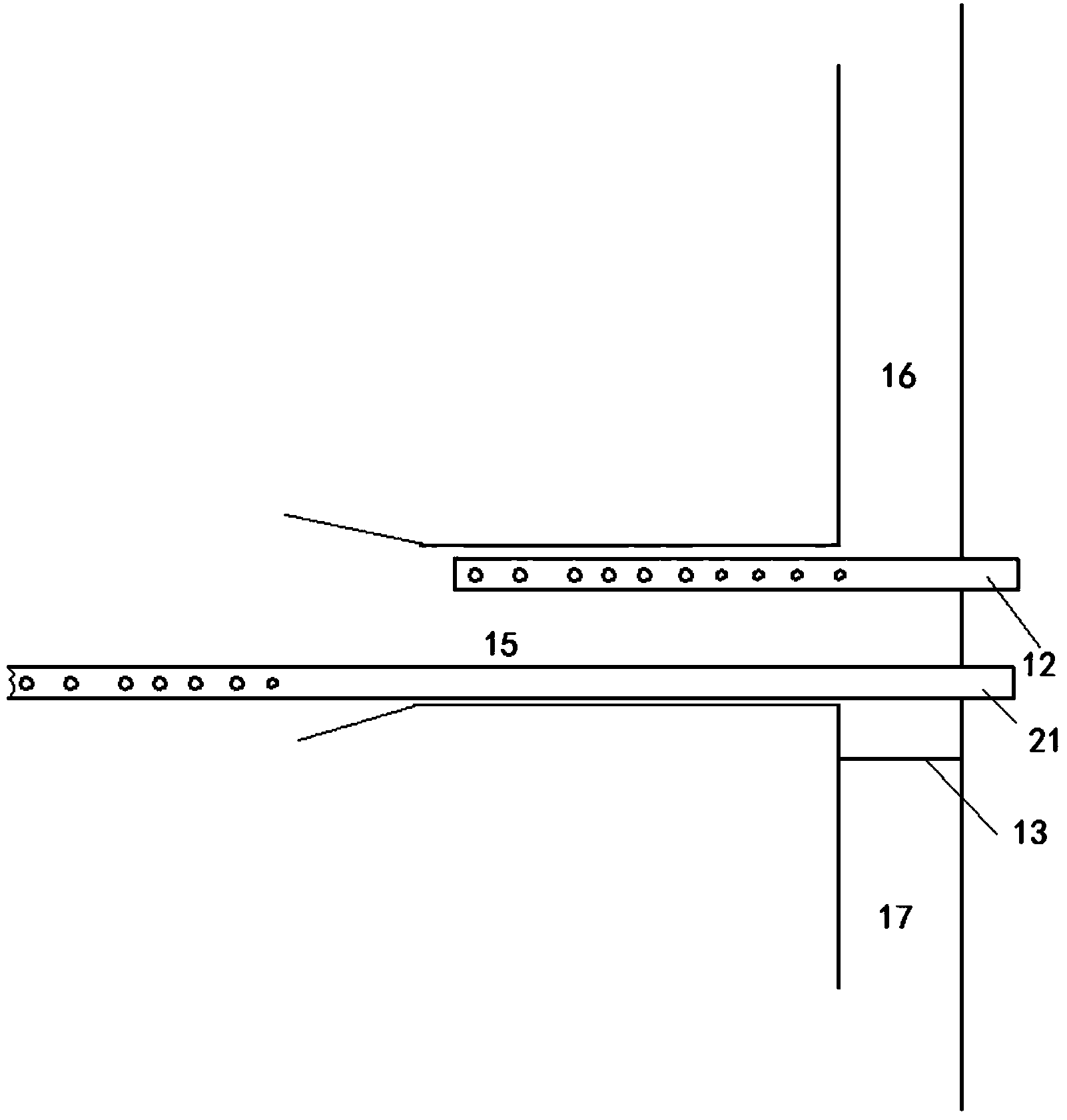

Screening device in super-fine grinding mill

ActiveCN103316754AIncrease the ventilation areaImprove ventilationGrain treatmentsEngineeringCement grinding

A screening device in a super-fine grinding mill comprises a barrel body and a bracket in the barrel body, wherein a bracket bottom plate is arranged at the periphery of the bracket; a front chamber and a rear chamber in the super-fine grinding mill are arranged on the left side and the right side of the bracket respectively; a front screen plate and a rear screen plate are connected with the left side and the right side of the bracket respectively; a front grate plate is connected with the left side of the front screen plate; a boss projecting out of the right side surface is arranged on the right side surface of the front grate plate; a screening chamber is formed between the right side surface of the front grate plate and the left side surface of the front screen plate; the top end of the boss props against the left side surface of the front screen plate. According to the screening device, a conventional cement grinding mill cabin baffle and a blind plate in the screening device are replaced with a rear grate plate, a ventilation area in the mill is enlarged, a smooth ventilation effect is achieved, powder can timely enter a rear cabin for grinding through the screening device from a front cabin, the excessive grinding and cushion effects of the front cabin are reduced, the grinding capability of a grinding cabin is improved, and the operation hour of the grinding mill is prolonged.

Owner:渑池德惠石油支撑剂有限公司

Carbide slag drying method for vertical mill

InactiveCN101481224AElected in a timely and effective mannerTake advantage ofDrying solid materials with heatHearth type furnacesSlagElectric consumption

The invention discloses a method of using a vertical mill for drying calcium carbide. Wet-discharged calcium carbide slag with a pre-drying water content of 12 percent and 18 percent is used as a raw material and is mixed with auxiliary raw materials, such as sandstone, sulfate slag and the like after calculation to be sent into a vertical mill. After entering the vertical mill and being rolled by mill rollers, the materials are rolled and splashed to the part of an air ring on the edge of a millstone and is carried up by the currents of the air ring of kiln tail waste gas, and the air ring has a high speed of 70 mm to 90 mm per second. Wet materials and the kiln tail waste gas have heat exchange, the powdery material after the heat exchange rises together with the currents to pass through the upper shell of the mill to enter the stage separation area of a separator, wherein the coarse powder falls back to the millstone and is milled again with the new-fed material, and the qualified fine powder after stage separation is together discharged out from the vertical mill with the currents to be collected as a finished product by a collector. The method provided by the invention can integrate the homogenization, the drying, the milling and the stage separation of the material into a whole, reinforces the homogenizing and drying functions, solves the problems that the calcium carbide has a high water content and fine granularity and can not be easily dried and milled, and has simple and compact technical procedures, high heat efficiency and low electric consumption.

Owner:HEFEI CEMENT RES DESIGN INST

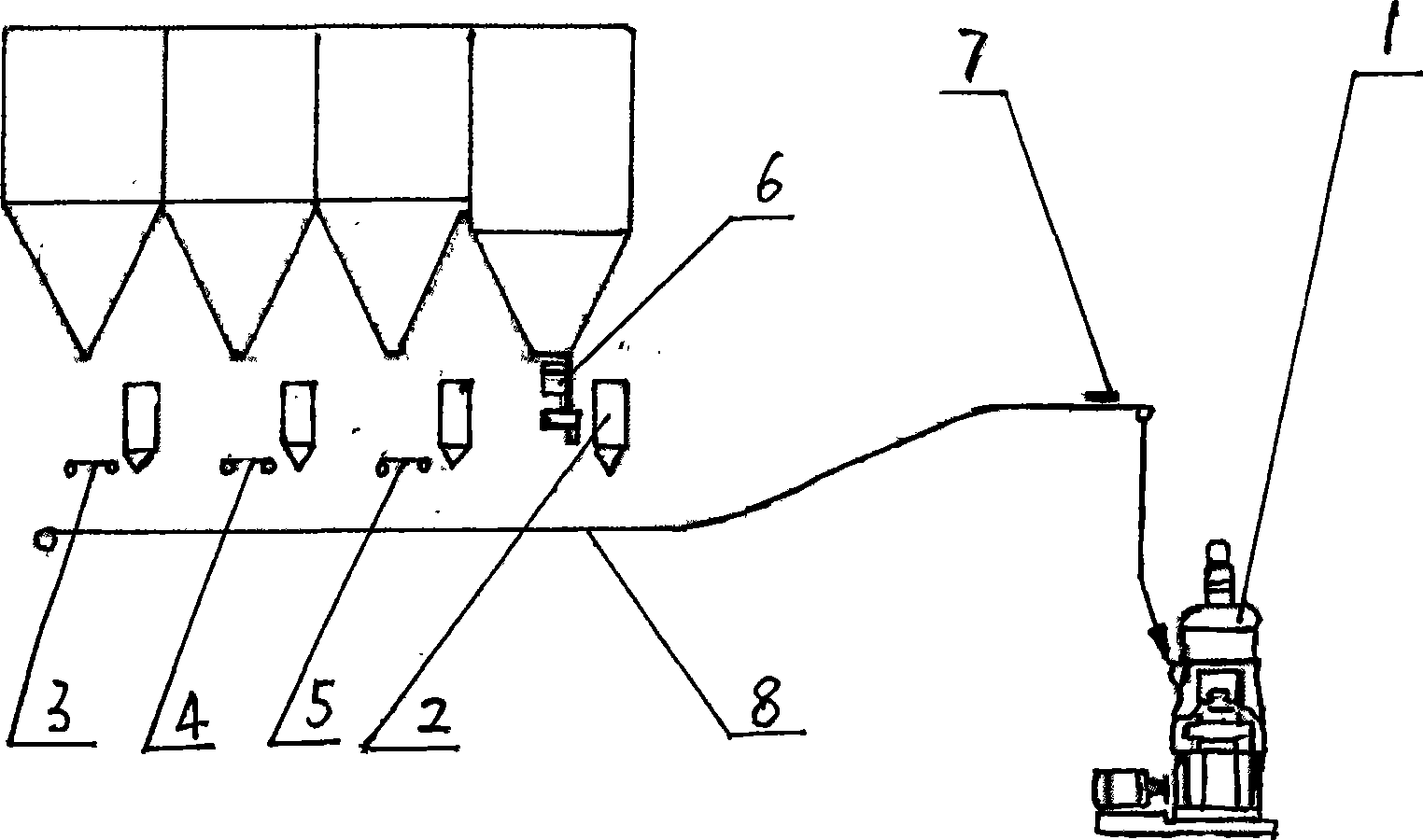

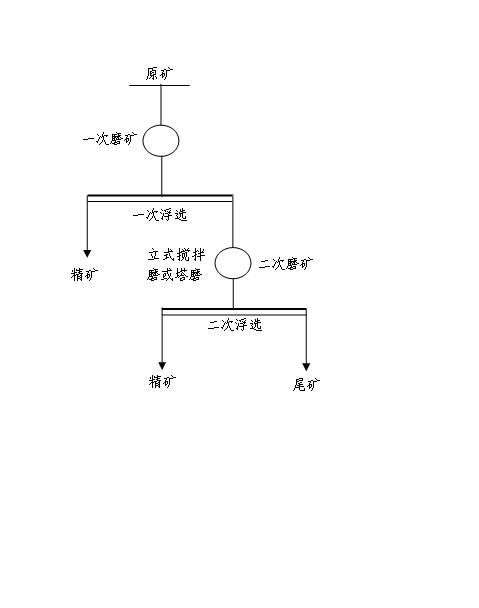

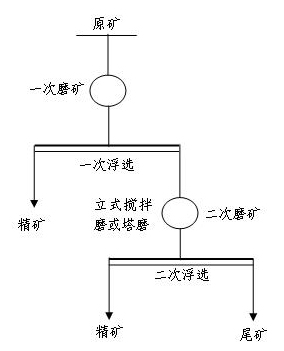

Ore grinding flotation silicon-removing method of bauxite

The invention relates to a process for removing impurities from bauxite, in particular to an ore grinding flotation silicon-removing method of bauxite, which comprises the steps of: carrying out primary floatation on the bauxite after rough grinding, wherein the floated foam is used as a concentrate product; carrying out secondary ore grinding on floating underflow; and carrying out secondary floatation after secondary ore grinding, wherein the floated foam is used as a concentrate product and the underflow is used as tailings to be discharged. The invention has the characteristics of proper granularity of flotation pulp, reasonable fraction distribution, shortened process flow, reduced mineral dressing cost and improved floatation recycling rate due to the adoption of reasonable configuration of ore grinding and floating and equipment selection.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Two-stage grinding-classifying process for preparing alumina pulp

InactiveCN1569339AGood abrasivenessImprove classification efficiencyGrain treatmentsAluminium oxides/hydroxidesEngineeringSolid content

The invention discloses a two-segment mineral grinding-classification process, it grinds the bauxite and lime in the rod mill, the grinded raw mine pulp is poured into a pump pool. The classified bottom flow after classified by water swirler is grinded in ball grinder, adjusts the best liquid and solid rate with proper alkali liquid, the discharged mine pulp is poured into the same pump pool, and adds in alkali liquid to maintain the solid content at 470-520g / L, and carries on classification to the compound mine pulp in the water swirler, the bottom flow enters the ball grinder to be grinded.

Owner:GUIYANG AL-MG DESIGN & RES INST

Grind grading technique for aluminum oxide raw material - monohydrallite

The invention relates to a grading process technology containing two procedures of grinding ore and grading in processing monohydrallite. Grinding equipment adopts two-bin overflow ball mill and grading equipment adopts hydraulic cyclone group, which cooperate with each other to form closed-circuit grading flow process. Two-bin overflow ball mill equips compartment board that can be adjusted to separate mill into two bins. The invention simplifies procedure and makes the operation convenient.

Owner:GUIYANG AL-MG DESIGN & RES INST

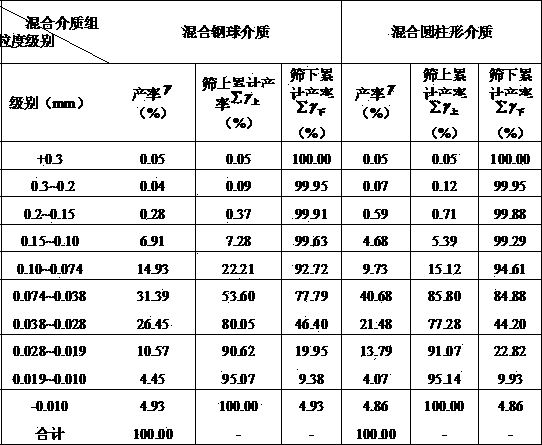

Cylindrical medium proportioning method for fine grinding of collophanite

The invention relates to a cylindrical medium proportioning method for fine grinding of collophanite. The method comprises the steps of determining the mechanical property of ores, performing screen analysis on feedstock of a grinding machine, deducting the grinding grade which is not required, converting the composition of the feeding size to be ground, calculating the steel ball diameter required by ore grains in all grades with a Duan's sphere diameter semi-theoretical formula, determining the steel ball ratio of the grinding machine according to the ore grain yield of each group of the feedstock to be ground and the yield of the required steel balls in different diameters, and then determining the ratio of the cylindrical mediums according to the steel ball ratio. The method is utilized to process the collophanite, the content of below 0.074mm grade can be improved, and the content of 0.074-0.038mm, which is in an easily-choosing grade, is improved. The ore grinding products obtained by the method have reasonability in grain fineness distribution, and the grading index in the following grading operation can be effectively improved.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

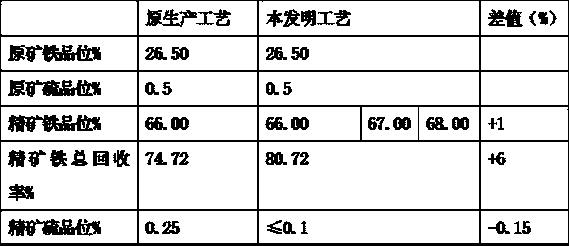

Beneficiation process for treating high-sulfur hematite-magnetic iron ore mixture

ActiveCN109675712AImprove iron gradeReduce manufacturing costWet separationGravity separationMaterials science

The invention relates to a beneficiation process for treating high-sulfur hematite-magnetic iron ore mixture. In the beneficiation process, treatment of raw ores with an iron grade being 25 -27 percent and a sulfur grade being 0.4-0.percent comprises the following step of obtaining a 58-62 percent primary overflow product with the overflow particle size being -0.074mm. The beneficiation process ischaracterized in that secondary closed circuit grinding is performed on the overflow product to obtain a product with the particle size being -0.3mm, coarse and fine particle classification is performed on the product with the particle size being -0.3mm with a high frequency fine screen II to obtain a coarse product with the particle size being 0.3-0.074mm and a fine product with the particle size being -0.074mm, beneficiation is performed on the coarse product with operation of low-intermediate intensity magnetic separation, gravity separation, low intensity magnetic separation, middling closed circuit regrinding and reverse flotation, beneficiation is performed on the fine product with operation of low-high intensity magnetic separation, middling closed circuit regrinding and reverse flotation, and iron concentrates with an iron grade being 66 percent or above and a sulfur grade being 0.1 percent or below are obtained. The beneficiation process has the advantages that technical indexes are qualified, and the economic benefit is remarkable.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

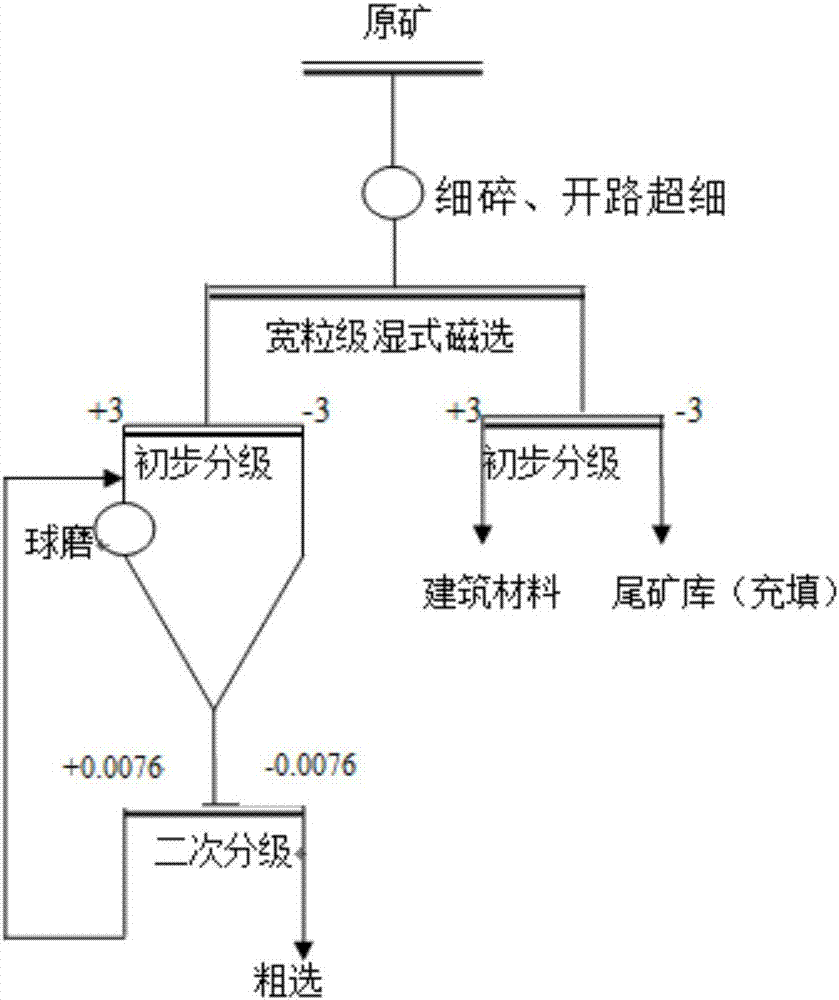

Beneficiation method for magnetic mixed ore

InactiveCN107029871AReduce grinding amountReduce overgrindingSolid separationGrain treatmentsUltra finePre treatment

The invention belongs to the field of beneficiation of black metal ore, and particularly relates to a beneficiation method for magnetic mixed ore. The beneficiation method for the magnetic mixed ore comprises the steps of pulverization of raw materials, pre-beneficiation of the pulverized raw materials, treatment of screened rough concentrate, and treatment of screened tailings. A rough concentrate primary-grading procedure used for screening the rough concentrate is additionally conducted after pre-screening of the raw materials and before treatment of the rough concentrate. Compared with a conventional magnetic ore beneficiation technique, a ZCLA preseparator is used for wet screening of products which are fine pulverized through a closed circuit and ultrafine pulverized through an open circuit, 20% of barren rocks in magnetic iron ore can be effectively removed, and grading can be achieved in advance through pre-screening of the concentrate, and thus part of products with qualified granularities directly enter the next production procedure; and the grinding quantity can be effectively reduced, the probability of excessive grinding is lowered, the grinding grade and the ore grinding efficiency are improved, and energy consumption for ore grinding is reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD

Ball mill

ActiveCN104258942AGuaranteed ventilation effectReduce the temperatureGrain treatmentsPulp and paper industryBall mill

The invention discloses a ball mill which comprises a ball milling barrel and a collecting bin, wherein the ball milling barrel is communicated to one end of the collecting bin through a bin outlet grate plate; a fan is connected to the upper part of the other end of the collecting bin through an air pipe, and a material storage is communicated to the lower part of the other end of the collecting bin through a material pipe; an air guide pipe is also arranged in the collecting bin, one end of the air guide pipe extends into the ball milling barrel, the other end of the air guide pipe extends into the air pipe, and an air baffle is arranged between the air guide pipe and the air pipe or the collecting bin; an air guide hole is formed in a collecting bin housing. Due to the adoption of the ball mill, the flow quantity and speed of airflow in a grinder can be increased according to the production needs, sufficient grinding time of materials in the grinder is guaranteed, and the quality and yield of finished products can still be ensured when the comprehensive moisture content of the grinding materials is relatively high.

Owner:张沁玥

Roller for mung bean huller capable of evenly stirring, shovelling and screening materials in real time

ActiveCN103798935AImprove work efficiencyReduce overgrindingFood treatmentRelative displacementMechanical engineering

Provided is a roller for a mung bean huller capable of evenly stirring, shovelling and screening materials in real time. The roller comprises a roller body, one end of the roller body is arranged on a rack bearing pedestal, the other end of the roller body is arranged on a rack mounting seat, the roller body can rotate around the axial center of the roller body, a mesh screen is arranged on the surface of the roller body, the inner wall of the roller body stretches out of a shovelling plate, and a hulling grinding wheel is arranged in the axial center of the roller body. The roller is characterized in that round holes or long round holes are formed in the mesh screen of the surface of the roller body, the shovelling plate on the inner wall of the roller body is divided into a plurality of sets in the circumferential direction at intervals, and three pieces form one set and are evenly distributed on the inner wall of the circumferential roller body at intervals. The round holes or the long round holes are adopted as mesh screen holes of the roller, completely-hulled whole mung beans or half mung beans can be screened conveniently, the built-in shovelling plate bodies are evenly distributed on the circumference of the roller, the materials are stirred and shoveled in the work process, relative displacement can be generated between the materials and the roller, and small-size materials are easier to screen. The whole device guarantees the milled rice rate and improves equipment production efficiency.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

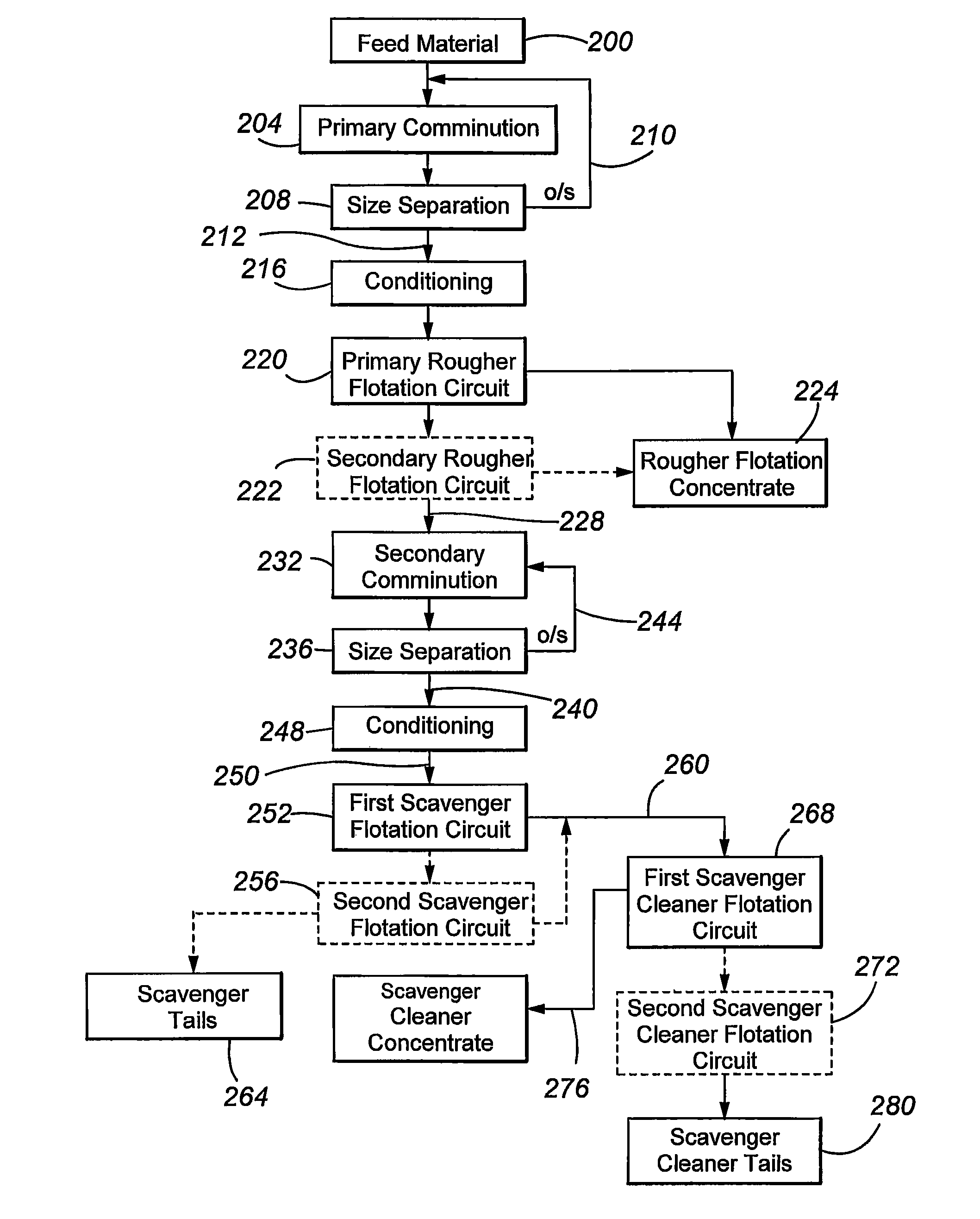

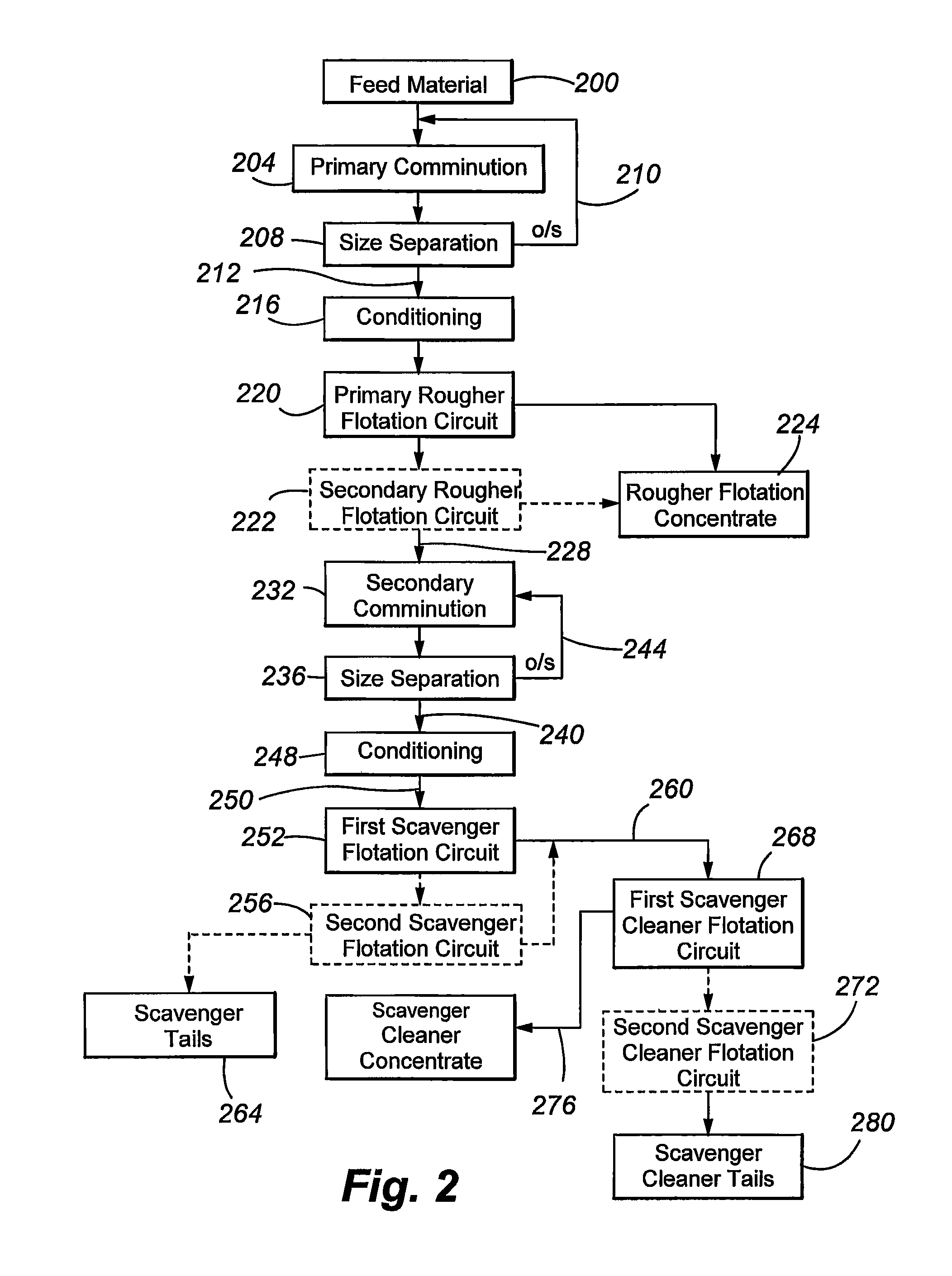

Process for recovering gold and silver from refractory ores

ActiveUS7922788B2High recovery rateEfficient flotationPhotography auxillary processesGold compoundsSulfideMaterials science

Owner:BARRICK GOLD

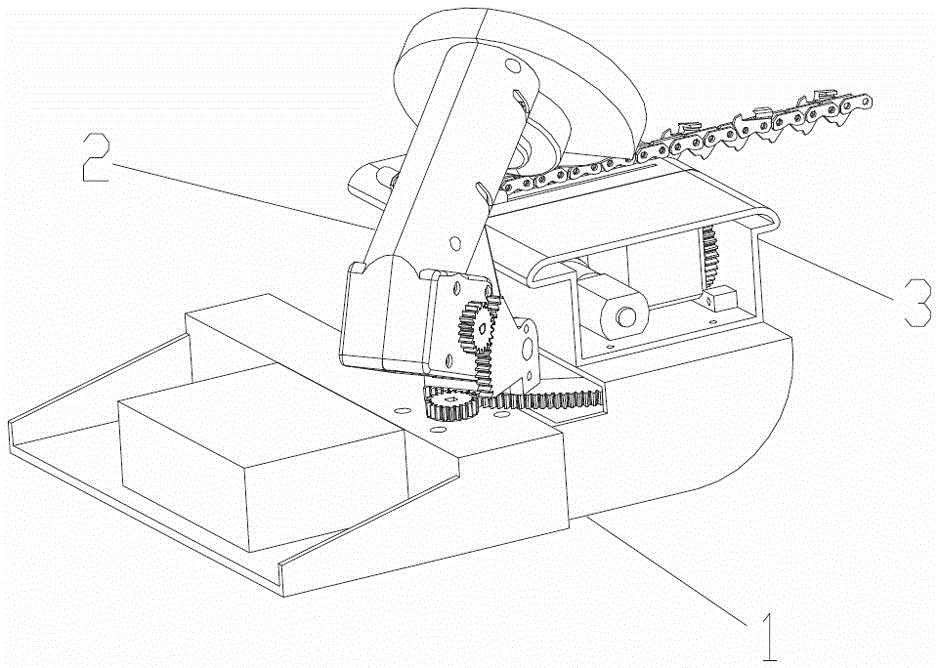

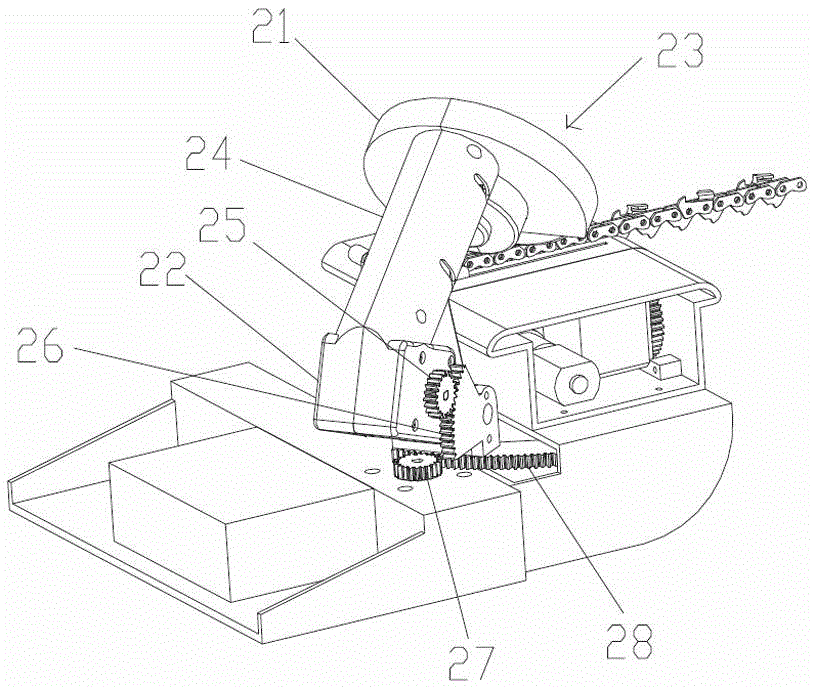

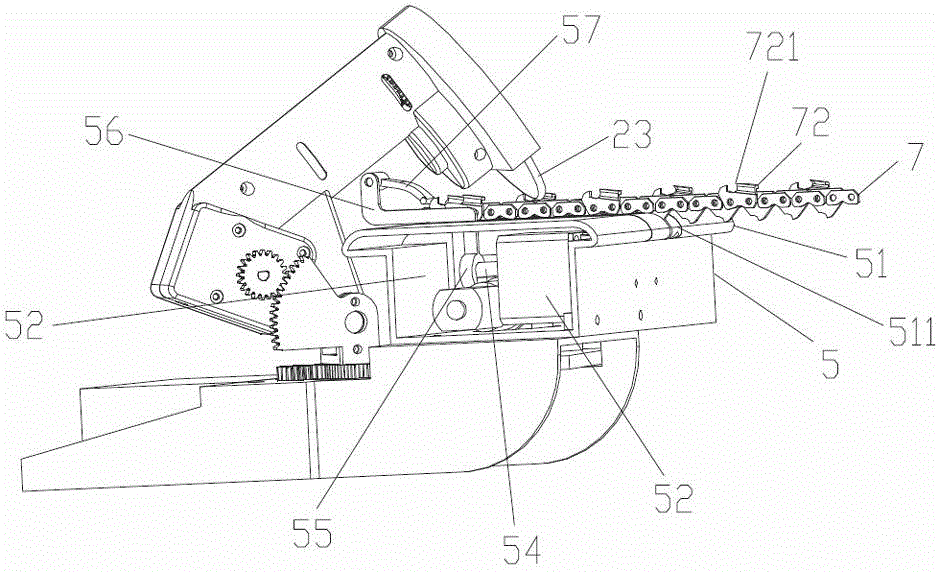

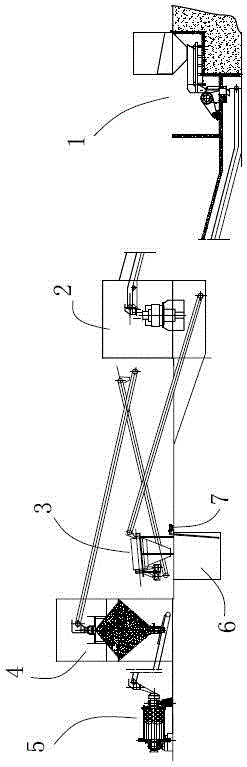

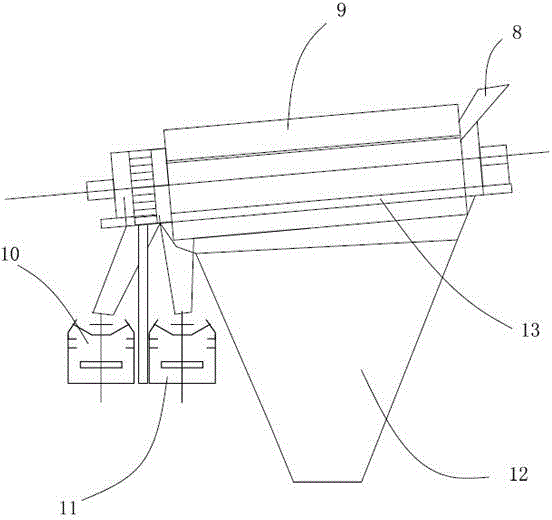

Full-automatic chain saw sharpener and shape saw sharpening method using same

InactiveCN104439515AHigh precisionReduce the chance of over-grinding or under-grindingSawing tools dressing arrangementsControl circuitChain saw

The invention discloses a full-automatic chain saw sharpener comprising a chain sharpening device and a chain feeder for feeding a chain. The chain feeder feeds the chain in such a manner: a cutting edge of a blade, to be sharpened, of the chain is fed to a sharpening position from front to back with the blade edges of the chain as references. The full-automatic chain saw sharpener further comprises a controller; the controller is used for coordinately controlling powers and sharpening settings required by actions of the chain sharping device and the chain feeder. The invention further discloses an auto-feed chain saw sharpening method; with the blade edges of the chain as references, the chain is fed from front to rear. The existing rear-to-front chain feeding manner is replaced with the front-to-rear chain feeding manner, thus chances of over-sharpening or failure of sharpening in the chain saw sharpening process are greatly slimmed; meanwhile, the actions are provided with distributed powers and a control board, and the sharpening process is precise and stable.

Owner:HANGZHOU SHARP GARDEN MACHINERY +1

Multi-stage separation sand machining production line

The invention relates to a multi-stage separation sand machining production line overcoming the defects that in the prior art, raw ore with the qualified granularity is prone to being excessively ground when secondarily crushed and ground, the content of ultrafine powder exceeds the standard, and the silicon sand particle yield and the unit manufacturing cost are affected. A two-stage screening system is arranged between a crusher and a small material bin and comprises a roller screen and a water flushing screen. A large particle returning belt is connected between the roller screen and the crusher. A medium particle front conveying belt is connected between the water flushing screen and the material bin. A small particle collecting pool is arranged at the lower portion of the two-stage screening system and connected with a post-grinding pool through a slurry pump and a pipeline. By means of the two-stage screening system, silicon sand crushed by the crusher is divided into large particles, medium particles and small particles according to the needed specification; the medium particles are conveyed into the material bin and enter a grinding machine; the small particles are directly conveyed into the post-grinding pool behind the grinding machine; and the large particles and the small particles do not enter the grinding machine, the phenomenon of excessive grinding is reduced, the work efficiency is improved, and material losses are reduced.

Owner:河源旗滨硅业有限公司

ball mill

ActiveCN104258942BGuaranteed ventilation effectReduce the temperatureGrain treatmentsPulp and paper industryBall mill

The invention discloses a ball mill which comprises a ball milling barrel and a collecting bin, wherein the ball milling barrel is communicated to one end of the collecting bin through a bin outlet grate plate; a fan is connected to the upper part of the other end of the collecting bin through an air pipe, and a material storage is communicated to the lower part of the other end of the collecting bin through a material pipe; an air guide pipe is also arranged in the collecting bin, one end of the air guide pipe extends into the ball milling barrel, the other end of the air guide pipe extends into the air pipe, and an air baffle is arranged between the air guide pipe and the air pipe or the collecting bin; an air guide hole is formed in a collecting bin housing. Due to the adoption of the ball mill, the flow quantity and speed of airflow in a grinder can be increased according to the production needs, sufficient grinding time of materials in the grinder is guaranteed, and the quality and yield of finished products can still be ensured when the comprehensive moisture content of the grinding materials is relatively high.

Owner:张沁玥

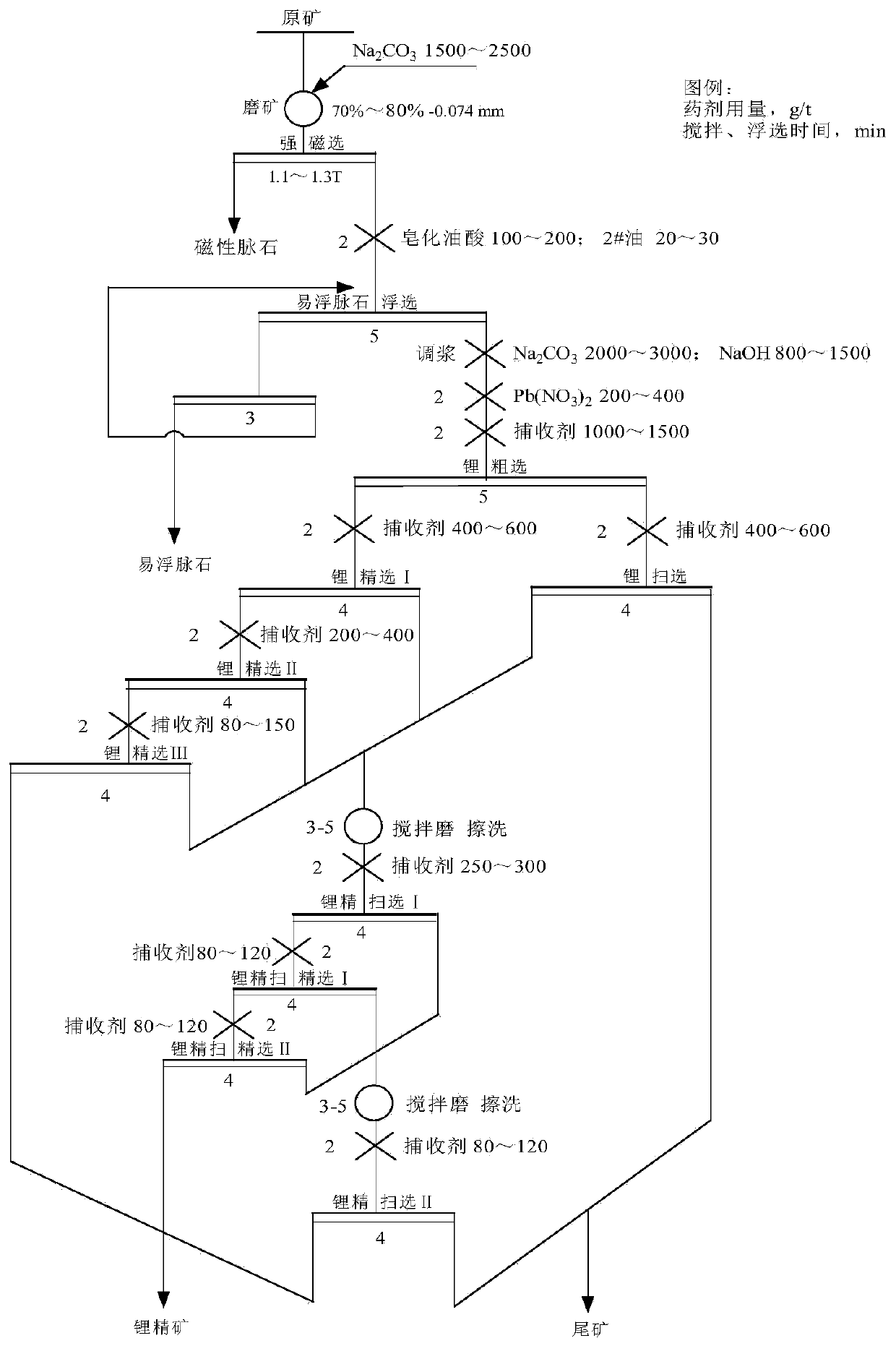

Spodumene ore flotation collecting agent, preparation method thereof and beneficiation process of clay mineralized spodumene ore

PendingCN111330743AImprove flotation effectImprove flotation efficiencyFlotationOXALIC ACID DIHYDRATEGallic acid ester

The invention relates to the field of beneficiation, and particularly provides a spodumene ore flotation collecting agent, a preparation method thereof and a beneficiation process of clay mineralizedspodumene ore. The spodumene ore flotation collecting agent comprises sodium oleate, gallic acid, tartaric acid, oxalic acid and lignin of specific content. The beneficiation process of the clay mineralized spodumene ore is mainly used for solving the problems of serious argillization and poor floatability caused by clay mineral materialization of spodumene ore, the spodumene ore flotation collecting agent is selected, a full-open-circuit process of independent scrubbing, regrinding and reconcentration of middlings is adopted for beneficiation, excessive accumulation of secondary mud caused bya conventional closed-loop process can be effectively avoided, adverse effects like overlarge agent dosage, high pulp viscosity and poor agent selectivity are alleviated, meanwhile, middling grindingand washing operation can be enhanced, and the defect that coarse grains are difficult to float is overcome, so that the grade of concentrate Li2O is improved, and lithium-containing minerals are fully recycled.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

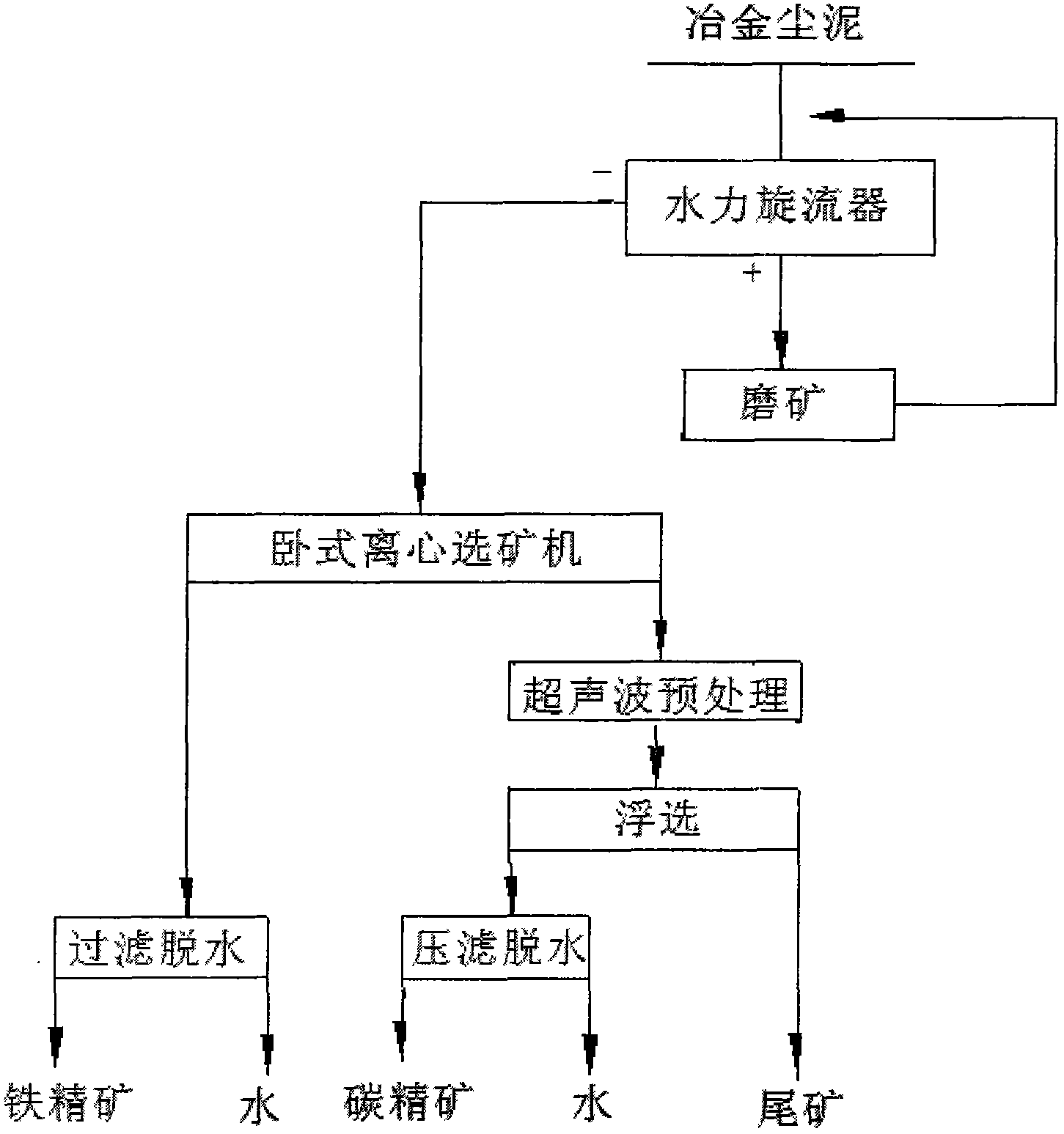

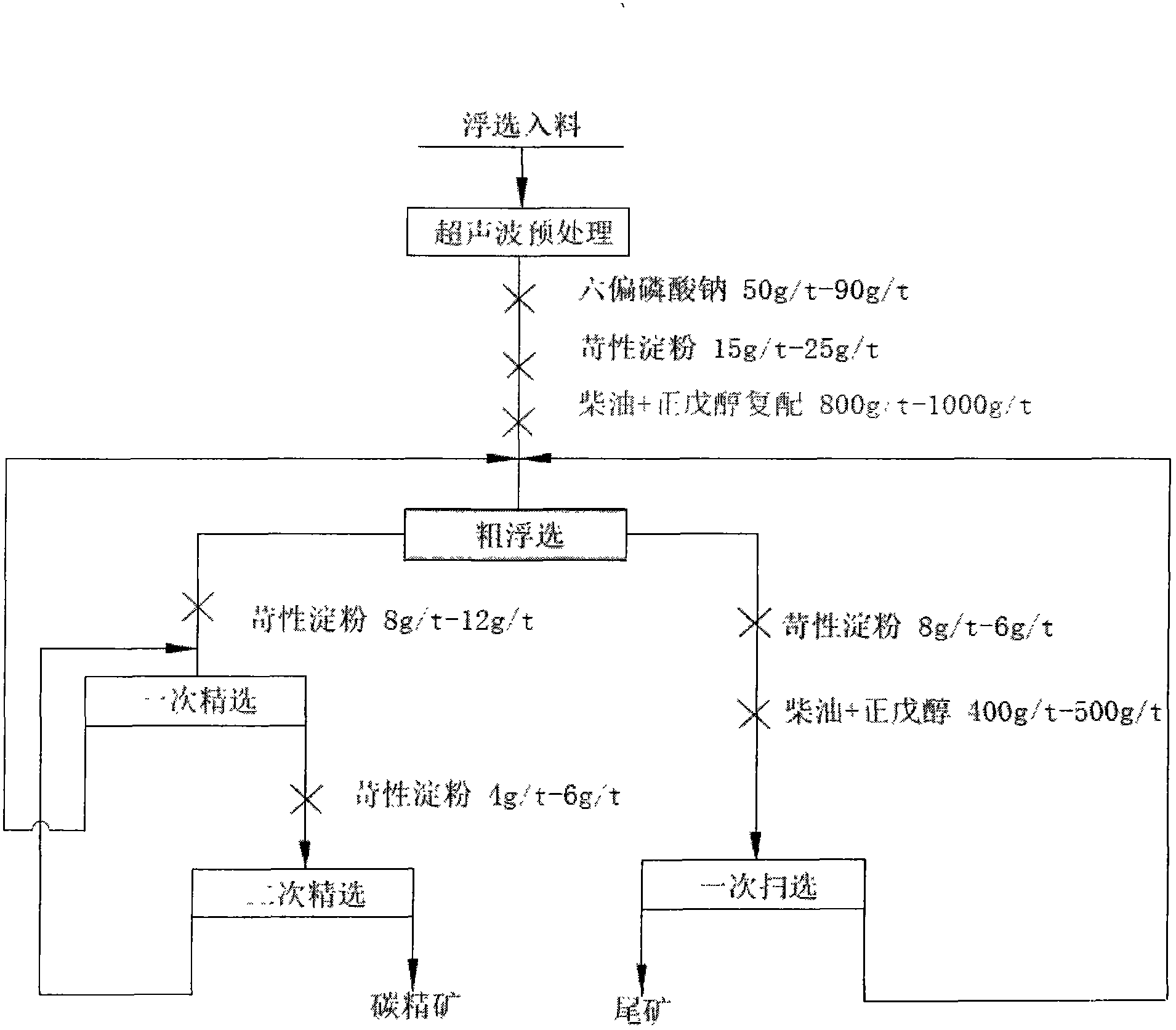

Processing and utilizing method for extracting carbon and iron from blast furnace metallurgy dust and sludge

InactiveCN103230831AGood for opening and dispersingImprove sorting effectRotary centrifugesFlotationSludgePolyacrylamide

A processing and utilizing method for extracting carbon and iron from blast furnace metallurgy dust and sludge belongs to the technical field of mineral processing. The method is characterized by including the steps that metallurgy dust and sludge containing polyacrylamide flocculant is processed, the metallurgy dust and sludge is graded through a hydrocyclone, coarse fraction products are ground and returned to grading operation, fine fraction products are subjected to once roughing and once fine selection through a horizontal centrifugal separator, and iron ore concentrate for metallurgy is obtained through filtering and dehydration operation. Ore pulp of tailing products of the horizontal centrifugal separator is processed through ultrasonic wave and dispersed by adding sodium hexametaphosphate, selective flocculant caustic starch is added, carbon is selected in a floatation mode under the effect of diesel and an n-amyl alcohol compound collecting agent, and carbon concentrate can be obtained through operation of once roughing, twice fine selection and once scavenging. The tailing products selected in the floatation mode are used as the final tailing products. The processing method for utilizing secondary resources of the blast furnace metallurgy dust and sludge containing the flocculant efficiently is provided and has important practical significance on cleaner production, recycling economy and energy saving and emission reduction in iron and steel industry.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com