Beneficiation method for magnetic mixed ore

A beneficiation method and mixed ore technology, applied in the direction of solid separation, grain processing, etc., can solve the problems of increasing the grinding load, not performing pre-selection and grading, and reducing the grinding efficiency, so as to reduce the amount of grinding, improve the grade of grinding and The effect of grinding efficiency and reducing energy consumption of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

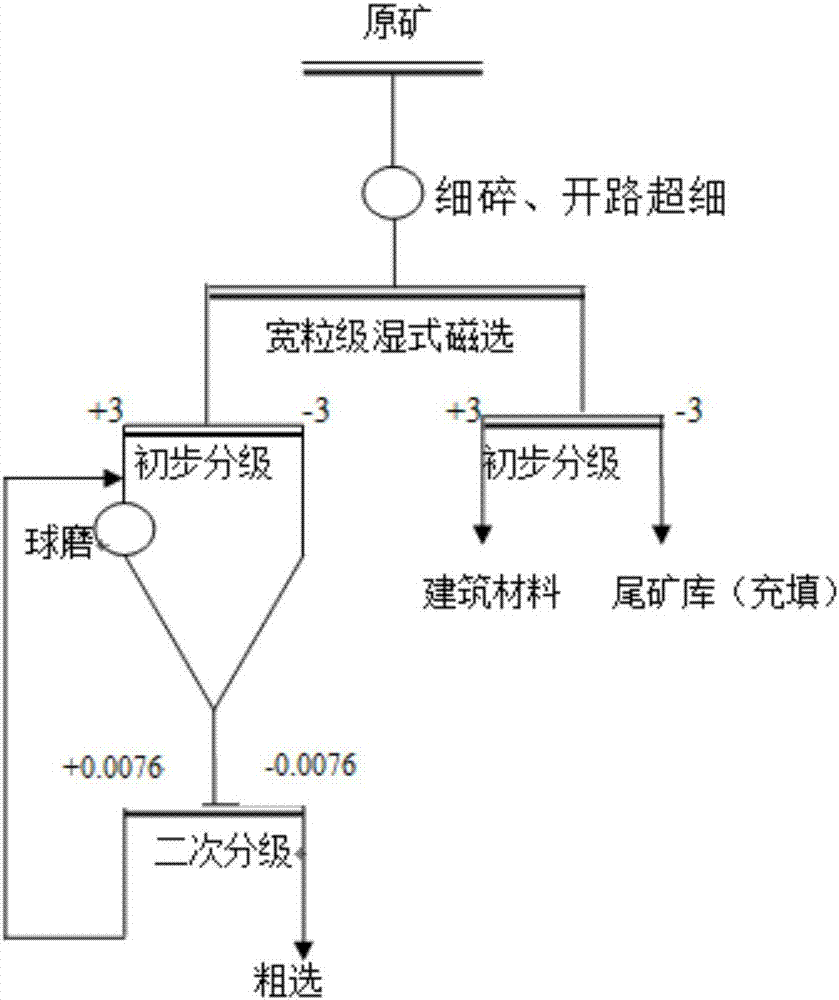

[0025] The invention discloses a mineral processing method for magnetic mixed ore. The mineral processing method includes crushing of raw materials, pre-selection of raw materials after crushing, treatment of rough concentrate after screening and treatment of tailings after screening. After pre-selection of raw materials and rough concentrate Before the treatment, there is a rough concentrate preliminary classification process for screening the rough concentrate. The addition of the rough concentrate preliminary classification process can make the raw material pre-selected and screened by the pre-selector. Concentrate products directly enter the next production process, avoiding the qualified coarse concentrate from being ground in the ball mill, which can effectively reduce the amount of grinding, reduce over-grinding, improve the grade of grinding and grinding efficiency, and reduce the energy consumption of grinding. It can not only reduce the work intensity of ball milling,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com