Efficient environment-friendly type beneficiation method for low-grade magnetic mirror iron ores

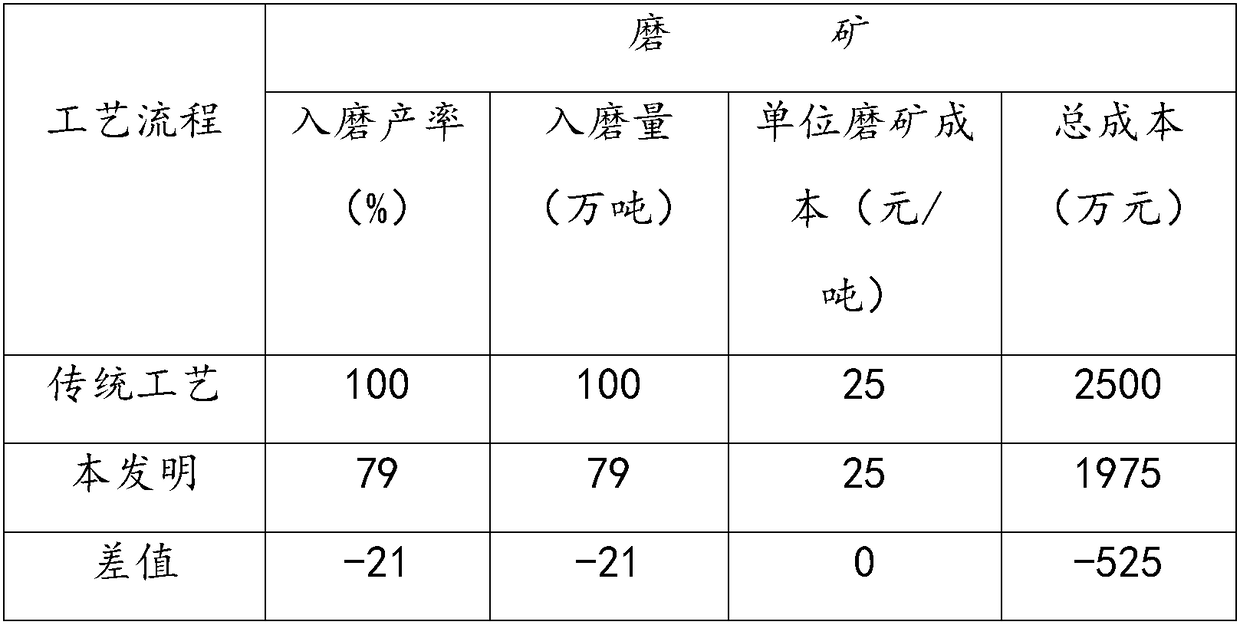

A beneficiation method and an environment-friendly technology, applied in the field of mixed iron ore beneficiation, can solve the problems of increasing the operating cost of the ball mill, the beneficiation workload, difficulty in efficient and environmentally friendly recycling, shortening the safety and life of the tailings pond, and reducing the weight. The effect of dressing operation cost, reducing tailings discharge, reducing the amount of ore feeding and the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

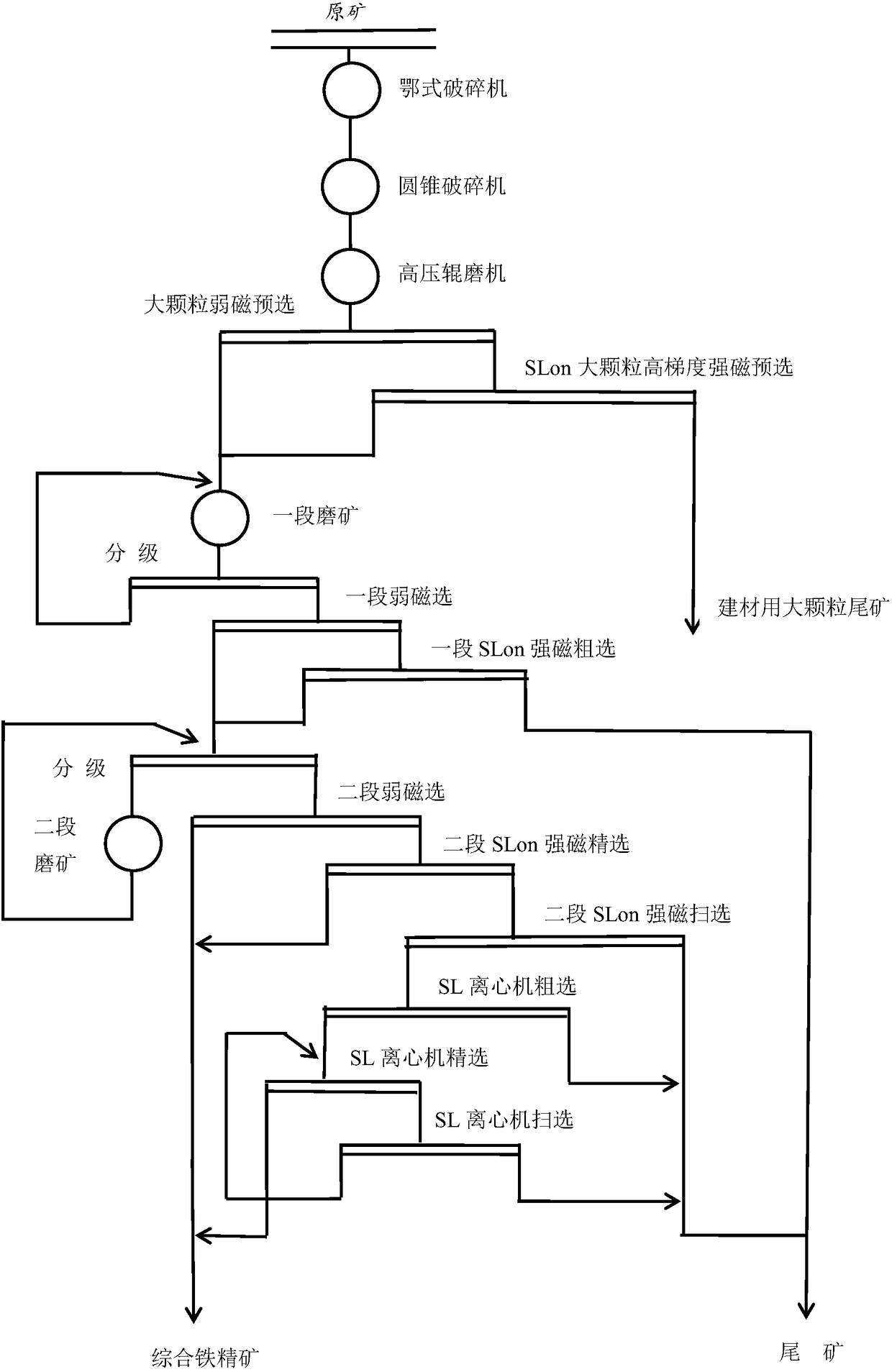

[0029] In order to further describe the present invention, an efficient and environment-friendly beneficiation method for a low-grade magnetic mirror iron ore of the present invention will be further described in detail by taking a magnetic mirror iron ore dressing in Anhui as an example below in conjunction with the accompanying drawings.

[0030] Depend on figure 1 Find out that a kind of magnetic mirror iron ore efficient and environment-friendly type mineral processing method concrete steps of the present invention are as follows:

[0031] A. Three-stage crushing of raw materials: The magnetic mirror iron ore lump (0-900mm) containing about 32% of total iron is roughly crushed to -45mm by the jaw crusher, and -28mm by the cone crusher, and then enters the high-pressure roller The mill crushes the large-grained ore to -5mm, and makes the ore slurry through the mixer;

[0032] B. Pre-selection by medium magnetic separator for large particles: the ore slurry made in step A i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com