Patents

Literature

98results about How to "Reduce the number of equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

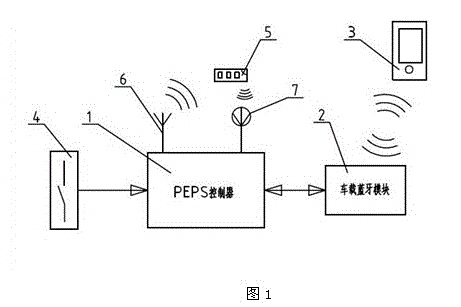

Intelligent automobile-key system based on bluetooth communication and control method thereof

InactiveCN103332170AEasy to useManipulation free fromAnti-theft devicesComputer terminalMobile phone

The invention provides an intelligent automobile-key system based on bluetooth communication, which comprises a PEPS (Passive Entry & Passive Start) controller, a vehicle-mounted bluetooth module, an electronic terminal and a door-handle switch, wherein the PEPS controller is connected with the vehicle-mounted bluetooth module and the door-handle switch, the PEPS controller is used for controlling a vehicle antitheft system and an engine system, the vehicle-mounted bluetooth module is used for realizing bluetooth communication with the electronic terminal, the electronic terminal has an intelligent automobile-key application program, and the door-handle switch is used for the input of user unlocking and locking requests. Because the vehicle-mounted bluetooth module exists, a vehicle is controlled to actively send out a bluetooth signal for actively identifying and authenticating the electronic terminal, such as a mobile phone, so that complicated operation is avoided.

Owner:JIANGSU ANZHIXIN ELECTRONICS TECH

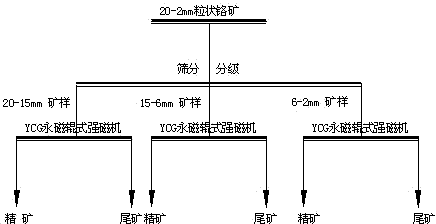

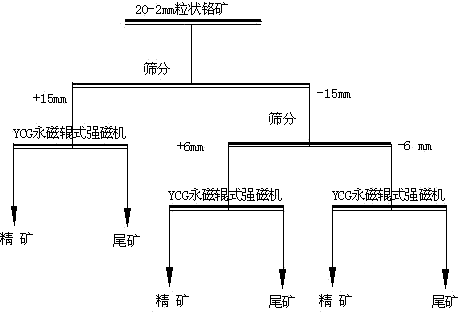

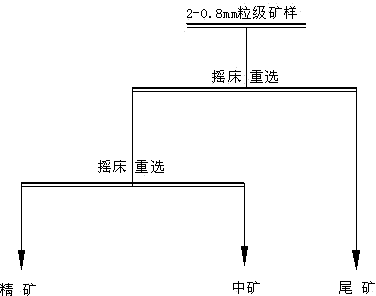

Novel beneficiation technology of high-grade ferrochrome ore

The invention discloses a novel beneficiation technology of high-grade ferrochrome ore. The novel beneficiation technology includes the following technological processes that ferrochrome ore is broken and is screened and classified into the ore of +20 mm fraction and the ore of -20 mm fraction. The ore of the +20 mm fraction receives manual back picking or hotching, large waste ore is thrown, and block concentrate is obtained. The narrow grade of the -20 mm fraction is screened and classified into four fractions, namely the 20-15 mm fraction, the 15-6 mm fraction, the 6-2 mm fraction and the 2-0 mm fraction. For the 20-15 mm fraction, the 15-6 mm fraction and the 6-2 mm fraction, a permanent magnet roller type intensity magnetic separator is used for performing dry intense magnetic separation. The 2-0 mm fraction is further screened and classified into the 2-0.8 mm fraction and the 0.8-0 mm fraction. For the 2-0.8 fraction, a shaker is selected again to obtain shaker gravity concentrate, and for the 0.8-0 mm fraction, a spiral chute and the shaker are used and a united procedure is selected again to obtain the thin-particle gravity concentrate. The novel beneficiation technology can be used for obtaining the concentrate and removing tailings in advance and has the advantage of being lower in energy consumption compared with other technologies. The technology can be used for grading chrome ore and can also be used for grading other weak magnetic iron minerals such as manganese ore, goethite, siderite and limonite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

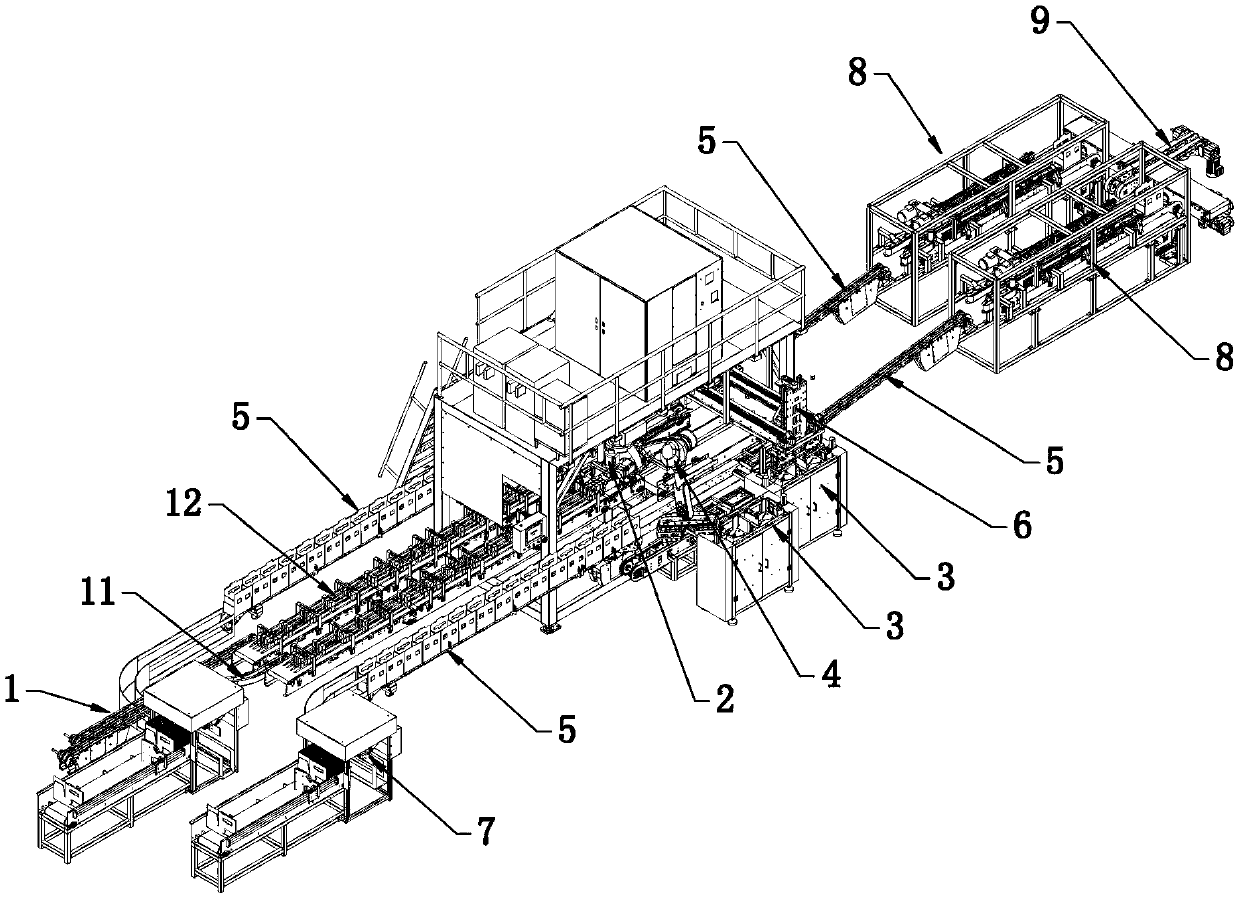

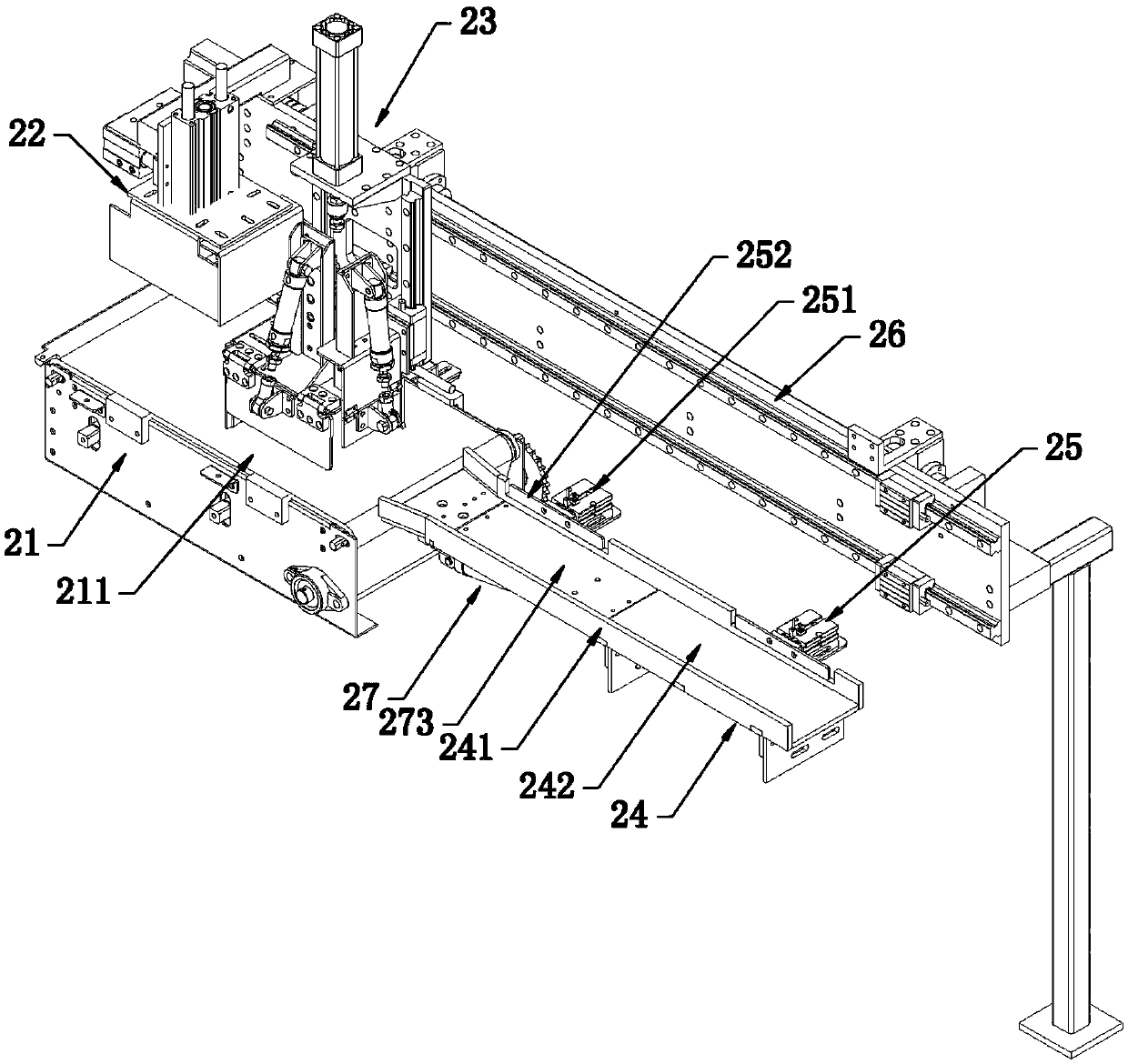

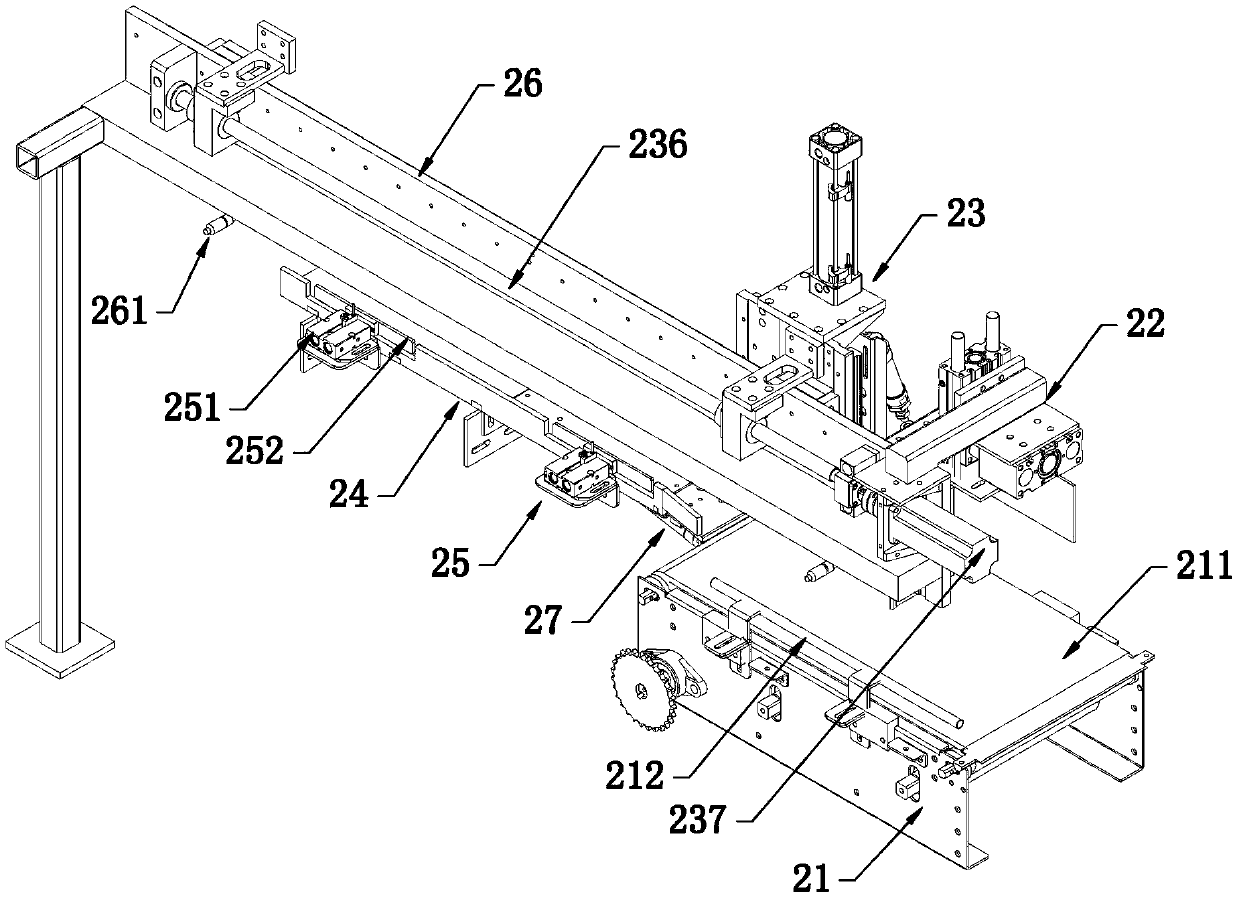

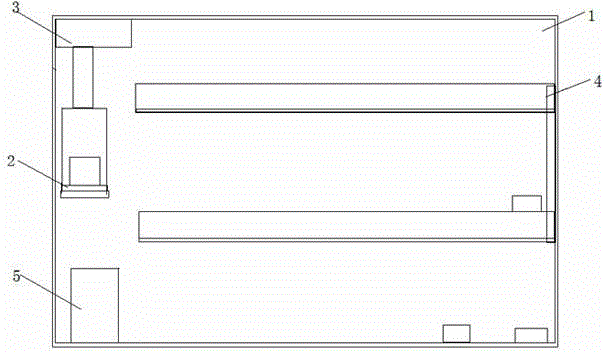

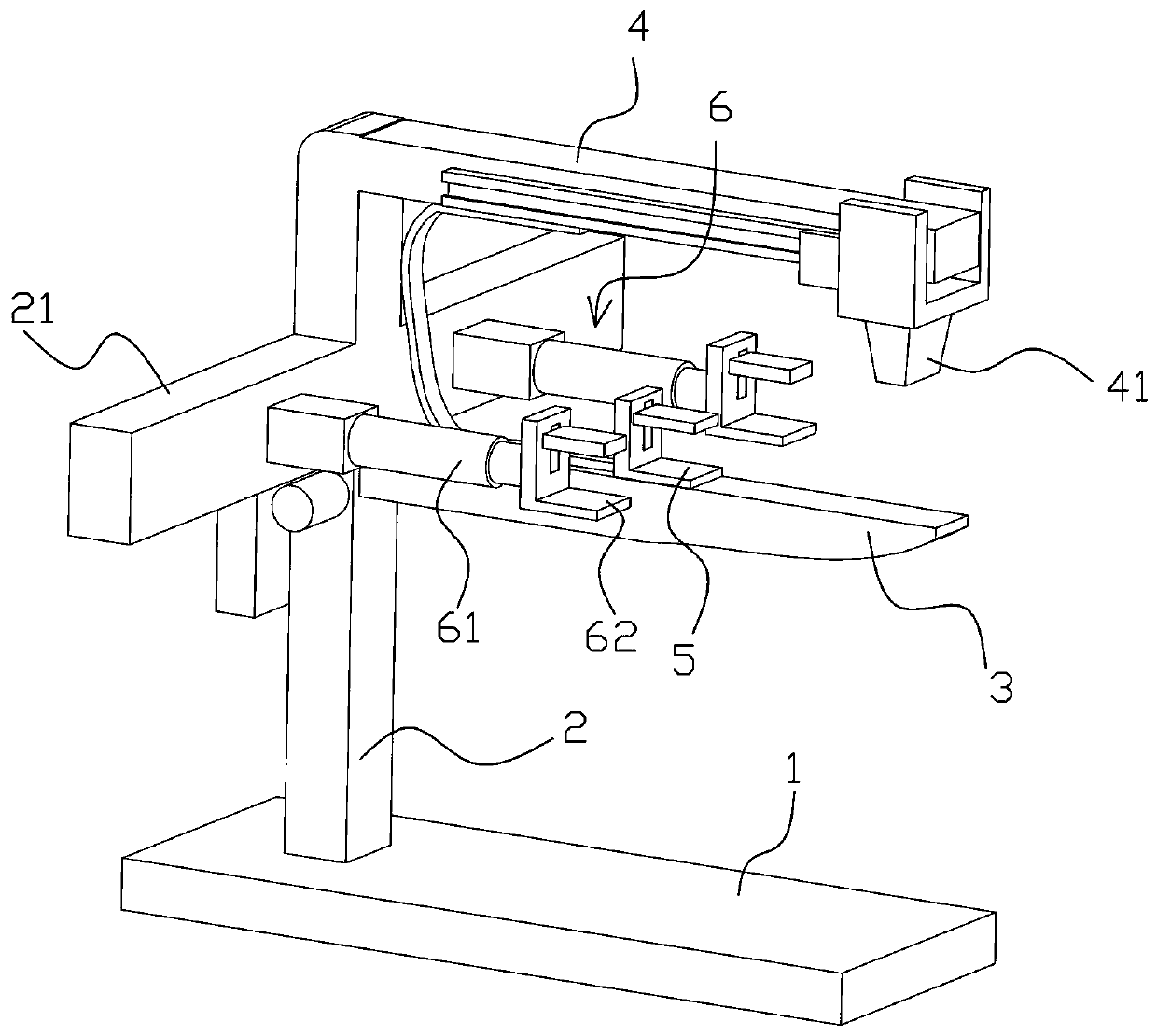

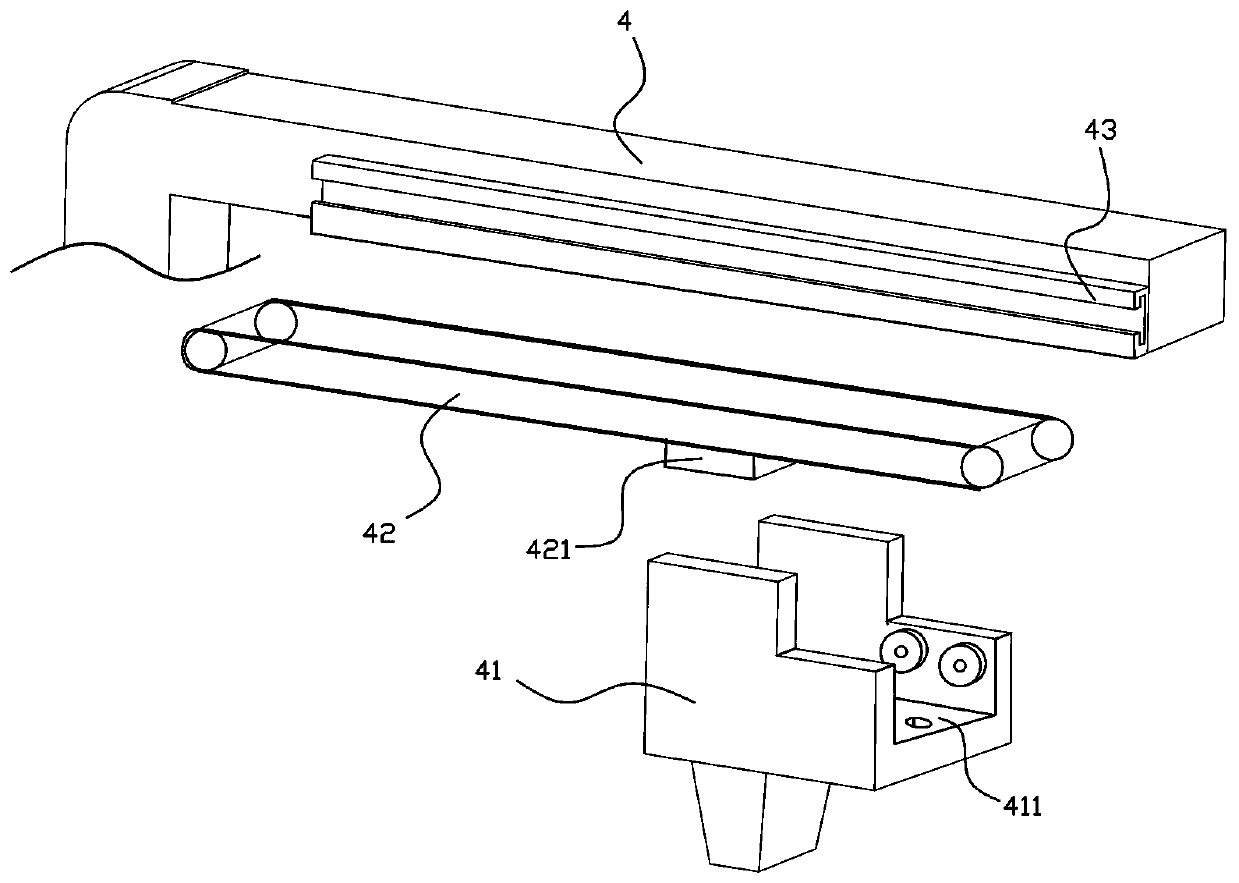

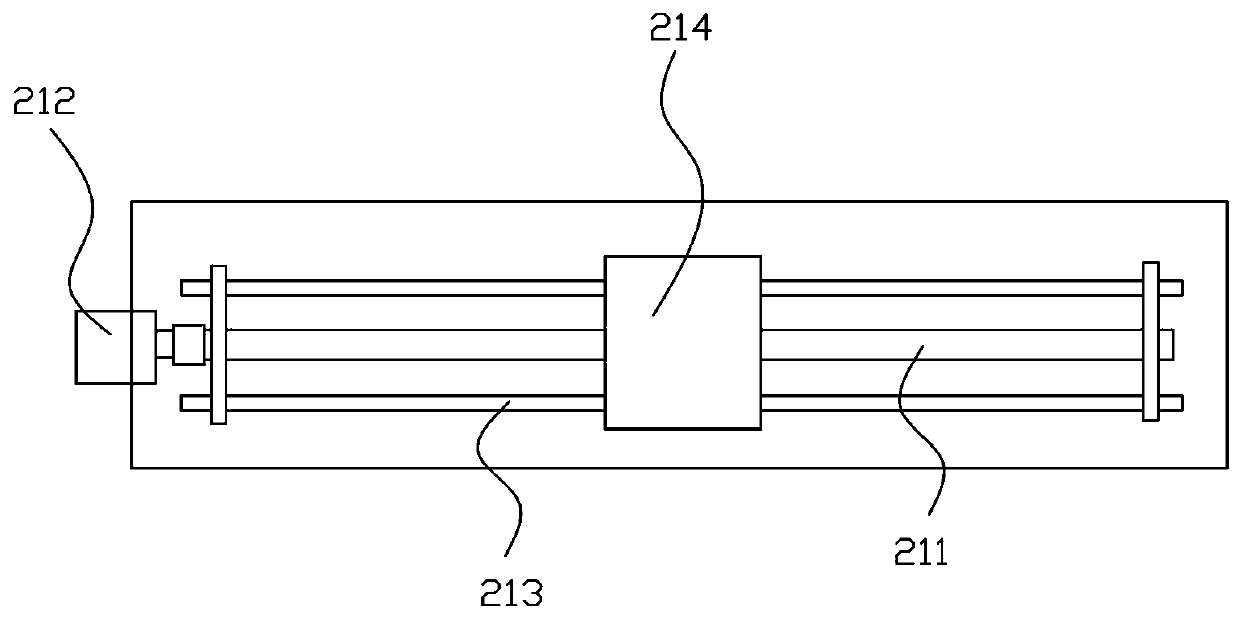

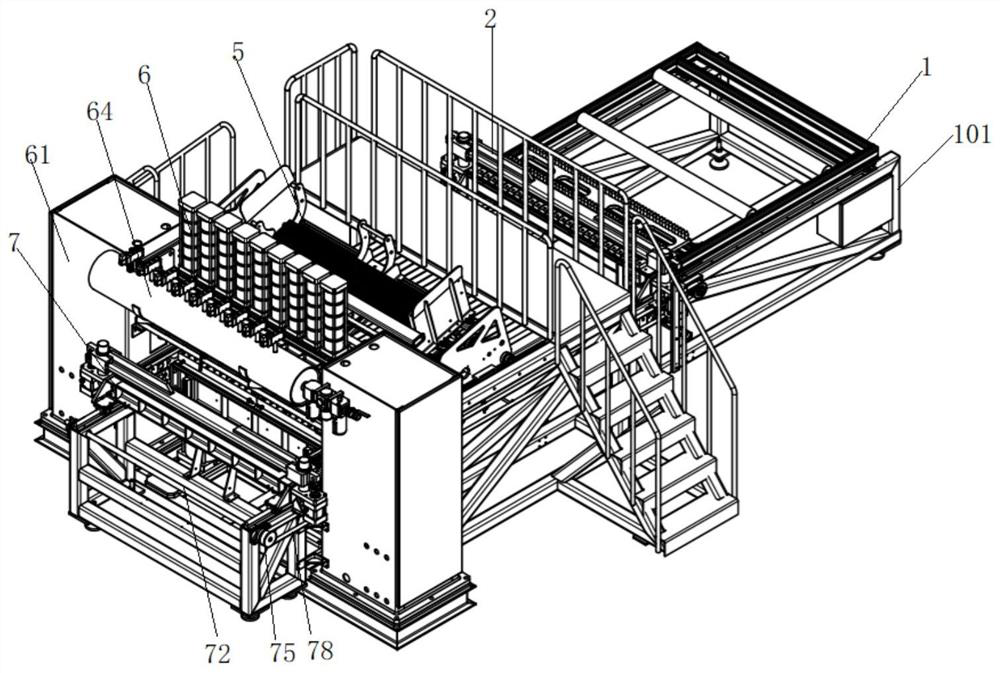

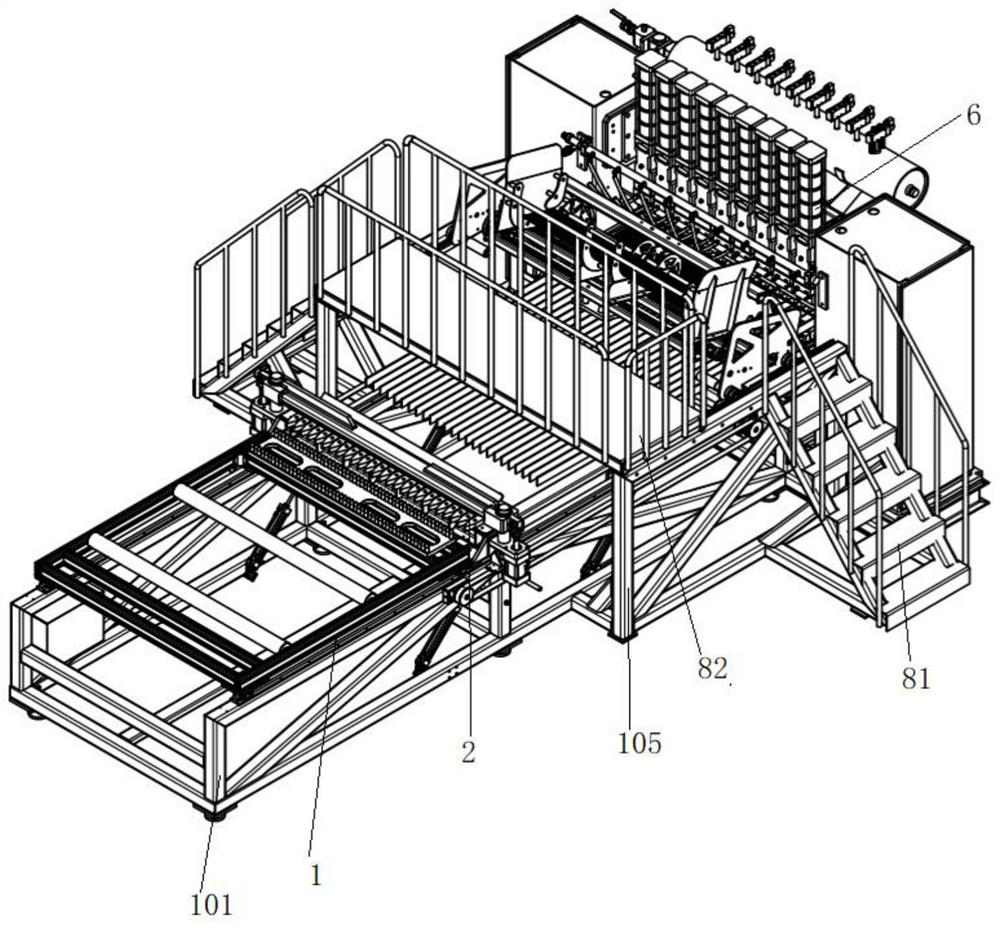

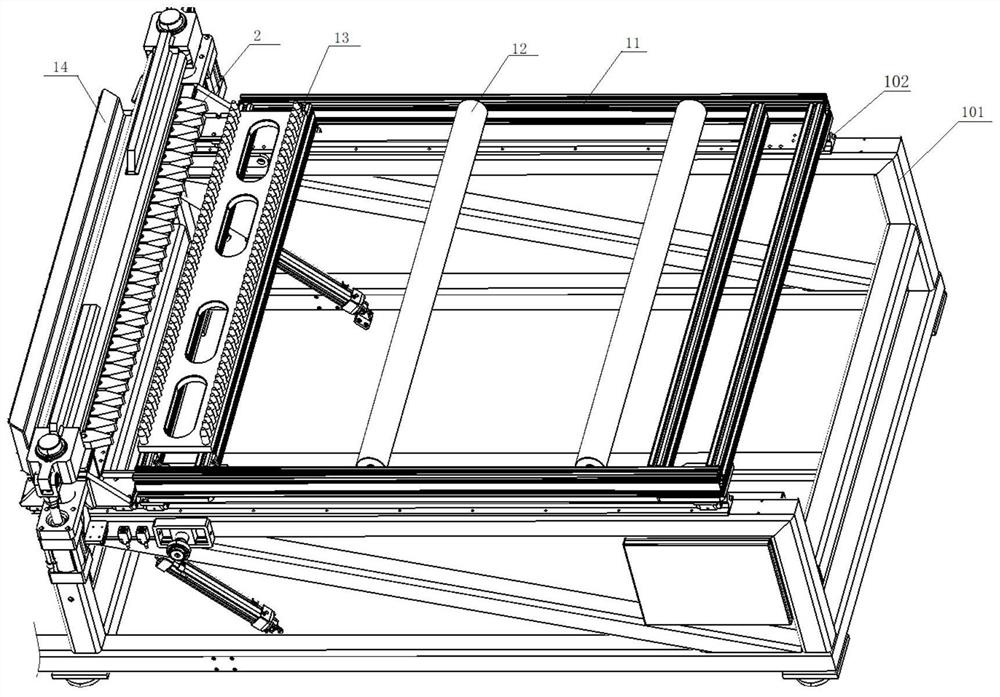

Automatic boxing system for second generation of tetra brik milk bag gift box

ActiveCN105501526AImprove the operating environmentImprove stabilityConveyorsPackagingEngineeringMechanical engineering

The invention discloses an automatic boxing system for a second generation of tetra brik milk bag gift box. The automatic boxing system comprises a separation mechanism (1), wherein the separation mechanism (1) comprises a primary separation mechanism (11) and two secondary separation mechanisms (12); an integration device (2) is correspondingly arranged at the tail end of each secondary separation mechanism (12), and two groups of partition board feeding mechanisms (3) and a milk box conveying line (5) which are corresponding are arranged beside each integration device (2) successively, the two groups of partition board feeding mechanisms (3) are respectively sleeved with lower partition boards, and a milk bag unit inbox mechanism (4) corresponds to an upper partition board straight-line module (6). A milk box sleeved with the partition board is conveyed to a corresponding lid buckling and box sealing machine (8) for lid buckling and box sealing through the milk box conveying line (5), and a two-in-one conveying mechanism (9) on the rear side of the lid buckling and box sealing machine (8) continues to convey the milk box. The automatic boxing system carries out automatic boxing in a two-in-one way, therefore reducing the speed, reducing links and increasing the output.

Owner:苏州澳昆智能机器人技术有限公司

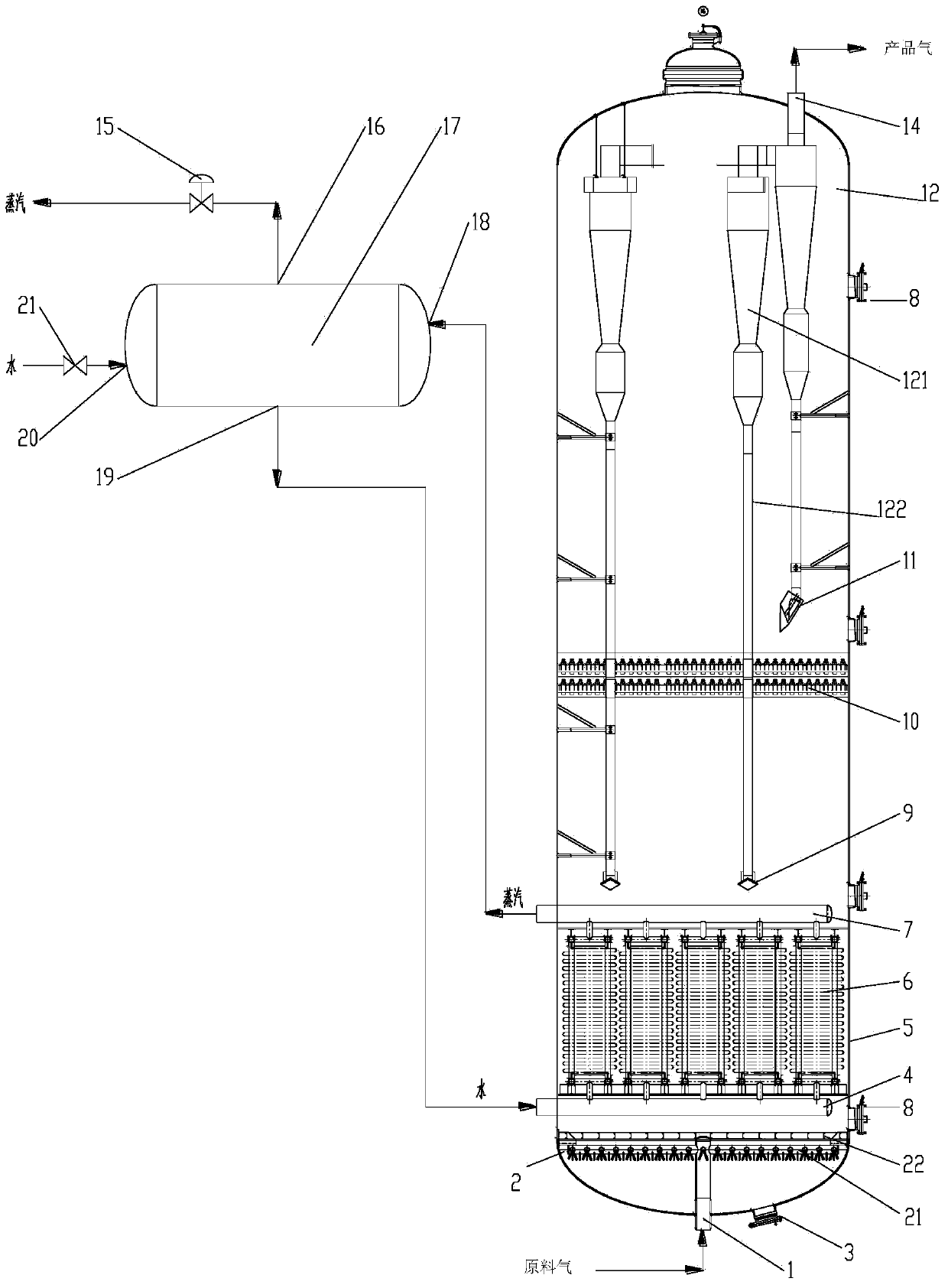

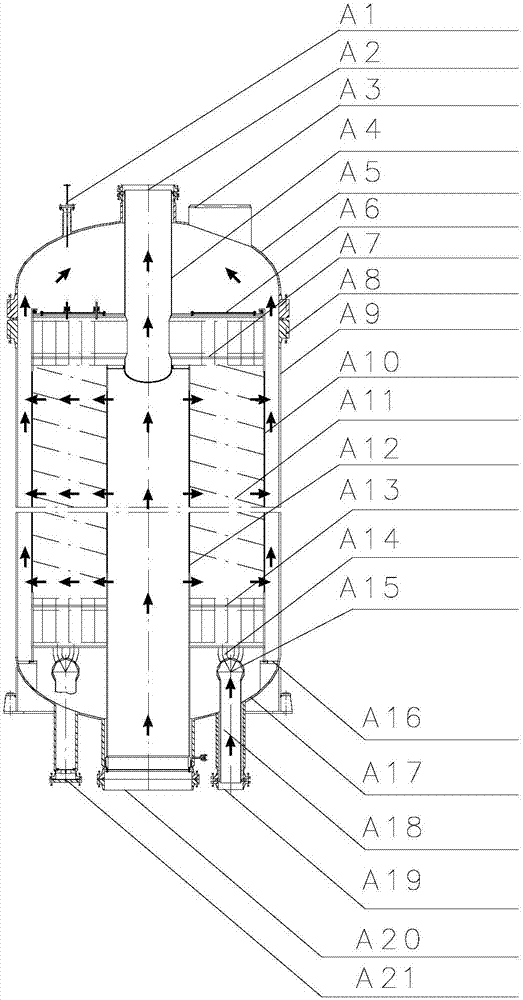

Methanation fluidized bed reactor

ActiveCN104001457AGuaranteed uptimeReduce consumptionGaseous fuelsChemical/physical processesFluidized bedMethanation

The invention provides a methanation fluidized bed reactor which is equipment for performing reaction on CO and H2 to generate methane and water and performing reaction on CO2 and H2 to generate methane and water at a certain constant low temperature. The methanation fluidized bed reactor comprises a cylindrical shell and inner parts, wherein a primary gas distributor and a secondary gas distributor are arranged at the bottom, and a catalyst is filled to form a catalyst bed; a heat exchange device consisting of a plurality of groups of heat exchange tubes is arranged in the catalyst bed; the lower ends of the heat exchange tubes in each group are communicated with a water inlet header pipe which is communicated with a water outlet of a steam drum, and the upper ends of the heat exchange tubes in each group are communicated with a steam outlet header pipe which is communicated with a steam inlet of the steam drum. According to the methanation fluidized bed reactor, heat continuously released during methanation reaction can be timely transferred through another medium, and the reaction can be performed at the constant low temperature.

Owner:尹明大

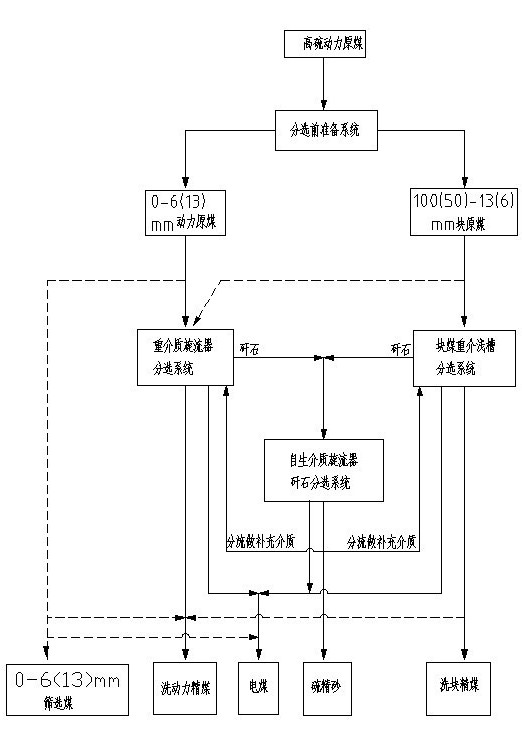

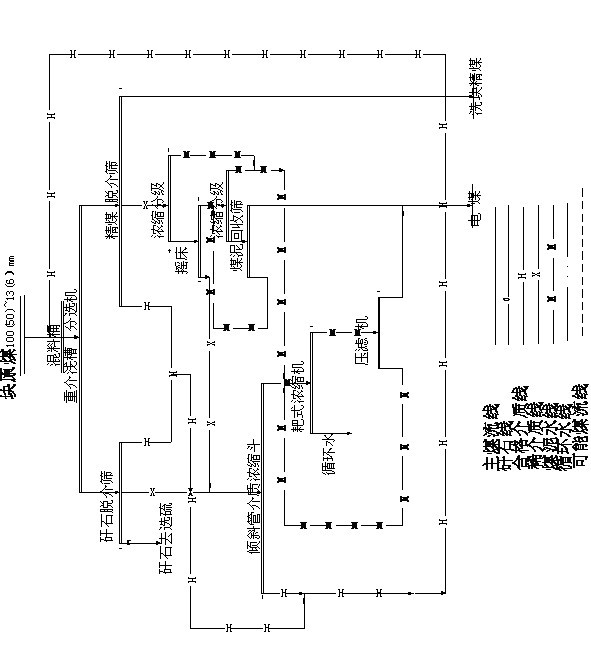

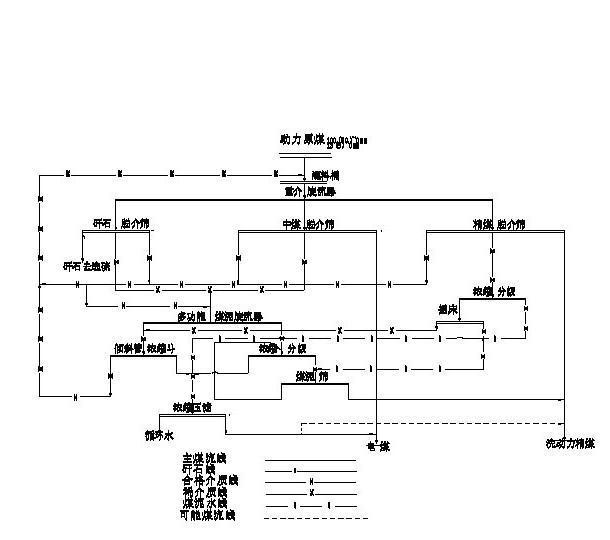

High-sulfur power raw coal sorting process

InactiveCN102489391AReduce manufacturing costSystem link simplificationSolid separationCoalProcess engineering

The invention relates to a high-sulfur power raw coal sorting process which comprises the following steps of: separating high-sulfur power raw coal into 100(50)-13(6) mm lump raw coal and 13(6)-0 mm power raw coal; leading the 100(50)-13(6) mm lump raw coal into a lump coal heavy medium shallow slot sorting system to discharge washed fine coal and gangue; leading the 13(6)-0 mm power raw coal into a heavy medium cyclone sorting system for sorting to discharge washed power fine coal and gangue; leading the gangue produced by both the lump coal heavy medium shallow slot sorting system and the heavy medium cyclone sorting system to enter an autogenous medium cyclone gangue sorting system for sorting to discharge ferric disulfide and electric coal, and simultaneously diverting fine ferric disulfide as a supplementary medium of the lump coal heavy medium shallow slot sorting system and the heavy medium cyclone sorting system; and finally processing the products of washed power fine coal, washed lump fine coal, ferric disulfide, electric coal and the like. The sorting system provided by the invention has simplified links, small floor space and low operating cost, the investment and operating cost of the whole factory is reduced by 15-20%; and meanwhile, the sorting system has good desulfurization property and obvious energy saving and emission reduction effects.

Owner:重庆南桐矿业有限责任公司选煤厂

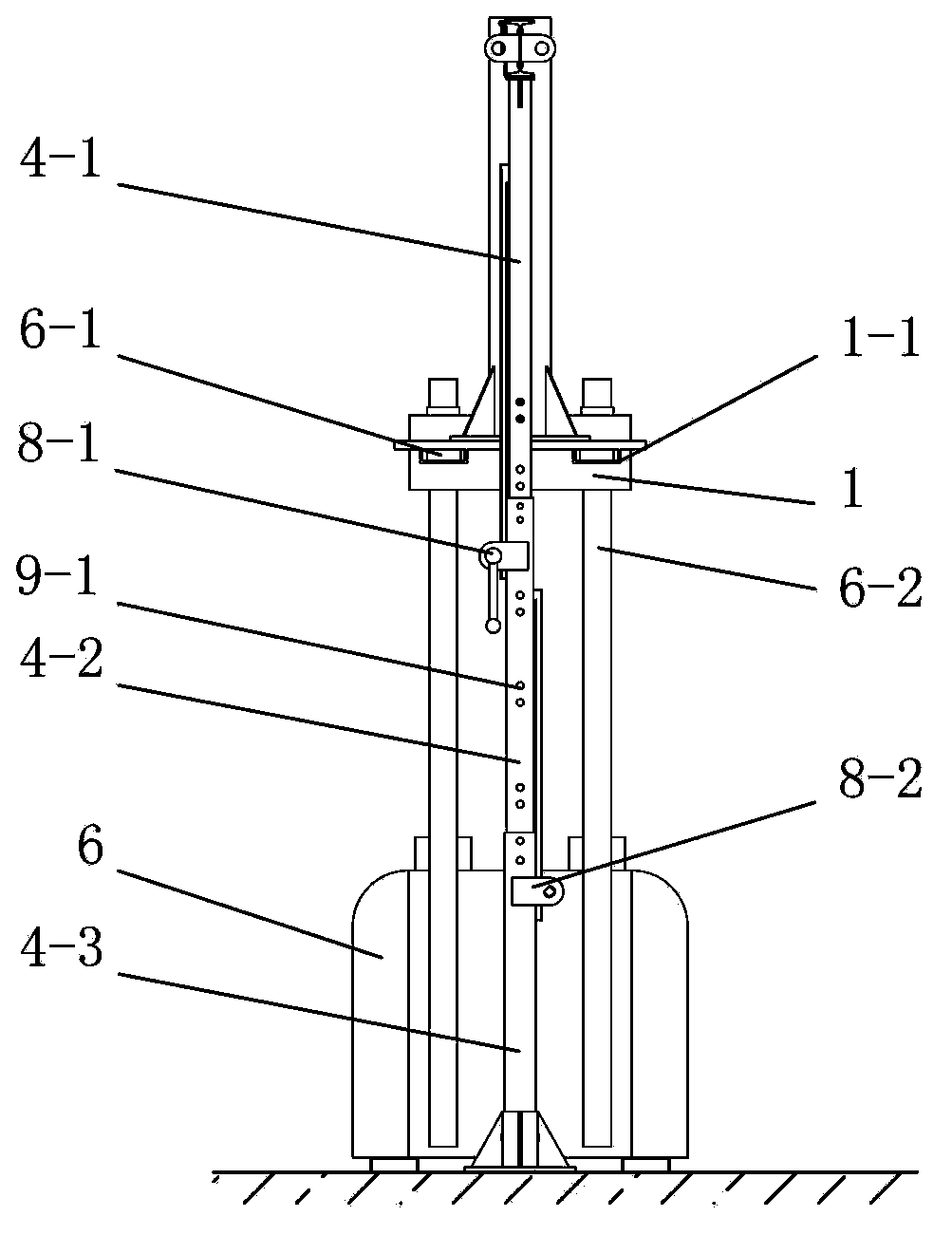

Intelligent suspension type stereo garage and work method thereof

The invention discloses an intelligent suspension type stereo garage, comprising a garage, a parking platform, a hoisting system, a moving system and an electrical control system; the parking platform is connected with the hoisting system, the moving system and the electrical control system; the hoisting system is arranged at the top of the garage; the moving system is connected with the hoisting system; the hoisting system and the moving system are connected with the electrical control system; an annular driving lane is arranged at the top of the garage. According to the intelligent suspension type stereo garage, the parking platform is hoisted by a hoisting chain in the hoisting system, and then the parking platform and a vehicle on the parking platform are moved to a position designated by a vehicle owner by the moving system, so the suspension type parking is realized, the structure of the stereo garage is simplified, and the problem of shortage of parking spaces is well solved while the cost is saved. The invention also provides the intelligent suspension type stereo garage and a work method thereof.

Owner:JIANGSU QIANYI IND

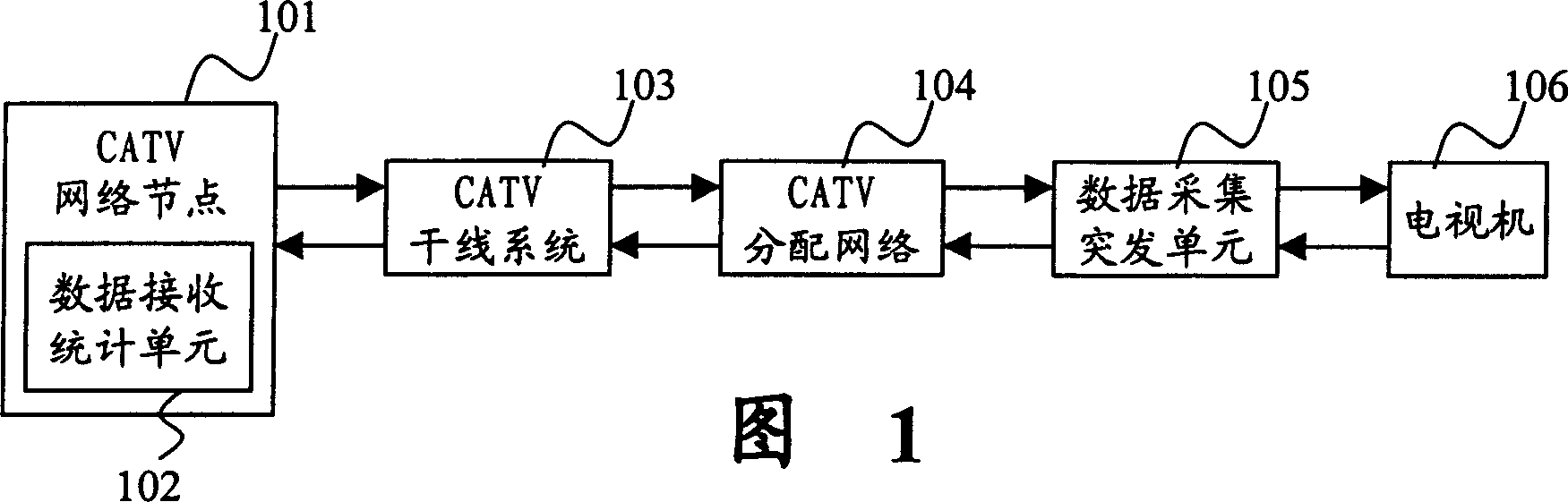

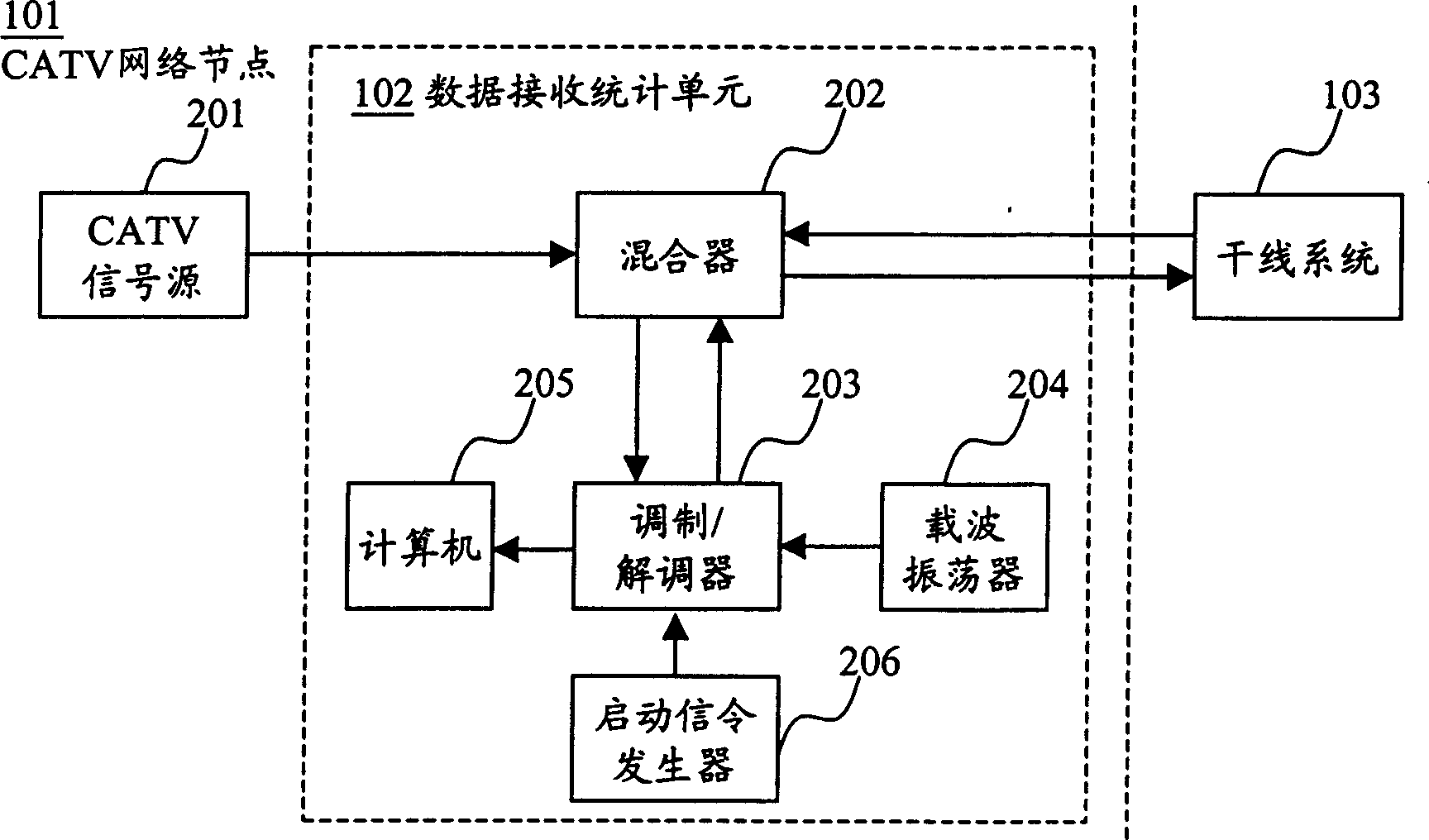

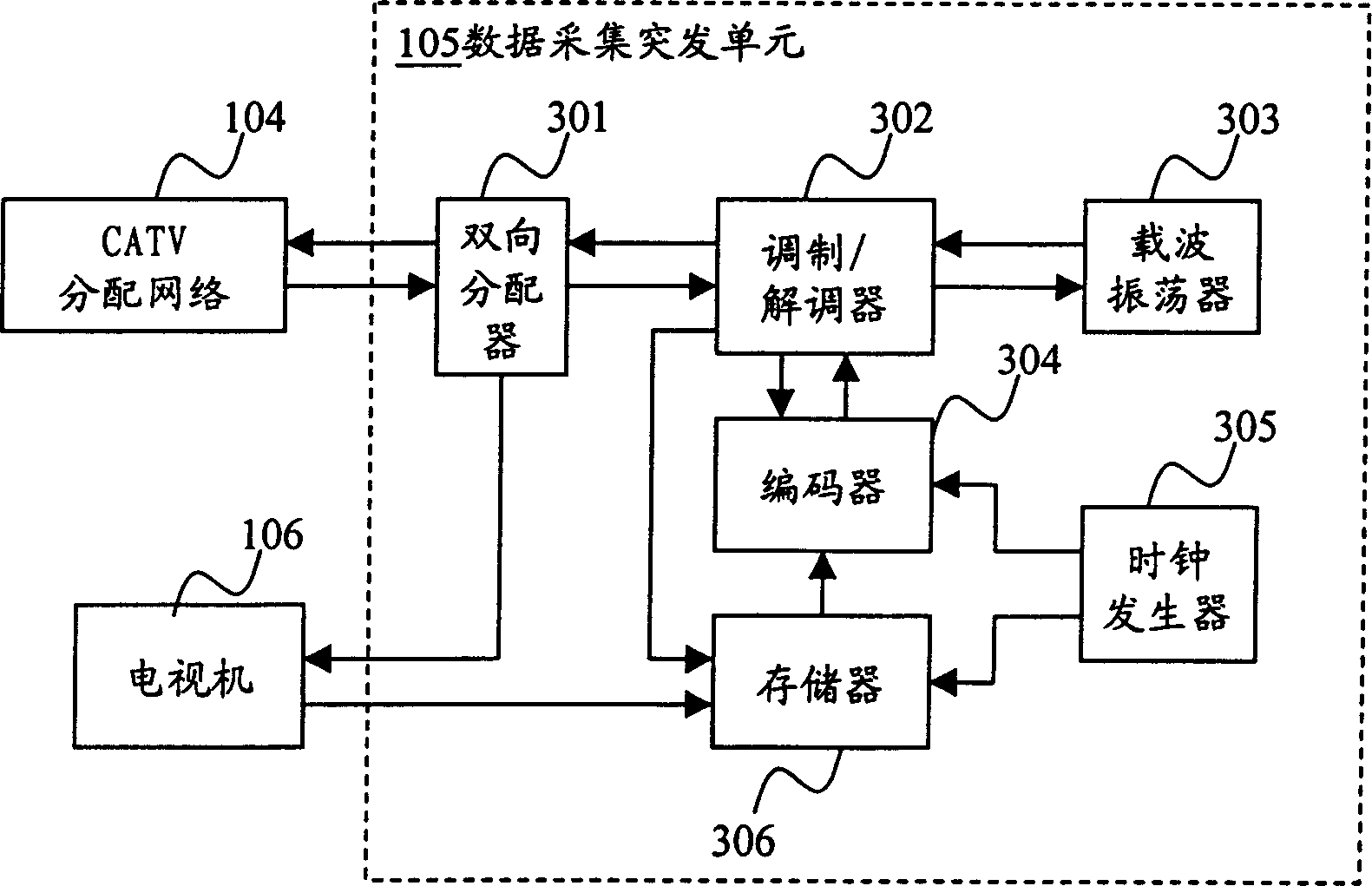

Automatic collection and statistical method and system for TV audience rating

InactiveCN1722821AEfficient managementSimple demodulationTwo-way working systemsElectrical cable transmission adaptationData acquisitionData science

This invention provides a method and system of automatically collecting and counting the television view rate, characterized in that the method comprises the following steps: a) the data receiving and counting unit 102 in CATV network node 101 will send data collecting open signal to the data burst collecting unit 105 in sampling user through the forward direction chain circuit of the two-way CATV network; b) the data collecting burst unit 105 will send the receive data to the receiving and counting unit 102 through the return chain circuit; c) the data receiving and counting unit will dressing, storing, analyzing and counting the returned data; d) getting the estimated value of view rate of the area covered by that network node. If gathering and processing the data of all network nodes, it can count the estimated view rate of bigger range.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

Flue gas denitration process for CO exhaust-heat boiler of FCC apparatus

ActiveCN103768932AImprove the mixing effectWell mixedDispersed particle separationEvaporationStreamflow

The invention discloses a flue gas denitration process for a CO exhaust-heat boiler of an FCC apparatus. Flue gas produced by an FCC regenerator is dedusted by a deduster, and before entering the CO exhaust-heat boiler, a cloud of flue gas is led out and used as a diluent gas for ammonia gas; and the flow of the diluent gas is 0.1 v%-5.0 v% of that of the original regeneration flue gas. The rest of the flue gas has energy recovered by a flue gas turbine, and is sent into the CO exhaust-heat boiler. The upper part of a high temperature evaporation section of the CO exhaust-heat boiler is provided with an ammonia injection grid, and an SCR denitration catalyst module is arranged between a low temperature evaporation segment and a high temperature economizer. The process provided by the invention uses FCC regeneration flue gas as the diluent gas for ammonia gas to dilute and carry the ammonia at the same time, so as to improve the mixing effect of ammonia gas and flue gas, not increase the rate of oxygen content rate of the CO exhaust-heat boiler, and avoid security risks; at the same time CO removal, waste heat recovery and denitrification of flue gas are accomplished in the CO exhaust-heat boiler, thereby omitting a separate SCR denitration reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

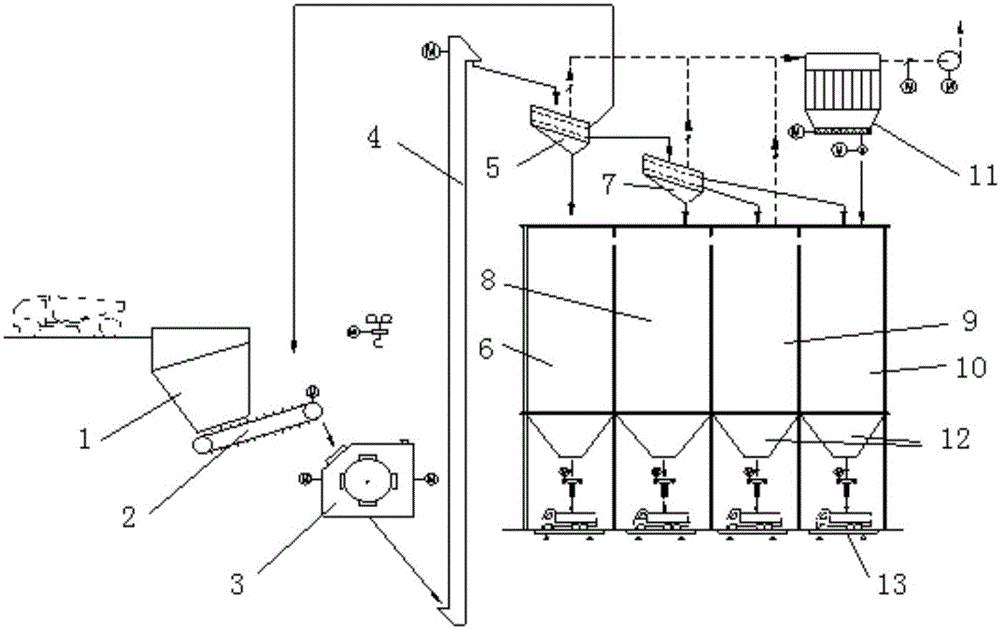

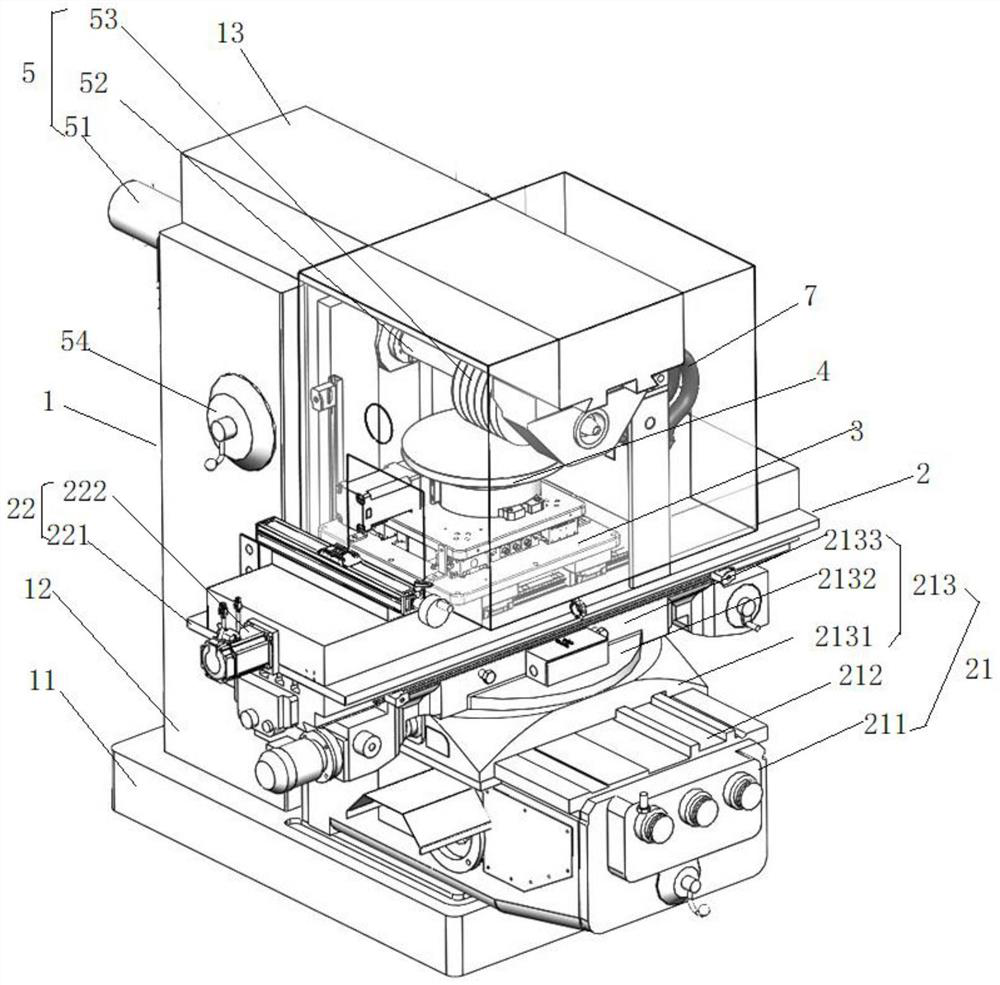

Efficient energy-saving concrete aggregate production line and method

ActiveCN105107571ASimple processReduce the number of equipmentGrain treatmentsProduction lineAutomatic control

The invention relates to an efficient energy-saving concrete aggregate production line. A feed inlet of a crusher, a plate type feeding machine, a hammer impact crusher, an elevator and a primary vibrating screen are sequentially connected. A primary coarse material outlet, a primary medium material outlet and a primary fine material outlet are formed in the primary vibrating screen and connected with the crusher, a first stock bin and a secondary vibrating screen respectively. A secondary coarse material outlet, a secondary medium material outlet and a secondary fine material outlet are formed in the secondary vibrating screen and connected with a second stock bin, a third stock bin and a fourth stock bin respectively. According to the efficient energy-saving concrete aggregate production line, the optimized scheme that the efficient crusher is used, the elevator is used for conveying and screening machines are arranged at the tops of the stock bins is adopted, in this way, the procedure is greatly simplified, the number of pieces of equipment is greatly reduced, and the number of dust raising points is also greatly reduced; a distributed control system (DCS) centralized full-automatic control scheme is adopted, and thus the efficient energy-saving concrete aggregate production line has the advantages that the number of required workers is small, the occupied area is small, investment is low, and energy consumption is low.

Owner:坚构建材科技集团有限公司

Little deformation welding process for mini car rear-axle housing

InactiveCN101407013AGood deformation controlReduce the number of equipmentArc welding apparatusEngineeringEnergy consumption

The invention discloses a small deformation welding process for a rear-axle housing of a mini vehicle, which belongs to the field of mechanical processing. The process comprises the welding of a middle segment assembly of a rear axle of the mini vehicle, the welding of a axle sleeve assembly of the rear axle of the min vehicle and the welding of the rear-axle housing assembly of the mini vehicle. The process has the advantages that: 1. a connecting disk is unnecessarily processed after being welded; 2. the welding order (welding unit) is reset for easy deformation control; 3. by adopting the rigid clipping welding, the product quality is ensured; and 4. compared with the prior art, the process has the advantages of few equipment, low process cost, low energy consumption, low processing cost, small manufacturing area, smooth logistics and high labor capacity.

Owner:CHENGDU HANYAN TECH +1

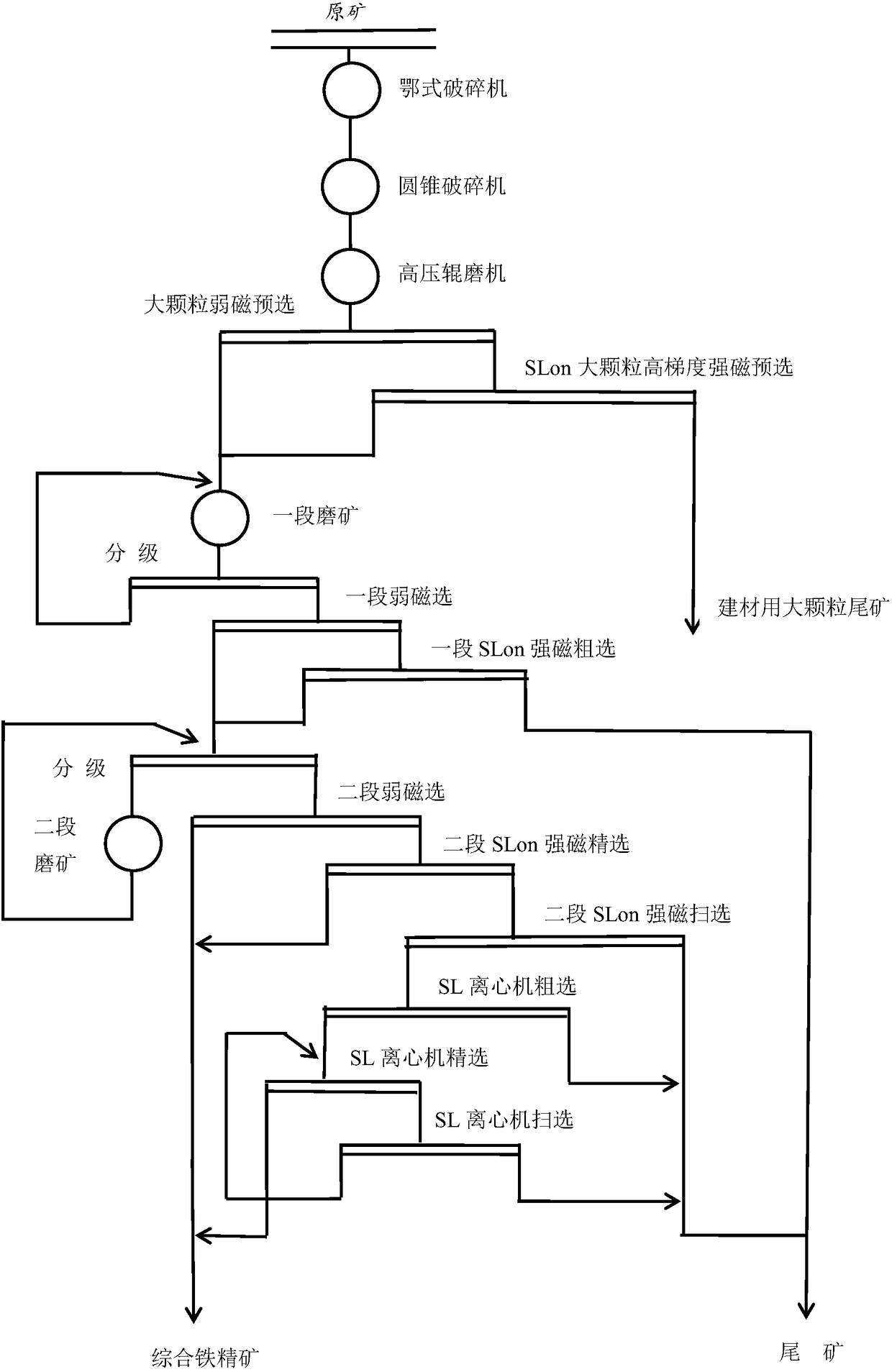

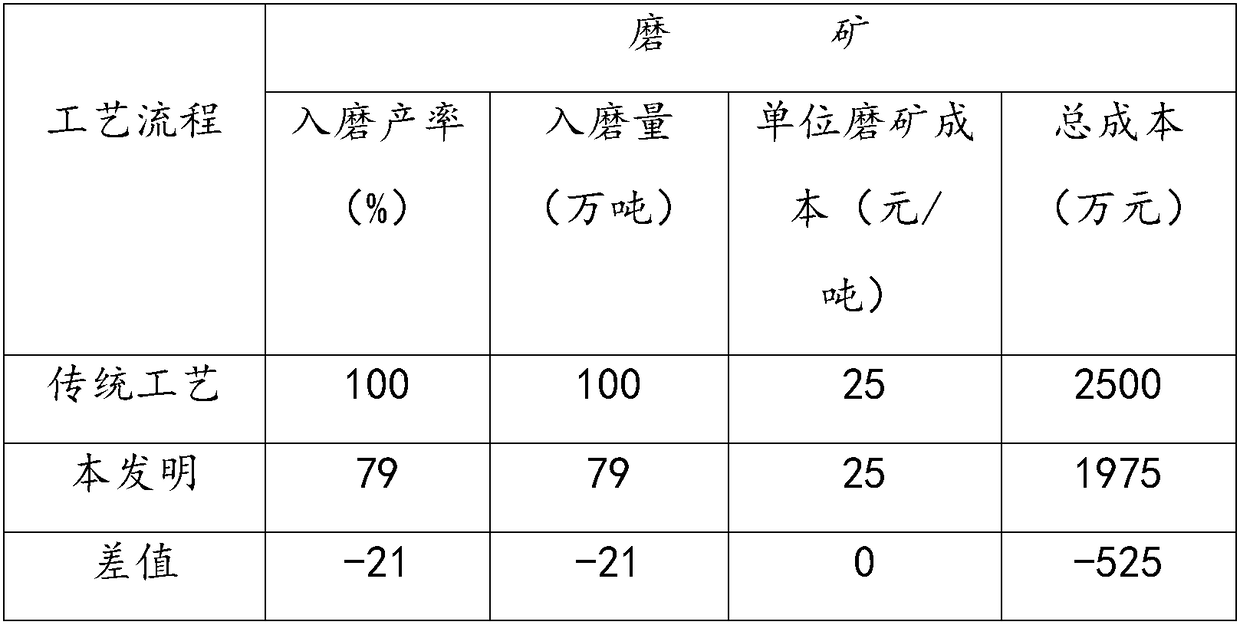

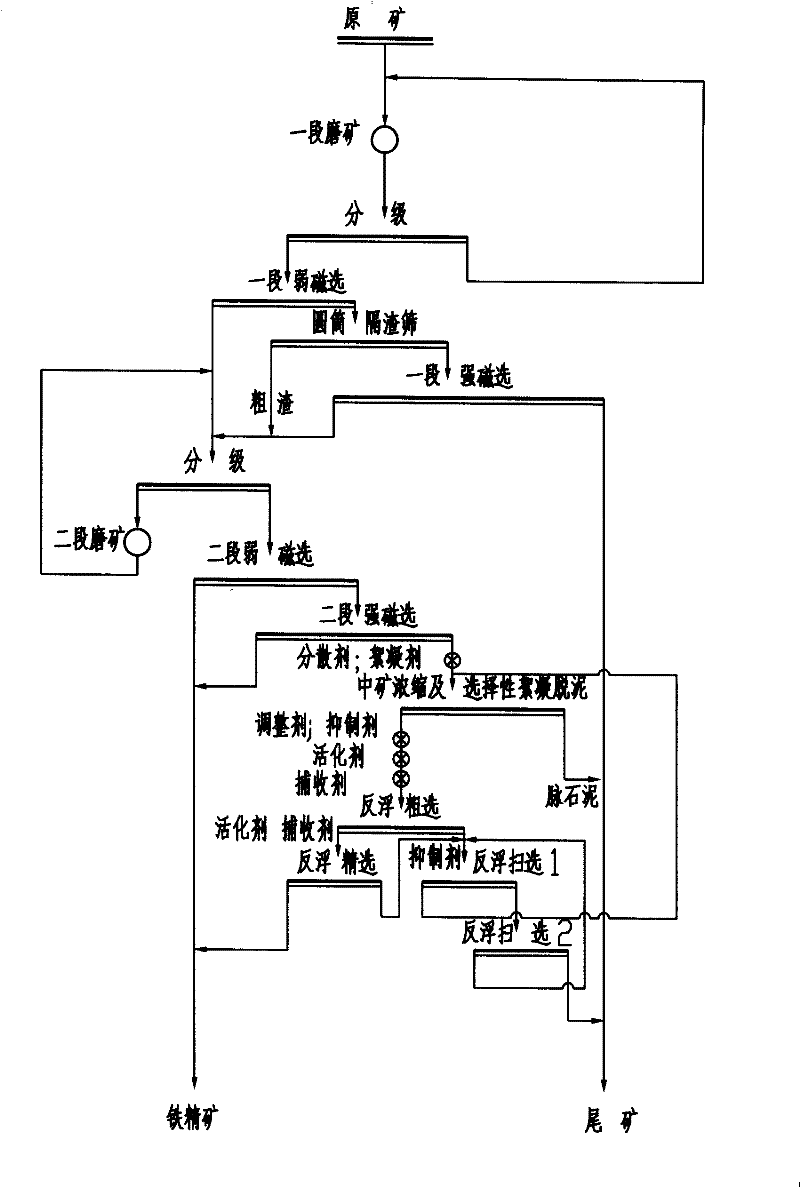

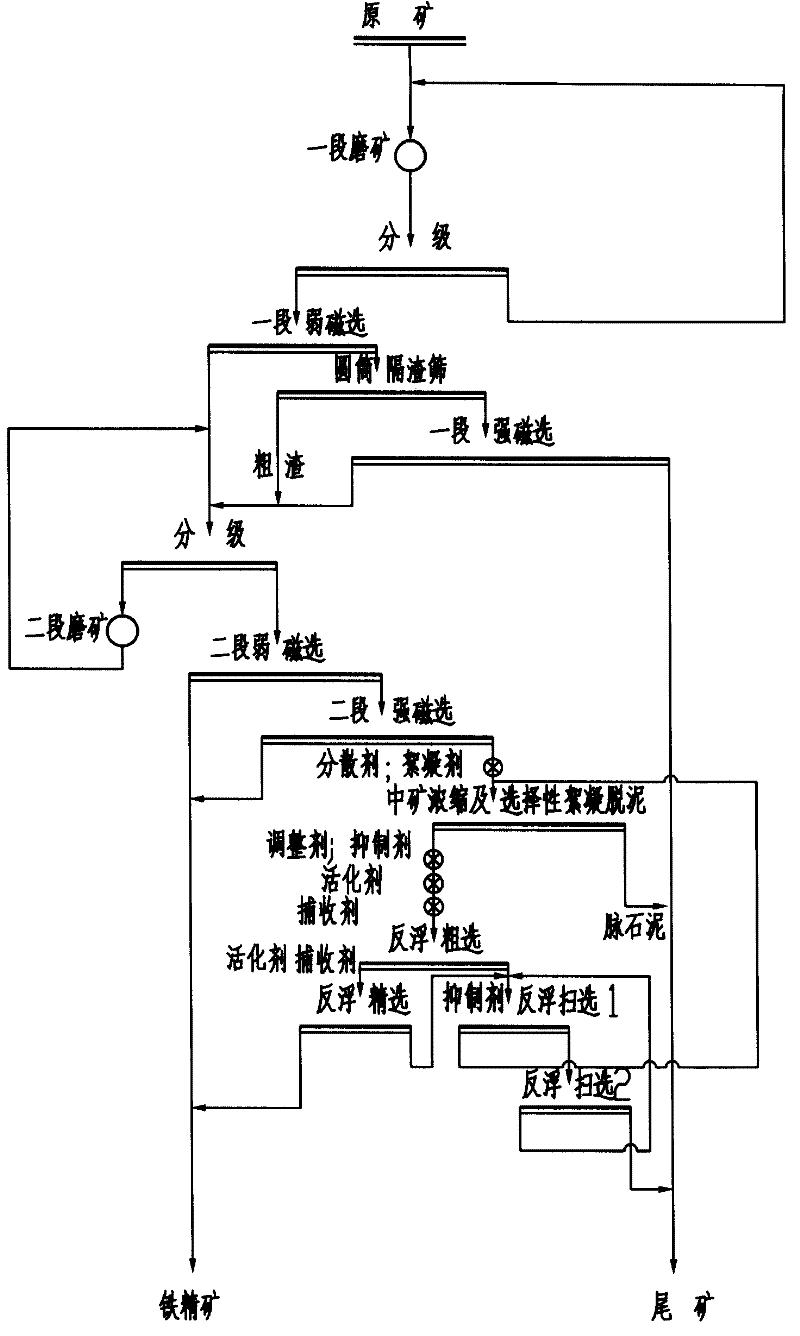

Efficient environment-friendly type beneficiation method for low-grade magnetic mirror iron ores

The invention discloses an efficient environment-friendly type beneficiation method for low-grade magnetic mirror iron ores. The efficient environment-friendly type beneficiation method is characterized in that iron ore concentrate which meets smelting requirements is obtained by adopting processes such as raw material three-stage crushing, large particle medium-magnetism and SLon strong-magnetismpre-selection, one-stage ore grinding and grading, one-stage weak magnetic-selecting and one-stage SLon strong magnetic-selecting, pre-grading and two-stage ore grinding and grading, two-stage weak magnetic-selecting and two-stage SLon strong magnetic-selecting and SL centrifugal machine selecting operation for the magnetic mirror iron ores. The efficient environment-friendly type beneficiation method can throw 21% of coarse-particle barren rocks through high-pressure roller-grinding, large-particle medium-magnetism pre-selecting and SLon strong-magnetism pre-selecting, and meets the beneficiation principle of preferably crushing instead of grinding and throwing as early as possible. A selecting process of roughing, cleaning and scavenging of a centrifugal machine is adopted, so that re-selecting operation completely replaces reverse flotation operation, and therefore, the efficient environment-friendly type beneficiation method is a pollution-free beneficiation method, is high in degree of automation, is great in processing amount, is liable to realize field operation and implementation, and greatly reduces manual operation.

Owner:WUHAN UNIV OF TECH

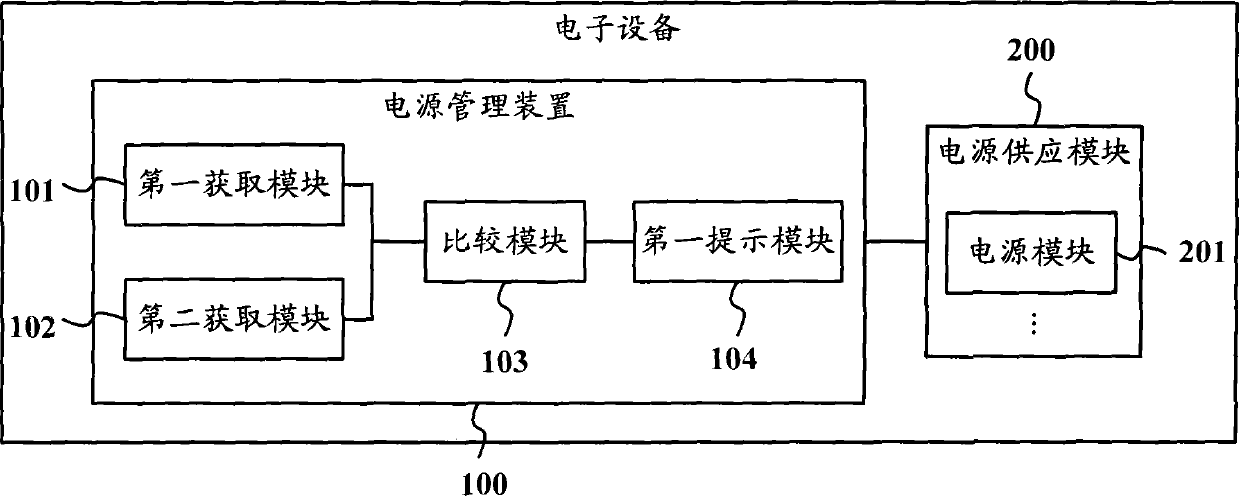

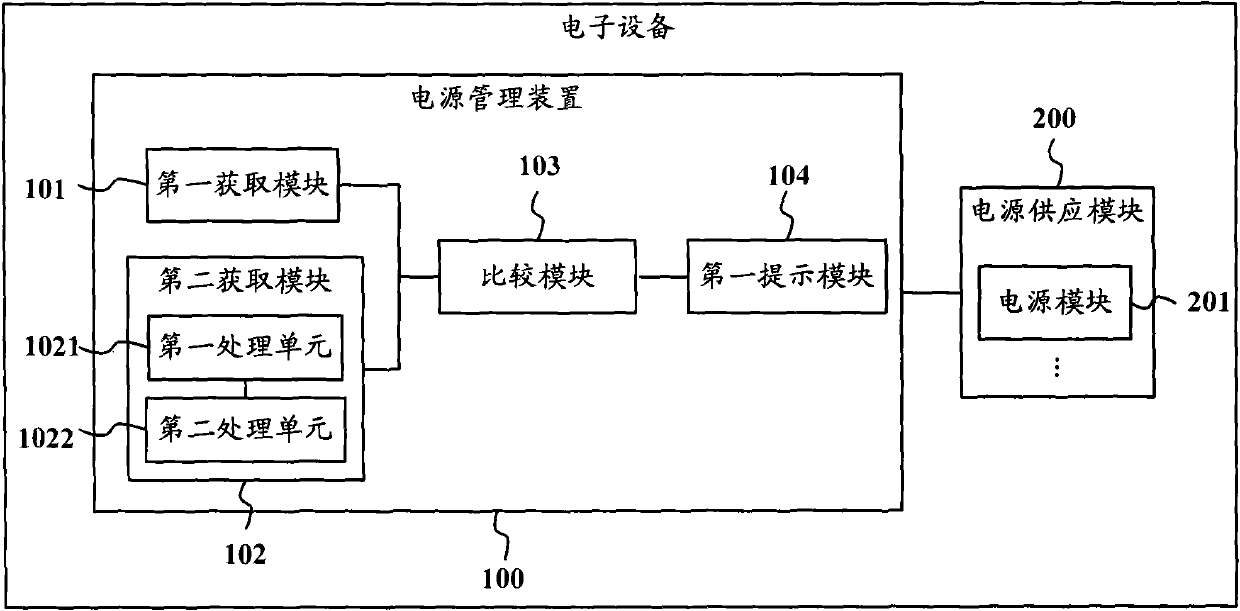

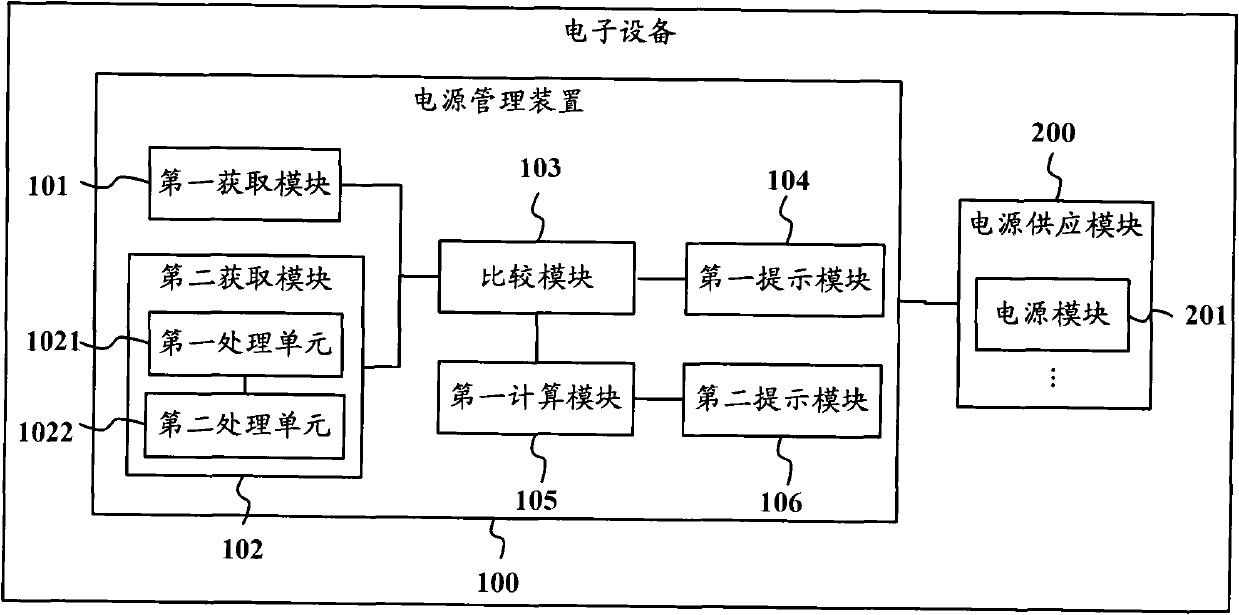

Power supply management apparatus, electronic equipment and power supply management method

InactiveCN102023694AReduce the numberReduce the number of equipmentVolume/mass flow measurementPower supply for data processingSupply managementElectric power

The invention provides a power supply management apparatus, a piece of electronic equipment and a power supply management method. The power supply management apparatus is applied in the electronic equipment and is connected with a power supply module in the electronic equipment. The power supply module comprises at least one power module. The power supply management apparatus comprises: a first obtaining module used for obtaining electric power load needed by the electronic equipment, a second obtaining module used for obtaining electric power load provided by the power supply module at present, a comparison module used for comparing the electric power load needed by the electronic equipment with the electric power load provided by the power supply module at present so as to obtain a comparison result, and a first prompt module used for generating a prompt message in dependence on the comparison result. The prompt message is used to prompt whether the power module needs to be increased or decreased at present. The invention can determine the coupling relation between the electric power load needed by the electronic equipment and the electric power load provided by the power supply module at present so as to reduce system costs.

Owner:LENOVO (BEIJING) LTD

Wind and light supplementary electric vehicle and production technology

InactiveCN101633321AReduce the number of equipmentReduce energy consumptionVehicular energy storageElectric propulsionCapacitanceAutomotive battery

The invention provides an electric vehicle which makes wind power technology supplementary with solar energy photovoltaic technology and takes an electric vehicle power supply system formed by storage battery charging capacitor mixing energy storing technology as energy sources, and also provides a production technology. The invention overcomes the shortages of small stored energy, short continuous driving mileage and insufficient repeated charging of the existing electric vehicle batteries, realizes continuous dynamic power supply to the electric vehicle or stores excess electric quantity to use by solar energy photovoltaic energy and wind power energy generated by air power in driving, utilizes renewable energy sources and a cycling power generation mode to provide energy power, reduces storage battery allocation amount and charging energy consumption, enlarges relative power storing capacity and increases continuous driving mileage.

Owner:王文明

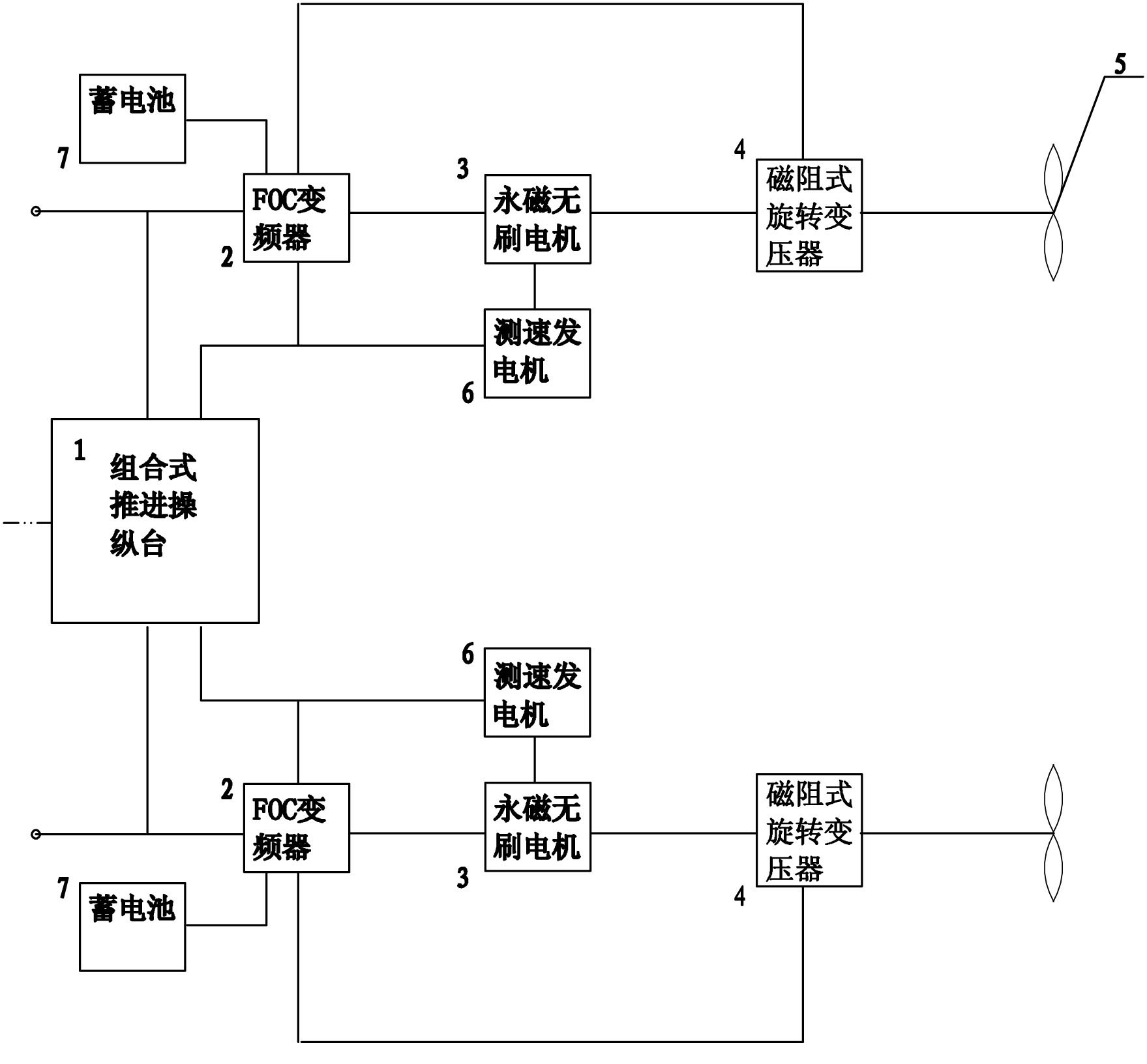

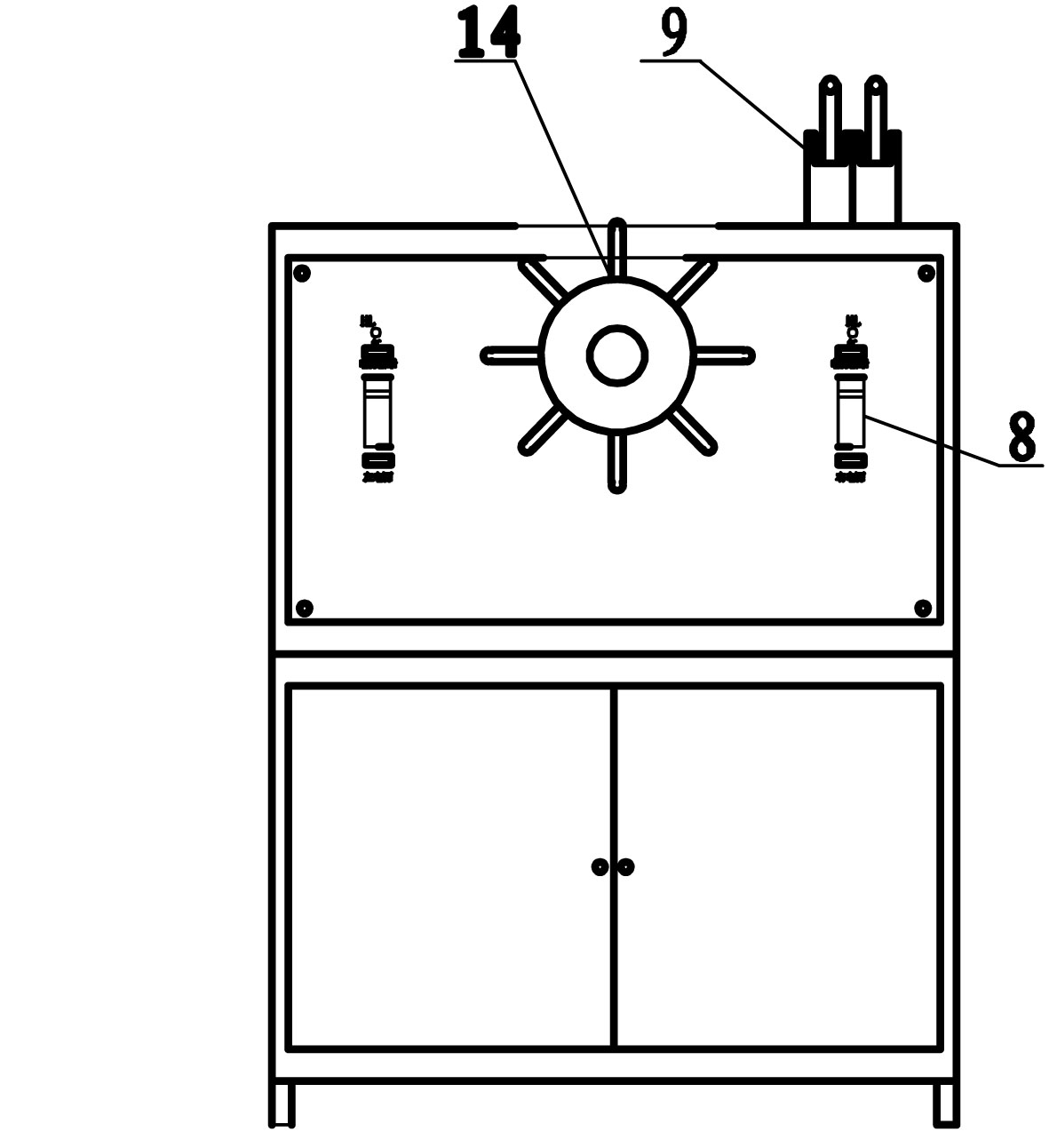

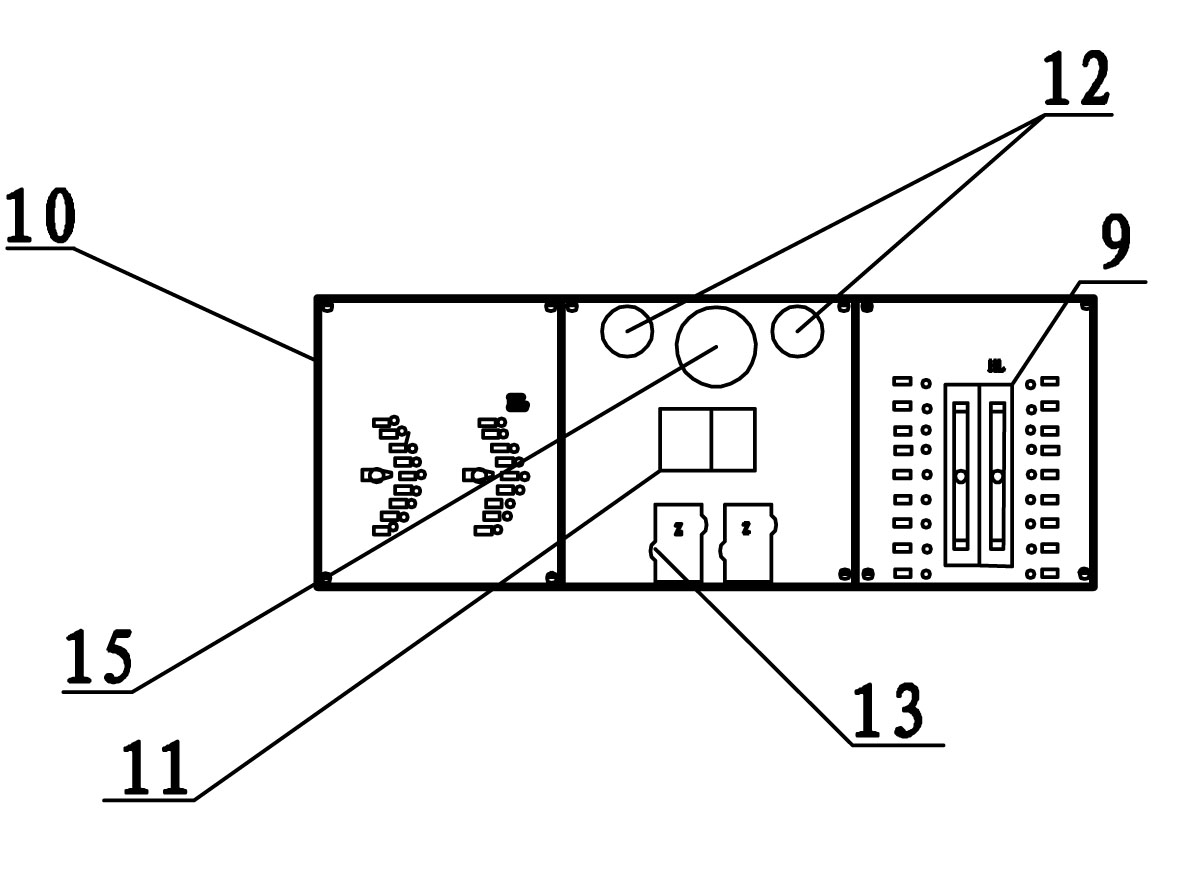

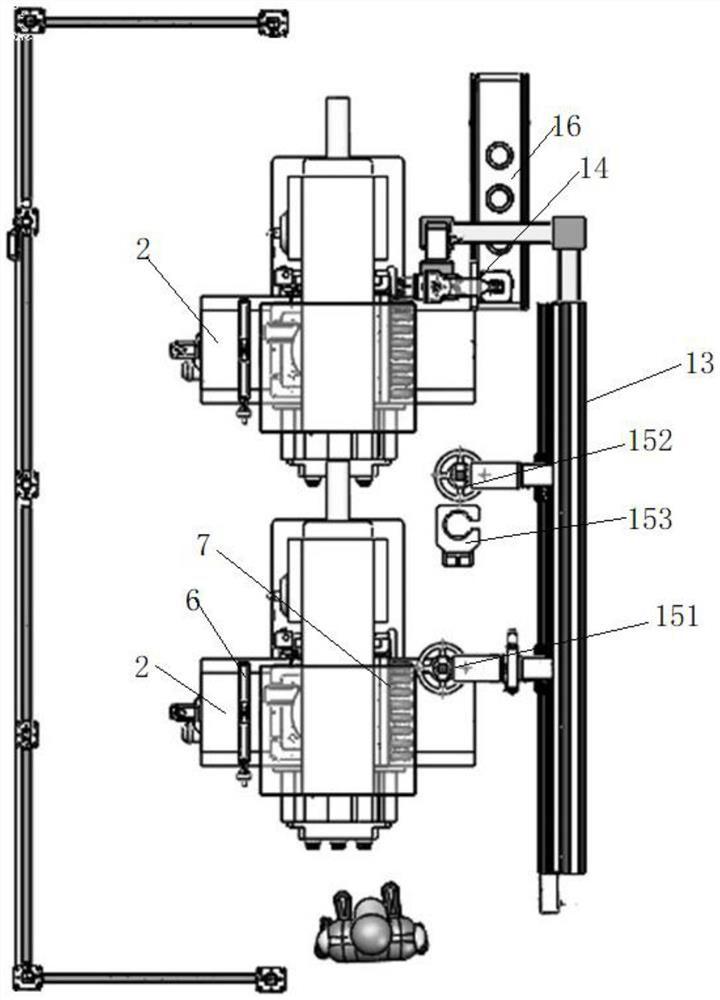

Propulsion device without gear box for vector control of permanent magnet synchronous motor of electric ship

InactiveCN102060096AImprove reliabilityHigh reliability and high performancePropulsion power plantsPropulsive elementsElectricitySynchronous motor

The invention relates to a propulsion device without a gear box for the vector control of a permanent magnet synchronous motor of an electric ship. Two power supplies are respectively electrically connected with an FOC (Field Oriented Control) vector control frequency converter through a propulsion operation platform and a cable; the FOC vector control frequency converter is electrically connected with a permanent magnet brushless synchronous motor through a cable; the permanent magnet brushless synchronous motor is coaxially connected with a rotary transformer and a propeller and mechanically connected with a speed indicating generator; the rotary transformer is electrically connected with the FOC vector control frequency converter through a cable; the speed indicating generator is electrically connected with the combined type propulsion operation platform through a cable; and the speed indicating generator and a storage battery are electrically connected with the FOC vector control frequency converter through cables. The invention directly drives the permanent magnet brushless synchronous motor by adopting the vector control without using the gear box and a brake, thereby optimizing the control characteristics of the electric ship and saving the electric energy.

Owner:庞志森 +6

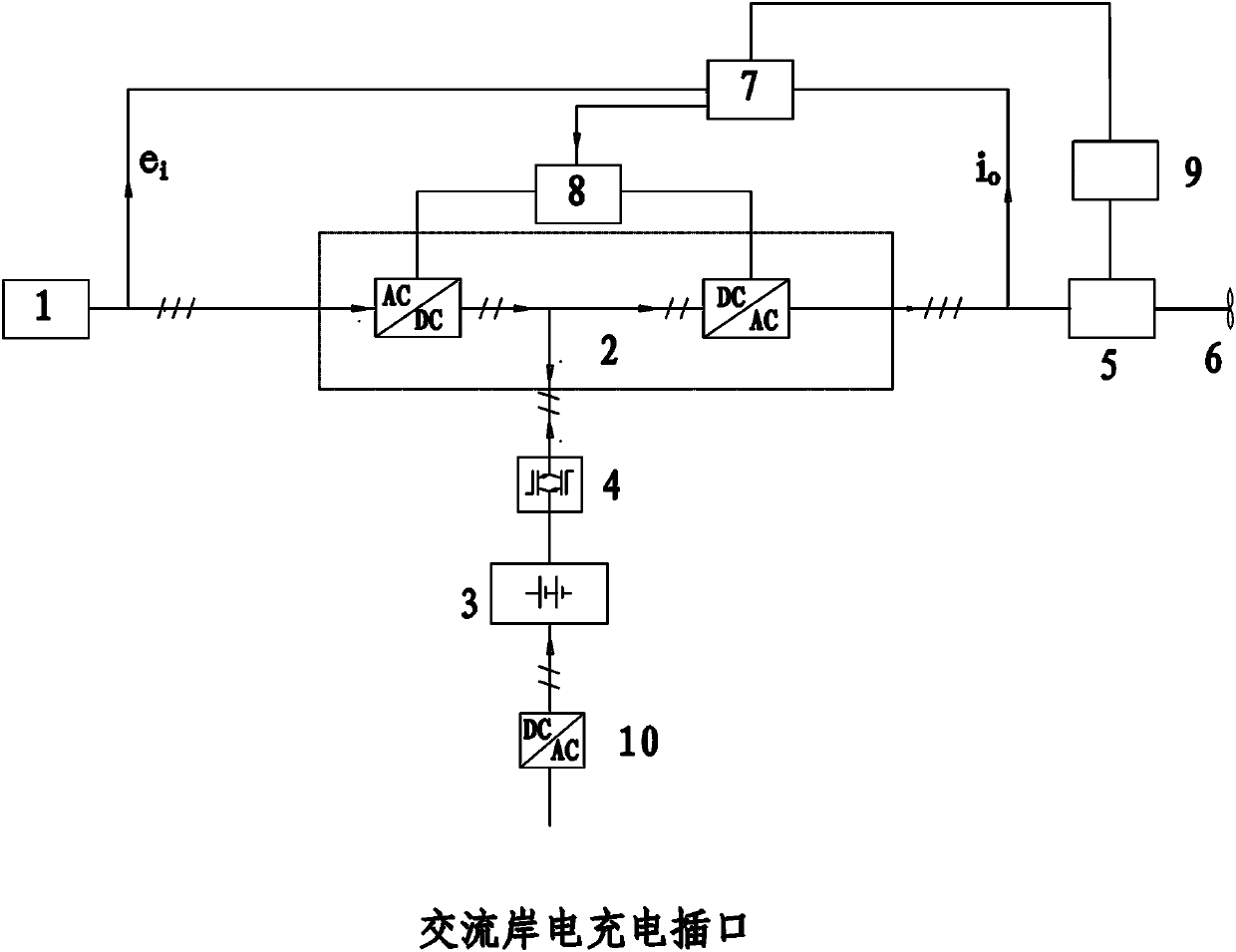

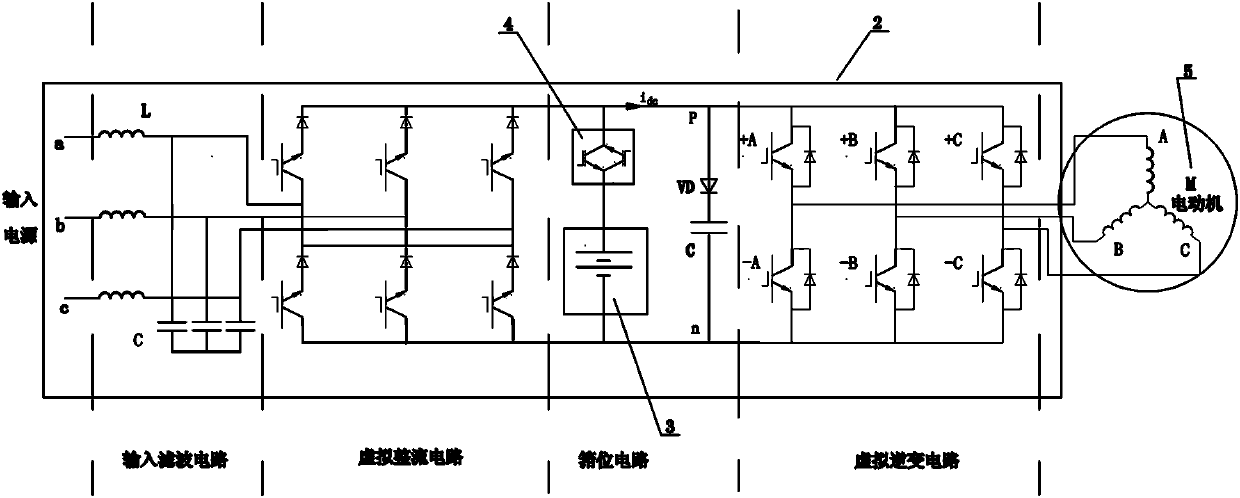

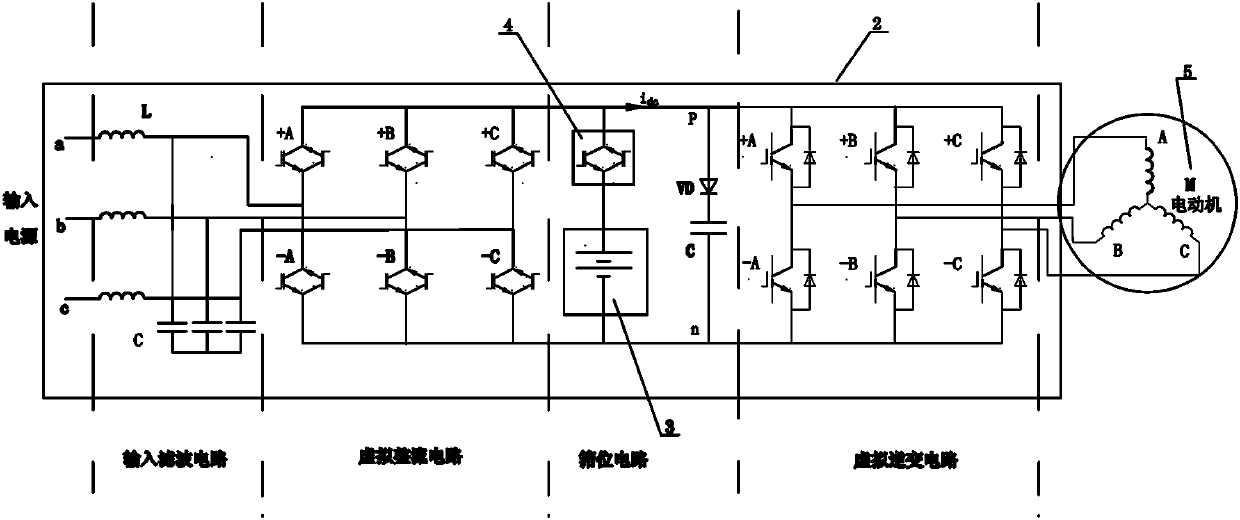

Indirect type matrix control system for electricity-oil hybrid energy conversion electric driving ship

InactiveCN103973183AEasy to save energyEasy to controlElectronic commutation motor controlAC motor controlMatrix convertersFrequency changer

The invention relates to an indirect type matrix control system for an electricity-oil hybrid energy conversion electric driving ship. A three-phase alternating current diesel generating set is connected with an input end AC / DC converter of an indirect type matrix converter, a three-phase alternating current propulsion motor is connected with an output end DC / AC converter of the indirect type matrix converter, a virtual direct current link clamping circuit of the indirect type matrix converter is connected with a both-way PWM switch, the both-way PWM switch is connected with a power storage battery pack, a switch commutation controller is connected with switch control circuits of the input end AC / DC converter and the output end DC / AC converter of the indirect type matrix converter, a direct torque control frequency converter is connected with the switch commutation controller, the three-phase alternating current diesel generating set, the three-phase alternating current propulsion motor and a speed sensor, and a charger is connected with the power storage battery pack. By means of the indirect type matrix control system, efficient connection and parallel operation of alternating currents and direct currents can be achieved, and efficient and energy-saving frequency-conversion stepless speed-regulation control over the propulsion motor can be achieved.

Owner:庞志森 +4

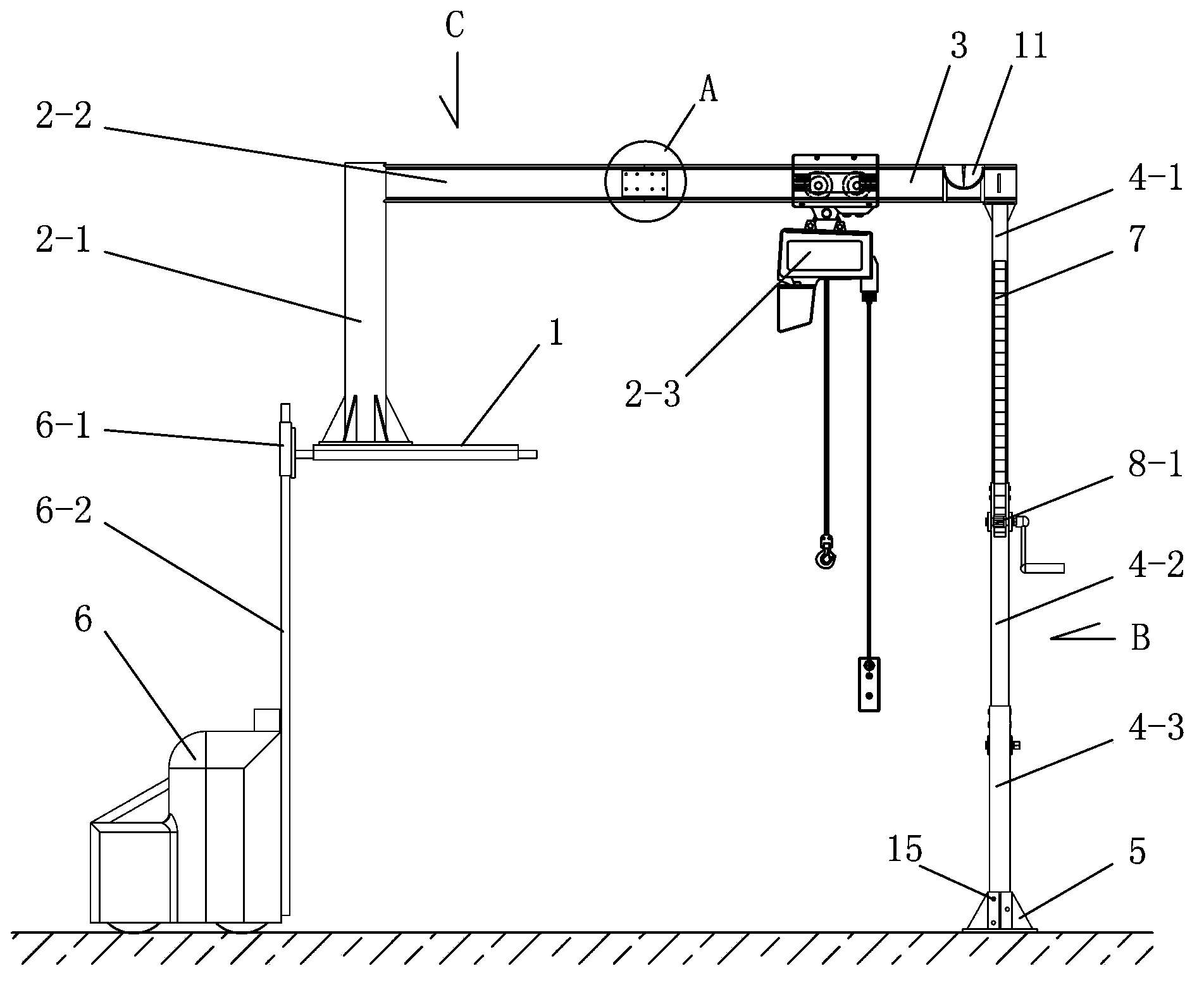

HGIS self-adaption emergency first-aid repair device and applications thereof

An HGIS self-adaption emergency first-aid repair device and applications thereof belong to the field of first-aid repair device. The emergency first-aid repair device is assembled on site through the following steps: a cantilever hanging base plate is arranged on a fork of a fork truck, the cantilever hanging base plate is provided with a cantilever hanging unit, a butt-joint crossbeam is arranged on the tail end of a cantilever crossbeam, a bearing pillar is arranged on the tail end of the butt-joint crossbeam, a bearing base is arranged on the lower part of the bearing pillar, the tail end of the butt-joint crossbeam and the top part of the bearing pillar are in a pin connection or hinge connection, and the cantilever hanging base plate, the cantilever hanging unit, the butt-joint crossbeam, the bearing pillar and the bearing base are all self-contained. When performing the first-aid repairing, the connections between group / part elements are in a fastener connection mode, and rapid assembly on the first-aid repair site is realized. After the first-aid repairing is finished, group / part elements can be rapidly decomposed, which is convenient for transportation, storage and maintenance separately. The whole emergency first-aid repair device adopts modular construction, and improves the work efficiency of examination, repairing and maintenance on site.

Owner:STATE GRID CORP OF CHINA +2

Inner wall cleaning device of cover type furnace for copper foil production and using method thereof

ActiveCN110849165AWide range of applicationsReduce the number of equipmentBell type furnacesIncrustation removal devicesSlagElectric machinery

The invention relates to the field of metallurgical equipment, and particularly relates to an inner wall cleaning device of a cover type furnace for copper foil production and a using method thereof.The device comprises a ring seat, wherein a vertically upward pipe column is fixed to the center of the ring seat; a driving mechanism is arranged on the pipe column; the driving mechanism is connected with a plurality of slag removing mechanisms used for removing slag on the inner side wall of an inner cover; a rotating table is rotatably connected to the top of the pipe column through a fixed shaft; a plurality of brush strips used for cleaning the inner top wall of the inner cover are arranged on the rotating table; the driving mechanism comprises a sliding block slidably connected to the pipe column; a rotating disc is rotatably connected to the sliding block; the rotating disc is in threaded connection with the pipe column; and a motor is fixed to the sliding block. According to the cover type furnace inner wall cleaning device for copper foil production and the using method thereof, the inner walls of inner covers with different specifications can be cleaned, the application range is wide, practicability is better achieved, the cleaning efficiency of the inner covers is improved, the labor intensity is reduced, the service life of the inner covers is prolonged conveniently, the efficient heat efficiency is kept, and the stable product processing quality is kept advantageously.

Owner:潘佳宁

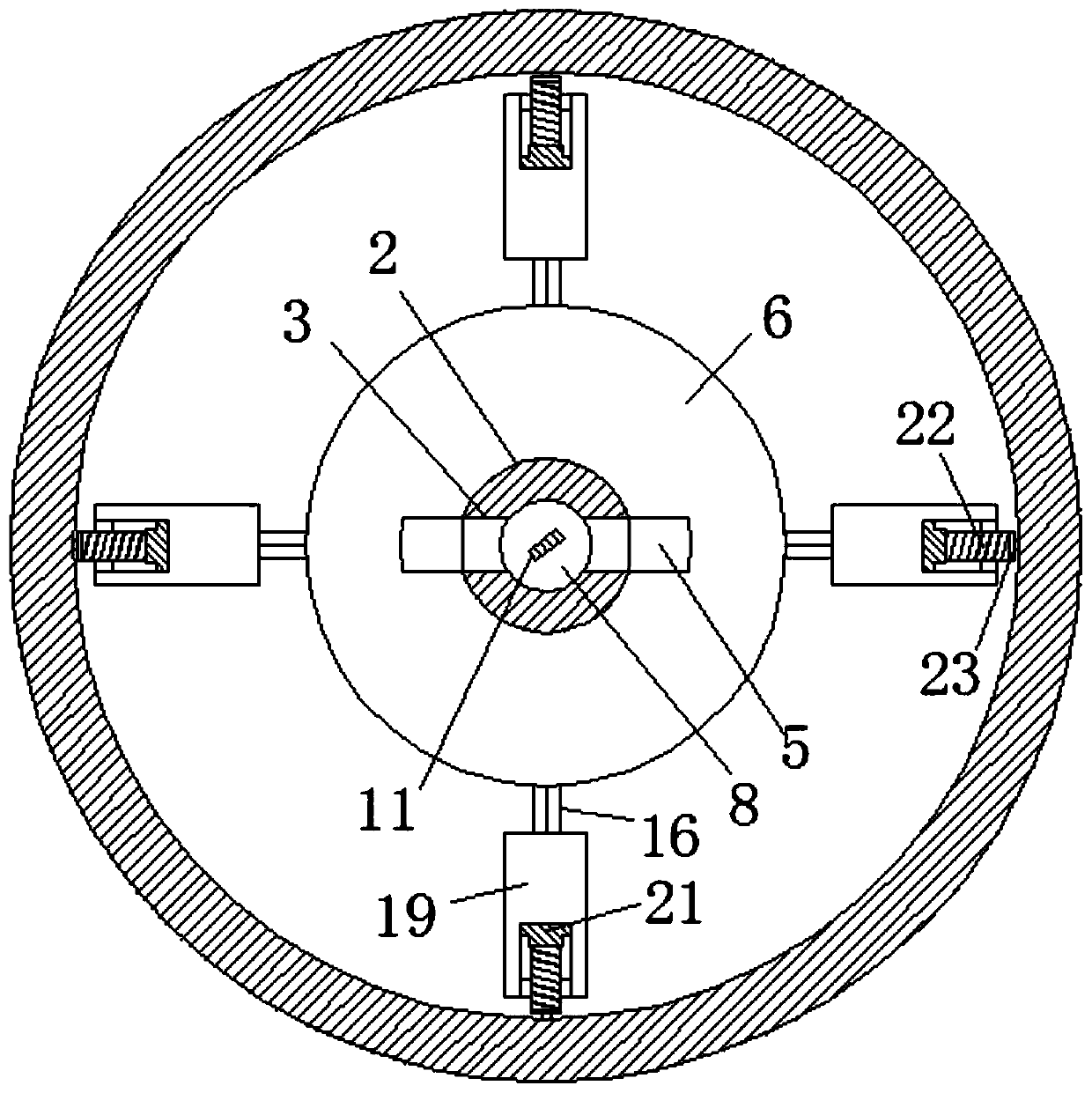

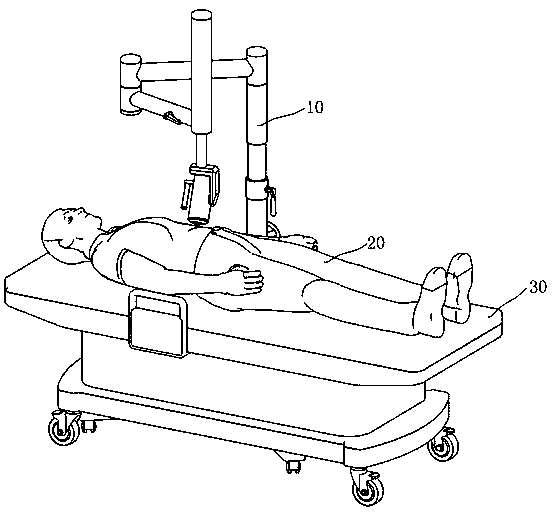

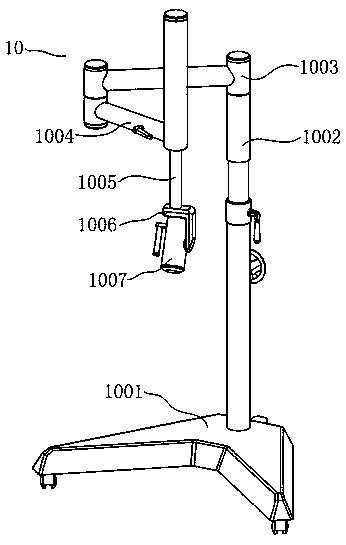

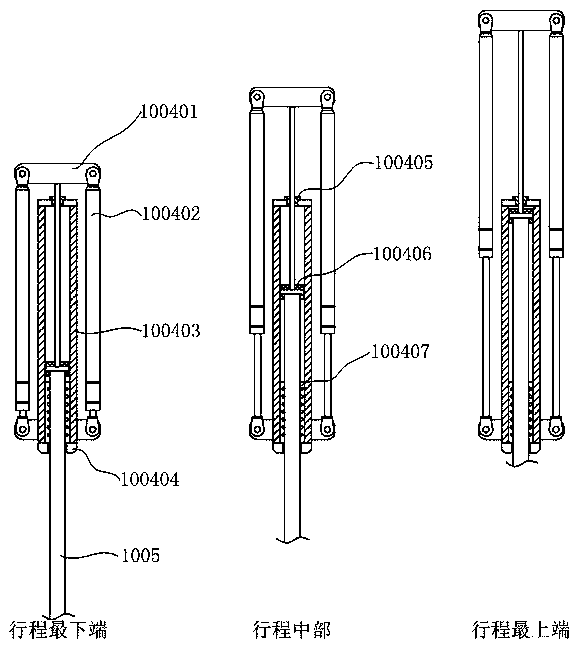

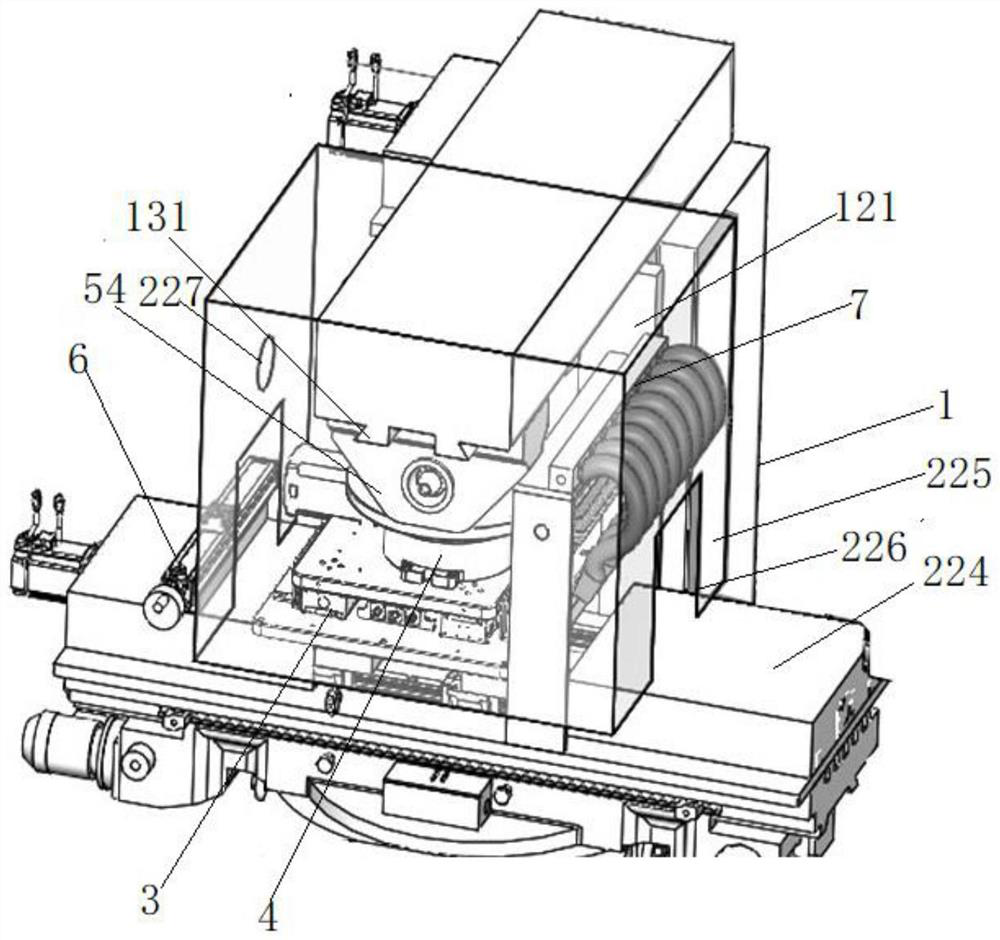

Magnetic control equipment with booster arm

PendingCN110974445AImprove stabilityReduce the number of equipmentDiagnosticsSurgical instrument supportRotational axisEndoscopic surgery

The invention discloses magnetic control equipment with a booster arm. The equipment includes a movable base, a stand column, a first horizontal movable shaft, a second horizontal movable shaft, a lifting shaft, a composite rotating shaft and an outer anchor magnet; and the outer anchor magnet is fixed on the booster arm, the outer anchor magnet can move arbitrarily in a certain space range and rotate arbitrarily around two mutually perpendicular axes, a gravity balance component is arranged in the vertical direction to balance the gravity of the magnet, and each joint is provided with a damper to realize hovering of the magnet at any position and any posture. The magnetic control equipment with the booster arm provided by the invention reduces the number of personnel for endoscopic surgery, reduces space occupied by the surgery, enhances stability of magnet positioning while maintaining flexibility of magnet attitude adjustment, is convenient to operate and flexible to control, and improves the efficiency and success rate of the surgery.

Owner:SHENZHEN JIFU MEDICAL TECH CO LTD

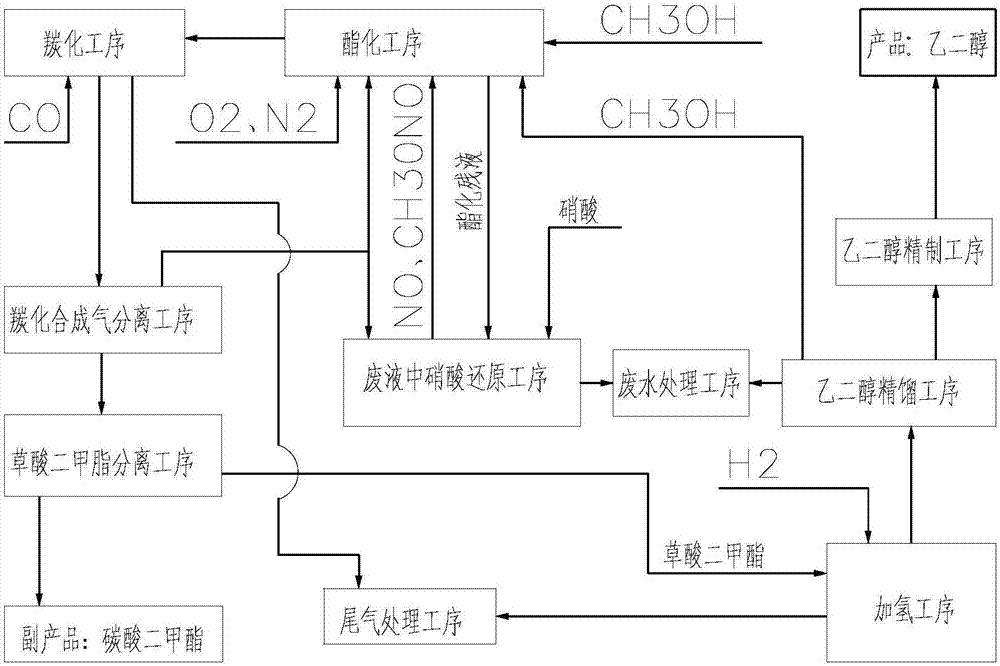

System and method for large-scale preparation of ethylene glycol from synthesis gas

ActiveCN106866363AReduce the number of device seriesReduce the number of equipmentOrganic compound preparationPreparation by carbon monoxide or formate reactionProtein carbonylChemistry

The invention discloses a system and a method for large-scale preparation of ethylene glycol from synthesis gas. A gas outlet of a methyl alcohol rectification and washing tower is connected to a gas inlet of an esterification tower; heavy components generated by reaction in the esterification tower are conveyed to a carbonylation reactor, and then residual liquid in the esterification tower is discharged; a gas inlet of the carbonylation reactor is connected with a gas outlet of the esterification tower; heavy components generated by reaction in the carbonylation reactor are conveyed to the methyl alcohol rectification and washing tower; after dimethyl oxalate at a material outlet of a dimethyl oxalate rectification and washing tower is heated and gasified, the material outlet of the dimethyl oxalate rectification and washing tower is connected with a gas inlet of a hydrogenation reactor, and then the dimethyl oxalate is discharged from a gas outlet of the hydrogenation reactor; an ethylene glycol purification tower is connected with a material outlet of an ethylene glycol rectification device; a gas outlet of the ethylene glycol rectification device is connected to the esterification tower; waste liquid in the ethylene glycol rectification device is discharged. The series number of devices is decreased, the number of sets of equipment is decreased, the engineering investment is reduced, generation of byproducts is reduced, and consumption is reduced.

Owner:NANJING DUNXIAN CHEM TECH

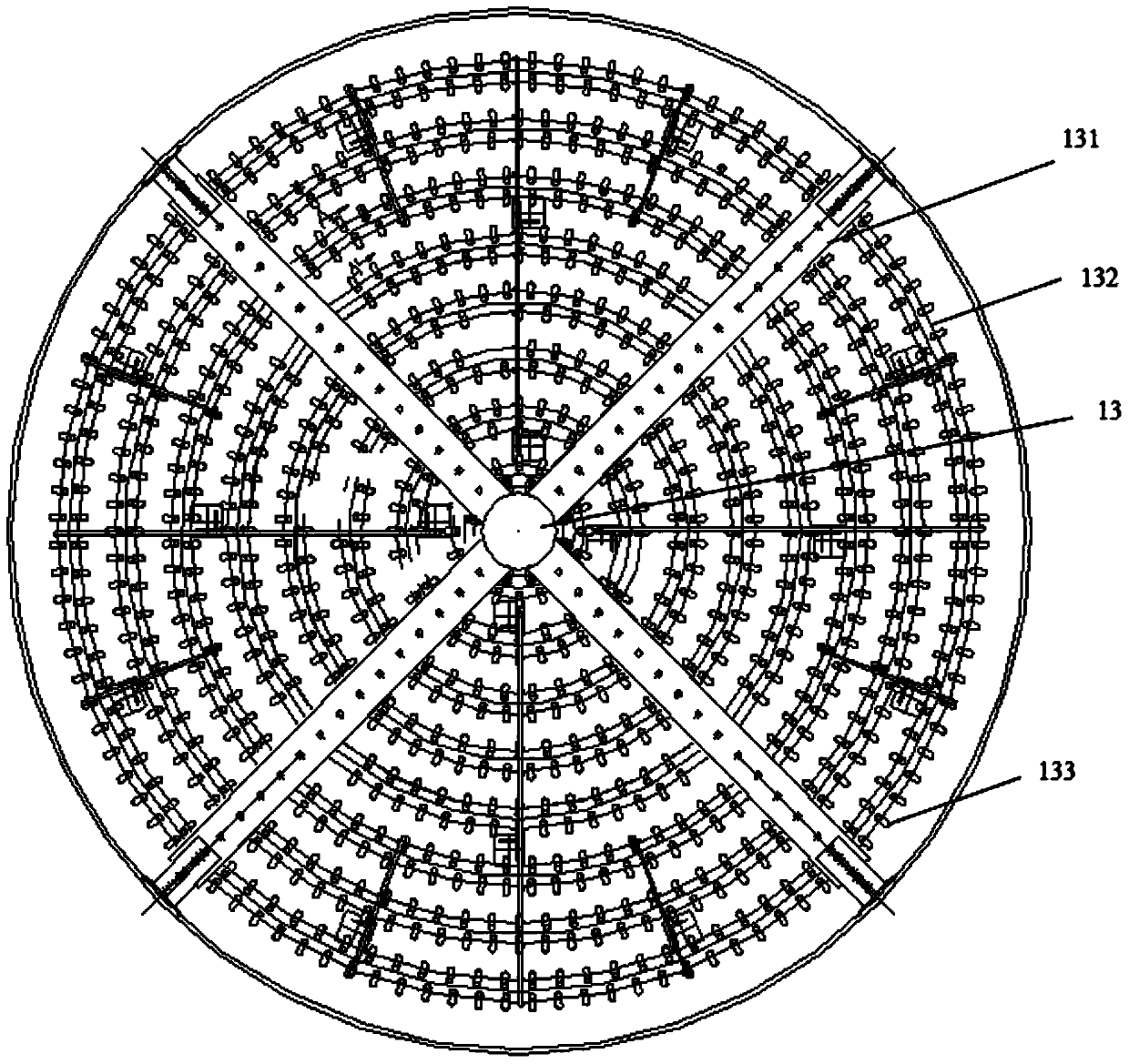

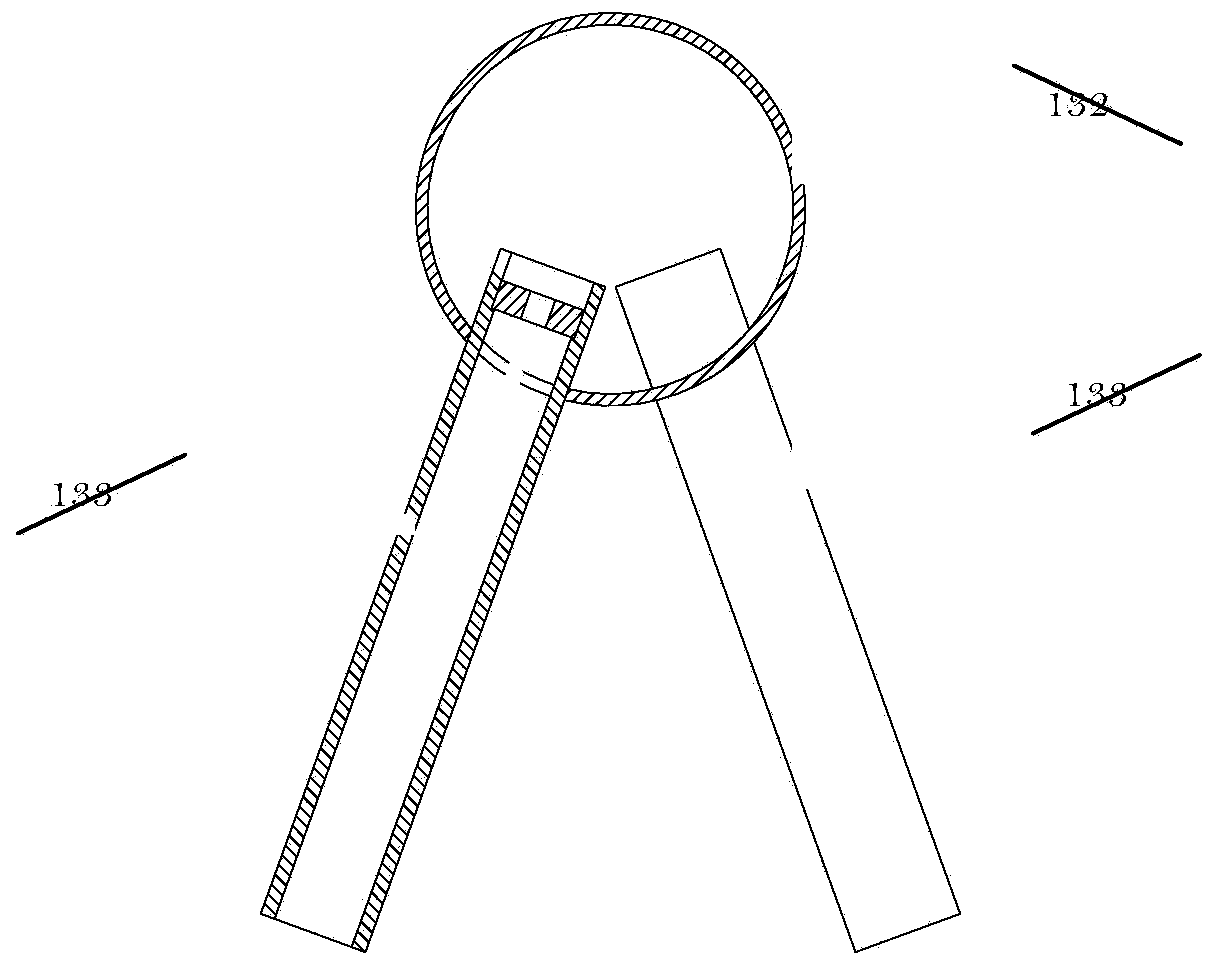

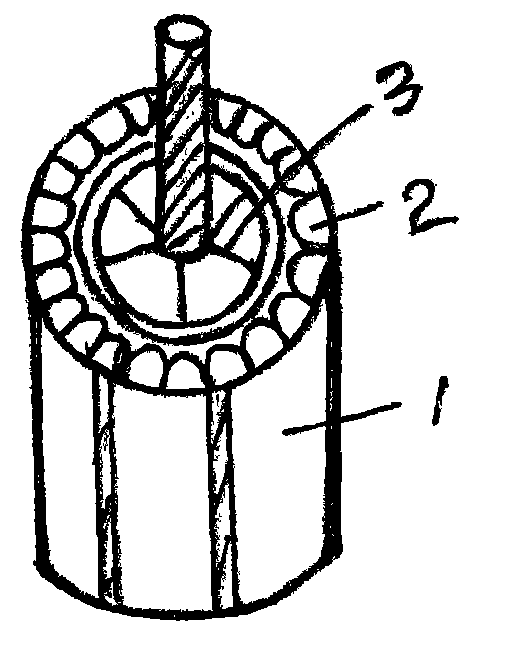

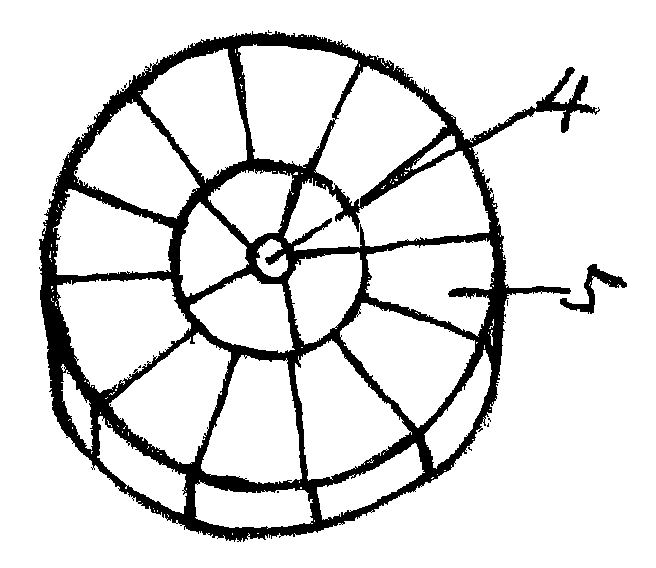

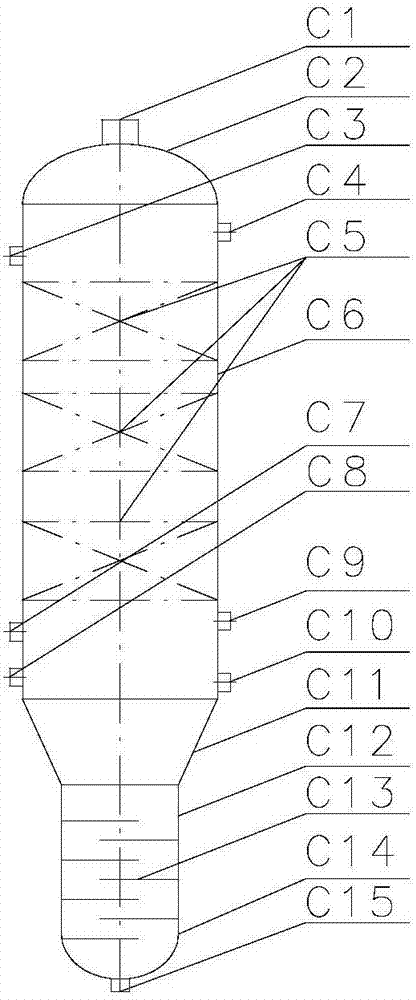

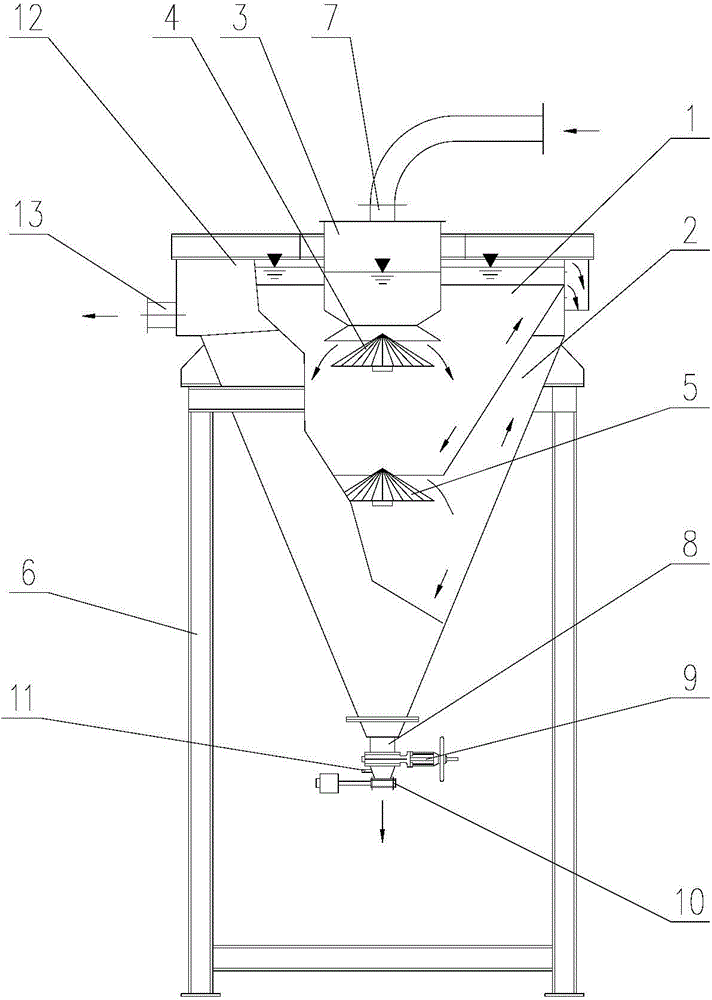

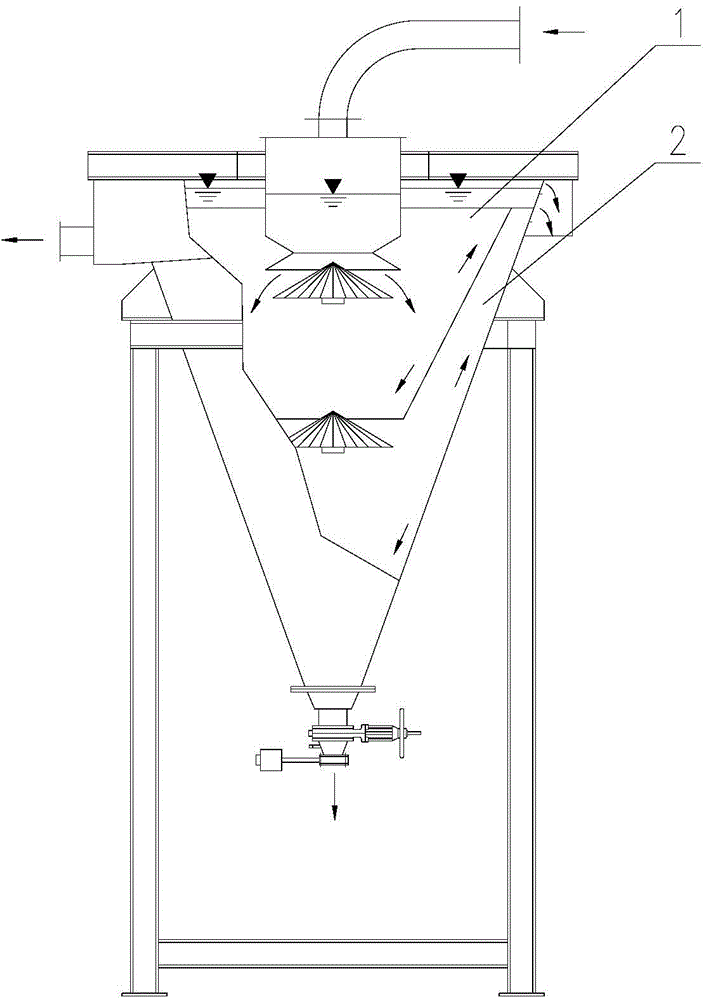

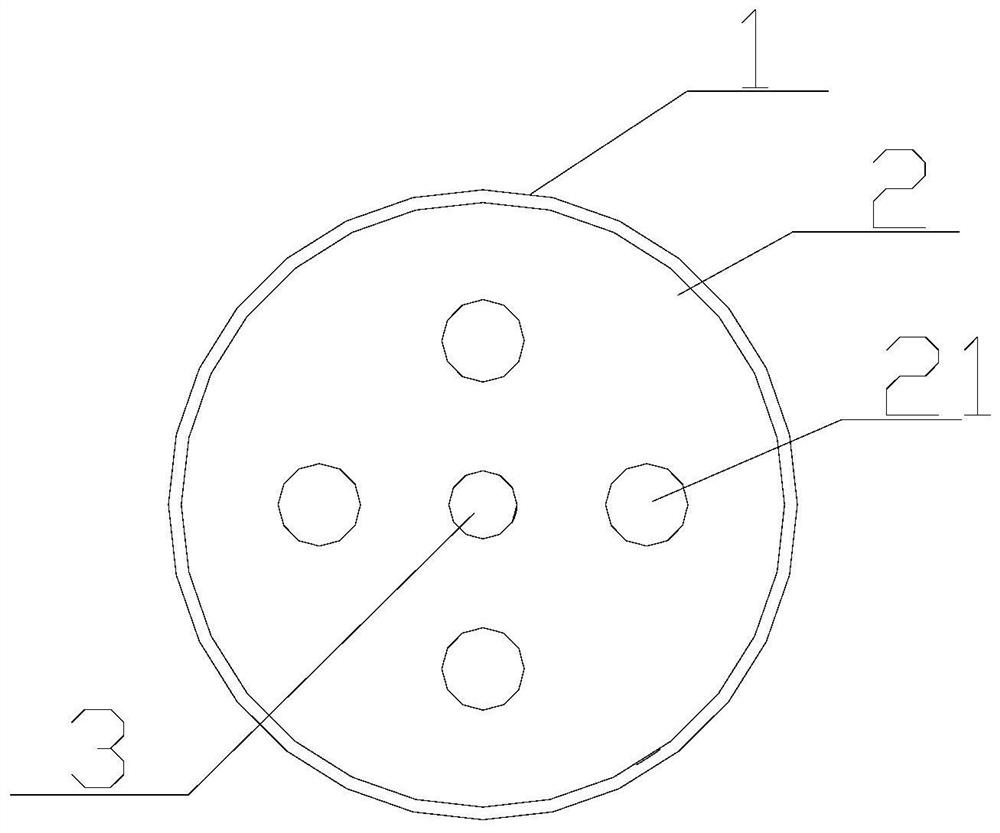

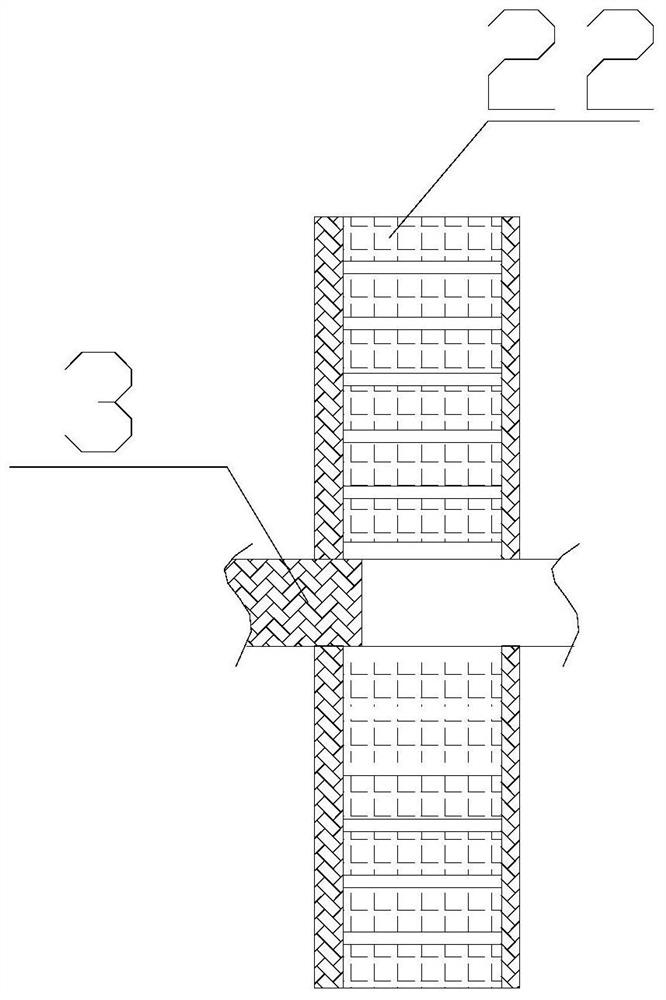

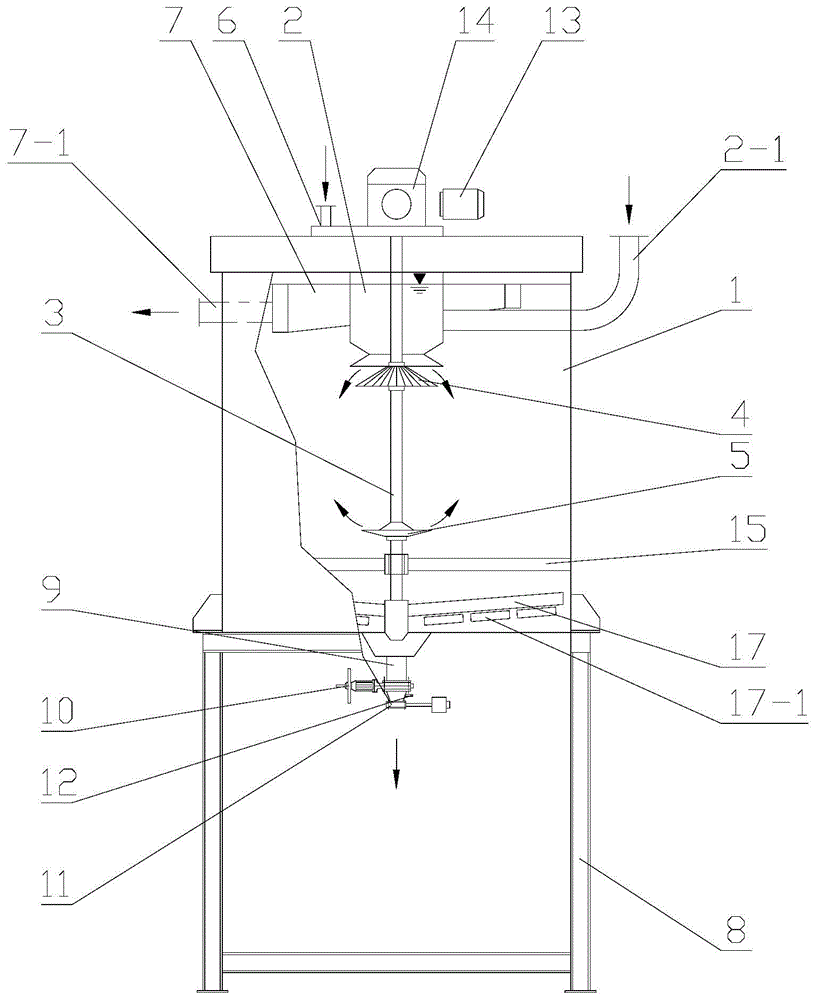

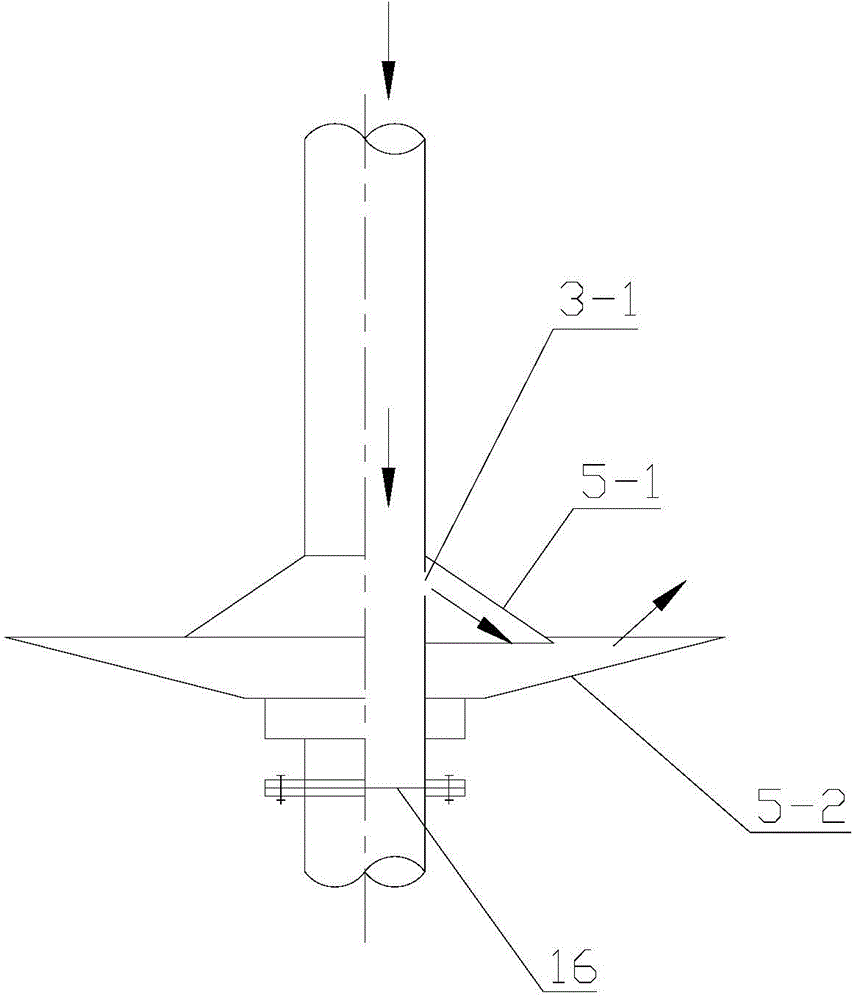

Multi-layer de-sliming thickener

ActiveCN104624393AHigh desliming and thickening efficiencyIncrease production capacityDifferential sedimentationEngineeringGrout

The invention discloses a multi-layer de-sliming thickener. The multi-layer de-sliming thickener comprises an upper cone (1), a receiving barrel (3), a lower cone (2) and an overflow groove (12). The upper cone (1) is of an inverted-cone shape, a lower distribution plate (5) is arranged at a discharging port in the bottom of the upper cone (1), and an upper sedimentation region is formed inside the upper cone (1). The receiving barrel (3) is arranged inside the upper cone (1) and provided with a feeding pipe (7), and an upper distribution plate (4) is arranged at a discharging port in the bottom of the receiving barrel (3). The lower cone (2) is of an inverted-cone shape, the upper cone (1) is sleeved with the lower cone (2), a grout valve is arranged at a bottom flow pipe (8) of the lower cone (2), and a lower sedimentation region is arranged inside the lower cone (2). The overflow groove (12) is formed in the periphery of an overflow opening of the upper cone (1) and the lower cone (2), and provided with an overflow pipe (13). The thickener has high de-sliming and thickening efficiency, the production capacity per unit area is high, and one thickener can achieve the using effect of performing thickening and de-sliming on two or more sections, and is a good choice for de-sliming in concentrating mills and particularly for selective flocculation de-sliming and thickening operation.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

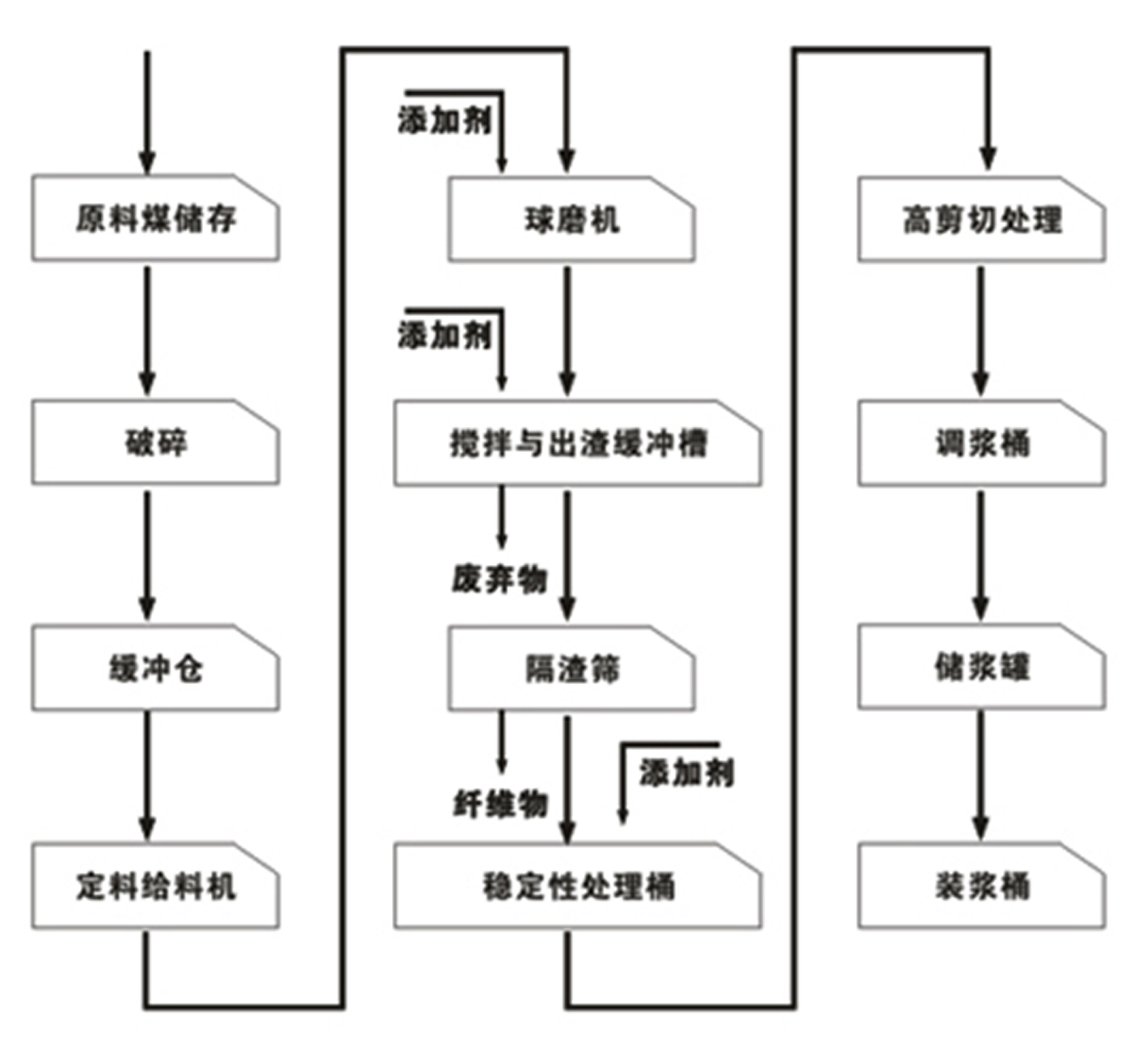

Method for preparing water coal slurry

InactiveCN101985571AHigh solid contentRealize large-scaleLiquid carbonaceous fuelsLump/pulverulent fuel preparationSlagProcess engineering

Owner:JIANGYIN DONGFA MACHINERY MFG

Semi-automatic box nailing machine

The invention relates to the technical field of carton processing, and discloses a semi-automatic box nailing machine. The semi-automatic box nailing machine comprises a chassis, a stand column, a cross beam, a large arm and a motor; a nailing mechanism is arranged at one end of the large arm; an electric control box for controlling the motor is arranged on the stand column and is electrically connected with a foot switch; a first clamping mechanism capable of reciprocating in the length extending direction of the cross beam is arranged on the cross beam; side arms are arranged on two sides ofthe stand column in an extending manner; a telescopic clamping arm which is parallel with the cross beam and can telescope in the extending direction of the cross beam is arranged on each side arm; each telescopic clamping arm comprises a telescopic arm and a second clamping mechanism arranged on the telescopic arm; and one end of each telescopic arm is connected to the corresponding side arm andcan reciprocate in the length extending direction of the corresponding side arm. The semi-automatic box nailing machine has the advantages that the operation safety is high, the requirement for the proficiency degree of an operator is low, the condition that many persons are provided for simultaneous working is not necessary, the semi-automatic box nailing machine is applicable to processing of multiple types of cartons, and folds do not appear easily.

Owner:淮安惠而邦企业管理有限公司

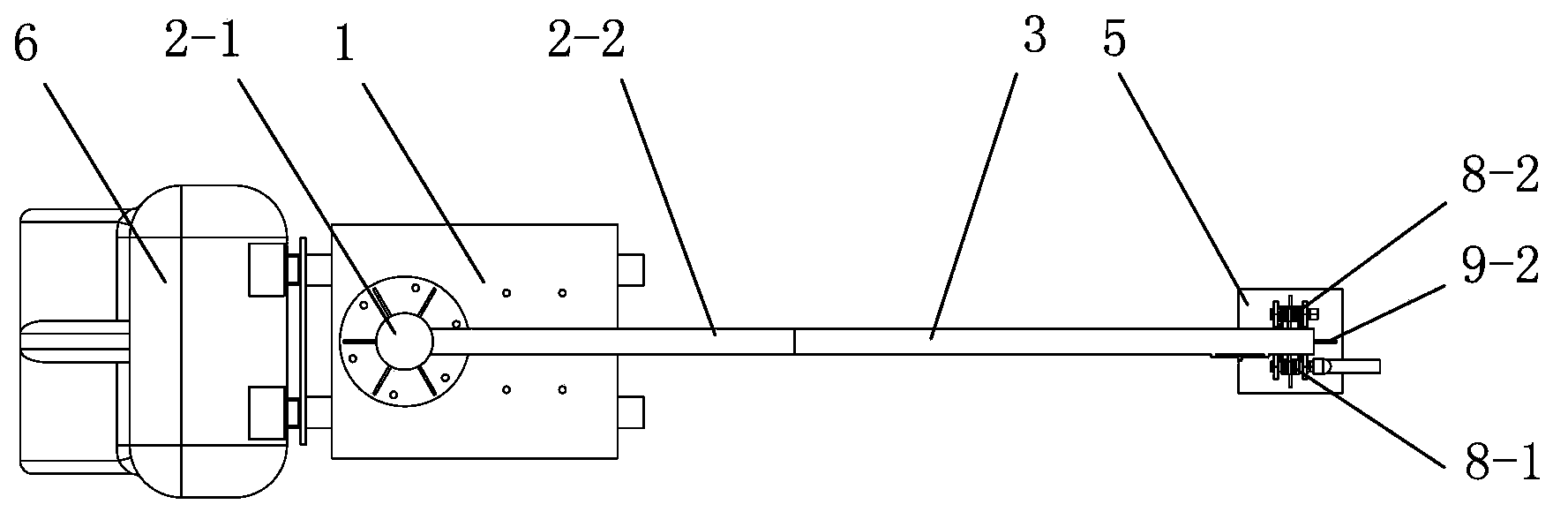

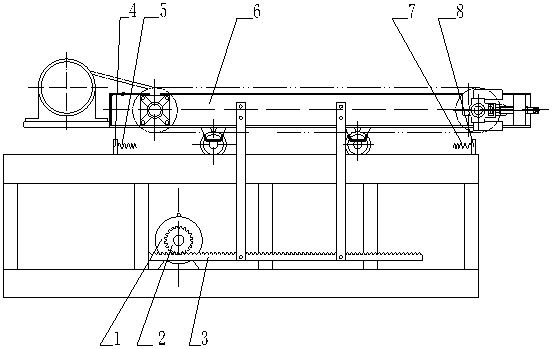

Reciprocating type rack fabric distributor

InactiveCN103253500AReduce the number of equipmentImprove work efficiencyConveyor partsProcess equipmentGear wheel

The invention discloses a reciprocating type rack fabric distributor. A roller is mounted on the lower portion of a belt conveyor which is arranged on a frame and can roll on the frame. A motor is arranged on the frame. A gear is arranged on an output shaft of the motor. A rack meshed with the gear to drive the belt conveyor to move is fixedly connected with the belt conveyor. A front travel switch and a rear travel switch are arranged on the frame. Compared with the prior art, the reciprocating type rack fabric distributor is mounted by a 90-degree angle with next process continuously working equipment such as a mesh net dryer. Even distribution of fabrics on the next process equipment is implemented by back and forth movement and running of a belt of the whole belt conveyor on the fabric distributor. A required fabric distribution width is controlled by the front travel switch and the rear travel switch; a workbench receiving fabric from the previous process equipment can be arranged in a length direction of the belt conveyor; the valid width can be controlled by the length of the belt conveyor; and formed fabric from multiple previous process equipment can fall onto one reciprocating type rack fabric distributor. With the coordination of the next process continuous working equipment, number of equipment can be reduced, and working efficiency is improved.

Owner:余洋 +1

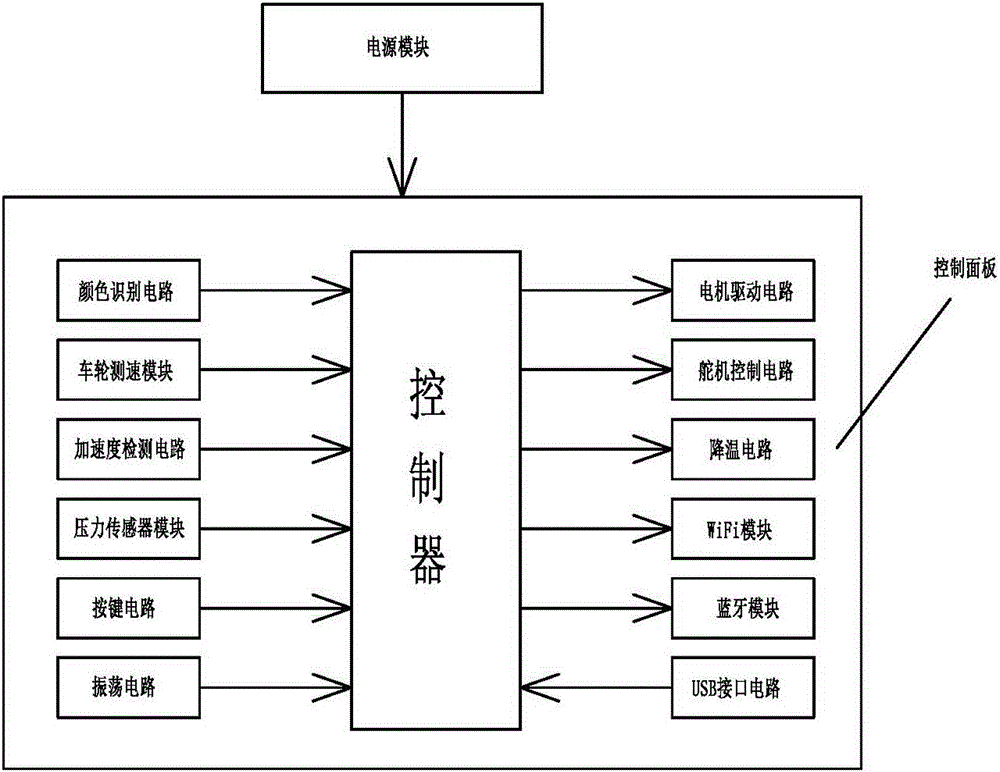

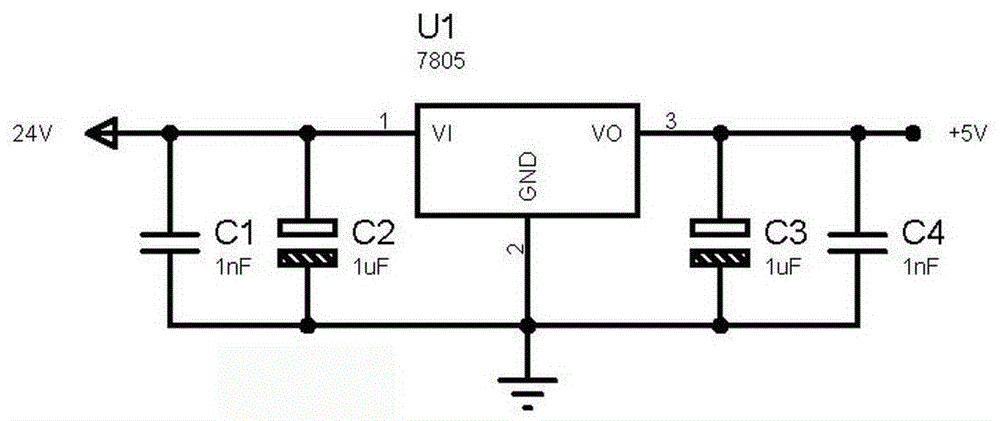

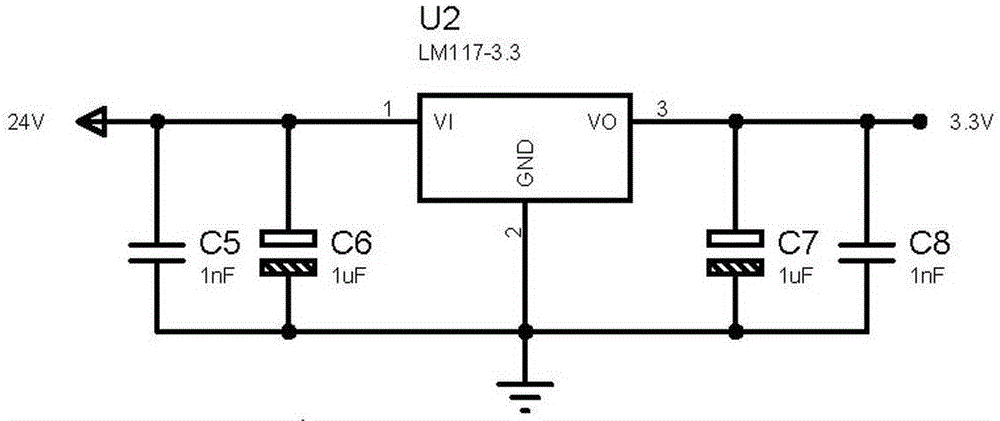

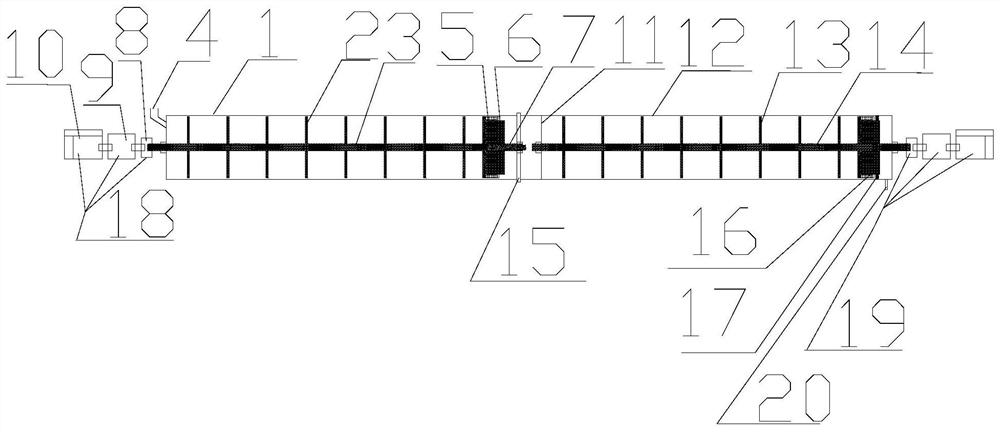

AGV trolley for recycling wave soldering fixture

InactiveCN106020209AReduce labor intensityReduce the number of equipmentPosition/course control in two dimensionsVehiclesObstacle avoidanceEngineering

The invention provides an AGV trolley for recycling a wave soldering fixture. The AGV trolley automatically carries the wave soldering fixture to the previous position and the AGV trolley automatically returns to the next position so that the equipping number of the wave soldering fixture can be reduced, occupation of the workshop space can be reduced and the production efficiency can be enhanced. The scheme is that the AGV trolley comprises a trolley body. The front part and the rear part of the trolley body are respectively provided with a forward first obstacle avoidance sensor and a backward second obstacle avoidance sensor. The trolley body is provided with a power supply module and a control panel. The power supply supplies power to the control panel. According to the AGV trolley for recycling the wave soldering fixture, the AGV trolley automatically carries the wave soldering fixture to the previous position and the AGV trolley automatically returns to the initial position to prepare for the next recycling work so that the labor intensity of work personnel can be reduced, the equipping number of the wave soldering fixture can be reduced, occupation of the workshop space can be reduced and the production efficiency can be enhanced.

Owner:HENAN UNIV OF URBAN CONSTR

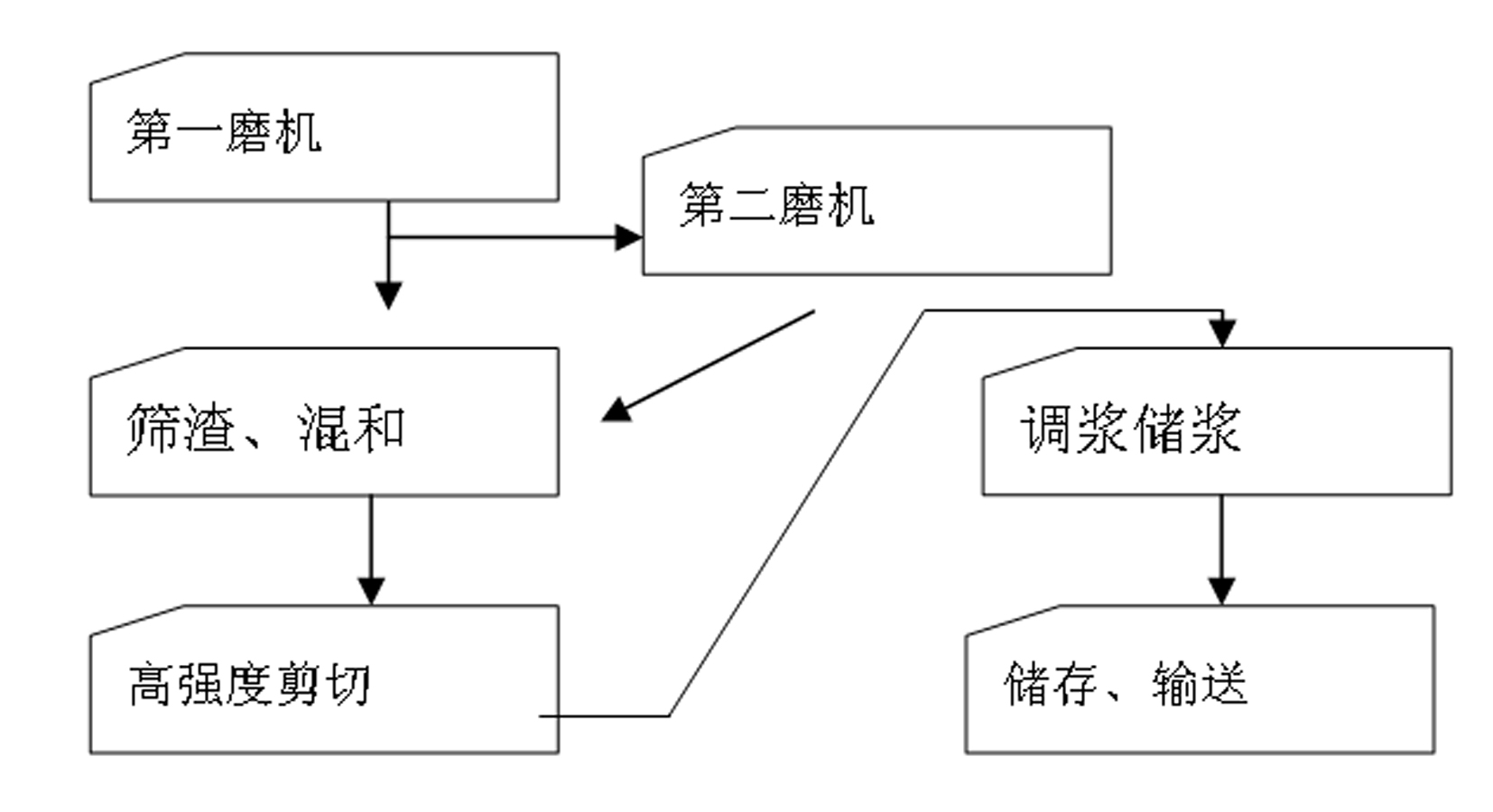

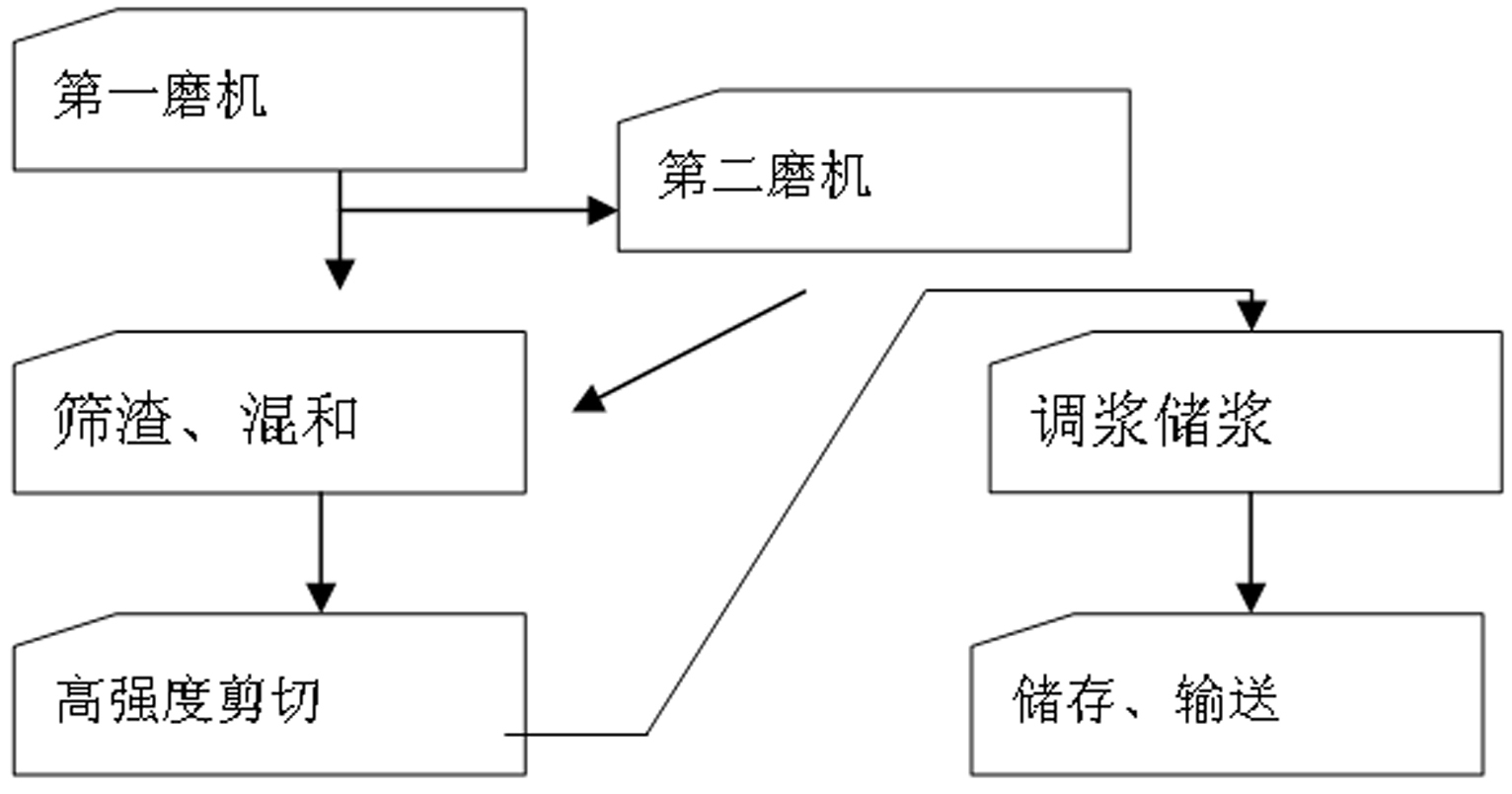

Two-stage grinding device

PendingCN111992302AReduce the number of equipmentSimplify the grinding systemGrain treatmentsGrindingManufacturing engineering

The invention provides a two-stage grinding device. The two-stage grinding device comprises a first-stage grinding system for finely grinding mineral materials and a second-stage grinding system for ultrafine grinding of the mineral materials, wherein the first-stage grinding system is serially connected with the second-stage grinding system; the first-stage grinding system comprises a first grinding unit and a first grading unit; and the second-stage grinding system comprises an end plate provided with a through hole, a second grinding unit and a second grading unit. The problems that the quantity of devices is excessive and the system is complex because a current transitional mill is required to be provided with separate grading operation after a grinding operation line, and coarse graded parts are returned to the mill for continuously grinding after grading are solved, the quantity of the devices is greatly reduced, the grinding system is simplified, and the cost, operating chargesand the grinding management difficulty are reduced.

Owner:中冶北方(大连)工程技术有限公司

Multi-direction and multi-station grooving production line and working method thereof

PendingCN113787226AReduce the number of equipmentIncrease productivityProfiling/shaping machinesShearing machinesProduction lineMachine

The invention discloses a multi-direction and multi-station grooving production line. The multi-direction and multi-station grooving production line comprises a first grooving machine, a second grooving machine, a product transplanting mechanism and a stacking and collecting device, wherein the first grooving machine and the second grooving machine are oppositely arranged and are matched with each other, the product transplanting mechanism is arranged on one side of the first grooving machine and one side of the second grooving machine, the stacking and collecting device is arranged on one side of a discharging port of the second grooving machine, and the stacking and collecting device and the second grooving machine are matched with each other. According to the multi-direction and multi-station grooving production line, the first grooving machine, the second grooving machine, the product transplanting mechanism and the stacking and collecting device are matched with each other, the first grooving machine and the second grooving machine are matched with the product transplanting mechanism, so that different surfaces of a product can be automatically machined; and the product transplanting mechanism and the stacking and collecting device are arranged, so that automatic assembly line type production is realized, the production efficiency is effectively improved, meanwhile, the number of personnel on the production line is reduced, and the labor cost is reduced.

Owner:太仓力达莱特精密工业有限公司

Intelligent cross rod pressure welding equipment integrating feeding, machining and discharging and working method

PendingCN114643439AFully automatedRealize intelligenceWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringWelding

The invention discloses an intelligent cross rod pressure welding device integrating feeding, machining and discharging, which comprises a conveying mechanism, a feeding clamping mechanism, a feeding clamping mechanism, a cross rod feeding mechanism, a welding mechanism and a discharging mechanism, and the conveying mechanism, the feeding clamping mechanism and the feeding clamping mechanism are all arranged on a conveying rack; the feeding clamping mechanism is arranged on the feeding rack, the transverse rod feeding mechanism is arranged on the feeding rack, the transverse rod feeding mechanism is arranged above the feeding clamping mechanism, the welding mechanism is arranged between the feeding clamping mechanism and the discharging mechanism, and the discharging mechanism is arranged on the discharging rack. Automatic feeding of flat steel is achieved through mutual cooperation of the conveying mechanism, the feeding clamping mechanism and the supply clamping mechanism, automatic feeding of transverse rods is achieved through the transverse rod feeding mechanism, selective welding is conducted on the intersection of the flat steel and the transverse rods through the welding mechanism, finished products are automatically taken out through the discharging mechanism, and the production efficiency is improved. And automation and intelligentization are truly achieved from feeding to welding to discharging, the manual labor amount is reduced, and the production efficiency is improved.

Owner:苏州鹄珂智能科技有限公司

Concentrated formaldehyde production technology

ActiveCN107501060AStable production continuityReduce consumptionOrganic compound preparationCarbonyl compound separation/purificationMixed gasFORMALDEHYDE SOLUTION

The invention discloses a concentrated formaldehyde production technology. The technology comprises the steps as follows: (1) refined methanol heated by a heater, crude methanol from a methanol recovery tower, waste gas from the top of a formaldehyde absorption tower as well as fresh air and steam enter a mixer under own pressure to be uniformly mixed, and mixed gas is obtained; (2) the uniformly mixed gas enters a formaldehyde reactor to be subjected to an oxidation reaction of methanol, and reaction gas is obtained; (3) the reaction gas enters the formaldehyde absorption tower, crude formaldehyde is extracted from the bottom of the formaldehyde absorption tower and sent to a formaldehyde concentrator, and concentrated formaldehyde is prepared; (4) a material discharged from the bottom of the formaldehyde concentrator is a concentrated formaldehyde solution with the mass fraction of formaldehyde larger than 60%. With the adoption of the concentrated formaldehyde production technology, the quality of concentrated formaldehyde is guaranteed effectively for a long time, the energy consumption of a production device is reduced, the system operation reliability is improved, the user production continuity is stabilized, and the technology has great significance for the whole production system.

Owner:KAIFENG LONGYU CHEM

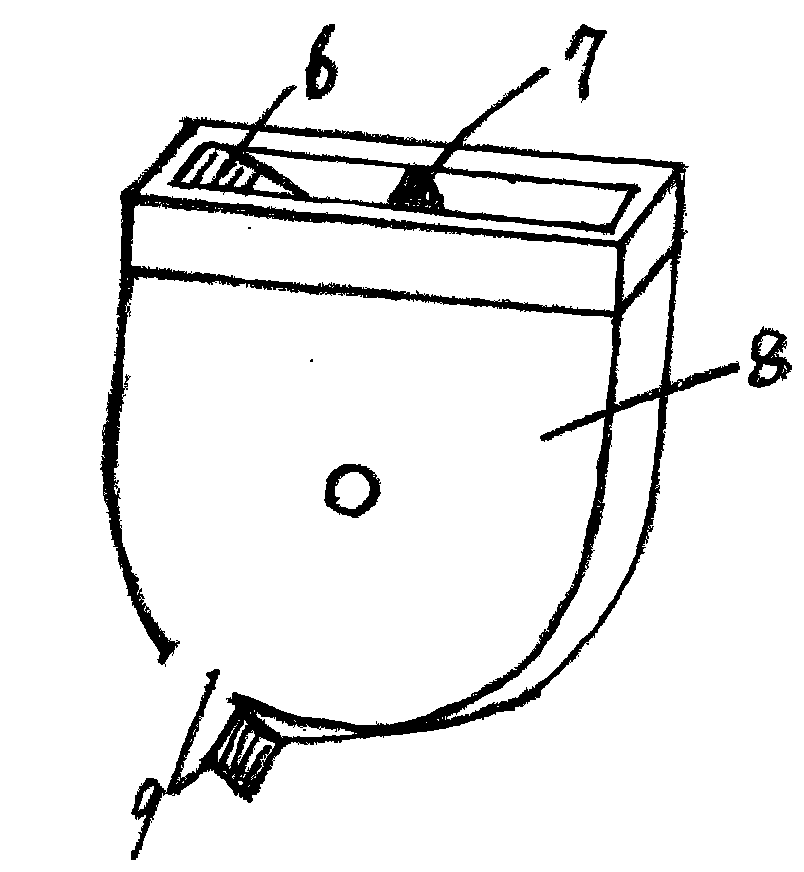

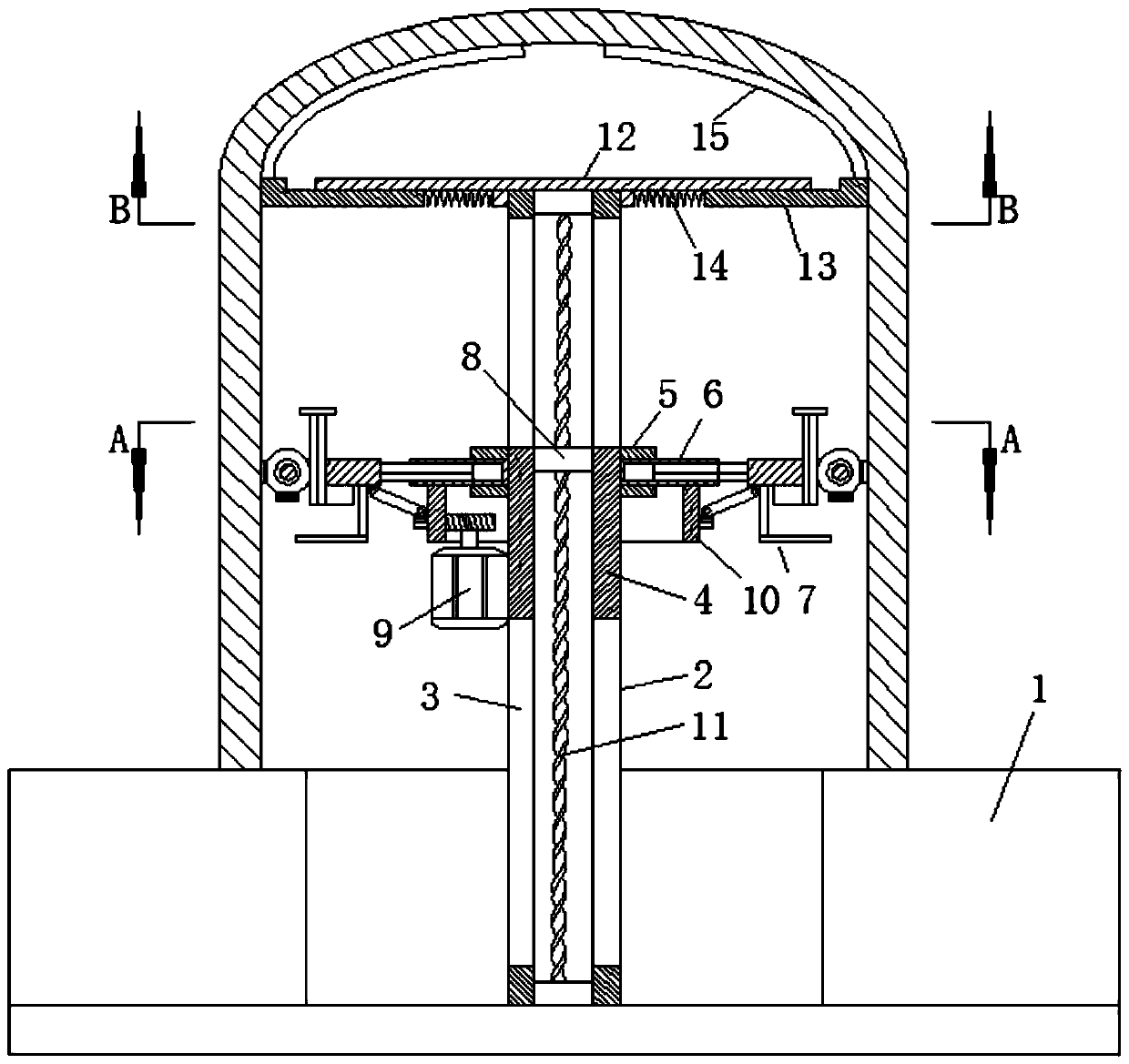

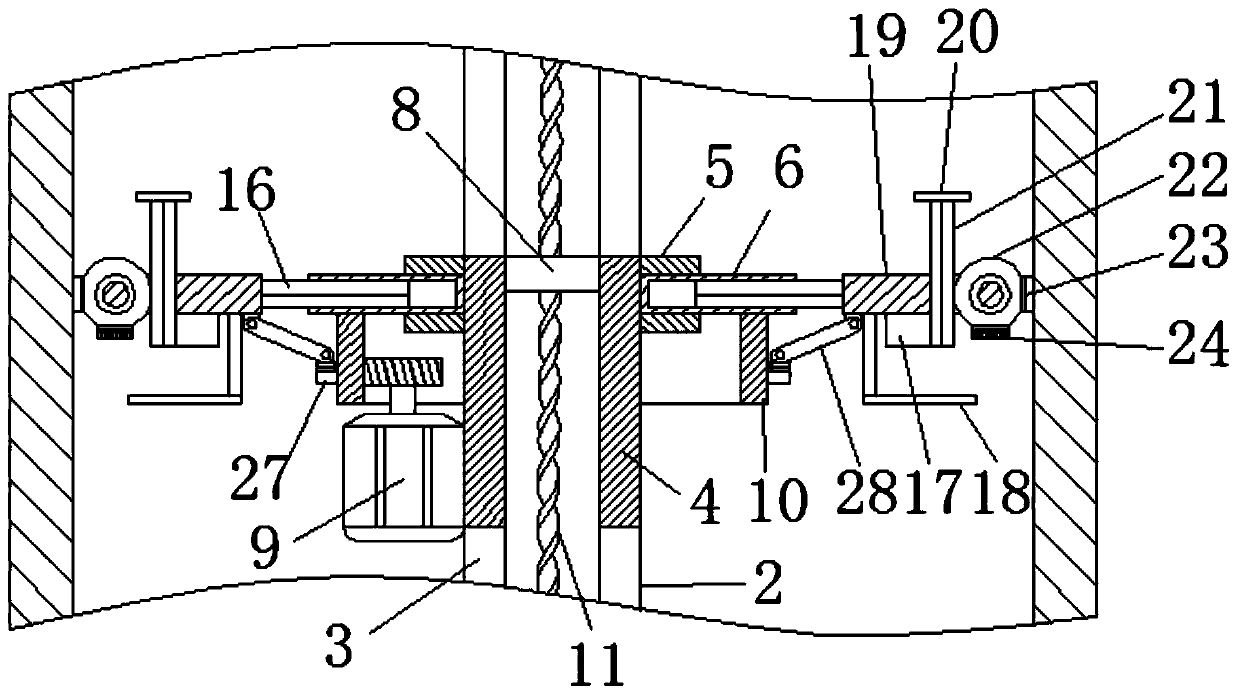

Slurry removal groove

The invention discloses a slurry removal groove. The slurry removal groove comprises a groove body (1), a material receiving cylinder (2), a central shaft (3), a distributor disc (4), a rinse water disc (5), a water supply device (6) and an overflow groove (7), wherein a slurry valve is arranged on an ore discharge pipe (9) at the bottom of the groove body (1), a feed pipe (2-1) is arranged on the material receiving cylinder (2), the central shaft (3) is arranged along the axial central line of the groove body (1), a drive device which drives the groove body (1) to rotate is arranged on the groove body (1), the distributor disc (4) is installed on the central shaft (3) and located below a discharge port at the bottom of the material receiving cylinder (2), the rinse water disc (5) is installed on the central shaft (3) and located on the middle lower area of the groove body (1), a water injection nozzle is arranged on the rinse water disc (5), the water supply device (6) is communicated with the water injection nozzle of the rinse water disc (5) through a channel in the central shaft (3), and an overflow pipe (7-1) is arranged on the overflow groove (7). The slurry removal groove is high in slurry removal and concentration efficiency, and large in production capacity per unit area, and can achieve use effects of two segments or even multiple segments of slurry removal and concentration.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

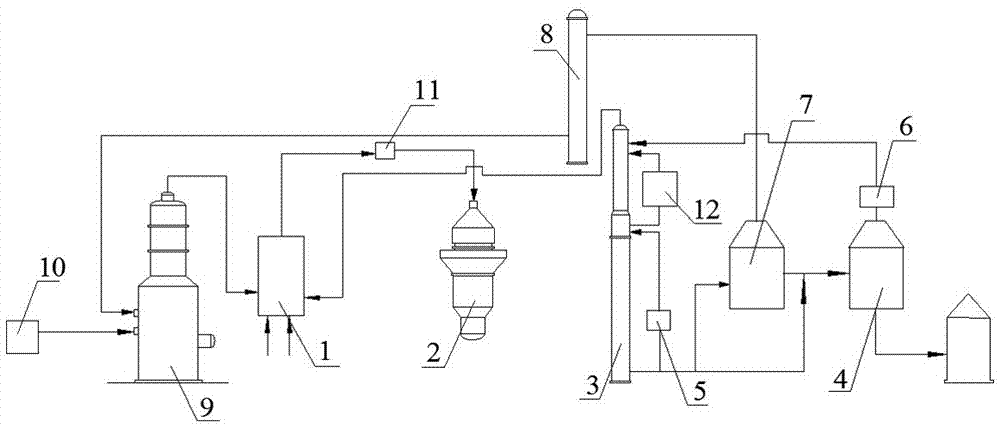

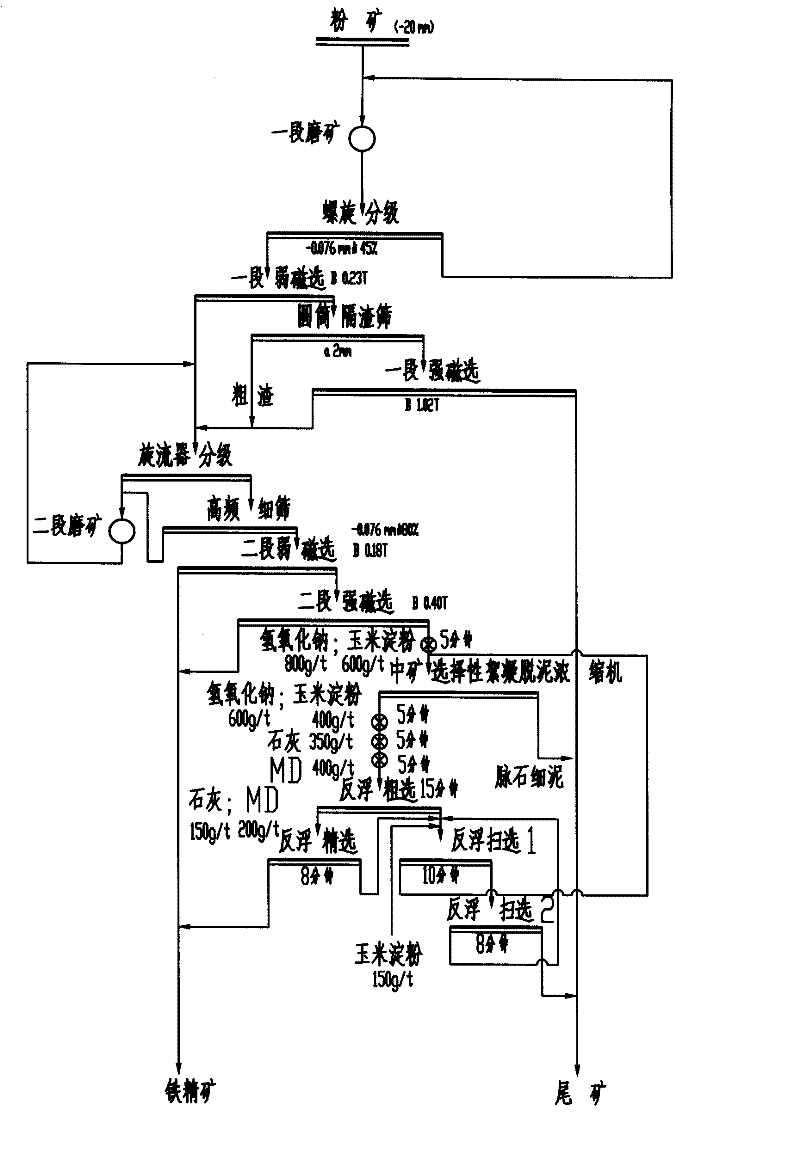

Beneficiation method for recycling specularite

InactiveCN101428248BReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

The invention discloses a benefication method for recovering specularite. The method comprises the processes of primary grinding, grading, primary low intensity magnetic separation, and tailings discarding by primary high intensity magnetic separation; rough concentrate pre-classification by the primary low intensity magnetic separation and the primary high intensity magnetic separation, secondary grinding, secondary low intensity magnetic separation to obtain concentrates, secondary high intensity magnetic separation to obtain concentrates; and selective flocculation desliming secondary conducted on high intensity magnetic separation tailings (middlings), and anionic reverse flotation. The method further comprises the step of arranging a cylindrical slag separating sieve before the primary high intensity magnetic separation. With the advantages that the iron concentrate grade and the iron recovery are high, the loss of granular iron minerals is low, the mineral process flow is short,concentrates and tailings can be obtained in advance and the energy consumption of the benefication is low, the invention can be used not only for selecting specularite ores, but also for selecting weakly magnetic iron minerals, such as hematite, goethite, siderite, limonite, and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com