Concentrated formaldehyde production technology

A production process and concentrated formaldehyde technology, which is applied to the preparation of carbon-based compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of long-term continuous supply and unstable quality of concentrated formaldehyde products, so as to optimize the production process and Operation method, improvement of utilization value, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

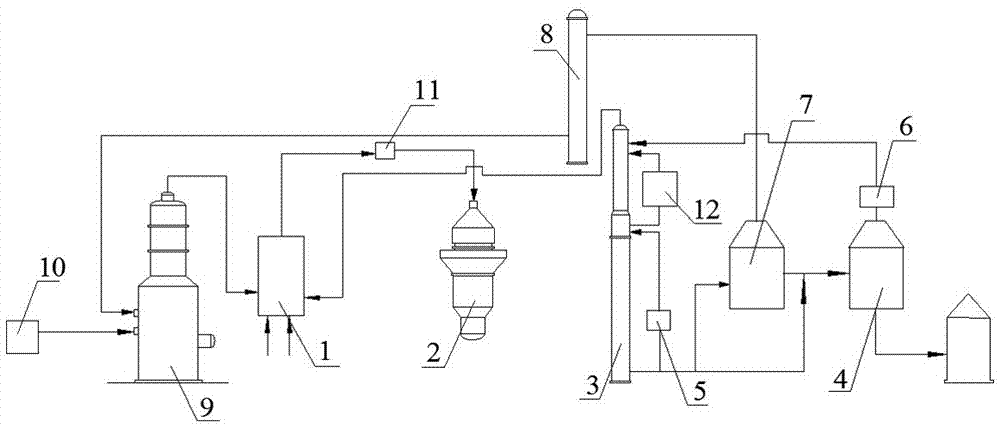

[0026] A kind of concentrated formaldehyde production technique, comprises the steps:

[0027] (1) The refined methanol heated by the heater 9, the crude methanol from the methanol recovery tower, the waste gas from the top of the formaldehyde absorption tower, fresh air and steam respectively enter the mixer 1 through their own pressure for uniform mixing to obtain a mixed gas;

[0028] (2) The uniformly mixed mixed gas enters the formaldehyde reactor 2, and under the catalysis of the silver catalyst, the oxidation reaction of methanol is carried out at 600-650°C to obtain the reaction gas;

[0029] (3) The reaction gas enters the formaldehyde absorption tower 3, and the formaldehyde in the reaction gas is absorbed by the desalted water sprayed on the top of the tower, and the waste gas that is not absorbed is discharged from the top of the formaldehyde absorption tower 3 and returned to the mixer 1 for reuse , the crude aldehyde is extracted from the bottom of the formaldehy...

Embodiment 2

[0040] A kind of concentrated formaldehyde production technique, comprises the steps:

[0041] (1) The refined methanol heated by the heater, the crude methanol from the methanol recovery tower, and the waste gas, air and steam from the top of the formaldehyde absorption tower respectively enter the mixer through their own pressure for uniform mixing to obtain a mixed gas; the temperature of the mixed gas 120°C, the volume ratio of the mixed gas is: air / methanol=0.35, steam / methanol=0.45, waste gas / methanol=1.40;

[0042] (2) The uniformly mixed mixed gas enters the formaldehyde reactor, and under the catalysis of the silver catalyst, the oxidation reaction of methanol is carried out at 600 ° C to obtain the reaction gas;

[0043](3) The reaction gas enters the formaldehyde absorption tower, and the formaldehyde in the reaction gas is absorbed by the desalted water sprayed on the top of the formaldehyde absorption tower, and the waste gas that is not absorbed is discharged fro...

Embodiment 3

[0047] A kind of concentrated formaldehyde production technique, comprises the steps:

[0048] (1) The refined methanol heated by the heater, the crude methanol from the methanol recovery tower, and the waste gas, air and steam from the top of the formaldehyde absorption tower respectively enter the mixer through their own pressure for uniform mixing to obtain a mixed gas; the temperature of the mixed gas The temperature is 122°C, the volume ratio of the mixed gas is: air / methanol=0.36, steam / methanol=0.46, waste gas / methanol=1.41;

[0049] (2) The uniformly mixed mixed gas first passes through the flame arrester and then enters the formaldehyde reactor. Under the catalysis of the silver catalyst, the oxidation reaction of methanol is carried out at 610°C to obtain the reaction gas;

[0050] (3) The reaction gas enters the formaldehyde absorption tower, and the formaldehyde in the reaction gas is absorbed by the desalted water sprayed on the top of the formaldehyde absorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com