Multi-direction and multi-station grooving production line and working method thereof

A multi-station, multi-directional technology, applied to work accessories, stone processing tools, positioning devices, etc., can solve problems affecting processing efficiency, affecting grooving processing accuracy, increasing worker workload, etc., to reduce cost input, Improve the scope of application and reduce the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

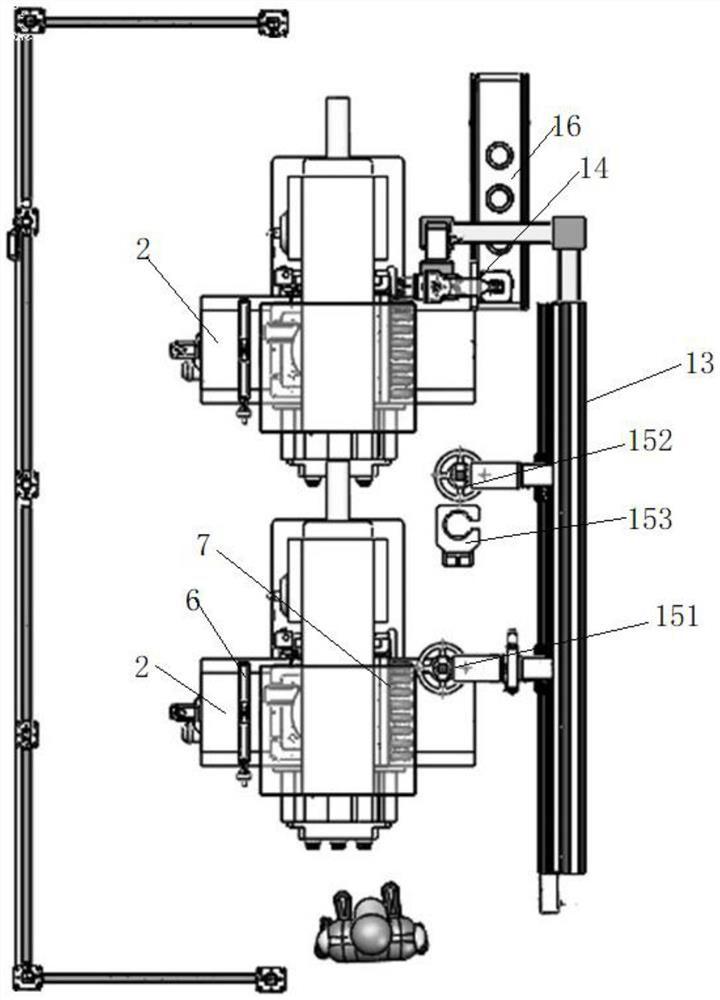

[0058] As shown in the figure, a multi-directional, multi-station grooving production line includes: a first grooving machine, a second grooving machine, a product transplanting mechanism and a stacking receiving device, the first grooving machine and the second grooving machine The two grooving machines are arranged oppositely, and the two cooperate with each other. The product transplanting mechanism is arranged on one side of the first grooving machine and the second grooving machine, and the stacking receiving device is arranged on the side of the second grooving machine. One side of the discharge port, and the two cooperate with each other.

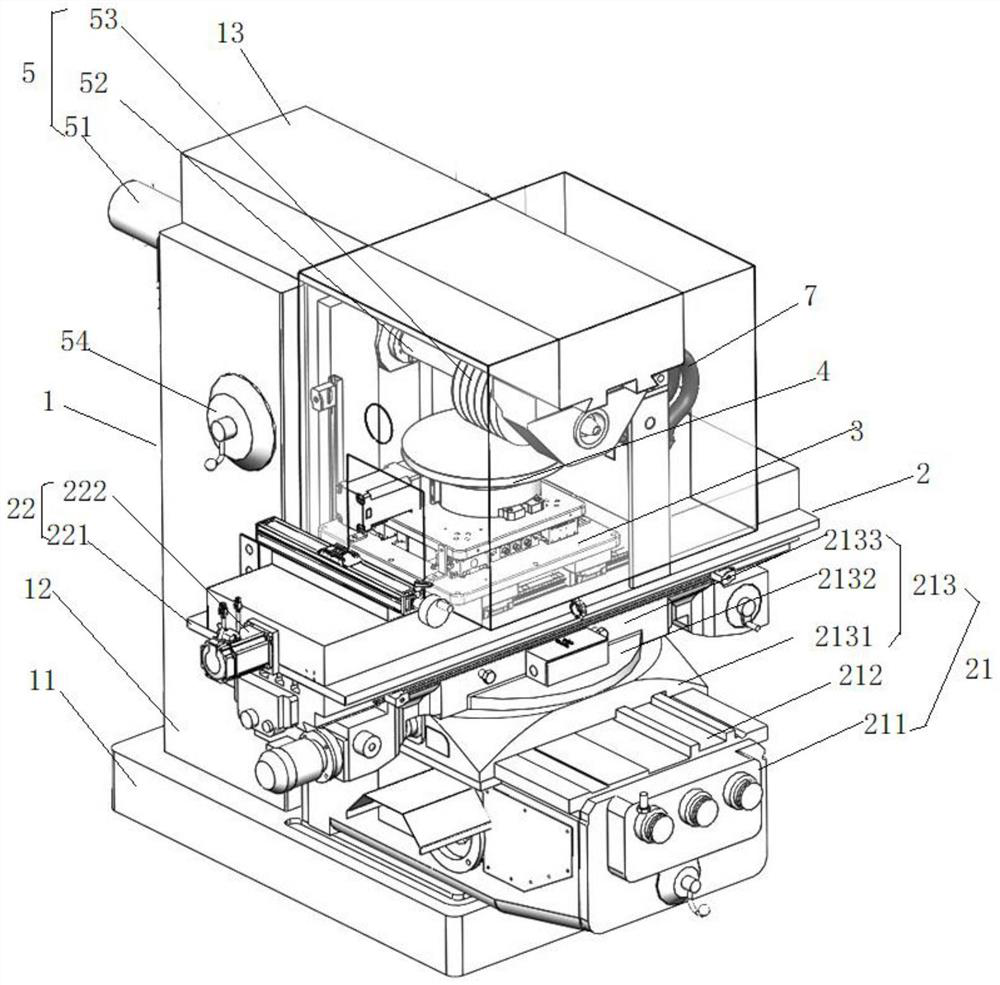

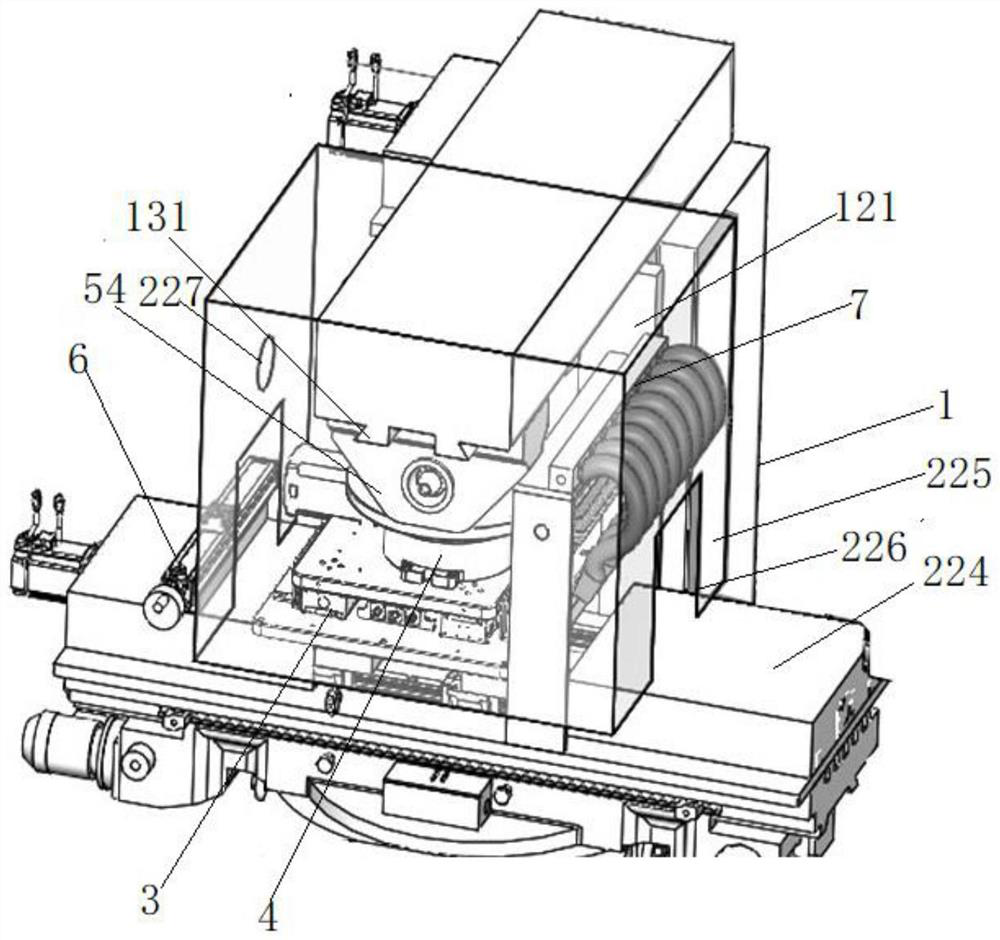

[0059] The first slotting machine and the second slotting machine described in this embodiment both include a frame 1, a position adjustment device 2, an alignment platform 3, a servo rotating platform 4 and a slotting mechanism 5, and the position adjustment device 2 is set On the frame 1, the alignment platform 3 is arranged above ...

Embodiment 2

[0078] As shown in the figure, a multi-directional, multi-station grooving production line includes: a first grooving machine, a second grooving machine, a product transplanting mechanism and a stacking receiving device, the first grooving machine and the second grooving machine The two grooving machines are arranged oppositely, and the two cooperate with each other. The product transplanting mechanism is arranged on one side of the first grooving machine and the second grooving machine, and the stacking receiving device is arranged on the side of the second grooving machine. One side of the discharge port, and the two cooperate with each other.

[0079] The first slotting machine and the second slotting machine described in this embodiment both include a frame 1, a position adjustment device 2, an alignment platform 3, a servo rotating platform 4 and a slotting mechanism 5, and the position adjustment device 2 is set On the frame 1, the alignment platform 3 is arranged above ...

Embodiment 3

[0101] The structure of a multi-directional, multi-station grooving production line described in this embodiment is the same as that in Embodiment 2.

[0102] The alignment platform 3 described in this embodiment includes a bottom plate 31 and an alignment plate 32, the alignment plate 32 is arranged above the bottom plate 31, and a set of limiters are arranged around the alignment plate 32 on the bottom plate 31. bit bar 33.

[0103] In this embodiment, the Y-axis moving component 22 is provided with a dust cover 224, and the dust cover 22 is provided with a protective cover 225 on the outside of the alignment platform 3, and the three sides of the protective cover 225 are provided with The door 226 is opened, and a dust suction port 227 is provided on one side of the protective cover 225 .

[0104] The working method of a multi-direction, multi-station grooving production line described in this embodiment is as follows: 1): First, place the product to be processed in the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com