Two-stage grinding device

A two-stage, two-stage grinding technology, applied in grain processing and other directions, can solve the problems of increasing management difficulty, high investment and operating costs, and excessive equipment, reducing the number of equipment, reducing costs, and simplifying grinding. The effect of the mining system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] If traditional mills are used for fine grinding and ultrafine grinding of mineral materials, an independent classification operation must be set up after the grinding line. Grinding, since the current grinding operation and grading operation are two independent operating systems, when performing multi-stage grinding operations, only each grinding operation line can be set independently, which leads to too many equipments and complex systems , not only high investment and operating costs, but also increases the difficulty of management.

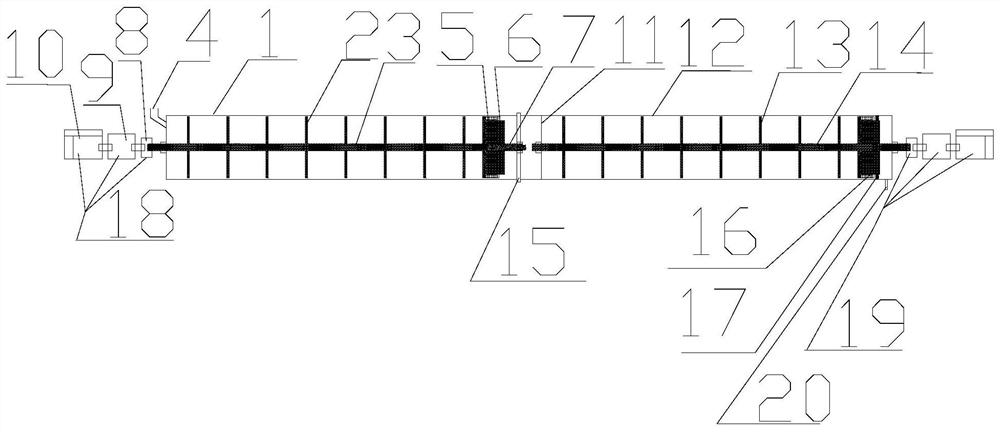

[0043] To solve the above problems, the present invention provides a two-stage grinding device. The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

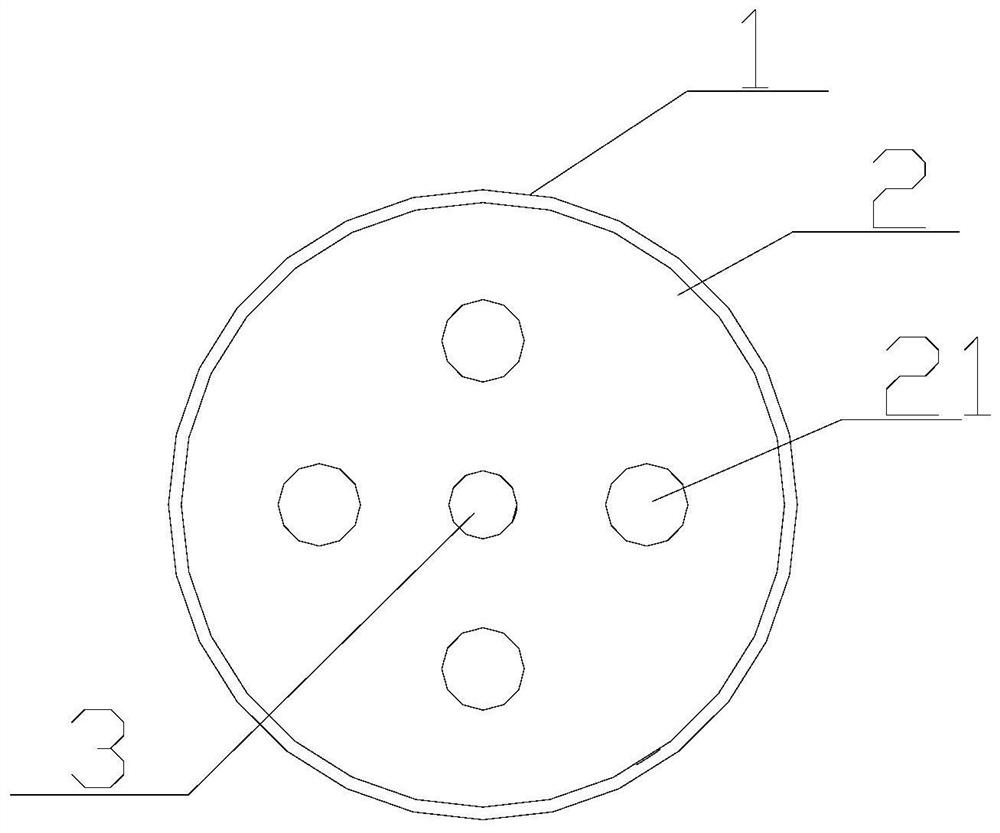

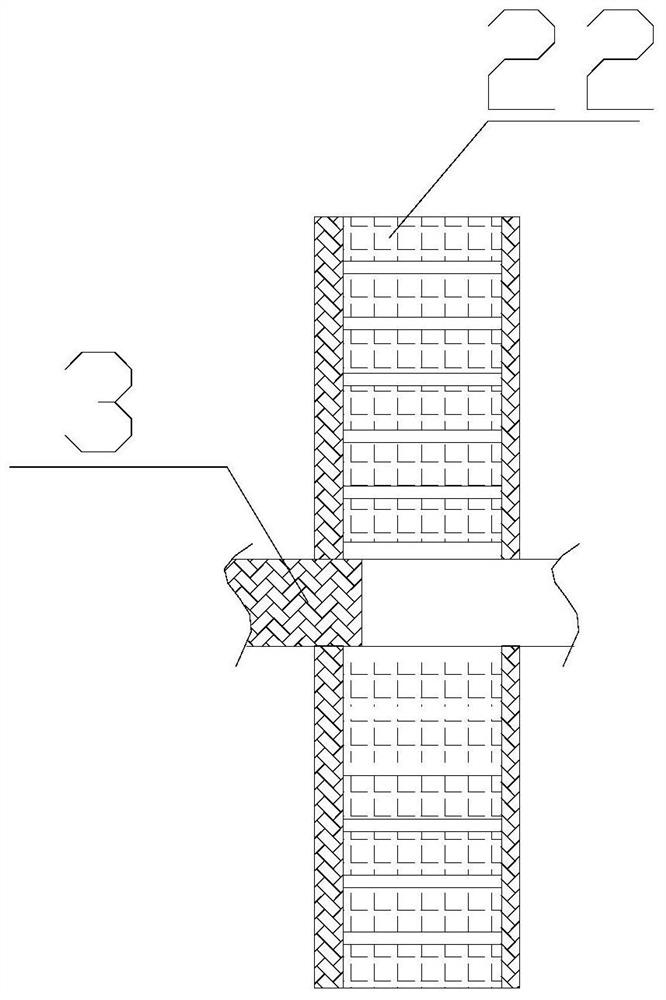

[0044] In order to illustrate the two-stage grinding device provided by the present invention, Figure 1-Figure 6 The structure of the two-stage grinding device is exemplarily marked from different angles. speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com