Patents

Literature

577results about How to "Meet the needs of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

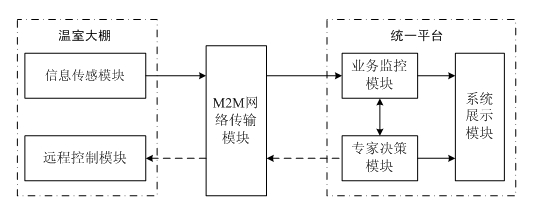

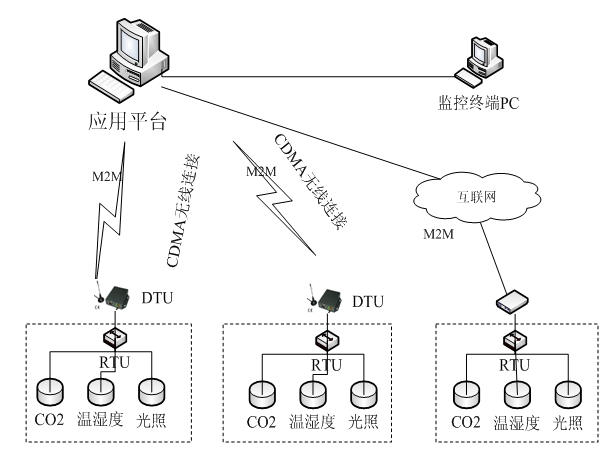

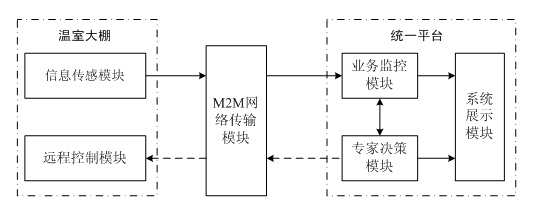

Remote monitoring and intelligent control system and method of agricultural greenhouse based on M2M framework

InactiveCN102035876AMeet the needs of productionMeet the needs of mass productionData processing applicationsClimate change adaptationAutomatic controlThird generation

The invention discloses a remote monitoring and intelligent control system and method of an agricultural greenhouse based on an M2M framework. The system comprises an information acquisition module, an M2M network transmission module, a service monitoring module, an expert decision module, a system display module and a remote control module. The method comprises: firstly, deploying a plurality of environmental parameter sensors in a glasshouse to collect key information; then, in an M2M mode, sending the key information to a centered platform via the Internet or the 3G network; storing, displaying and analyzing data in the centered platform; combining with a crop model and an expert system to output decision information; and issuing a control order via the Internet or the 3G network. The system can avoid the limitation of the local automatic control system of the common greenhouse and realizes the situation that the production in a plurality of greenhouses is supported on one platform, thus the system has good expansibility and supports scale application. The system provides the means for checking systems and issuing orders on the Internet and a mobile terminal, is convenient and can transmit information by the broadband Internet and the 3G communication network.

Owner:JIANGSU HONGXIN SYST INTEGRATION

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyester or polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

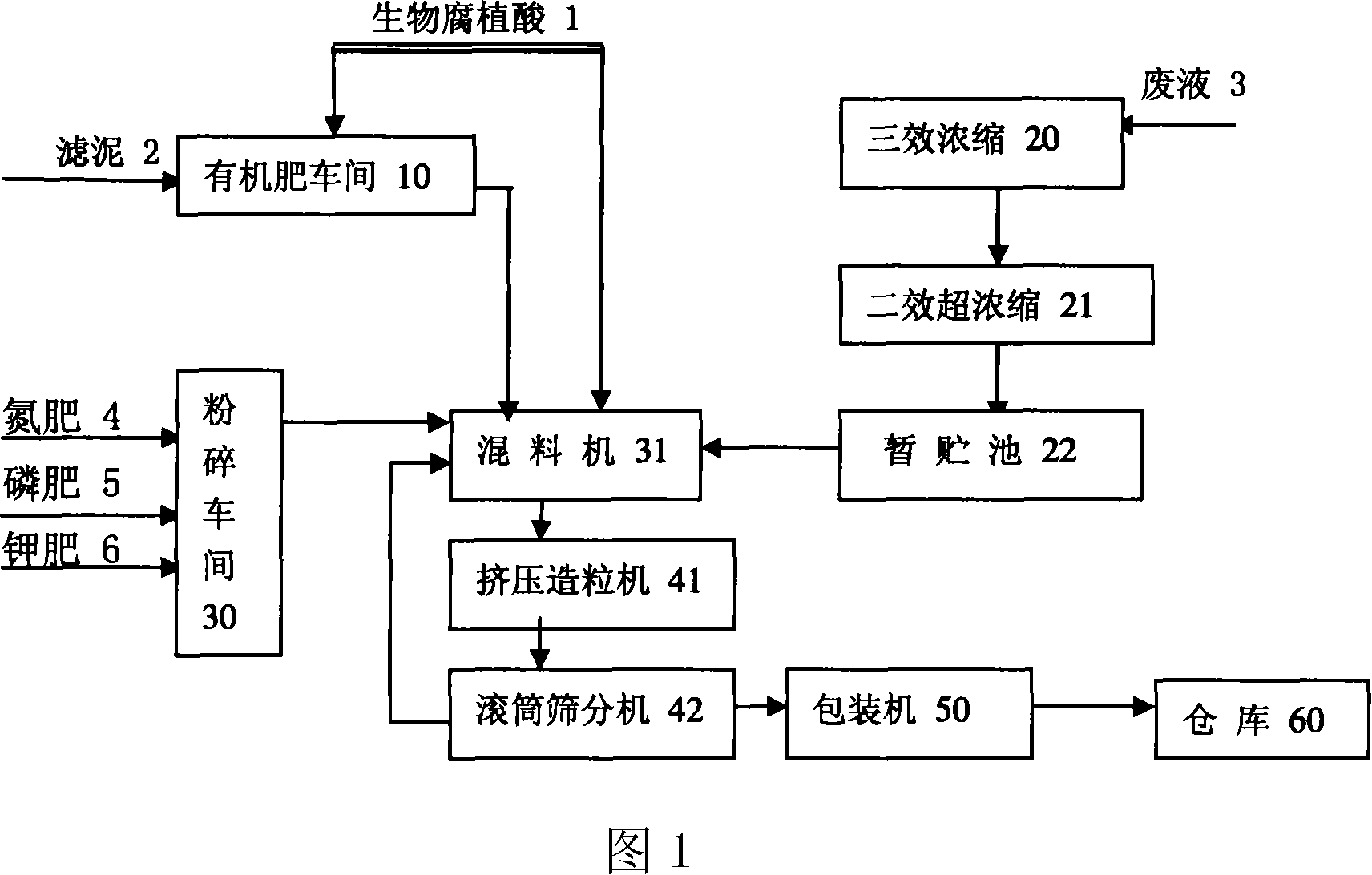

Method of manufacturing organic, inorganic compound fertilizer with molasses zymolysis waste liquor and lime sludge

InactiveCN101108779AImprove efficiencyLow efficiencyBio-organic fraction processingClimate change adaptationLiquid wasteContinuous fermentation

The invention provides a method producing the organic-inorganic compound fertilizer by the molasses fermentation waste liquor and the lime sludge, which relates to a method producing the fertilizer through fermentation and solves the problem of reclaiming and processing the molasses fermentation waste liquor continuously on a large scale. The method of the invention is that the biological humic acid with weight per cent of 0.4 per cent to 0.6 per cent and made by the bagasse is mixed with the lime sludge of 65 per cent to 68 per cent, bagasse powder of 10 per cent to 12 per cent, wheat bran of 1.5 per cent to 2.5 per cent and regulator of 16 per cent to 25 per cent to ferment fully and continuously in a shorter time. The fermented materials with water of 10 per cent to 12 per cent are gained after opening and drying and are crushed into the lime sludge organic fertilizer. The molasses fermentation waste liquor with water of 90 per cent is condensed to the hyperconcentration liquor with water of 26 per cent to 28 per cent by the three-effect forced circulating concentration system and then through the two-effect scraping and steaming hyperconcentration system. The hyperconcentration liquor of 30 per cent to 33 per cent and the biological humic acid of 9 per cent to 10 per cent are stirred and mixed uniformly based on the weight per cent and are added with the fertilizer of 32 per cent to 34 per cent and the lime sludge organic fertilizer of 25 per cent to 27 per cent to stir to produce the organic-inorganic compound fertilizer through dry extrusion and prilling.

Owner:越百年创新肥业(海南)有限公司

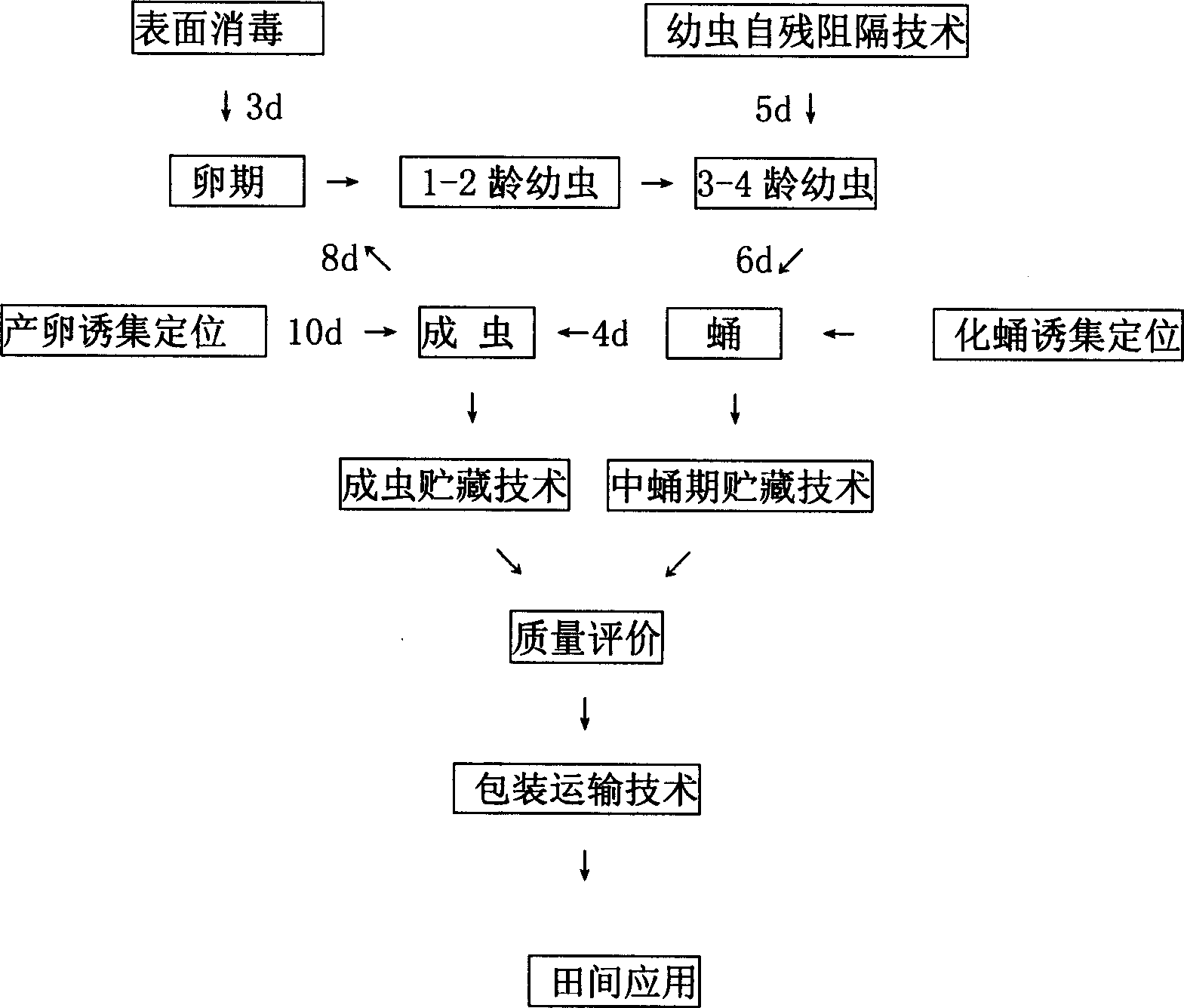

Artificial progagation method for ladybird beetle and lacewing fly

InactiveCN1631127AEfficient reproductionImprove reproductive efficiencyAnimal husbandryAphisHost plants

The invention provides an artificial propagation method for ladybird beetle and lacewing fly which comprises the steps of, aphid culturing, using wheat, lima bean, cabbage, radish as host plant for aphid culturing, and ladybug lacewing fly raising, ovum period management, larva nourishing, chrysalides growth, product refrigeration, and packaging.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

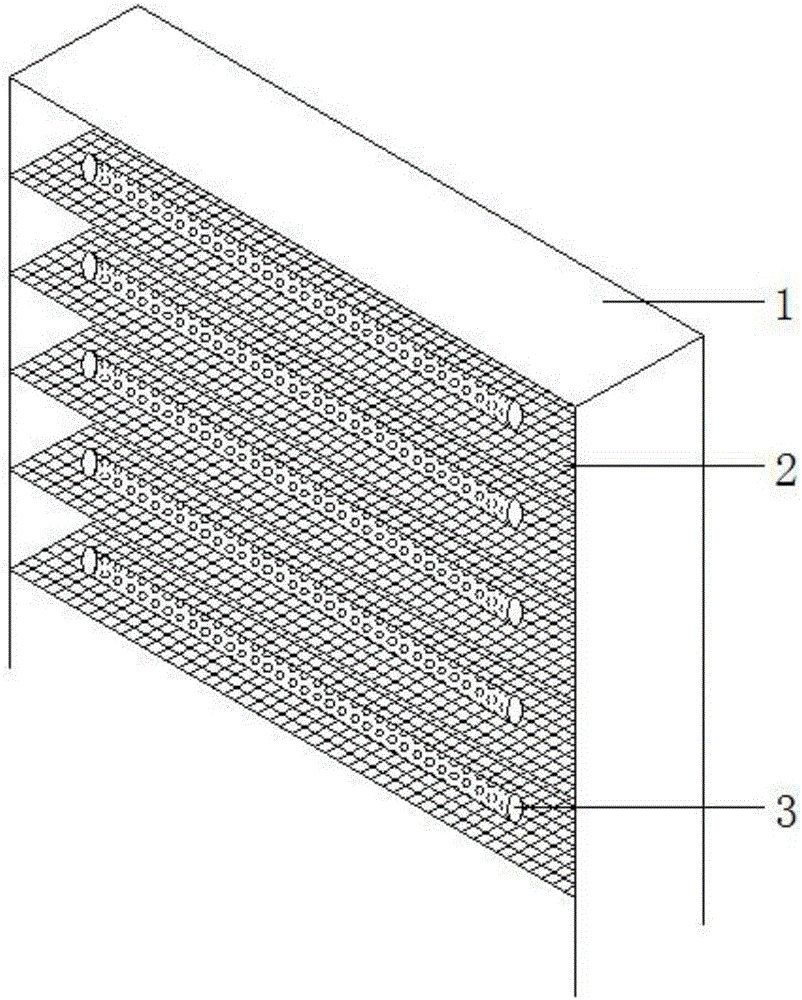

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

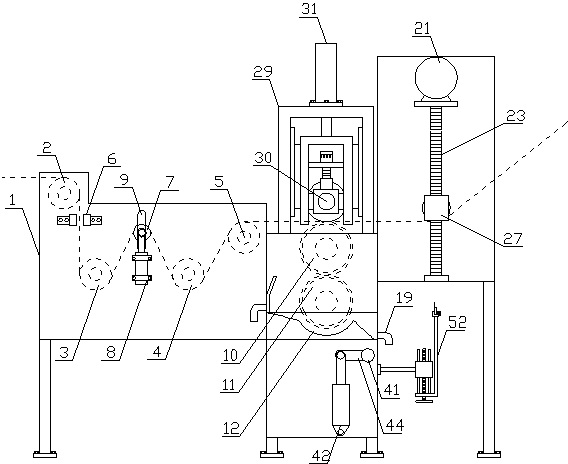

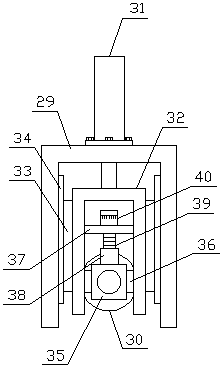

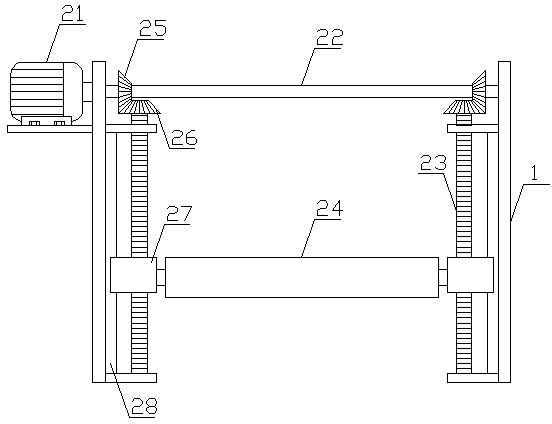

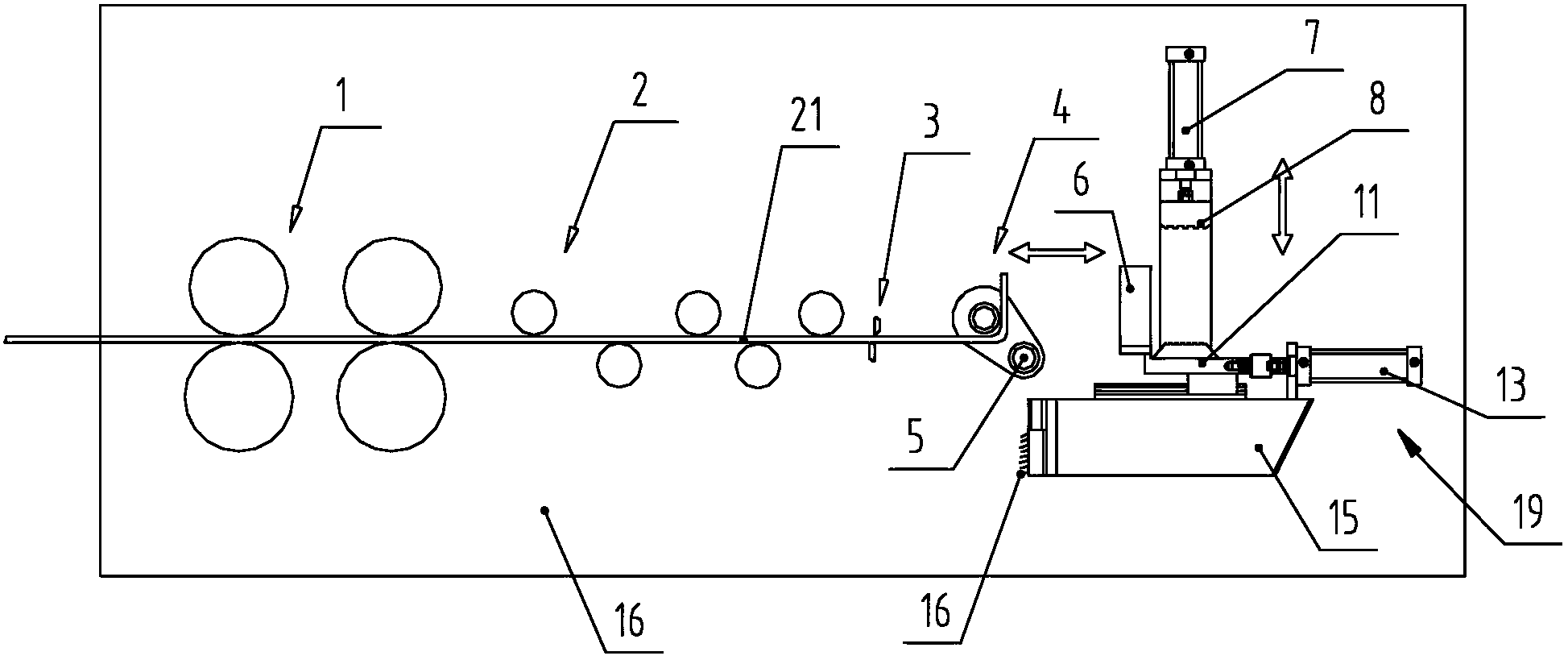

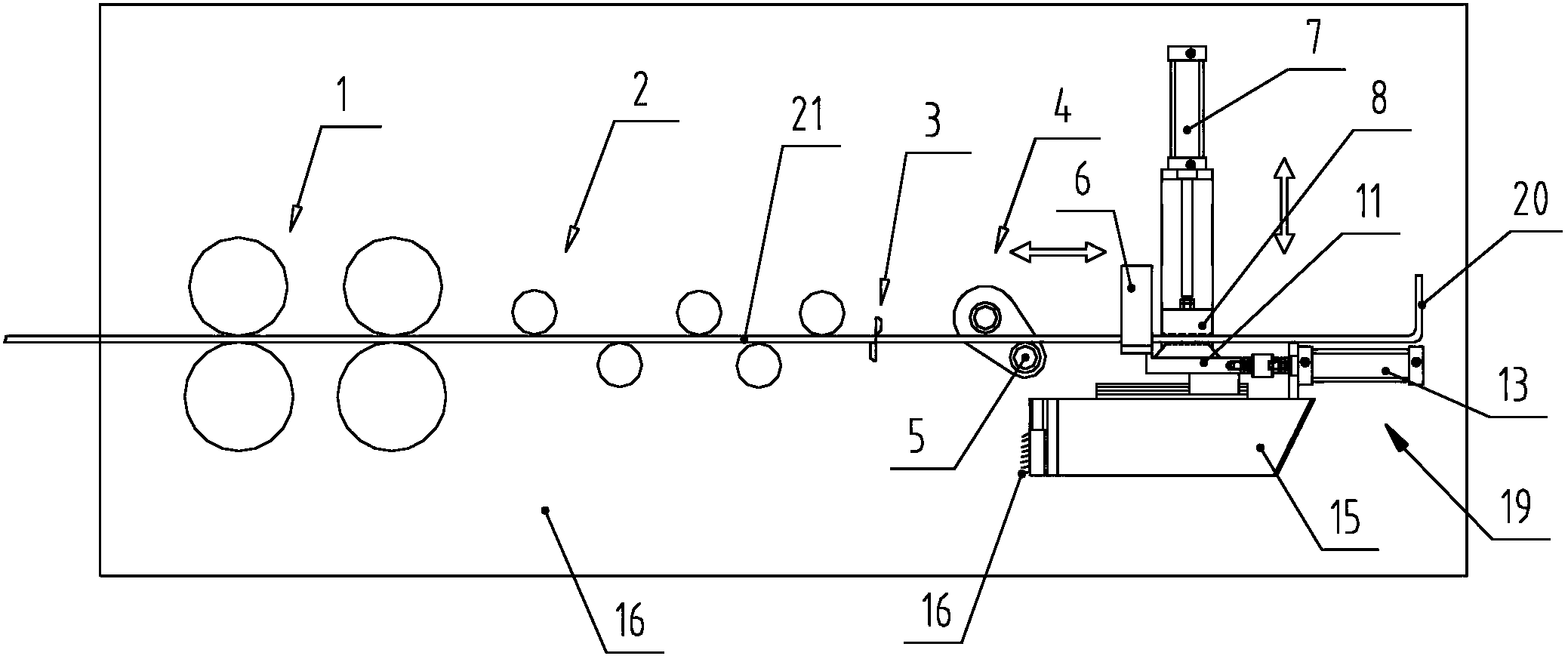

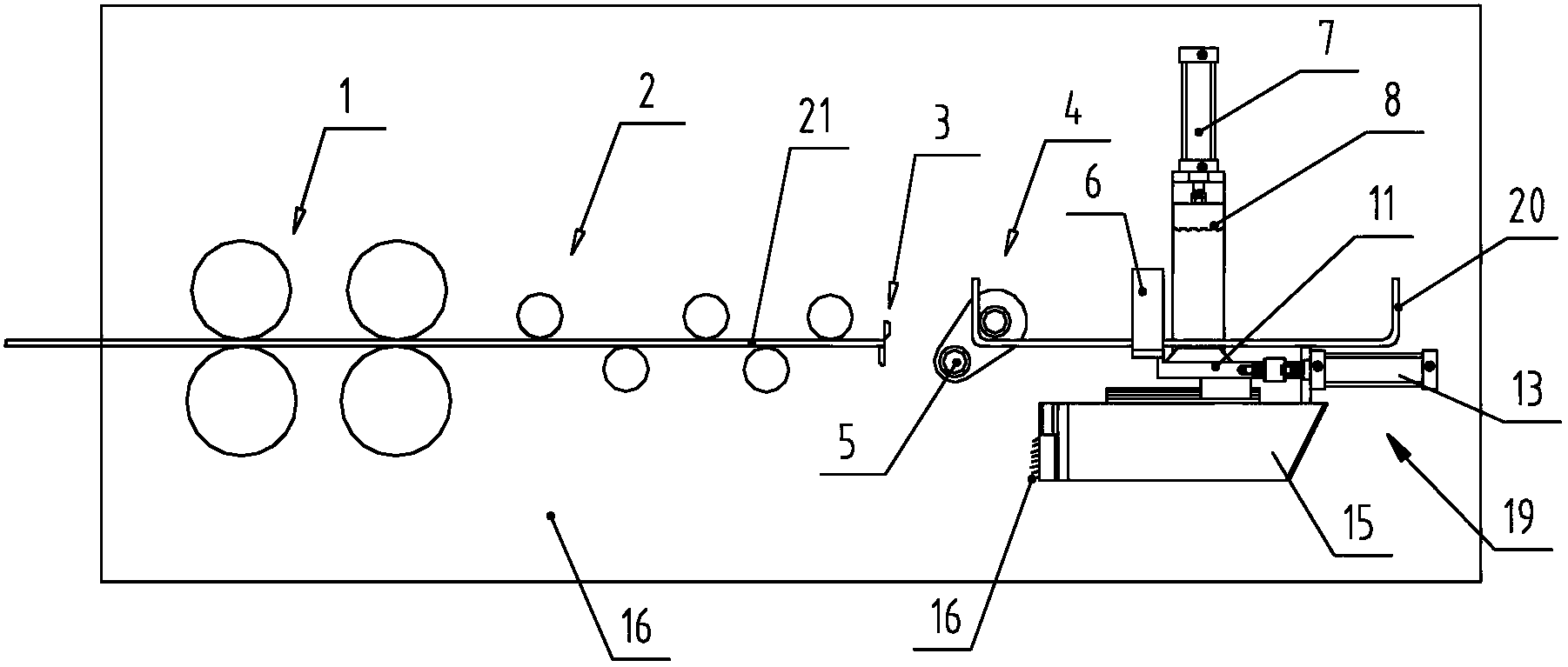

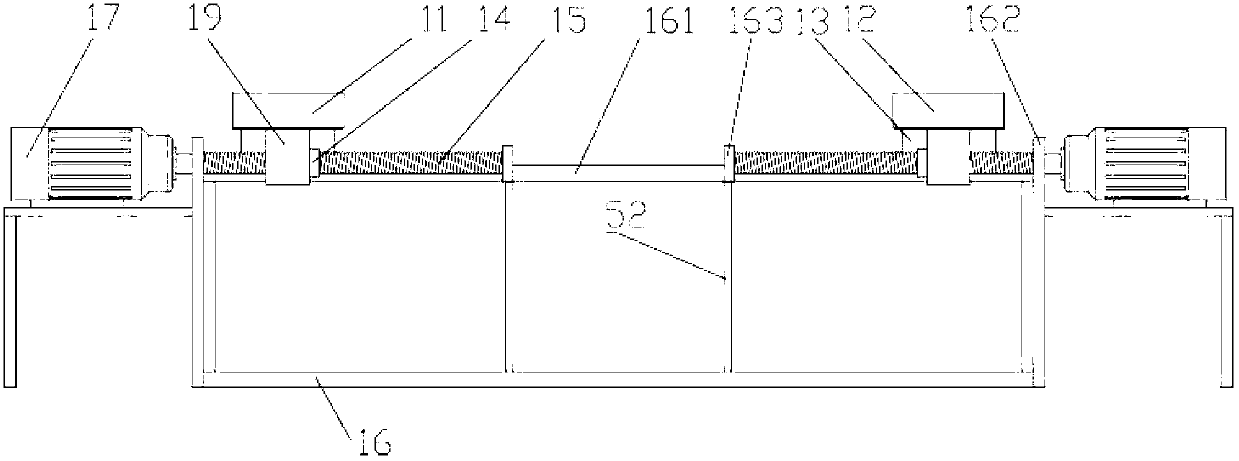

Thin film conveying gluing device

ActiveCN104163356AAdjustable tensionGuarantee stabilityArticle deliveryWebs handlingDrive shaftEngineering

The invention discloses a thin film conveying gluing device and belongs to the field of thin film processing equipment. The thin film conveying gluing device comprises a main support, a film guide mechanism, a film gluing mechanism and a film discharging mechanism, wherein the film guide mechanism, the film gluing mechanism and the film discharging mechanism are sequentially arranged on the main support in the thin film conveying direction. The film guide mechanism comprises a first film guide roller, a second film guide roller, a third film guide roller and a fourth film guide roller, wherein the first film guide roller, the second film guide roller, the third film guide roller and the fourth film guide roller are sequentially connected to the main support horizontally and rotationally in the thin film conveying direction. A static electricity eliminating board is arranged between the first film guide roller and the second film guide roller. A tension adjusting roller is arranged between the second film guide roller and the third film guide roller. The film gluing mechanism comprises a film pressing mechanism, a gluing roller, a glue feeding roller and a film gluing groove, wherein the film pressing mechanism, the gluing roller, the glue feeding roller and the film gluing groove are sequentially arranged from top to bottom. The surface of the gluing roller is attached to the surface of the glue feeding roller. The film gluing groove is an arc-shaped groove matched with the glue feeding roller in shape. The film discharging mechanism comprises a driving motor, a driving shaft, a driving screw and a film discharging roller. The thin film conveying gluing device is simple in structure, thin films can be glued rapidly, efficiently and evenly, and the requirement for production is met.

Owner:浙江耀阳新材料科技有限公司

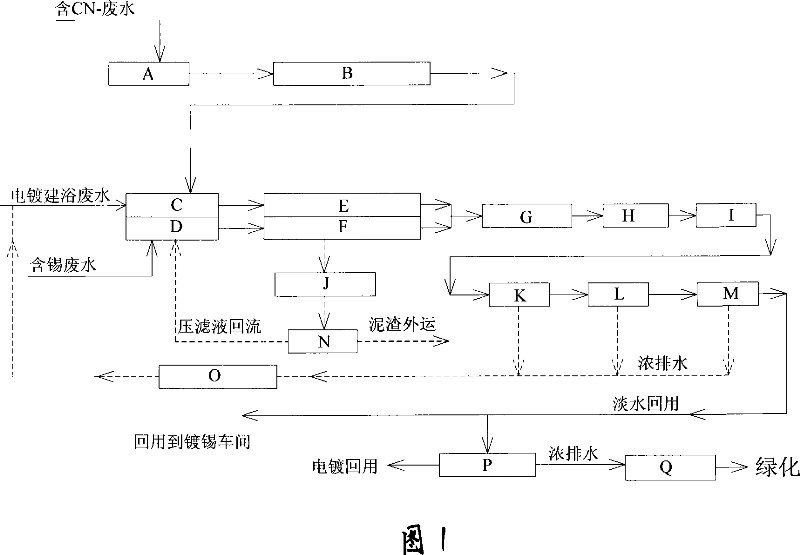

Electroplating wastewater treatment reclaiming technique

ActiveCN101041534AReduce contentHigh desalination rateTreatment using aerobic processesGeneral water supply conservationFiltrationUltrafiltration

The invention discloses a reclaimed craft to dispose electroplating waste water, which comprises the following steps: adopting oxidation-reduction and chemical precipitation disposing method and film technology (fold filtration, hyperfiltration, Na filtration and reverse osmosis desalination) deep purifying method; avoiding accumulation of salt effectively; reverse osmosis sloughing monovalent salt at last grade; trapping bivalent salt in innocent treatment system; proceeding depositing treatment continually; removing accumulating BOD and COD in water body through biochemical treatment effectively; realizing zero discharge of waste water.

Owner:JINAN JINGHENG ELECTRONICS

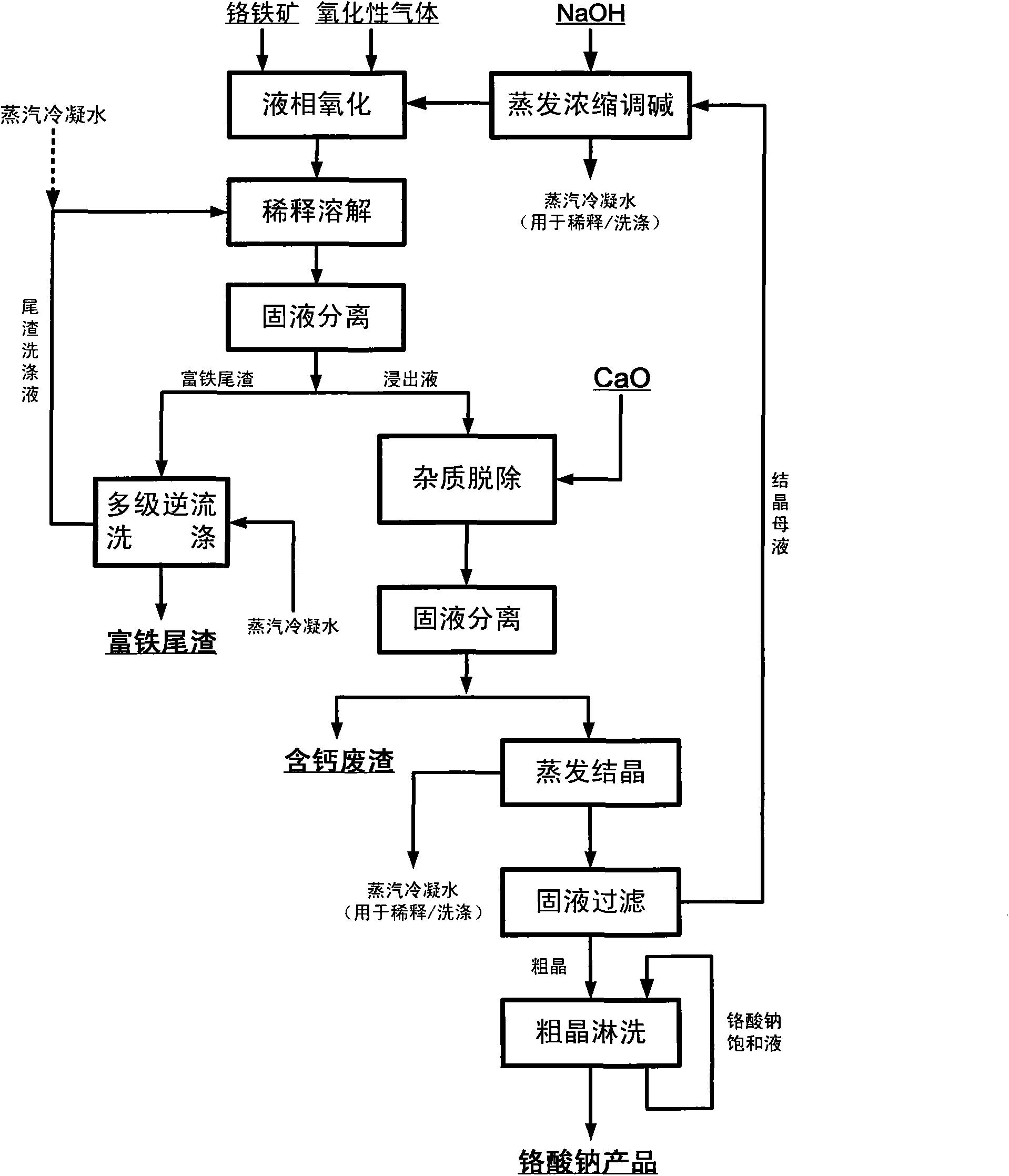

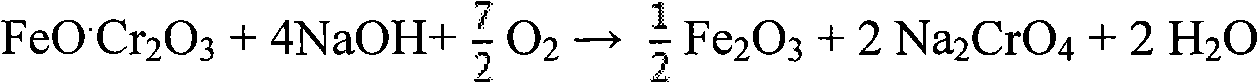

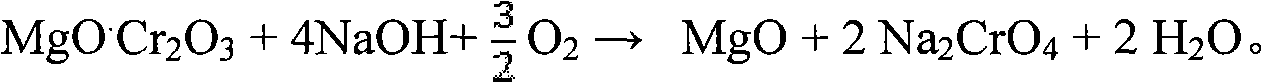

Method for pollution-free production of sodium chromate by pressure leaching of chromite

ActiveCN101817561AObvious superioritySimple ingredientsChromates/bichromatesReaction temperatureHydrometallurgy

The invention belongs to the field of chromite hydrometallurgy and chromium chemical industry, and in particular relates to a method for the pollution-free production of sodium chromate by pressure leaching of chromite. The method comprises the following steps of: 1) reacting the chromite with oxidizing gas in solution of NaOH; 2) diluting the product obtained by the step 1) and making subcrystalline sodium chromate to fully enter a liquid phase; 3) performing solid-liquid separation on the solid-liquid mixed slurry obtained by the step 2); 4) adding calcium oxide into the obtained diluent for removing impurities; and 5) evaporating and crystallizing the obtained solution without the impurities to obtain a sodium chromate crystal and crystallization mother solution; after the solid-liquid separation, rinsing the sodium chromate crystal by using saturated solution of sodium chromate; and drying to obtain a qualified sodium chromate product. The method has the advantages of simple reaction system component, no difficultly separated phase introduced in the system, contribution to high-efficiency separation of the sodium chromate, great reduction in reaction temperature, low energy consumption, effective reduction in production cost of the sodium chromate, and high chromium leaching yield.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

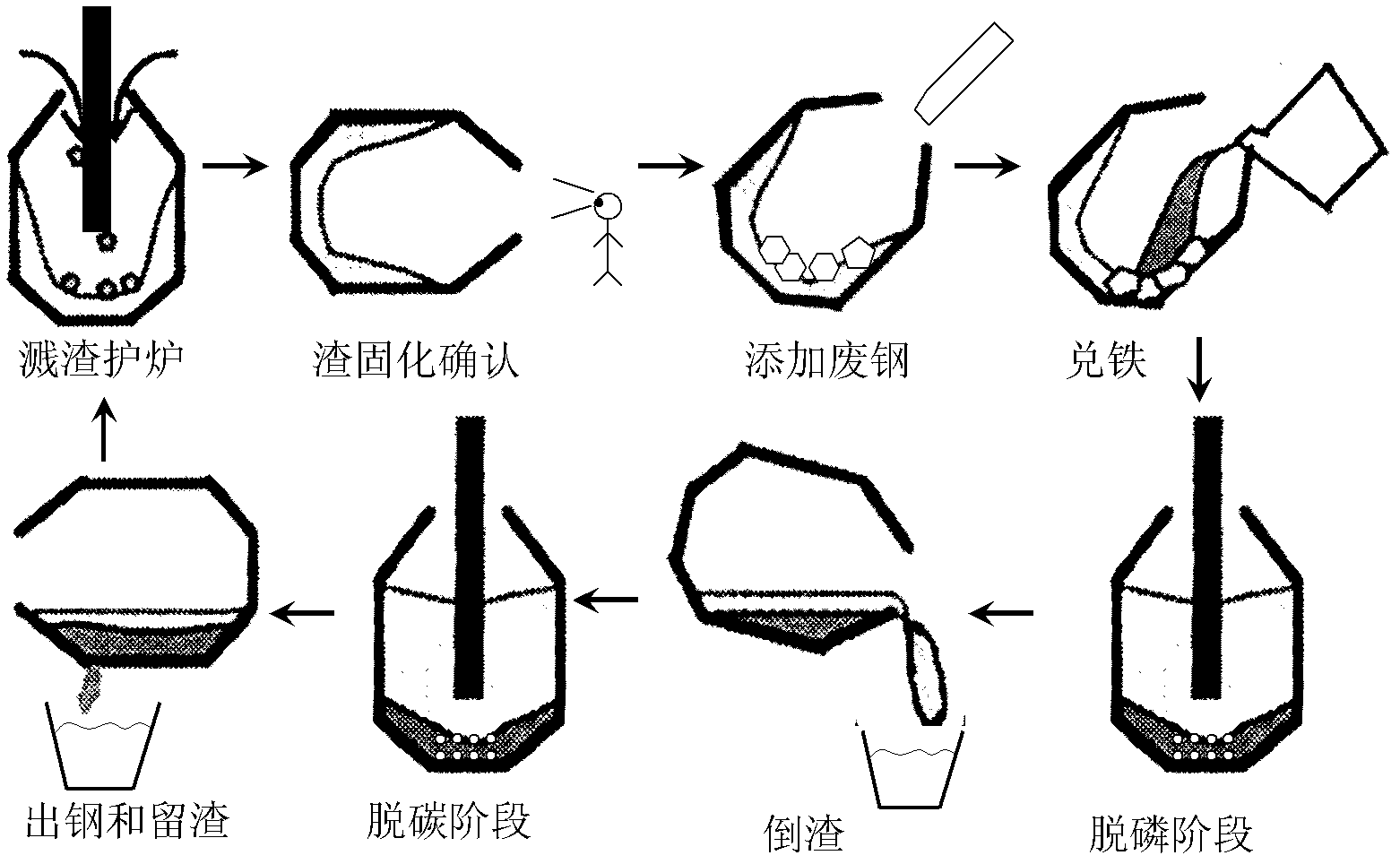

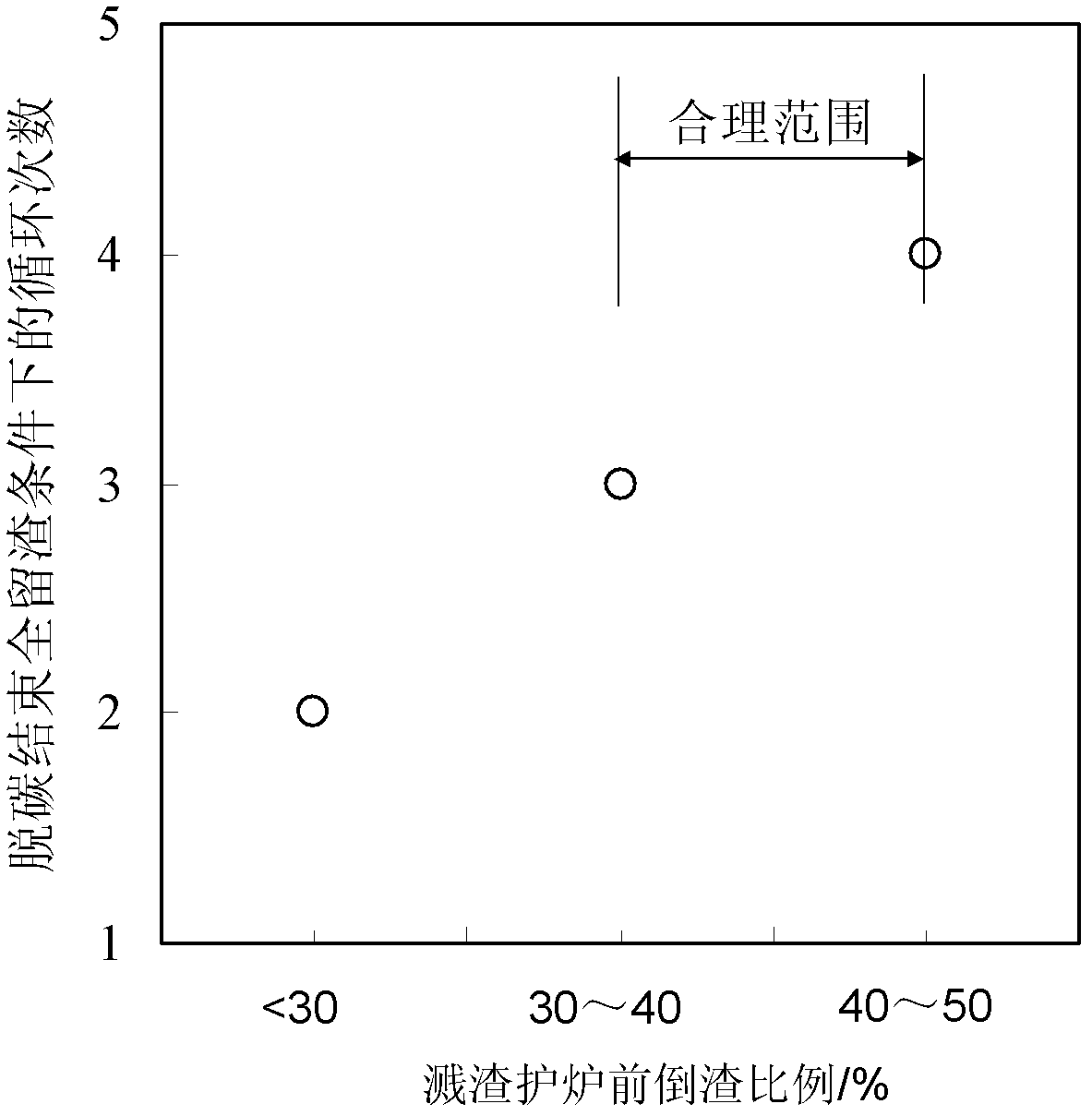

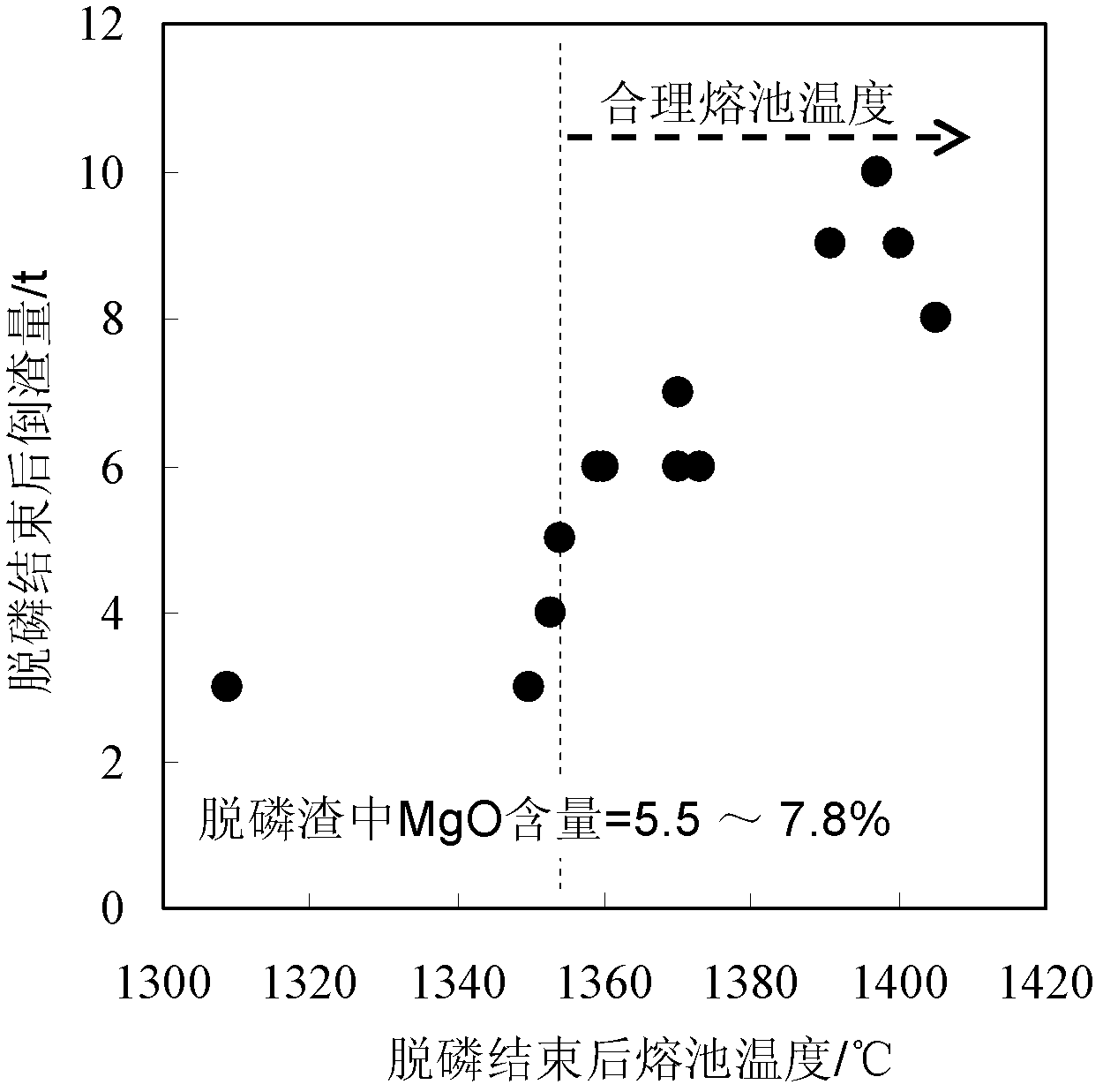

Convertor steelmaking method capable of reducing slag quantity

ActiveCN102212640AProtective liningReduce metal splashManufacturing convertersProcess efficiency improvementDolomiteScrap

The invention belongs to the technical field of convertor steelmaking, and provides a convertor steelmaking method capable of reducing slag quantity. The process flow disclosed by the invention is circular process flow starting with step of protecting a furnace by slag splashing and ending with the step of remaining slag in the furnace. The process flow specifically comprises the following eight stages: protecting a furnace by slag splashing; curing liquid slag in the furnace; adding scrap steel; adding molten iron; blowing-dephosphorizing at a first stage; deslagging in the middle; blowing-decarbonizing at a second stage; tapping; and remaining slag in the furnace. Compared with the conventional convertor steelmaking process, the convertor steelmaking provided by the invention has the beneficial effects that lime consumption is lowered by 40.5%, light-roasting dolomite consumption is lowered by 76.8%, and the total consumption of the lime and light-roasting dolomite is lowered by 55.5% on the premise that phosphorus content at the end point is not more than 0.015%.

Owner:SHOUGANG CORPORATION

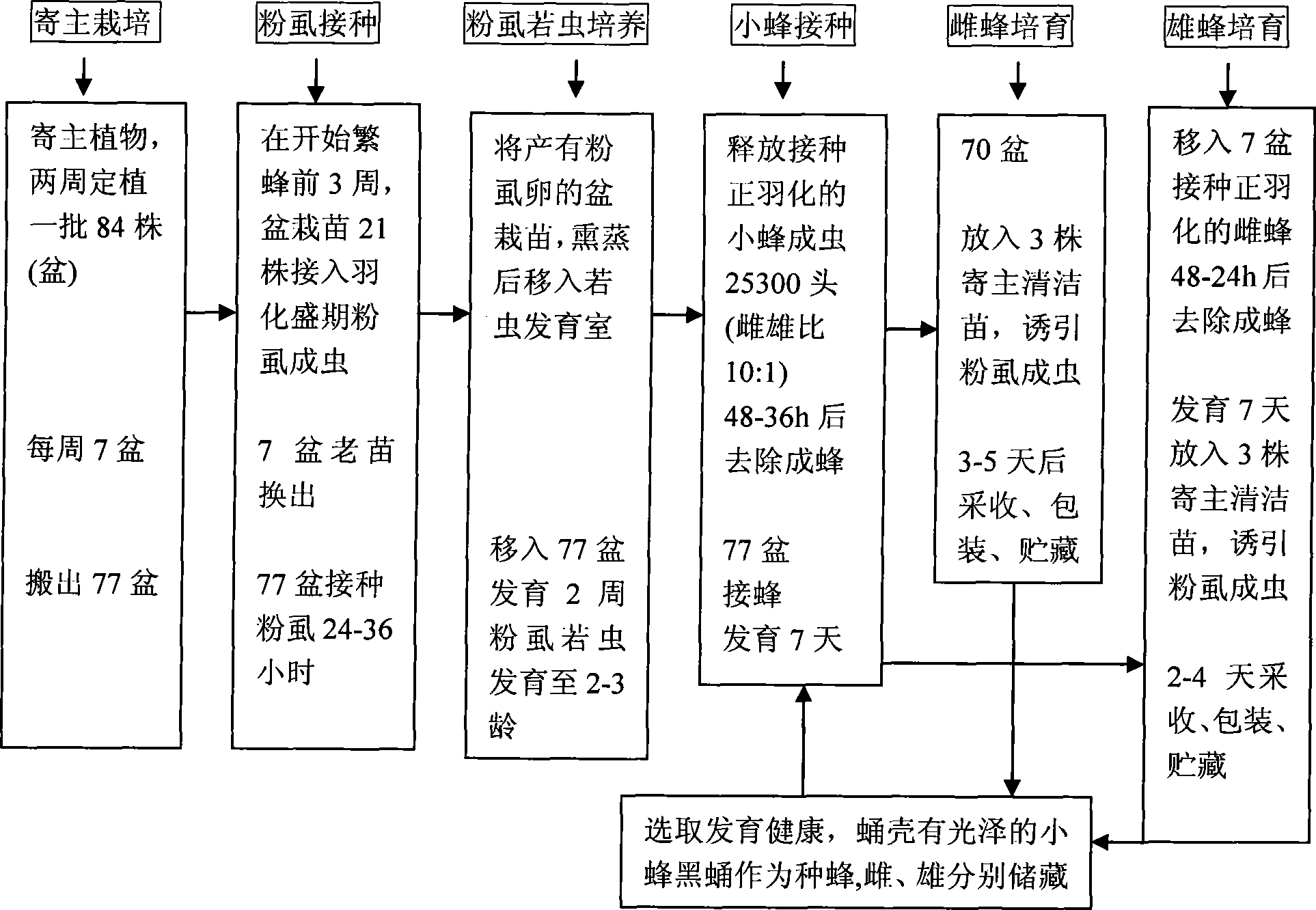

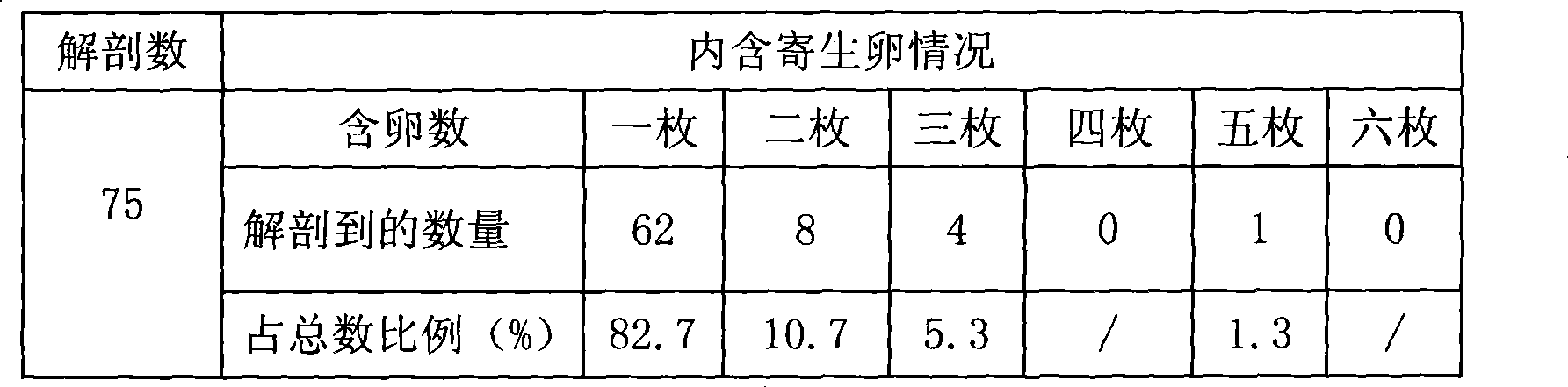

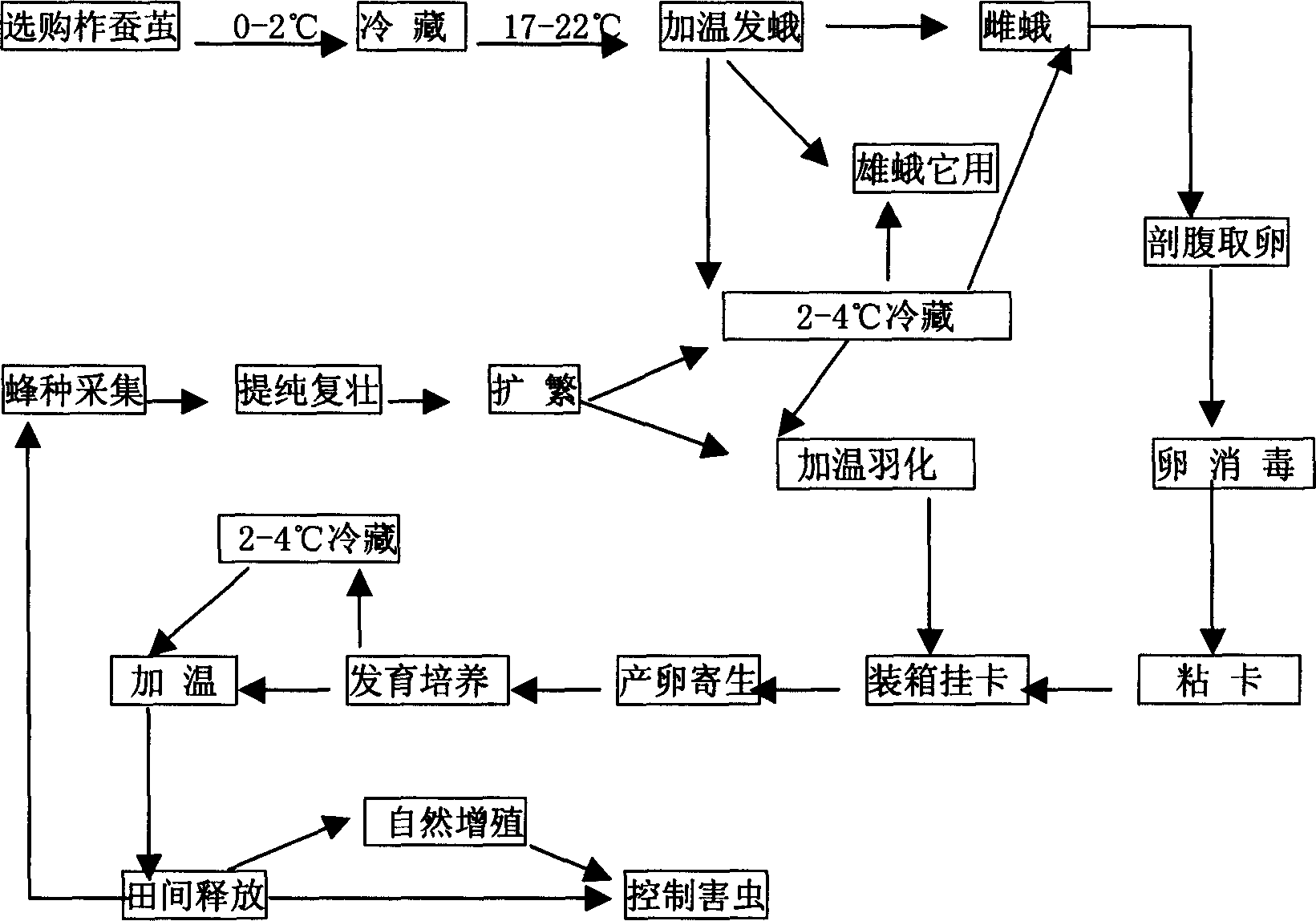

Encarsia Sophia artificial propagation production method

The invention discloses a pale yellow Encarsia chalcid artificial propagation production method, comprising the following steps: collection and propagation of the pale yellow Encarsia chalcid species; host production; whitefly inoculation reproduction and development; inoculation and breeding of chalcid; drone cultivation; chalcid and whitefly separation; pupae collection; card making; and breeder selection. The proposal of the invention helps to improve the superior bee species selection, propagation and release, and realizes the high-quality, high-efficiency and high-scale reproduction of pale yellow Encarsia chalcid; moreover, the method is suitable for large-scale production and is applied to the technical field of agricultural pest biological control to prevent and control the greenhouse whitefly and other agricultural pests to meet production needs.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Preparation method for high-viscosity 107 glue

ActiveCN102558563AHigh yieldSimple preparation processAdhesivesTetramethylammonium hydroxideBoiling point

The invention relates to a preparation method for high-viscosity 107 glue. The preparation method comprises the following steps of: adding a certain amount of DMC (Dimethyl Carbonate) and 107 glue of which the viscosity is 100-1,500 cs or a certain amount of DMC into a reactor provided with a stirrer, a thermometer and a condensation reflowing pipe, starting stirring, heating to a certain temperature, and adding an alkali catalyst, wherein the alkali catalyst comprises one of potassium hydroxide, tetramethylammonium hydroxide pentahydrate, tetrabutyl phosphorus oxychloride or silicon alkoxidealkali gel of the alkalis; undergoing a balanced reaction at the temperature for certain hours, and directly neutralizing or heating for decomposing the alkali catalyst; and adding a phosphoric acid or silanol hydrochloric acid gel neutralizing agent of which the mass is equal to that of the catalyst under the condition that neutralization is performed, or directly heating for decomposing the alkali catalyst under the condition that neutralization is not performed, continuously stirring for 1 hour, and removing low-boiling-point substances. The high-viscosity 107 glue prepared with the methodhas the advantages of simple preparation process, stable viscosity, high product yield and capability of meeting production requirements.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

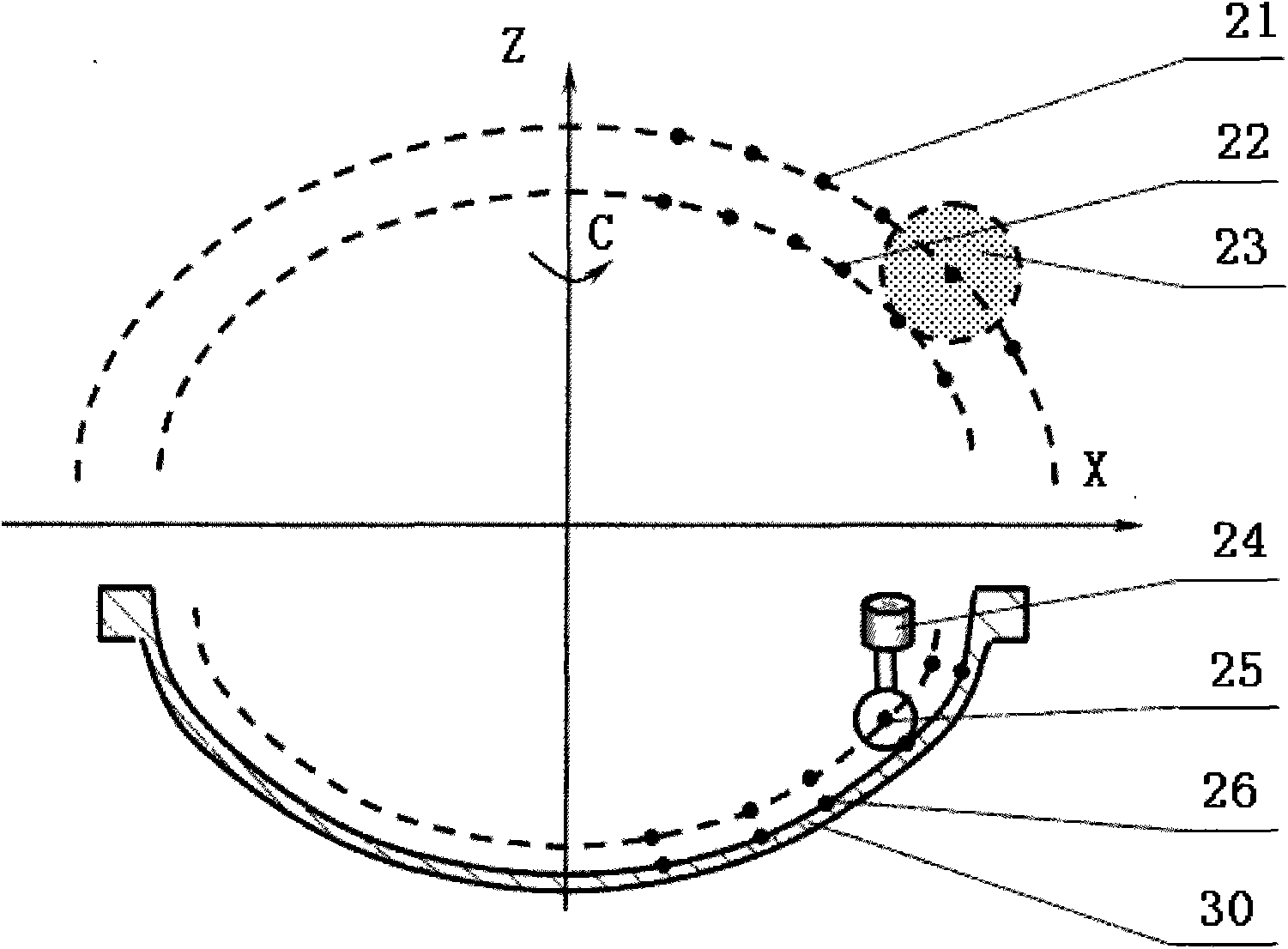

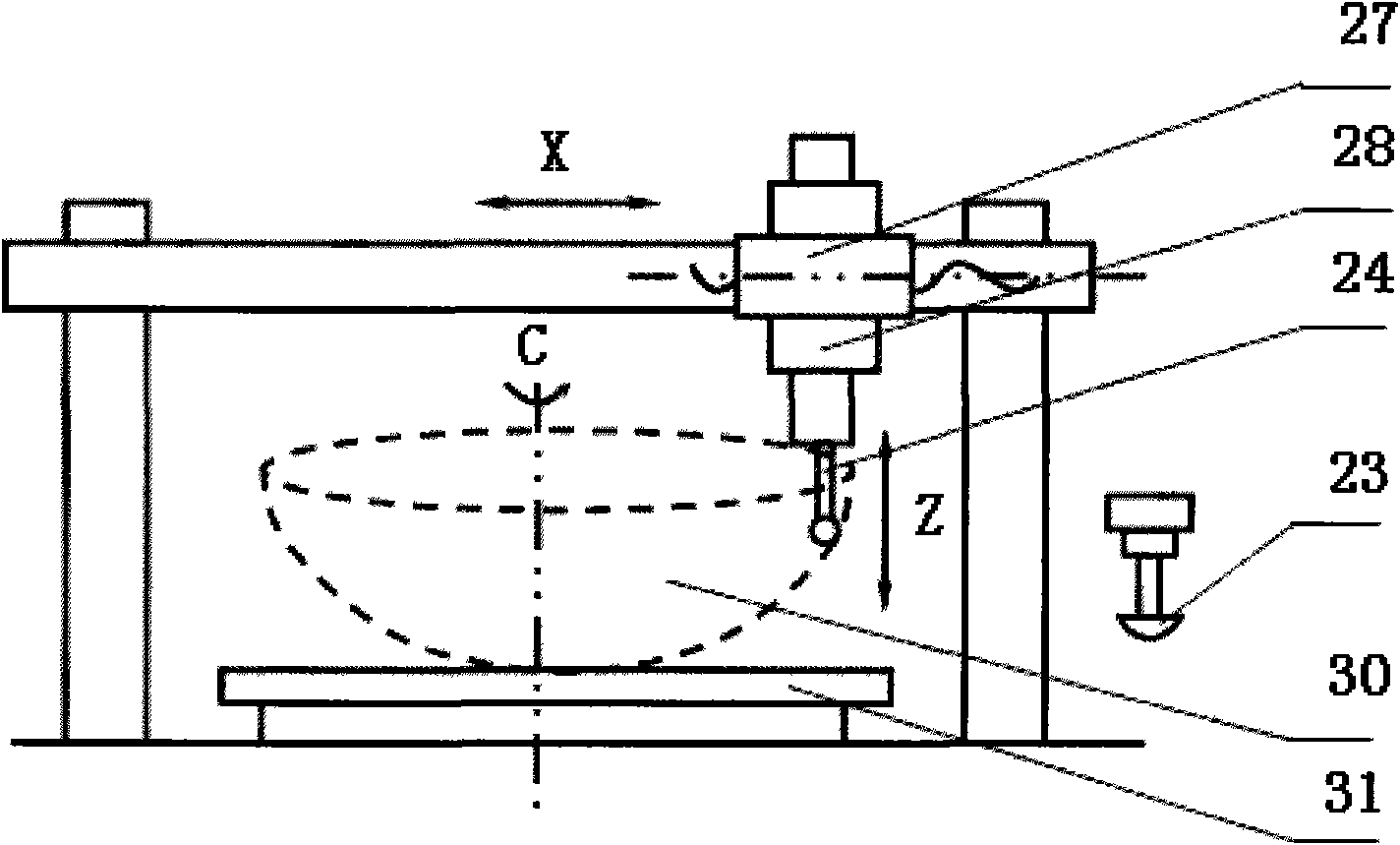

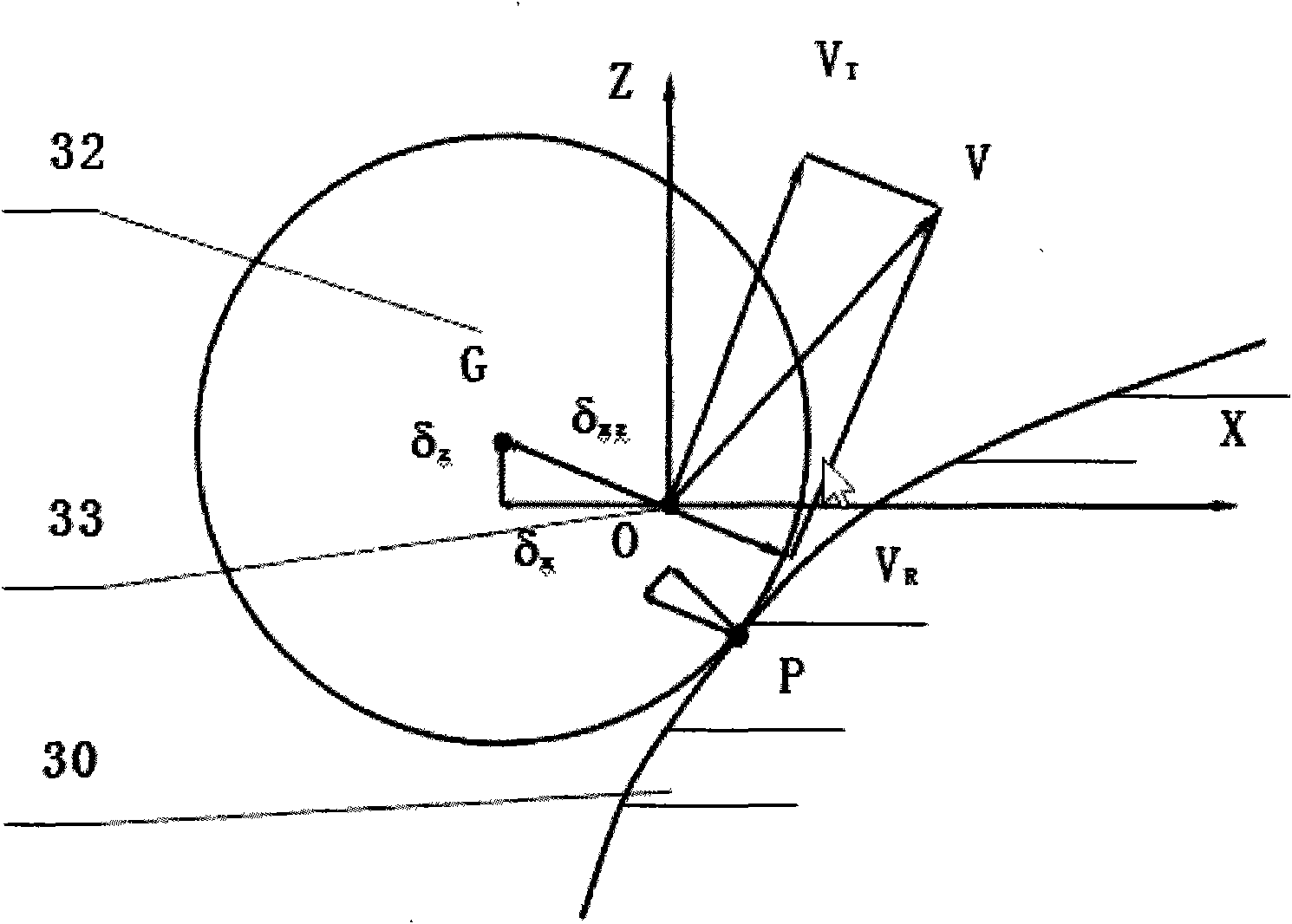

Pairing processing method of large-sized and irregular revolving molding surface member

InactiveCN101612713AImprove machining accuracyImprove processing efficiencyMeasurement devicesComputer controlThree dimensional simulationData acquisition

The invention discloses a pairing processing method of a large-sized and irregular revolving molding surface member. In the method, a three-dimensional simulation measuring head is utilized to carry out automatic tracing and measuring and data collection on a practical fitting curved surface of a covering, a data point set [p] of the centre of a sensing finger pommel of the three-dimensional simulation measuring head is obtained, mathematical treatment with isometry calculation is carried on the obtained data point set [p], a corresponding point set [p1] of the practical surface of the covering is obtained, location optimization is carried out on theoretical covering curved surface, and a digital pairing processing point set [Q] of the surface of a honeycomb sandwich is generated, compensation to the radius of a grinding wheel is carried out, a point set [M] of a movement locus of the centre of the grinding wheel is obtained, the three-axis linkage interpolation method taking C axis of a rotation axis as a benchmark is adopted, and the upper surface and the lower surface of the honeycomb sandwich are respectively ground and processed. The invention realizes integration of measurement, mathematical treatment and digital treatment of the large-sized and irregular revolving molding surface member and has high treatment precision and high treatment efficiency; in addition, the product percent of pass is 100 percent, and the production period is shortened to three days from ten days so as to meet the needs of production.

Owner:DALIAN JIAOTONG UNIVERSITY

Physical degumming method of ramie

InactiveCN1624213AReduce environmental pollutionReduce degumming costsMechanical treatmentStrong acidsEngineering

This invention relates to a method of degumming Boehmeria nivea. The process is: fresh Boehmeria nivea (or commercial original Boehmeria nivea) ->immersion in warm water-> mechanical hemp knocking and washing ->boiling off in hyperthermia and heavy pressure (or immersion in warm water) -> mechanical hemp knocking and washing -> refined dry hemp. This method, assuming the characteristics of environmental protection, high efficiency and high qualities, greatly reduces the degumming cost, avoids the pollution of strong acid and strong base in waste solution to the environment, for this process makes use of existing machinery of degumming. Instead of using such chemical materials as strong acid and strong base, the method is high-temp high-pressure cooking, immersion in warm water, mechanical beating and washing for removing extraneous cells of Boehmeria nivea liber.

Owner:HUNAN AGRICULTURAL UNIV

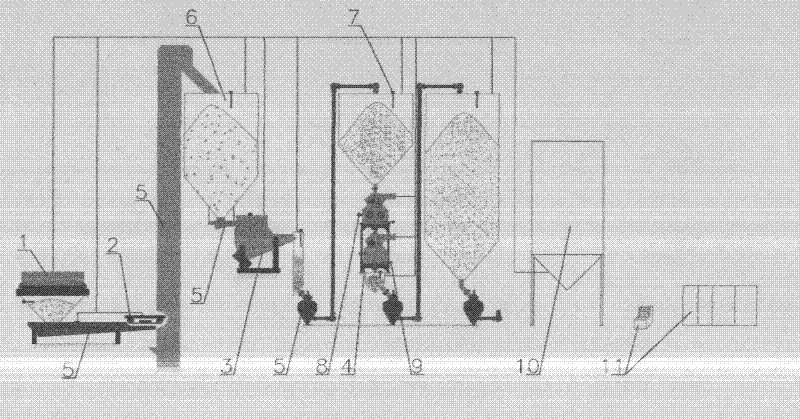

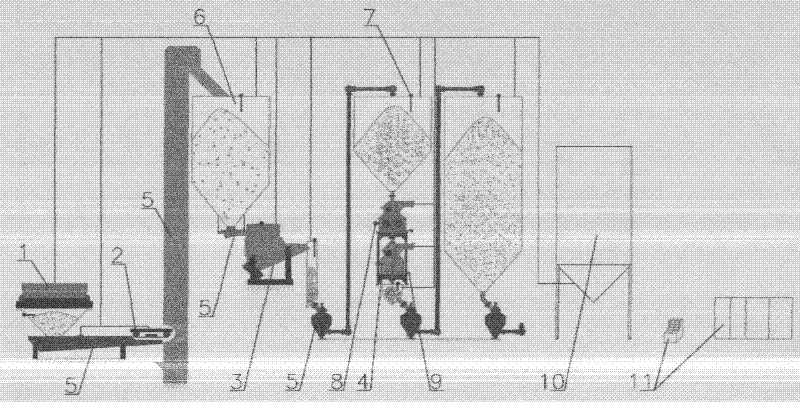

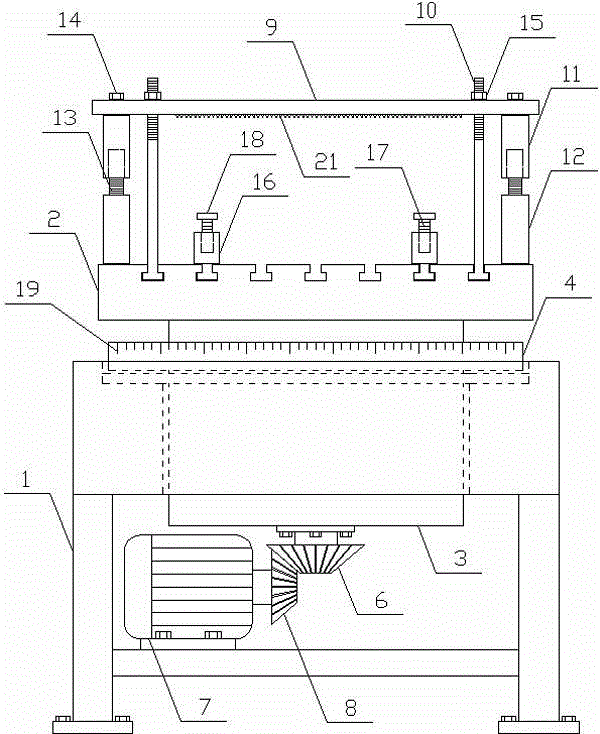

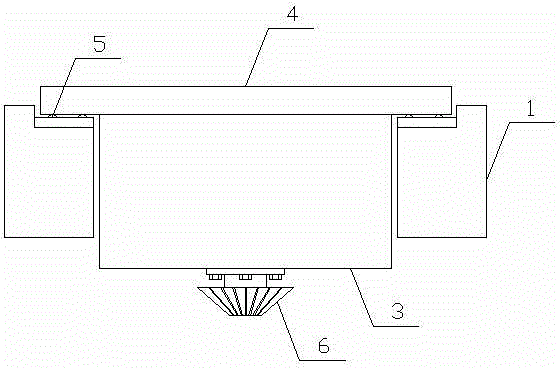

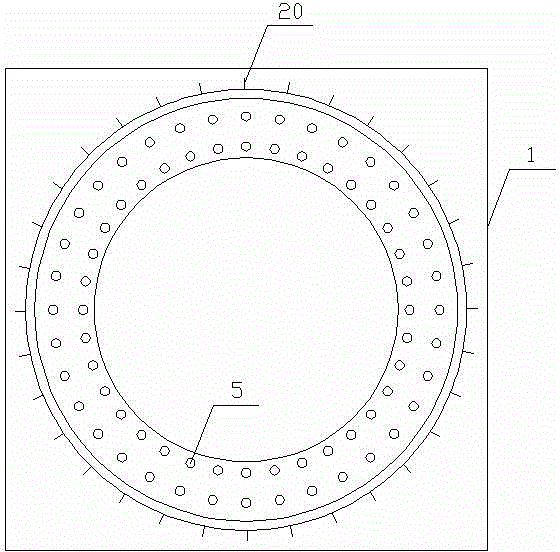

Digital resin sand regeneration system

InactiveCN102233405AMeet the needs of productionAutomatic production controlMould handling/dressing devicesEngineeringElectric control

A digital resin sand regeneration system comprises a vibrating knockout device, a magnetic separation device, a vibrating crushing device, an intermittent grinding regeneration unit, a conveying device, a sand storehouse, a dedusting device, a computer control system, etc. The main working principle is as follows: waste sand blocks are vibrated and crushed into smaller blocks and scattered sand by the knockout device; magnetic separation is performed to remove iron beans and flash; crushing is performed by the crushing device to obtain granular scattered sand; stripping, grading and temperature adjustment are performed by the intermittent grinding regeneration unit to remove micro powder included in the sand, and the sand temperature is adjusted to a temperature required by the process; and the sand is conveyed to the sand storehouse to keep in reserve. Through the additionally installed computer control system which comprises a material level sensor, a temperature sensor, a pressure sensor, and a corresponding electric control component, the whole production line can realize the target control of technological parameters and stock sand amounts; mainly-controlled technological parameters are: stripping rate (loss on ignition, LOI), micro powder content, sand temperature and sand amount; and technical guarantee is provided for the digital production management of the whole factory. Digital control of molding resin amount, hardening stripping time, and sand using amount is basic guarantee for solving energy saving and consumption reduction, improving productivity, and increasing yield.

Owner:于彦奇

Enveloping process for micro-capsule animal medicament

ActiveCN102319181AMeet the needs of productionReduce energy consumptionOrganic active ingredientsMicrocapsulesBiotechnologyFluidized bed drying

The invention relates to the field of processing of animal medicaments, in particular to an enveloping process for a micro-capsule animal medicament. The enveloping process for the micro-capsule animal medicament comprises the following steps of: weighing materials; preparing soft materials; granulating by extruding and rolling; drying with a fluidized bed; coating; polishing; drying with the fluidized bed; sieving; detecting a product and the like to prepare the micro-capsule animal medicament. Compared with a fluidized bed liquid atomizing enveloping process, the enveloping process related to be invention has the most outstanding advantages of high production efficiency, simple product enveloping process, difficulty in causing the phenomenon of sticking, reduction in the energy consumption of a unit product by over 60 percent, capability of meeting the practical requirements of the animal medicament on large production amount and low production cost and contribution to wide popularization and application of the micro-capsule animal medicament.

Owner:GUANGDONG WENS DAHUANONG BIOTECH +1

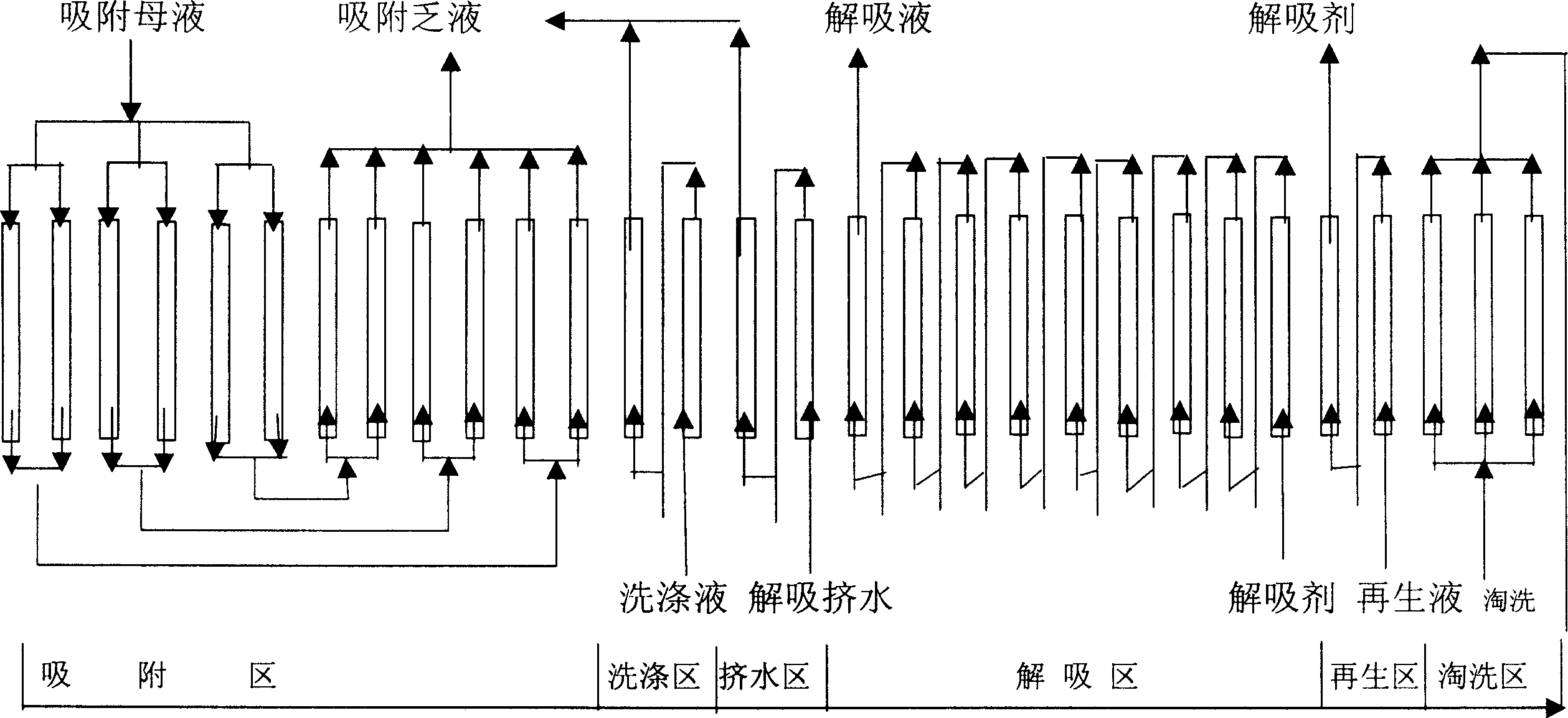

Method for extracting metallic gallium from aluminium oxide production procedure

ActiveCN1912153AMeet the requirements for extractionIncrease concentrationProcess efficiency improvementSeparation technologyAqueous sodium hydroxide

The invention relates to a method for extracting gallium from alumina production flow. It adopts ISEP ion separation technique and adsorption gallium chelating resin. Its technology conditions are as follows: back flow adsorbing that liquor in Bayer process is processed by two stage series connection to make gallium concentration difference be 50-60 mg / L; back flow washing by 0.5-1N sodium hydroxide solution for the resin; back flow desorbing by 2-3N sodium hydroxide and 0.6-1.0N sodium sulfide solution; back flow rebirthing by 0.5-1N sodium hydroxide solution for the resin. It has the advantages of short flow, simple operation, little resin abrasion, high automation etc.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

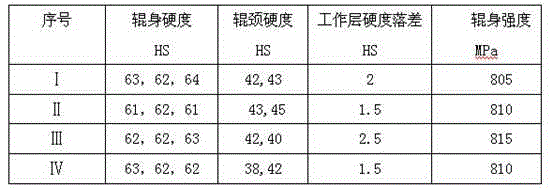

Heat treatment method for one-piece casting hot-rolled strip supporting roller

InactiveCN104561504AFine grainImprove wear resistanceFurnace typesHeat treatment furnacesTemperature treatmentMicrostructure

The invention discloses a heat treatment method for a one-piece casting hot-rolled strip supporting roller and belongs to the technical field of roller heat treatment methods. The heat treatment method is used for carrying out heat treatment on the one-piece casting hot-rolled strip supporting roller. According to the technical scheme, the heat treatment method comprises the following steps of entirely heating the roller to a certain temperature by virtue of a resistance furnace, then transferring the roller to a differential temperature furnace for further heating the surface layer of a roller body to a higher temperature, carrying out heat preservation for enough time, tapping, and carrying out spray quenching and tempering treatment so that the microstructure of the roller body is changed into bainite and the microstructures of a roller neck are sorbite and pearlite. By the differential temperature treatment method, the one-piece casting hot-rolled strip supporting roller exhibits excellent wear resistance and comprehensive mechanical properties, so that the wear resistance, thermal cracking resistance and accident resistance of the roller body are improved. By innovating the heat treatment method for the one-piece casting hot-rolled strip supporting roller, the problem that no heat treatment method is suitable for the one-piece casting hot-rolled strip supporting roller in a long term is solved, the quality of the roller is significantly improved, and user requirements in use and enterprise economy benefits are met.

Owner:TANGSHAN IRON & STEEL GROUP

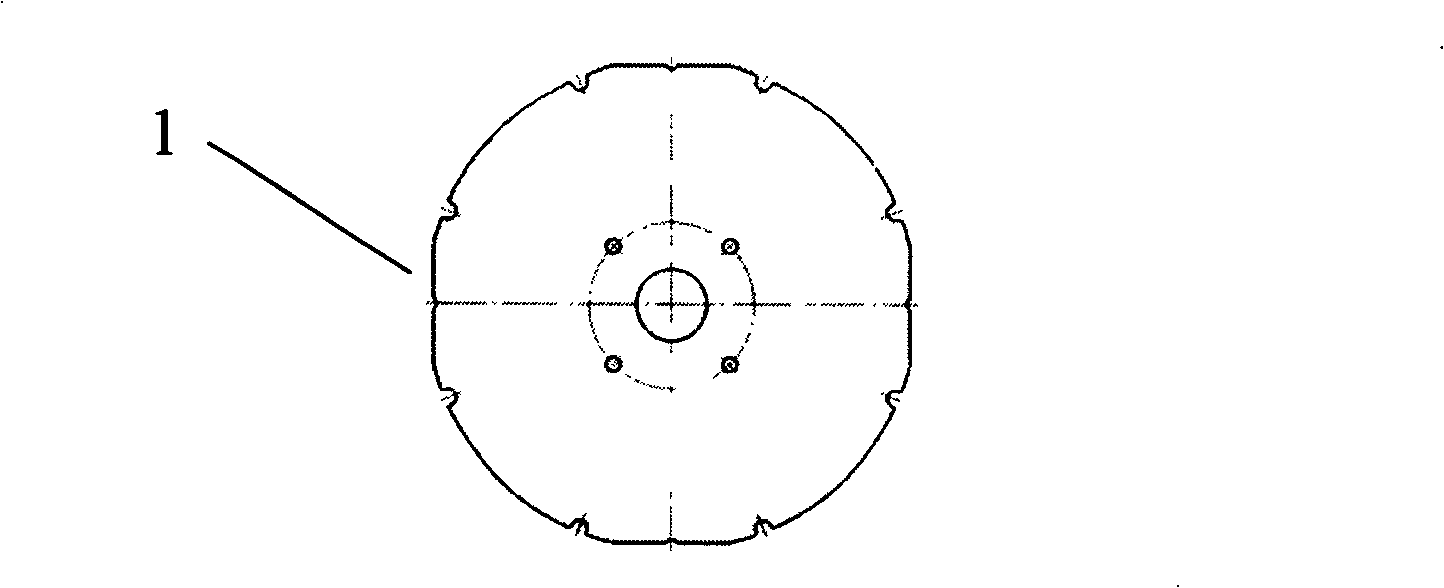

Roundness measuring instrument and measuring method thereof

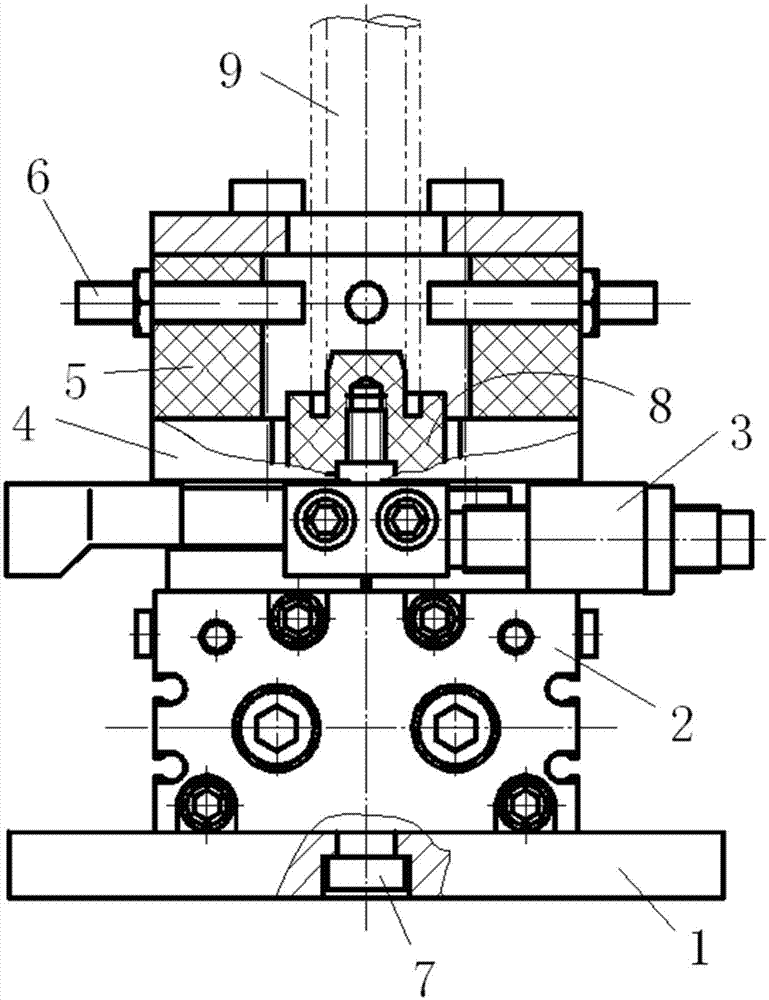

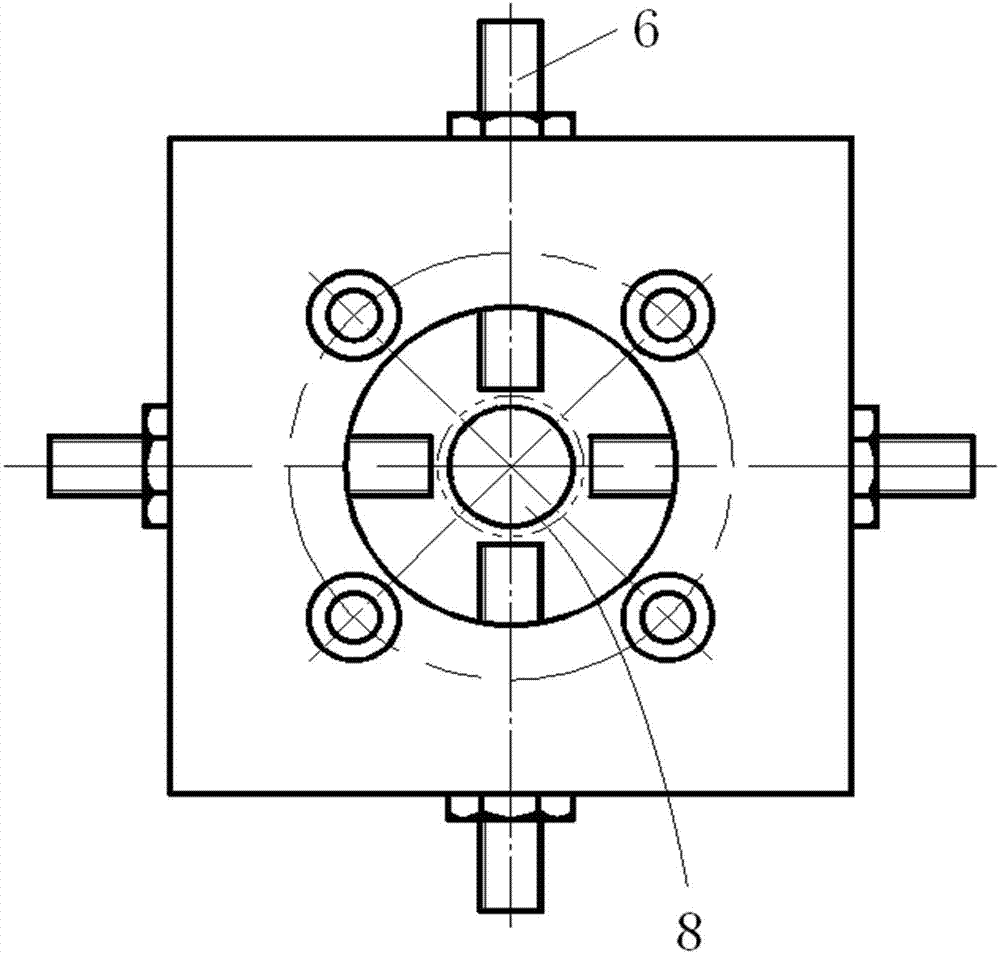

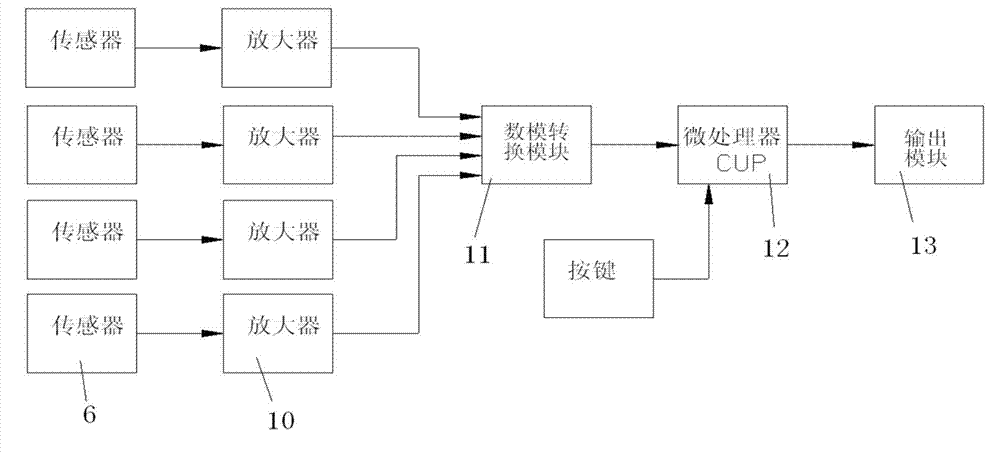

ActiveCN103542830AQuick measurementApplicable environment applicationMeasurement devicesMeasuring instrumentEngineering

The invention relates to the technical field of machining and detection and discloses a roundness measuring instrument comprising a base and a signal processing unit. A sensor support that is of an up-down-through hollow structure is arranged on a platform arranged on the base, and four displacement sensors which are in crossed arrangement are mounted on the sensor support. A mandrel is fixedly arranged on the base and penetrates the platform to extend into the sensor support. A mount is arranged at the top end of the mandrel and located right below the four displacement sensors. The invention further discloses a measuring method of the roundness measuring instrument. By means of four-point synchronous measurement, the measurement speed is increased greatly.

Owner:SHANGHAI SANDA AUTOMOBILE PARTS

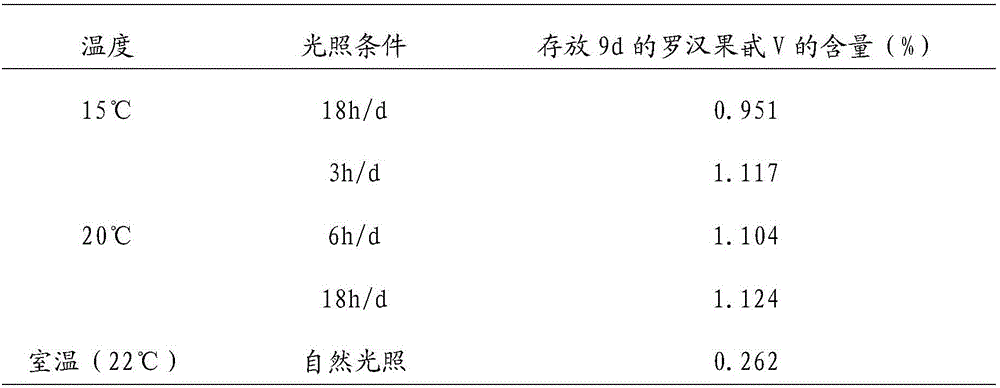

Method for promoting after-ripening of siraitia grosvenorii

The invention discloses a method for promoting after-ripening of siraitia grosvenorii and belongs to the technical field of siraitia grosvenorii processing. The method comprises the following steps: a step (1) of picking green siraitia grosvenorii at 5:00 am to 7:00 am at a green siraitia grosvenorii picking season, lightly taking and lightly placing the green siraitia grosvenorii into a container, timely transporting the green siraitia grosvenorii to a warehouse, taking the picked green siraitia grosvenorii out of the container, and flatly laying the green siraitia grosvenorii one by one on a shelf; a step (2) of adjusting the temperature in the warehouse to 15-25 DEG C, causing the illumination conditions to be 30-60 W scattering white light, and performing illumination for 3-18 h every day, causing the illumination intensity to be 800-1580 lx, and performing processing for 6-9 d in total. According to the method, the raw material can be effectively utilized; first the postprocessing time is shortened, and the production efficiency is improved; second the content of momordica glycosides of siraitia grosvenorii prior to the processing is improved, and the raw material with a high content of mogroside-V is provided for the extraction of the momordica glycosides; third the raw material moulding during the after-ripening is prevented, the quality of momordica glycoside V extract is guaranteed, and the method has important effects and significance for development of the siraitia grosvenorii industry.

Owner:GUILIN NATURAL INGREDIENTS CORP

Breeding method for new cabbage type rape line

InactiveCN106134982AEasy to viewReduce erucic acid contentPlant genotype modificationSocial benefitsAgricultural science

The invention discloses a breeding method for a new cabbage type rape line, and belongs to the field of a plant new variety breeding method. According to the breeding method disclosed by the invention, a cabbage type rape line is synthesized by interspecific hybridization of cabbages and Chinese cabbages, and the synthesized cabbage type rape line is subjected to quality genetic improvement of economical characters, erucic acid and glucosinolate so as to breed one new ornamental rape line with a bran-new petal color and a bran-new stalk color; the new cabbage type rape line meets both requirements for ornamental value and oil use, and brings greater economic benefits and social benefits for rape production and the tour and sightseeing industry.

Owner:INST OF IND CROPS HENAN ACAD OF AGRI SCI

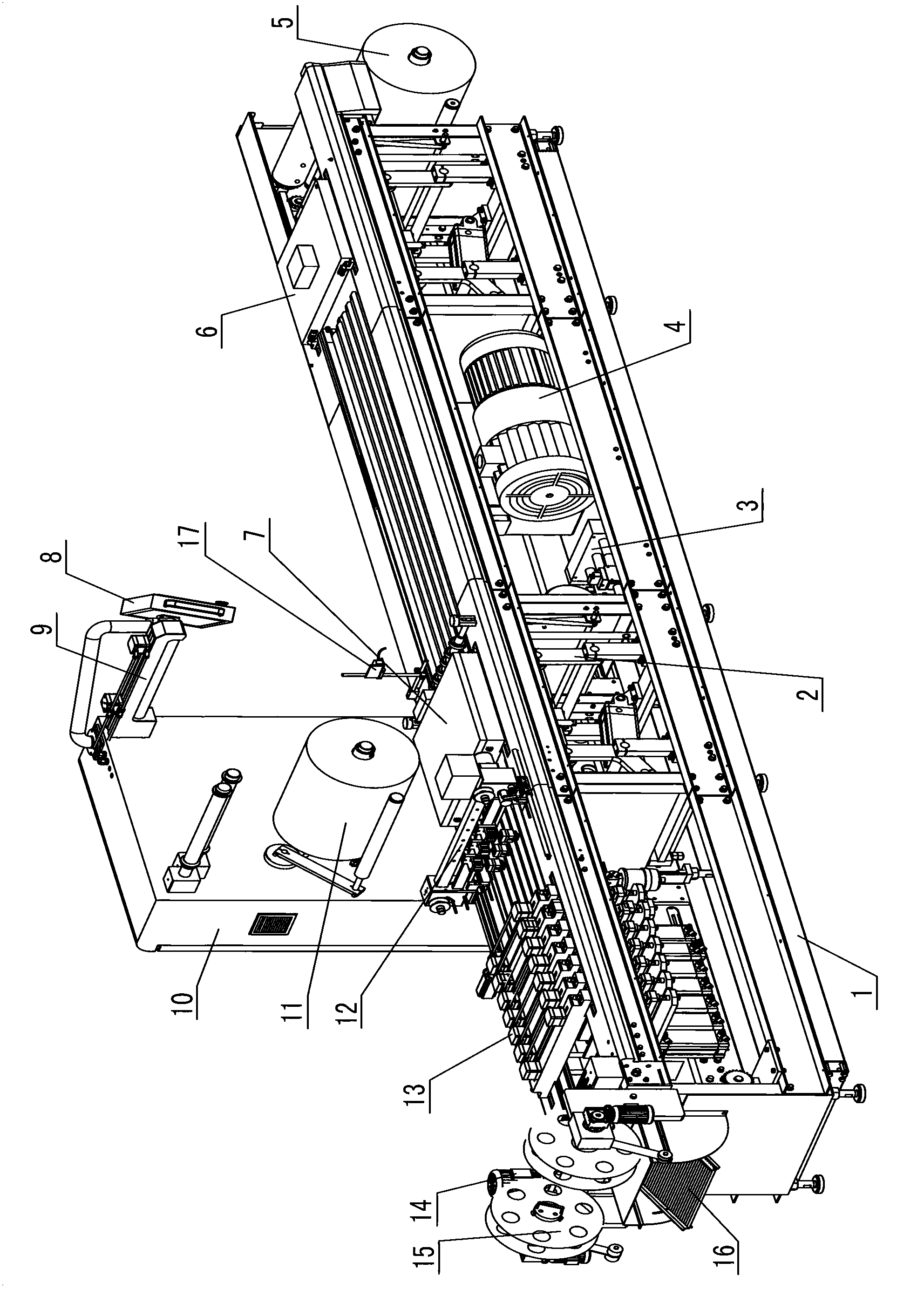

Automatic continuously drawing vacuum package machine

InactiveCN102837849AVersatileHigh degree of automationWrapper twisting/gatheringPackaging automatic controlEngineeringLoop control

The invention discloses an automatic continuously drawing vacuum package machine, comprising a frame as well as a package system, a control system and a capsule rolling device which are arranged on the frame; the package system comprises a drawing shaping device, a material filling device, a package device and a cutting device; the drawing shaping device is arranged at one end of the frame, connected with the control system and used for drawing and shaping a capsule film; the material filling device is connected with the control system, and arranged behind the drawing shaping device on the frame and used for filling the material to be packaged; the package device is connected with the vacuum pump at the lower part of a packaging machine along with the control system at the same time and provided with a vacuum chamber; the cutting device is connected with the control system and provided with cross and longitudinal cutters; the drawing shaping device comprises a heating device and a shaping device; the control system is a servo closed-loop control system. The automatic continuously drawing vacuum package machine is complete in function, high in degree of automation and low in maintenance cost of a device; the working efficiency and the safety are improved; the package of a plurality of different products and different package forms can be realized on the same one device, thereby meeting the requirement of the food production.

Owner:INNER MONGOLIA SANZHULIANG NATURAL OATS IND CORP

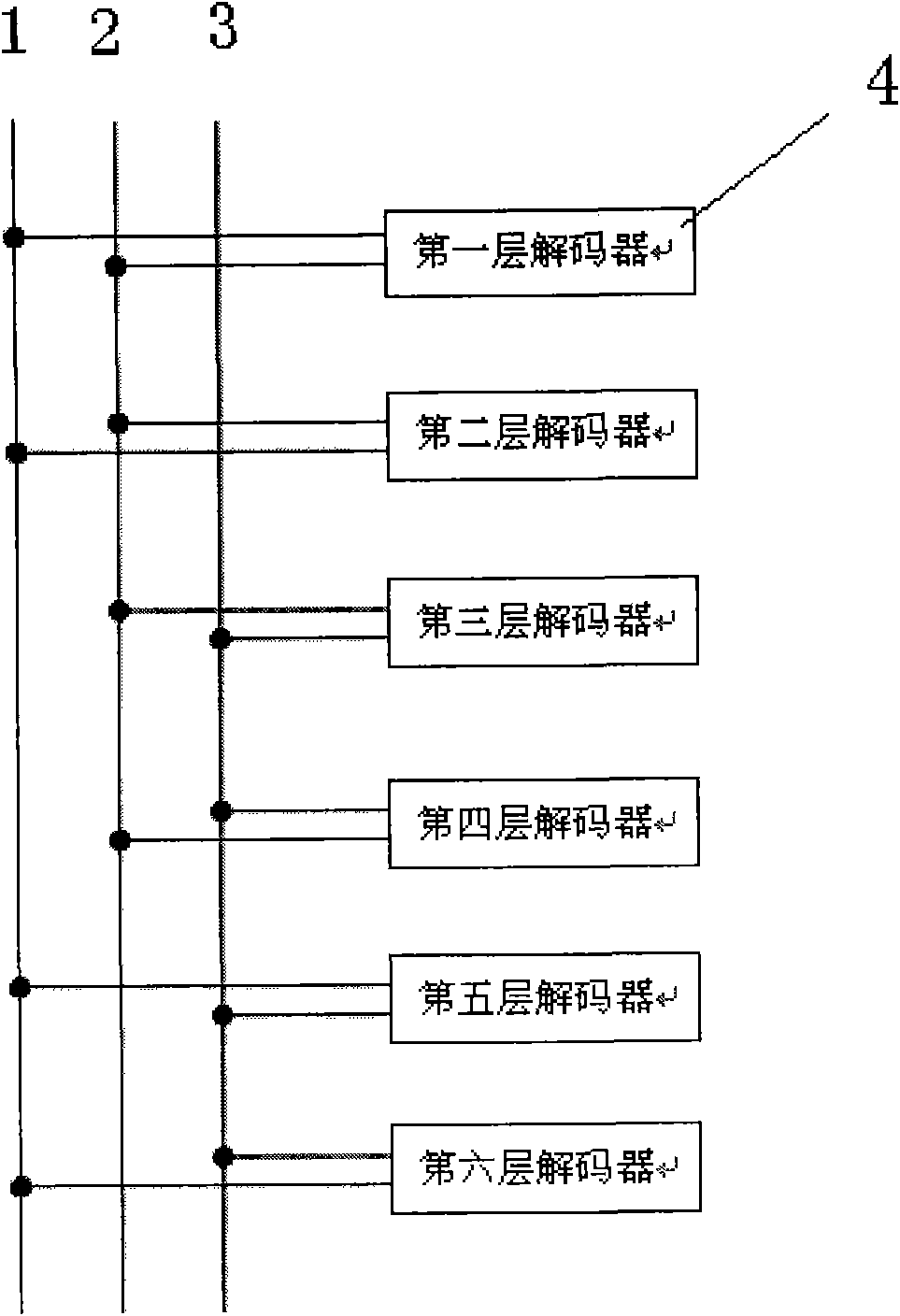

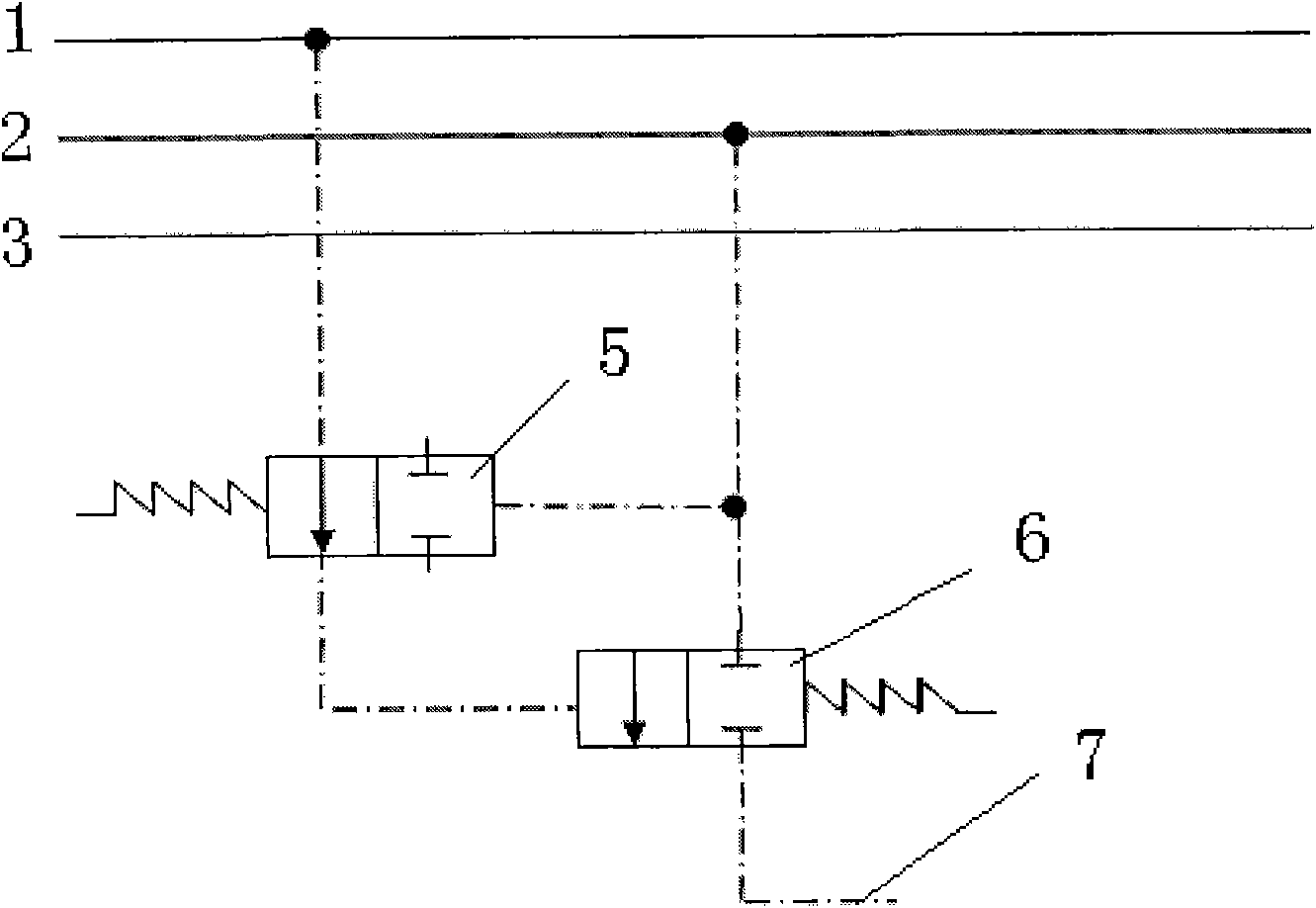

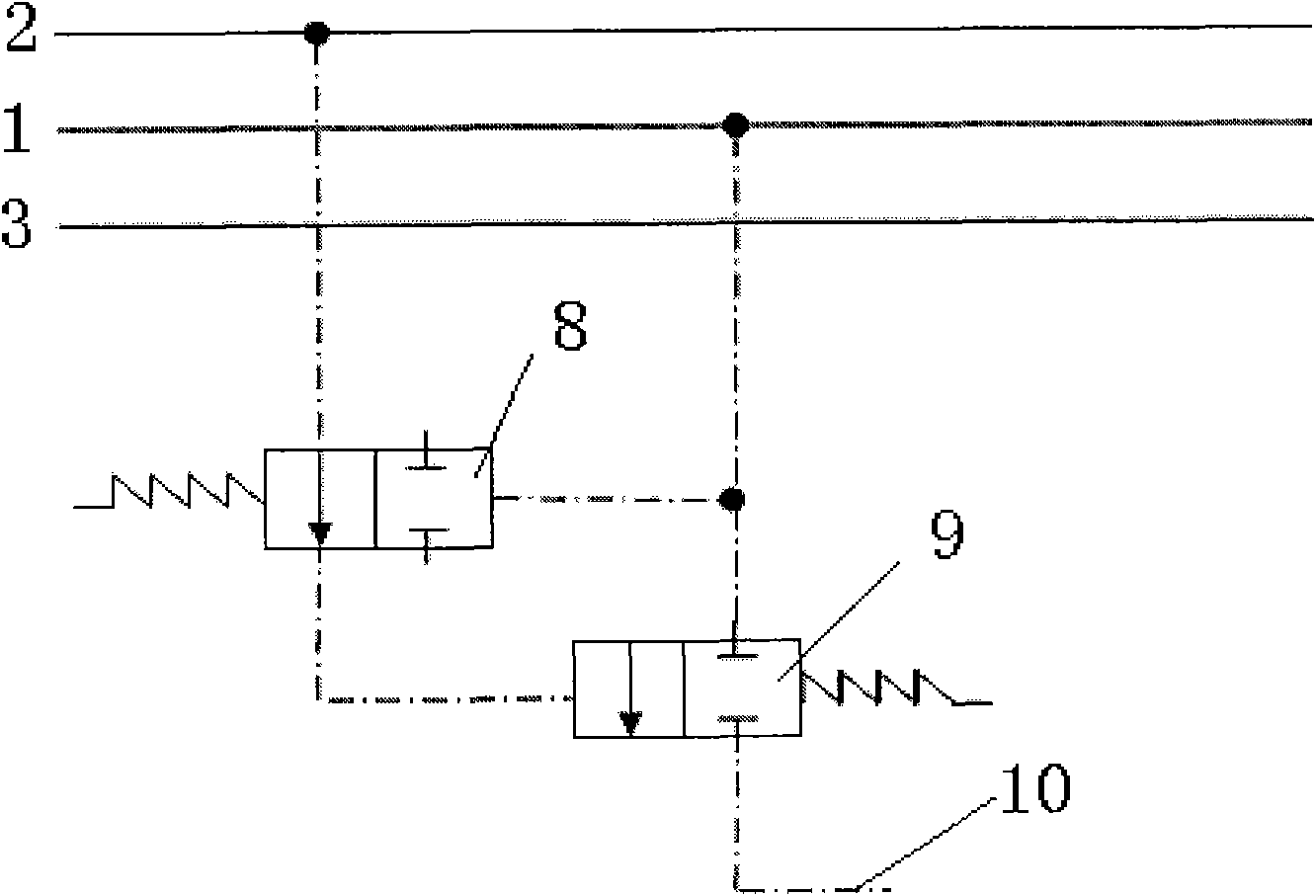

Underground position selecting hydraulic decoding method and device of intelligent well

ActiveCN102031953AMeet the needs of productionImprove standardizationFluid removalWell/borehole valve arrangementsDecoding methodsLine tubing

The invention relates to an underground position selecting hydraulic decoding method and device of an intelligent well. Pn2=n*(n-1) target layers are controlled by using n hydraulic control pipelines, each target layer is provided with a decoder connected with two hydraulic control pipelines, the two hydraulic control pipelines are respectively used for controlling two target layers through the change of pressure-supplying sequences of the decoder; the decoder comprises a normally open type two-position two-way valve and a normally closed type two-position two-way valve which are connected between the two hydraulic pipelines, the normally open type two-position two-way valve is communicated with the hydraulic control pipeline firstly supplying pressure, the normally closed type two-position two-way valve is communicated with the hydraulic control pipeline supplying the pressure later, the oil outlet end of the normally open type two-position two-way valve is connected with a control oil cavity of the normally closed type two-position two-way valve, the control oil cavity of the normally closed type two-position two-way valve is connected with the hydraulic control pipeline supplying the pressure later, and the oil outlet end of the normally closed type two-position two-way valve is communicated with an underground target layer flow control valve. The invention can realize the purpose that a plurality of underground production layers are selected and controlled by using fewer control pipelines.

Owner:CHINA NAT OFFSHORE OIL CORP +1

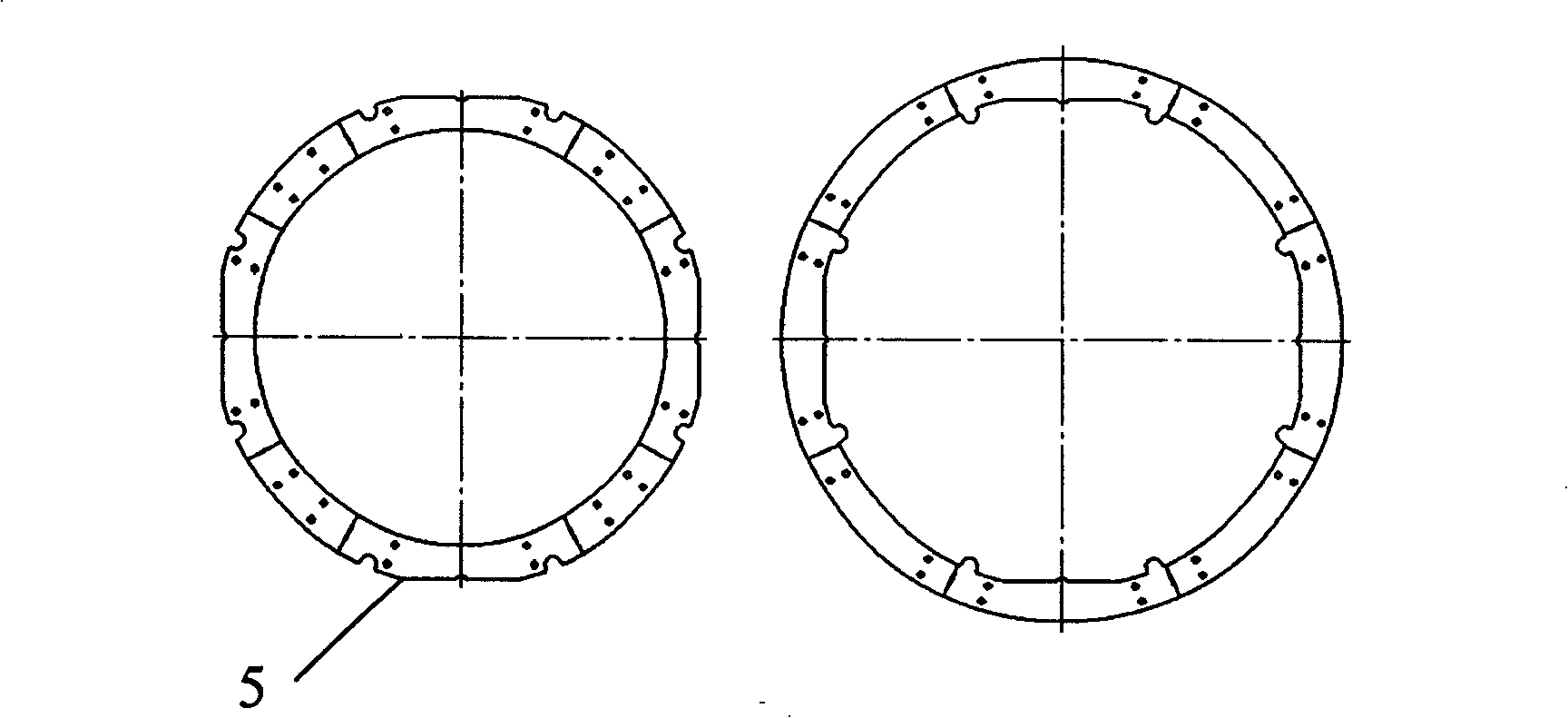

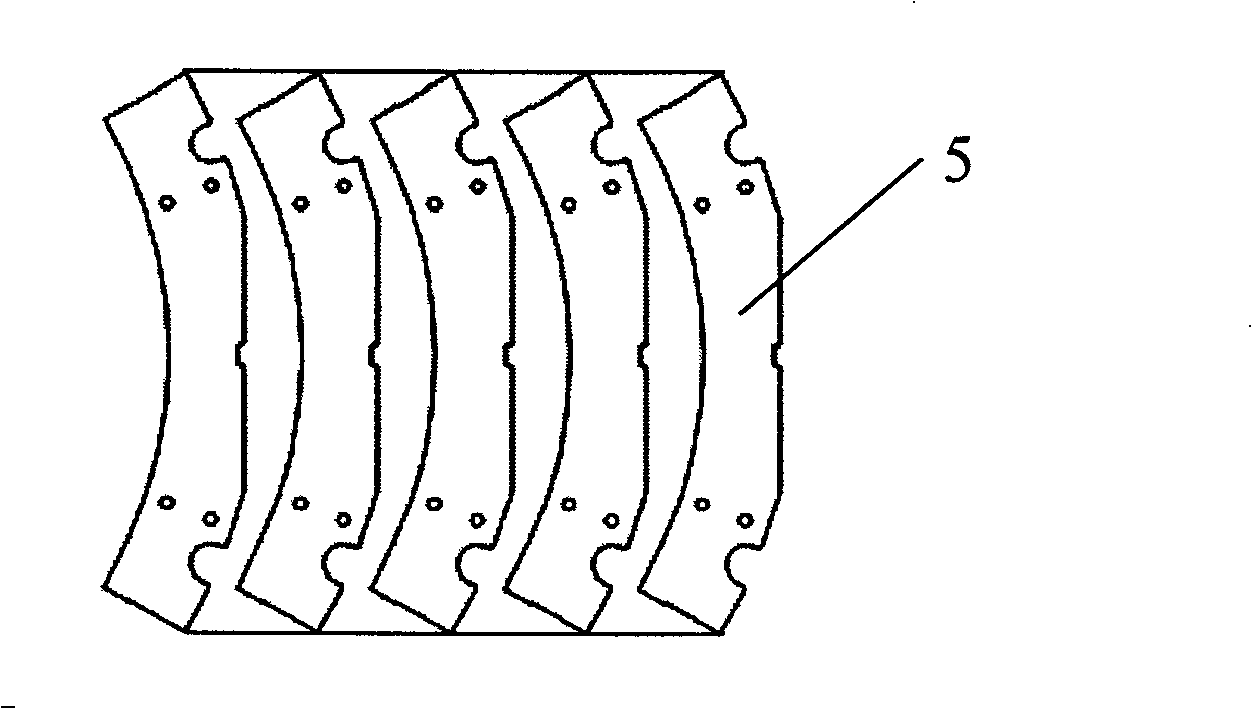

Silicon steel sheet punching die blade blocks and processing technique

The invention discloses a stamping die edge block for silicon steel sheets and a processing technique thereof. The processing technique of the edge block comprises planning-milling and linear cutting procedures. In addition, in the whole process flow, the common dimensions of the edge block are firstly processed and then the critical dimensions of the edge block are processed. The stamping die edge block for silicon steel sheets has a wider main body in replacement of the long and narrow body of the prior edge block. In addition, the bland of the die edge block is proportioned in singe piece, thus reducing the release of the total stress and deformation correspondingly. The stamping die edge block for silicon steel sheets and the processing technique thereof can better solve the problem of stress release and ensure the machining precision of the die edge block, thereby ensuring that high quality silicon steel sheets are produced through the die edge block.

Owner:上海电气集团上海电机厂有限公司

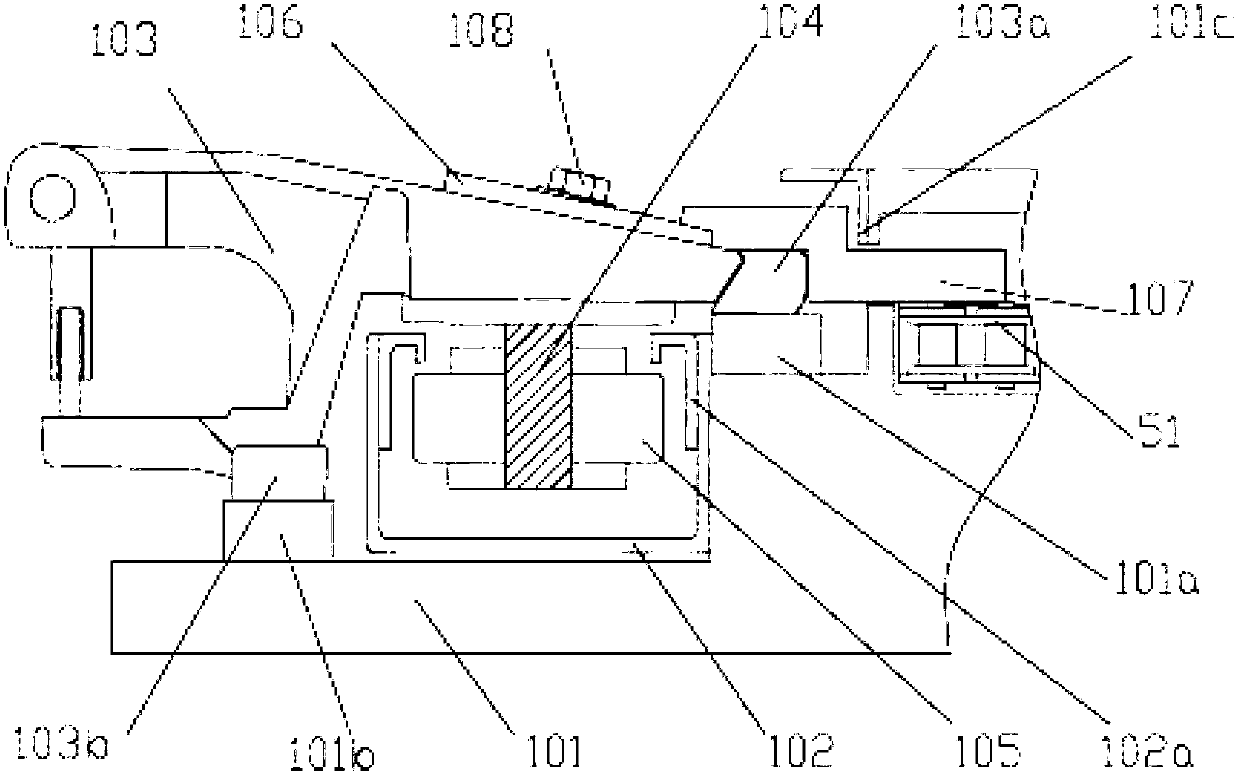

Multifunctional reinforcing steel bar automatic hoop-bending machine bending from two ends of reinforcing steel bar

The invention discloses a multifunctional reinforcing steel bar automatic hoop-bending machine bending from the two ends of a reinforcing steel bar. The multifunctional reinforcing steel bar automatic hoop-bending machine comprises a machine frame, wherein a traction mechanism, a straightening mechanism, a shearing mechanism and a bidirectional bending mechanism are axially arranged on the machine frame along the upstream of the reinforcing steel bar sequentially; a multifunctional mechanism is also arranged on the machine frame on the upstream of the bidirectional bending mechanism; the multifunctional mechanism comprises a compression moving mechanism, a material-pushing mechanism and an overall retraction mechanism; the material-pushing mechanism is used for pushing a hoop bar which is formed in a bending way; and the overall retraction mechanism is used for pulling the compression moving mechanism and the material-pushing mechanism into the inner side of a machine shell panel or pushing the compression moving mechanism and the material-pushing mechanism to a working position. The multifunctional reinforcing steel bar automatic hoop-bending machine has the beneficial effects that the other end of the reinforcing steel bar which is sheared by the shearing mechanism can be bent, long hoop bar products with hooks at the two ends can be bent rapidly and at one time, the requirement of production is met, and the production efficiency is high. The multifunctional reinforcing steel bar automatic hoop-bending machine is simple in structure, low in cost, high in adaptability, wide in production range, and has complete functions.

Owner:TJK MACHINERY TIANJIN

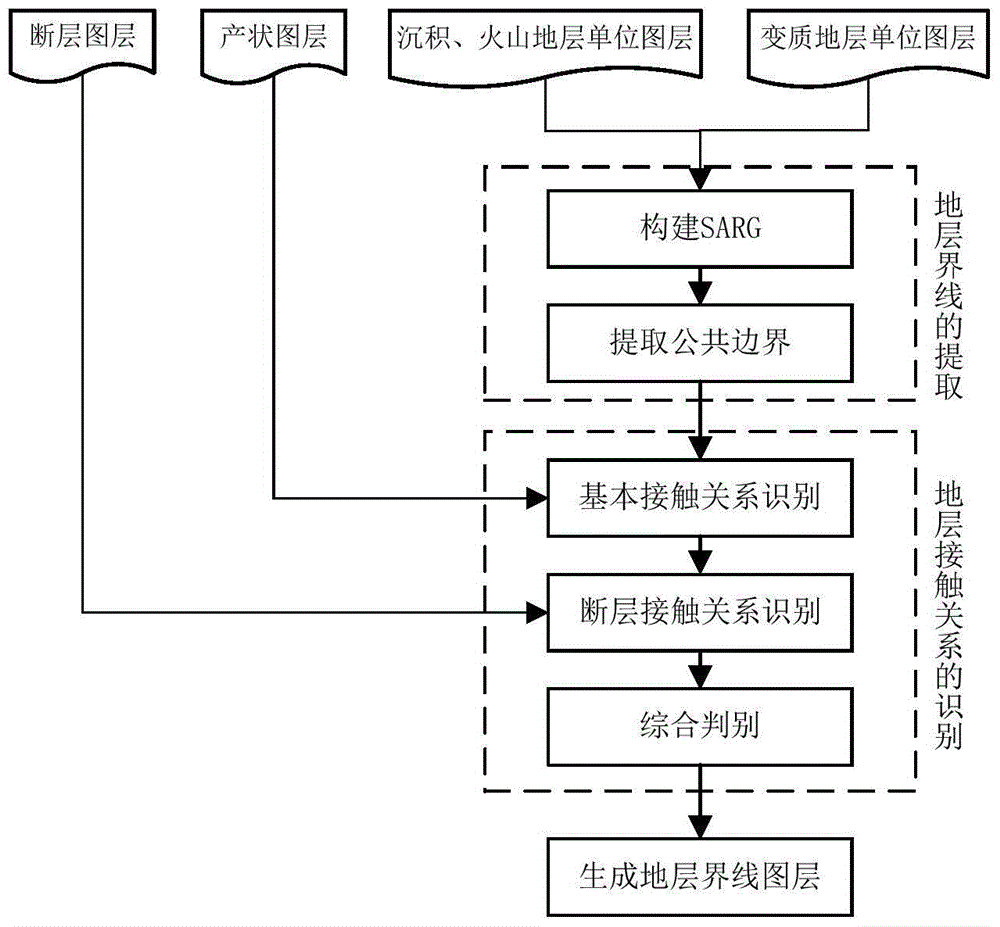

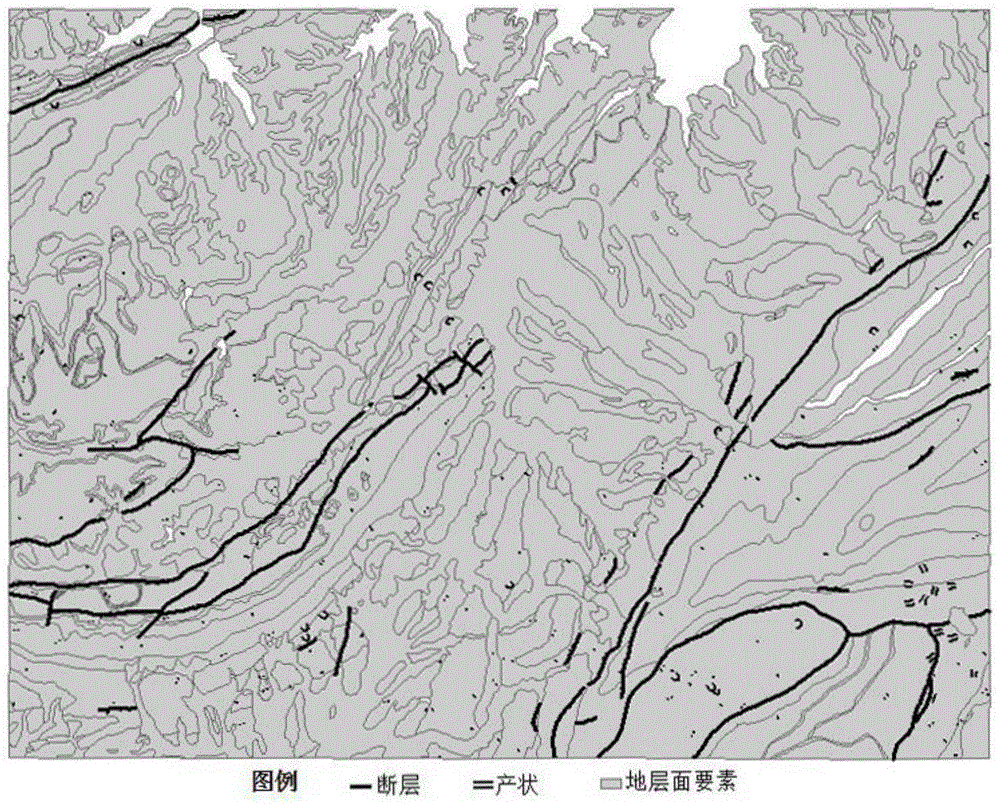

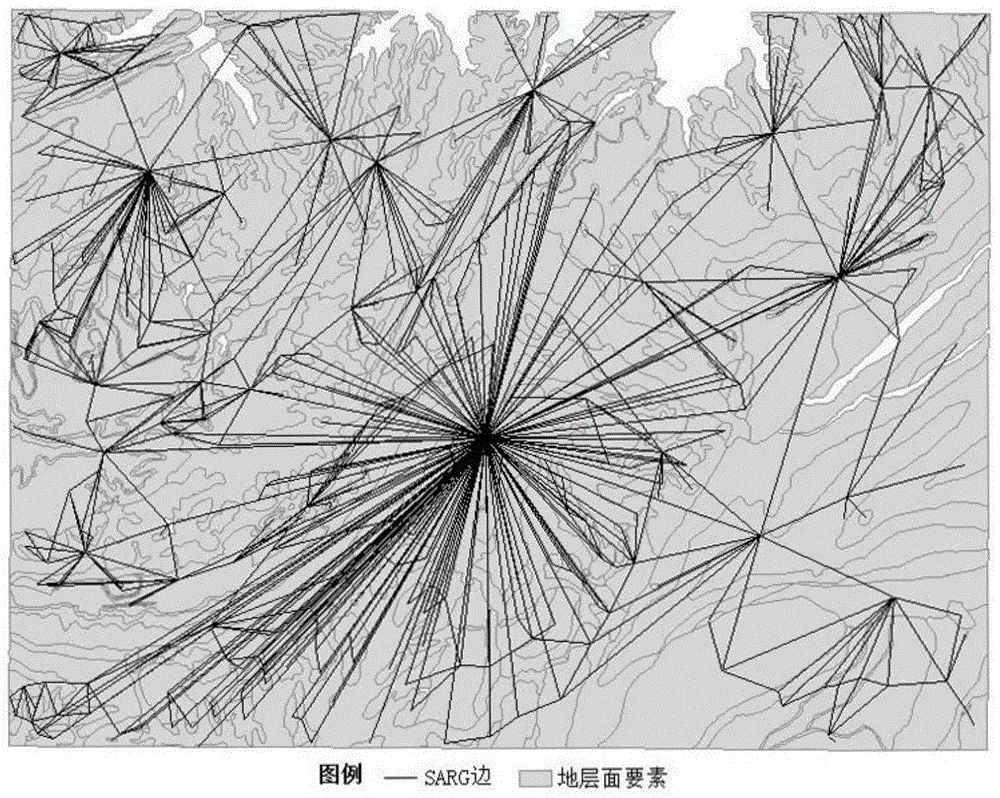

Automatic generation method of stratum boundary map layer

InactiveCN105701848AMeet the needs of productionAvoid human errorTexturing/coloringAdjacency relationComputer science

The invention discloses an automatic generation method of a stratum boundary map layer. The method comprises the following steps of (1) based on deposition, a volcanic stratum boundary map layer and a metamorphic stratum unit map layer, searching all the adjacent stratums in the map layers and constructing a stratum adjacency relation map; (2) based on the stratum adjacency relation map, extracting a common boundary of the adjacent stratums and generating a stratum boundary; (3) based on a faultage map layer, identifying a faultage contact relation; (4) based on a occurrence map layer, identifying a basic contact relation and completing automatic generation of the stratum boundary map layer. Compared to a manually-made method, by using the method in the invention, the generated stratum boundary map layer is high-efficient and fast; through reducing a manual participation degree, introducing of a manual error is avoided as far as possible; and a need of geologic map space database stratum boundary map layer making is satisfied.

Owner:NANJING NORMAL UNIVERSITY

Novel stentering setting machine

InactiveCN102733133AEasy to adjustEnsure the quality of stenter settingStretchingGraphiteMechanical engineering

The invention provides a novel stentering setting machine comprising a guide device, a drawing mechanism, an operation platform and a cropping device, wherein the cropping device is arranged behind the drawing mechanism and the operation platform is placed between the guide device and the drawing mechanism; the drawing mechanism comprises a feeding rail, an oven and a heat exchange device; the feeding rail passes through the oven and the heat exchange device is arranged above the oven; a waste gas outlet pipe of the oven is communicated with a waste gas inlet pipe of the heat exchange device; a hot air outlet pipe of the heat exchange device is communicated with a hot air inlet pipe of the oven; a guide rail adjusting device is additionally arranged between two guide rails, so that the distance between a left guide rail and a right guide rail can be accurately adjusted and each guide rail is respectively adjustable; the novel stentering setting machine is suitable for machining a plurality of types of cloth; meanwhile, cloth tongs slide on graphite and do not generate oil stains; the two connected cloth tongs can be finely adjusted to ensure the stentering setting quality; and an adjustable range of a wrap angle of spreading rolls and a textile is large and the two spreading rolls can be adjusted, so that the spreading effect is good.

Owner:ZHEJIANG RILI INDAL

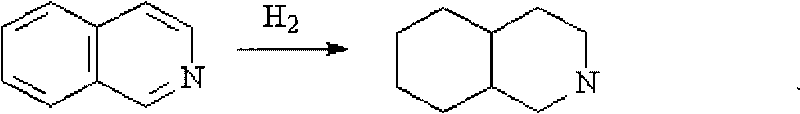

Purification method of isoquinoline

ActiveCN101747269AMeet the needs of productionSimple processOrganic chemistryPurification methodsIsoquinoline

The invention provides a new purification method of isoquinoline, and the purified isoquinoline has high purity and low impurity and can meet the requirement of various mechanical manufacture, in order to reach the goal, the technical scheme of the invention comprises: 1) performing acid-cleaning and alkalic-cleaning to wash oil (one distillate of coal tar) to obtain rough quinoline distillate and then performing rectification to obtain distillate containing 85 to 90 percent of isoquinoline, 2) taking the distillate containing 85 to 90 percent of isoquinoline as starting material, after crystallizing by cooling and melting by heating up, cutting the distillate into a plurality of distillates when heating up, performing N sections of the repeated operation of cooling and melting by heating up on the end distillate in the plurality of distillates to obtain isoquinoline with the purity of larger than or equal to 99 percent. The invention has the benefits that the technology is relatively simple, the cost is low, the purity of isoquinoline of the obtained product is larger than or equal to 99 percent, the impurity content is low, the method can meet the requirement of mechanical manufacture, and effectively reduces the production cost.

Owner:上海鼎素精细化工有限公司

Artificial progagation method for Anastatus spp.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

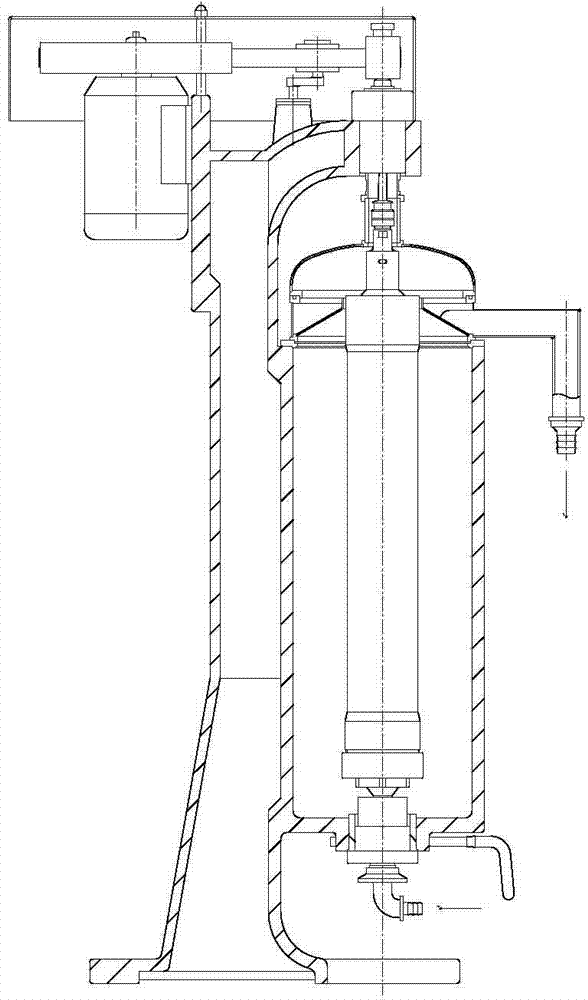

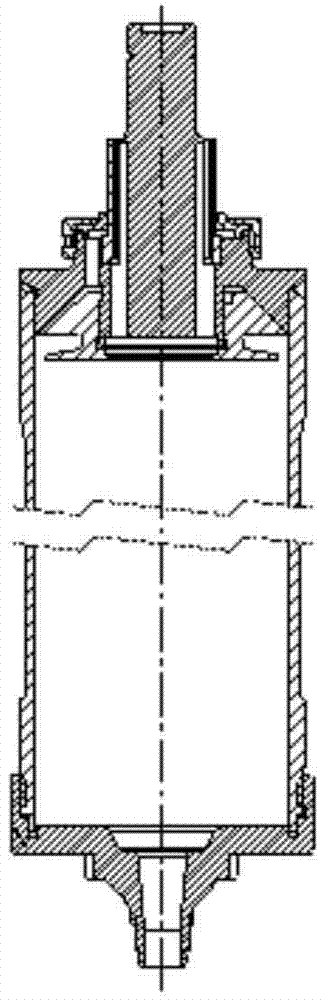

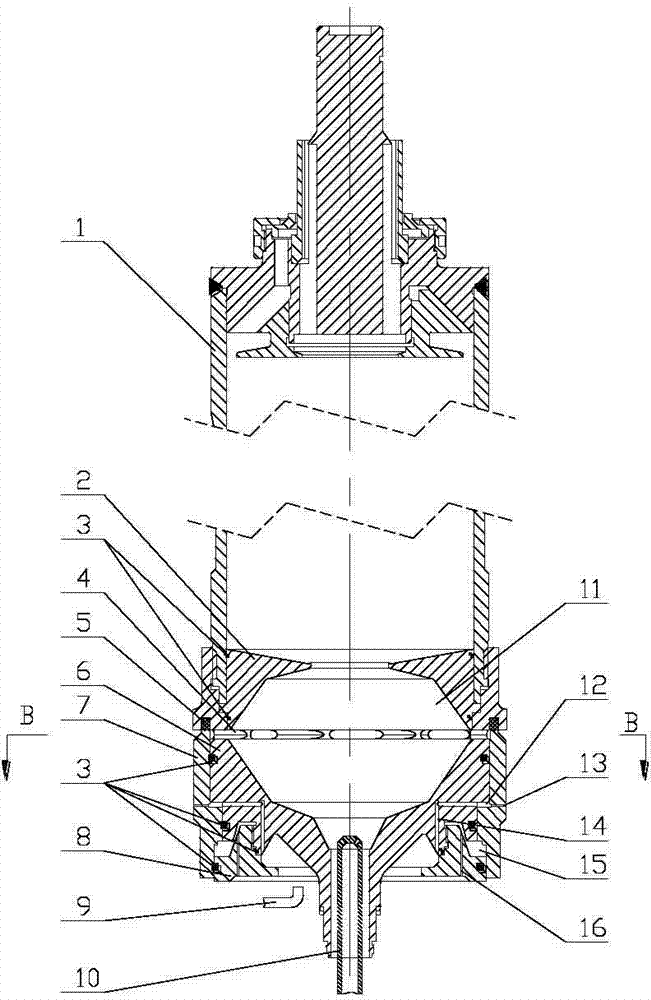

Tubular centrifuge drum and control method

The invention specifically discloses a tubular centrifuge drum and a control method. The tubular centrifuge drum comprises a drum barrel and a bottom shaft cover, wherein a liquid outlet is formed in the upper part of the drum barrel; a blocking disc which is matched with the bottom of the drum barrel is arranged on the bottom of the drum barrel; an opening is formed in the bottom of the blocking disc; the bottom shaft cover is arranged below the blocking disc; a slag discharging hole is formed between the blocking disc and the bottom shaft cover; a ring valve capable of vertically moving is arranged on the outer ring of the bottom shaft cover; a liquid receiving concave ring is arranged on the bottom end face of the bottom shaft cover; a hydraulic oil cavity is formed between the liquid receiving concave ring and the ring valve; an annular space is formed after the ring valve and the bottom shaft cover are mounted, and is used as an operating water cavity; a drain hole is formed in the ring valve; a feeding nozzle is inserted in the bottom of the bottom shaft cover along the axis direction. The working principle of a tubular centrifuge is changed from the modes of continuous separation, halt and manual slag discharging to the modes of continuous separation and automatic slag discharging, halt is not needed during slag discharging, the working rotating speed is not reduced, the feeding does not stop, and the working efficiency is greatly improved.

Owner:QINGDAO NUOKAIDA MACHINERY MFG

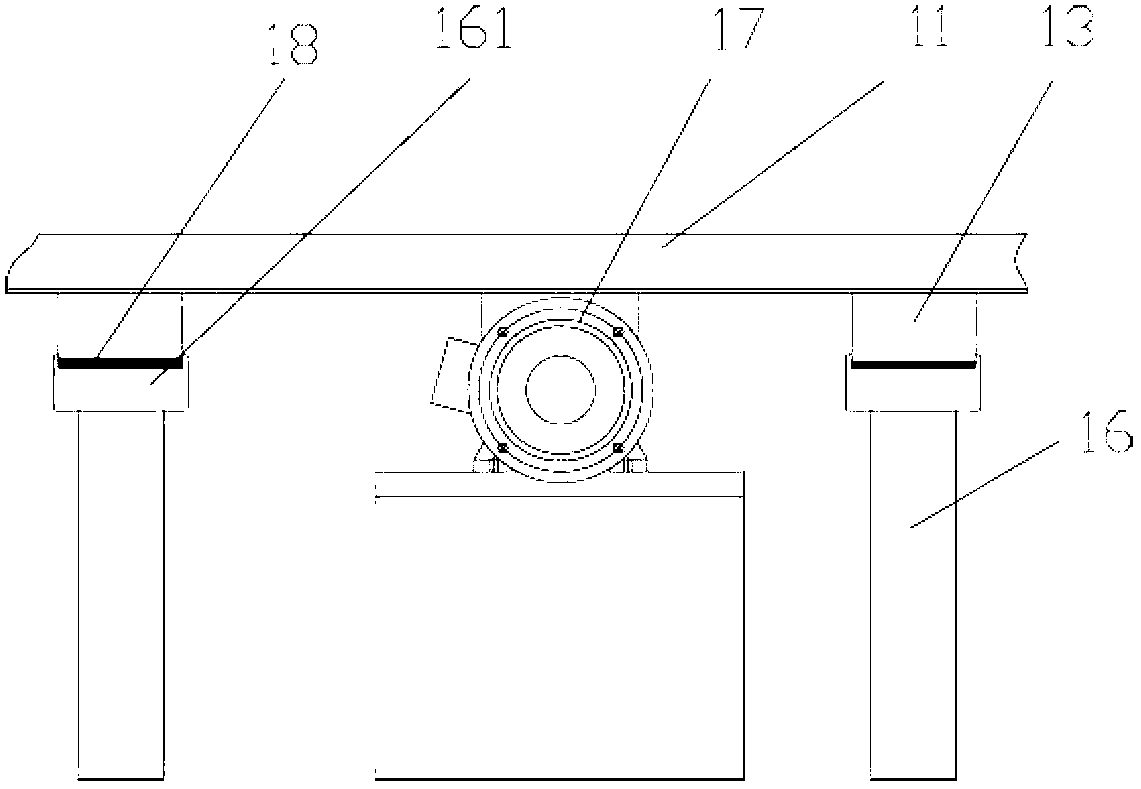

Workpiece fixing and rotating device

InactiveCN104440221AEffective rotationFixed and accuratePositioning apparatusMetal working apparatusGear wheelDrive motor

The invention discloses a workpiece fixing and rotating device and belongs to the field of machining devices. The workpiece fixing and rotating device comprises a fixed base and a machining platform, wherein the machining platform is horizontally arranged on the fixed base, a rotary shaft is vertically fixed below the machining platform, a bearing plate is horizontally arranged on the outer side of the rotary shaft, multiple balls are evenly arranged between the bearing plate and the fixed base, a main bevel gear is vertically arranged at the output end of a driving motor, an auxiliary bevel gear is meshed with the main bevel gear, multiple through T-shaped grooves are horizontally and evenly formed in the upper side of the machining platform, a compressing mechanism and a lifting mechanism are arranged on the machining platform, the pressing mechanism comprises a pressing plate, a pressing lead screw, a lifting sleeve and a fixing circular truncated cone, and the lifting mechanism comprises a lifting base, a lifting lead screw and a lifting plate. The workpiece fixing and rotating device is simple in structure and capable of rapidly and efficiently fixing a workpiece, accurately rotating the workpiece according to machining requirements and meeting production requirements.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com