Silicon steel sheet punching die blade blocks and processing technique

A stamping die and processing technology, applied in the field of silicon steel sheet stamping die block and its processing technology, can solve the problems of easy release of internal stress, irregular stress release, difficult processing technology, etc., to achieve less deformation and reduce total Effects of stress relief and deformation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

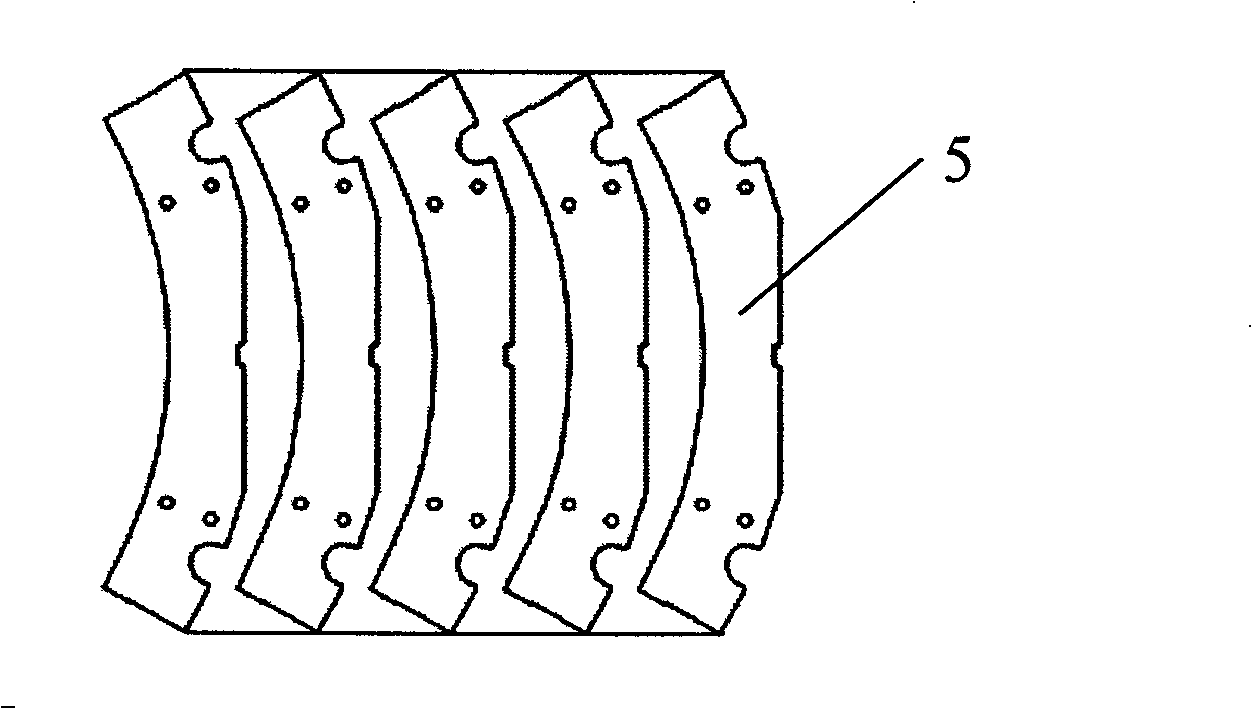

[0032] The present invention provides a kind of processing technology of silicon steel sheet stamping die blade block, below with the processing technology of silicon steel sheet stamping die punch blade block 6 to illustrate, refer to Figure 4 with Image 6 , including the following steps:

[0033] a. Use a planer and milling machine to process six surfaces 6a, 6b, 6c, 6d, 6e, and 6f, and finish the four surfaces 6b, 6d, 6e, and 6f as positioning surfaces.

[0034] b. Using the four surfaces 6b, 6d, 6e, and 6f as positioning surfaces, the blade block 6 is positioned on a surface grinder, and the surface grinder processes the upper and lower planes 6g1 and 6g2 of the blade block 6;

[0035] c. Use the corresponding planes processed in steps a and b as the positioning surface, position the blade block 6 on the clamp bed, and the pin holes 6h1, 6h2, 6h3, and 6h4 on the clamp bed process the wire cutting and threading of the blade block 6 The wire cutting threading hole of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com