Patents

Literature

233results about "Mechanical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS20130017394A1High consistency refiningIncrease surface areaMaterial nanotechnologyFinely-divided cellulose conservationMicrometerPaperboard

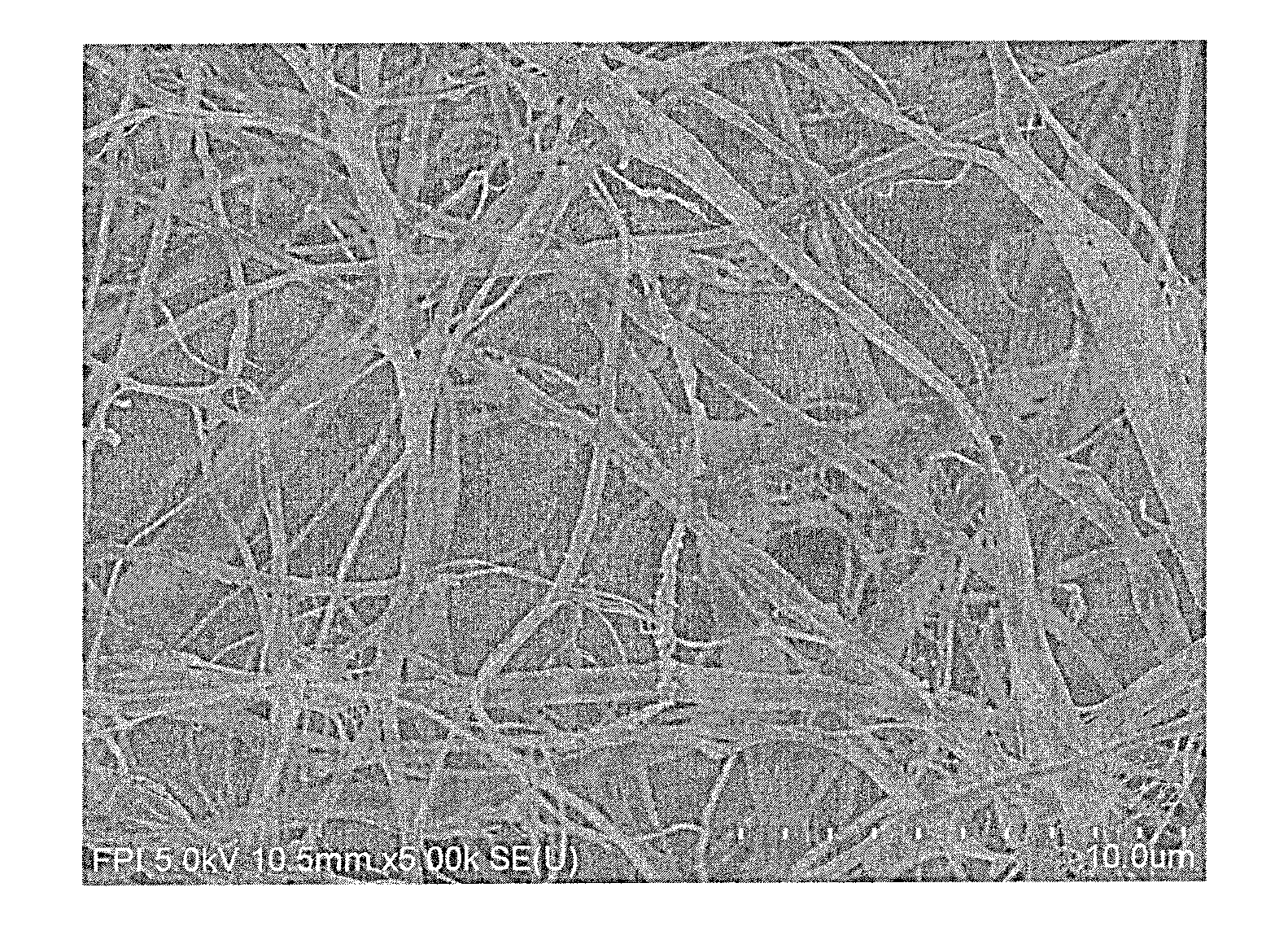

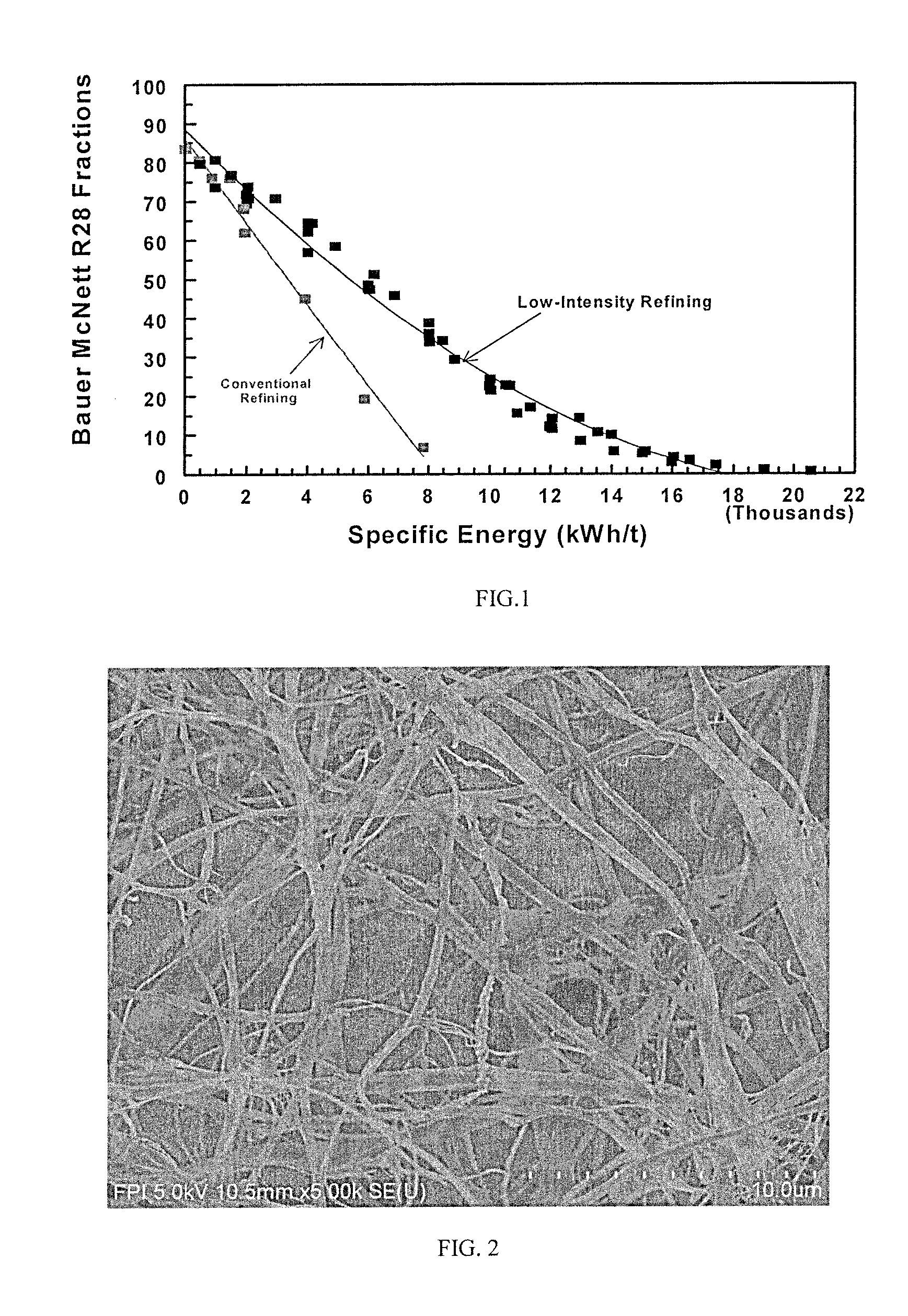

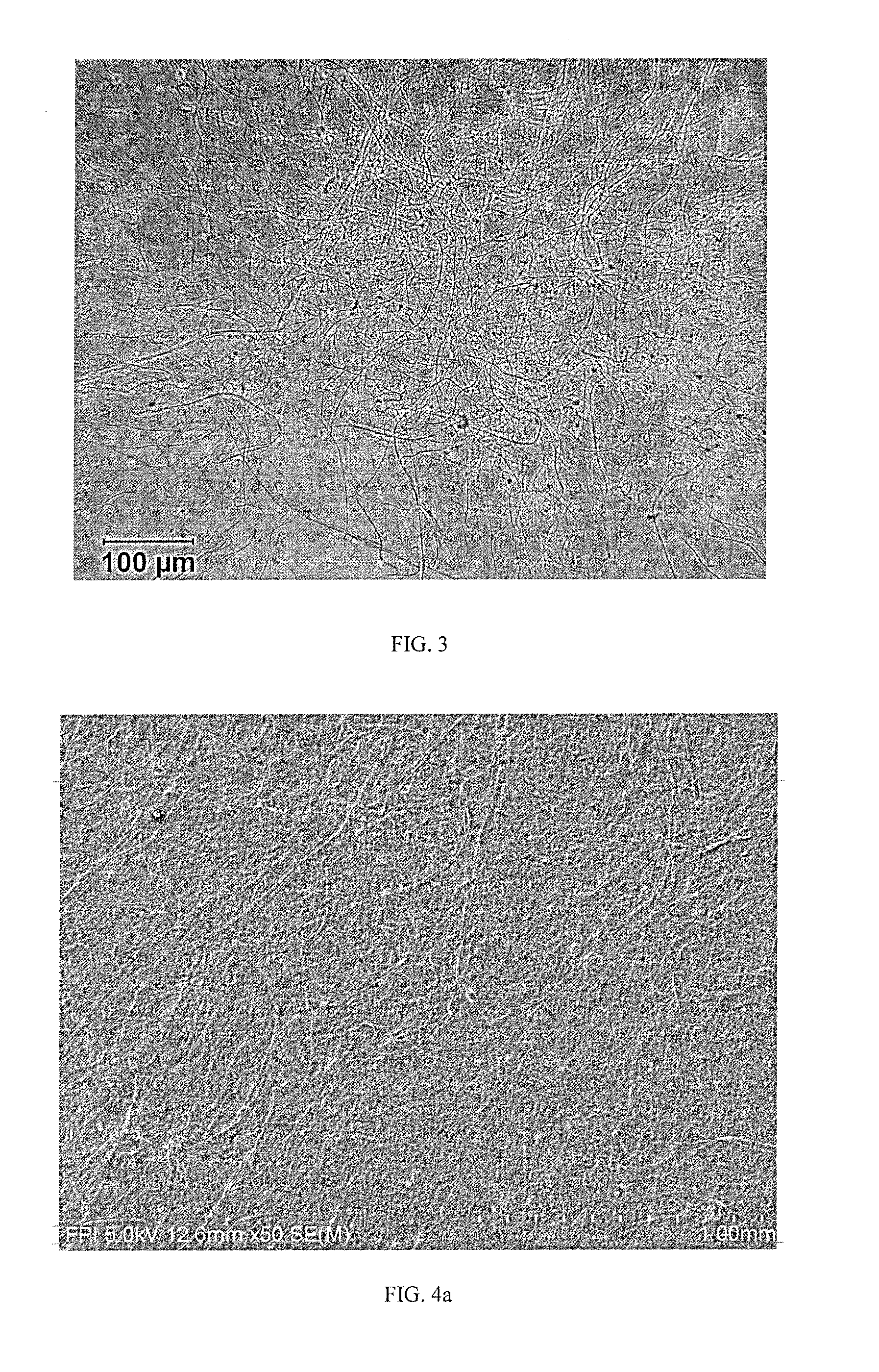

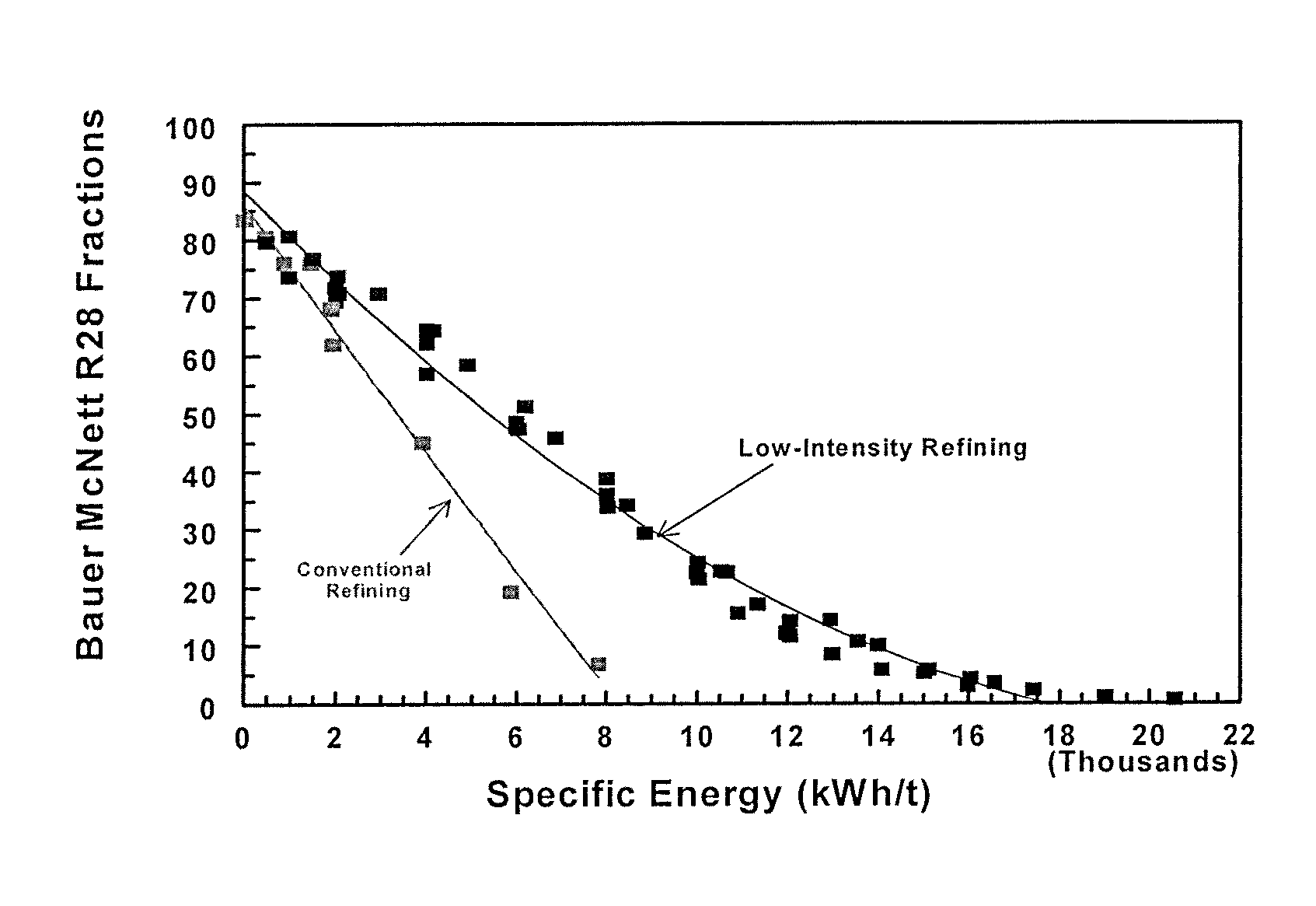

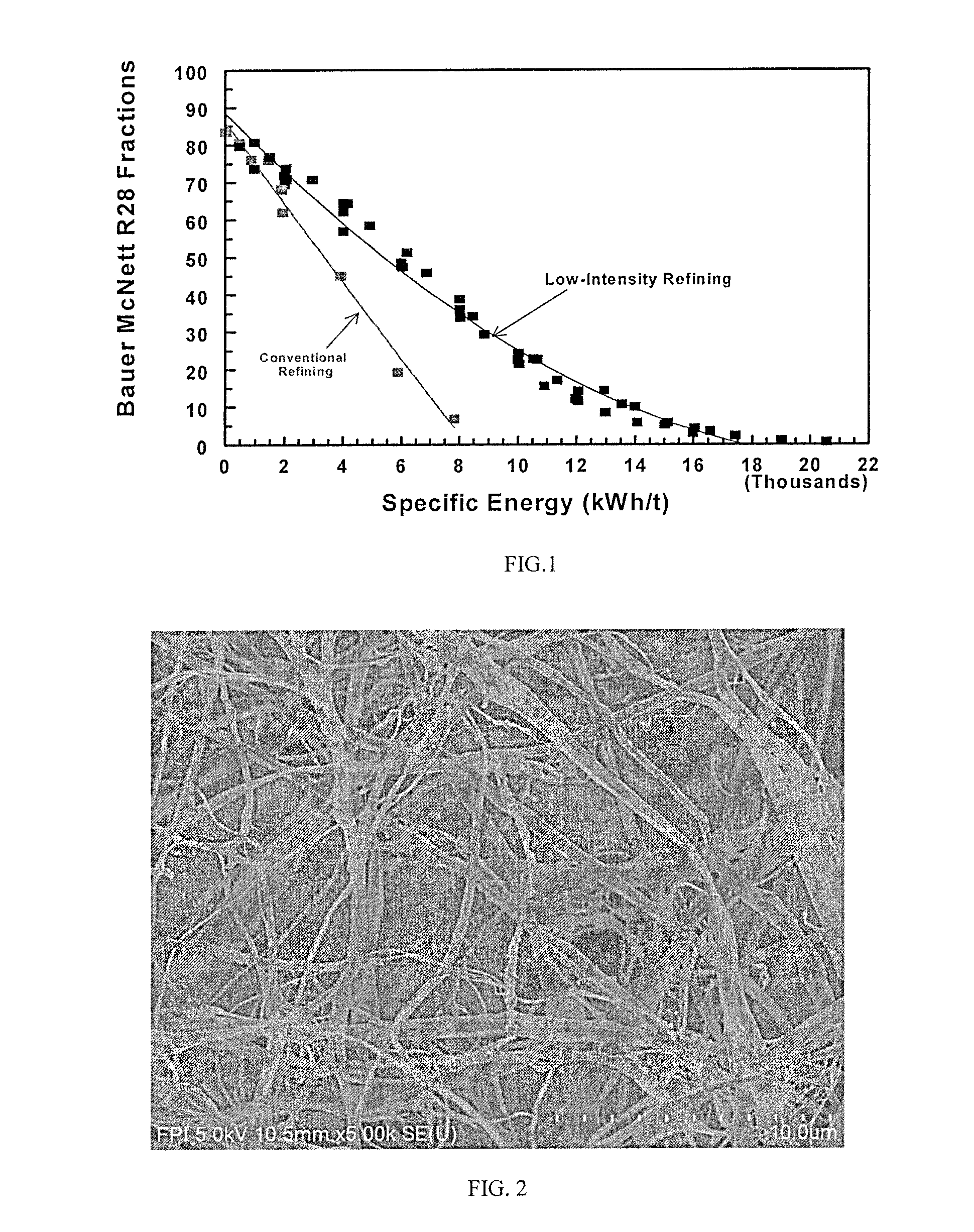

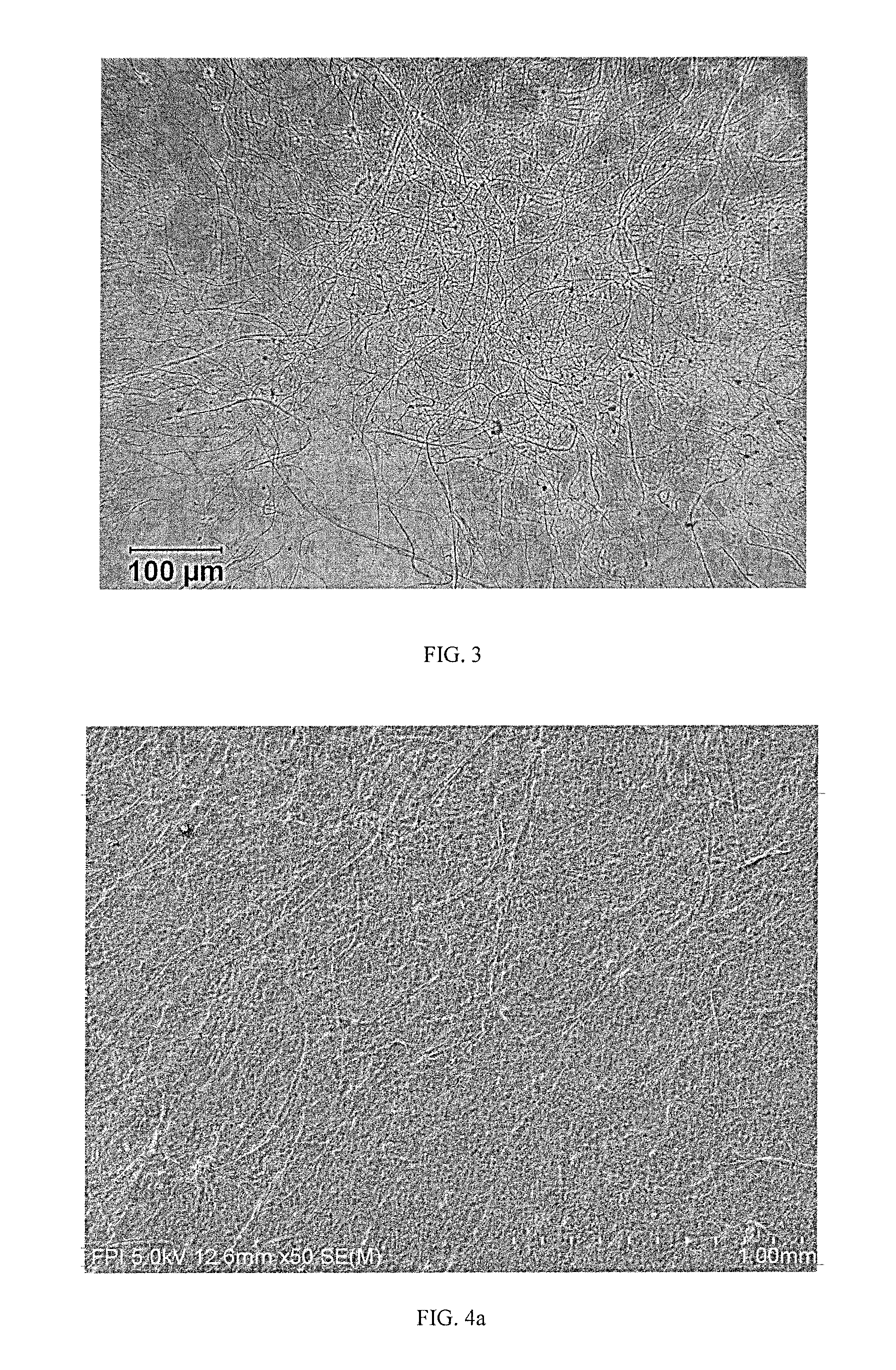

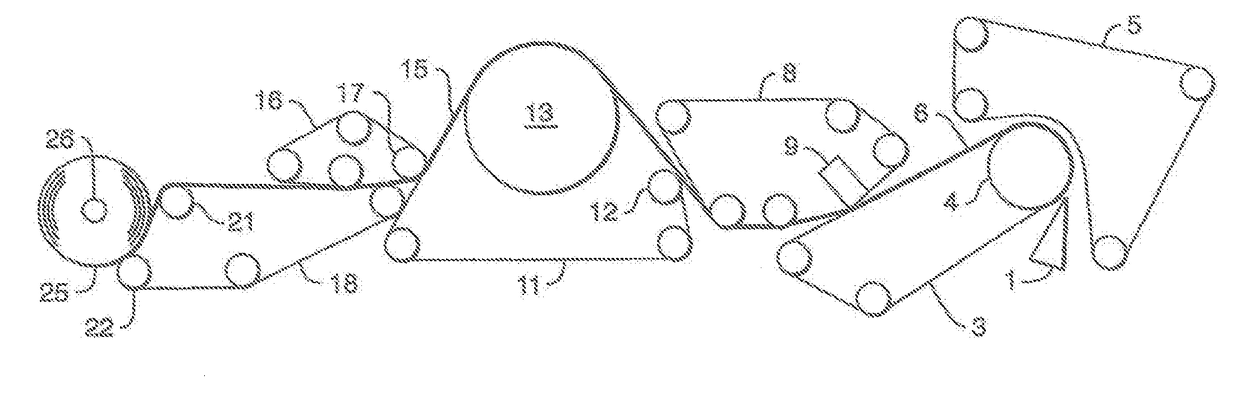

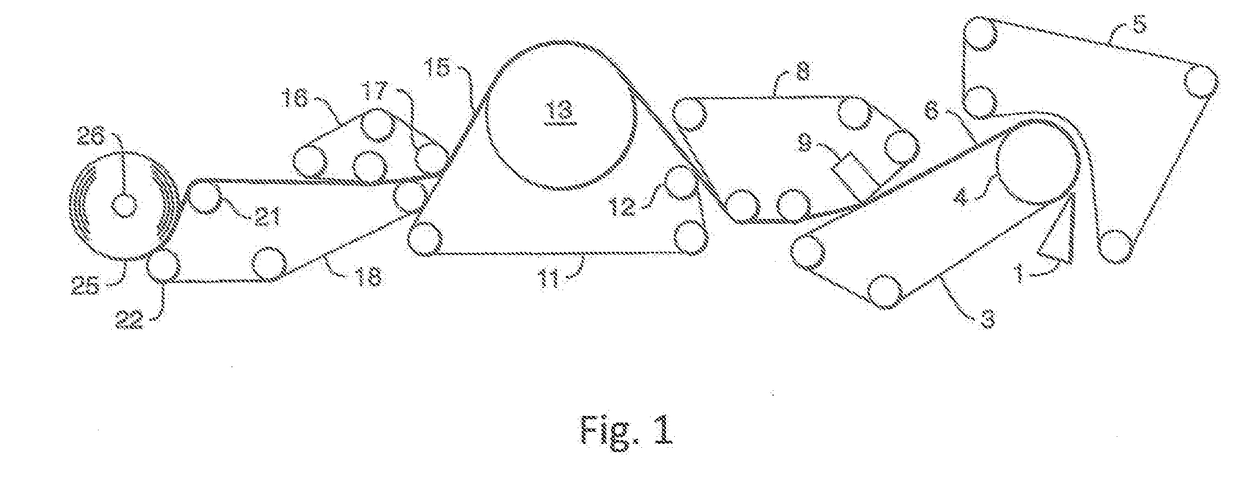

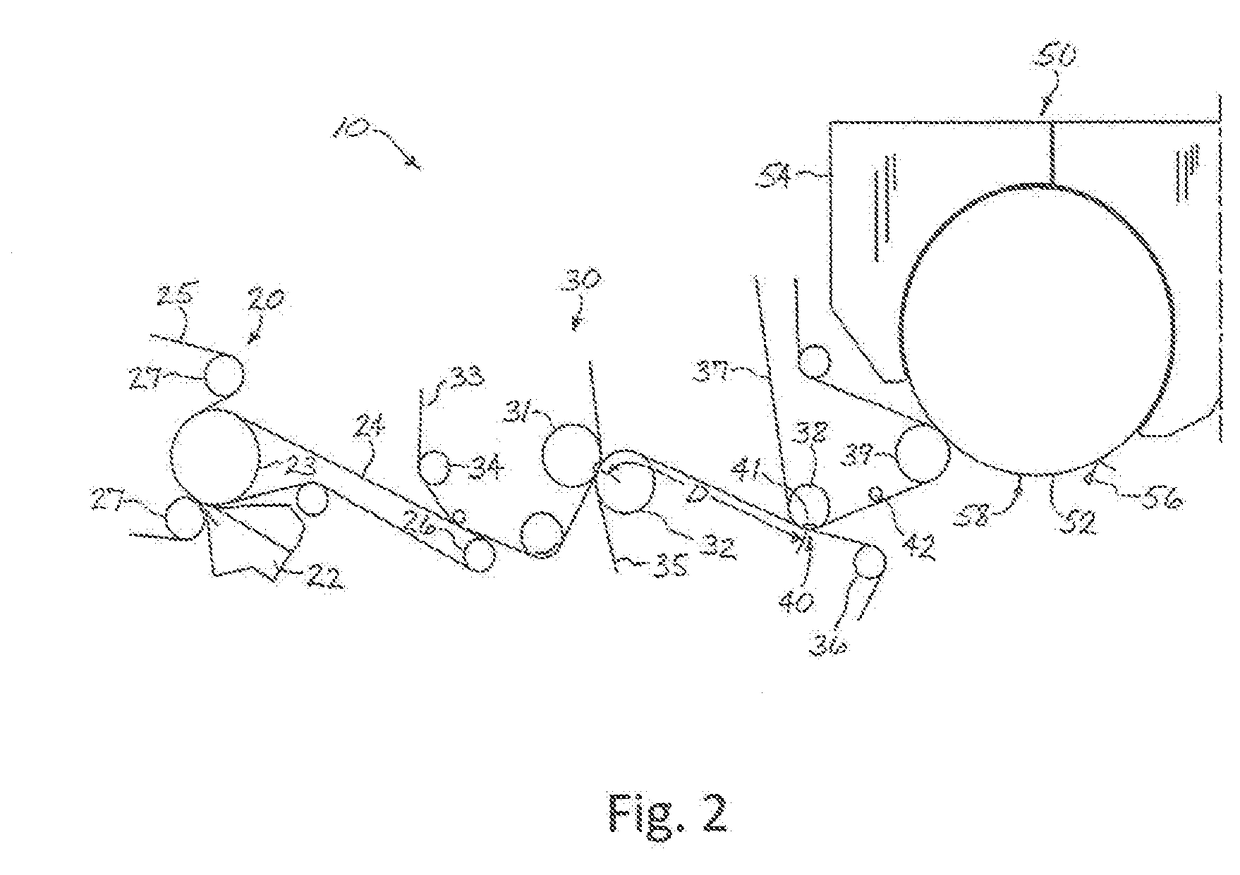

A method to produce on a commercial scale, high aspect ratio cellulose nanofilaments (CNF) from natural lignocellulosic fibers comprises a multi-pass high consistency refining (HCR) of chemical or mechanical fibers using combinations of refining intensity and specific energy. The CNF produced represents a mixture of fine filaments with widths in the submicron and lengths from tens of micrometers to few millimeters. The product has a population of free filaments and filaments bound to the fiber core from which they were produced. The proportion of free and bound filaments is governed in large part by total specific energy applied to the pulp in the refiner, and differs from other cellulose fibrillar materials by their higher aspect ratio and the preserved degree of polymerization (DP) of cellulose, and are excellent additives for the reinforcement of paper, tissue, paperboard and the like. They display exceptional strengthening power for never-dried paper webs.

Owner:FPINNOVATIONS INC

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS9051684B2Improve consistencyImprove scalabilityFinely-divided cellulose conservationReed/straw treatmentMicrometerPaperboard

Owner:FPINNOVATIONS INC

Manufacturing method of ramie based on sectioned circulation

ActiveCN101624727AGet rid of dependenceReduce dosageMechanical treatmentBacteriological rettingChemical treatmentCarding

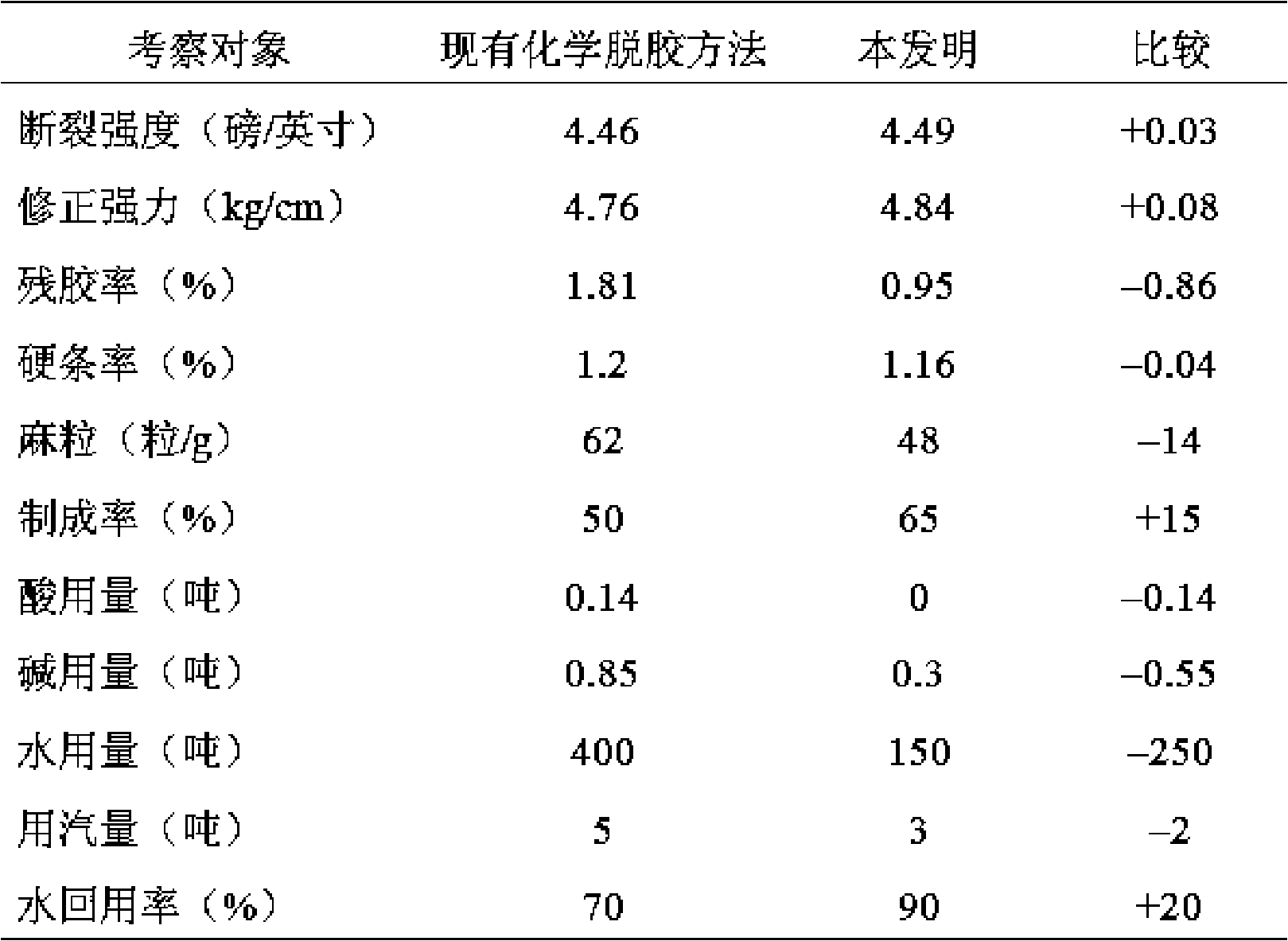

The invention discloses a manufacturing method of ramie based on sectioned circulation, belonging to the manufacturing method of textile fibre and solving the problems that the prior method has a large quantity of waste water, serious pollution and high cost. The method comprises following steps: pretreatment of primary ramie, chemical treatment, biological treatment and post treatment; the pretreatment improves the degree of looseness of the primary ramie through beating, ultrasound or extraction; the biological treatment degrades pectin, hemicellulose and others impurities through bio-enzyme or microbial fermentation; the chemical treatment further degrades residual pectin and others impurities through alkali boil-off; the post treatment obtains refined dry ramie by beating, whitening, water scrubbing, dehydration, oil feeding, drying, carding and baking. The quality of the product meets the requirements of first-class GB / T 20793-2006, the degumming yield rate is improved by 15%, the water consumption is reduced by at least 60%, the method is free from using acid, the alkali charge is reduced by 65%; water, the alkali and the bio-enzyme used in each step are recyclable; the byproducts can be recycled in time, the sewage quantity is small and the pollution level is low.

Owner:HUAZHONG UNIV OF SCI & TECH

Pieparation method for fabricating raw bamboo into spinnable bamboo fibers

A method for preparing primary bamboo to be spinnable bamboo fibre includes cutting bamboo into pieces, placing prepared bamboo pieces in pressure container for obtaining coarse fibre, using mildew aqueous solution to remove lignin, pectin, sugar and fat out from the fibre; rolling and dividing the fibre, bleaching and rinsing the fibre for softening; dewatering and adding reinforcer to enhance fibre strength; using emulsifier to process fibre for having desired compliance and drying it for obtaining spinnable bamboo fibre.

Owner:刘忆萍

Fabric strip for spinning and its processing method

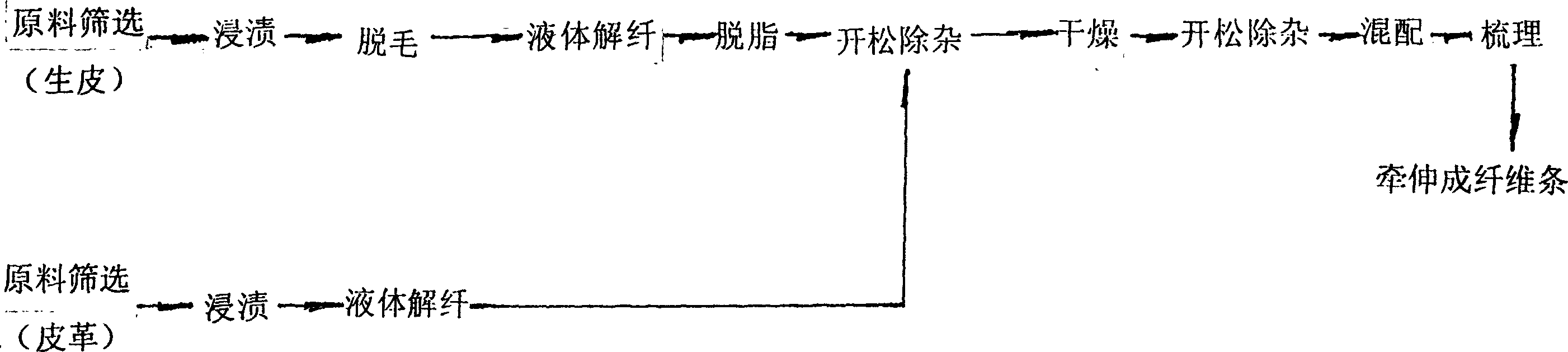

The invnetion relates to a spinning fiber rod comprised of 5-100% collagen fiber and residual textile fiber. Wherein, the process method comprises: screening material, dipping, defibering, degreasing, cleaning, dewatering, drying, opening to remove impurity, mixing, carding, and drafting. This invention can obtain material from wide source, has well applicability, high tensile strength, well moisture / oil absorption properties, and fit to spread in textile industry.

Owner:张立文

Method for preparing bamboo fiber from bamboo

InactiveCN1415790APromote growthWide variety of sourcesMechanical treatmentFibre treatment to obtain bast fibreFiberAcid washing

A process for preparing bamboo fibres from bamboo includes preparing raw material, softening, water washing, rolling, water washing, treating by urea and oxygen, water washing, boiling in alkali solution, water washing, bleaching by urea and oxygen, acid washing, dewatering, loosening and drying in air. The said bamboo fibres can be used to weave cold fabrics.

Owner:DONGHUA UNIV

Production method of carex meyeriana fiber

ActiveCN102660779AImprove degumming effectImprove performanceVegetable materialMechanical treatmentFiberSulfite salt

The invention discloses a production method of a carex meyeriana fiber. The production method adopts the following process flow: taking carex meyeriana raw grass, boiling, carrying out primary processing, carrying out pre-degumming treatment by an ultrasonic wave, carrying out primary washing, carrying out alkali oxidation and degumming bath, pickling, carrying out secondary washing, drying, feeding oil, opening and carding to obtain the carex meyeriana fiber, wherein water is used as a medium in the step of the pre-degumming treatment by the ultrasonic wave, when the frequency is 28-40HZ and the temperature is 50-70 DEG C, the pre-degumming treatment by the ultrasonic wave is carried out for 60-90 minutes, and NaOH is added when the treatment is carried out within 20-30 minutes so as to enable the alkali concentration of the solution to reach 5-15g / l; in the step of alkali oxidation and degumming bath process, carex meyeriana can be put in an alkali oxidation extracting solution to enable the temperature to rise to 90-100 DEG C, heat preservation and boiling are performed for 1-2 hours; the alkali oxidation extracting solution is prepared from the following ingredients: 6-9g / l of sodium hydroxide, 8-12g / l of hydrogen peroxide, 2-4% of sodium polyphosphate serving as an additive of carex meyeriana mass, 2-4% of magnesium sulfate and 1-3% of sodium sulfite.

Owner:TIANJIN POLYTECHNIC UNIV

Multi-density tissue towel products comprising high-aspect-ratio cellulose filaments

Owner:MERCER INT

Ultra rapid conditioning of cotton fiber for testing and processing

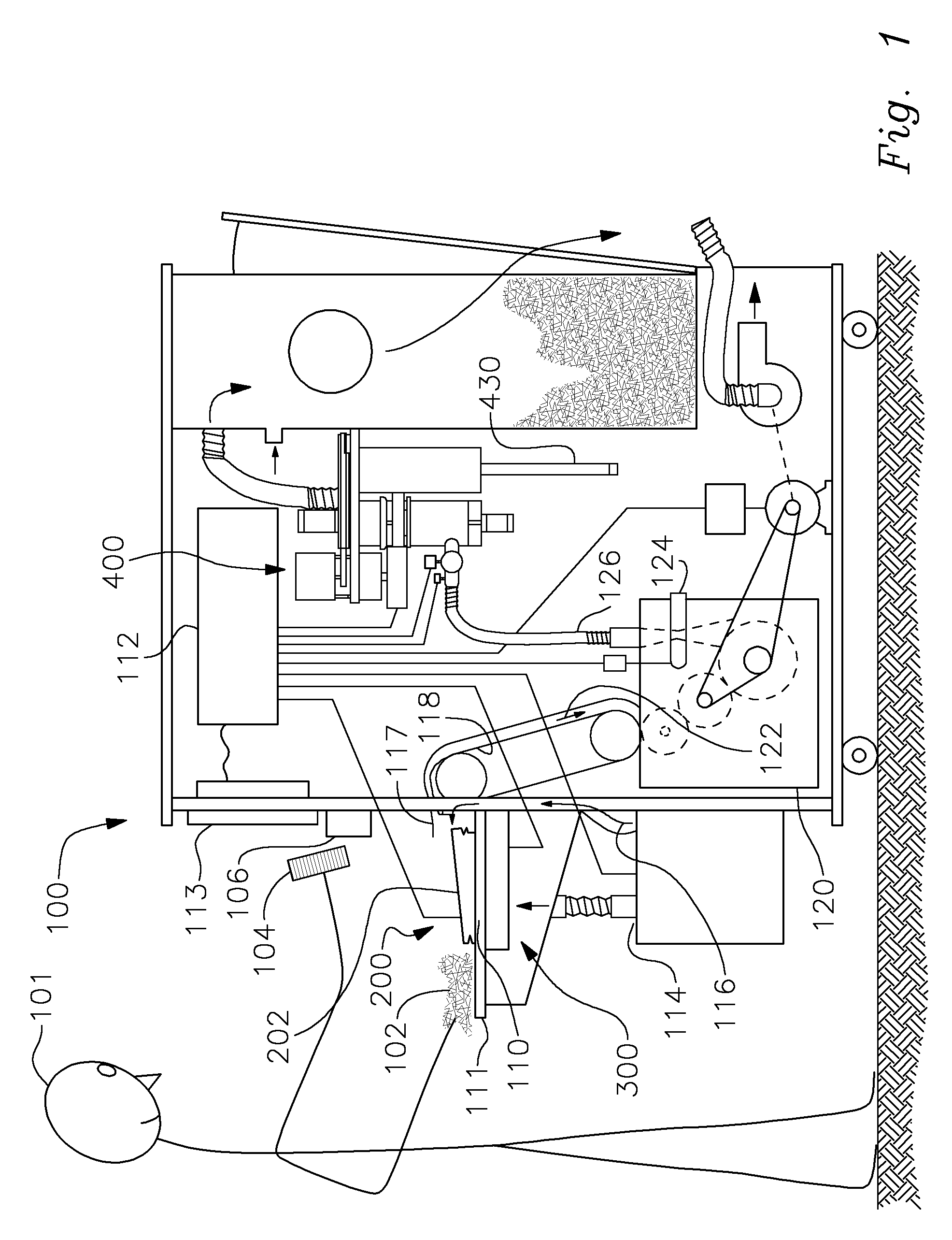

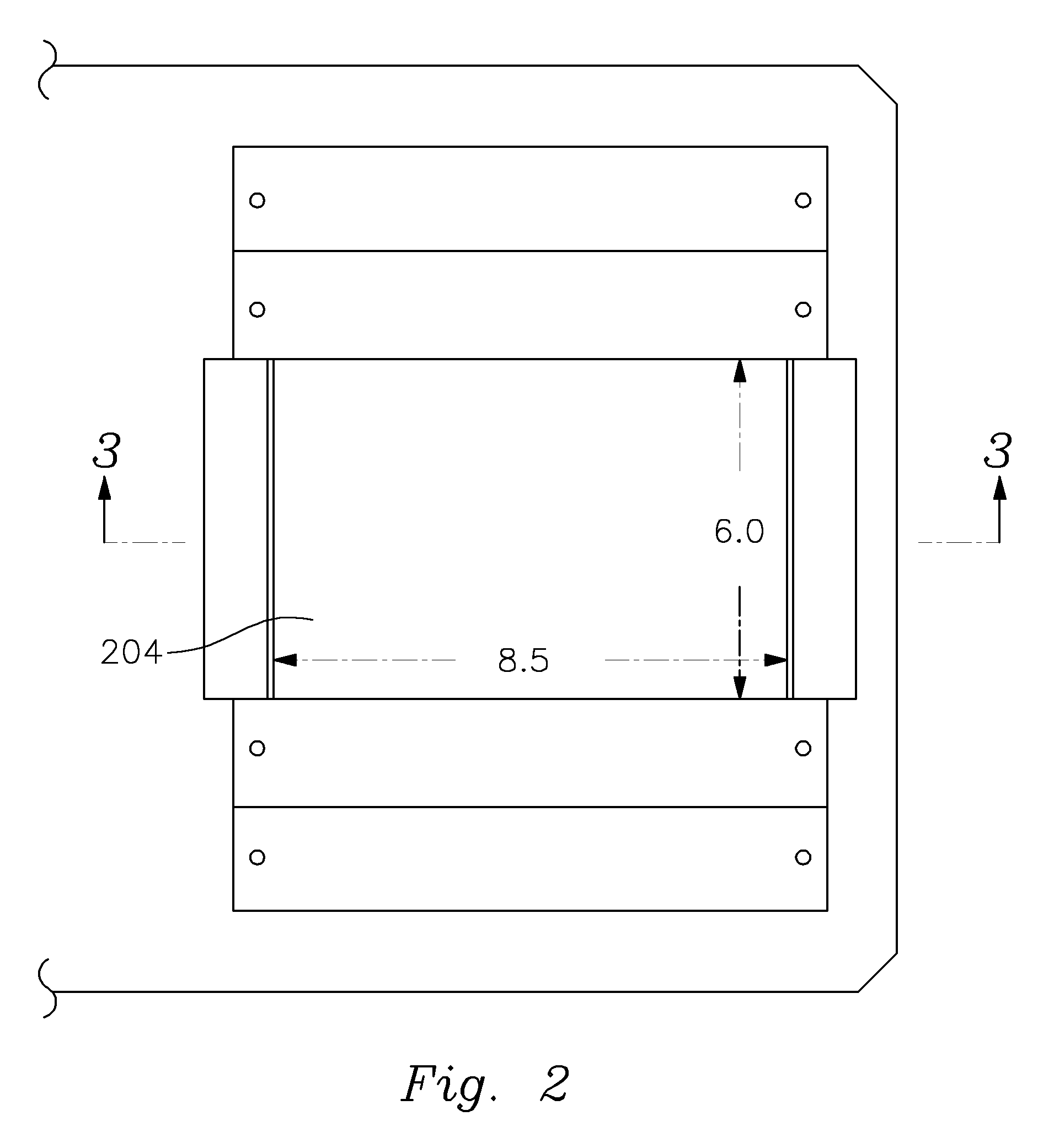

InactiveUS20020178547A1Increase speedSafety devices for fibre treatmentCarding machinesFiberEngineering

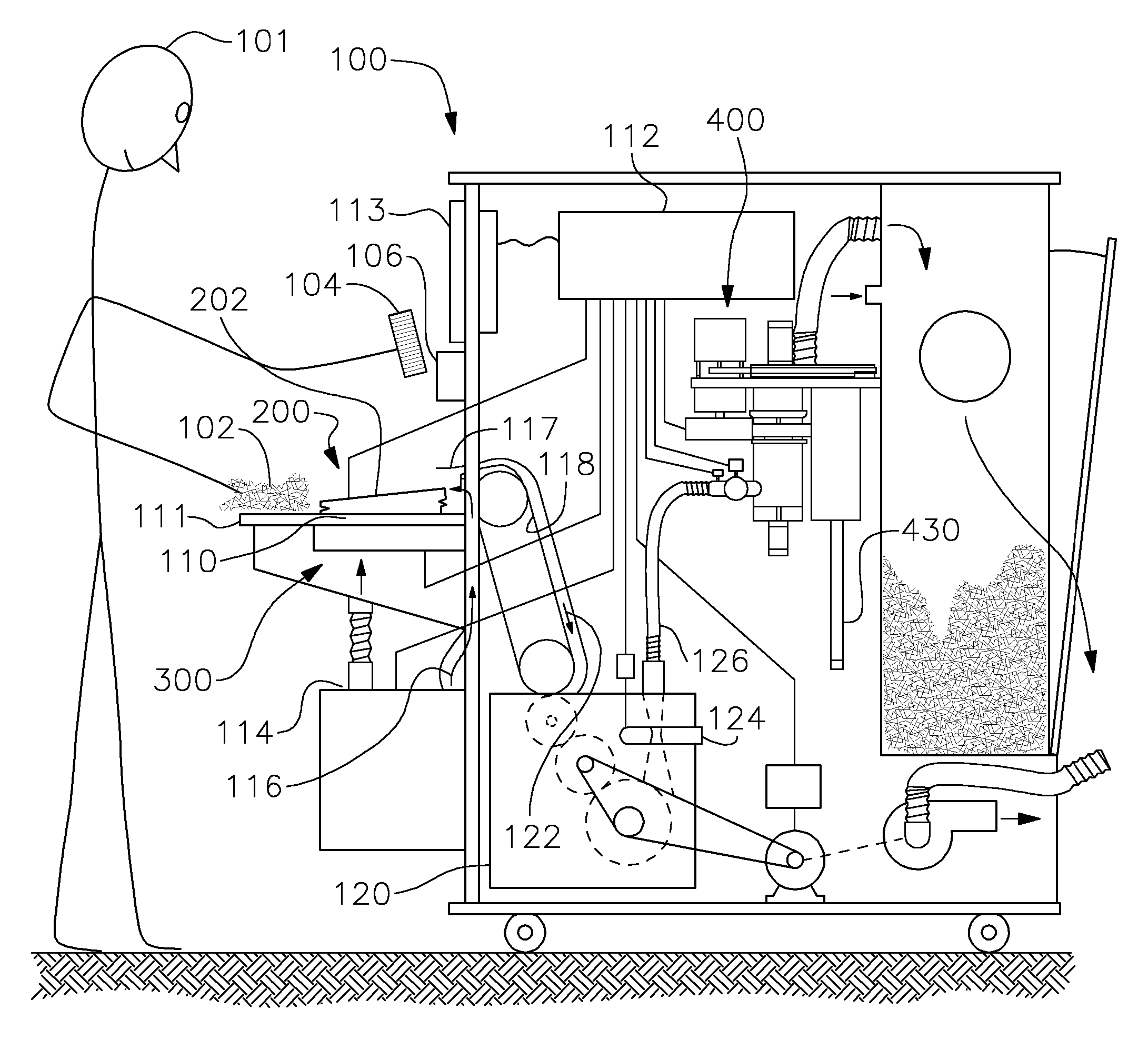

<heading lvl="0">Abstract of Disclosure< / heading> Machines for ultra-rapidly conditioning cotton fiber. In one embodiment, a machine includes a conditioning chamber for receiving cotton fiber formed into a sheet-like body. The conditioning chamber is defined on one side by an impervious plate and on an opposite side by a perforated plate. The sheet-like body of cotton fiber is pressed between the impervious and perforated plates. An air conditioner is connected for driving a conditioned gas flow through the perforations and then laterally through the sheet-like body of cotton fiber. In another embodiment, a conditioning chamber is defined on one side by an impervious plate and on an opposite side by a distribution plate having a series of alternating passages connected for respectively delivering gas flow to the cotton and for allowing gas flow to exit from the cotton. As a result, relatively short path lengths are achieved. An air conditioner is connected for driving a conditioned gas flow through the passages for delivering gas flow. In a processing embodiment for conditioning fiber being pneumatically transported by a gas flow, fibers are collected to form a thin mat. Aerosolized liquid is delivered to the thin mat, and then conditioned fiber from the thin mat is re-delivered into the gas flow.

Owner:SHOFNER ENG ASSOC INC

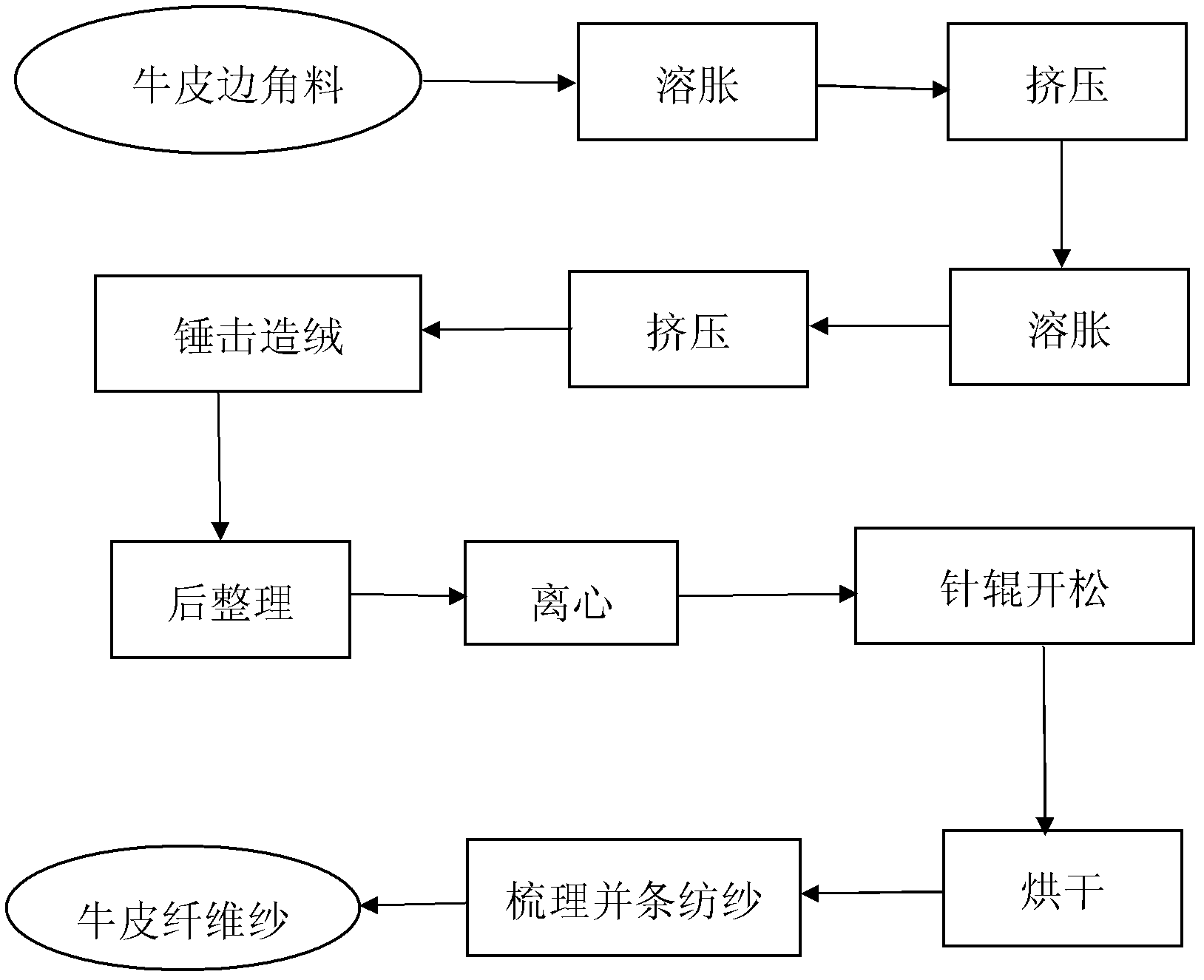

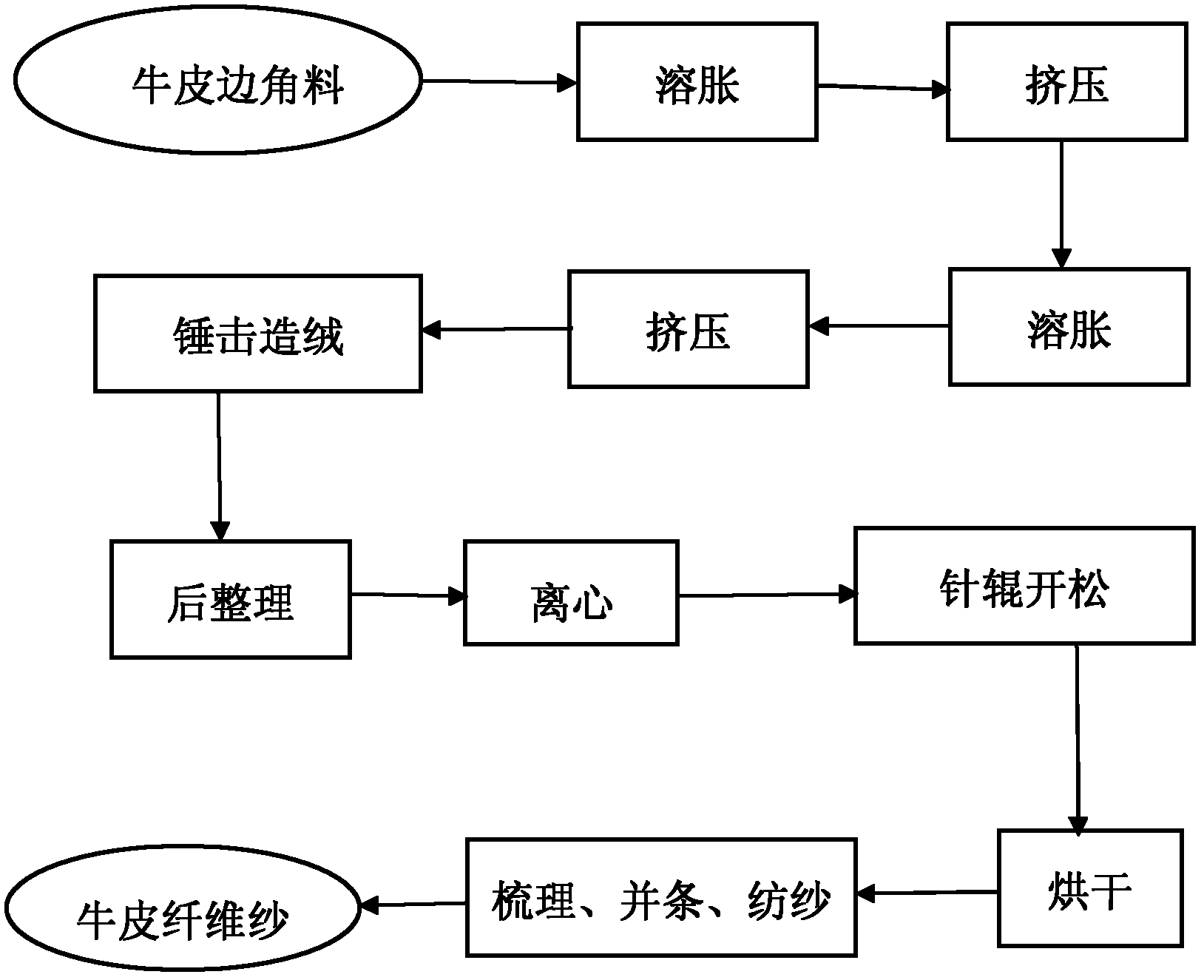

Method for preparing cowhide fiber yarns from cowhide leftover materials

The invention belongs to the technical field of the utilization of cowhide leftover materials, and relates to a method for cowhide fiber yarns from cowhide leftover materials, which comprises the following steps of: performing screening, color separation, impurity removal, puffing, softening, extrusion, repeated soaking and extrusion, hammering and flocking, after treatment, loosing and drying on the cowhide leftover materials sequentially to obtain cowhide fibers with the length of between 15 and 50 millimeters and the fineness of between 0.5 and 2.2 D; and performing carding, drawing and spinning on the cowhide fibers sequentially to obtain the cowhide fiber yarns. In the method, the cowhide leftover materials discarded in the production process of leather are used as raw materials, so the cost is low, and the cowhide leftover materials are turned into wealth; and the obtained cowhide fibers for preparing the cowhide fiber yarns are high in finished product rate and uniform in fineness.

Owner:沈中全 +1

Antigen-free porcine dermal collagen fibers

ActiveCN102121133AGood biocompatibilityGood mechanical propertiesSuture equipmentsAnimal materialAntigenCarding

The invention discloses antigen-free porcine dermal collagen fibers and a preparation method thereof. The antigen-free porcine dermal collagen fibers with excellent performance and wide application are prepared by using purified porcine skin as a raw material and adopting a method of combining physics, chemistry and biochemistry to perform a series of treatment such as fluffing, fiber decomposition, fiber separation, carding and the like on the purified porcine skin on the premise of ensuring good mechanical property of the purified porcine skin unchangeable. The antigen-free porcine dermal collagen fibers have good biocompatibility, good mechanical property and proper degradability, and can be widely applied to preparation of medicinal biological materials such as tissue engineering scaffold materials, hemostatic materials, medicinal operation stitches and the like.

Owner:SICHUAN UNIV

Method for extracting collagen fibers from offal produced during tanning process

InactiveCN102492998AHigh extraction rateNo pollution in the processAnimal materialMechanical treatmentChemical treatmentUltrasound device

The invention discloses a method for extracting collagen fibers from offal produced during a tanning process. At present, the offal produced during the tanning process is treated through a chemical treatment method which has the defects that though the product added value is higher, the treatment is complex, the cost is high, secondary pollution is generated, the offal utilization ratio is low, and a great quantity of leather waste cannot be effectively utilized all along. The method provided by the invention comprises the following steps: selecting blocky wet blue leather scrap, immersing the wet blue leather scrap in soda lye for 36 to 48 hours, treating the tumefied wet blue leather scrap with ultrasonic equipment for 20 to 30 min, passing the wet blue leather scrap through a high-pressure water jet device slowly, drying, and finally beating and opening through a cotton carding machine to ensure complete separation between the collagen fibers and obtain the collagen fibers. The invention mainly adopts the physical and mechanical method, so as to ensure that trivalent chromium cannot be converted into poisonous hexavalent chromium; environment pollution is avoided; and the extraction rate of collagen fiber approximately reaches 70 percent.

Owner:JIAXING UNIV

Production technology for natural bamboo fibers

ActiveUS20140000761A1Simple and high-efficient producing methodImprove adaptabilityWood working apparatusPlant material mechanical workingFiberMaterials science

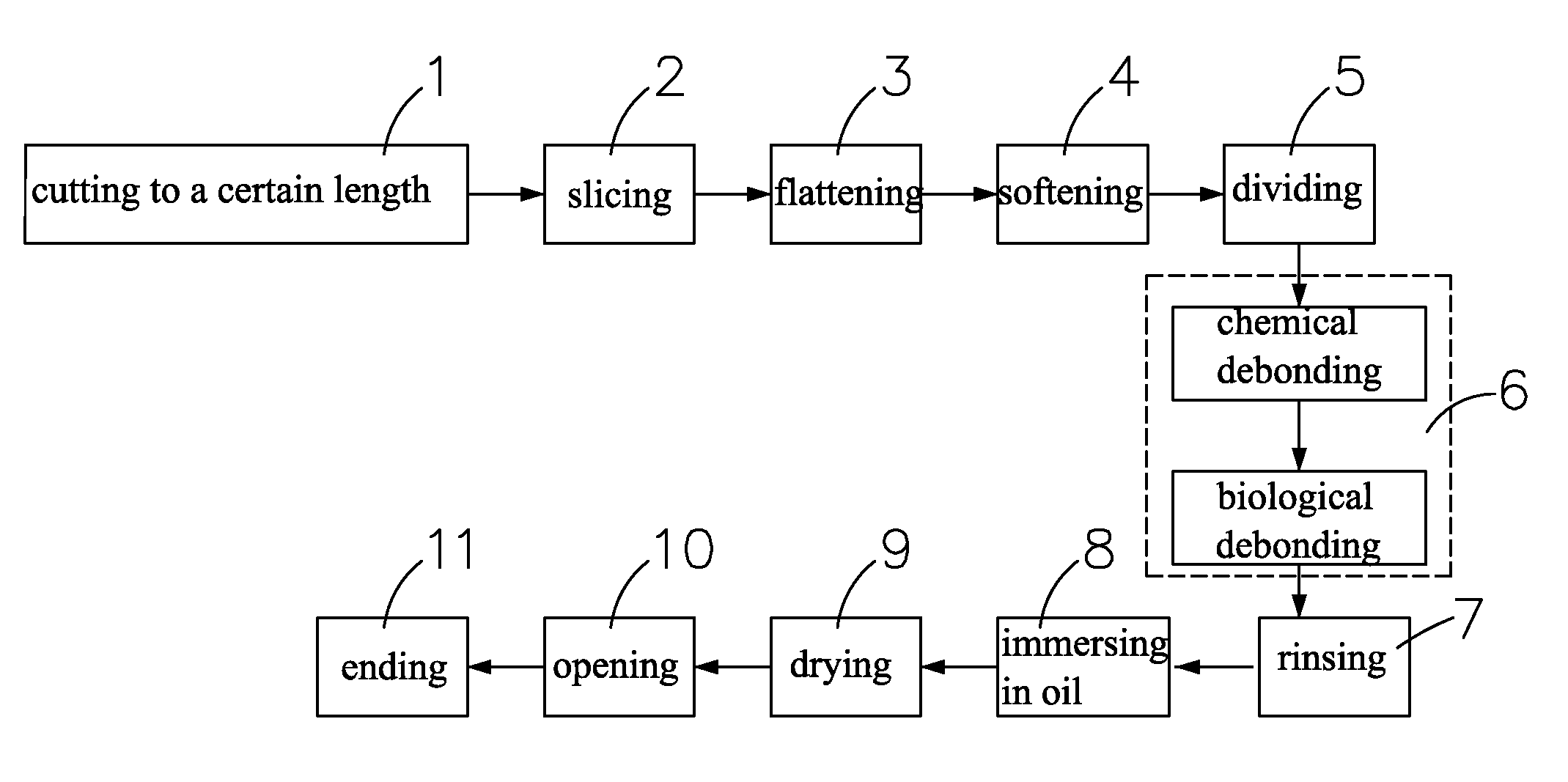

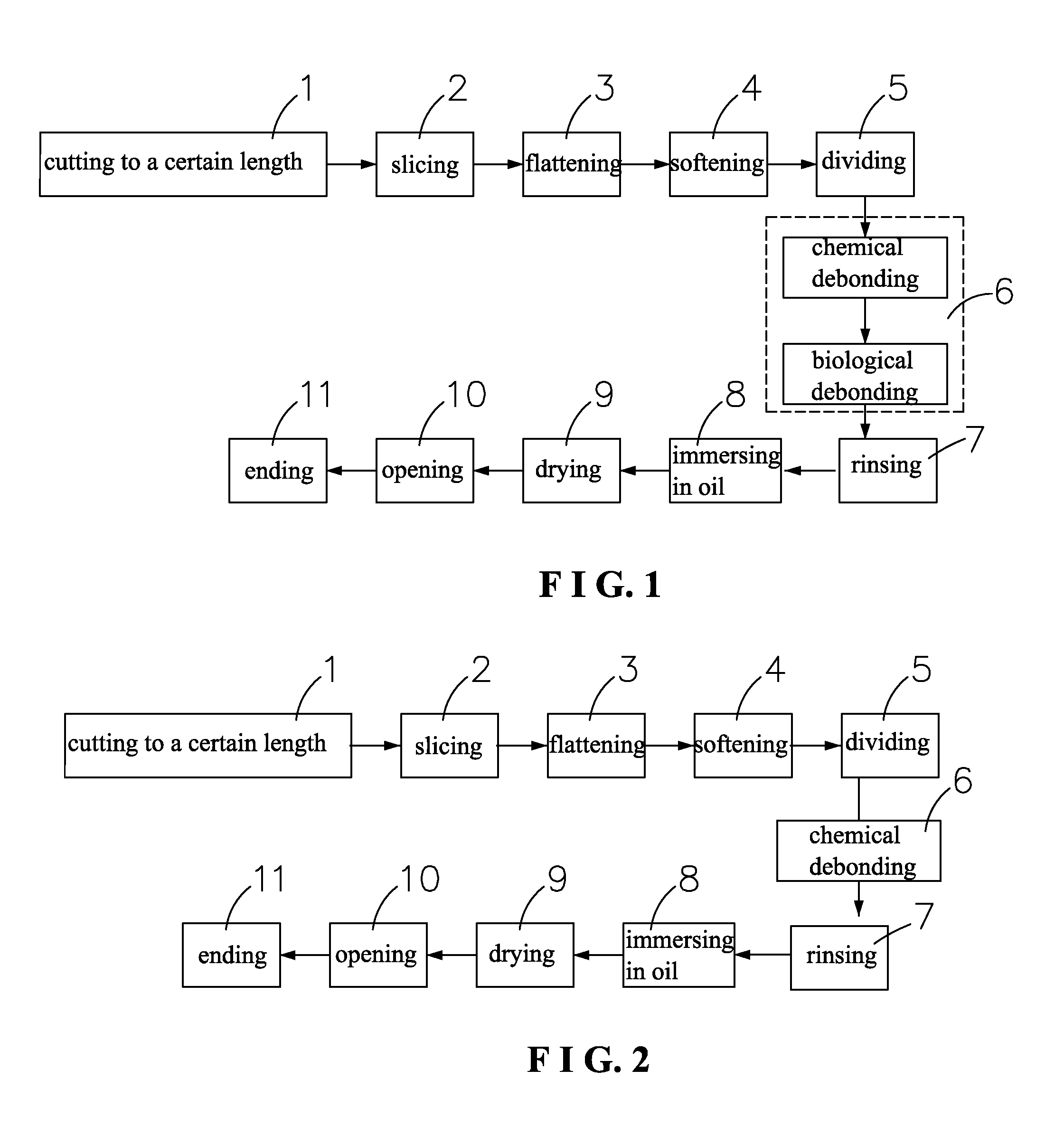

A production technology for natural bamboo fibers is applied in producing woven bamboo fibers, non-woven bamboo fibers, and reinforcing composite bamboo fibers. The woven bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding, rinsing, soaking in oil, drying, and opening. The non-woven bamboo fibers and the reinforcing composite bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding (optional), rinsing, and drying.

Owner:ZHANG YI

Natural bamboo fiber and its production process and application

The present invention discloses one kind of spinnable natural bamboo fiber and its production process and application. The natural bamboo fiber has a fineness of 1600-1900 counts and a length of that between bamboo joints. The production process includes the steps of the pre-treatment of bamboo, the bamboo fiber treating and the post-treatment of bamboo fiber. The step of bamboo fiber treating includes soaking, steaming at normal pressure, rolling, neutralizing and water washing, enzyme treating with amylase, the secondary steaming and the secondary water washing. The natural bamboo fiber produced based on the process of the present invention is superior in fineness, strength, etc. and can meet the requirement of textile in producing high quality yarn and fabric.

Owner:吴苏明

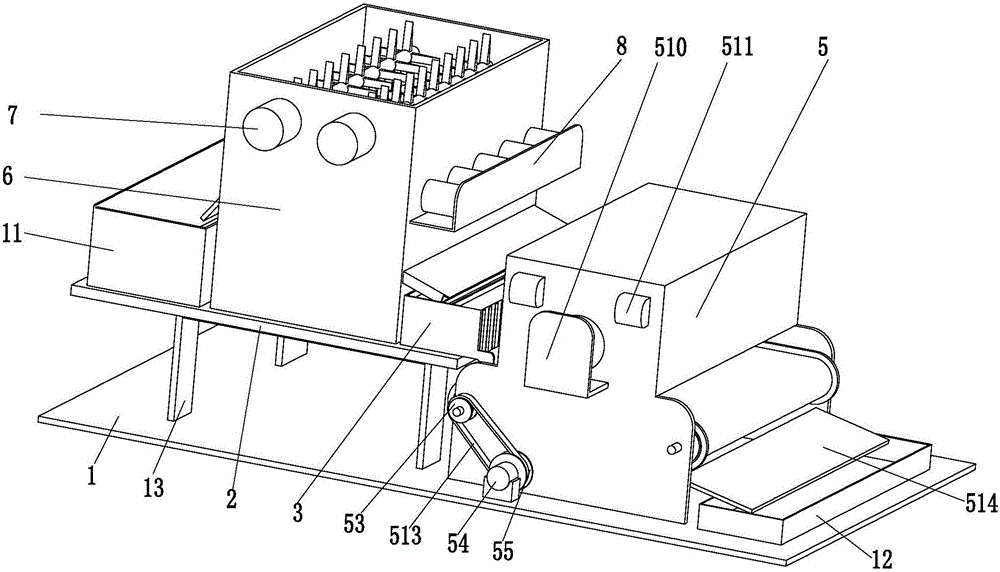

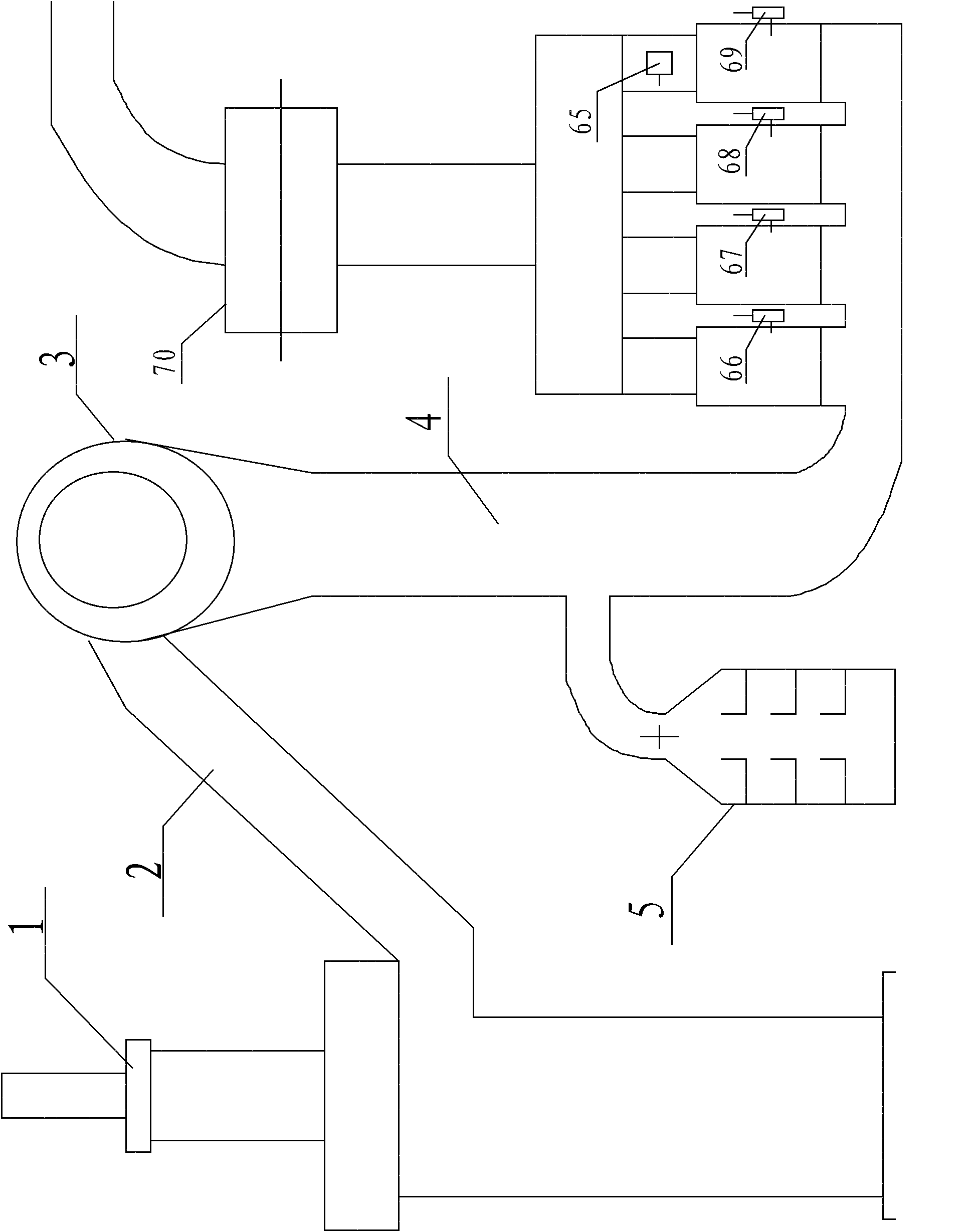

Automatic cotton boll separation and drying machine capable of recycling biomass straw

The invention relates to an automatic cotton boll separation and drying machine capable of recycling biomass straw. The automatic cotton boll separation and drying machine comprises a bottom plate, wherein two support racks are mounted at the upper end of the bottom plate; support plates are mounted on the two support racks; a collecting frame I is mounted on the support plates; a processing tank is mounted on the support plates; discharge channels are formed in both the left end and the right end of the processing tank; two shearing mechanisms are arranged on the processing tank; five separation mechanisms are arranged at the right end of the processing tank; the inner wall of the left end of the processing tank is connected with a first screening mechanism through a hinge pin; the inner wall of the right end of the processing tank is connected with a second screening mechanism through another hinge pin; a cutting mechanism is mounted at the right ends of the support plates; and a drying mechanism is mounted at the left end of the bottom plate. By adopting the automatic cotton-boll separation and drying machine, functions of automatically collecting and drying cotton bolls can be achieved, cotton straw for biomass power generation can be automatically recycled, and the automatic cotton boll separation and drying machine has the advantages of being free of manual operation, simple to operate, high in working efficiency and the like.

Owner:汉泰生物科技(威海)有限公司

Method for fabricating needling non-woven fabrics fabrics made from plant fiber having natural fragrance for slow releasing fragrance

InactiveCN1600929ABig investmentProduction is not complicatedLayered productsGaseous substancesPunchingPlant fibre

A nonwoven cloth releasing frangrance slowly is prepared by selecting one or above two natural plants having frangrant smells, opening plants to obtain plant fibres, using 50-75% of chemical fibre and 25-50% of obtained plant fibres as raw material, mixing and needle punching then for making nonwoven cloth with slowly-released frangrance.

Owner:马赛麟

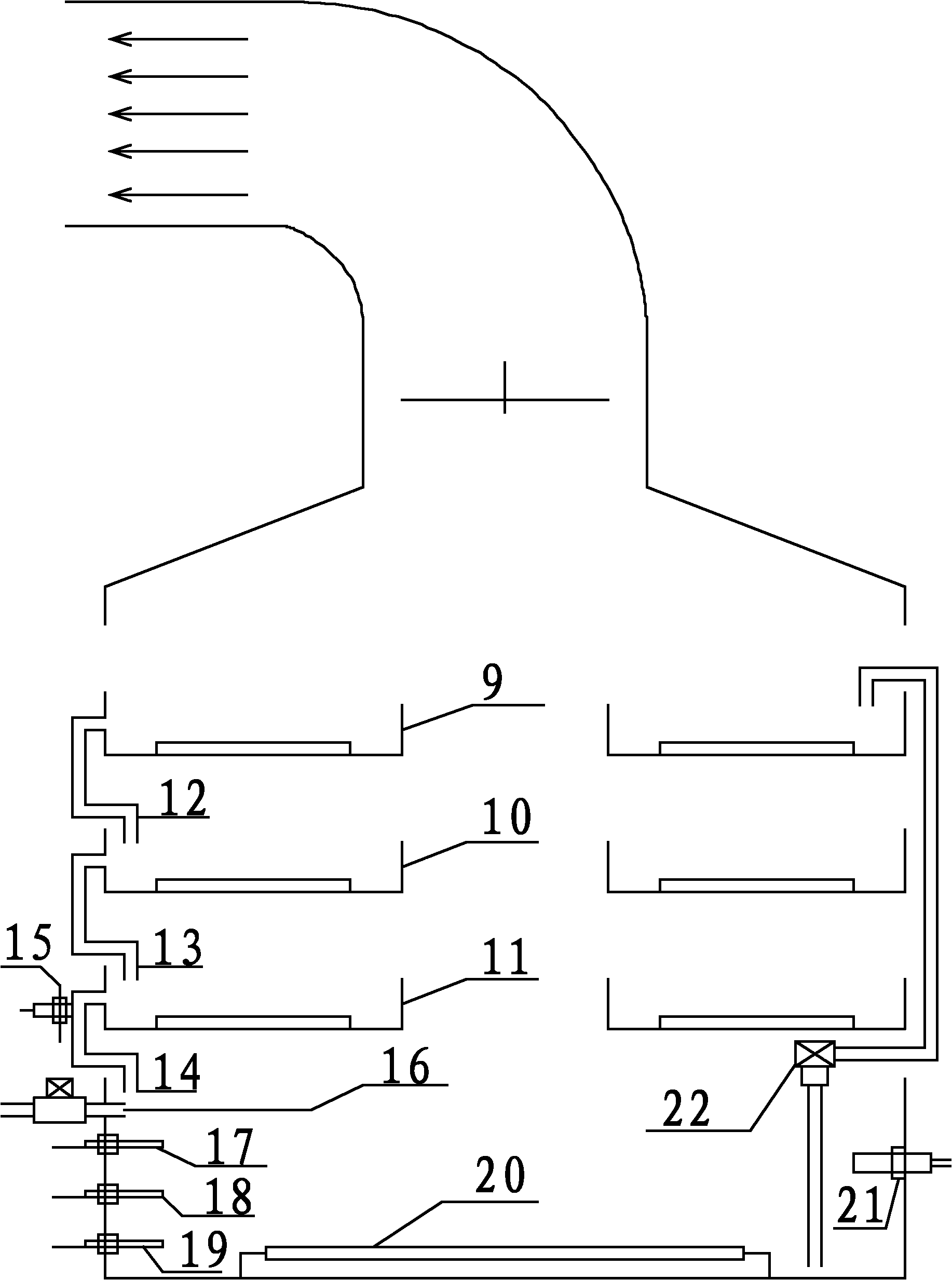

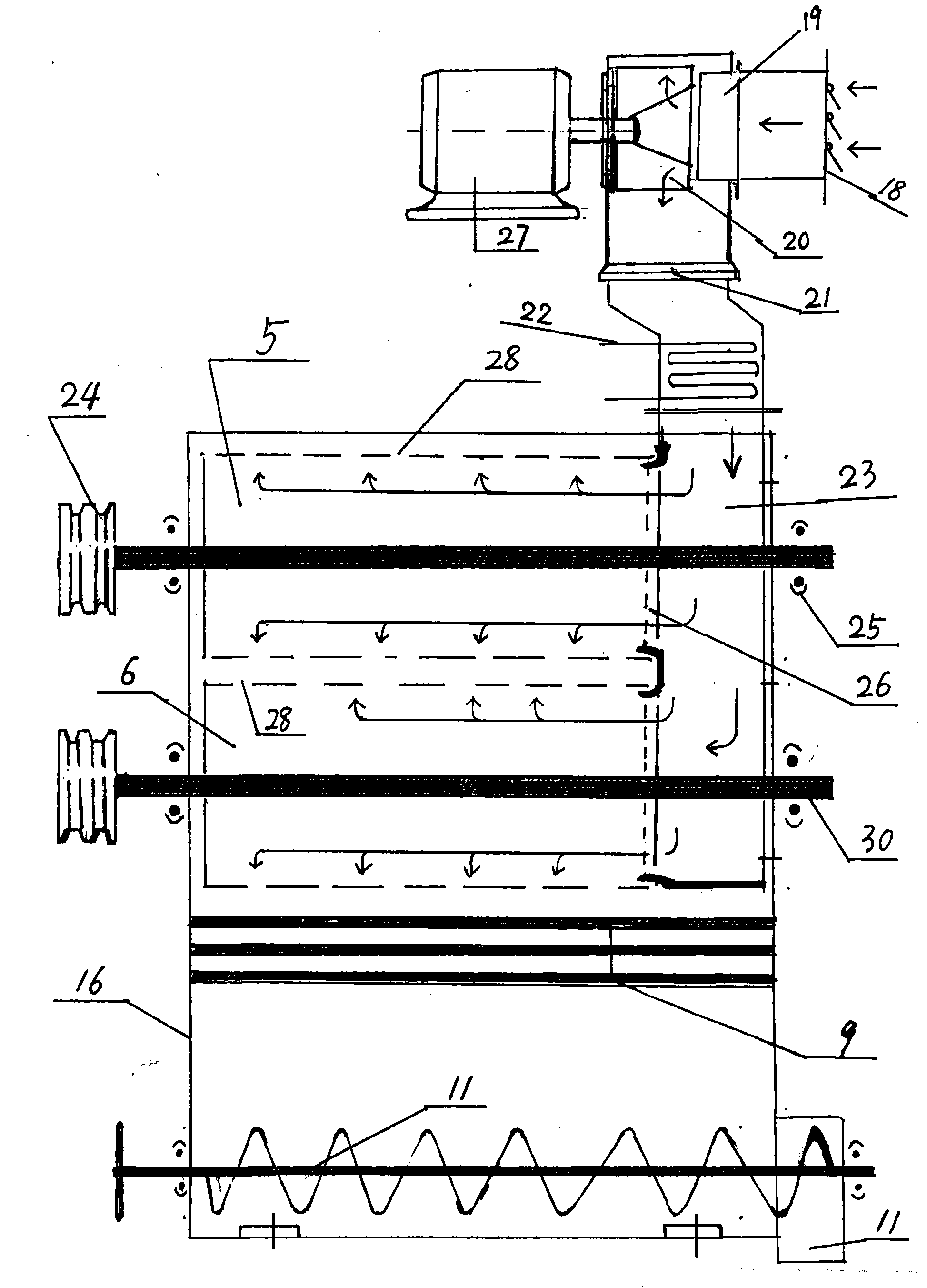

Cleaning machine for purifying and electrically drying seed cotton

ActiveCN102560692AIncrease contact timeDistribute quicklyMechanical treatmentAgricultural engineeringElectric machinery

The invention provides a cleaning machine for purifying and electrically drying seed cotton, comprising a frame with a seed cotton inlet and a seed cotton outlet, and a drying and cleaning device arranged in the frame, wherein the drying and cleaning device is composed of a hot air device and a plurality of groups of electric heating barbed ball rollers; an impurity discharging grid is arranged at the periphery of each group of electric heating barbed ball roller; the adjacent two impurity discharging grids are connected by a baffle; a purifying device for discharging crust or dead cotton is arranged right below the drying and cleaning device in the frame; and the drying and cleaning device and the purifying device are both connected with a driving motor for providing power to the drying and cleaning device and the purifying device. The cleaning machine has functions of cleaning impurities such as a large quantity of crusts and dead cotton, small amount of leaf scraps, dusts, small sand stones and sterile seeds, and drying seed cotton, so that the cleaning machine can be used as a purification type seed cotton cleaning machine normally. According to the machine, the installation process is simplified, the device investment cost is drastically reduced, the installation cost and the production operation cost are reduced, the manual work is reduced, and the installation space is saved, so that the machine is a high-efficient seed cotton cleaning machine.

Owner:JINAN RUNTONG ANJI MACHINERY

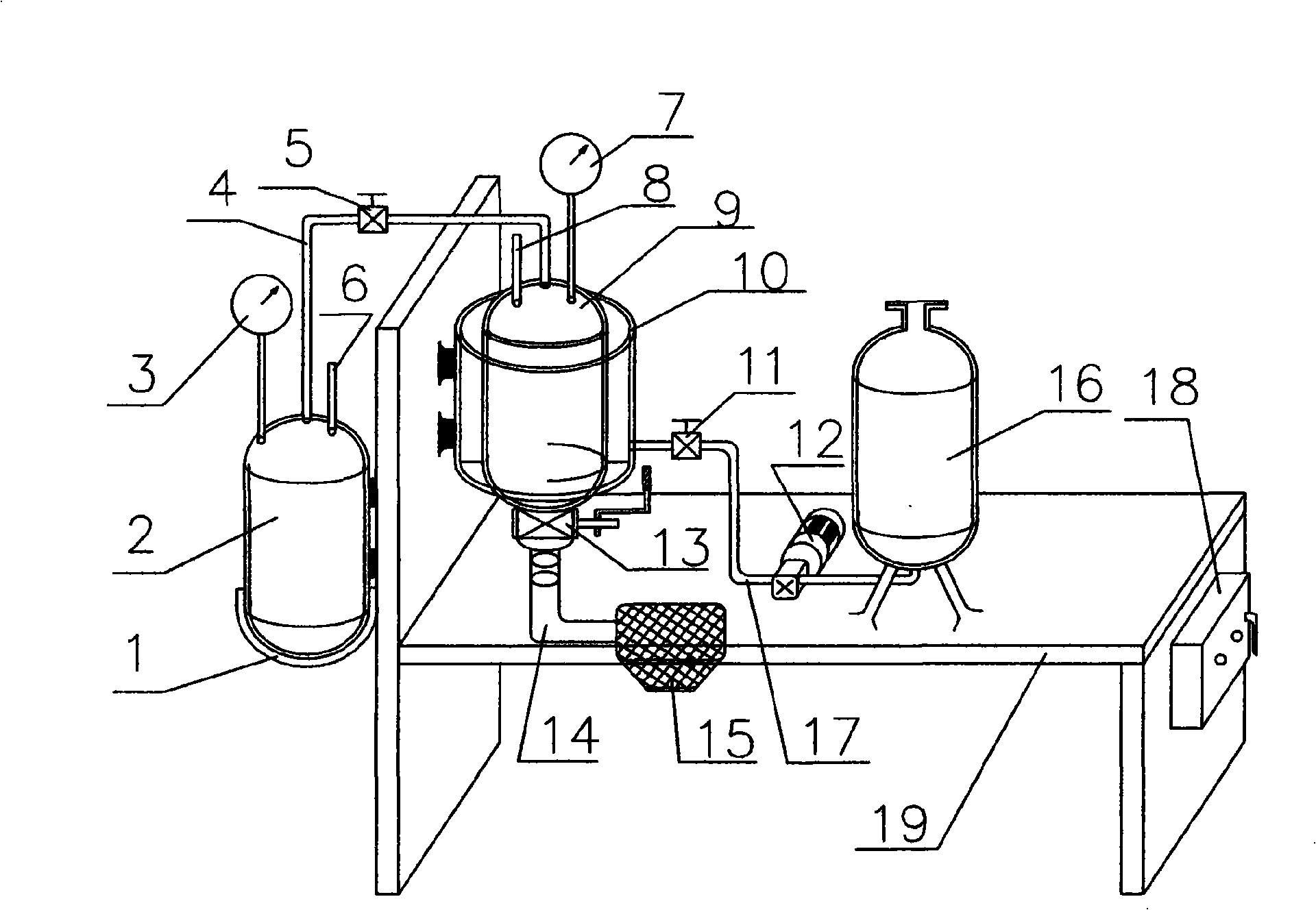

Method for refrigerating filature with no need of boiling cocoons

InactiveCN1446951AModerately absorbentReduce adhesive forceMechanical treatmentEngineeringThermal water

A cold storage method without boiling for reeling silk includes cold storage of fresh cocoon, loading in netted basket, putting in vacuum tank, vacuumizing, hot water osmosis, discharging water and repeating relative steps. Its advantages are high efficiency and high quality.

Owner:SICHUAN UNIV TIANYOU BIOLOGIC ENG

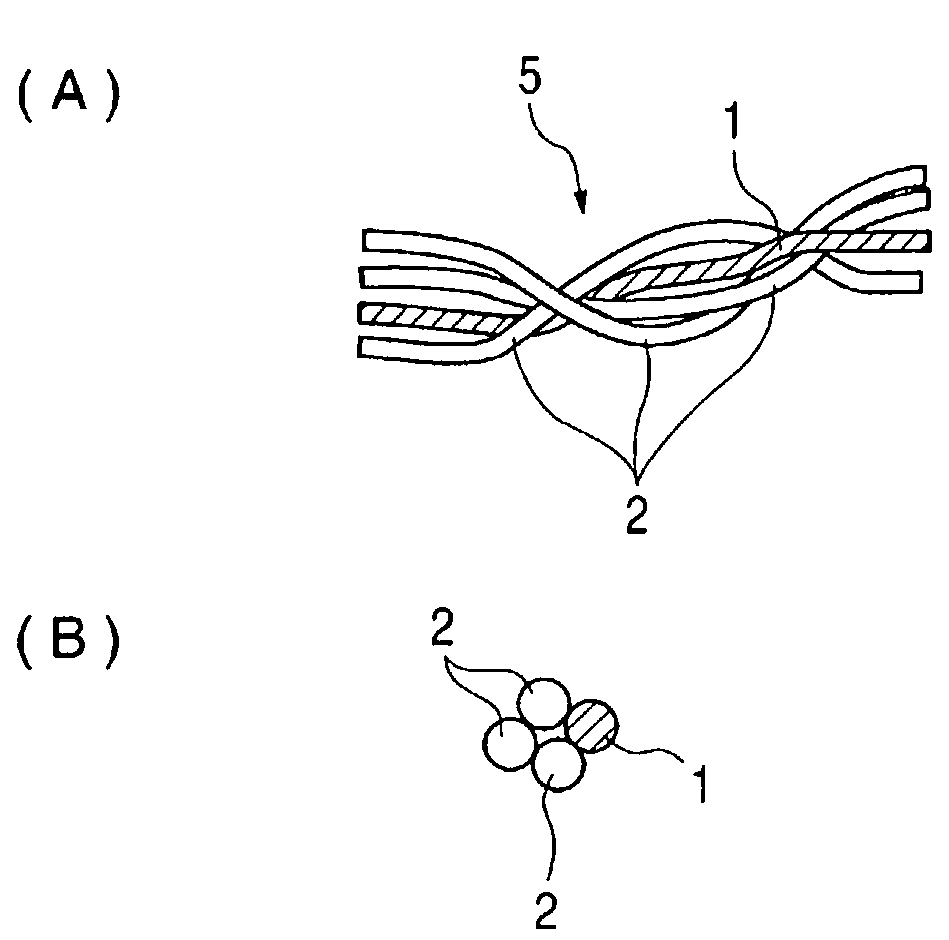

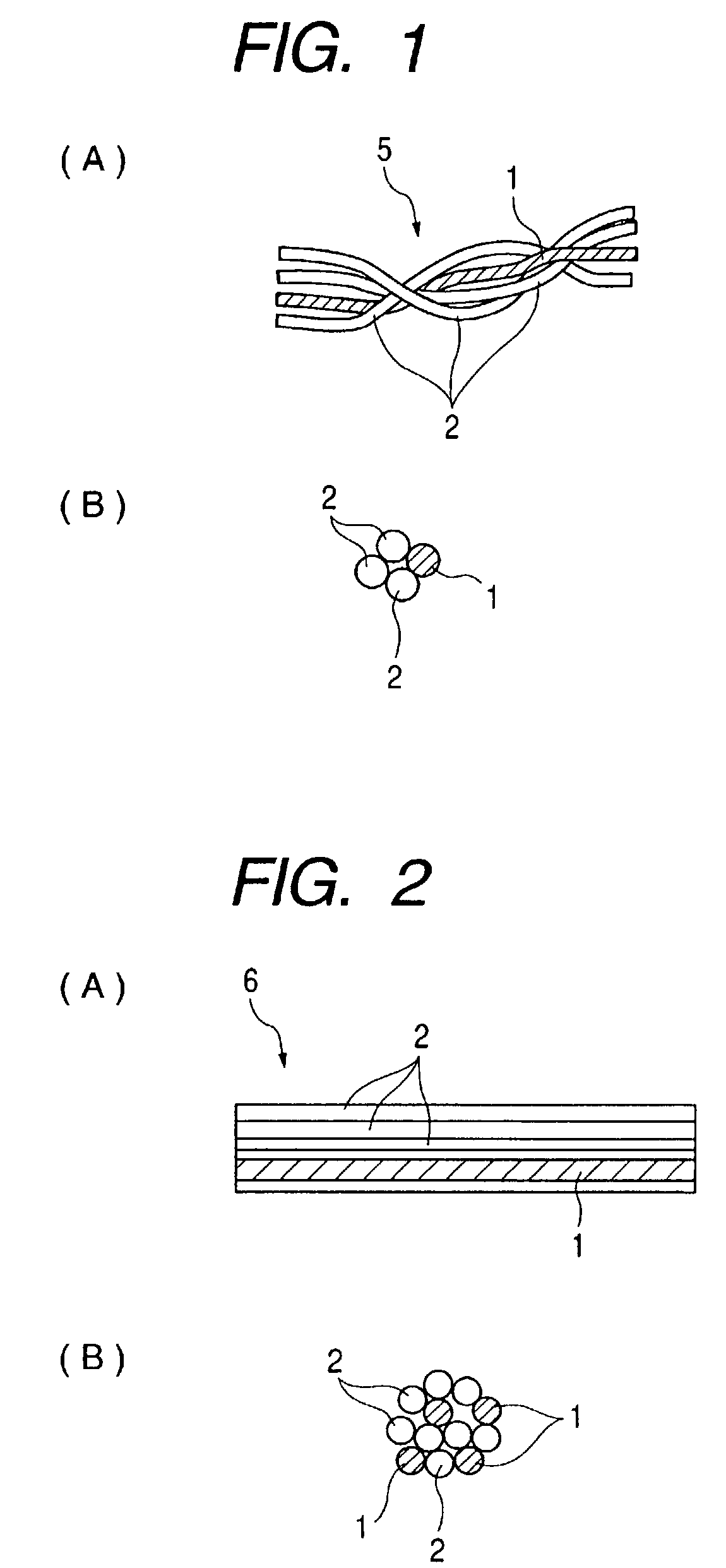

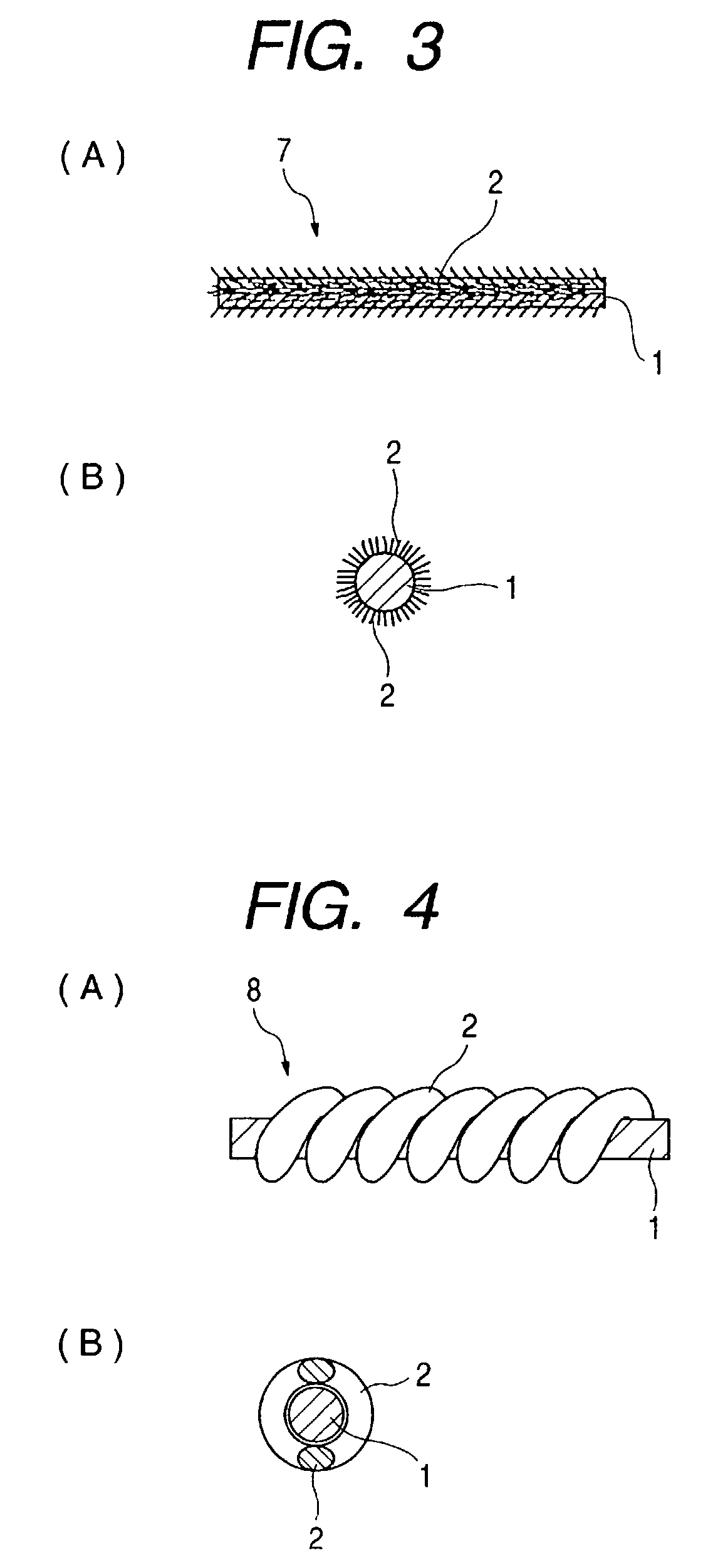

Cloth for loudspeaker diaphragm, loudspeaker diaphragm, and loudspeaker

ActiveUS7311174B2High tensile strengthIncrease productionTransducer detailsPolymeric diaphragmsFiberYarn

In a diaphragm for a loud-speaker of the present invention, an increase in tensile strength is averagely attained as a whole, and the over all diaphragm is uniformly colored without showing any lattice pattern. The diaphragm includes a woven fabric comprising yarns made from a blend of a plurality of fibers wherein at least one of the plurality of fibers is PBO (poly(p-phenylene benzobisoxazole)) fiber.

Owner:RAKUTEN GRP INC

Processes for recycling carpet and products of such processes

Methods for the recycling of carpet are disclosed that produce clean face fiber suitable for industrial use. The methods allow the recovery of face fiber material, for example a polyester or a polyamide, from carpets that includes a face fiber material and a backing material, and include the steps of heating the carpet to a temperature lower than the melting point of the face fiber material, but higher than the initial thermal decomposition temperature of the backing material, for a time and at a temperature sufficient to thermally decompose, pyrolyze, or oxidize at least a portion of the backing material, rendering the backing material friable, that is more friable than the untreated backing; and applying mechanical force to the carpet so as to liberate the friable backing material from the face fiber material.

Owner:SHAW INDS GROUP

Process for making leather facing fabric suede and products made thereby

InactiveCN1632188AReduce wasteReasonable configurationFur mechanical treatmentMechanical treatmentFiberYarn

A processing technology of leather fiber fleece, its main feature is to select, color-separate and trim the leftover leather materials in different periods and add the required water, penetrant, slaked lime, softening treasure and ammonium sulfate in the drum equipment. Reverse-rotate brushing, dry and fluff the leather fiber fleece to become a leather fiber product, the fiber length of which is not less than 16 mm. The invention recycles the leftovers of the leather fiber into the leather fiber fleece through a scientific processing technology, so as to make the leather fiber fleece Fiber fleece is woven into cloth to meet the needs of industry and life.

Owner:苏立暖

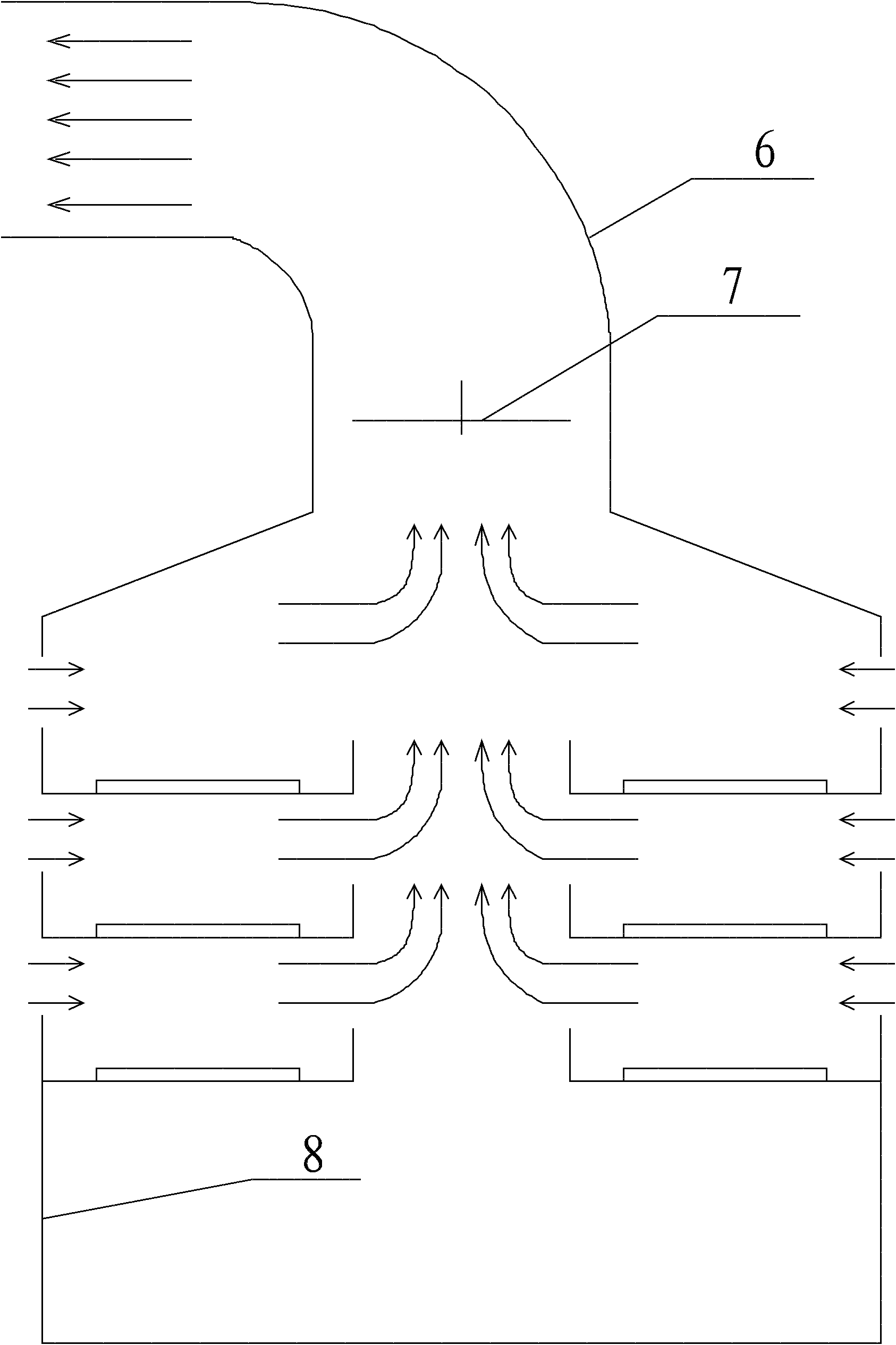

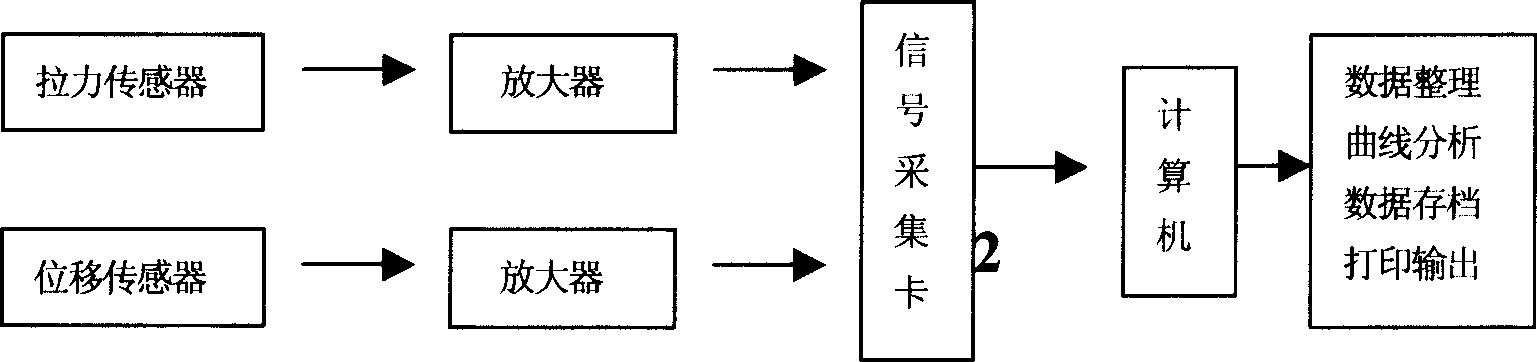

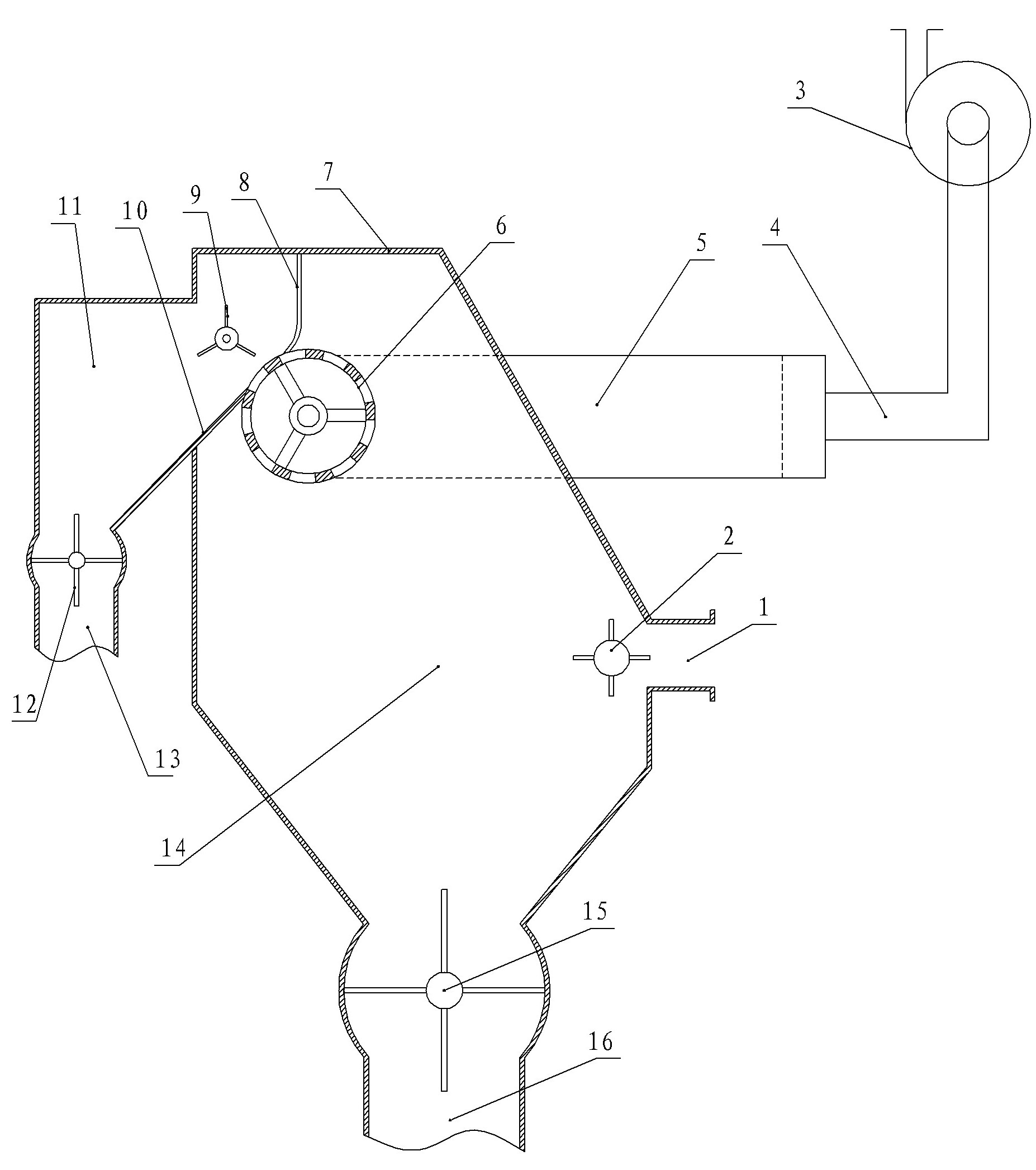

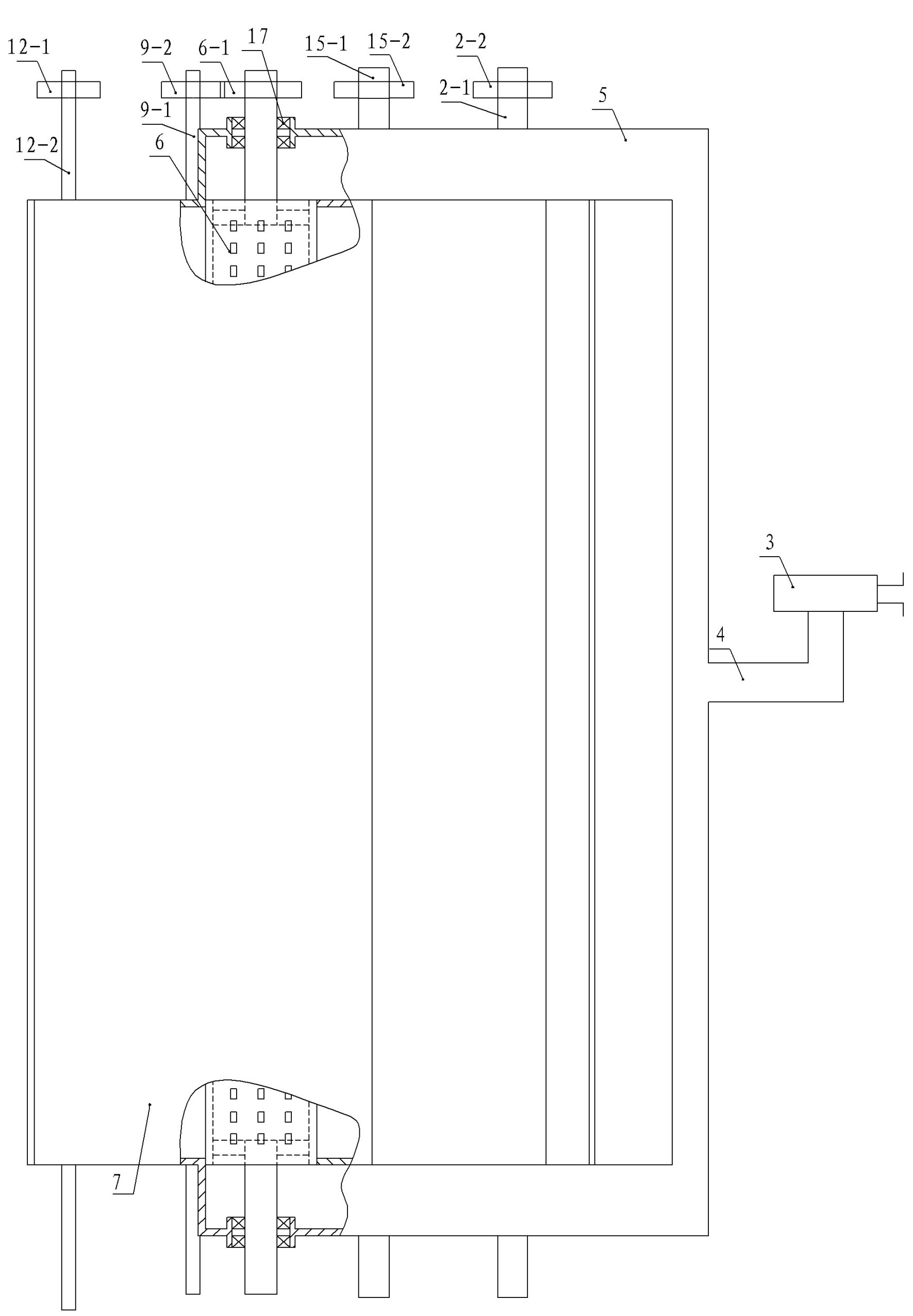

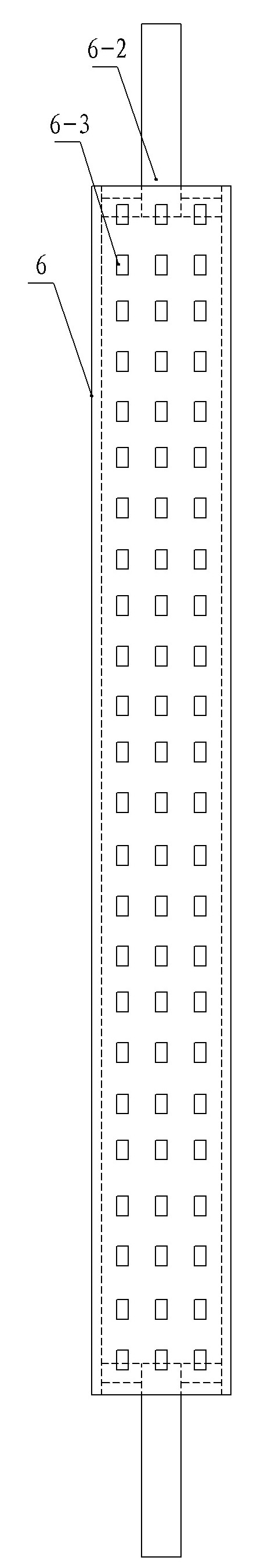

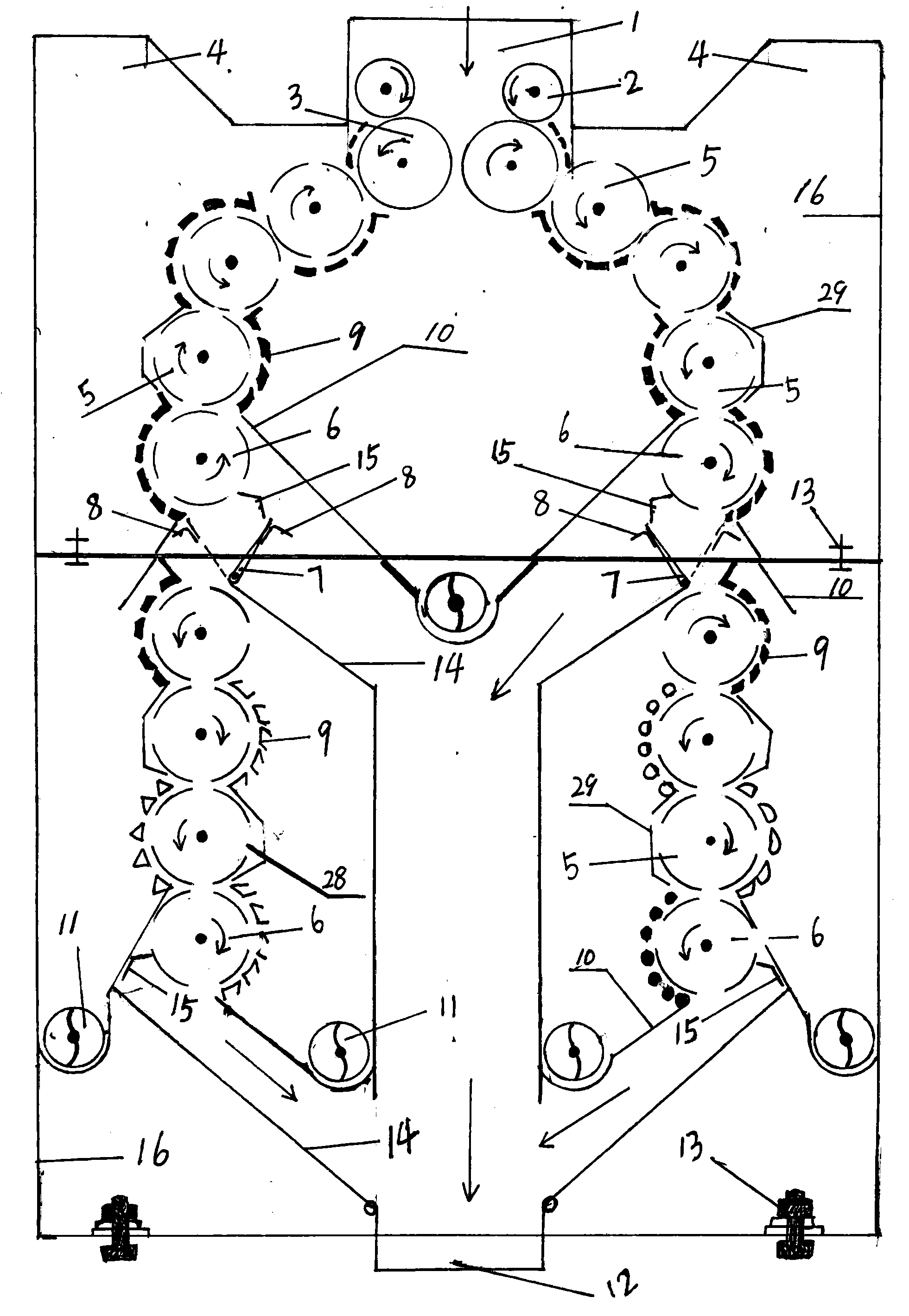

Full-automatic ultrasonic lint humidification system

InactiveCN102080267AReduce volumeEasy humidificationPackagingMechanical treatmentMicrocontrollerSolenoid valve

The invention provides a full-automatic ultrasonic lint humidification system, which consists of a frame, a humidifier, a mist exhaust fan, a mist outlet pipeline, an atomization area, a water tank and an electric control part, and is characterized in that: three layers of atomization area are arranged; an overflow pipe is arranged on the outer edge of each layer of atomization pot; a water measuring probe is arranged on a lower-layer overflow pipe; a water level probe, a heating pipe and a temperature sensor are arranged in the water tank; and the electric control part consists of a power circuit, a singlechip circuit, a control display circuit, a detection circuit for water level in the water tank, water temperature in the water tank, moisture regain of seed cotton, the number of cotton ginning machine benches, atomization pot overflow water, and total current for humidification, and a control circuit for a water inlet solenoid valve, atomized water heating, an electric pump for supplying atomized water, the mist exhaust fan, alarm and an ultrasonic atomization module. After the system is powered up, main technical parameters for system operation are detected by detection circuits, and are analyzed and processed by the singlechip, and a corresponding electric control part is started to work to control the system to normally operate. The system has the advantages of high automation degree, low energy consumption and uniform humidification.

Owner:HANDAN CHINA COTTON UNIS COTTON IND SCI & TECH

Method for drawing and modifying wool fibre

InactiveCN1916263ALiquid/gas/vapor textile treatmentMechanical treatmentPolymer scienceNatural fiber

The present invention relates to a wool fibre modification method, belonging to the field of natural fibre technology. Said method includes the following steps: preimpregnation treatment of wool fibre, twisting and drawing, heating and moistening, first setting, rinsing, secondary setting and drying so as to obtain high-count fine wool.

Owner:DALIAN POLYTECHNIC UNIVERSITY

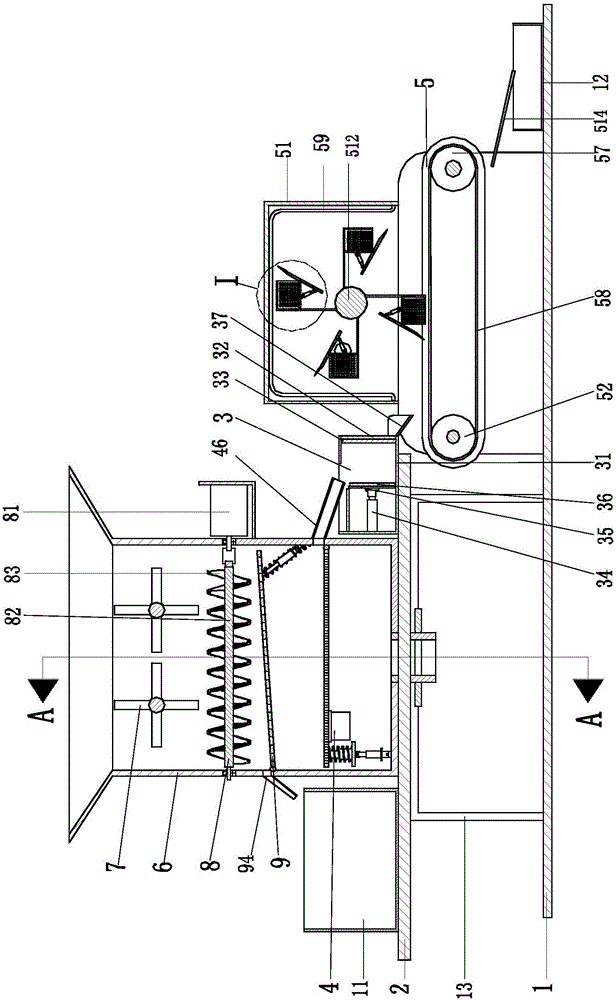

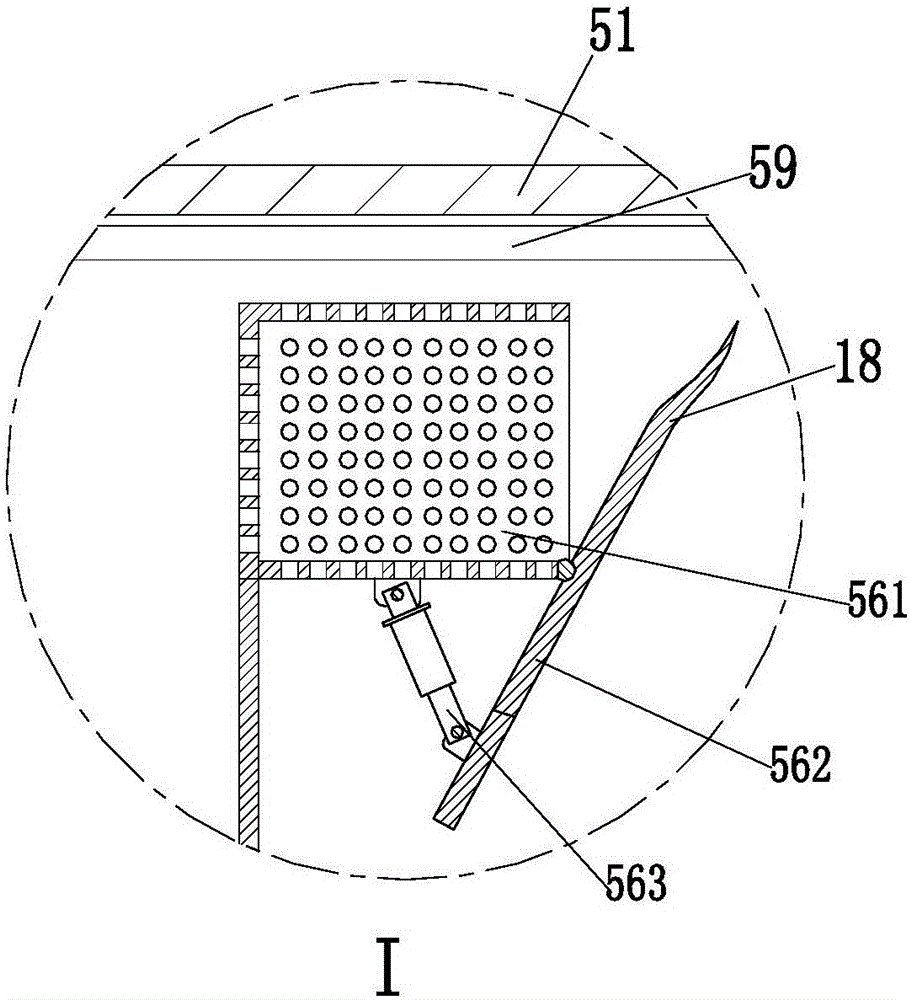

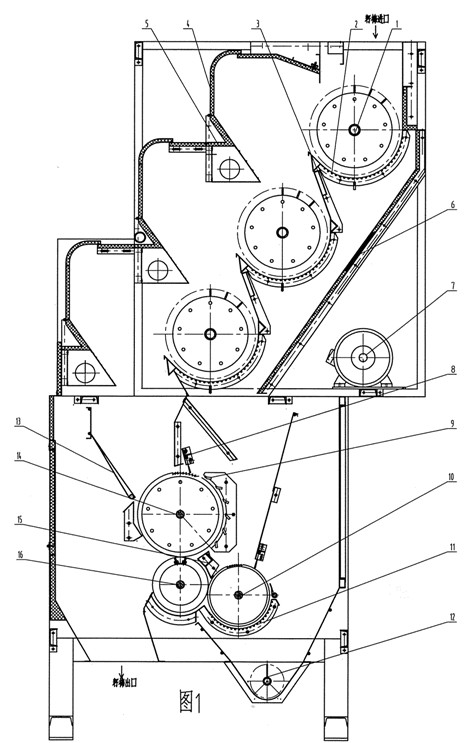

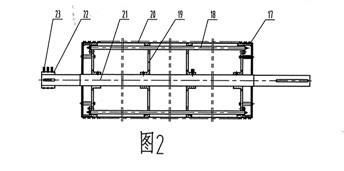

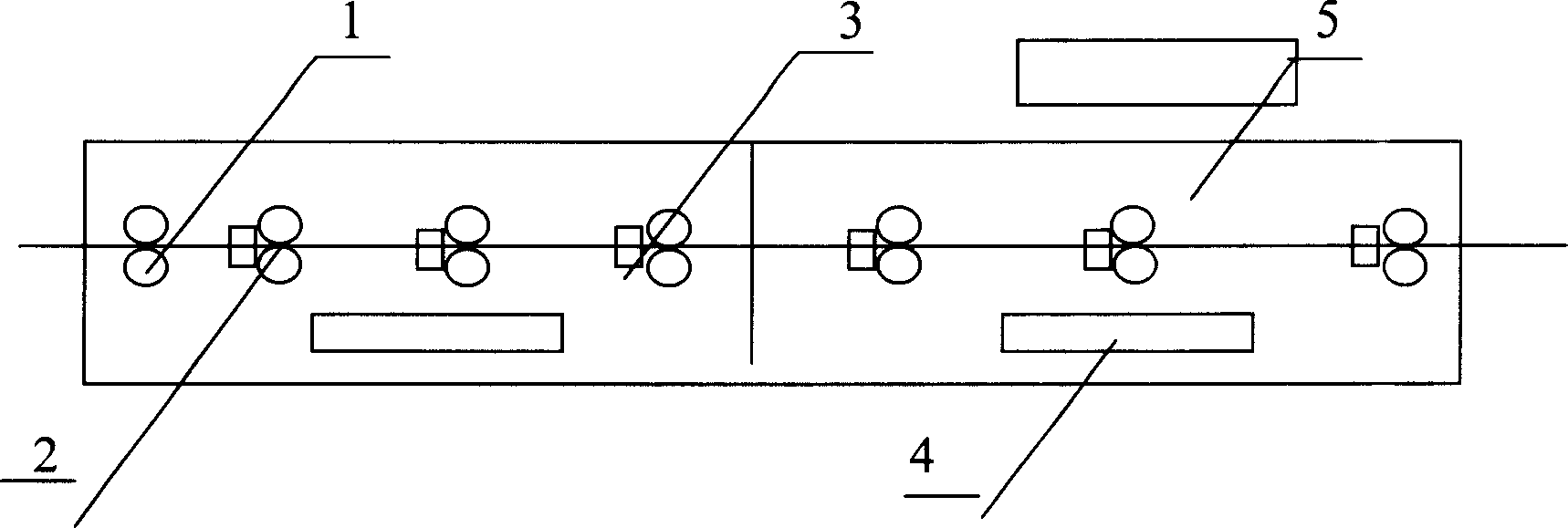

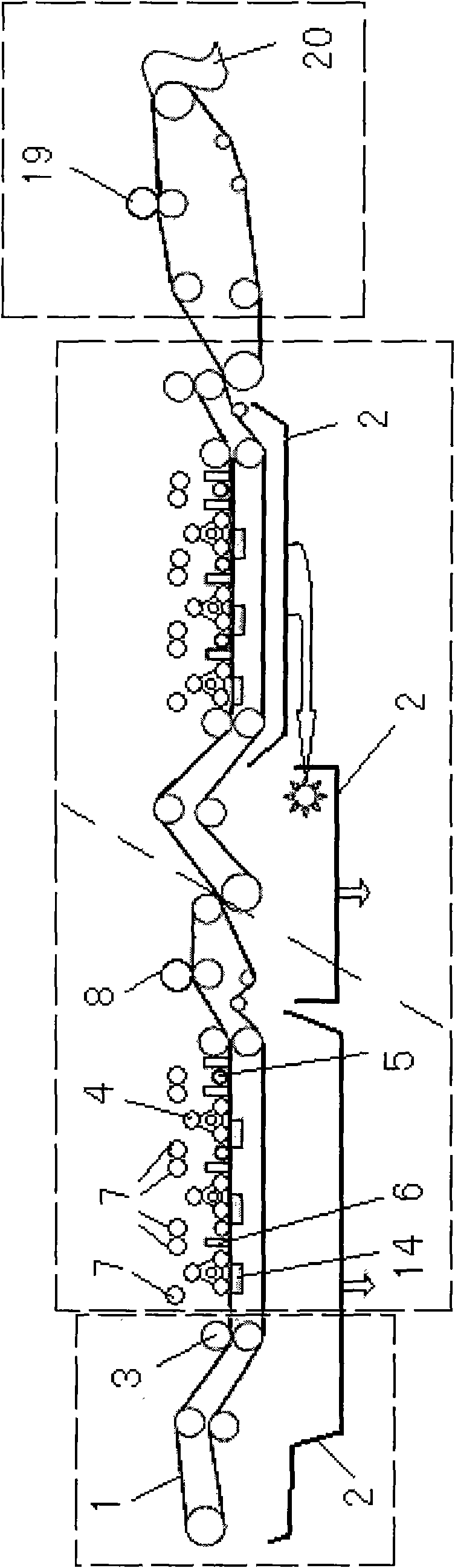

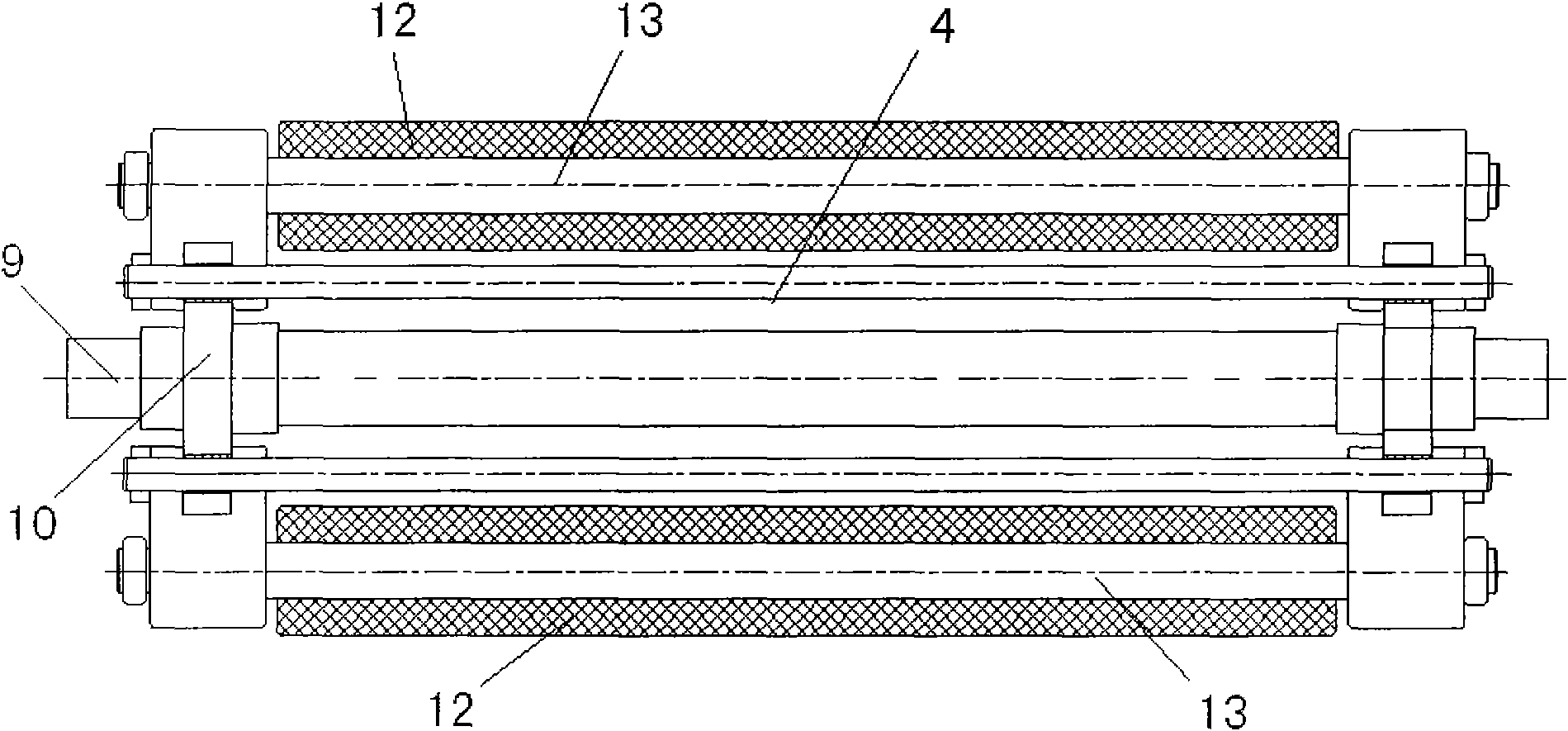

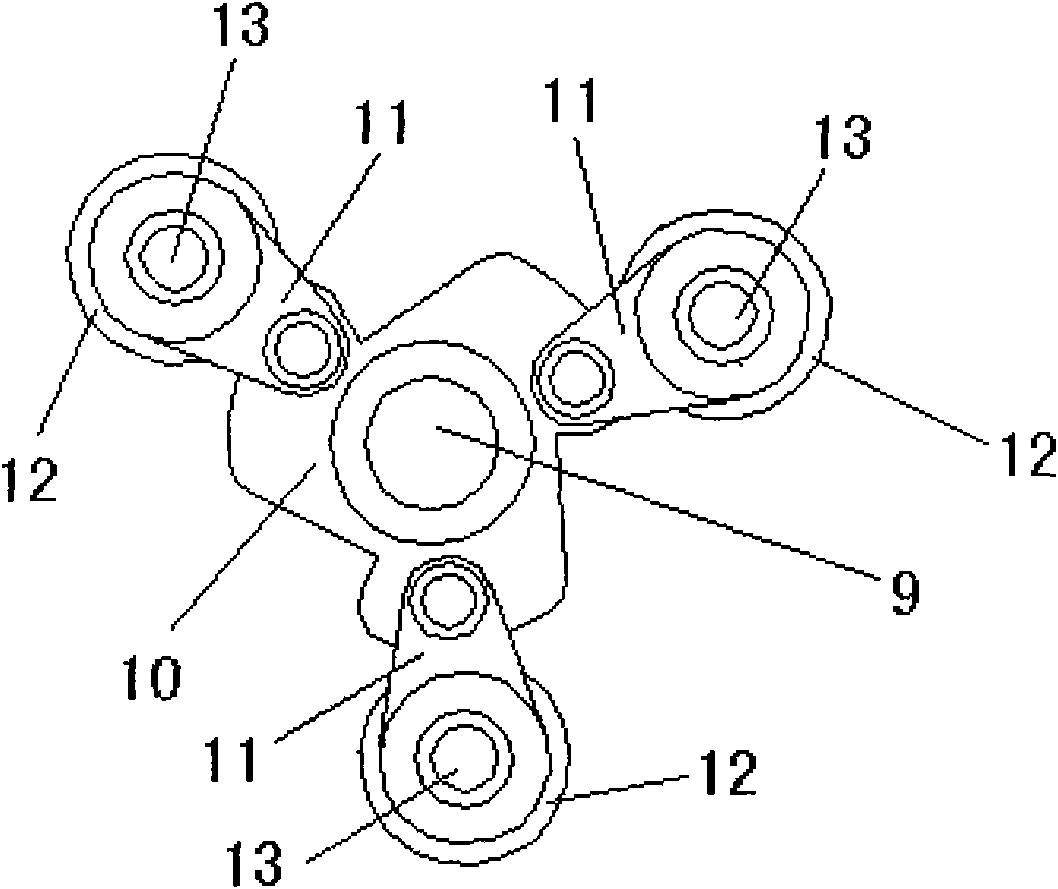

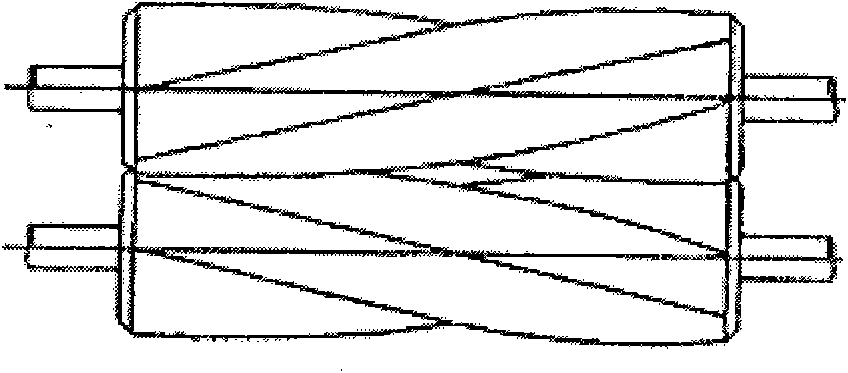

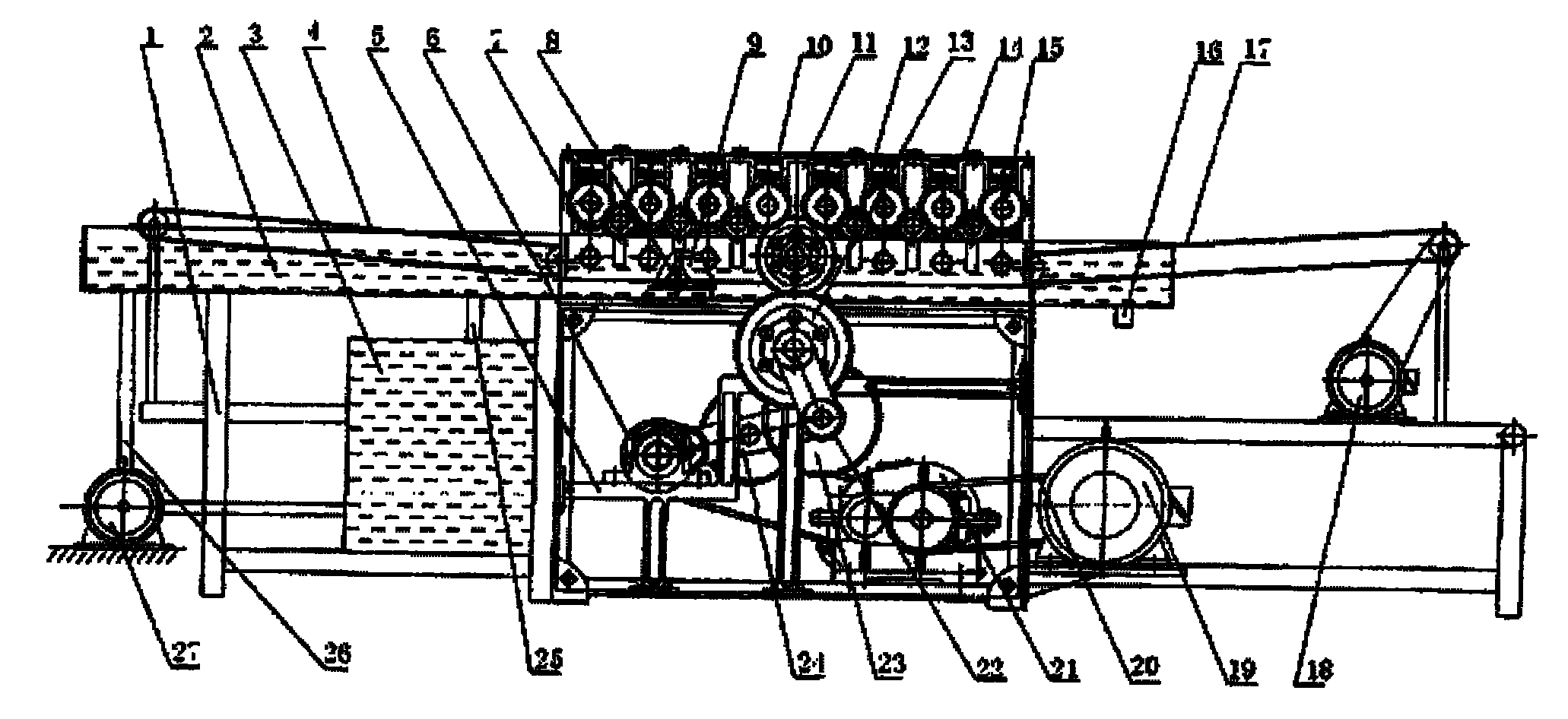

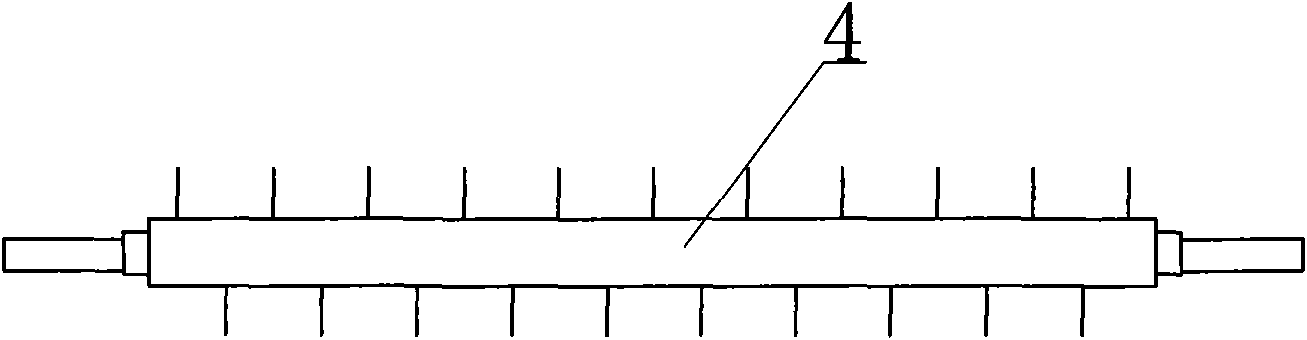

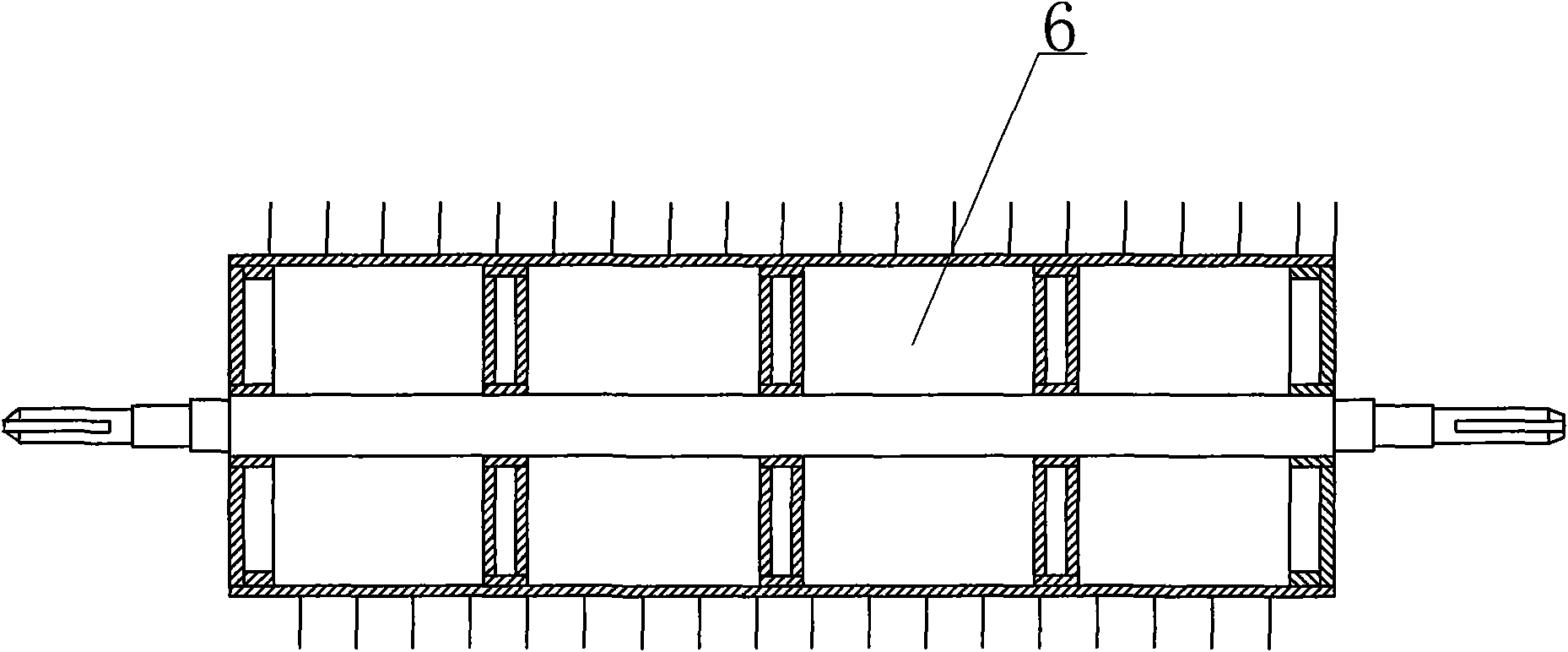

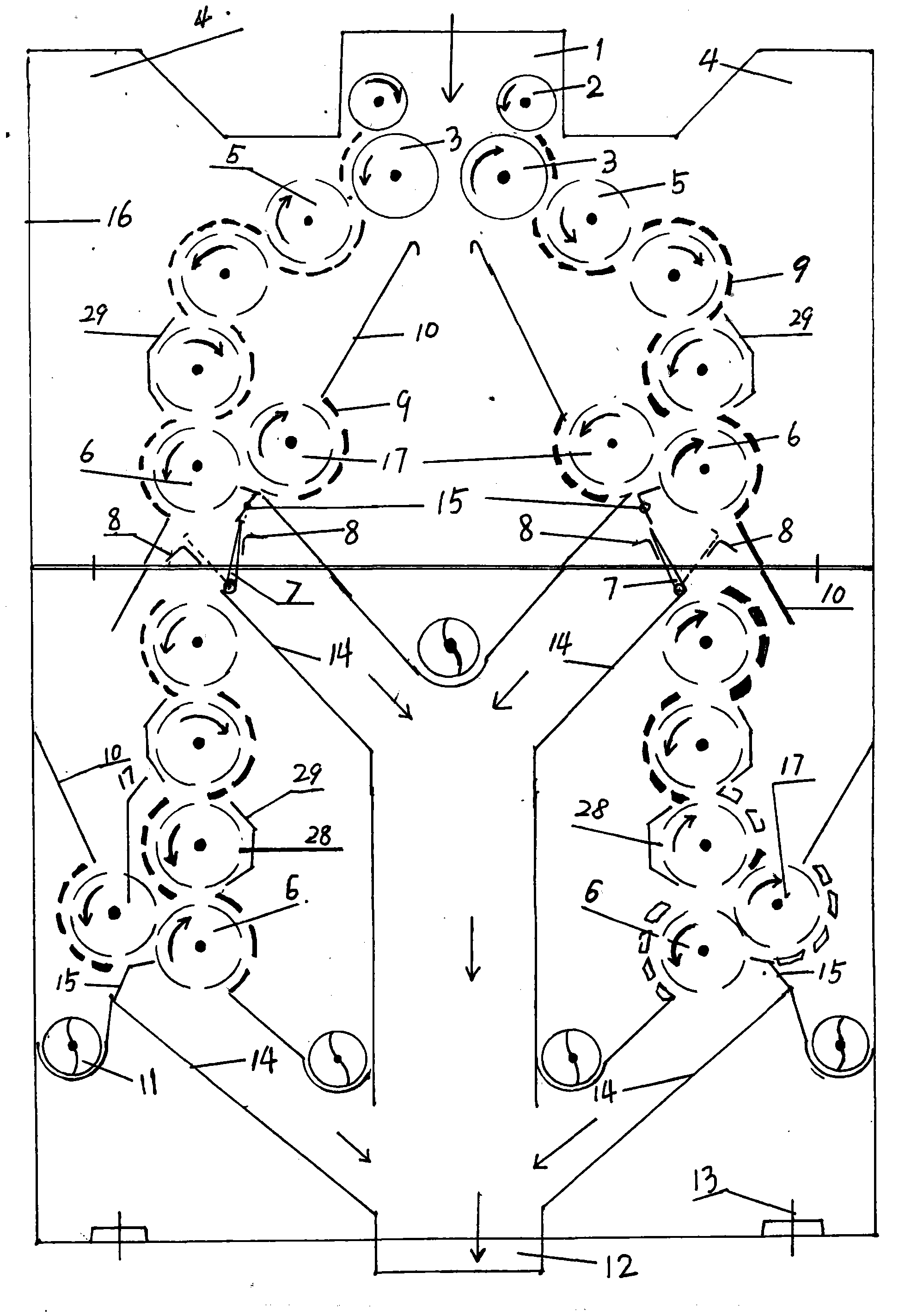

Fiber bundle dividing and washing method and device

ActiveCN101851789AGuaranteed cleanlinessHit evenlyMechanical treatmentFibre treatment to obtain bast fibreCardingFiber bundle

The invention relates to a fiber bundle dividing and washing method and a fiber bundle dividing and washing device. The method comprises the following steps of: 1) arranging a plurality of groups of fiber dividing and washing units and a fiber output unit on a frame, wherein each unit is provided with a running rotating crawler; 2) passing a feeding roller through a crawler input end of each fiber dividing and washing unit so as to convey the fiber bundle forward, making the fiber bundle enter a fiber dividing and washing area which is provided with a beater and a fiber dividing roller at intervals, simultaneously opening a high pressure water pipe which is arranged above the beater and the fiber dividing roller, and performing washing soaking, beating, carding and fiber dividing on the fiber bundle edges; 3) feeding the fiber treated by the previous fiber dividing and washing unit to the next fiber dividing and washing unit for continuous fiber dividing and washing; and 4) feeding the fiber treated by the last fiber dividing and washing unit into a fiber dividing input area, performing water squeezing operation through a squeezing roll, feeding the fiber into a cloth arrangement mechanism, arranging and folding the strip-shaped fiber through the cloth arrangement mechanism, and feeding the fiber into a fiber storage box. The fiber bundle dividing and washing method and the fiber bundle dividing and washing device can be widely applied to fiber dividing and washing treatment for various bast fibers, leaf fibers, and grass family fibers.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +3

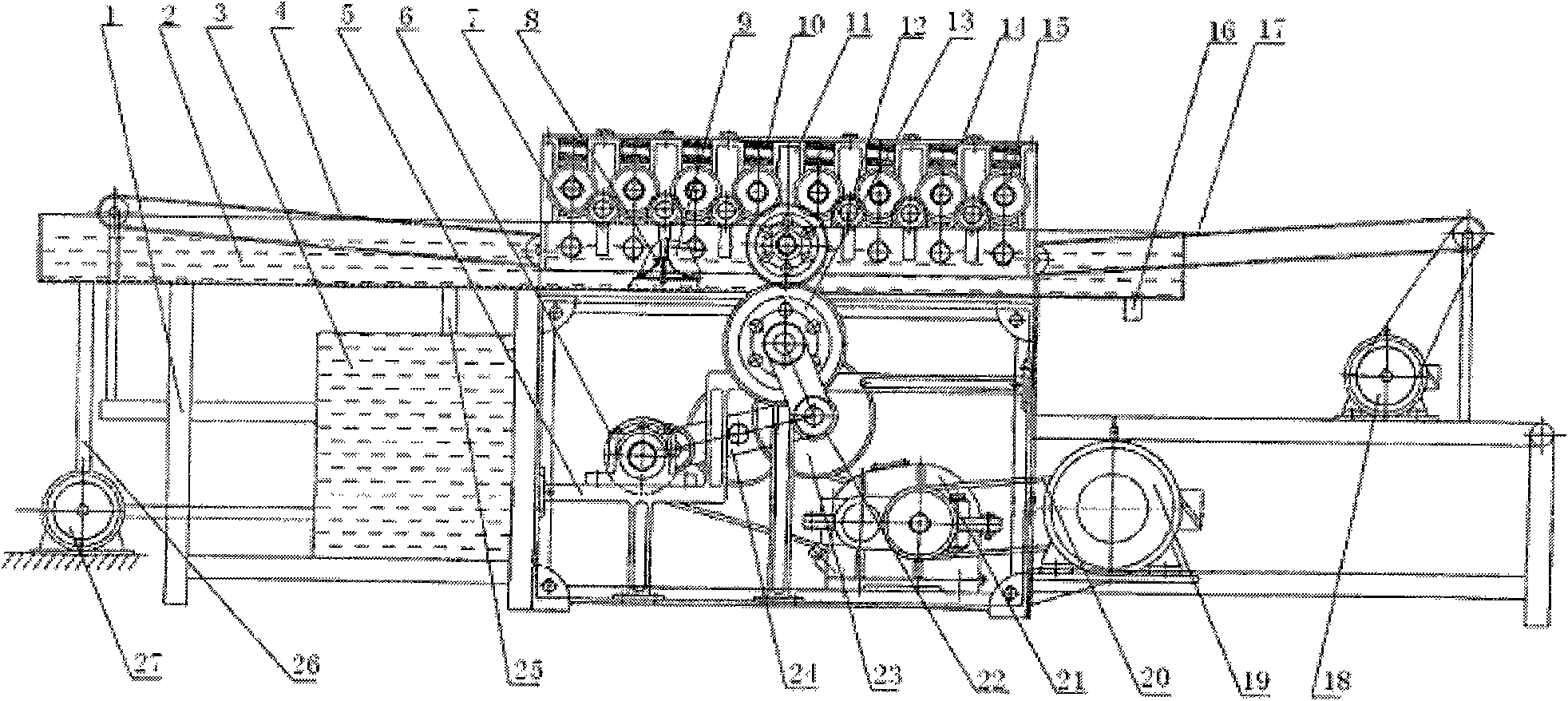

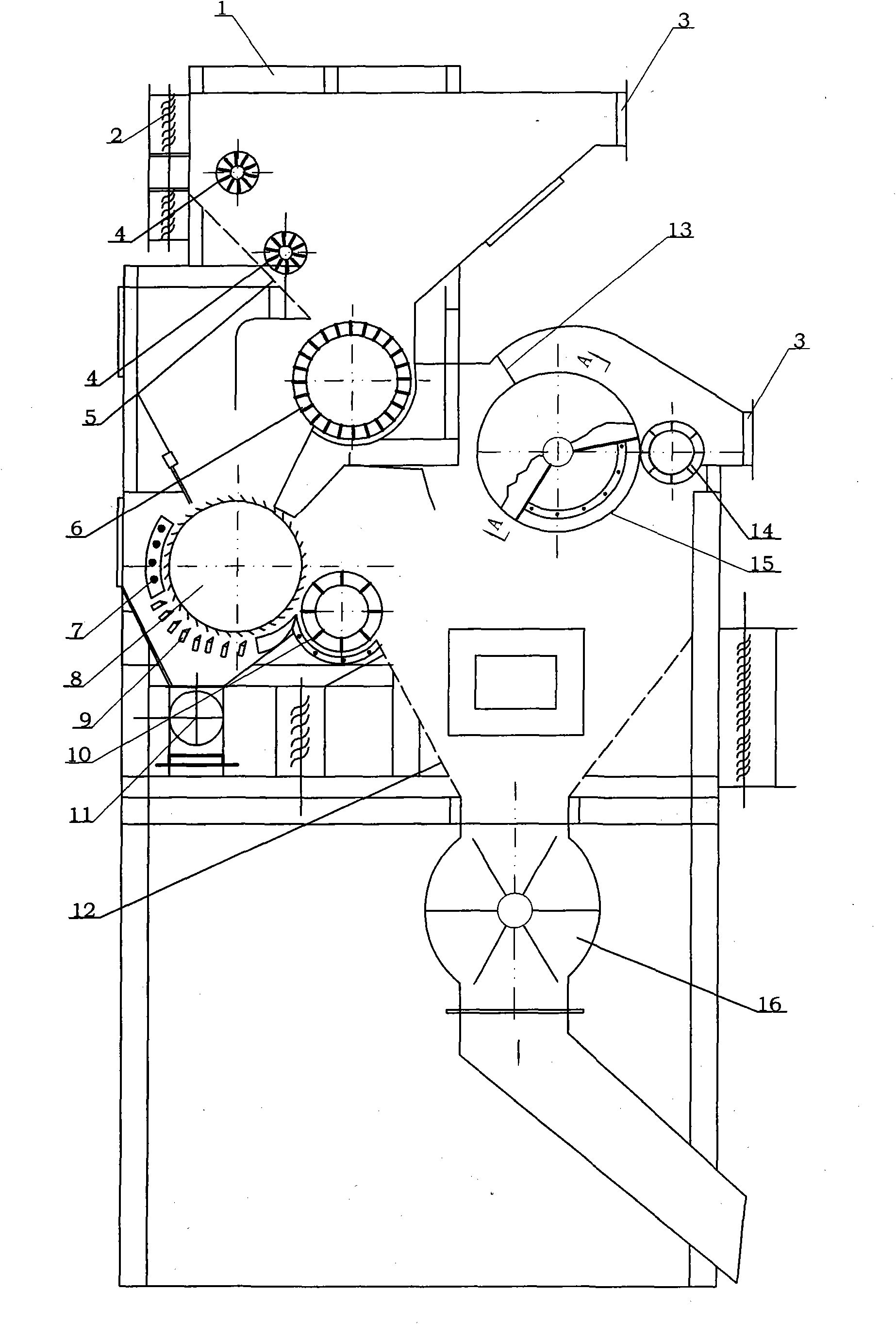

Washing dispersion machine of degummed ramie fiber

InactiveCN101775664ANo emissionsImprove work efficiencyMechanical treatmentWater dischargeMachine control

The invention relates to a washing dispersion machine of a degummed ramie fiber, which comprises feeding and outputting ramie curtain delivering mechanisms, a rolling and defibering mechanism, a roller driving mechanism, a washing diversion mechanism and a machine control system, wherein the feeding and outputting ramie curtain delivering mechanisms are respectively arranged at the head end and the tail end of the rolling and defibering mechanism. The washing dispersion machine has the advantages of high working efficiency, water circulation recycling, no waste water discharge (deslagging by using little amount of water during cleaning equipment), cleanness of ramie, no damage to the ramie and low working noise.

Owner:湖南润久科技有限公司

Distributary seed cotton foreign fiber capturing cleaner

InactiveCN101597803AEfficient exclusionReasonable structural designFibre separationMechanical treatmentFiberEngineering

The invention belongs to a mechanism for removing impurities in seed cotton, in particular to a distributary seed cotton foreign fiber capturing cleaner. In a first-grade cleaning chamber, two winding rollers are arranged on an inclined lateral wall formed by an air inlet screen plate; a feeding hole of a second-stage cleaning chamber connected with the first-grade cleaning chamber is provided with a barbed nail roller of which one lateral roller surface is matched with the inner wall of the second-stage cleaning chamber; a trash outlet of the barbed nail roller is provided with a sawtooth roller of which the roller surface is evenly distributed with sawteeth; one side of the sawtooth roller is sequentially provided with a trash grid rod and a trash grid plate which are matched with the sawtooth roller, and the other side of the sawtooth roller is provided with a cotton brushing roller; two lateral walls of a third-stage cleaning chamber connected with the second-stage cleaning chamber is formed by an air inlet mesh screen plate; a foreign light fiber separating roller is arranged at the upper part of the third-stage cleaning chamber; an airflow baffle is arranged at the upper part of the separating roller; the cotton brushing roller arranged at an air outlet of third-stage cleaning chamber is matched with the separating roller; and a discharging hole of the third-stage cleaning chamber is provided with a star stripper. The invention can effectively remove various foreign fibers and impurities mixed in the seed cotton, improve the quality and the grade of ginned cotton and achieve high production efficiency.

Owner:王礼华

Device for cleaning profile fibers of negative-pressure seed cotton

InactiveCN102212889AAvoid secondary mixingAvoid intercommunicationMechanical treatmentFiberBrush device

The invention discloses a device for cleaning profile fibers of negative-pressure seed cotton. The device for cleaning the profile fibers comprises a shell. The interior of the shell is divided into a separating area and a profile fiber collecting area; a feeding port and a discharging hole are connected at the separating area, and an impurity discharging hole is connected at the profile fiber collecting area; wind stopping devices are arranged at the discharging hole and the impurity discharging hole respectively, and an opening and casting roll is arranged at the feeding port; a long-hole dust cage is arranged at the communicating position of the separating area and the profile fiber collecting area, an air hose communicated with the end part of the shell is arranged outside the shell, and a draught fan is connected at the air hose end; and a baffle plate which is approximately tangent to the long-hole dust cage is arranged in the shell, and an impurity brushing device is arranged in the profile fiber collecting area close to the long-hole dust cage. The long-hole dust cage is arranged in the shell of the profile fiber cleaning device, therefore, small profile fibers in the seed cotton can be winnowed by strong negative-pressure wind, the light and small profile fibers are absorbed into a rotary drum and discharged out through an exhausting pipe, a local strong wind area is formed on the surface of the long-hole dust cage through the impurity brushing device when in air separation, and large profile fibers absorbed on the surface of the long-hole dust cage are blown away and collected and discharged through the special separating area so as to prevent the profile fibers from being mixed in cotton secondarily.

Owner:张连军

Seed cotton cleaner

The invention provides a seed cotton cleaner, and belongs to cotton processing machines. The seed cotton cleaner is characterized in that a cylinder structure, a machine frame structure, a distribution angle and the steering direction in the prior art are changed, the cleaning length is lengthened, a diversion roller, a process adjusting plate and a side air inlet device are additionally arranged, and according to design, process and technology requirements, a recovery roller and a brushing roller, a fan and an air feed pipeline, a hot air pipeline network and an air amount adjusting device are selectively arranged. Automatic cotton feeding, cleaning and drying are integrated, most of impurities in seed cotton can be cleaned through one-time cotton cleaning, the seed cotton after being cleaned is good in appearance, cotton loss is little, generation of neps and cotton yarn is greatly reduced, and the seed cotton which is proper for processing is provided for follow-up procedures. The seed cotton cleaner is suitable for impurity cleaning and processing of mechanical cotton picking, quick manual cotton picking, hand cotton picking and cotton by-products. On the condition that an existing cylinder structure is not changed, only the distribution angle and the steering direction of a cylinder are changed, and a certain cleaning effect can be achieved.

Owner:李通

Treating process of kapok fiber for producing non-woven sanitary material

InactiveCN1888152AAvoid damageIncrease the lengthCarding machinesBleaching apparatusKapok fiberSoftening

The present invention discloses treating process of kapok fiber for producing non-woven sanitary material. The treating process includes the following steps: opening kapok fiber material in a cotton opening and cleaning system, depurating, making lap, carding into web, boiling, defatting and bleaching, softening, water washing, neutralizing, spun drying, stoving and baling. The kapok fiber is soft, high in adsorbability, and suitable for producing sanitary material.

Owner:XINLONG HLDG GROUP

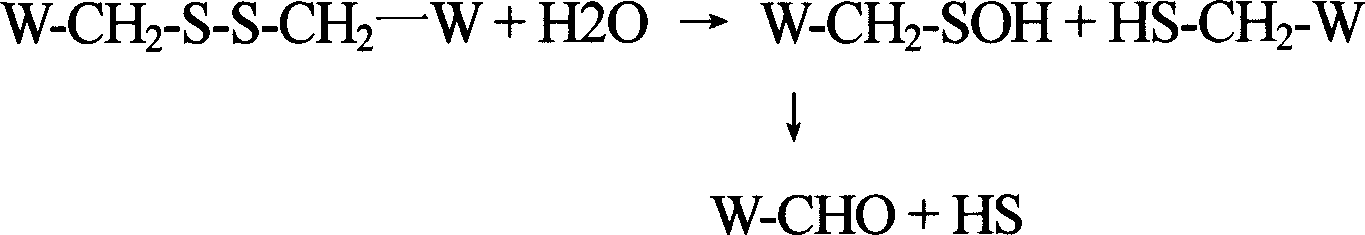

Flash-explosion hemp degelatinizing technology with cryogenic processing and device

InactiveCN101255609AAvoid damageAchieve primary separationMechanical treatmentFibre treatment to obtain bast fibreEngineeringHigh pressure

The invention relates to a hemp degumming technology using a steam explosion with a low-temperature treatment and a device. The invention relatest to the hemp degumming technology, in particular to the steam explosion hemp degumming technology, comprising: firstly ramie is marinated for 15 hours in the temperature of 25 deg C; then the ramie which is already marinated by water is put into a groove which contains a solution of NaOH with a concentration of 18 percent to be processed alkali treatment; then the ramie is kept in high pressure; after being kept in high pressure the hemp fiber is processed a decompression steam explosion treatment with the low-temperature treatment. The hemp degumming technology of the invention has the advantages of that a low rate of incomplete glue, light fibre damage, no pollution, reducing cost of degumming, saving degumming time.

Owner:LANYAN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com