Patents

Literature

80results about "Fur mechanical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecofriendly bio-process for leather processing

The present invention relates to an eco-friendly beam house process for de-hairing of leather using commercially available enzymes that obviates the use of lime and other alkalis. The present invention also provides an alternate process for opening the fibers of leather using commercially available enzymes. The present invention further provides a three-step process for tanning hide or skin in a narrow pH range of from about 7.5 to about 8.5.

Owner:COUNCIL OF SCI & IND RES

Process for making leather facing fabric suede and products made thereby

InactiveCN1632188AReduce wasteReasonable configurationFur mechanical treatmentMechanical treatmentFiberYarn

A processing technology of leather fiber fleece, its main feature is to select, color-separate and trim the leftover leather materials in different periods and add the required water, penetrant, slaked lime, softening treasure and ammonium sulfate in the drum equipment. Reverse-rotate brushing, dry and fluff the leather fiber fleece to become a leather fiber product, the fiber length of which is not less than 16 mm. The invention recycles the leftovers of the leather fiber into the leather fiber fleece through a scientific processing technology, so as to make the leather fiber fleece Fiber fleece is woven into cloth to meet the needs of industry and life.

Owner:苏立暖

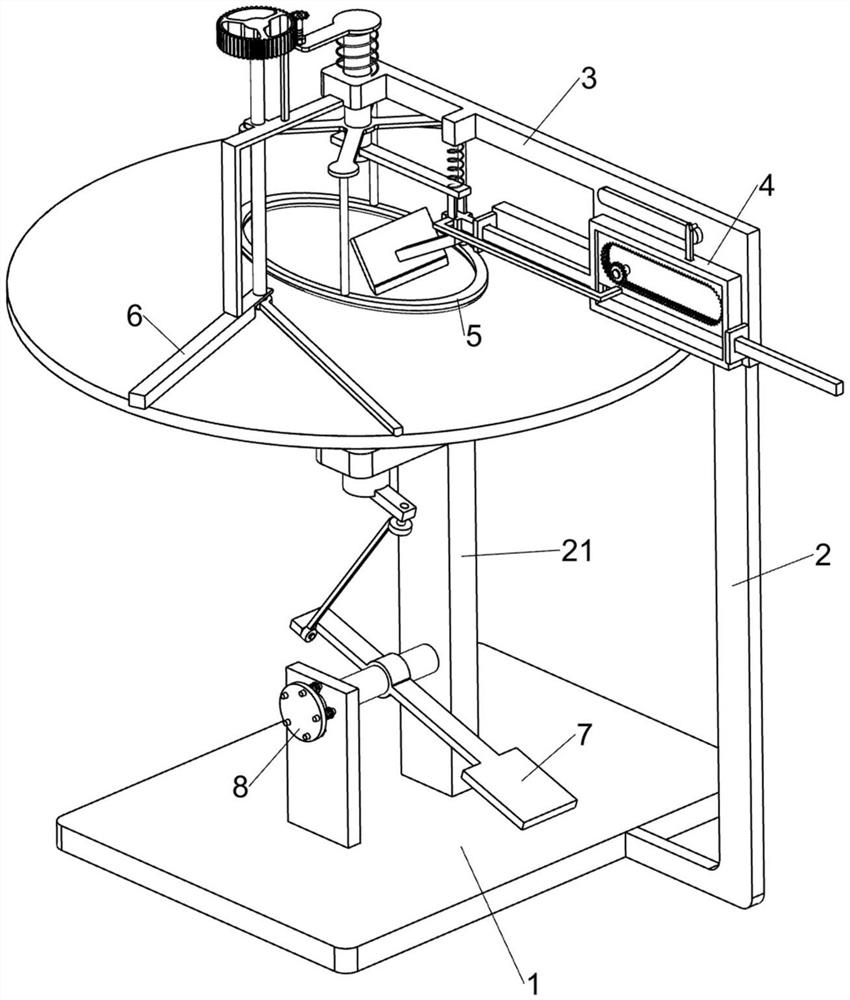

Fur grinding device for fur processing

ActiveCN109055623AQuality improvementImprove efficiencyLeather manufacturingFur mechanical treatmentEngineeringGrinding wheel

The invention discloses a fur grinding device for fur processing, and relates to the technical field of fur processing application. The fur grinding device comprises a bottom plate, a fixing platform,a fixing mechanism, a fur grinding mechanism, a separating mechanism, a first fixing plate, a second fixing plate, a connecting rod, a first cylinder, a protruding block, a bracket, a compression roller, a servo motor, a second cylinder, a transmission motor, a grinding wheel, a lead screw, a first slider, a bearing block, a telescopic rod, a fixing frame, a connecting frame, a second slider, a first sliding bar, a baffle, a chute, a chute, a second sliding bar, a shovel plate, a connecting plate and a storage box. The fur grinding device has the beneficial effects that the separating mechanism is arranged on the fur grinding mechanism, and therefore the baffle on the separating mechanism can scrape fat and residual meat attached to fur from the fur, the shovel plate movably connected with the baffle is used, the fat and the residual meat accumulated on the side wall of the baffle can be sent to the storage box for centralized collection and storage, the problem that the chippings generated by the fur grinding are difficult to be collect and process is solved, and the fur grinding efficiency is effectively improved.

Owner:JIASHAN SHENGLAISI CASHMERE

Production process for new donkey-hide glue

InactiveCN106176814AImprove qualityReasonable process designLeather manufacturingLeather clicking/perforating/clickingSkin blanchingHigh fat

The invention discloses a production process for new donkey-hide glue. The production process mainly comprises the following steps: selection of dried pig skin, soaking, processing, cutting, washing, skin blanching, extraction, centrifugal concentration, oil extraction, charging, condensation, glue cutting and glue airing. According to the process, a flow is reasonable in design, and oil extraction processing is performed for the characteristic of relatively higher fat content of the pig skin; a specific process parameter is set according to the component characteristic of the pig skin, so that the process is high in adaptability to different types of pig skin as well as glue yield, and the obtained new donkey-hide glue is high in quality.

Owner:山东福牌阿胶股份有限公司

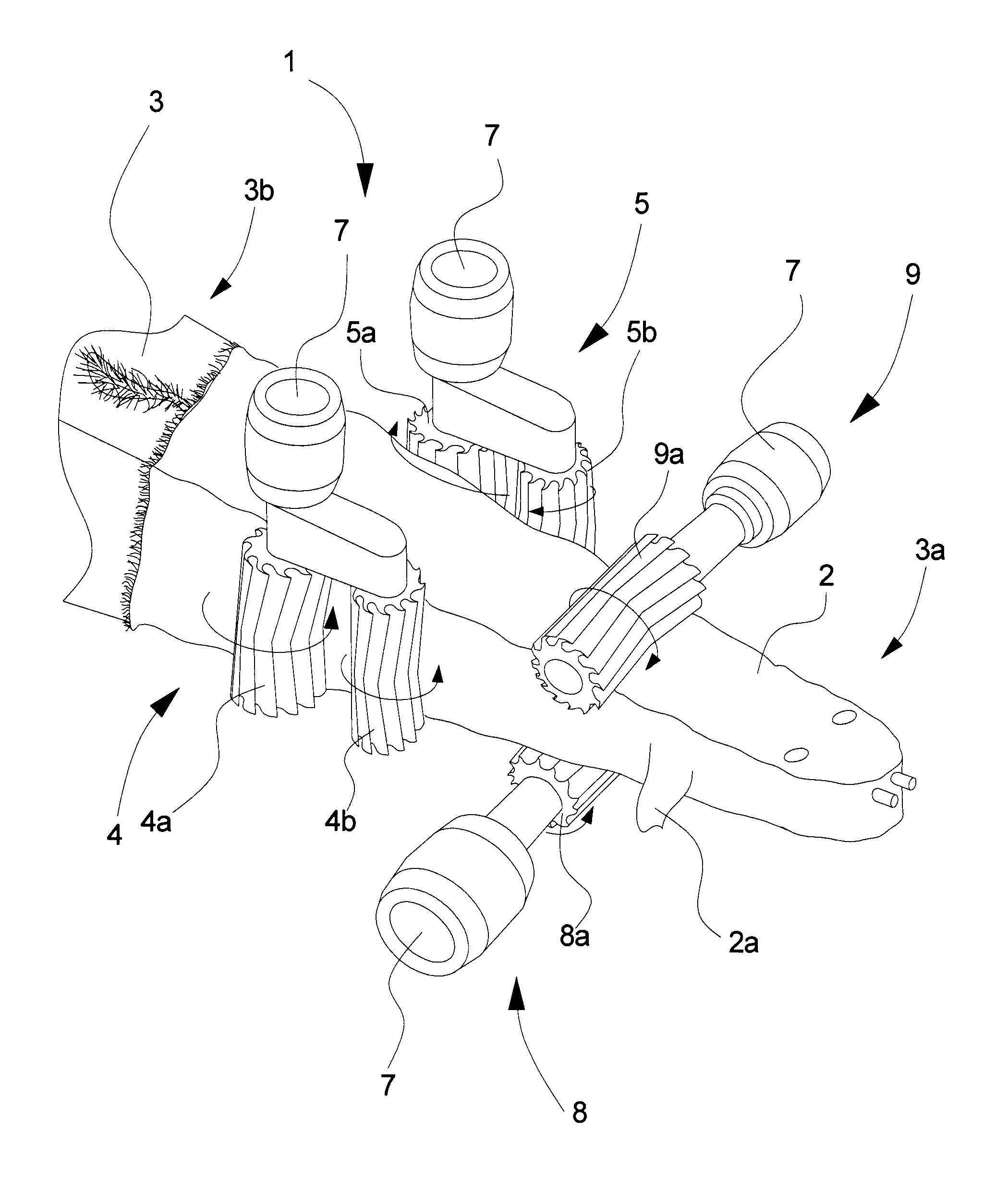

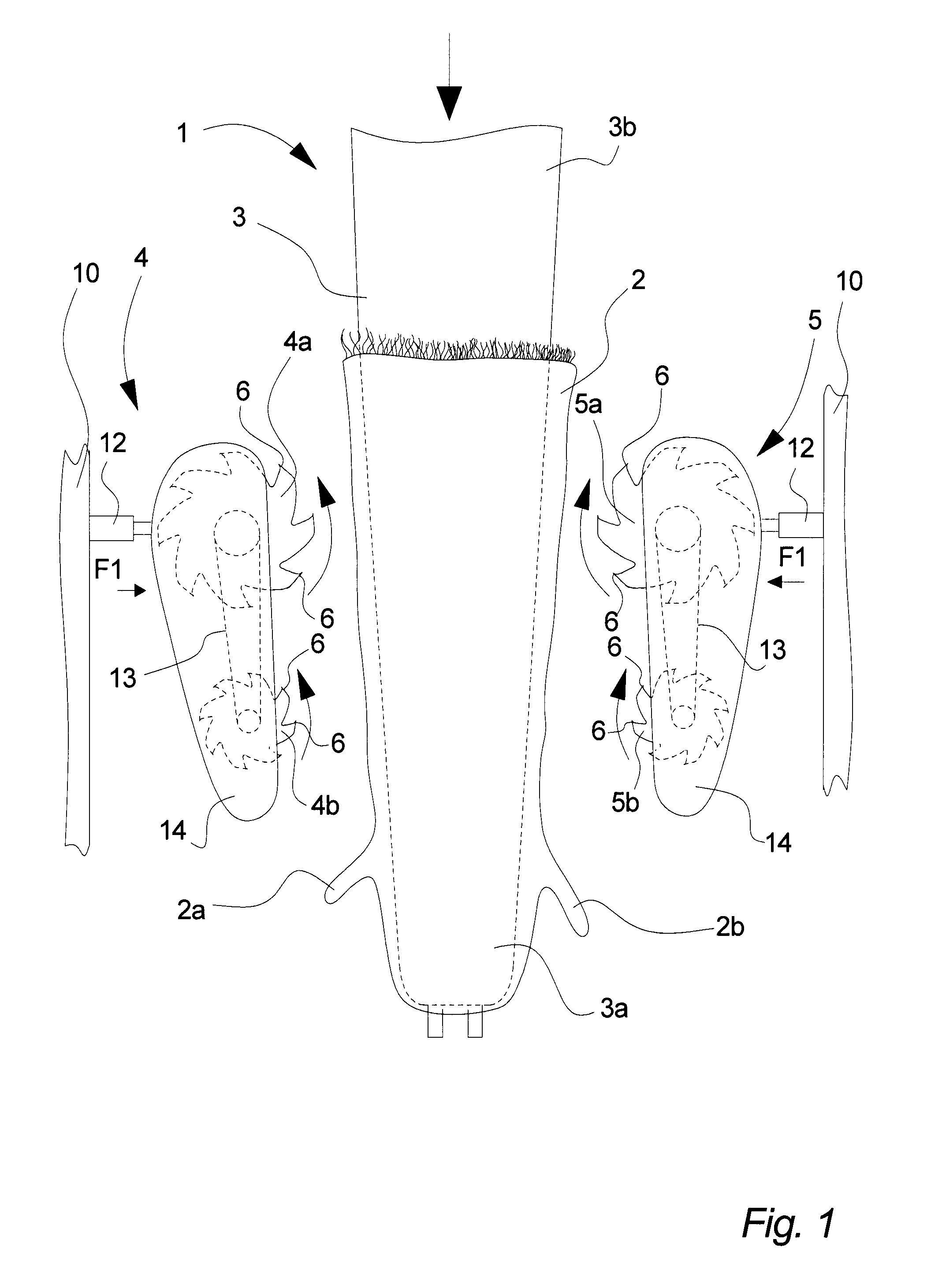

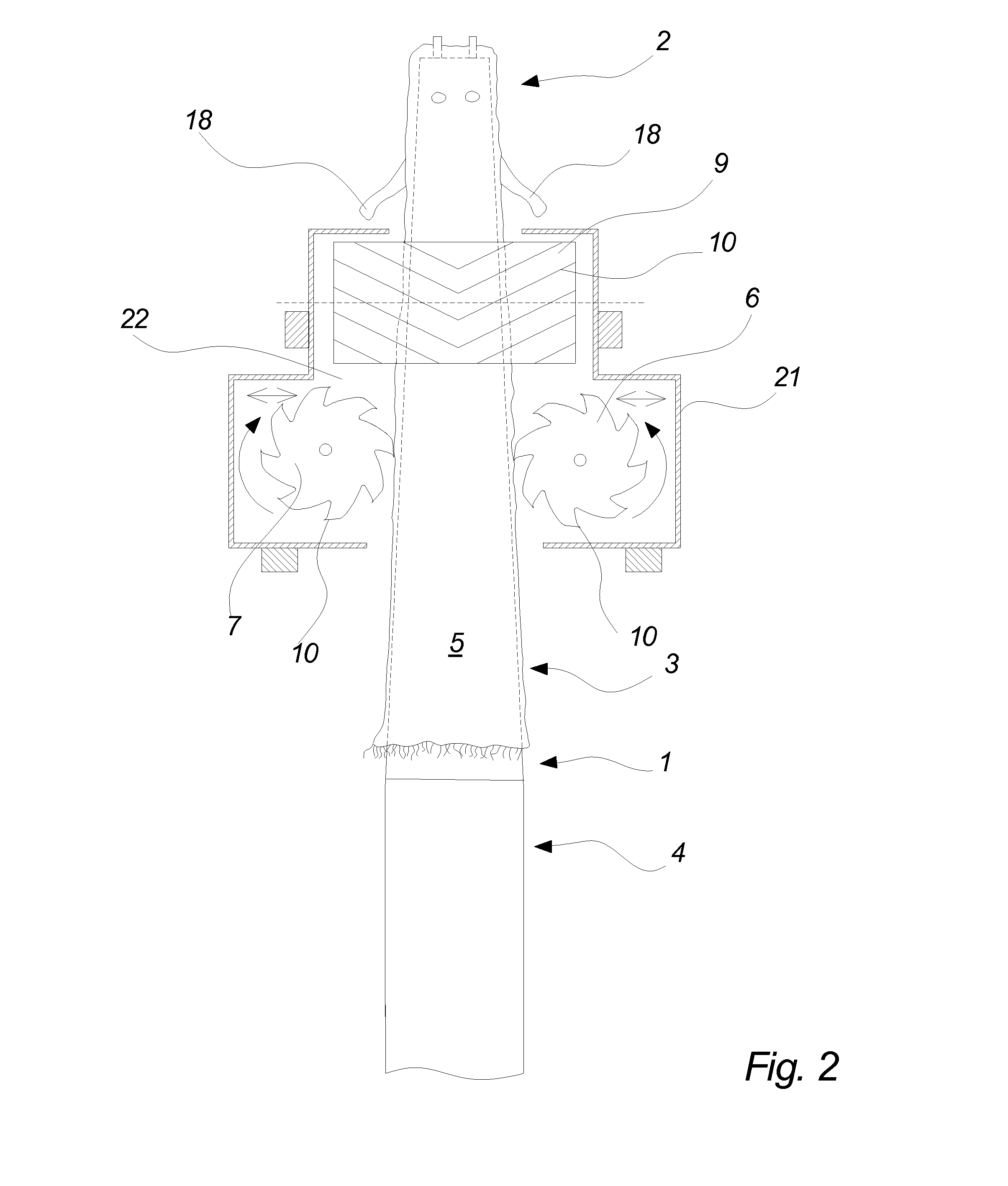

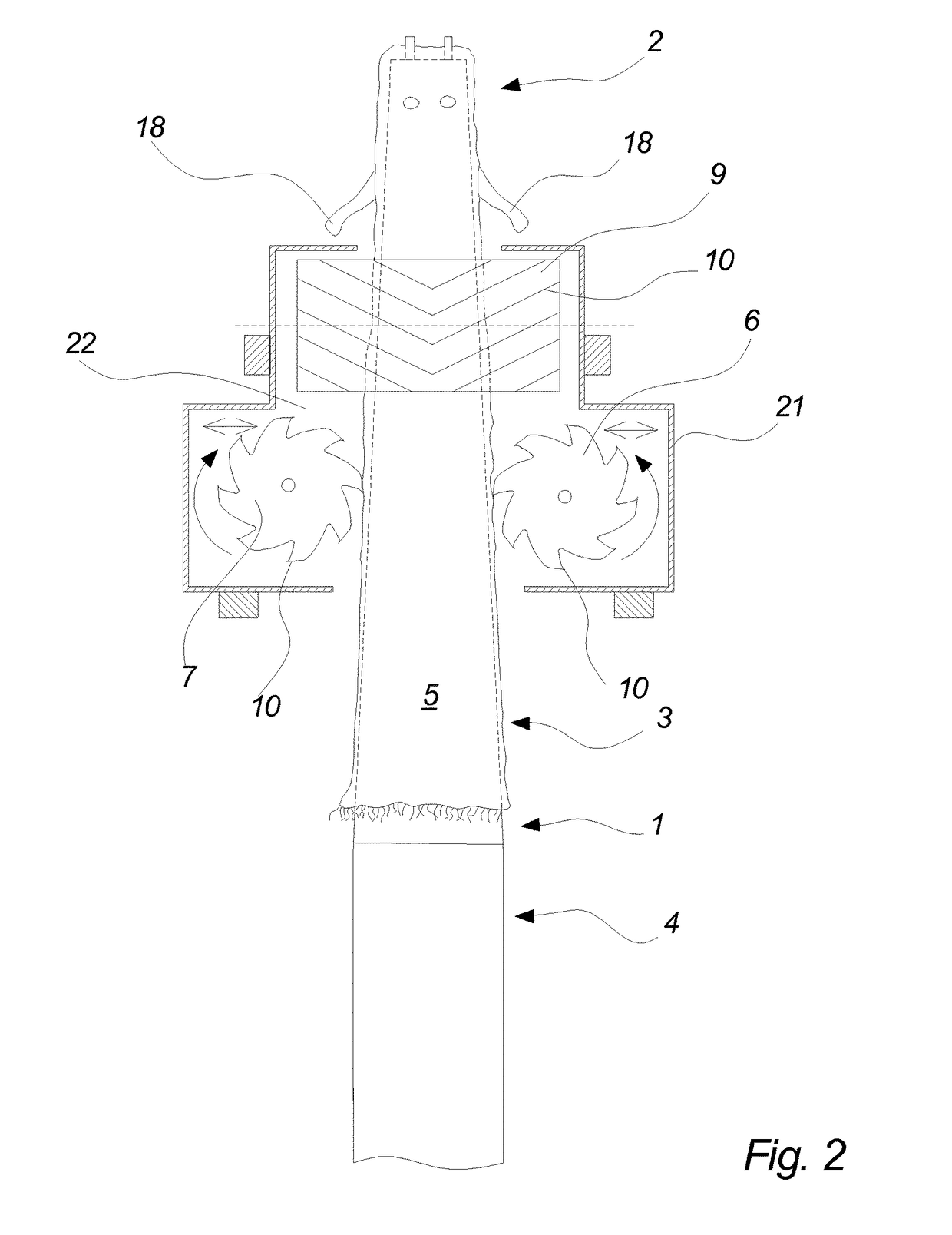

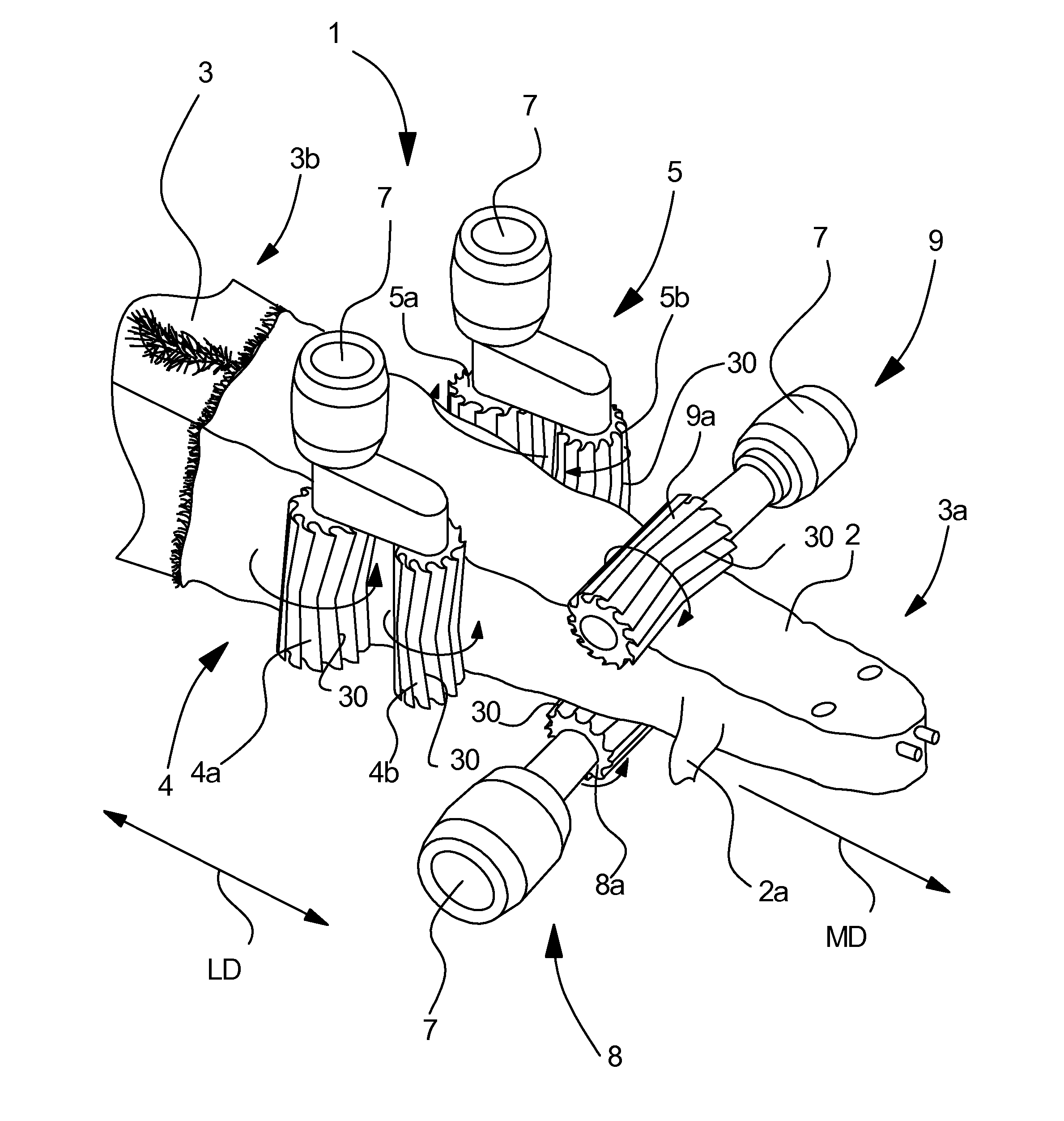

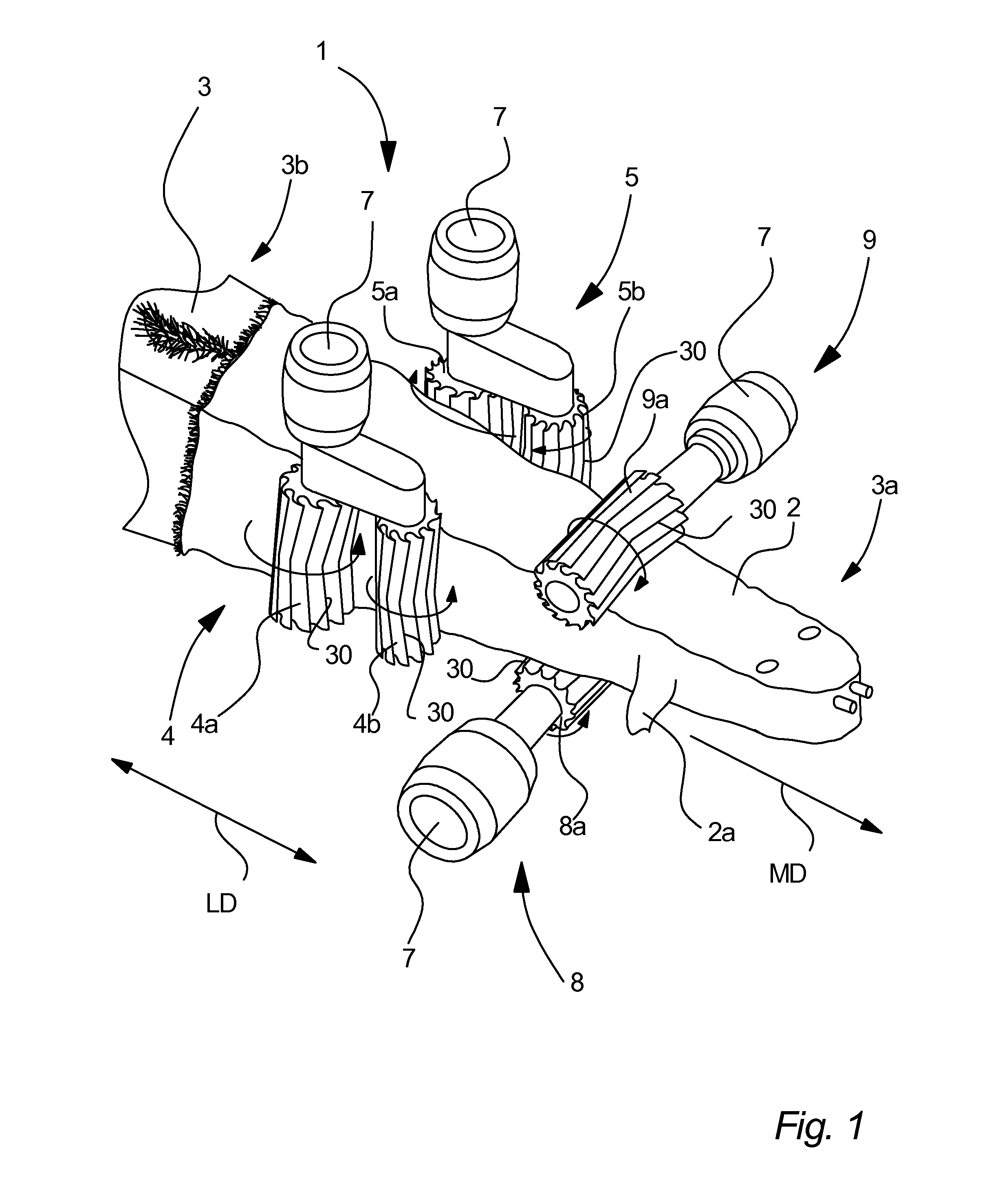

Apparatus for processing fur

InactiveUS20130139559A1Leather manufacturingFur mechanical treatmentContact pressureBiomedical engineering

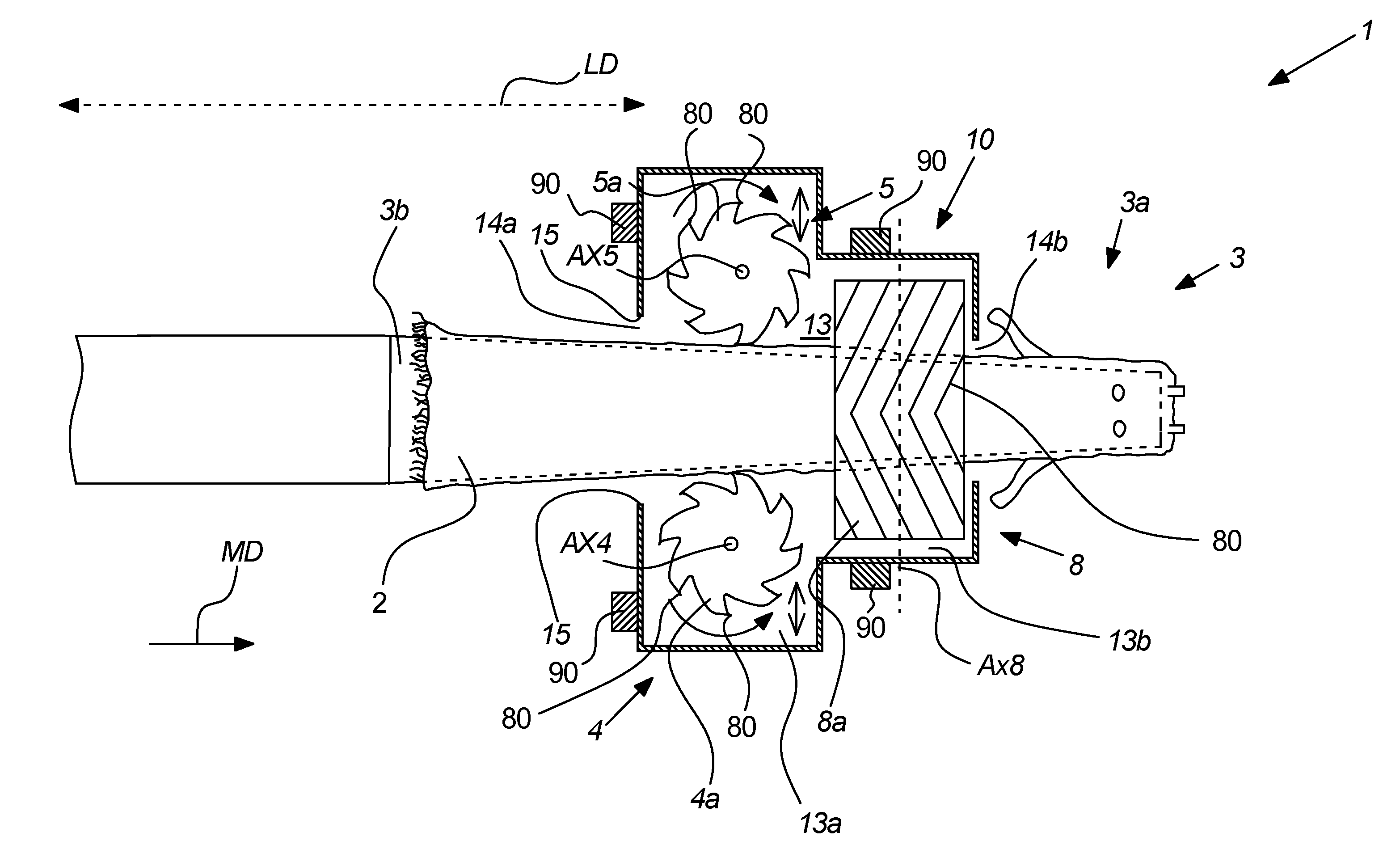

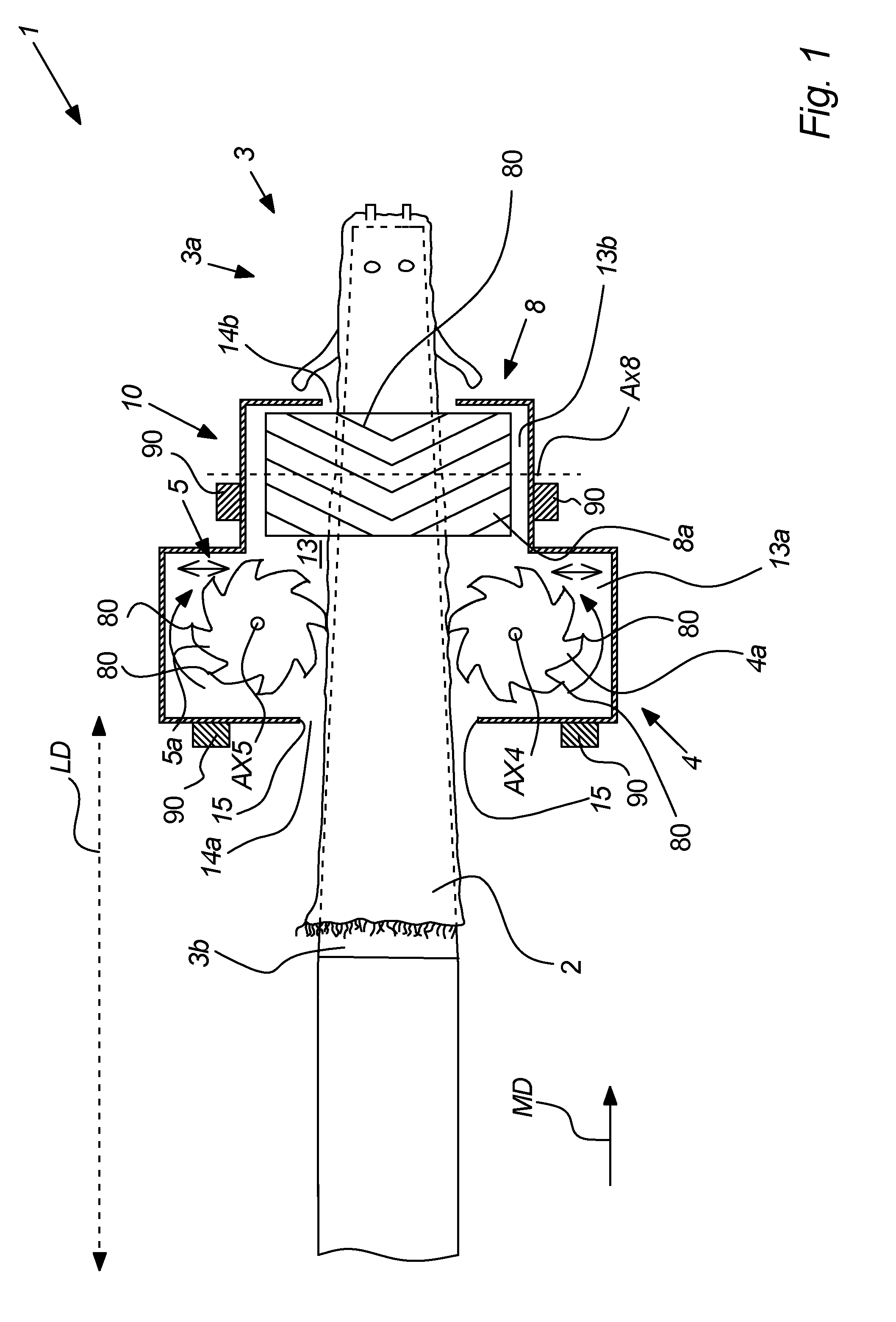

The invention relates to an apparatus (1) for processing the skin side of a tubular fur (2), which apparatus comprises: a tapering mandrel (3) with a first part (3a) that is thinner than a second part (3b) of the mandrel, on which mandrel (3) the tubular fur (2) can be drawn from the first part of the mandrel (3a) towards the second part of the mandrel (3b) so that the skin side of the fur (2) faces outwards and the fur side of the fur faces inwards towards the mandrel (3), at least a first scraper unit (4) and a second scraper unit (5), each scraper unit comprising at least a first scraper roller (4a, 5a) which, during operation and in contact with the skin side, is arranged to rotate so that scraping elements (6) on the scraper roller (4a, 5 a) scrape the skin side of the fur (2) on opposite sides of the mandrel (3). The mandrel (3) and the scraper units (4, 5) are arranged to be moved in relation to each other in the longitudinal direction of the mandrel, where the scraper units (4, 5) are arranged to be movable towards and away from the mandrel (3) and comprise a pressure arrangement arranged to apply to said at least one scraper roller (4a, 5a) a contact pressure against the skin side, and where the apparatus comprises a damper arrangement for damping the movement of the scraper units (4, 5) towards and / or away from the mandrel.

Owner:EIKON TECH HLDG

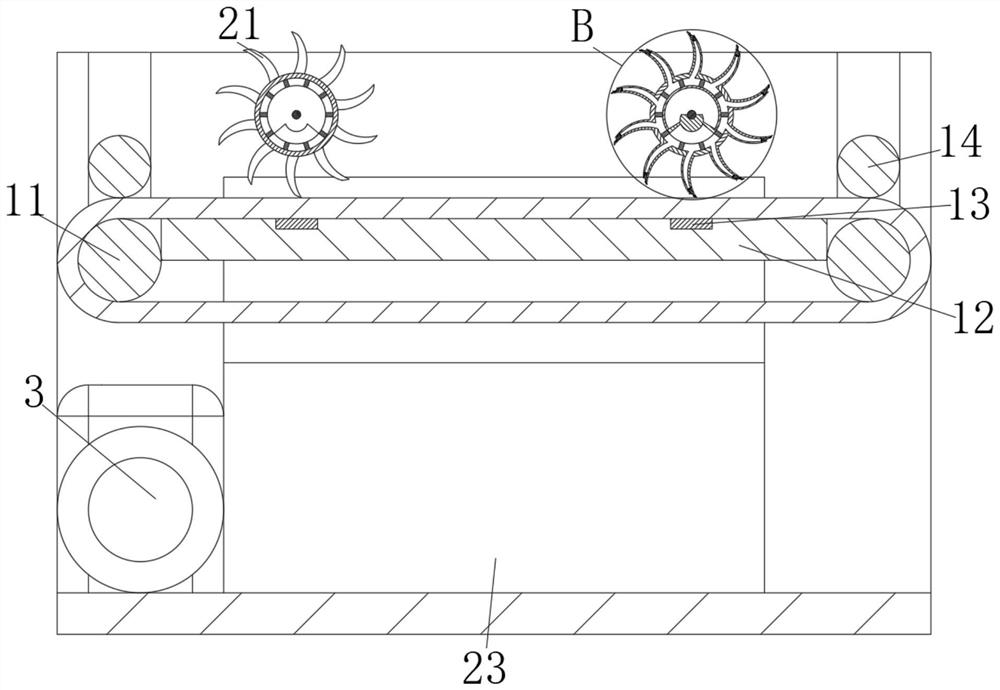

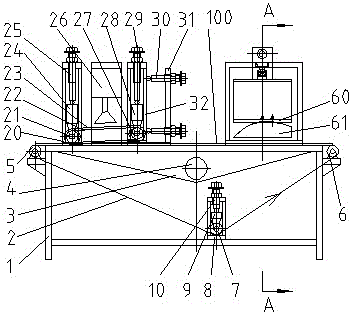

Fur surface cleaning device for poultry/animal fur product

InactiveCN112921132AImprove cleaning efficiencyEasy to useFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusAnimal scienceSurface cleaning

The invention discloses a fur surface cleaning device for a poultry / animal fur product, and relates to the technical field of fur cleaning devices. The fur surface cleaning device for the poultry / animal fur product comprises a fixed support, wherein a rotary mechanism is movably connected to the position, close to the top end, of the outer wall of the fixed support, a rotary cleaning mechanism is arranged at the position, close to the top end, of the outer wall of the fixed support, the outer wall of the rotary cleaning mechanism is movably connected with the outer wall of the rotary mechanism through the arranged fixed support, and a power device is arranged at the position, close to the bottom end, of the outer wall of the fixed support. According to the fur surface cleaning device for the poultry / animal fur product, poultry / animal fur flatly laid at the top end of a conveying belt can be scraped and sucked, dust on the surface of the poultry / animal fur and falling fur flocks and hair flocks are separated from the surface of the poultry / animal fur and enter the device to be collected, the efficiency of the device in cleaning the surface of the poultry / animal fur is improved, and the device is convenient to use.

Owner:李跃刚

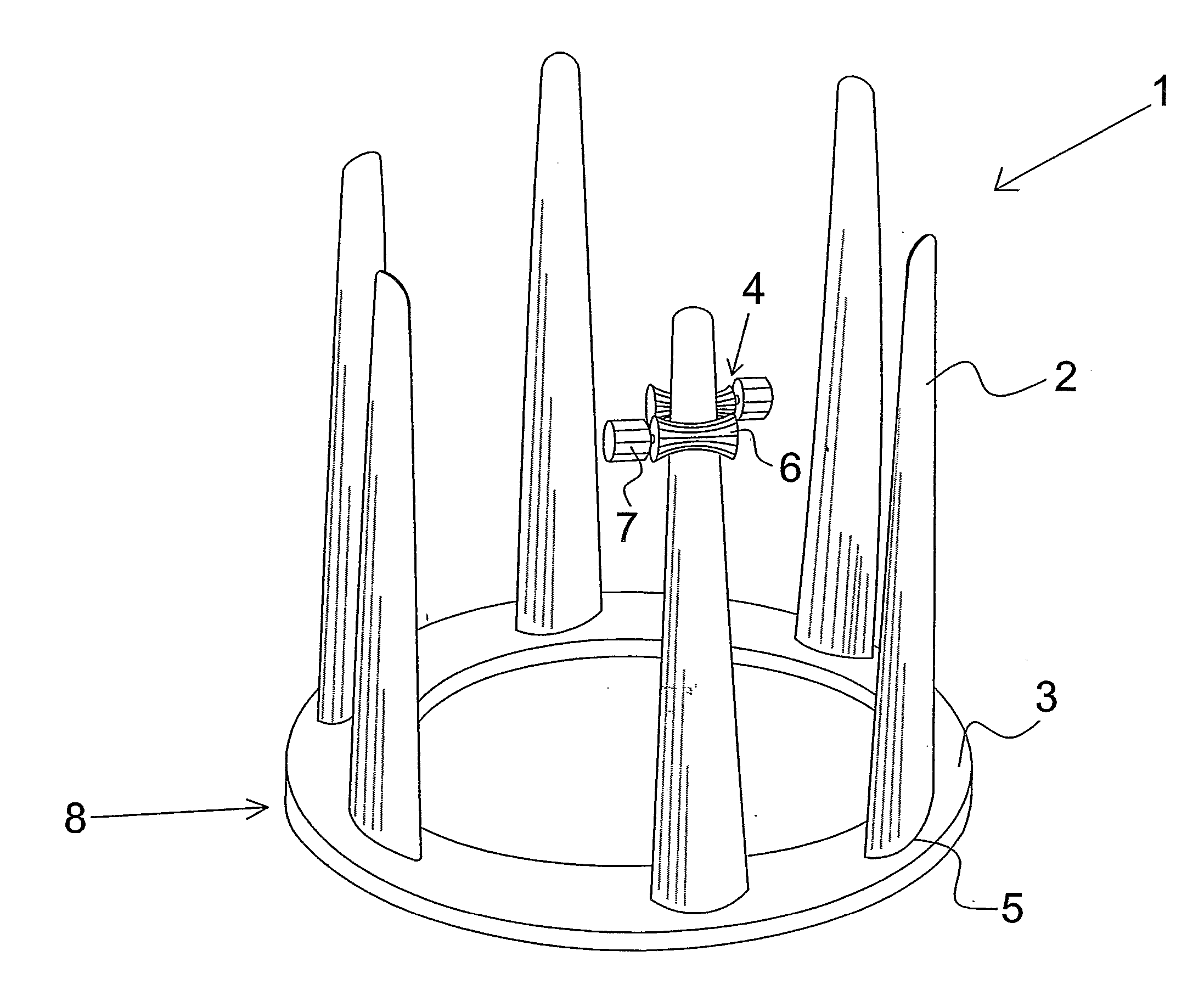

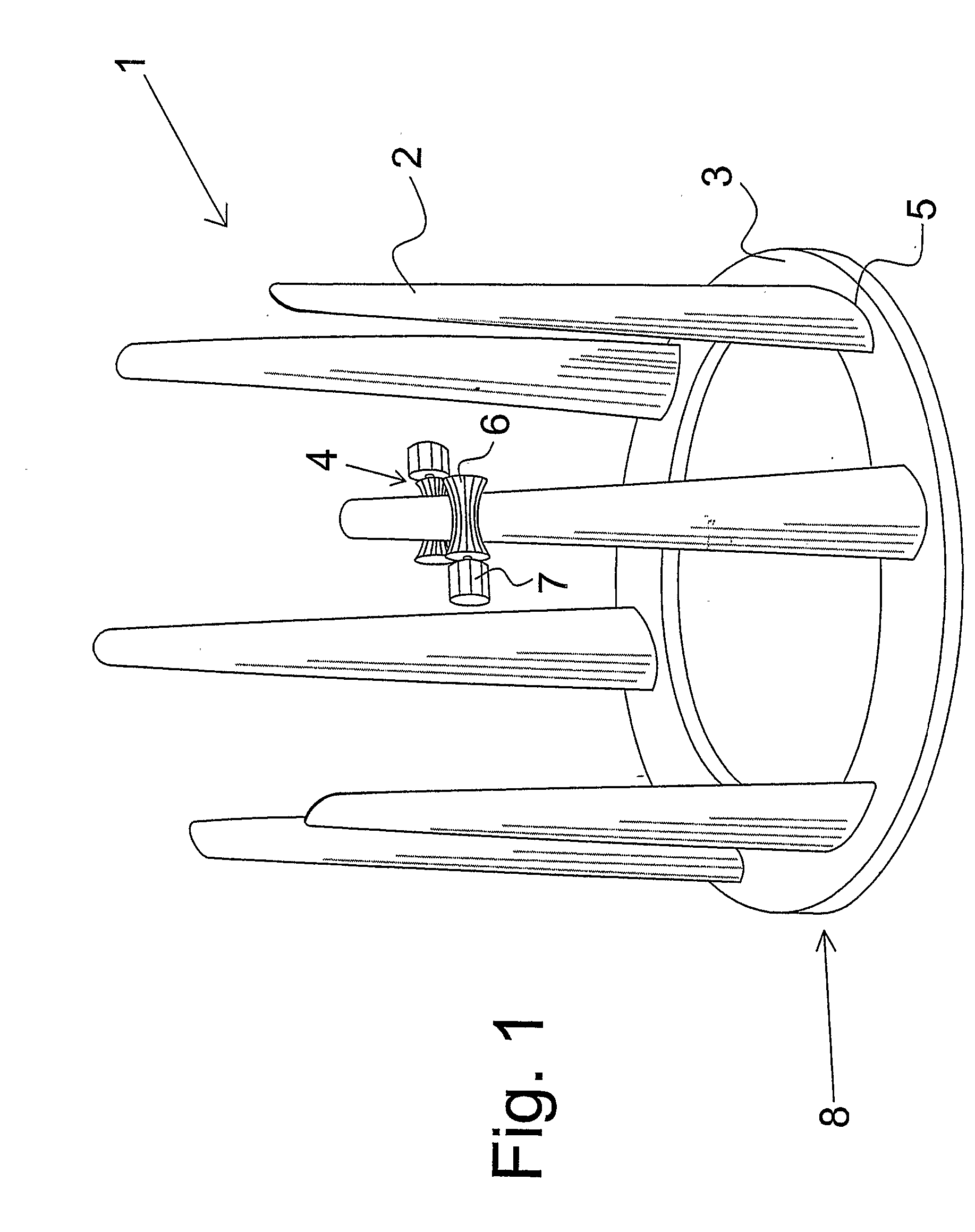

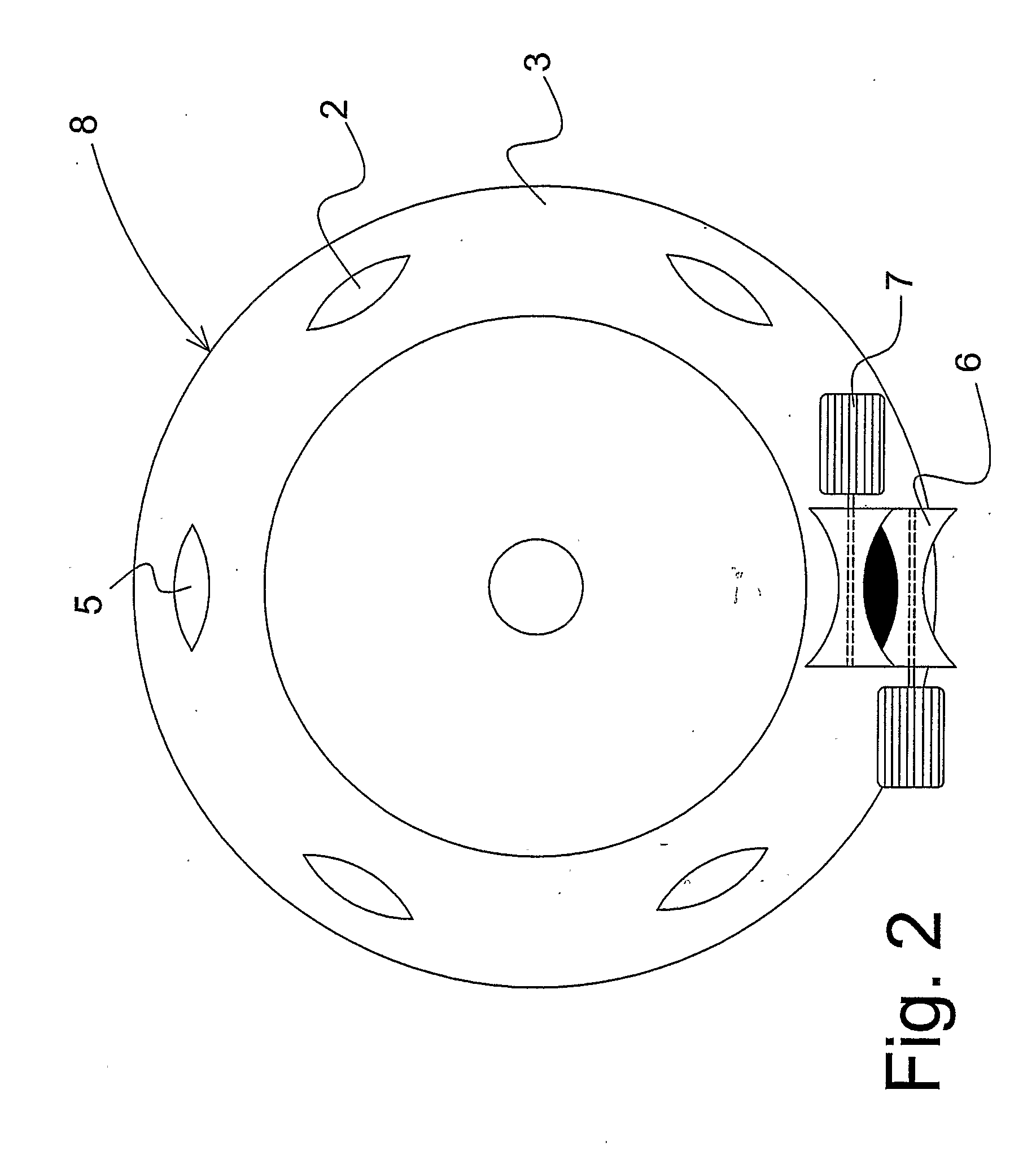

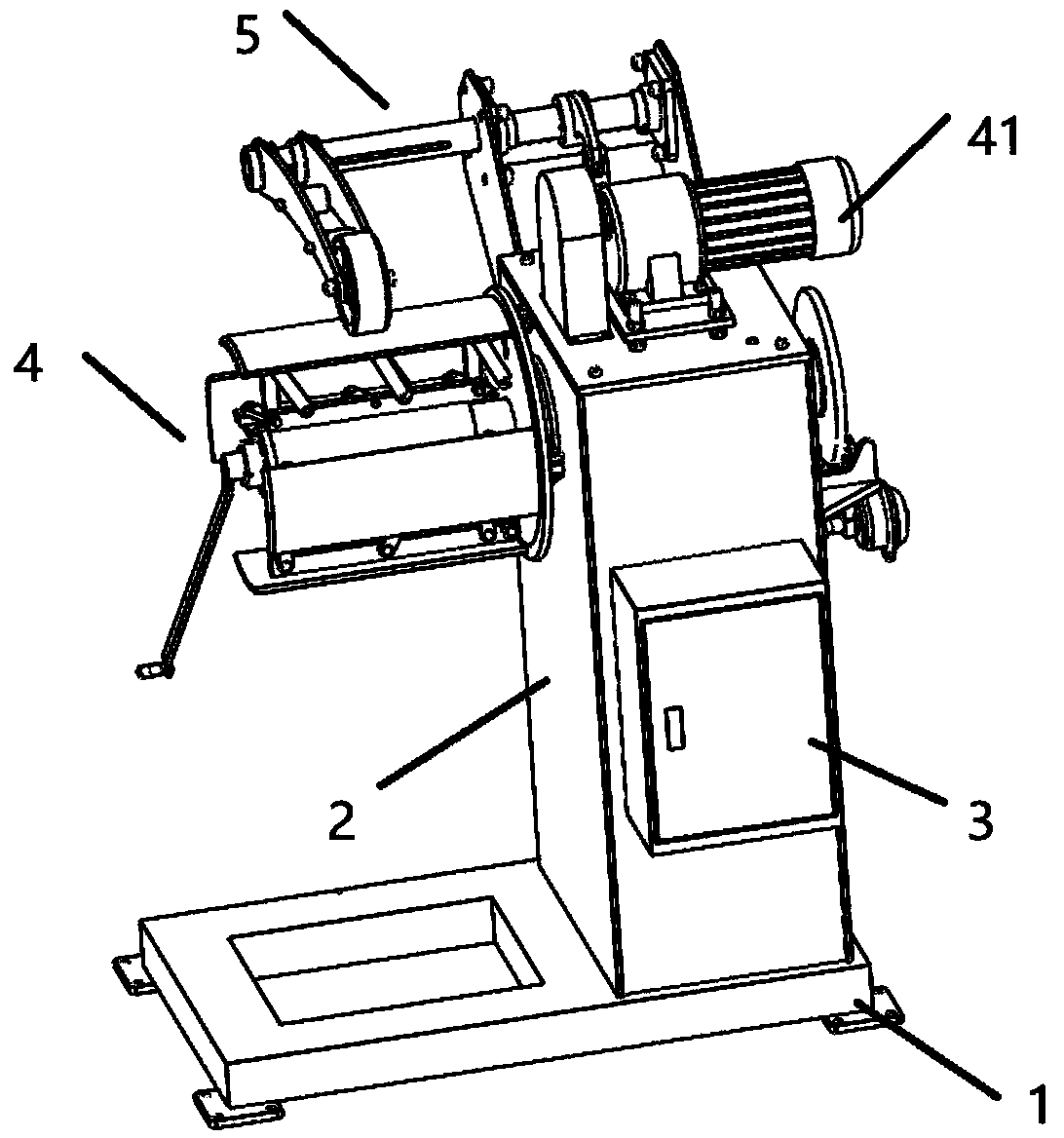

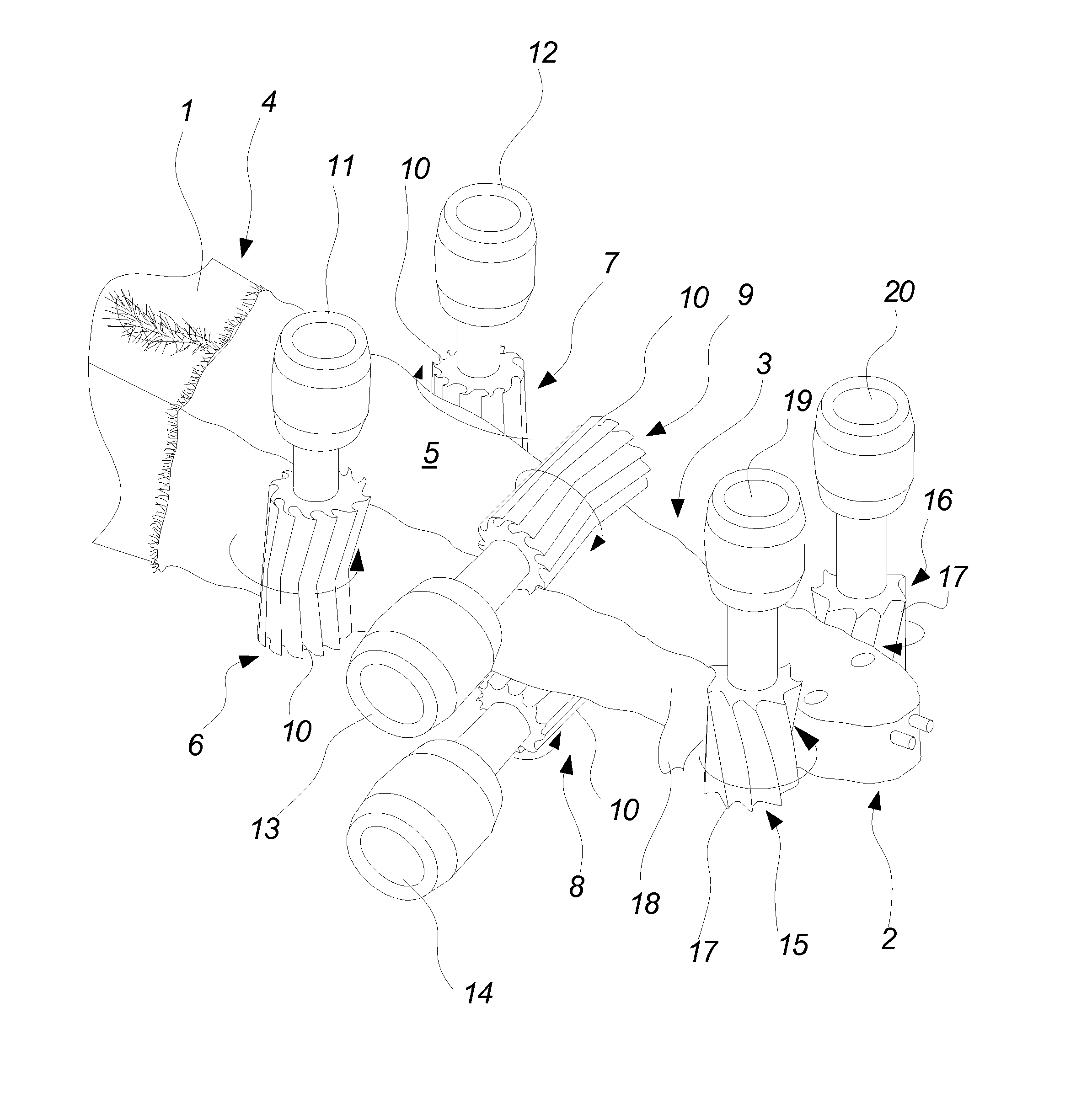

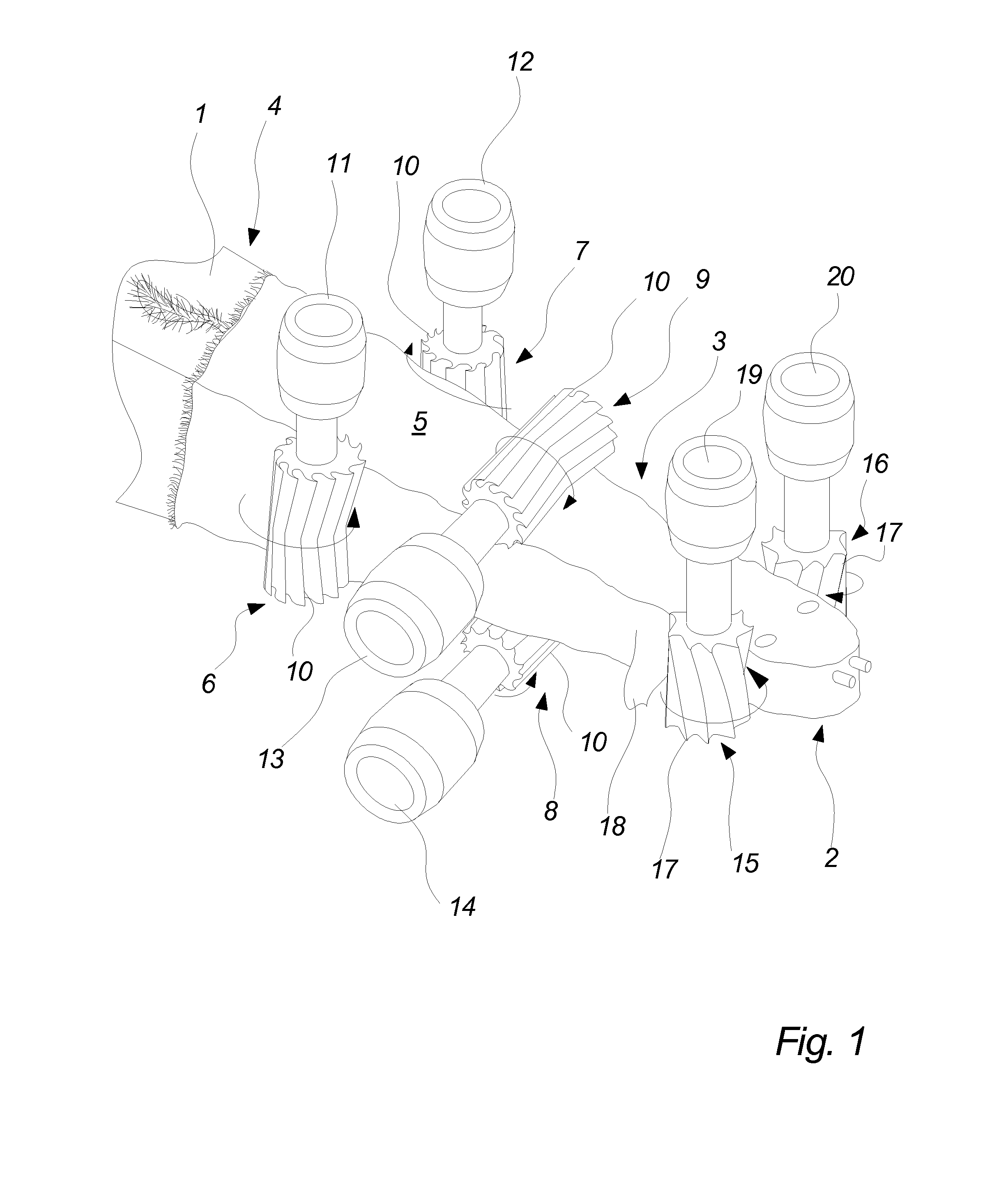

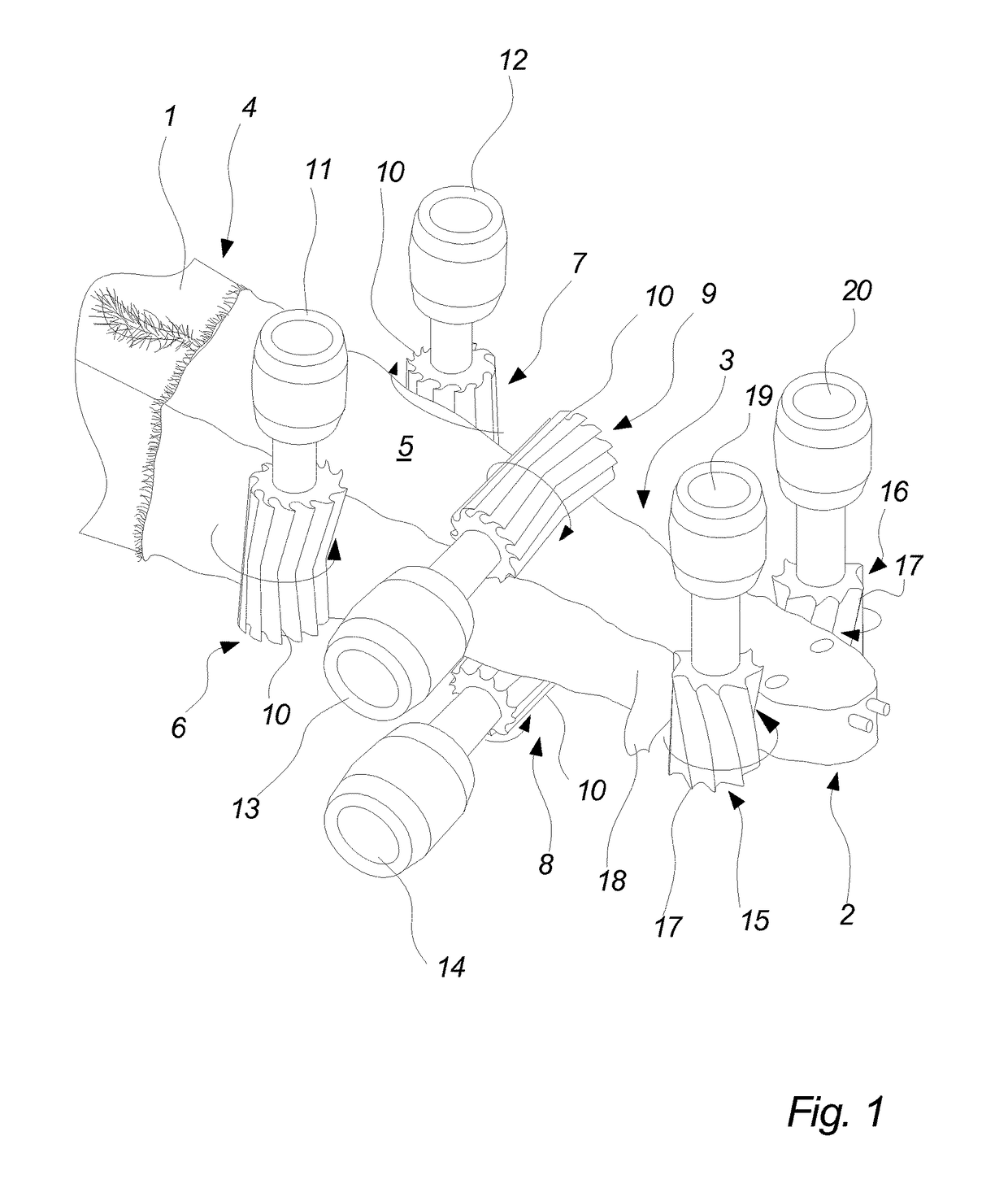

Apparatus and Method for Processing Fur

InactiveUS20070277565A1Prevent rotLess timeLeather manufacturingFur mechanical treatmentEngineeringMotor drive

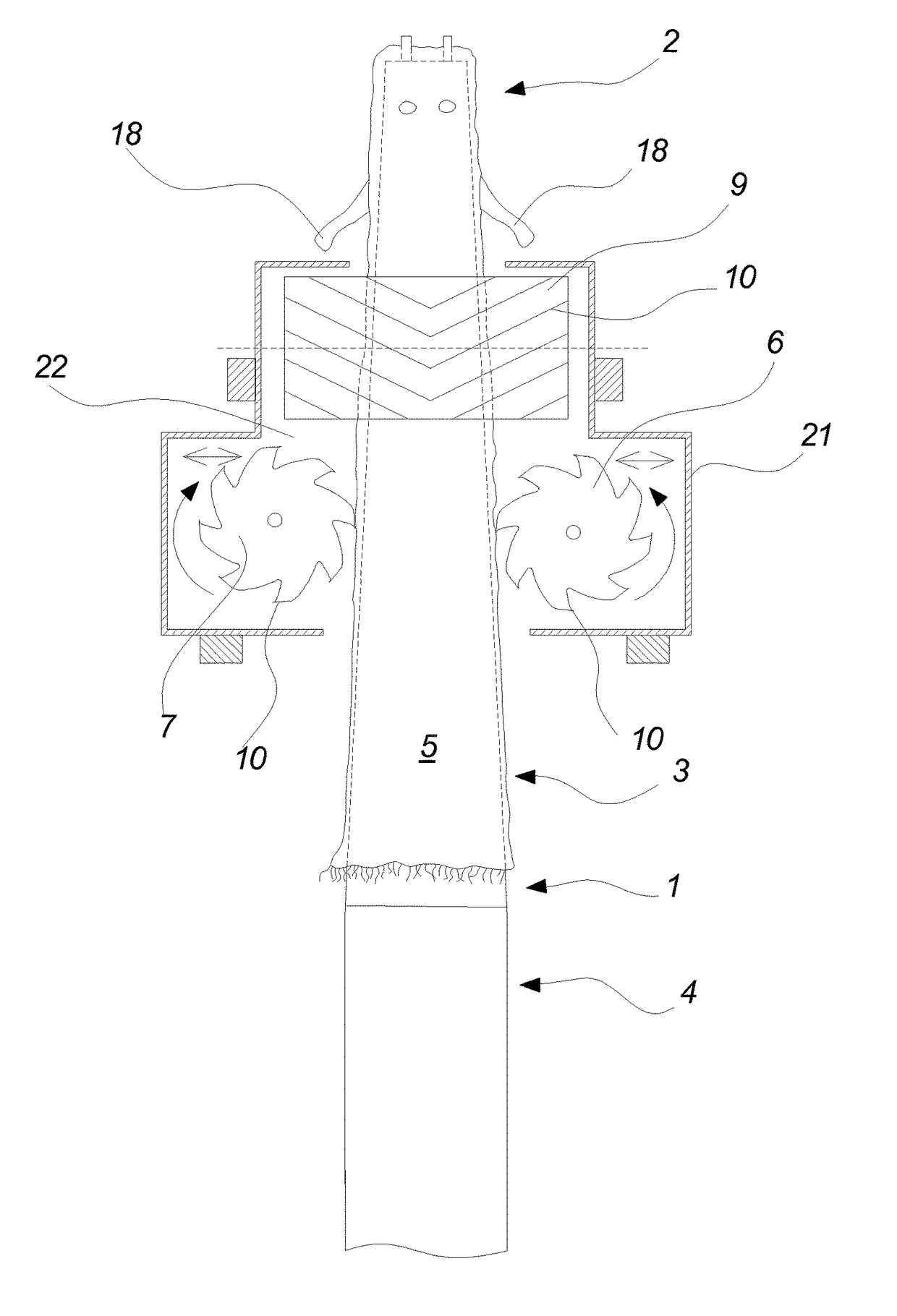

An apparatus (1) and method for processing fur, including a number of mandrels (2) and at least one motor-driven scraping roller (6), where the fur is disposed on the mandrel (2) with an inner side facing outwards, where the apparatus (1) includes an motor system (8) with a number of fixing means (5) that are adapted for holding a lower end part of the mandrels (2) which are disposed at an upright angle relative to the fixing means (5), the motor system adapted for moving the mandrels (2) past a number of processing positions. A fur is placed on a mandrel (2) with an inner side facing outwards in a preferably first processing position; where a motor system (8) moves the mandrel (2) to a second procession position; where the scraping unit (4) is lowered down over the mandrel (2) and is moved downwards along its outer side whereby remains of fat and flesh are scraped off; where the motor system (8) moves the mandrel (2) further to a third processing position where the cleaning unit is lowered down over the mandrel (2) and is moved downwards along its outer side whereby the fur is cleaned and sawdust with residual fat is sucked away; where the motor system (8) moves the mandrel (2) further to a fourth processing position where the combined removing and turning unit holds a pointed end of the fur while a suction chamber simultaneously provide for turning the fur; and where the motor system (8) moves the mandrel (2) on to a next processing position which is preferably constituted by the first processing position.

Owner:VIND BORGE

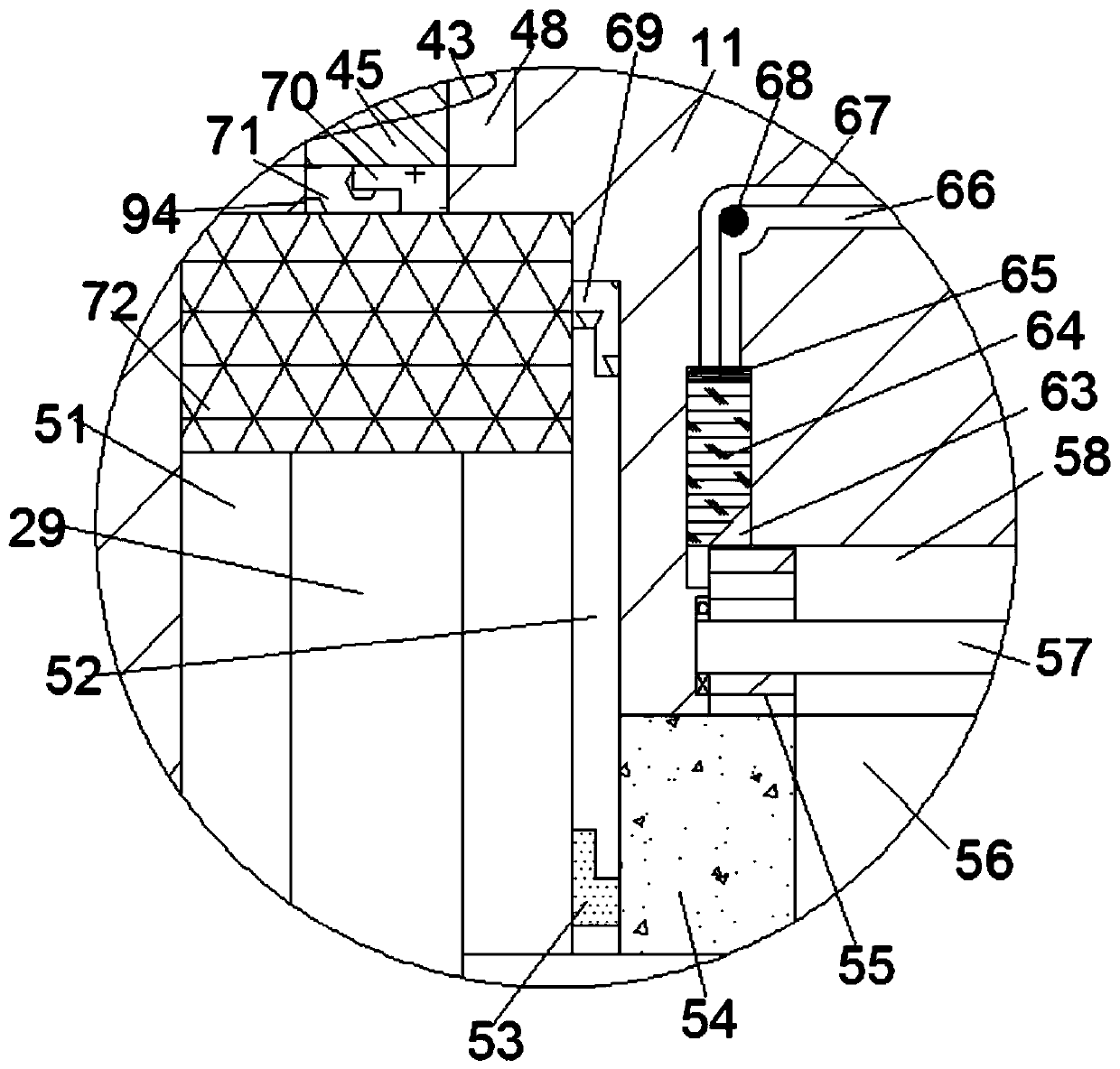

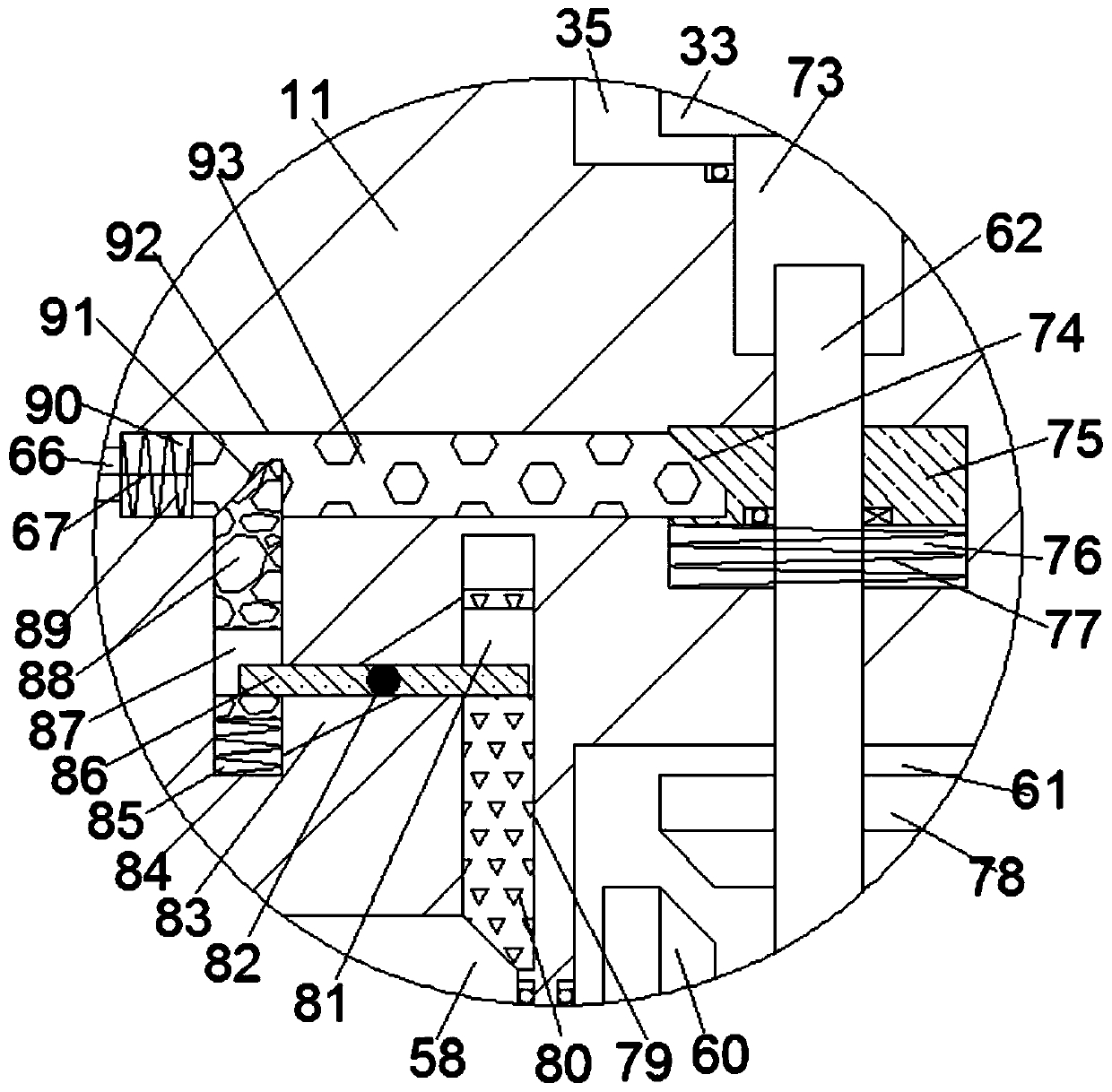

Device for scraping oil on inner surface of fur

InactiveCN109971897AQuality improvementQuality assuranceFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusEngineering

Owner:安徽省卓创信息科技服务有限公司

Treatment device for animal raw materials

ActiveCN110273031ASave time at workSimple structureFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusTotal efficiencyAnimal fur

The invention discloses a treatment device for animal raw materials. The treatment device for the animal raw materials comprises a device body, a fixing device arranged in the device body, a switching device arranged in the device body and a buckling device arranged in the device body; and the fixing device comprises a working cavity formed in the device body, a workbench is fixedly connected to the inner wall of the lower side of the working cavity, and first rotating cavities are symmetrically formed in the inner walls of the left side and the right side of the working cavity in a communicating manner. According to the treatment device for the animal raw materials, the structure is simple, operation is convenient, animal fur trimming can be automatically conducted, and animal fur can be fully trimmed to be bright and clean in the working process; in addition, the steps that the device achieves forward twisting, reverse twisting and fur turning are compact, the single-piece working time is shortened, and the total efficiency is improved; the treatment device is driven by one power source, and therefore energy sources can be better saved; and fixation is more steady through the symmetrical fixing device, long-time repeated work can be conducted, and the human operation time is shortened.

Owner:解波

Leather cleaning and impurity removal device

InactiveCN106755622AEasy to cleanFree from influenceFur mechanical treatmentHydraulic cylinderEngineering

The invention discloses a leather cleaning and impurity removal device. The leather cleaning and impurity removal device comprises a cleaning and impurity removal box body, wherein a water inlet pipe is installed at the other side of the cleaning and impurity removal box body; a first electromagnetic valve is installed on the water inlet pipe; the water inlet pipe is connected with a washing liquid box through a connection pipe; a second electromagnetic valve is installed on the connection pipe; a slide groove is formed in the inner wall of the bottom of the cleaning and impurity removal box body; a slide block is installed in the slide groove; an operation platform is installed at the top of the slide block; movable grooves are installed in the inner walls of the two opposite sides of the cleaning and impurity removal box body; driven gears are installed on the upper part of a drive gear; the two driven gears are connected through a rotary rod; fixing buckles are installed at the two sides of the rotary rod; the fixing buckles are connected with a hydraulic cylinder through a hydraulic rod; a sewage discharge hole is formed in one side of the hydraulic cylinder; a leather cleaning cylinder is installed on the rotary rod; a plurality of scraping plates are installed on the leather cleaning cylinder; soft cleaning brushes are installed between every two adjacent scraping plates; and water outlet holes are formed in the soft cleaning brushes. The leather cleaning and impurity removal device is convenient to use and good in cleaning effect.

Owner:邹城市众光日用品销售有限公司

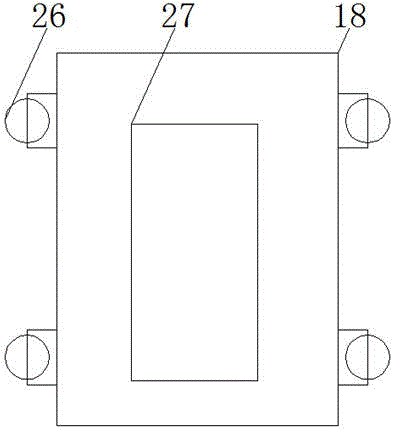

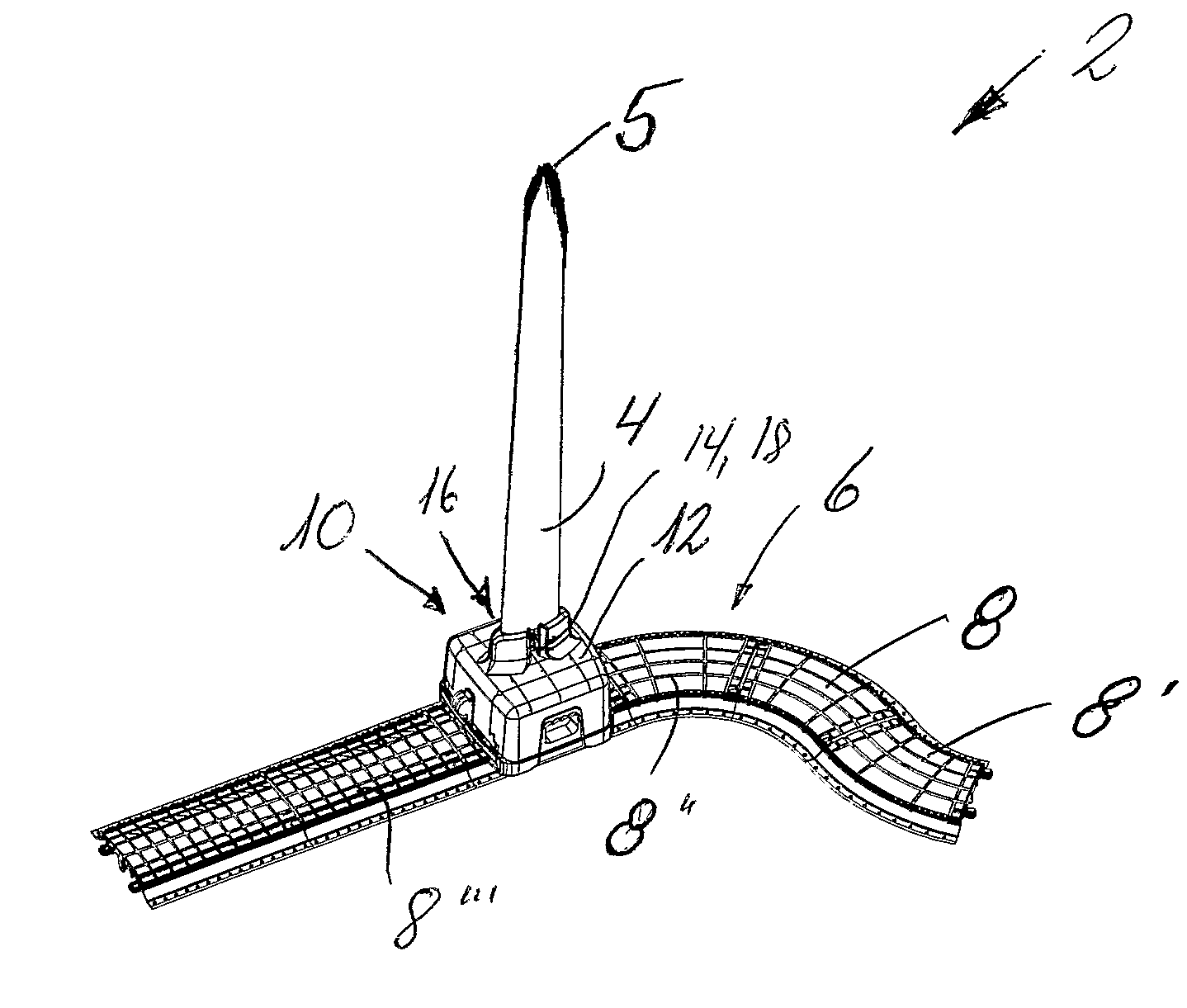

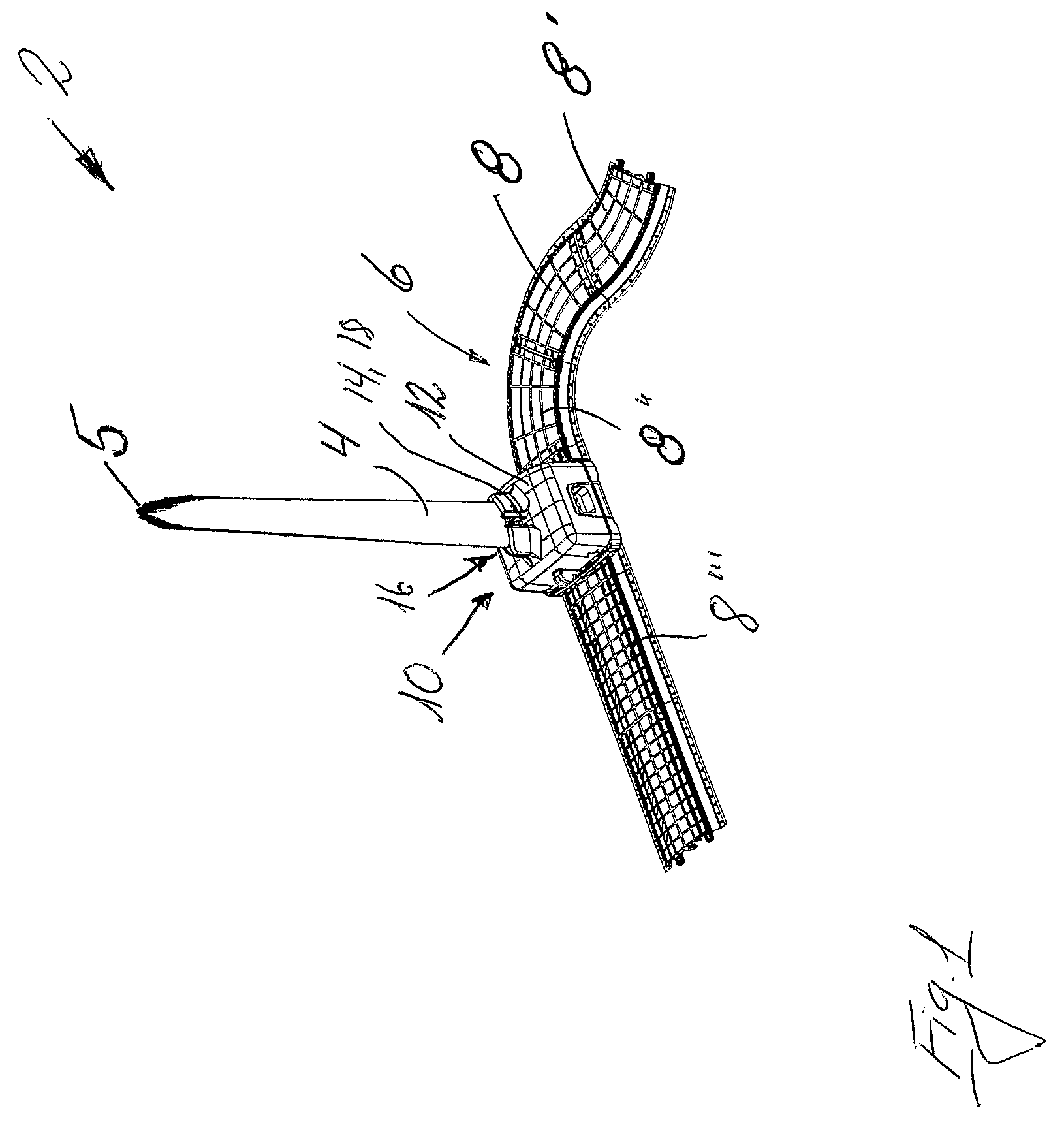

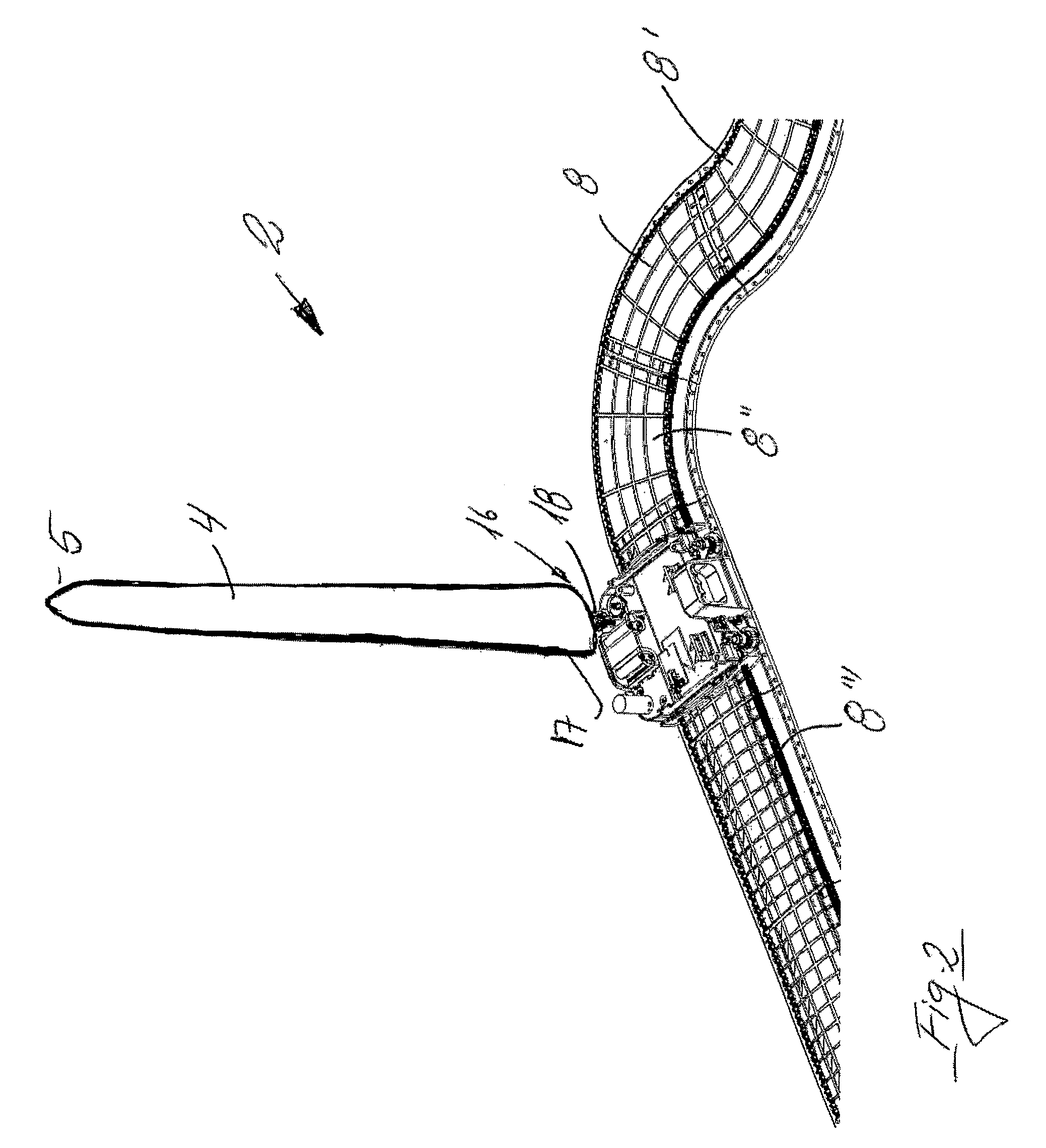

Mink-fox transportation system for individual transfer/transport in connection with the production of mink/fox pelts

InactiveUS7987795B2Effective labour-saving productionEasy to cleanRailsLeather manufacturingMinkSelf driven

A mink / fox transportation system (2) for individual transport in connection with the production of mink / fox furs, for example, the transport of upright-standing expansion pelt boards (4), with or without tanned, or tanned and dried pelts, to one or more relevant receiving stations (170, 172), has at least one, preferably a plurality, of self-driven traction units / carriages (10) driven along a predetermined transport path in the form of a track (6) which is formed of track elements (8,8′,8″,8′″) that have been assembled together configured to the arrangement of the particular production facility. The traction units / carriages (10) have a housing (12) with an upwardly-facing side (20) in which an opening (14) is formed for receiving a blunt part (18) extending from the foot end (16) of the pelt board, or surrounds a smaller part of the whole of the foot end of a pelt board.

Owner:MINKPAPIR

Tanning and dyeing technique of mink skin with functions as fur and leather

ActiveCN105925733AReasonable pretreatmentImprove qualityTanning treatmentPre-tanning chemical treatmentAnimal furPulp and paper industry

The invention relates to a processing technique of animal fur, in particular to a tanning and dyeing technique of mink skin with functions as fur and leather. The technique comprises the following steps of (1) green hide selection and pre-processing, (2) water soaking, freshness recovery, oil removal and grease removal of green hide, (3) nitrate leaching and degreasing, (4) pickling and softening, (5) aluminum tanning, (6) neutralizing, (7) oil tanning, (8) dry cleaning, milling of leather and arranging, (9) chrome tanning, and (10) buffing and dyeing. According to the technique, the design is reasonable, reasonable pre-processing is conducted on the green hide, the quality of the green hide is improved, the subsequent processing technique is simplified, the number of varieties of reagents used for the technique is decreased, the processing cost is low, the production efficiency is high, the quality of finished mink skin is high, the coat color is bright, and the fur is smooth.

Owner:桐乡市雄鹰皮草股份有限公司

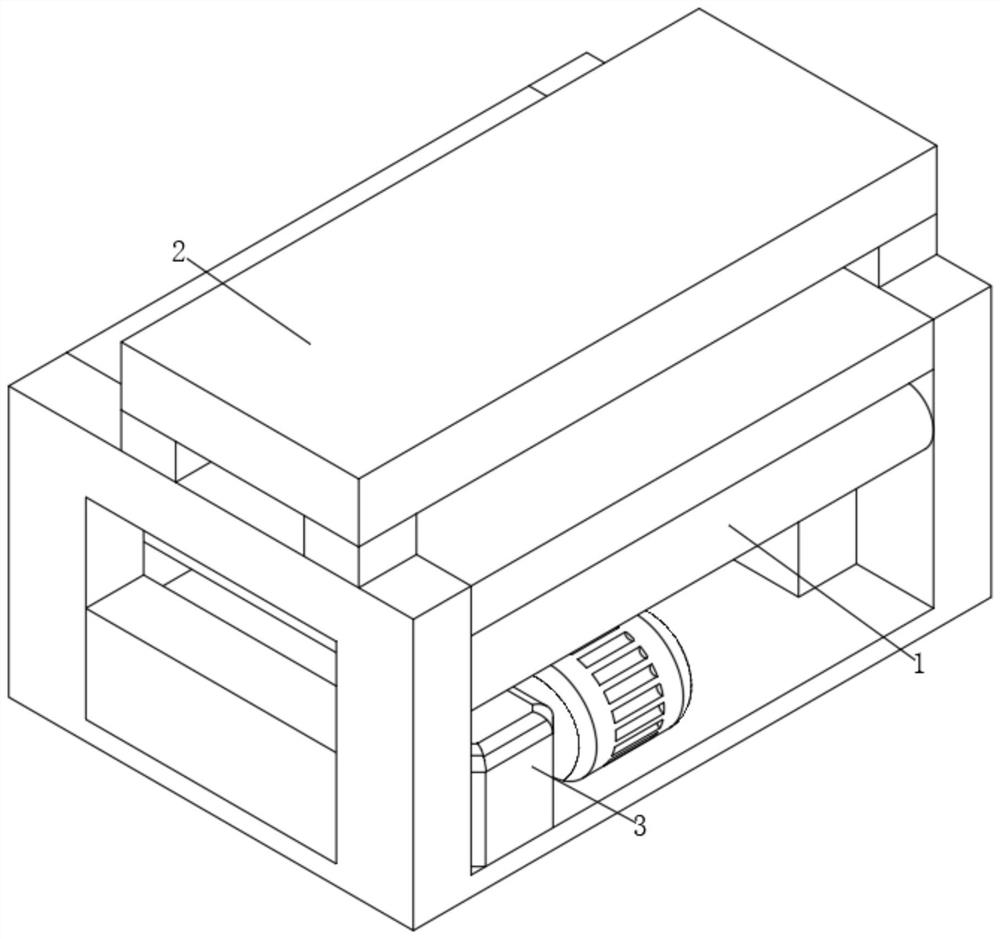

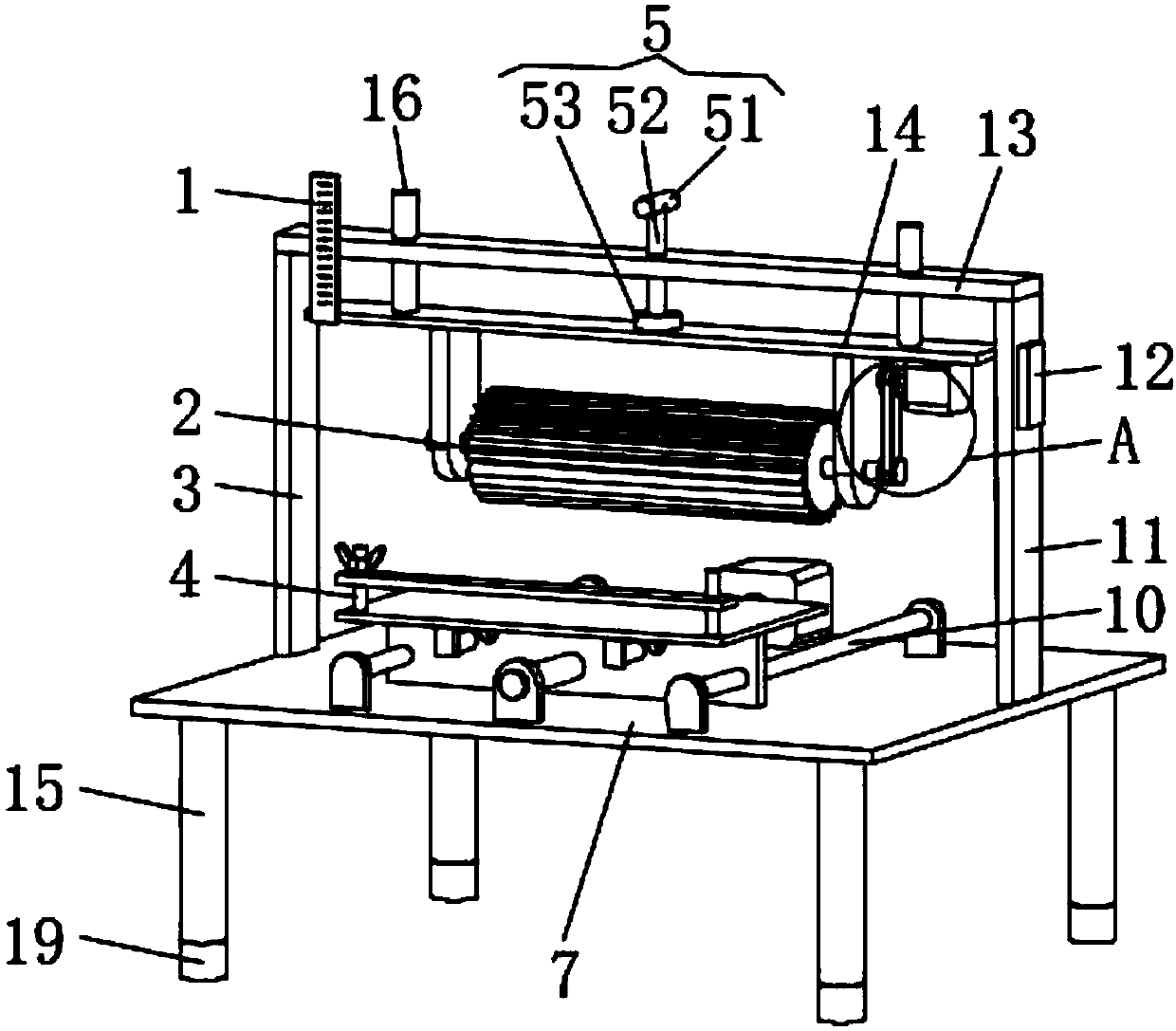

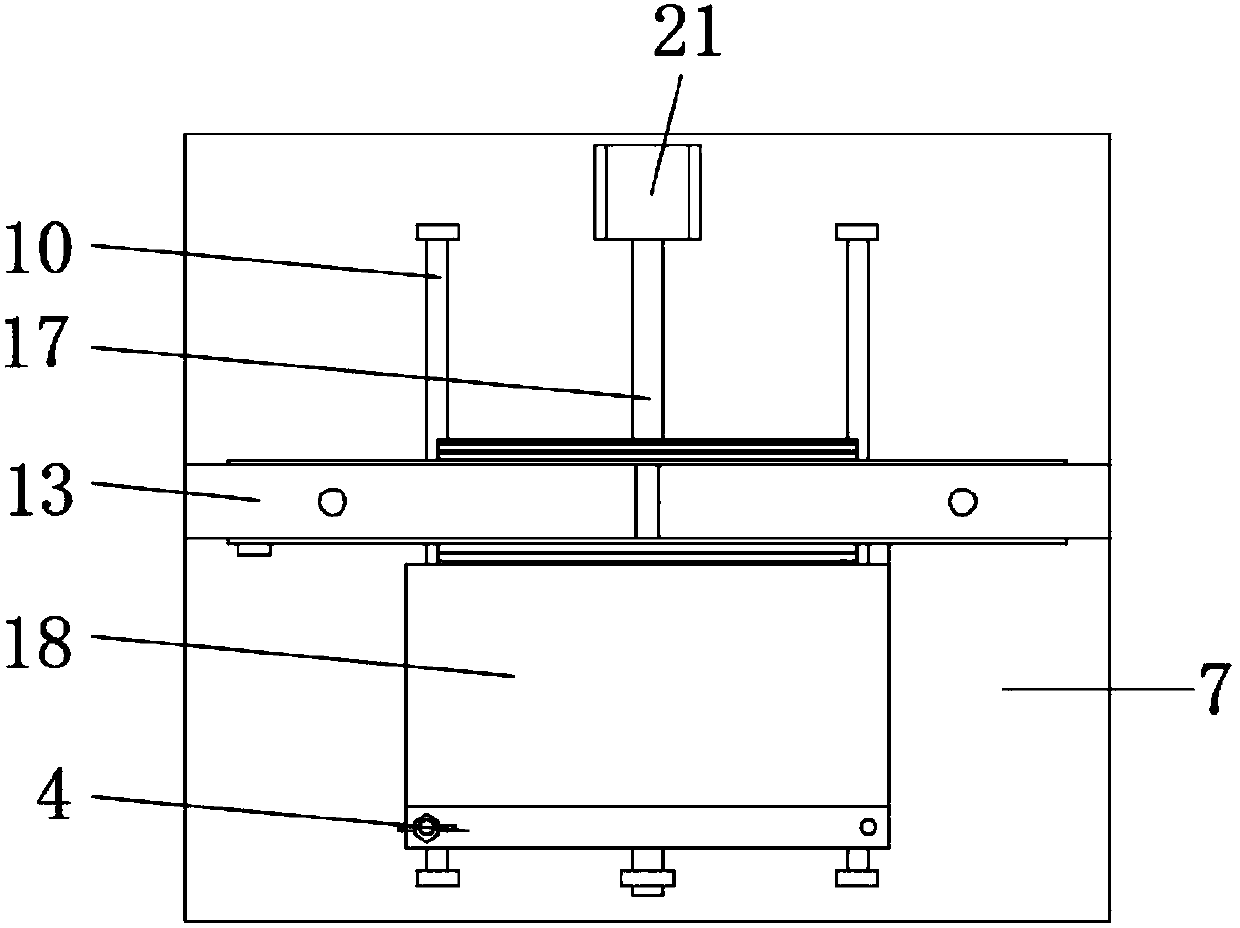

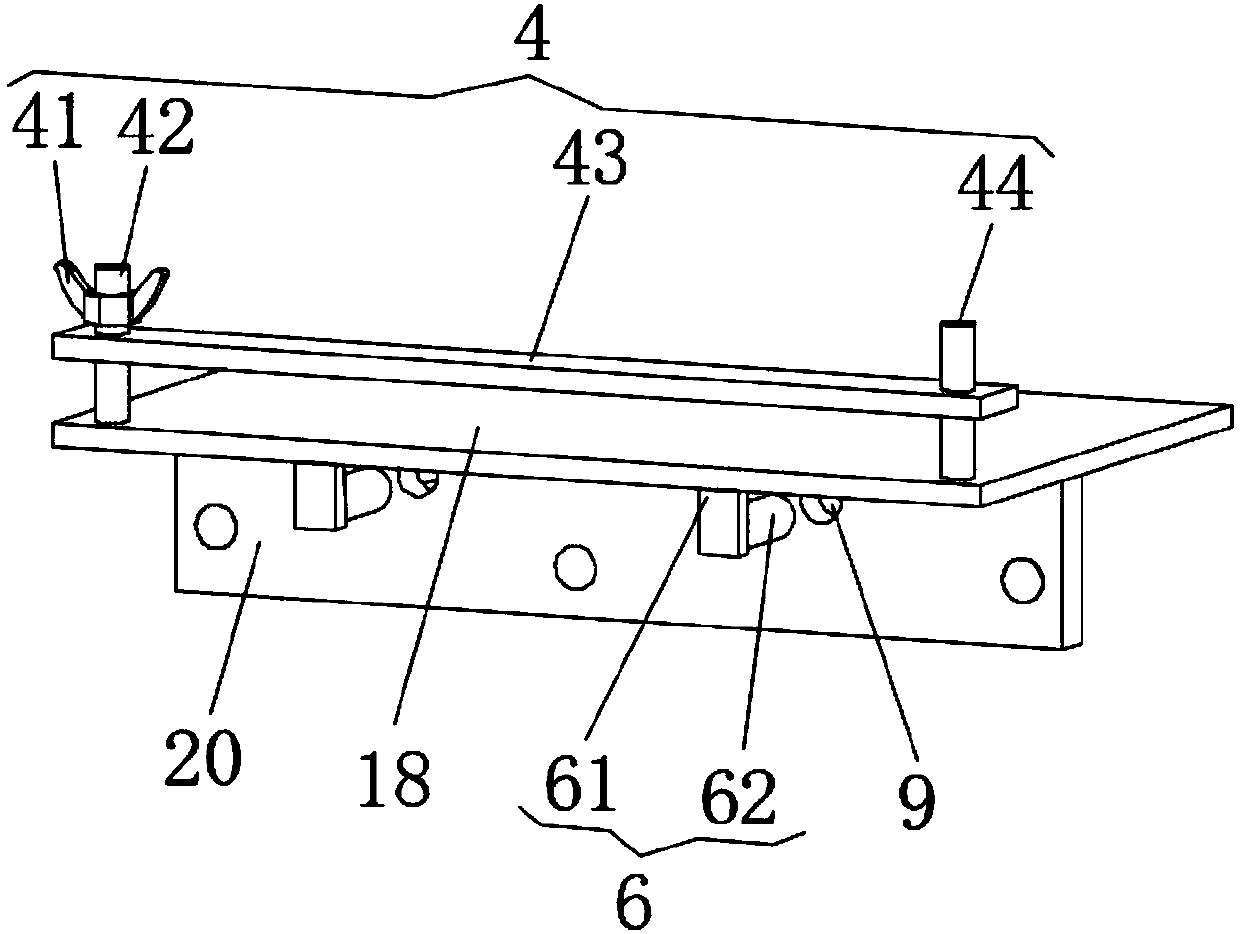

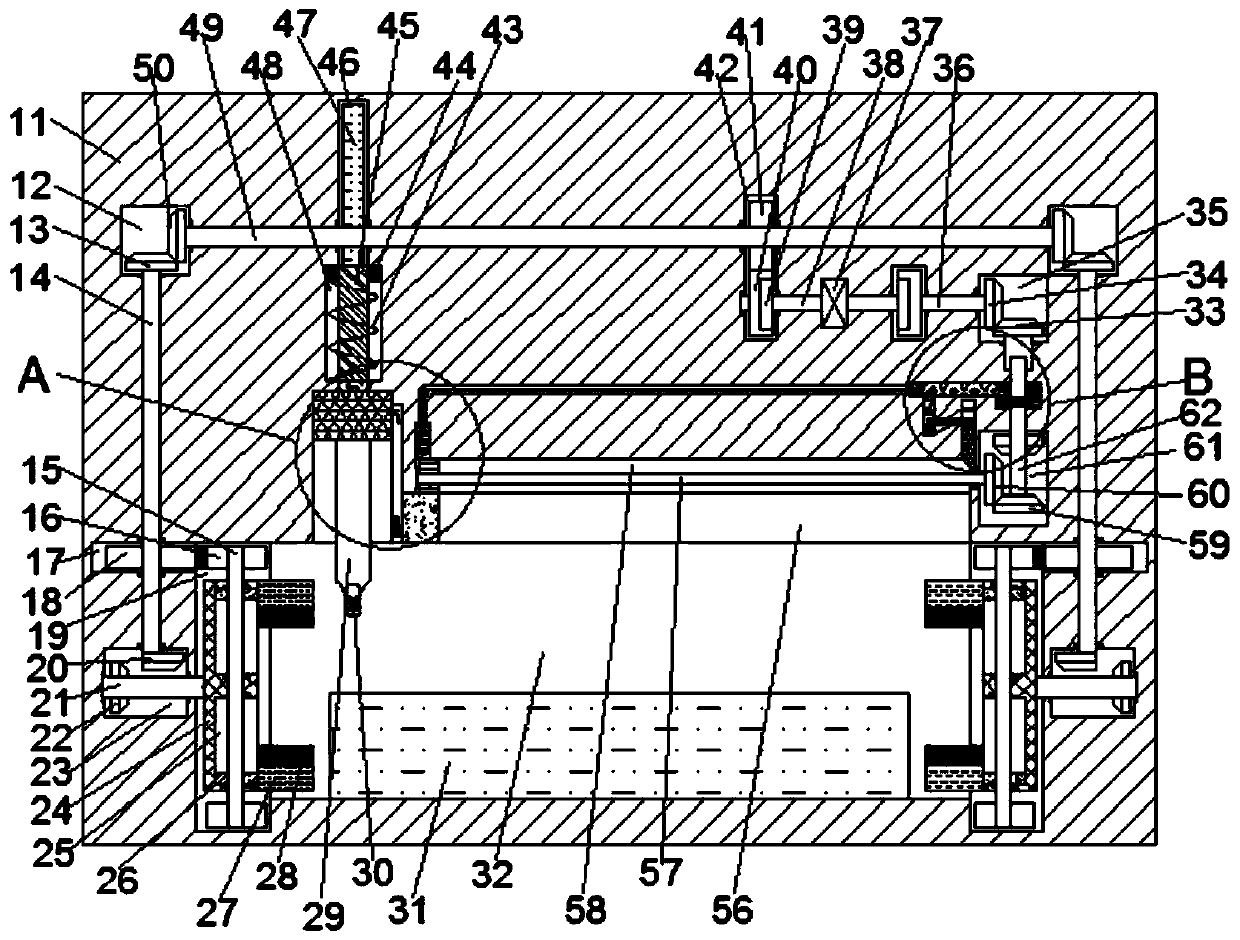

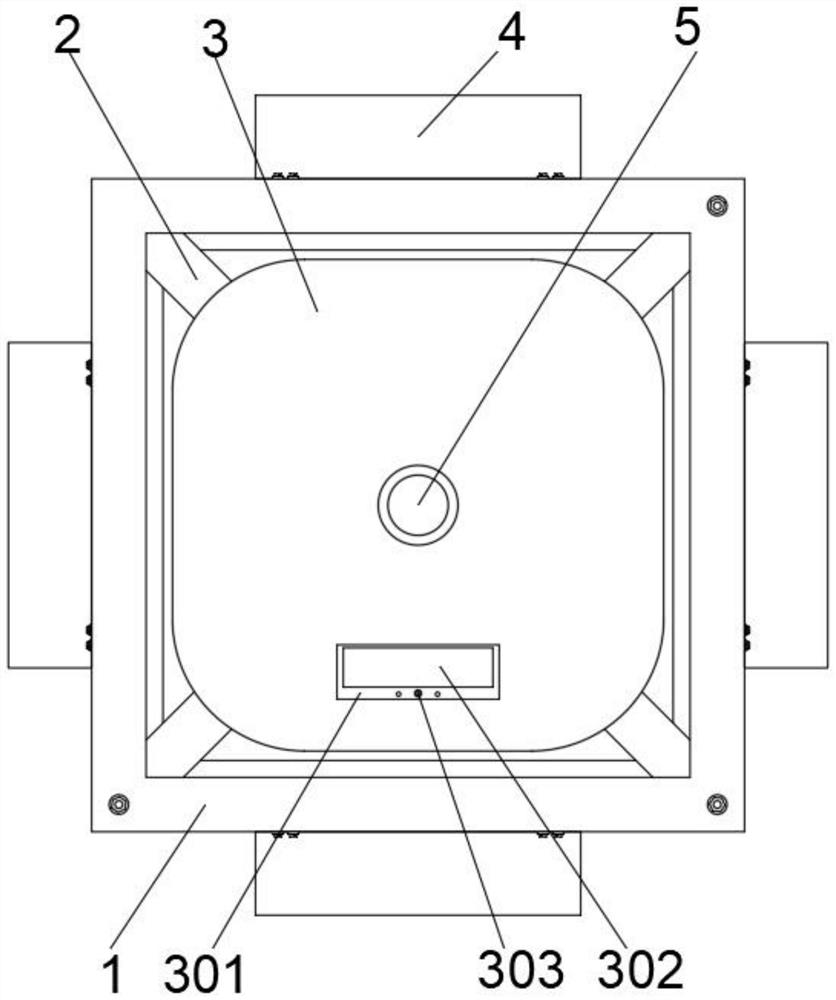

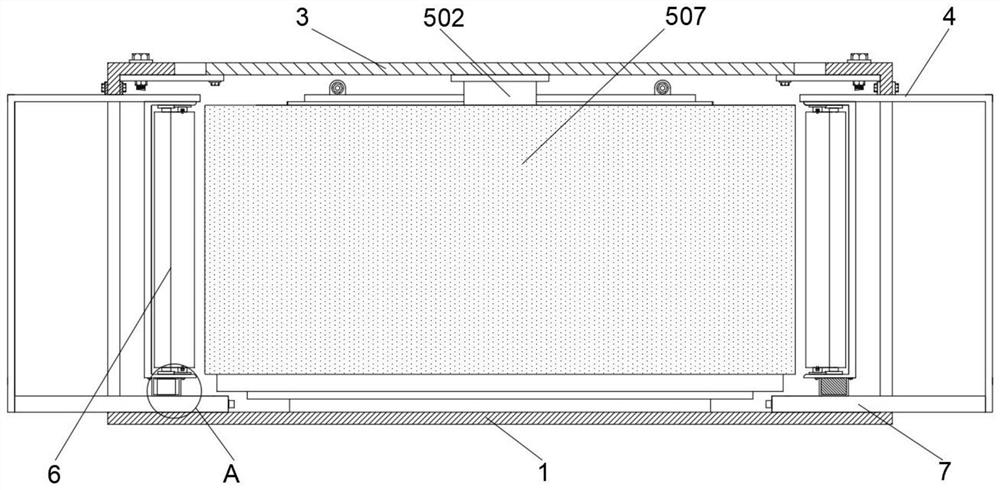

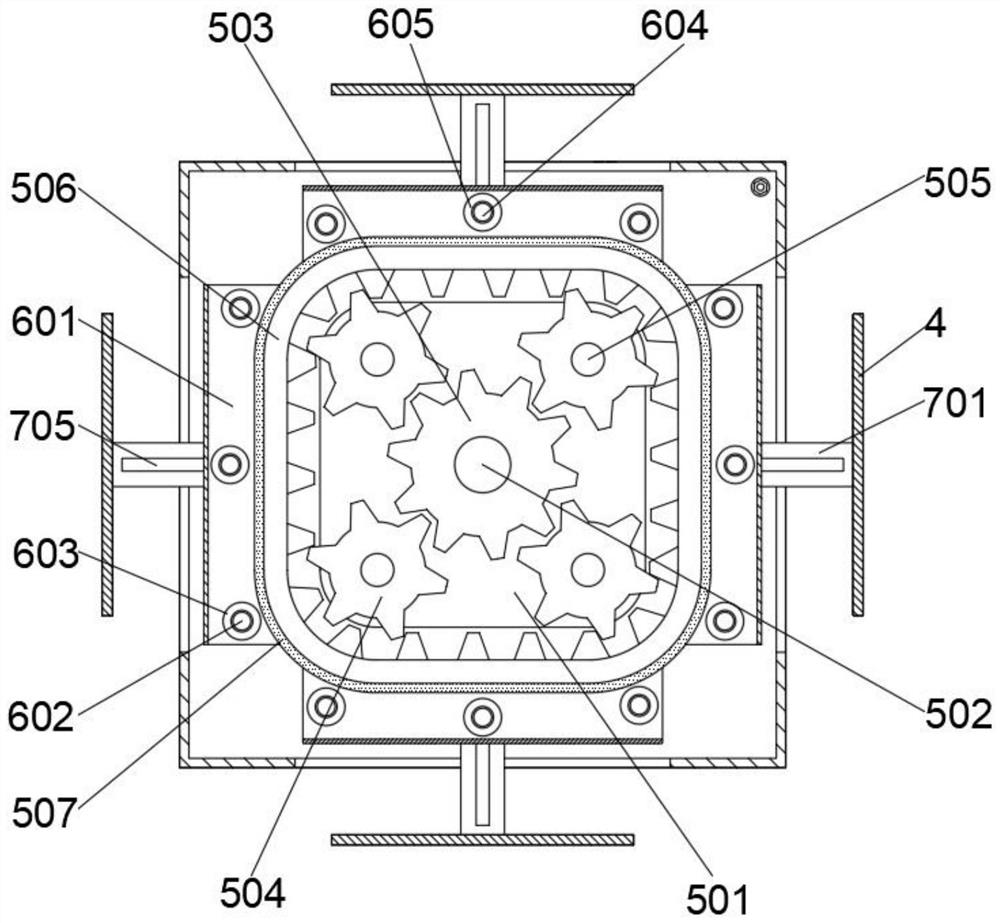

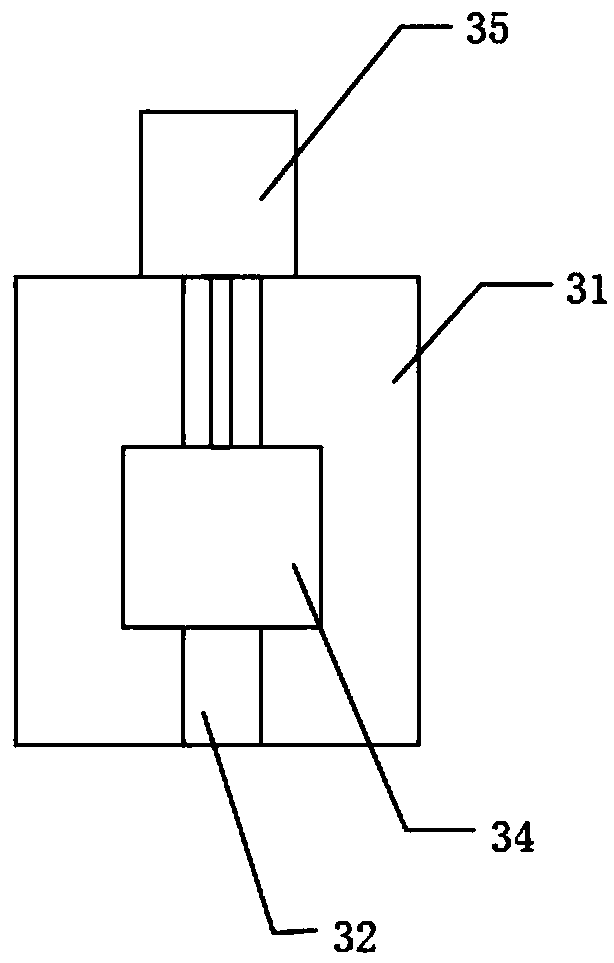

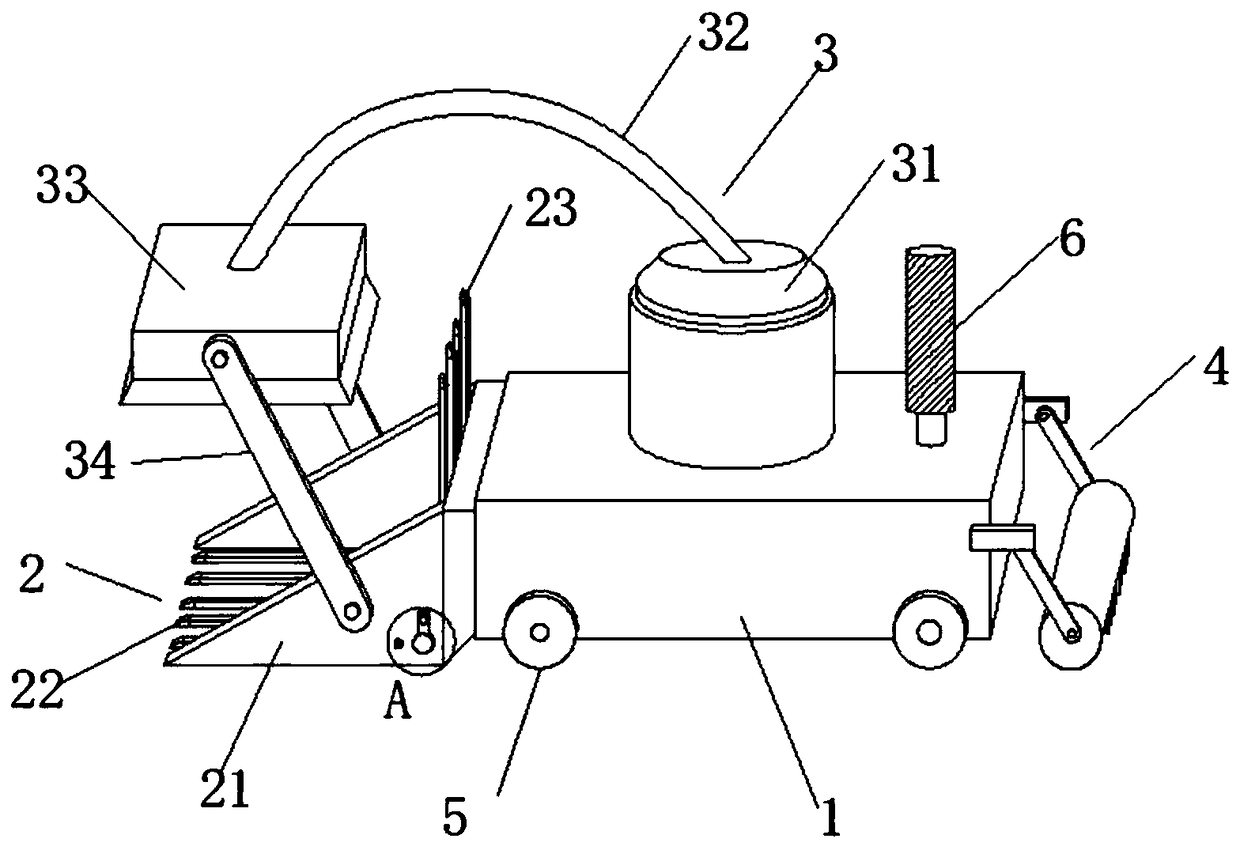

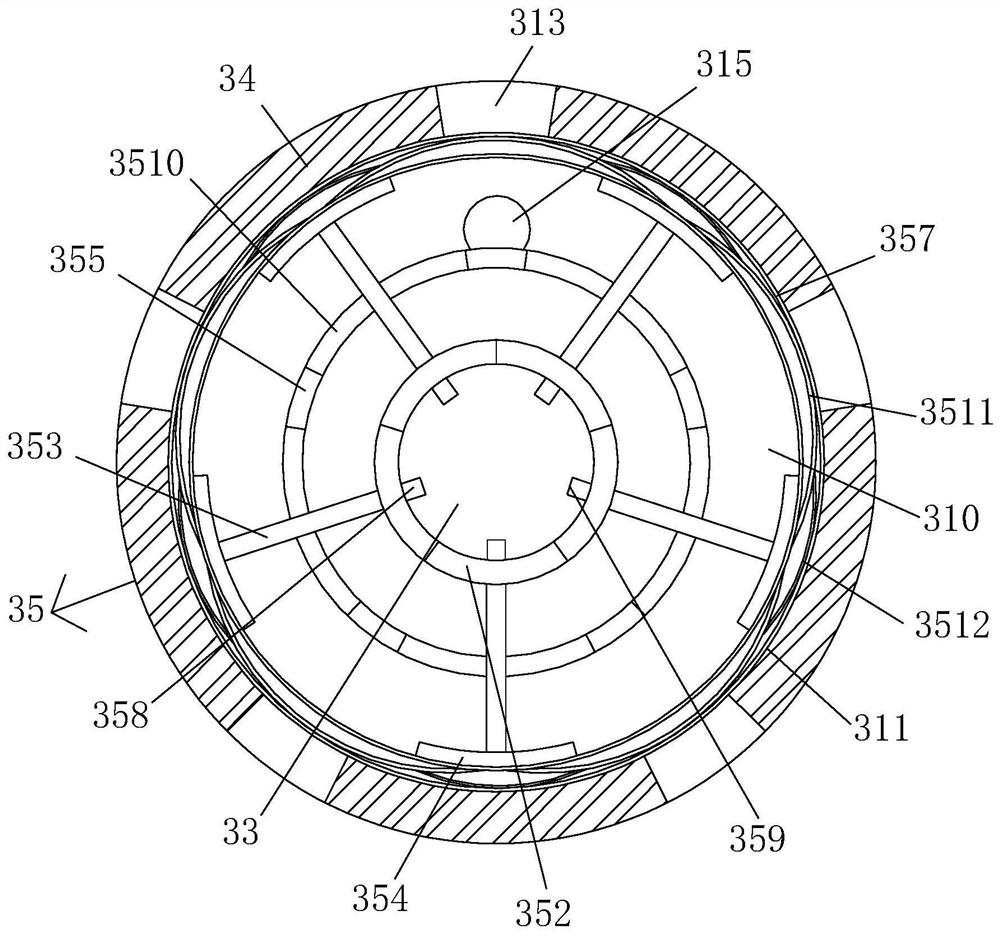

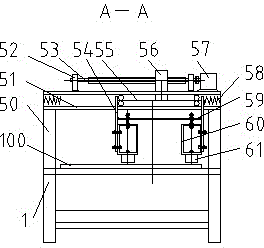

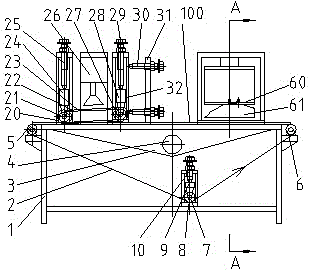

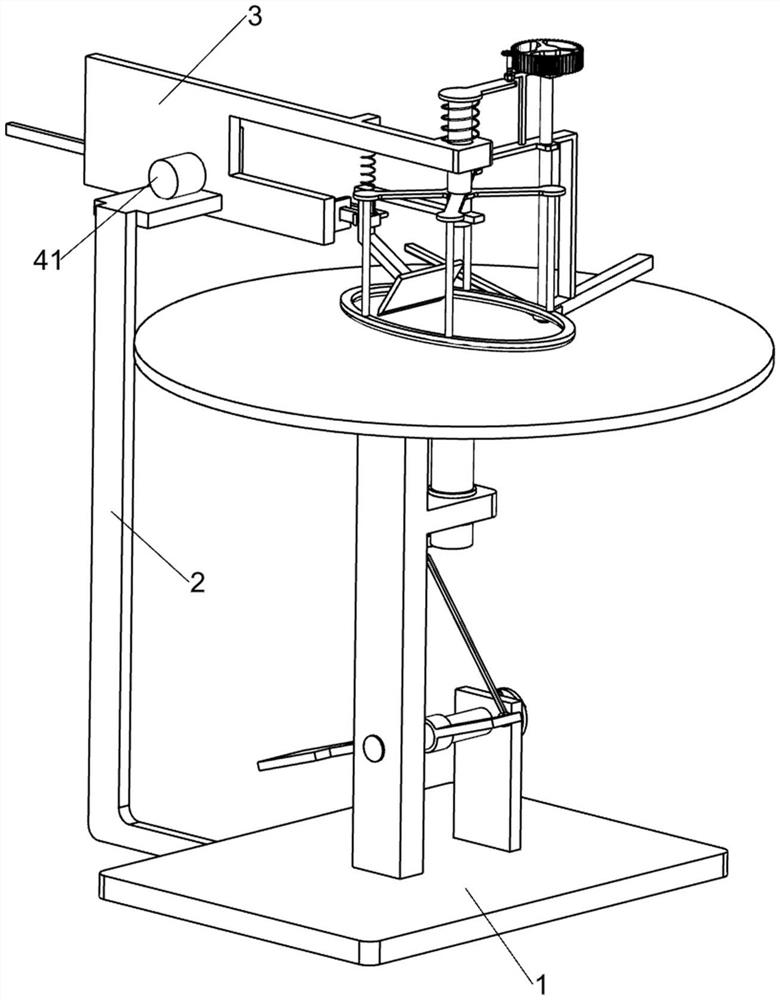

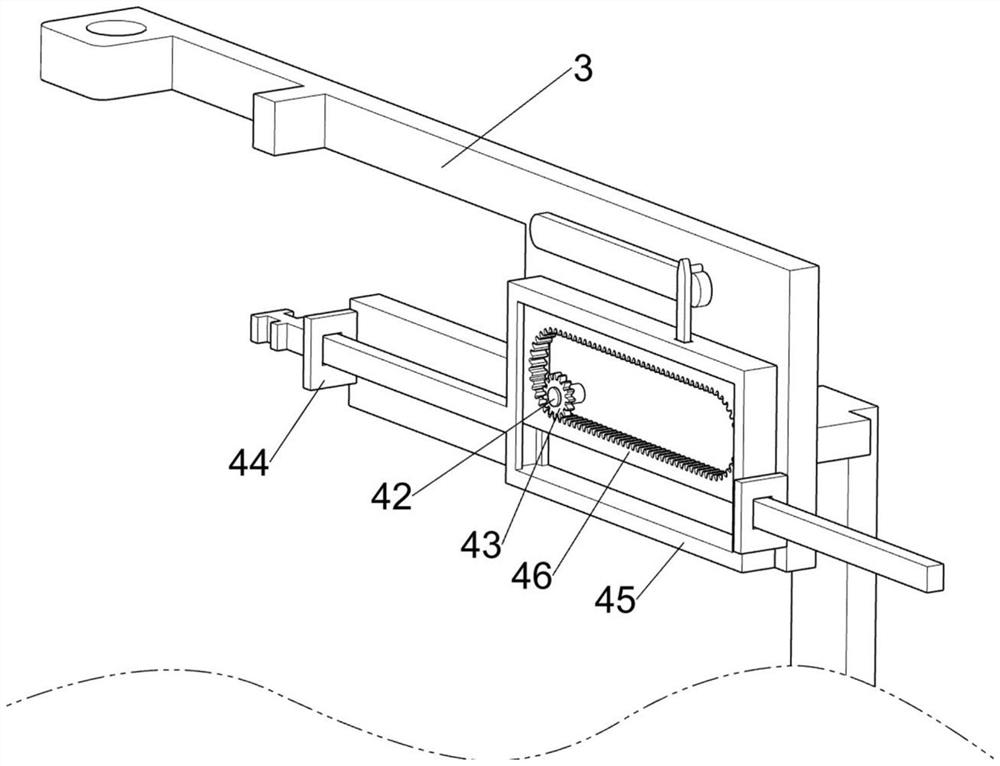

Intelligent buffing device for luggage fur processing

ActiveCN113999942ADegree of controllableQuality improvementFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusMechanical engineeringIndustrial engineering

The invention discloses an intelligent buffing device for luggage fur processing, and relates to the technical field of buffing devices. The intelligent buffing device is provided with a ring grinding assembly and is matched with a buffing detection assembly, a horizontal driving assembly and a squeezing and fixing assembly, on the basis that multiple pieces of fur are integrally and synchronously ground, the purpose that when the fur is ground, the fur grinding degree is synchronously detected and constant pressure is fed back is further achieved, so that the leather grinding degree is controllable, the leather grinding effect is better, the equipment is more intelligent and higher in efficiency, the quality of ground leather is better, and the problems that traditional equipment can only grind fur singly, the grinding degree cannot be detected, the intelligent regulation and control cannot be carried out, and the fur quality during the buffing process is reduced are solved.

Owner:宿州市海得利箱包有限公司

Tan sheep fur processing technology, tan sheep fur and fur product

ActiveCN109022630AGuaranteed shrinkage temperatureGuaranteed softness and comfortTanning treatmentPre-tanning chemical treatmentEngineeringChromium

The invention discloses a tan sheep fur processing technology, tan sheep fur and a fur product, and belongs to the field of fur finishing. The processing technology includes the steps of tanning and dry finishing of the processed tan sheep fur before tanning; and the tanning includes white tanning and neutralize re-tanning, and the dry finishing includes wool combing and hanging washing. The characteristics of natural nine-lane bends of the tan sheep fur are maintained, and low formaldehyde and no chromium are achieved, the tan sheep fur is obtained through the processing technology, the fur product includes the tan sheep fur, the natural nine-lane bends are well preserved, soft, glossy, green, and environmental protection, and the added value is greatly improved.

Owner:宁夏西部皮草有限公司

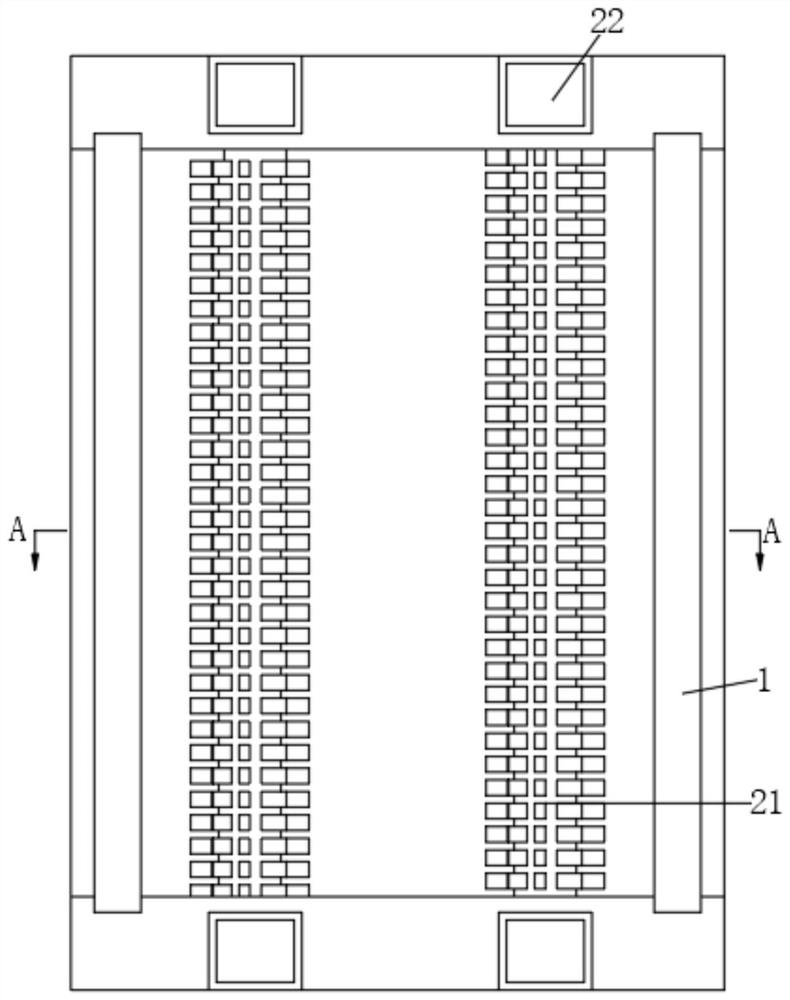

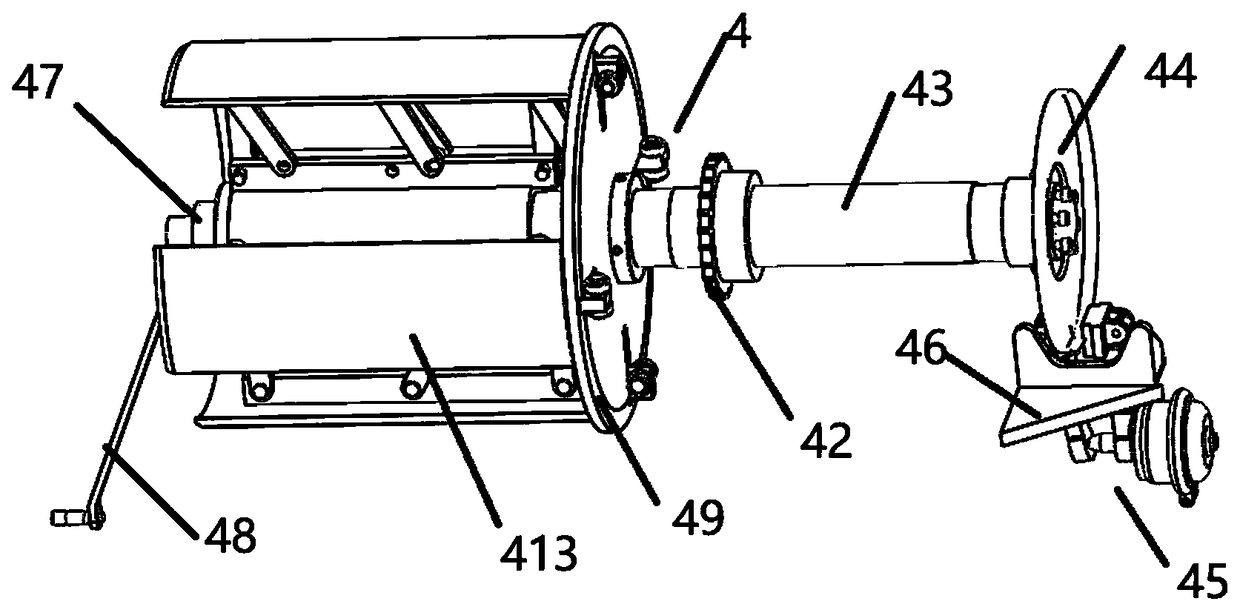

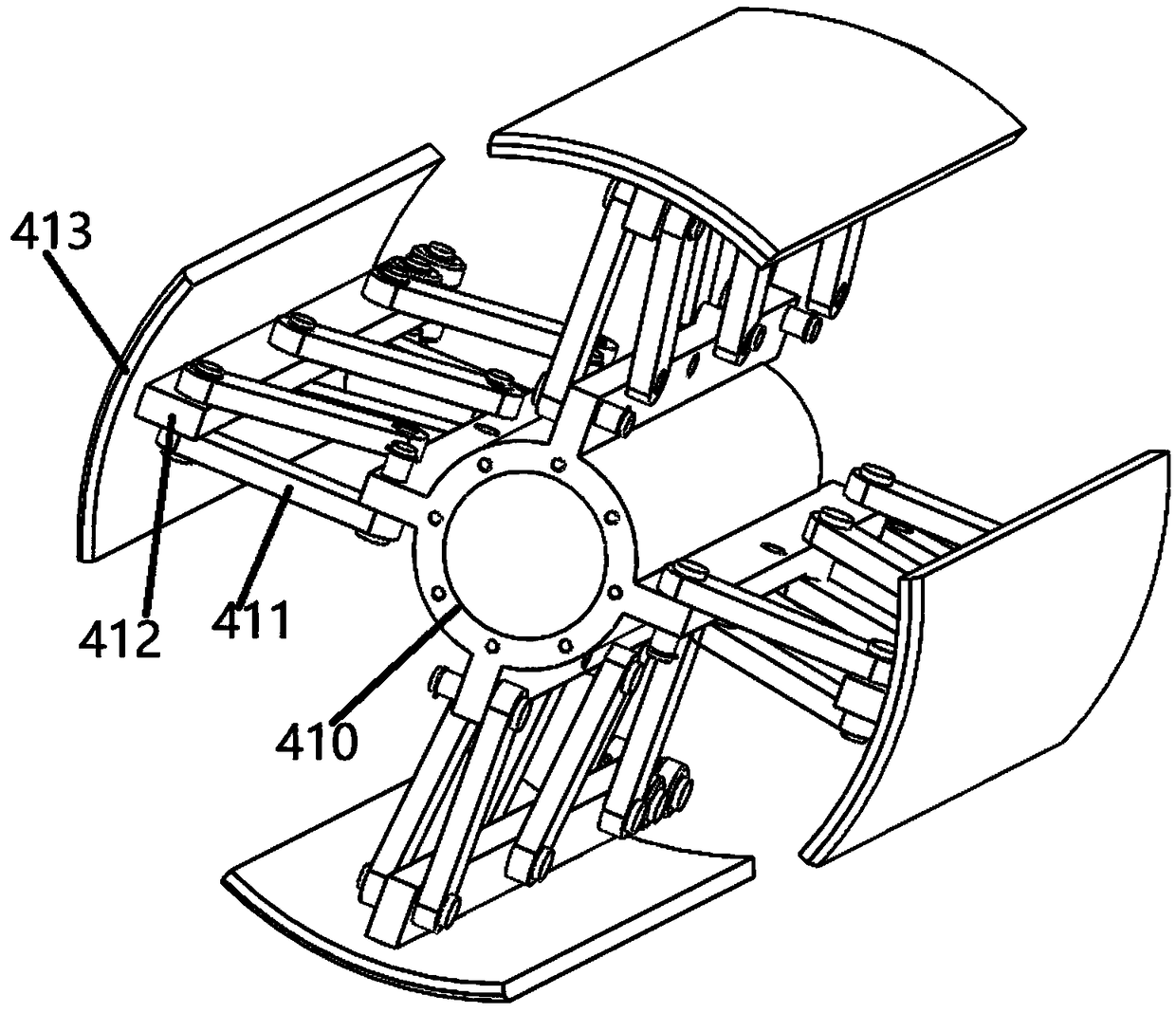

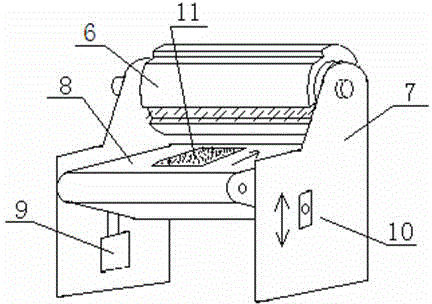

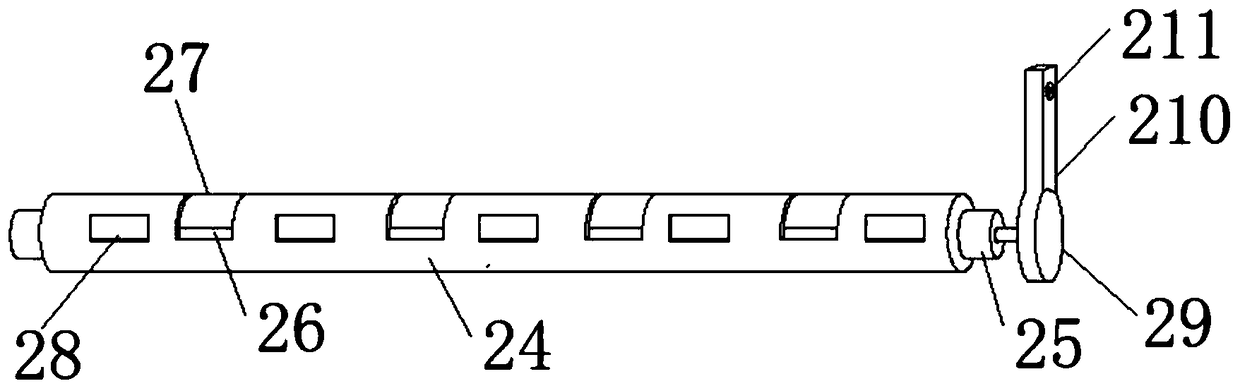

Bundle rolling device for fur collection

InactiveCN108998586AGuaranteed smooth and tightFur mechanical treatmentEngineeringMechanical engineering

The invention discloses a bundle rolling device for fur collection and relates to the technical field of fur processing application. The bundle rolling device for fur collection comprises a base, a supporting frame, a power distribution cabinet, a bundle rolling mechanism, a pressing mechanism, a transmission motor, a gear, a transmission shaft, a disk wheel, a braking mechanism, a fixed plate, ascrew cap, a rotary handle, a fixed disk, a sleeve, a connecting frame, a fixed base, a supporting plate, a first brake sheet, a second disk sheet, a first bracket, a fixed frame, a telescopic rod, afirst air cylinder, a second bracket, a mounting frame, a second air cylinder, a first transmission rod, a rotary rod, a second transmission rod and a rolling wheel. The bundle rolling device for furcollection has the following beneficial effects: the second air cylinder can drive one end of the first transmission rod through a movable rod to move up and down, the first transmission rod of an arc-shaped structure drives a second transmission rod through the rotary rod to rotate within a certain range, and one end of the second transmission rod moves downwards to press the fur bundled on the supporting plate, so the fur is guaranteed to be flat and compact when the fur is bundled.

Owner:JIASHAN SHENGLAISI CASHMERE

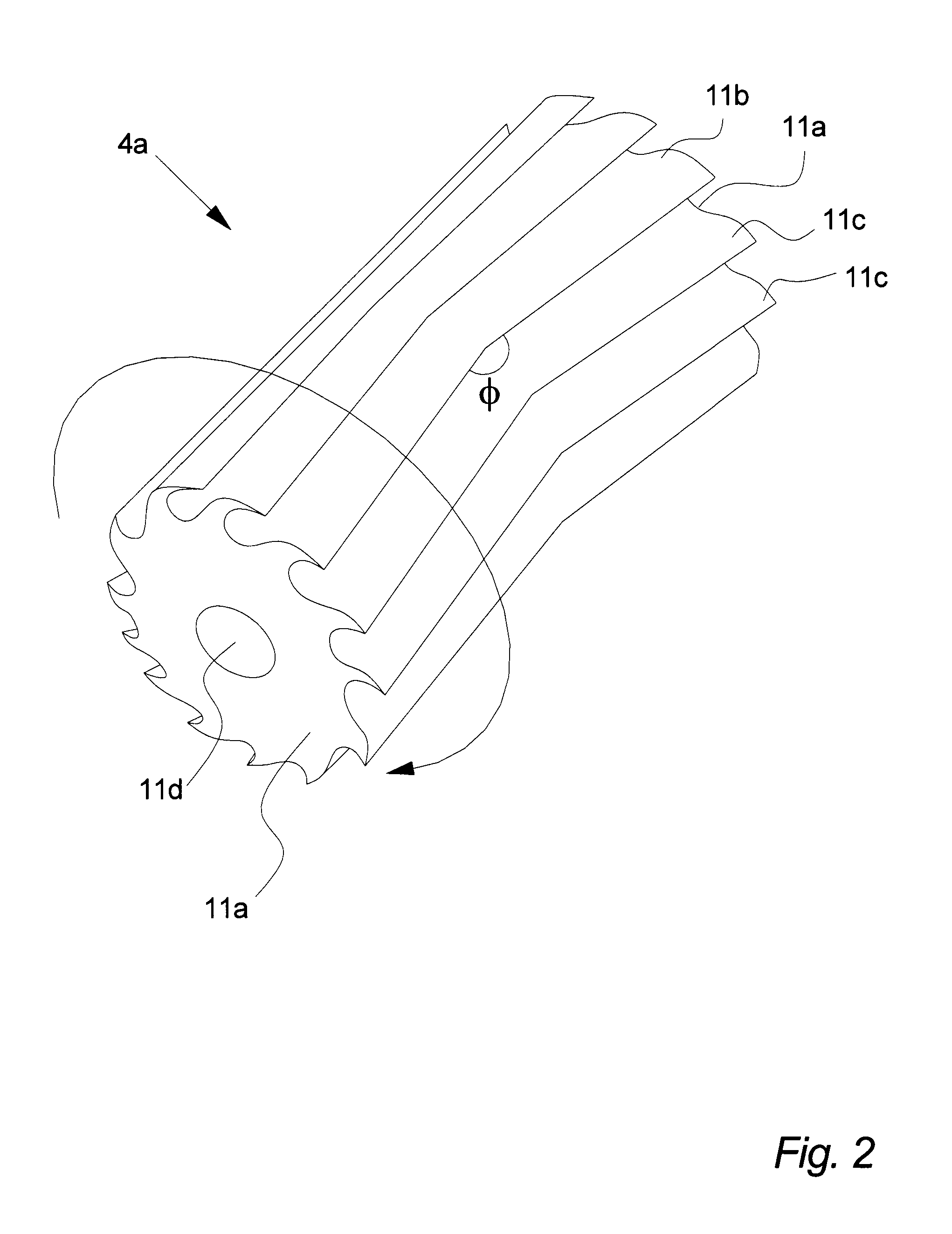

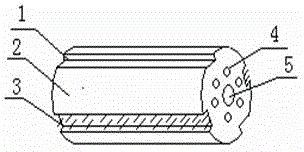

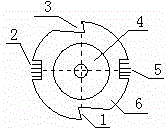

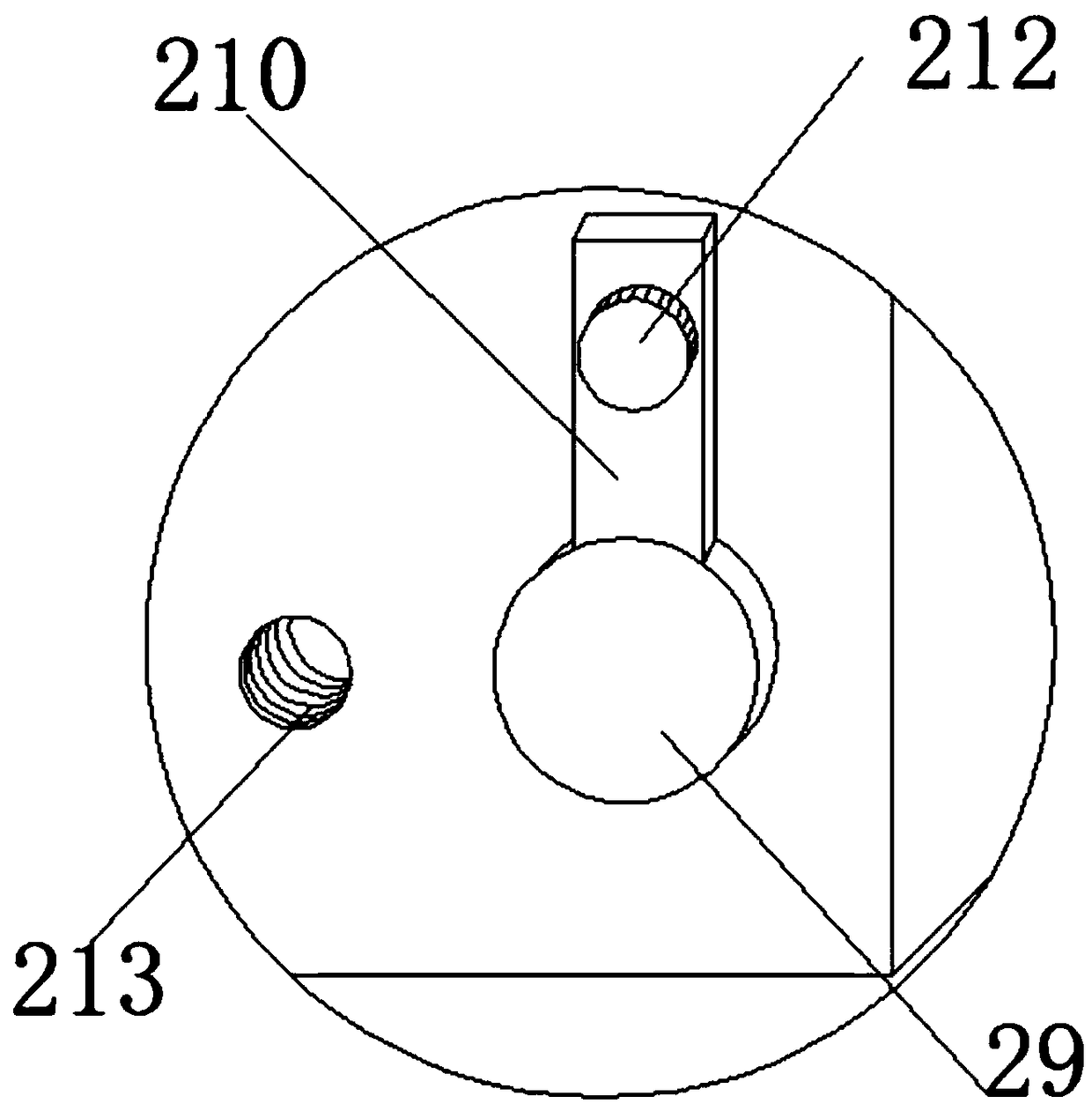

Hair ironing and combing roller for fur processing and application of hair ironing and combing roller

InactiveCN104480232AImprove processing qualityImprove processing efficiencyFur mechanical treatmentMarine engineeringCombing

The invention relates to a hair ironing and combing roller for fur processing. Two hair scraping teeth and two hair combing teeth are arranged on the surface of a cylindrical hair ironing and combing roller along the axial direction respectively, the two hair scraping teeth and the two hair combing teeth are positioned at two ends of two radial central lines of the hair ironing and combing roller respectively, the two radial central lines are perpendicular to each other, a hair ironing surface is positioned on the surface of the hair ironing and combing roller between the hair scraping teeth and the hair combing teeth, a central shaft hole is formed in the center of the hair ironing and combing roller, axial electric heating pipe through holes are uniformly distributed along the radial circumference between the surface of the hair ironing and combing roller and the central shaft hole, and electric heating pipes are arranged in the electric heating pipe through holes; and the hair ironing and combing roller is mounted on a hair ironing and combing device for hair ironing and combing of fur. The hair ironing and combing roller provided by the invention has the advantages that by adopting the hair ironing and combing roller for integrated processing of the fur, the processing efficiency is improved, and the processing quality of the fur can also be greatly improved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

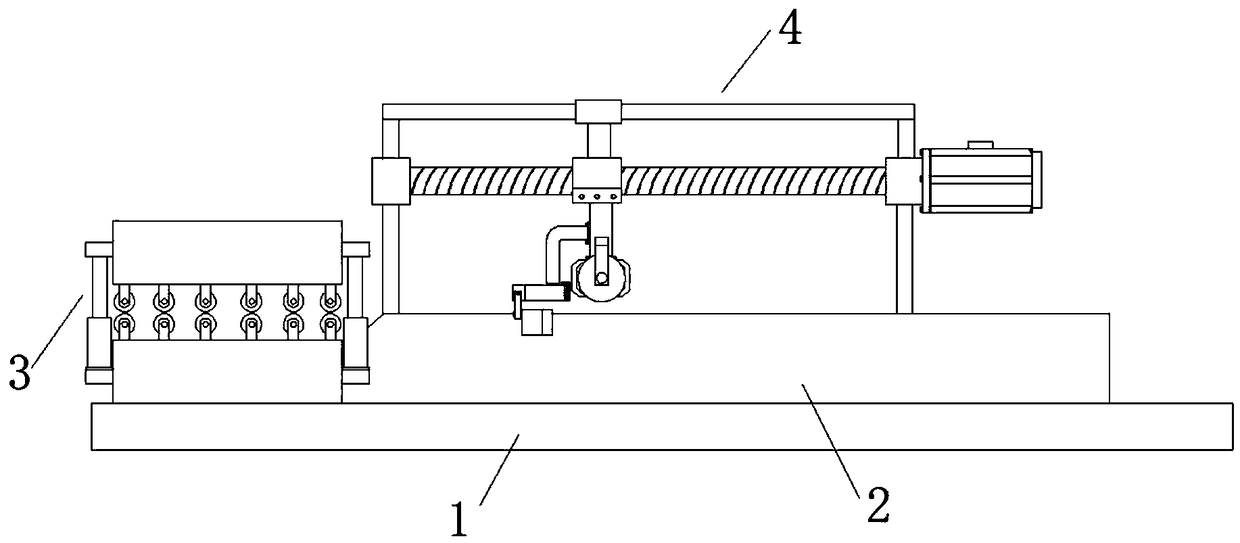

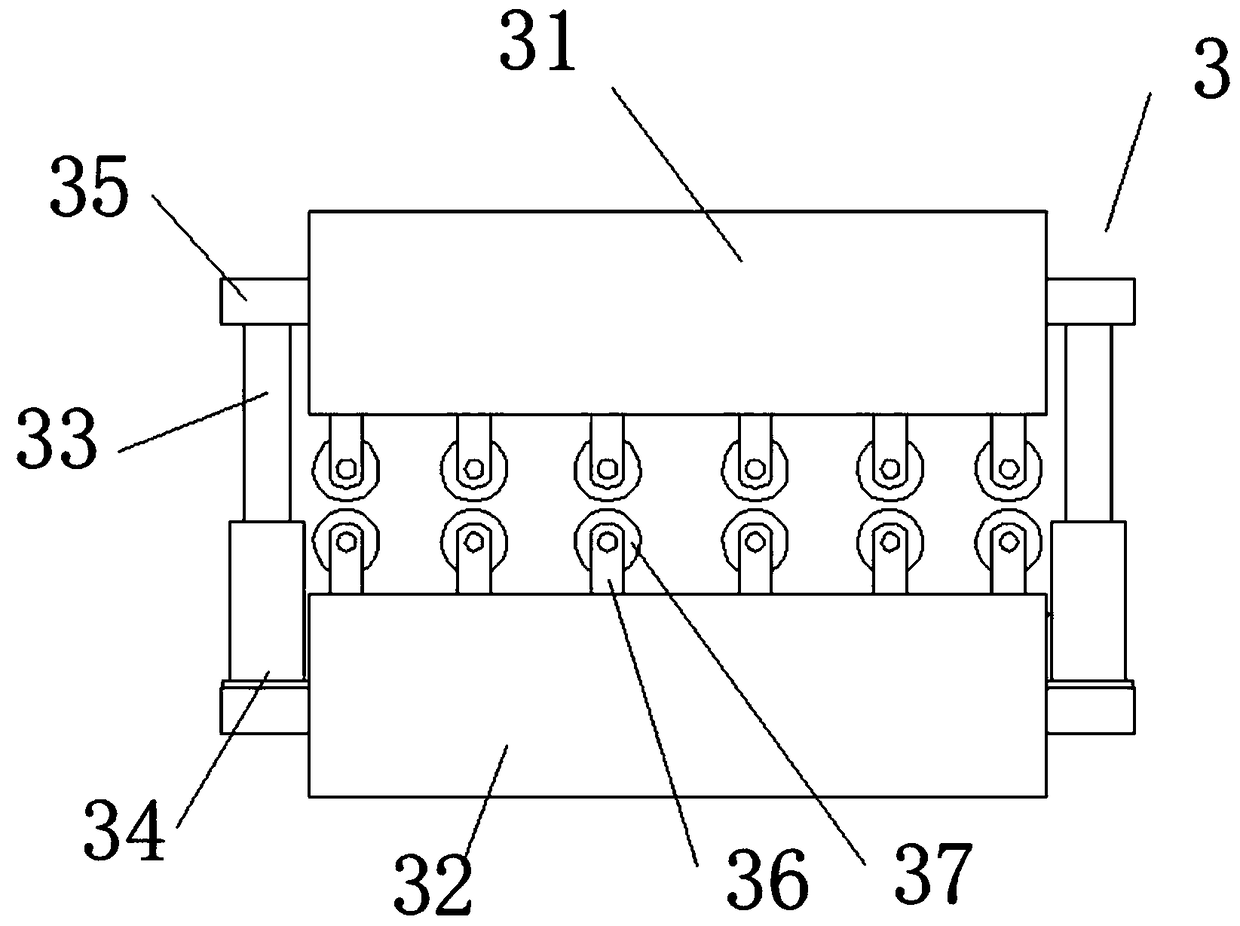

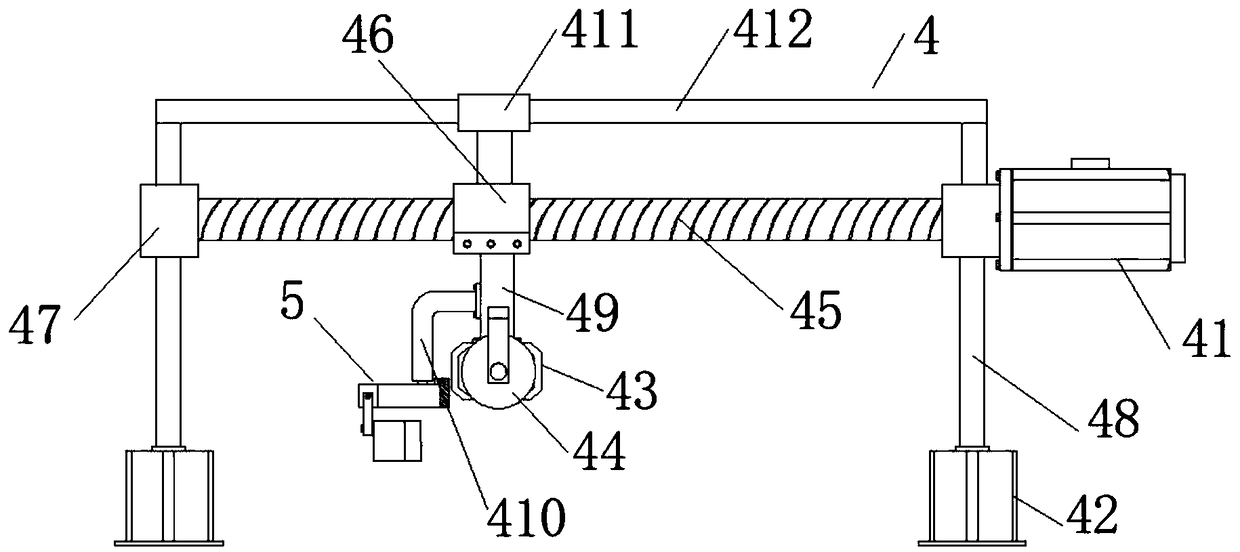

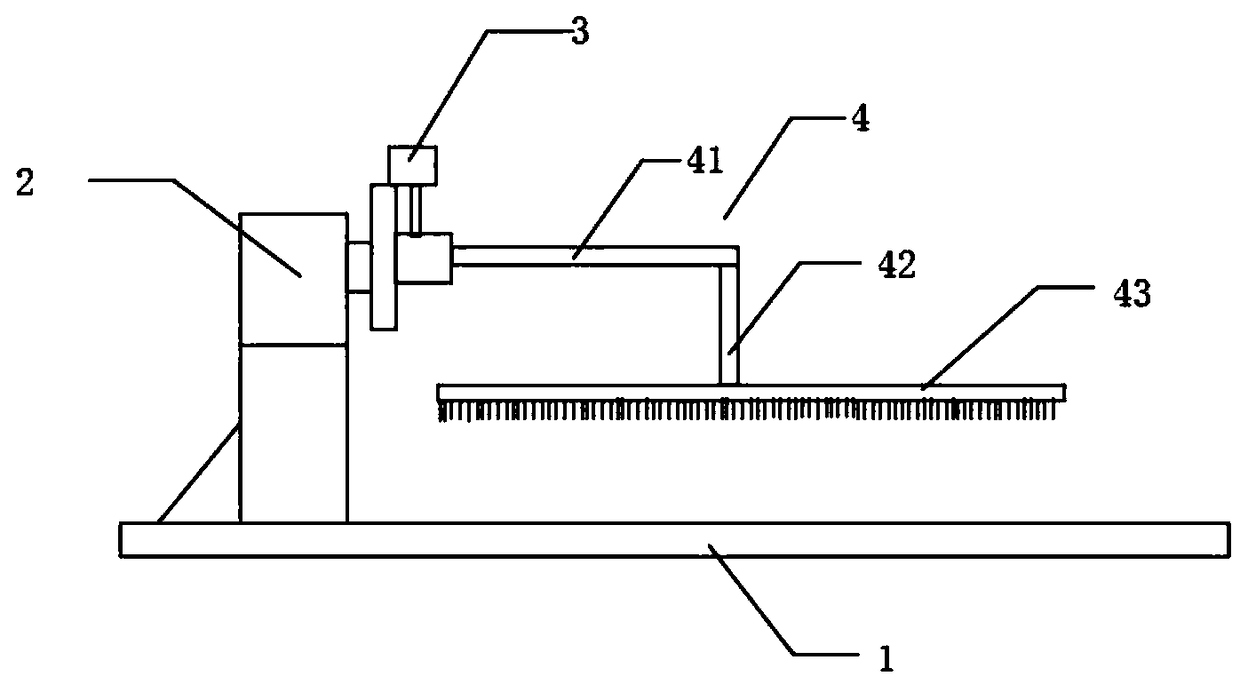

Hair carding equipment for fur processing

InactiveCN108913821AInvolving noveltyIncrease productivityFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusEngineering

The invention relates to the technical field of fur production and provides hair carding equipment for fur processing. The hair carding equipment comprises a base, and further comprises a first movable assembly which is fixed at the left side of the upper end of the base, a second movable assembly which is connected with the first movable assembly, and a hair carding assembly which is connected with the second movable assembly. The hair carding equipment for the fur processing, provided by the invention, is novel and ingenious; furs are manually placed at the upper end of the base and are manually fixed; then the first movable assembly and the second movable assembly are matched with a hairbrush to card hairs, so that the production efficiency is easy to improve and the hair carding quality is improved.

Owner:JIASHAN SHENGSHIDE FUR GARMENT

Grooming device for fur processing

InactiveCN108866253AImprove applicabilityIncrease flexibilityFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusEngineeringFalling hairs

The invention discloses a grooming device for fur processing, relating to the technical field of fur processing and application. The grooming device comprises a fixed table, a shaving mechanism, a suction mechanism, a combing mechanism, a roller, a grip, a fixed plate, a first shaving rod, a second shaving rod, a fixed shaft, a catch pin, a fixed rod, a clamping slot, a welding slot, a turntable,a paddle, a screw hole, a fixed bolt, a clamping hole, a vacuum cleaner, a rubber hose, a suction head, a first bracket, a fixed frame, a second bracket, a fixed seat and a combing rod. The grooming device has the beneficial effects that the second shaving rod which is the same as the first shaving rod is arranged on the shaving mechanism, and a user can adjust the position of the second shaving rod by rotating the paddle, so that the position of the second shaving rod can be changed according to the type of fur, and roan and falling hairs on different types of fur can be removed by the secondshaving rod and the first shaving rod in cooperation, thereby effectively improving the applicability and flexibility of the grooming device. The grooming device has the advantages of simple structure, complete functions and better grooming effect.

Owner:JIASHAN SHENGLAISI CASHMERE

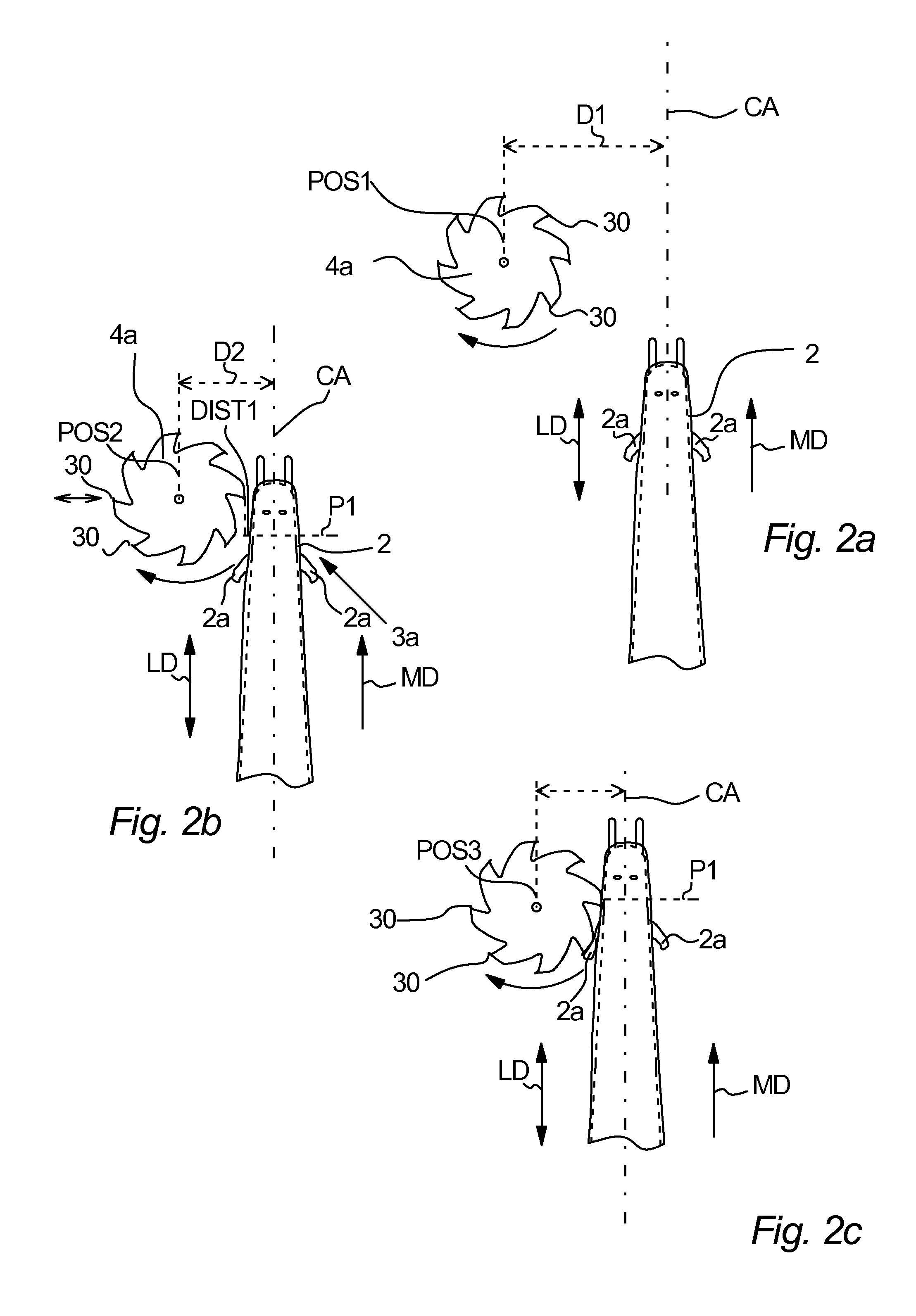

Displacement of scraping rollers

InactiveUS20150218664A1Easy to closeSmall sizeLeather manufacturingFur mechanical treatmentRelative motionSurgery

An apparatus is disclosed for processing the skin side (5) of a tubular pelt (3), the apparatus comprising an elongated tapering mandrel (1) for supporting the pelt with its skin side turned outwards, a scraping device comprising a first set of primary scraping roller (6, 7) arranged on opposing sides of the mandrel and a second set of primary scraping rollers (8, 9) arranged on other opposing sides of the mandrel, the scraping device further comprising primary rotation means (6, 7, 8, 9) for rotating said primary scraping rollers during processing of a pelt so as to engage a skin side of the pelt, moving means for conducting a relative movement between the scraping device and the mandrel in the longitudinal direction of the mandrel, and displacement means for displacing at least one scraping roller in the direction of the axis of rotation of said scraping roller.

Owner:EIKON TECH HLDG

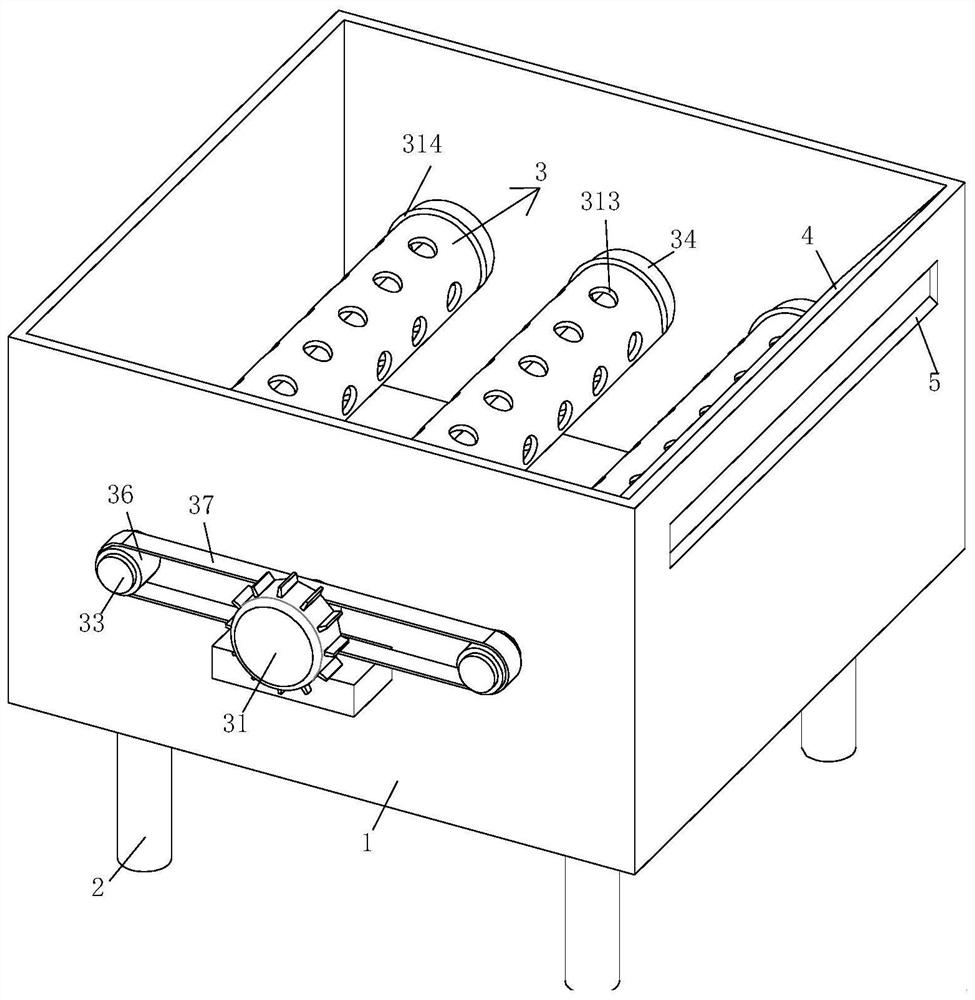

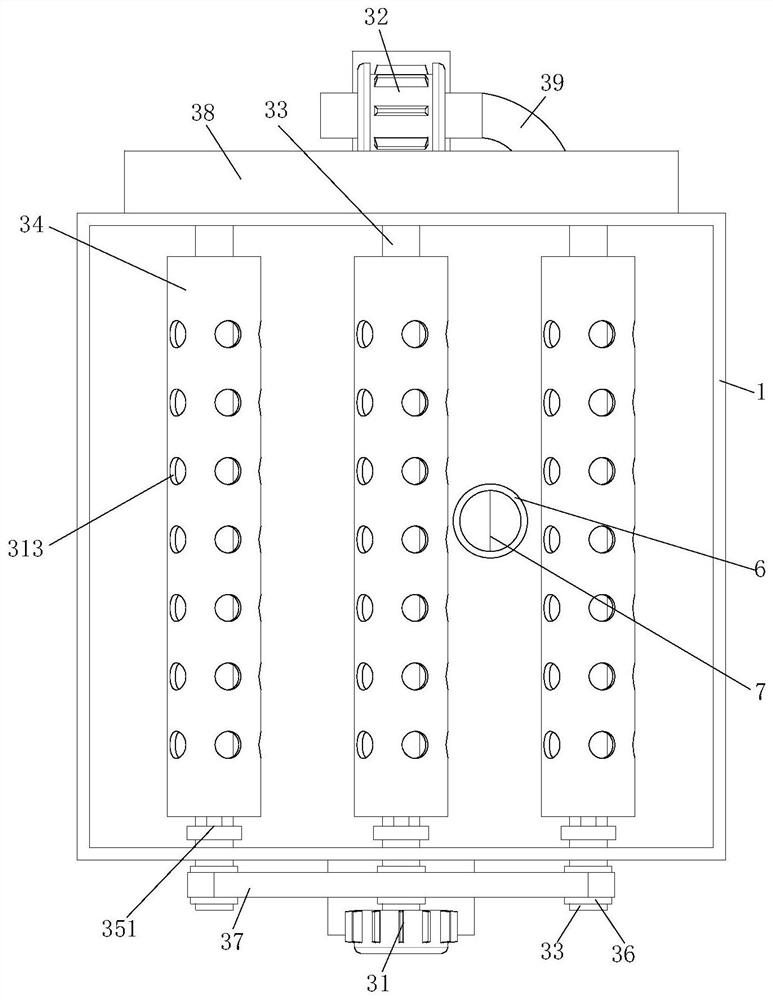

Inflatable cleaning device used for processing of long fur

ActiveCN112029929AIncrease spacingHigh activityFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusEngineeringMechanical engineering

The invention provides an inflatable cleaning device used for processing of long fur, and relates to the field of fur processing. The inflatable cleaning device used for processing of the long fur comprises a cleaning box used for cleaning the fur, supporting legs used for supporting the cleaning box, and an inflatable bubble layer cleaning mechanism used for fixing the fur and movably cleaning the fur, wherein the supporting legs are fixedly connected with the bottom of the cleaning box, and the inflatable bubble layer cleaning mechanism is arranged on the cleaning box. According to the inflatable cleaning device used for processing of the long fur, in order to avoid the situation that broken hair is hard to clean during fur cleaning, it is designed that the fur can be expanded, the fur is moved in the expanding process to remove broken hair, and a cleaning range is formed by dense bubbles to block the broken hair, so that the problems that when ordinary fur is processed, broken hairgenerated during trimming can hardly be removed from other hair, multiple cleaning steps are needed for a large amount of the broken hair, not only is a lot of cleaning time consumed, but also energyconsumption required for cleaning is high, and the processing efficiency is affected to a certain degree are effectively solved.

Owner:梁朝晖

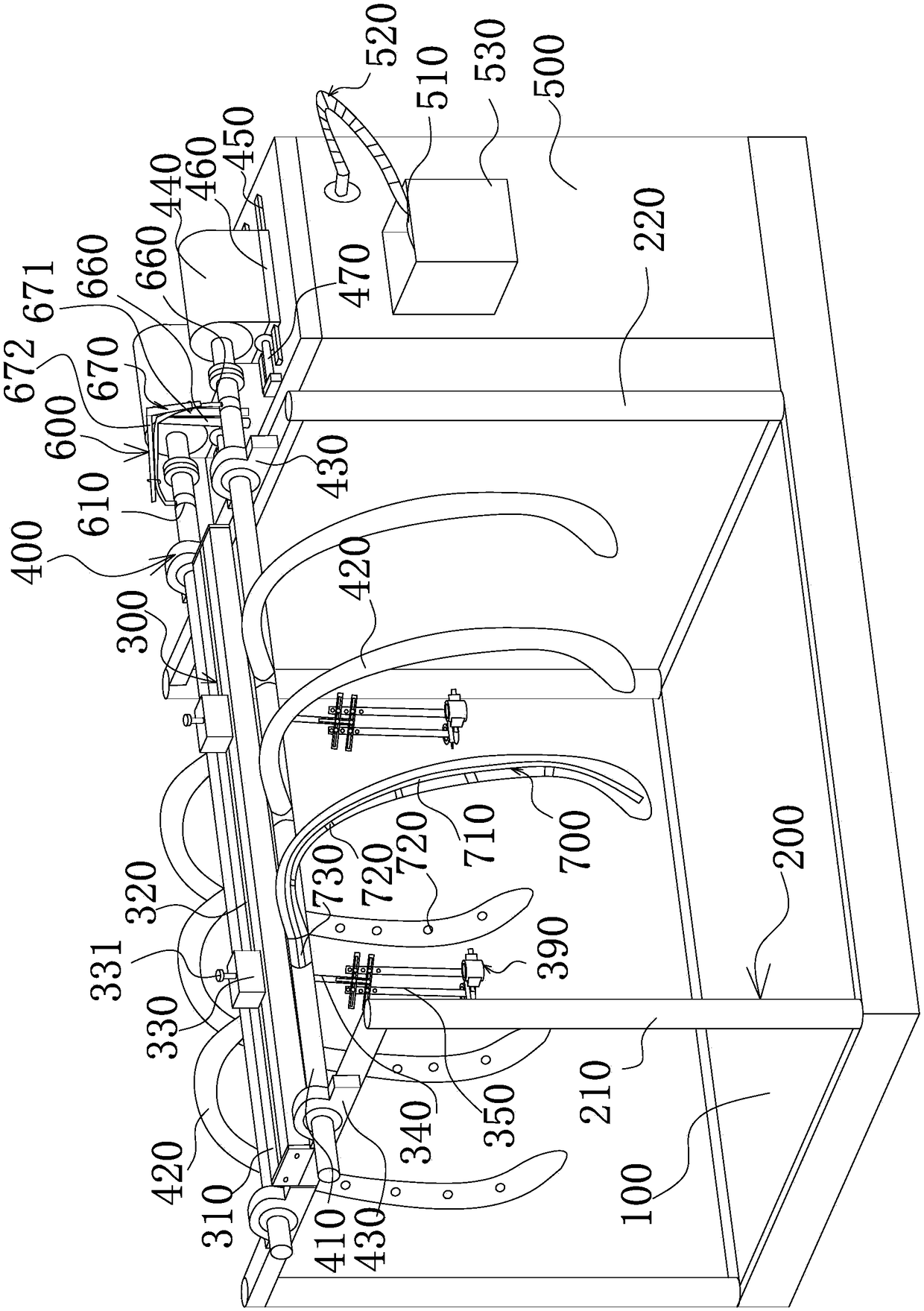

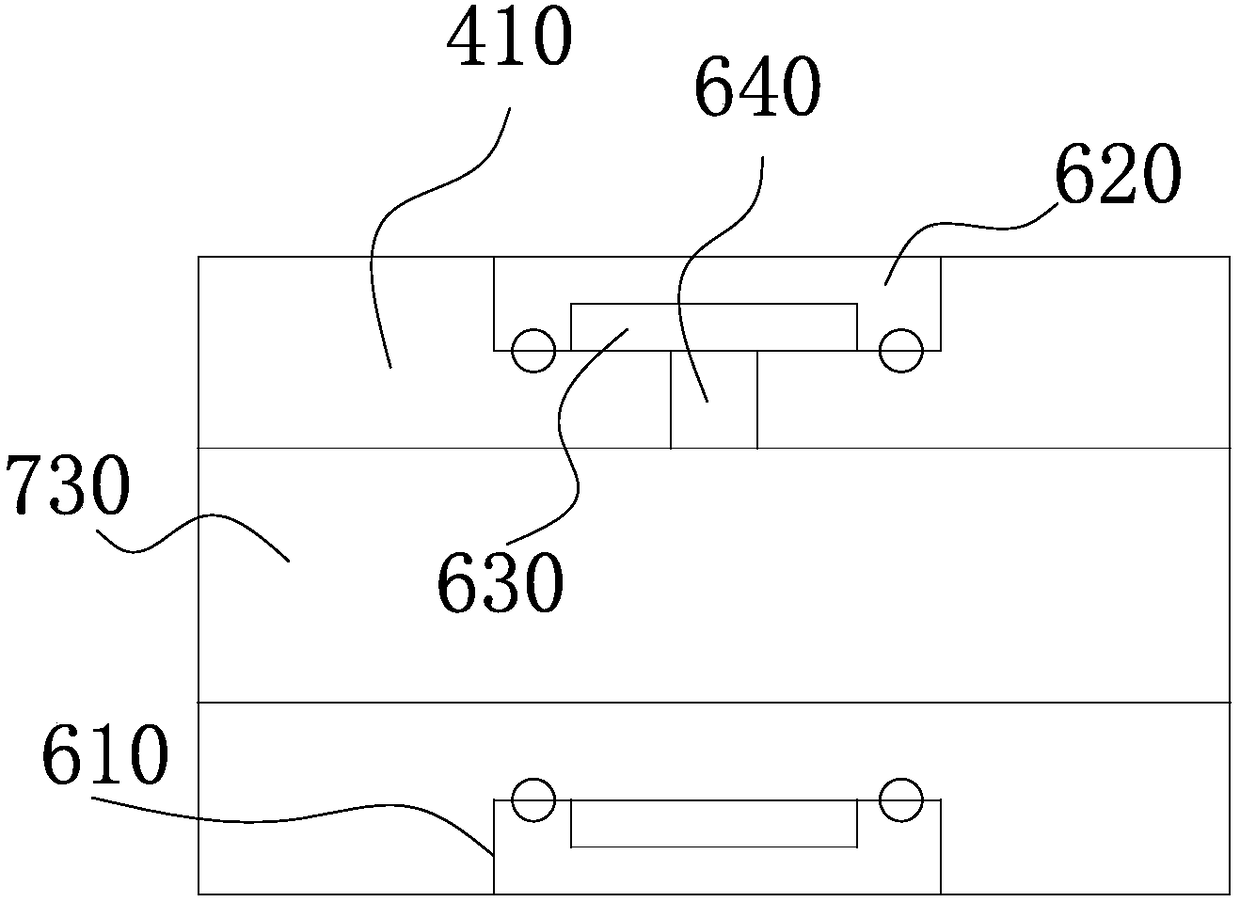

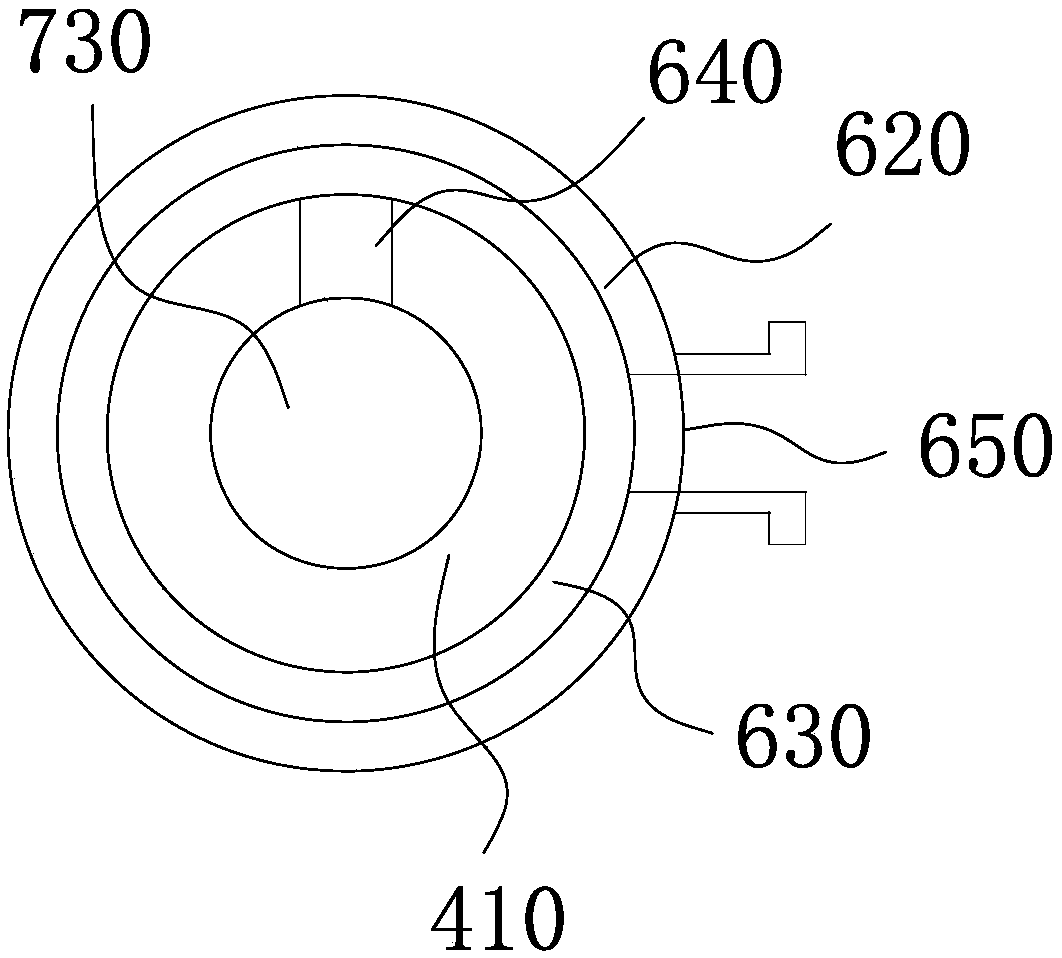

Preprocessing mechanism convenient to improve unhairing efficiency of lambs

InactiveCN108124937AImprove removal efficiencyImprove hair removal efficiencyFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusEngineeringMechanical engineering

The invention relates to the technical field of preprocessing device of unhairing of lambskin, in particular to a preprocessing mechanism convenient to improve unhairing efficiency of lambs. The preprocessing mechanism comprises a base, wherein a frame body and an inflating assembly are arranged on the base; the inflating assembly is connected with an inflating device through a deformation pipe; the inflating device comprises a cylindrical main body; a through hole penetrating through two ends of the main body is formed in the main body; an inflating needle is arranged on the upper side wall of the through hole, and passes through a needle inserting control mechanism which can drive the inflating needle to move in an axial direction of the through hole in a reciprocating manner; a lamb foot positioning mechanism for clamping lamb feet is arranged in the through hole, and comprises upper clamping assemblies arranged on the upper side wall of the through hole; a lower clamping assembly is arranged on the lower side wall of the through hole; a clamping area is formed between the upper clamping assemblies and the lower clamping assembly; and an inflating and banding mechanism is arranged at one end facing the air discharging end of the inflating needle, of the main body. Compared with the prior art, the preprocessing mechanism has the advantages that the design is more reasonable,and the unhairing efficiency can be improved.

Owner:张茶花

Cover arrangement for an apparatus for processing fur

InactiveUS20150052955A1Controlled flow of removedEasy to solveLeather manufacturingFur mechanical treatmentEngineeringStructural engineering

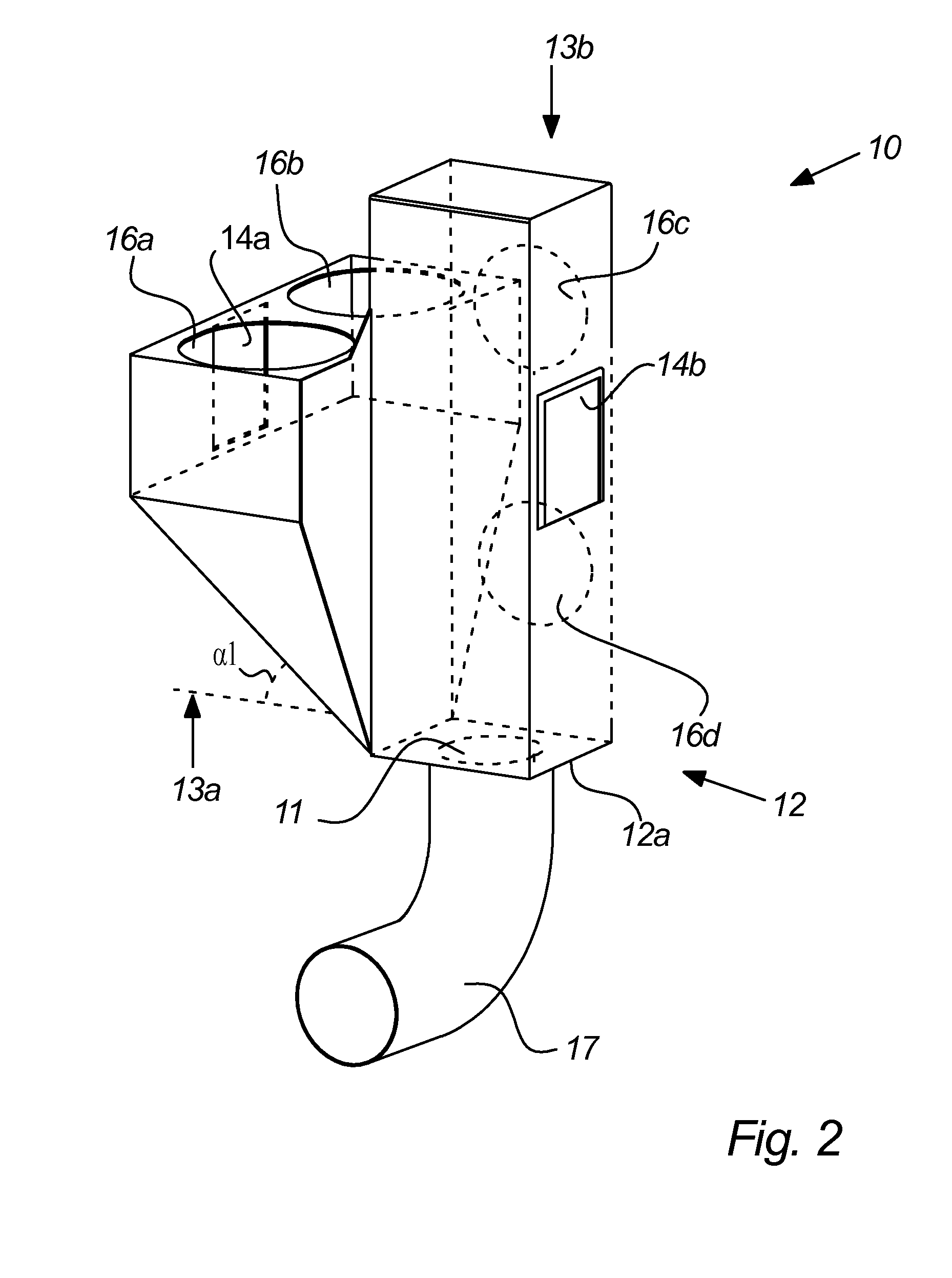

An apparatus for processing the skin side of a tubular fur, including a mandrel on which the tubular fur can be drawn from a first part of the mandrel towards a second part of the mandrel so that the skin side of the fur faces outwards and the fur side of the fur faces inwards towards the mandrel, one or more scraper units, each scraping unit having at least one scraper means configured for scraping the skin side when the fur is arranged on the mandrel, and a cover including a compartment and an outlet, where the cover is configured for enclosing at least a part of the mandrel and at least one of the scraper means in the compartment during operation, where the outlet is arranged in a bottom part of the cover, the bottom part being arranged below the at least one scraper means, and where the cover has walls with inner surfaces configured for leading material removed from the skin side by means of one or more of the one or more scraper means towards the bottom part.

Owner:EIKON TECH HLDG

Displacement of scraping rollers

InactiveUS9631247B2Easy to closeSmall sizeLeather manufacturingFur mechanical treatmentEngineeringMechanical engineering

An apparatus is disclosed for processing the skin side (5) of a tubular pelt (3), the apparatus comprising an elongated tapering mandrel (1) for supporting the pelt with its skin side turned outwards, a scraping device comprising a first set of primary scraping roller (6, 7) arranged on opposing sides of the mandrel and a second set of primary scraping rollers (8, 9) arranged on other opposing sides of the mandrel, the scraping device further comprising primary rotation means (6, 7, 8, 9) for rotating said primary scraping rollers during processing of a pelt so as to engage a skin side of the pelt, moving means for conducting a relative movement between the scraping device and the mandrel in the longitudinal direction of the mandrel, and displacement means for displacing at least one scraping roller in the direction of the axis of rotation of said scraping roller.

Owner:EIKON TECH HLDG

Double face leather production process capable of eliminating electrostatic interaction in double face leather product processing process

InactiveCN111979362ASolve the problem of electrostatic adsorption dustImprove hygieneTanning treatmentPre-tanning chemical treatmentEconomic benefitsProcess engineering

The invention provides a double face leather production process capable of eliminating electrostatic interaction in a double face leather product processing process, which comprises the following steps of: performing water return and retanning on double face leather crust leather, and performing wool dyeing, plate dyeing and acid pickling to obtain double face leather colored leather; carrying outroll ironing and shearing on the woolen cover surface of the double face leather colored leather obtained in the previous step, then finishing, and carrying out roll ironing again to obtain a semi-finished product; and spraying an antistatic agent on the plate surface of the semi-finished product obtained in the previous step to obtain a double face leather product. The problem of electrostatic dust adsorption in the processing process is effectively solved, the durability and high-efficiency effects are remarkable, the comprehensive performance such as sanitation, attractiveness and safety of a double face leather product can be improved, and the processing difficulty of the double face leather product is reduced. The technical means is economical and environmentally friendly, the problems of adhesion of dust and scurf of a double face leather finished product and the like caused by static electricity are avoided, and meanwhile, the product has the characteristics of thinness, lightness and softness, the tearing strength reaches the standard, the hexavalent chromium content is extremely low, and the economic benefit and the environment-friendly benefit are remarkable.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

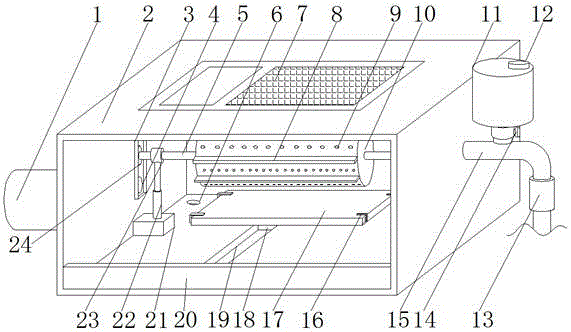

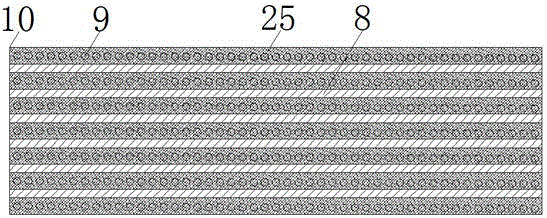

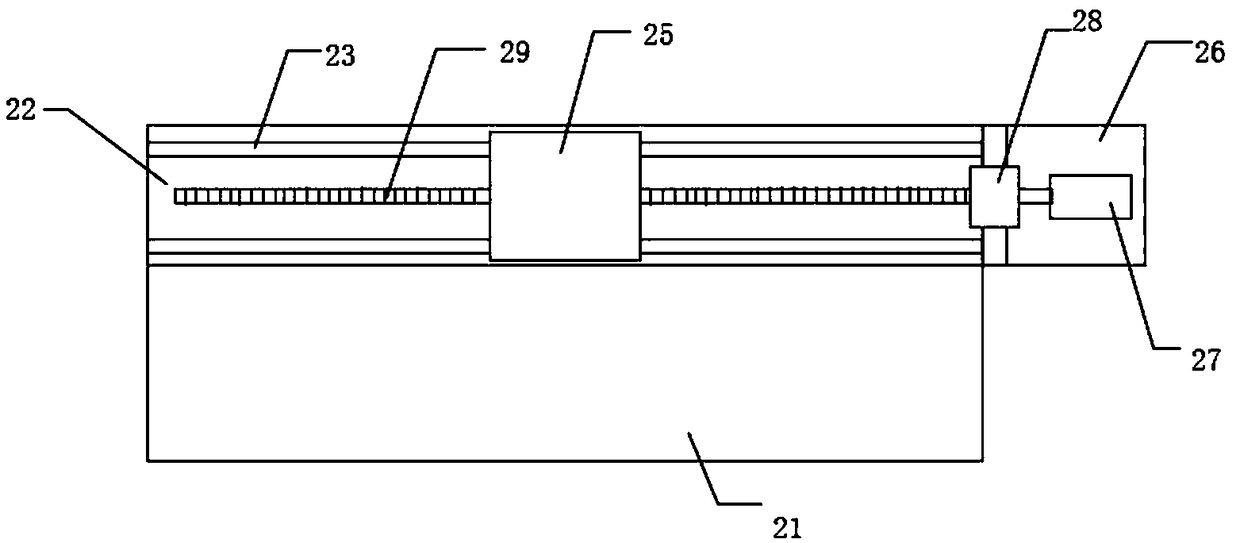

Hair ironing and combing machine

InactiveCN103952501AReduce labor intensityAvoid harmFur mechanical treatmentMotor driveWorking environment

The invention relates to an animal hair ironing and combing machine, and especially relates to a hair combing machine used for wool, rabbit hair and the like. A hair combing step is needed in the making of fur clothes, present routine technologies are characterized in that fur ironing is carried through using an iron by a worker and hair manpower combing is carried out by using a comb, and the above mode has the disadvantages of low hair combing efficiency, large worker labor intensity, bad working environment, and easy damage, frequent replacement and large use cost of the comb. The hair ironing and combing machine in the invention is characterized in that a motor drives a conveying net to convey fur, the fur is adsorbed by a fan, fur is ironed by using high temperature steam, and another motor drives a group of uniformly arranged steel needle arrays to repeatedly move in order to comb the fur; and compared with combing machines in the prior art, the hair ironing and combing machine has the advantages of great increase of the work efficiency, mitigation of the worker labor intensity, maximal avoiding of the damages of high temperature steam in summer to the worker, and substantial reduction of the use cost because of long term use and unlikely damage of the steel needles.

Owner:ZHENJIANG COLLEGE

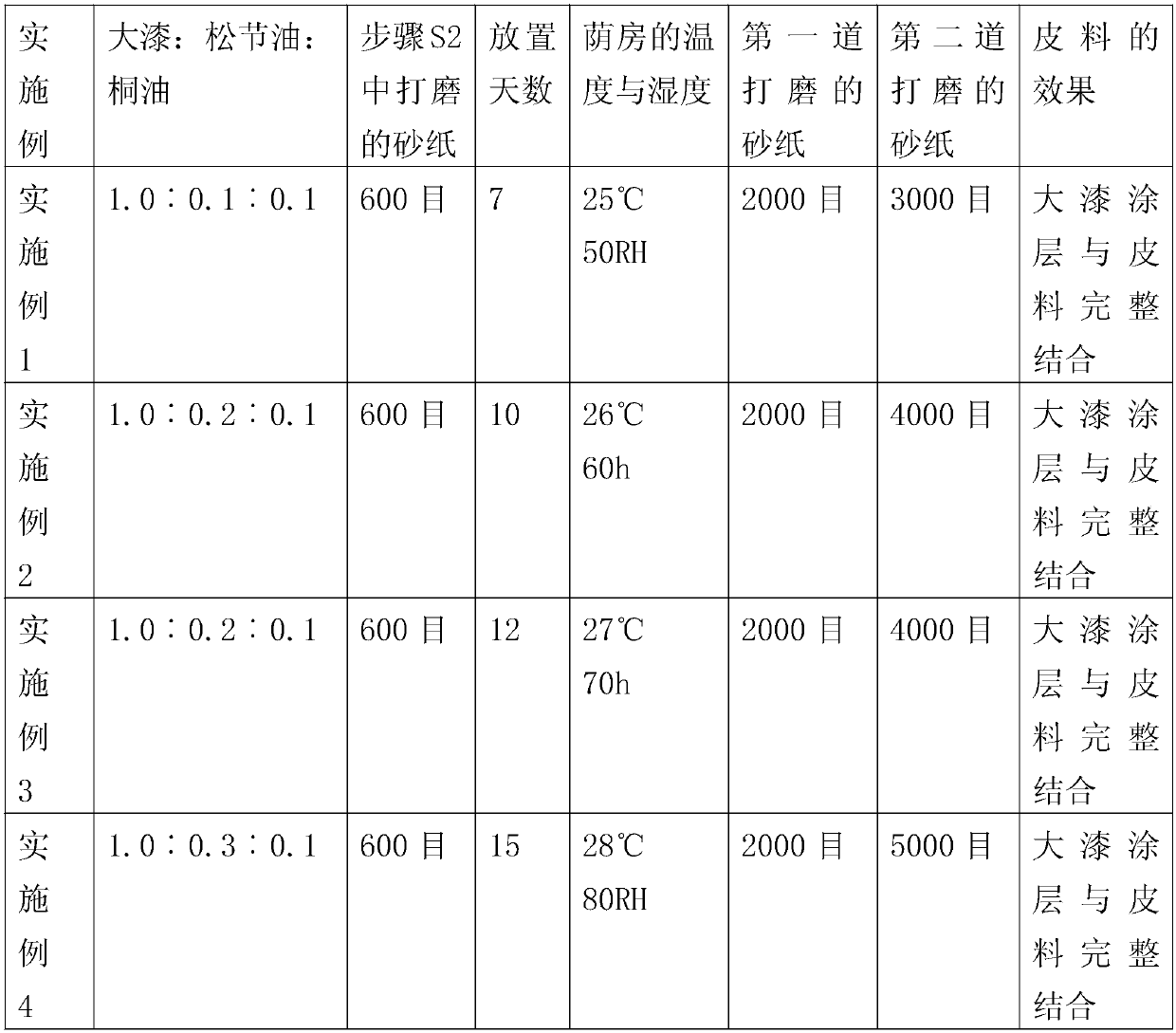

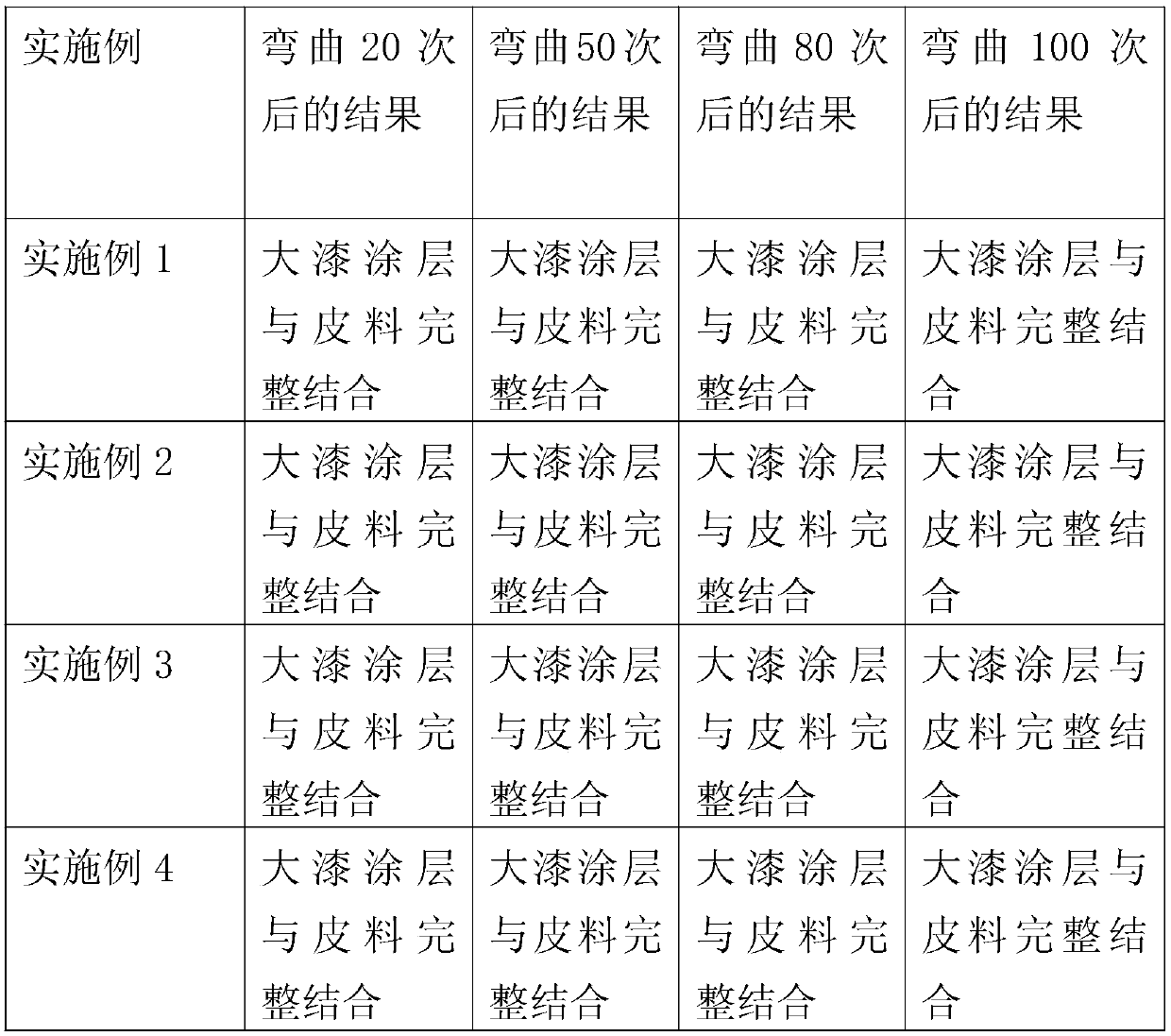

Rubbing polishing treatment method for Chinese lacquer on surface of leather

InactiveCN107828921ARetain textureEasy to solveFur mechanical treatmentLeather surface mechanical treatmentWaxLacquer

The invention relates to a rubbing polishing treatment method for Chinese lacquer on the surface of leather. The rubbing polishing treatment method comprises the following steps that S1, the Chinese lacquer, turpentine oil and tung oil are uniformly mixed proportionally, and Chinese lacquer paint is prepared; S2, wax or oil on the skin layer of the surface of the leather is polished with abrasivepaper, and the leather is pretreated; S3, the Chinese lacquer paint is completely smeared on the surface of the leather, and the leather is put at a cool and wet place to be naturally dried after sufficiently absorbs the Chinese lacquer paint; S4, after the leather is put at the place for some days, the Chinese lacquer paint is completely solidified on the surface of the leather and forms a Chinese lacquer coating layer, primary polishing is conducted on the solidified Chinese lacquer coating layer through the adhesive paper so that a lacquer film covering the surface can be removed, and then,secondary polishing is conducted the solidified Chinese lacquer coating layer through the adhesive paper; and S5, after the solidified Chinese lacquer coating layer is polished to be smooth, the leather is cleaned with clean cloth, and buffing is conducted. According to the rubbing polishing treatment method, the Chinese lacquer and the leather are combined, a lacquer-leather combining layer is formed on the surface of the leather, and the artistry and value of the leather are improved.

Owner:福州三分慵懒文化传播有限公司

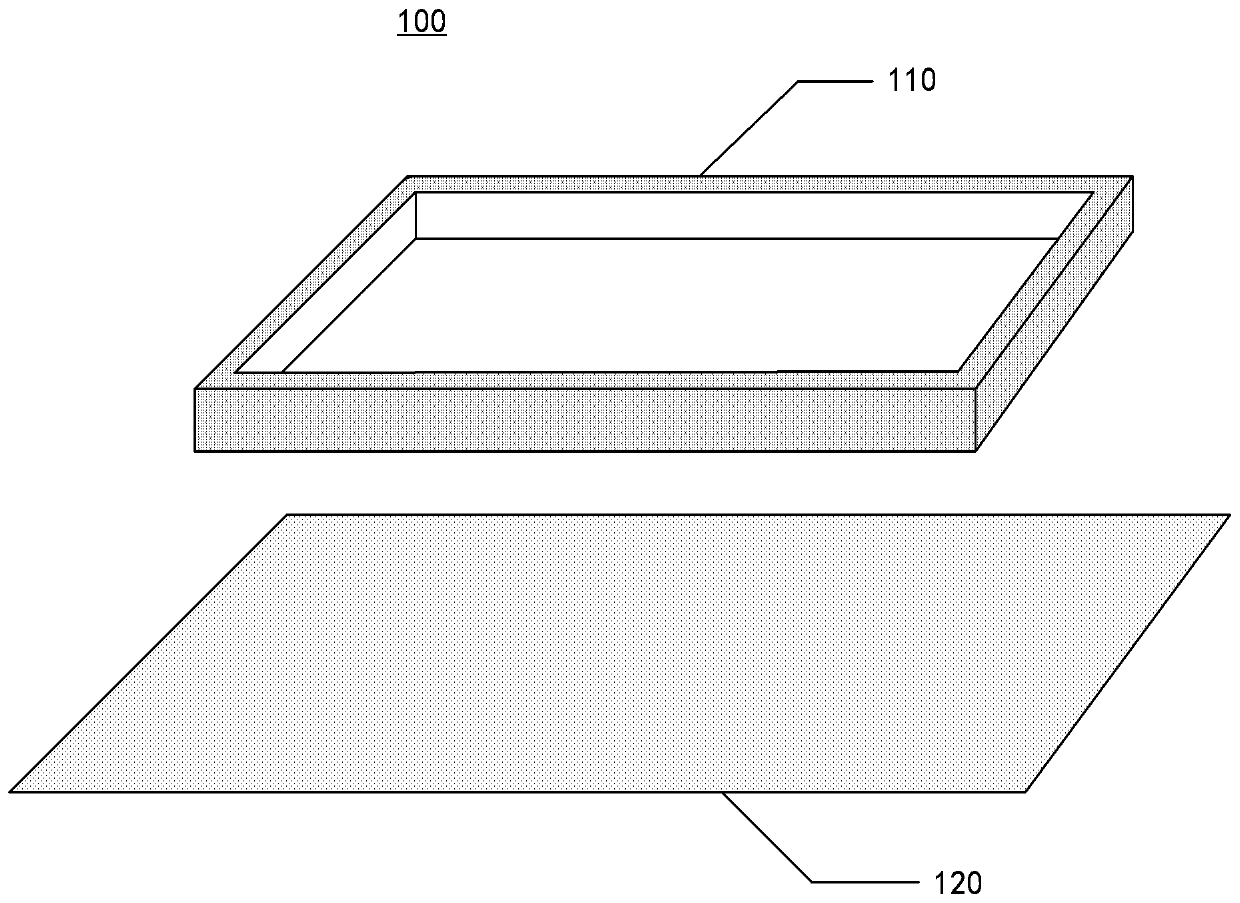

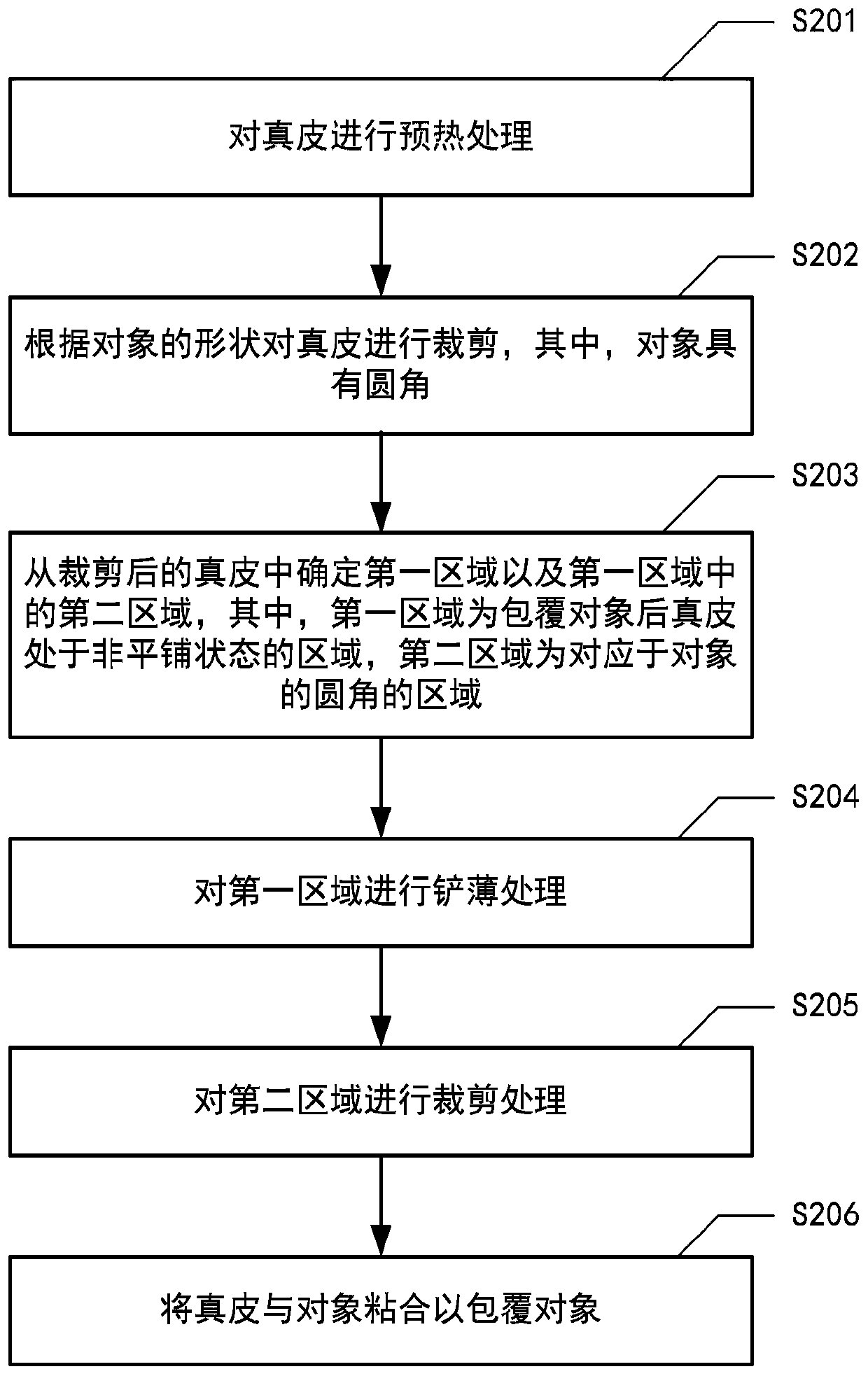

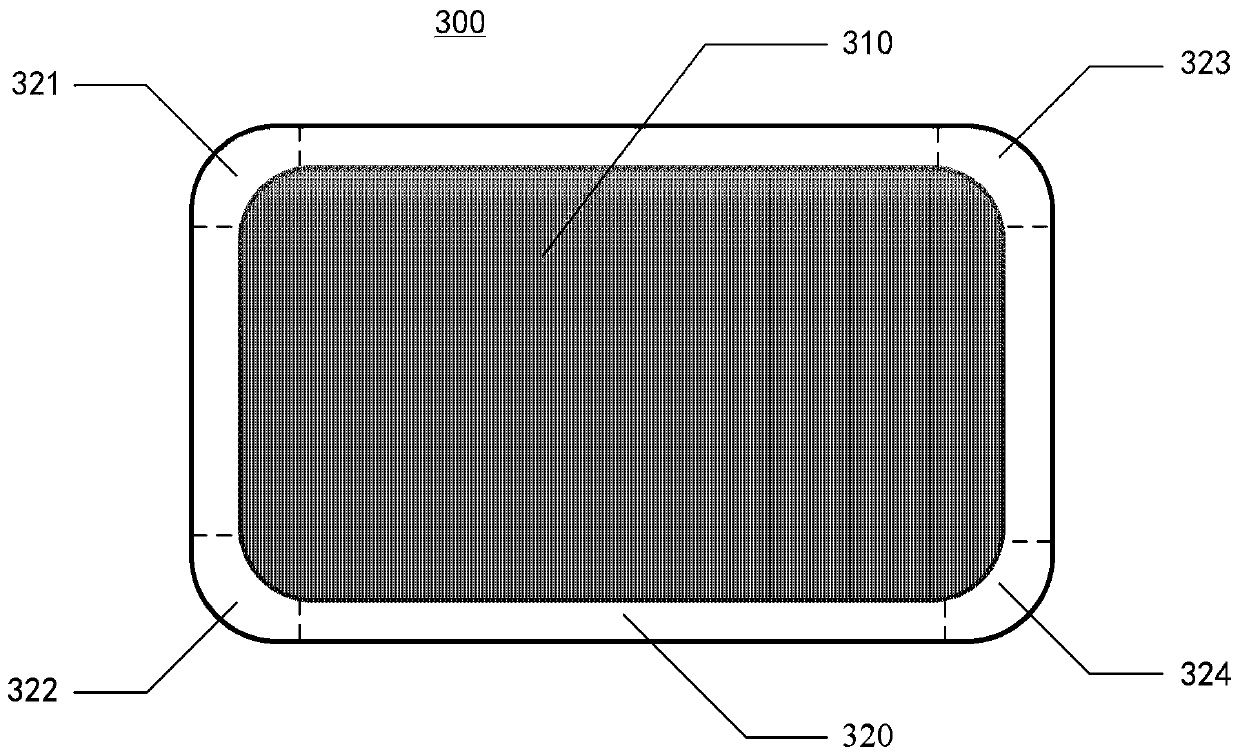

Method of coating subject with genuine leather

InactiveCN110923369ALeather clicking/perforating/clickingFur mechanical treatmentMechanical engineeringIndustrial engineering

The invention provides a method of coating a subject with genuine leather. The method comprises the following steps: preheating genuine leather; cutting the genuine leather according to the shape of an object, the object having a fillet; determining a first area and a second area in the first area from the cut genuine leather, the first area being an area where the genuine leather is in a non-tiled state after the object is coated, and the second area being an area corresponding to the fillet of the object; thinning the first area; cutting the second area; and bonding the genuine leather withthe object to coat the object.

Owner:LENOVO (BEIJING) LTD

Cattle hide shoveling frame capable of fixedly scraping and preventing scratching

ActiveCN113462823AAchieve a fixed effectEasy to adjustFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusRotational axisAnimal science

The invention relates to a cattle hide shoveling frame, in particular to a cattle hide shoveling frame capable of fixedly scraping and preventing scratching. The cattle hide shoveling frame comprises a bottom plate, a supporting rod, a supporting plate, a rotating shaft, a base plate and the like, the supporting rod is fixedly connected to one side of the bottom plate, the supporting plate is fixedly connected to the top of the bottom plate, the rotating shaft is connected to the supporting plate through a bearing, and the base plate is fixedly connected to the rotating shaft. Through cooperation of a power shaft, a small gear, a pushing frame and devices of a reciprocating pushing assembly, hair scraping is conducted on the cattle hide, the effect of scraping hairs on the cattle hide with the same force is achieved, through cooperation of a lifting groove rod, a quadrangular frame, an arc-shaped fixing ring and devices of a cattle hide extruding and positioning assembly, the cattle hide is pressed, and the effect of fixing the cattle hide is achieved.

Owner:三明市尚谷食品生产有限公司

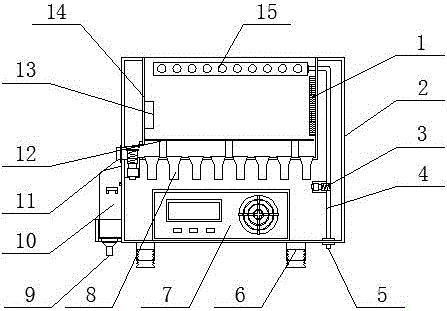

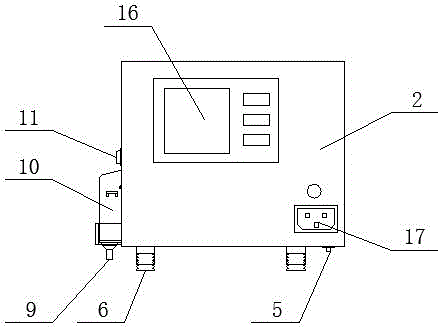

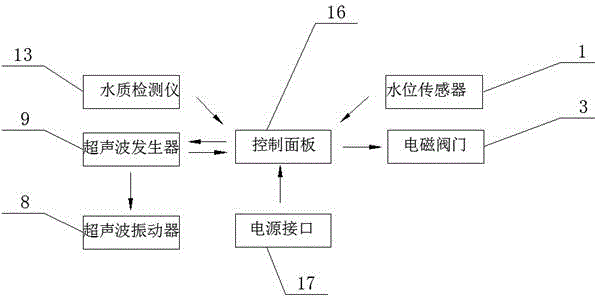

Ultrasonic leather cleaning machine

InactiveCN106733913ASolve the problem of not being able to judge whether the leather needs to be cleaned twiceScientific and reasonable structureFur mechanical treatmentCleaning using liquidsWater dischargeWater quality

The invention discloses an ultrasonic leather cleaning machine. The ultrasonic leather cleaning machine comprises a cleaning machine body and a filtering barrel. Foot pads are arranged at the bottom of the cleaning machine body, a water inlet is formed in one sides of the foot pads, the filtering barrel is installed on one side of the cleaning machine body, a filtering-barrel water discharging opening is formed below the filtering barrel, a water discharging opening is formed in one side, close to the upper portion of the filtering barrel, of the cleaning machine body, and a control panel is arranged on the front surface of the cleaning machine body. The ultrasonic leather cleaning machine is scientific and reasonable in structure and safe and convenient to use; as a water level sensor is arranged, the problem that water cannot be automatically added to be at the required water level of the cleaning machine is solved, the water adding amount can be automatically controlled, artificial monitoring is not required during water adding, and labor is reduced; as a water quality detector is arranged, the problems that the water quality after being cleaned cannot be detected, and whether leather needs to be subjected to secondary cleaning or not cannot be judged are solved; the water quality after being cleaned can be detected, and therefore whether secondary cleaning is required or not is judged.

Owner:邹城市众光日用品销售有限公司

Apparatus for processing the skin side of a fur

InactiveUS20150114049A1Reduce time delayAdequate scrapingLeather manufacturingFur mechanical treatmentBiomedical engineeringCutis

An apparatus for processing the skin side of a tubular fur where one or more scraping means are configured for being arranged in a first position away from a mandrel of the apparatus with a first distance in relation to the center axis of the mandrel, and in a third position where the scraping means are configured for being in contact with the skin side so as to process the skin side of the fur, where the one or more scraping means are furthermore configured for being arranged in a second predefined position being arranged between the first position and the third second position with a second predefined distance in relation to the centre axis of the mandrel, and the apparatus is configured for automatically releasing the scraping means from the second position towards the third position when predetermined criteria is complied with.

Owner:EIKON TECH HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com