Cattle hide shoveling frame capable of fixedly scraping and preventing scratching

A technology of cowhide and positioning components, which is applied in the field of cowhide removal racks, can solve the problems of manual continuous adjustment, and achieve the effect of quickly adjusting the position of cowhide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

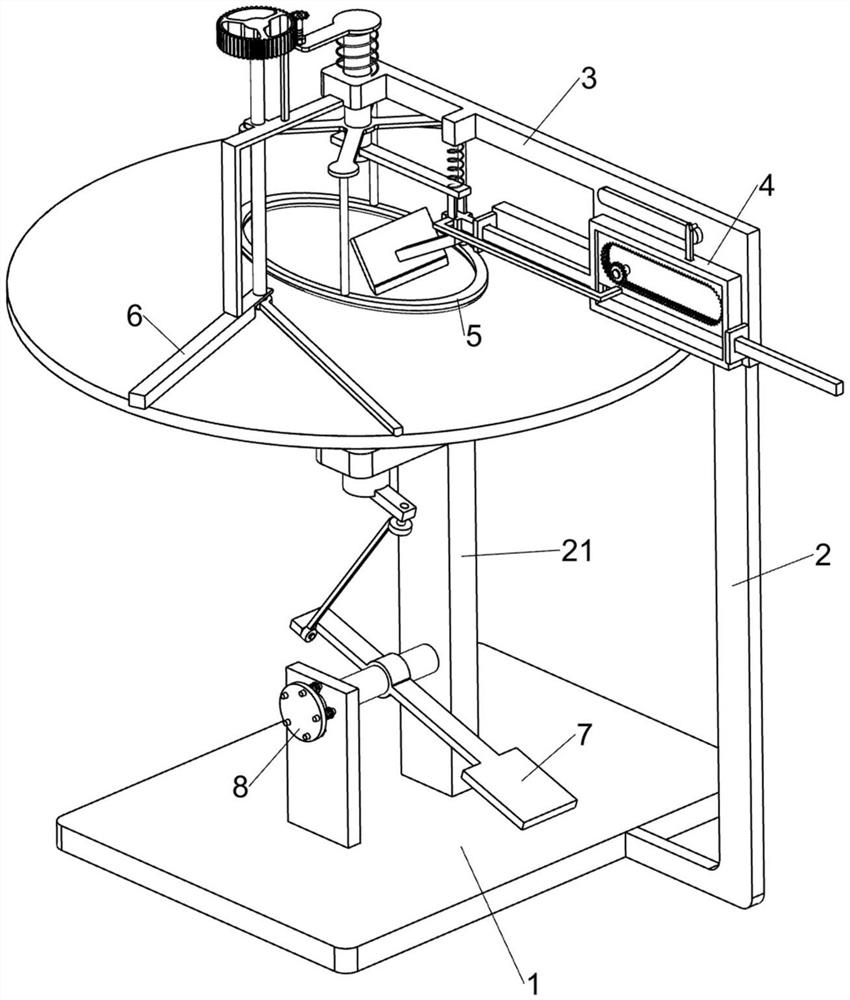

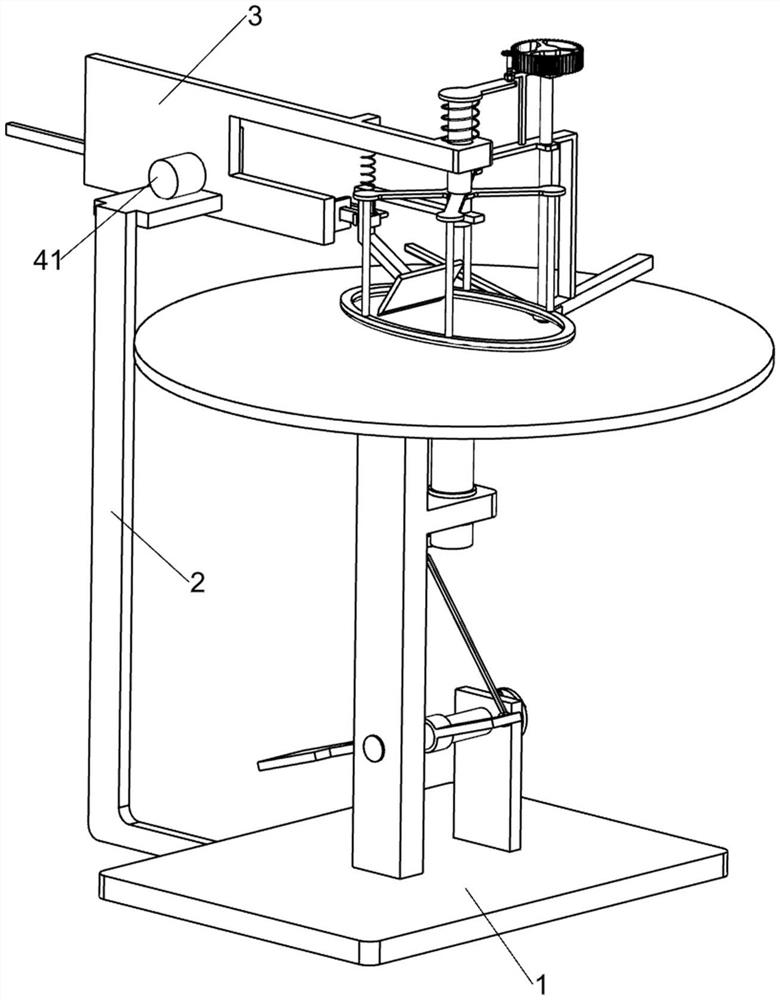

[0027] A cowhide shovel frame capable of fixed scraping and anti-scratch, such as Figure 1-2 As shown, it includes a bottom plate 1, a support rod 2, a support plate 21, a rotating shaft 22, a chassis 23, a mounting plate 3, a reciprocating push assembly 4 and a cowhide extrusion positioning assembly 5, and a support rod 2 is fixedly connected to one side of the bottom plate 1. The top of the bottom plate 1 is fixedly connected with a support plate 21, the support plate 21 is connected with a rotating shaft 22 through a bearing, the top of the rotating shaft 22 is fixedly connected with a chassis 23, the chassis 23 is used to place cowhide, and the upper part of the support rod 2 is fixedly connected with a mounting plate 3 , the mounting plate 3 is fixedly connected with a reciprocating push assembly 4, and the reciprocating push assembly 4 is used to shave the cowhide to achieve the effect of shaving the cowhide with the same force. The support plate 21 is fixedly connected ...

Embodiment 2

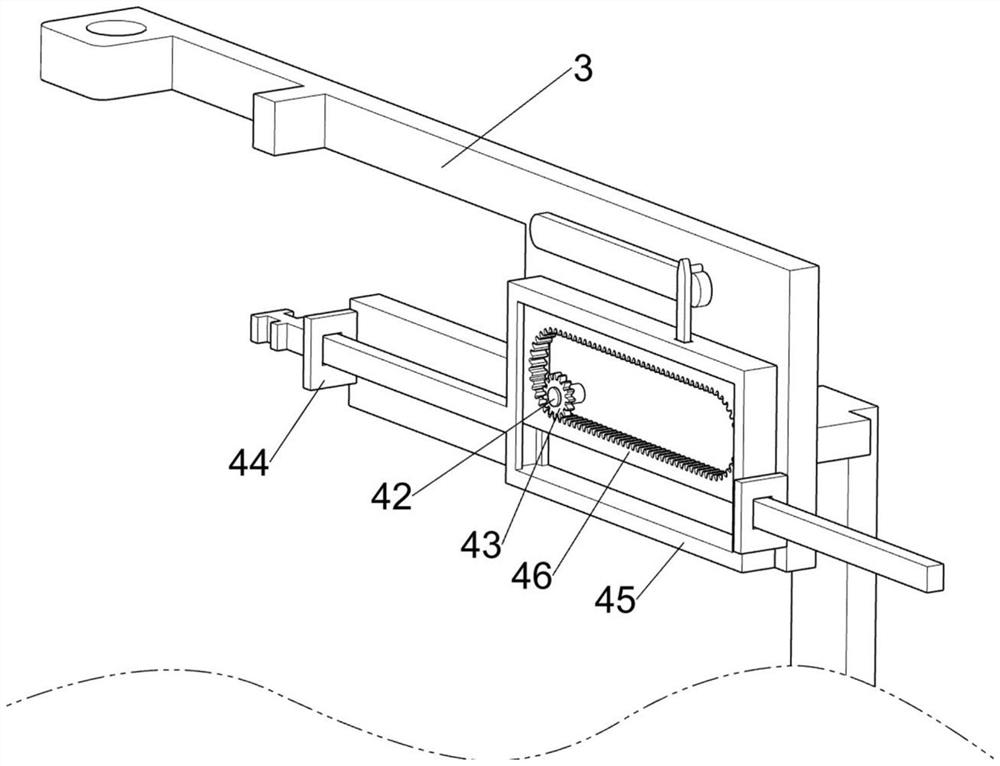

[0029] On the basis of Example 1, such as Figure 3-8 As shown, the reciprocating push assembly 4 includes a motor 41, a power shaft 42, a pinion 43, a guide plate 44, a push frame 45, a moving ring gear plate 46, a moving rod 47, a tension spring 48, a pressing plate 49, a scraping plate 410 and Connecting rod 411, motor 41 is fixedly connected to the top of support rod 2, and power shaft 42 is fixedly connected to the output shaft of motor 41. 3 is fixedly connected with a pair of guide plates 44, the guide plate 44 is slidably connected with a push frame 45, and the inside of the push frame 45 is slidably connected with a moving ring gear plate 46, and the moving ring gear plate 46 meshes with the pinion 43, and the moving ring gear The upper side of the plate 46 is fixedly connected with a moving rod 47, the moving rod 47 passes through the push frame 45 and contacts the installation plate 3, and one end of the push frame 45 is slidably connected with a scraper plate 410, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com