Structure of door ring assembly for washing machine

A component structure and washing machine technology, applied in the field of washing machines, can solve the problems of hook and bayonet falling off, and achieve the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

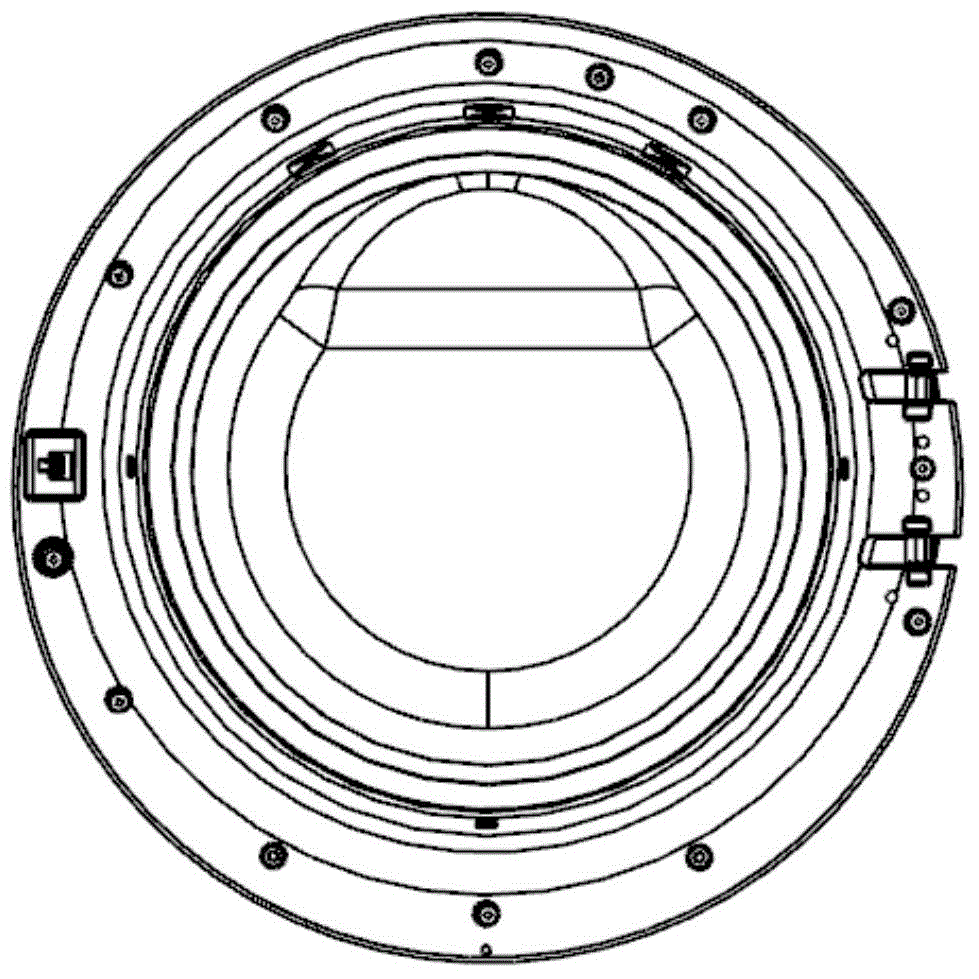

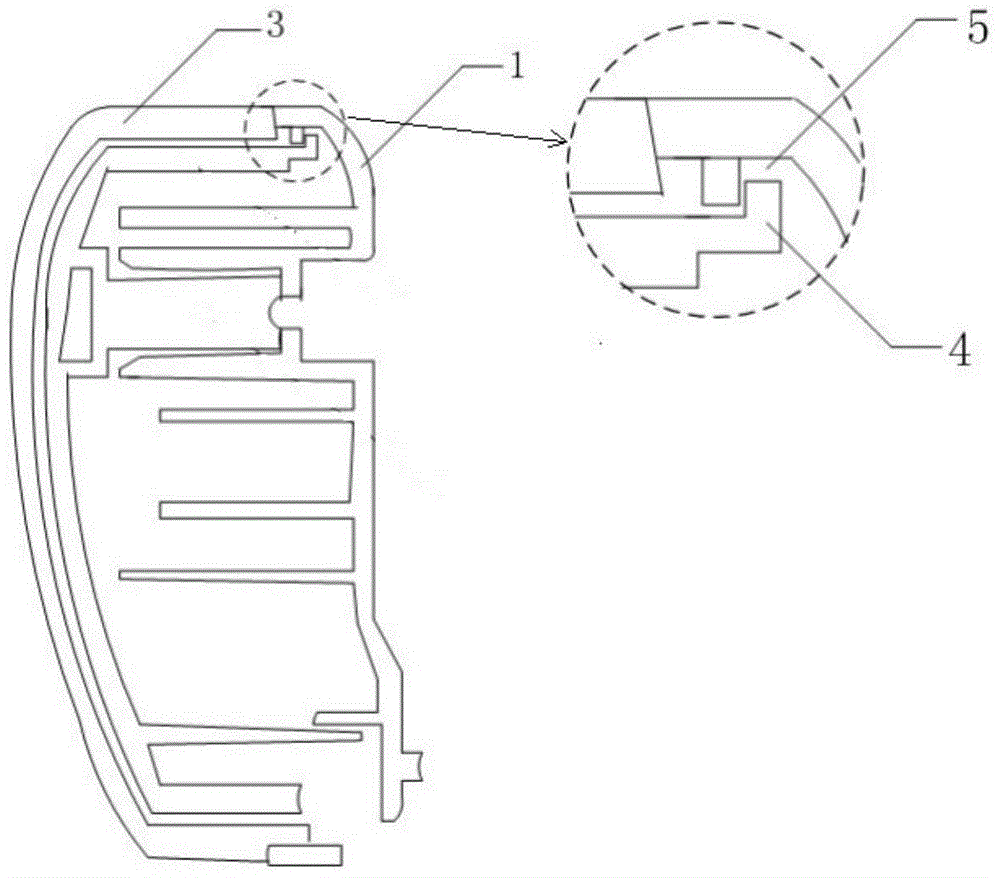

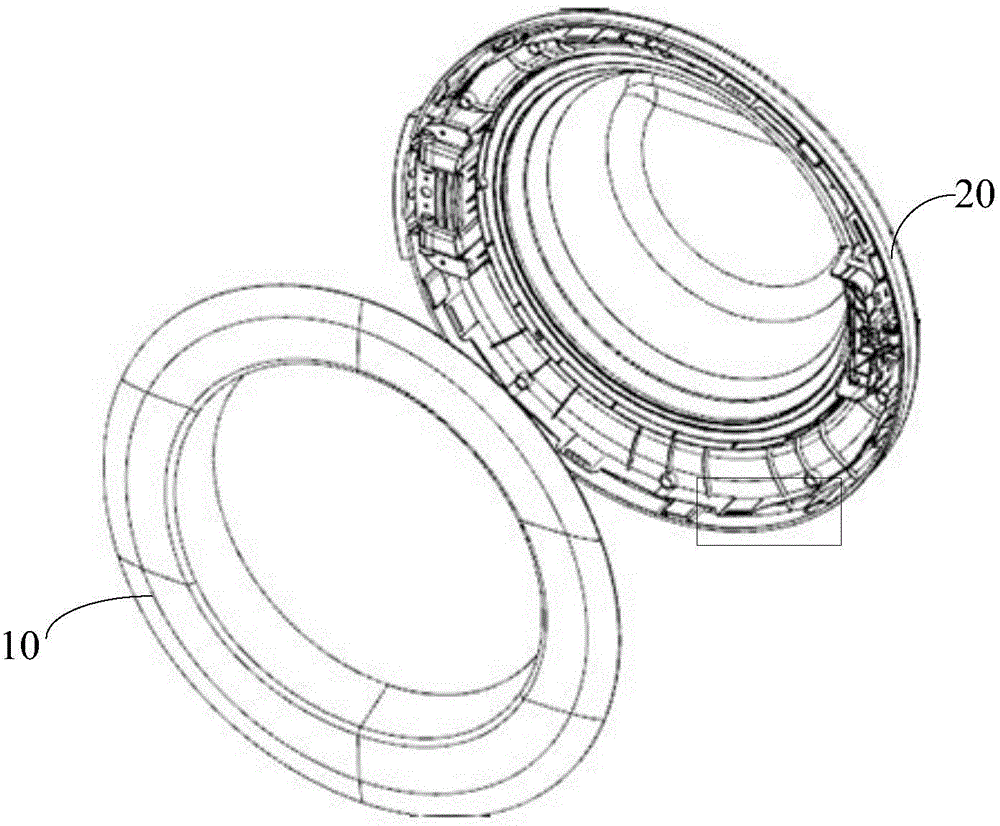

[0022] The invention discloses a door ring assembly structure of a washing machine, which comprises a front door ring and a rear door ring which are cooperatingly installed, a plurality of front door ring assembly ribs are arranged inside the front door ring, a plurality of rear door ring assembly ribs are arranged inside the rear door ring, the front door ring assembly ribs and the rear door The ring assembly ribs are correspondingly provided with a number of buckles and slots for mutual assembly, and the front door ring assembly ribs and the rear door ring assembly ribs are interference assembled through the buckles and the slots.

[0023] The invention achieves the purpose of assembly through the interference fit between the buckle and the slot, simplifies the assembly process and improves the assembly effect.

[0024] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com