Ultrasonic leather cleaning machine

A cleaning machine, ultrasonic technology, applied in the direction of fur mechanical treatment, small raw hide/large raw hide/leather/fur mechanical treatment, small raw hide/large raw hide/leather/fur treatment, etc. , There is no water level sensor and other problems, to achieve the effect of scientific and reasonable structure, labor reduction, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

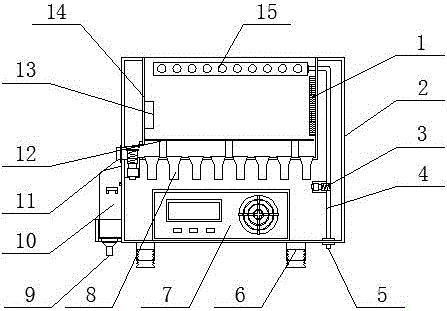

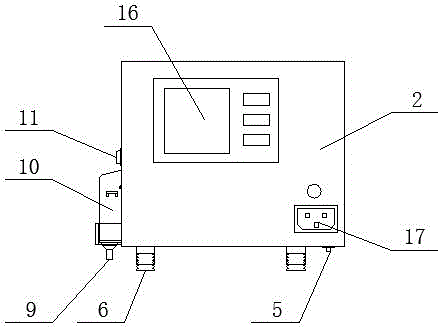

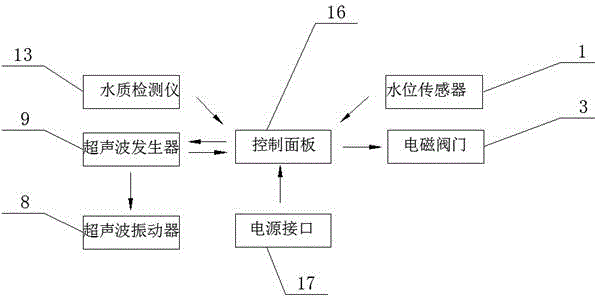

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0017] see Figure 1-3 , the present invention provides a technical solution: including a cleaning machine body 2 and a filter bucket 10, a foot pad 6 is provided at the bottom of the cleaning machine body 2, a water inlet 5 is provided on one side of the foot pad 6, and the filter bucket 10 is installed in the cleaning machine One side of the body 2, and the bottom of the filter barrel 10 is provided with a filter barrel drain 9, and one side of the washing machine body 2 is provided with a drain 11 near the top of the filter barrel 10, and the front surface of the washing machine body 2 A control panel 16 is provided, and a power supply interface 17 is provided near the lower right position of the control panel 16 on the front surface of the cleaning machine body 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com