Hair ironing and combing machine

A carding machine and ironing technology, which is applied in the field of carding machines, can solve the problems of high labor intensity, low carding efficiency, and easily damaged combs, etc., and achieve the effects of reducing labor intensity, improving work efficiency, and not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

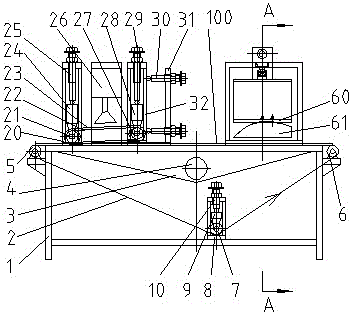

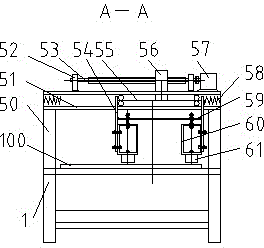

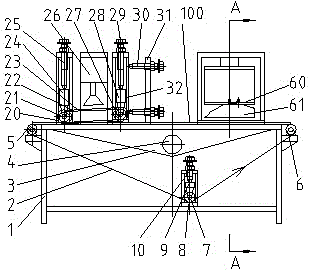

[0016] The present invention will be further described in detail below in conjunction with the first embodiment of the accompanying drawings.

[0017] An ironing and carding machine, characterized in that the machine is composed of a fur conveying device, a steam ironing device and a combing device, the steam ironing device and the combing device are installed above the fur conveying device, and the steam ironing device is located on the right side of the combing device side.

[0018] The fur conveying device is mainly composed of a frame 1, a conveying net 2, an air bucket 3, a driving roller 5, a driven roller 6 and a tensioning roller 7, and the conveying net 2 is connected with the driving roller 5, the driven roller 6 and the tensioning roller 7 respectively. Contact, the fur 100 is placed flat on the conveyor net 2, the driving roller 5 and the driven roller 6 are respectively installed on the frame 1, and can rotate around their own axis, the tension roller 7 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com