Hair ironing and combing roller for fur processing and application of hair ironing and combing roller

A carding roller and fur technology, which is applied in the field of fur processing, can solve the problems of poor effect and unconnected processes, and achieve the effect of improving processing quality and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

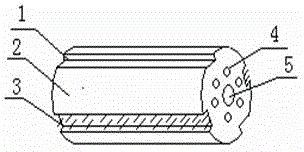

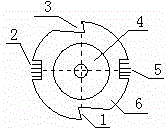

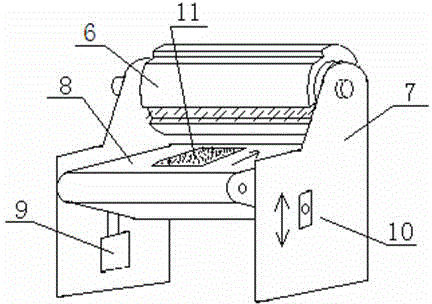

[0018] A kind of ironing and combing roller for fur processing, such as figure 1 , 2 As shown, two shaving teeth 1 and two combing teeth 3 are respectively arranged on the surface of the cylindrical ironing and combing roller in the axial direction, and the two shaving teeth 1 and two combing teeth 3 are respectively located on the radial centerline of the two ironing and combing rollers. The two ends of the two radial center lines are perpendicular to each other. The ironing surface 2 is located on the surface of the ironing and combing roller 6 between the shaving teeth 1 and the combing teeth 3. The center of the ironing and combing roller 6 is provided with a central shaft hole 5, and the ironing and combing roller Between the surface of 6 and the central shaft hole 5, axial electric heating tube through holes 4 are evenly distributed along the radial circumference, and electric heating tubes are installed in the electric heating tube through holes 4.

[0019] In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com