Patents

Literature

37results about How to "Retain texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stone decoration board

The invention relates to a stone decorated board, comprising a stone decorated faceplate layer, a heat preservation layer and a strengthened layer. Composed of three layers, including the stone decorated faceplate layer, the heat preservation layer and the strengthened layer, the stone decorated board is much better in heat preservation and energy conservation effects than thick and heavy stone boards. Meanwhile, adopting stone boards with thickness of 0.5-5mm, the stone decorated board maintains the original grain and texture of natural stone and is reduced in weight. The stone decorated board is simple and reasonable in structure and is easy to construct.

Owner:温州麦克辛石业有限公司

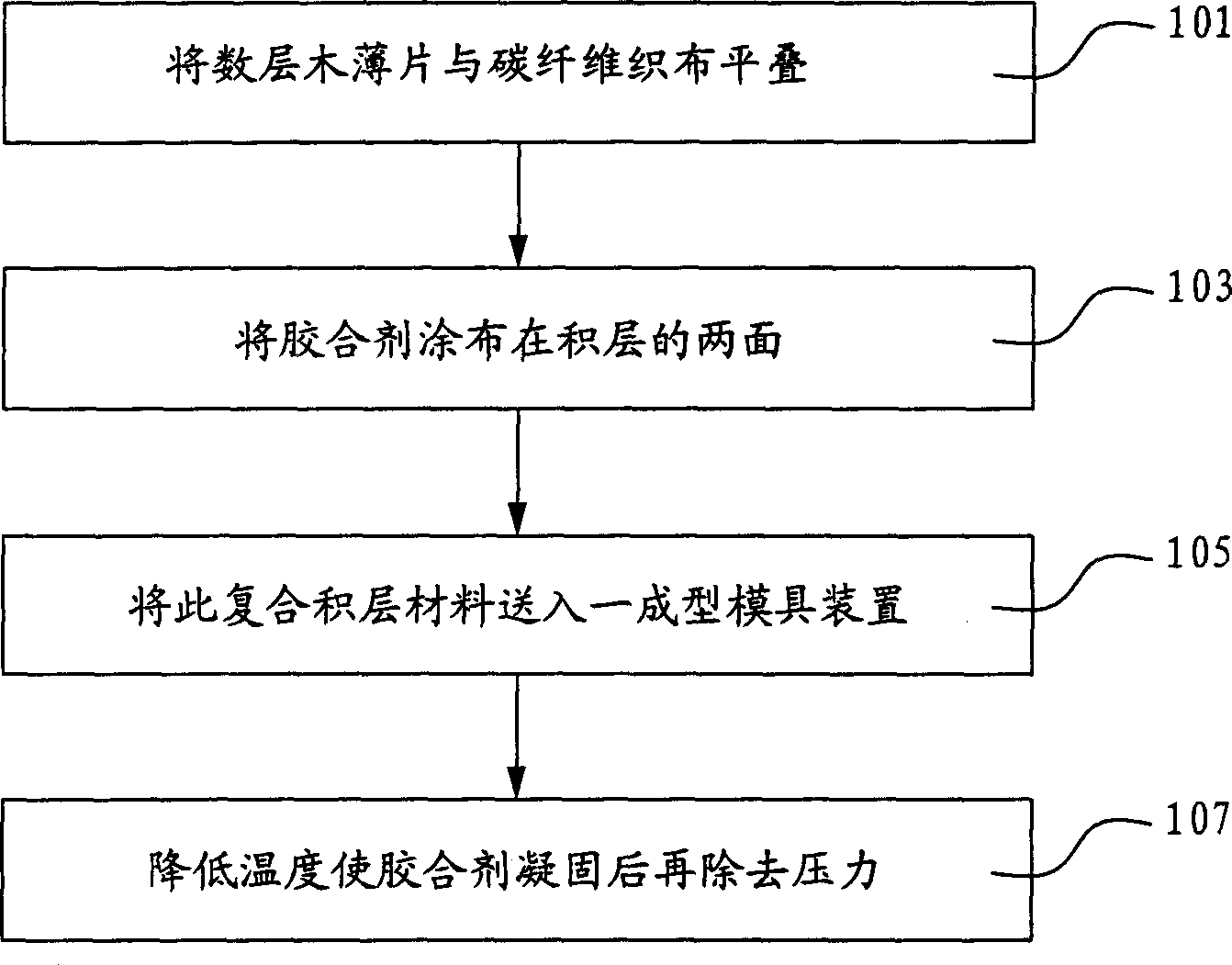

Composite material veneer containing carbon fiber weaving cloth and its preparation method

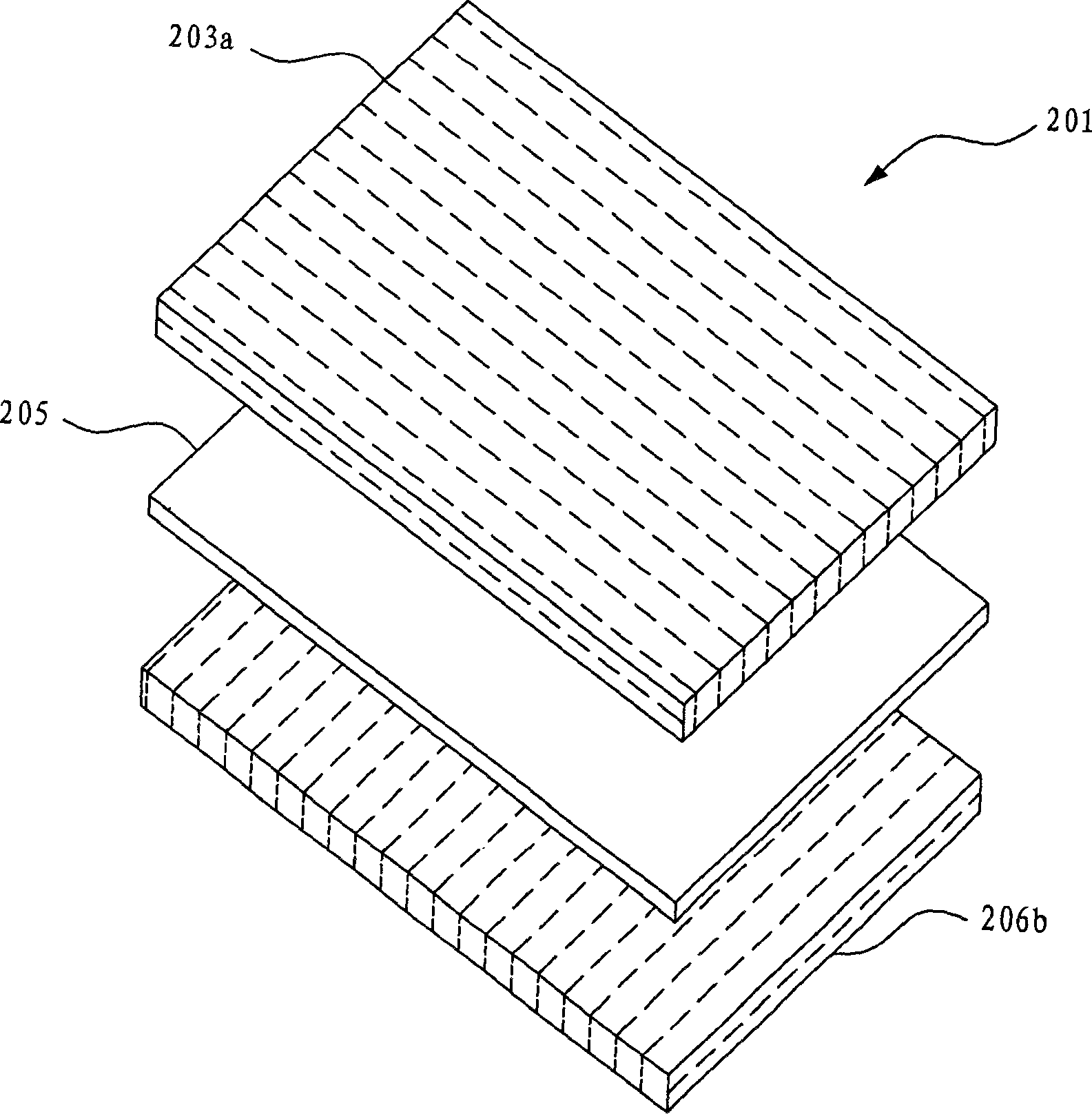

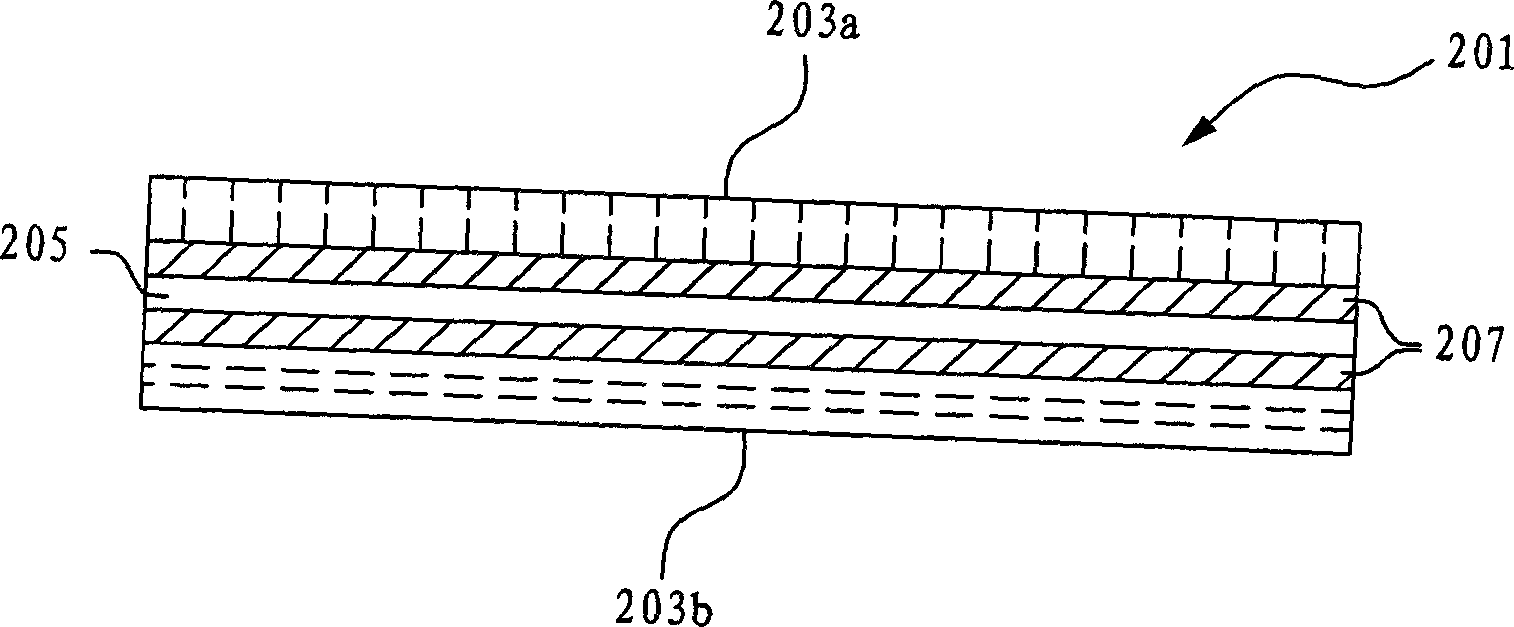

InactiveCN1824477AImprove strength and toughnessReduce thicknessWood veneer joiningWood layered productsFiberCarbon fibers

The present invention discloses a composite material veneer board containing carbon fibre fabric and its production method. It is characterized by that said invention uses urea resin as gluing agent between sandwiches, and makes the composite laminated material containing several layers of carbon fibre fabric and wood chips undergo the processes of heating and pressurization so as to obtain the invented composite material veneer board.

Owner:ASUSTEK COMPUTER INC

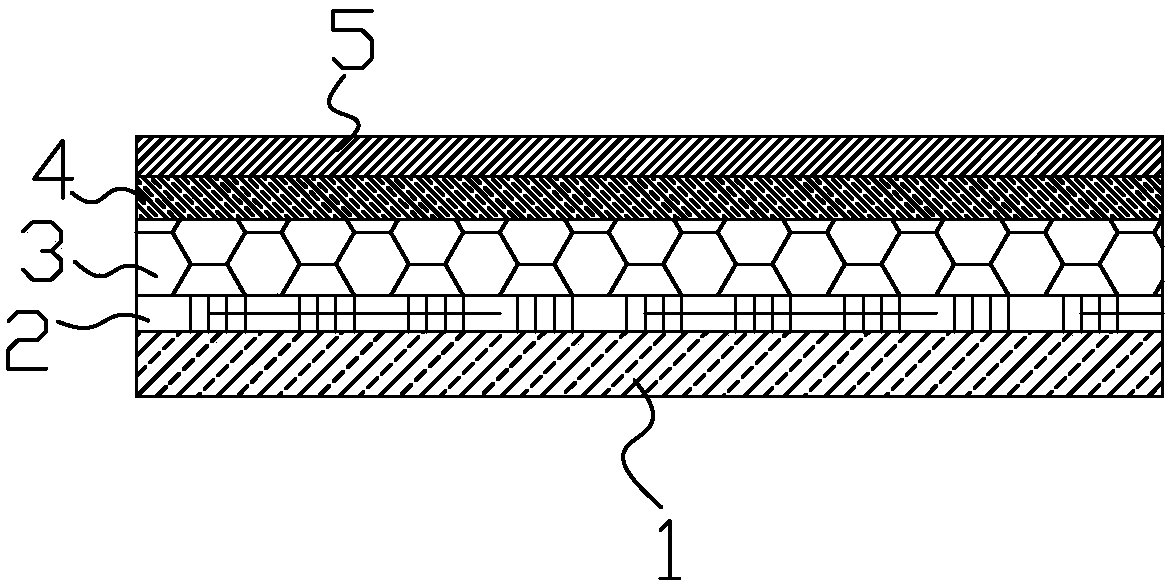

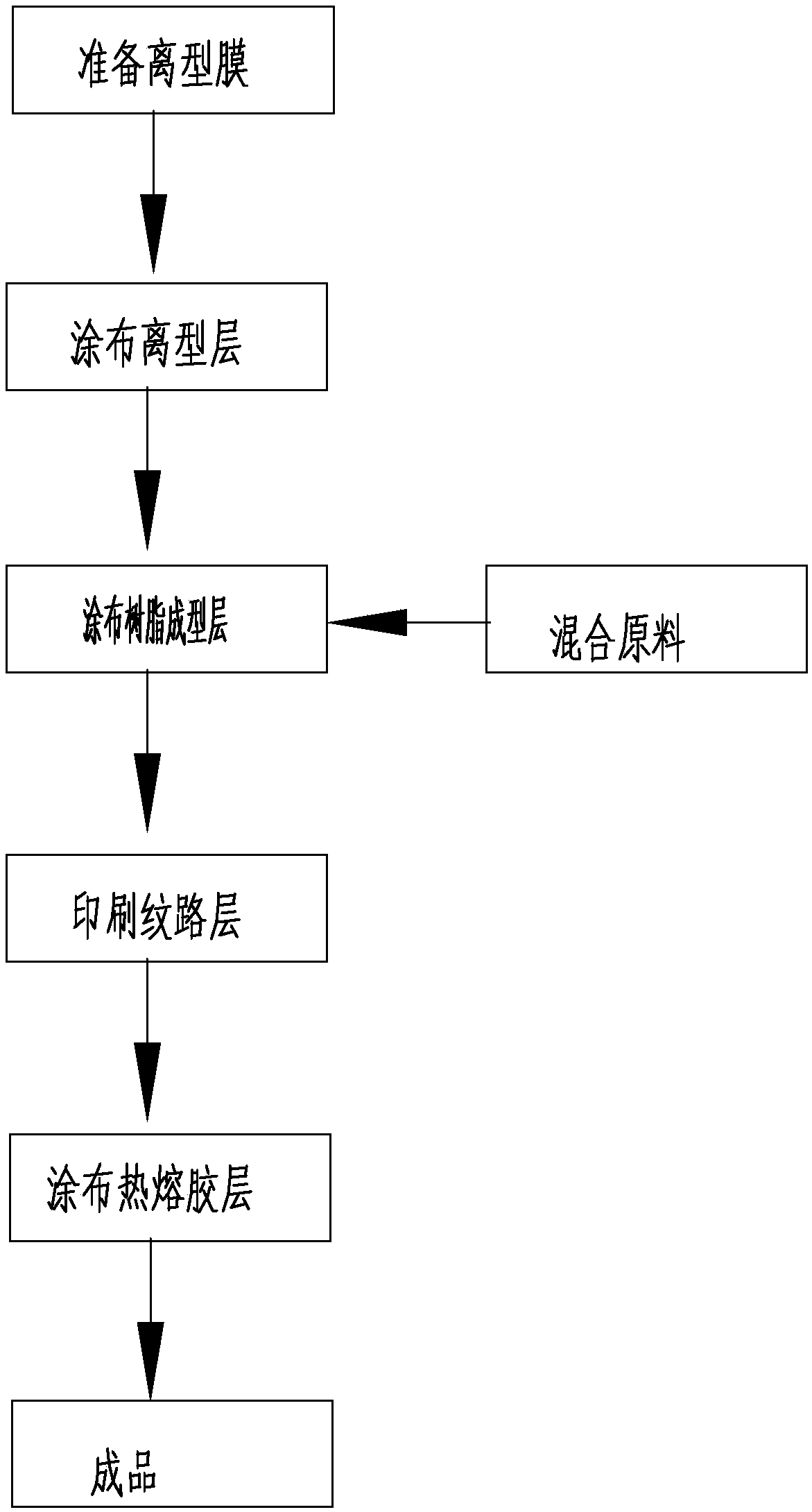

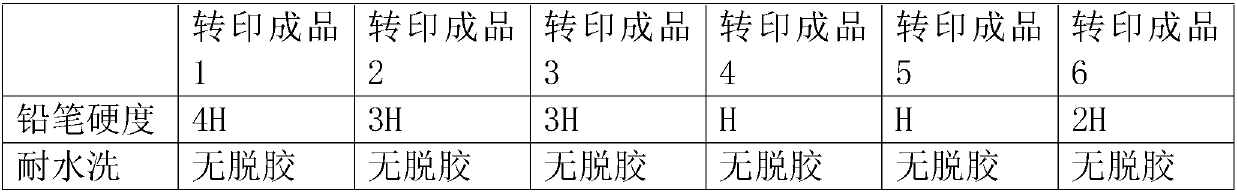

Scratch-resistant grain lettering film and manufacturing method thereof

The invention relates to the field of application of TPU materials, and provides a scratch-resistant grain lettering film and a manufacturing method thereof. The problem of poor scratch resistance ofa grain lettering film in the prior art is solved. The scratch-resistant grain lettering film comprises five parts, ie., a hot melt adhesive layer, a grain layer, a resin forming layer, a release layer and a release film, and the resin forming layer is prepared from, in percentages by weight, 60-70% of TPU, 5-15% of ABS, 10-20% of stearic acid-modified wollastonite powder, 1-5% of a compatibilizer, 1-5% of polysiloxane and 0-2% of a leveling agent. The scratch-resistant grain lettering film has strong scratch resistance, and can be applied to zipper film and a plurality of shoe and clothing thermal transfer products which need to have scratch resistance, and the shortcoming of the scratch irresistance of a grain lettering film on the existing market can be overcome.

Owner:福建新力元反光材料有限公司

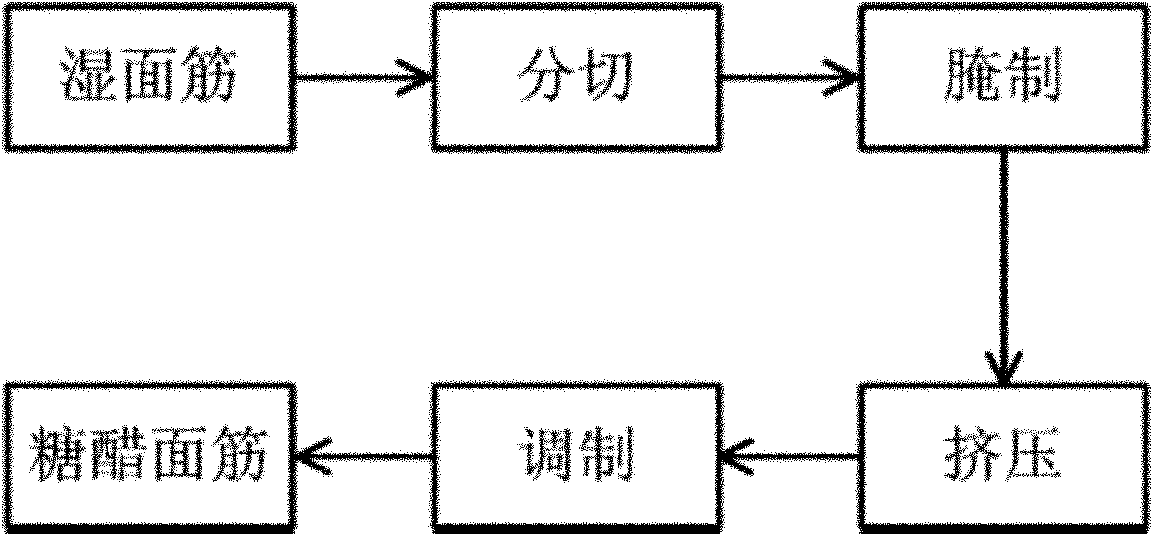

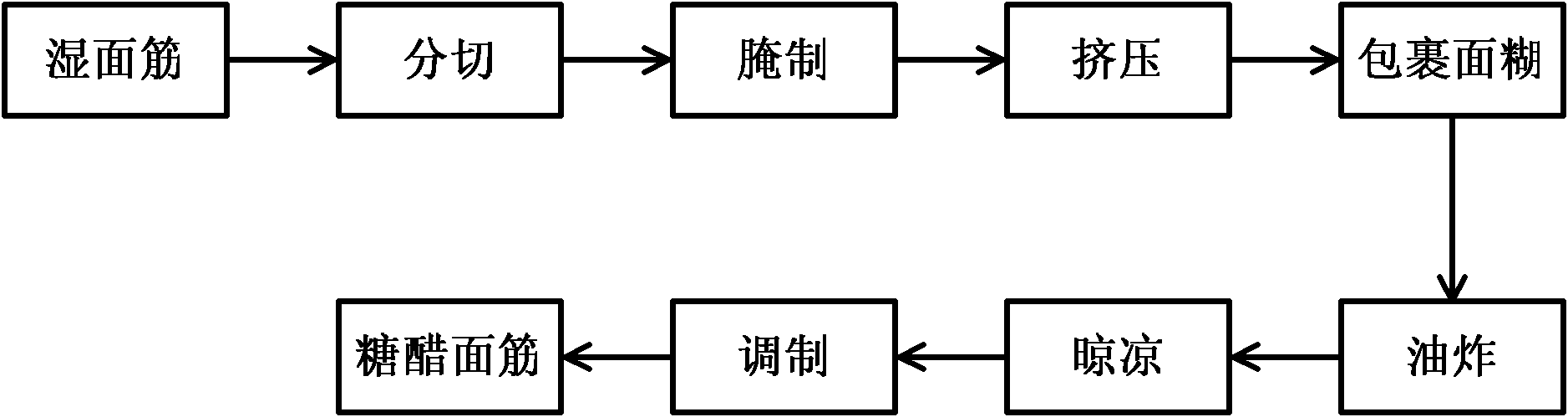

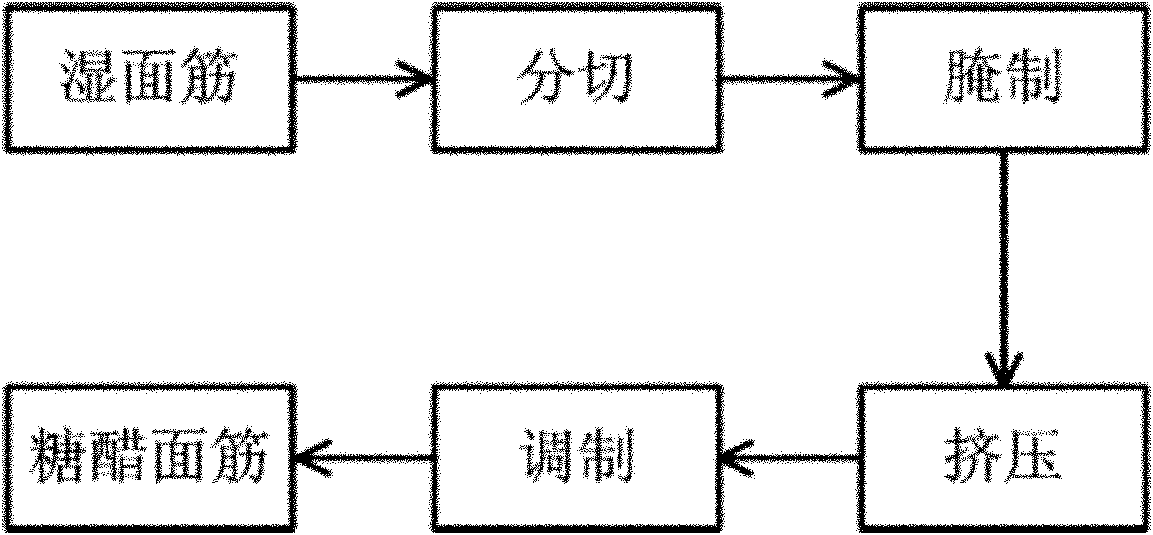

Method for preparing sugar and vinegar gluten

The invention relates to a method for preparing sugar and vinegar gluten, which comprises the following steps of: stewing wet gluten at the high temperature to obtain water gluten, and cutting the water gluten into gluten blocks; immersing the gluten blocks into sugar-containing pickled solution for pickling; taking the pickled gluten blocks out, extruding, and draining part of pickled solution from the gluten; and frying and mixing vinegar seasoning starch and the extruded gluten blocks uniformly in a hot pot for blending to obtain the sugar and vinegar gluten. The sugar and vinegar gluten prepared by the preparation method has yellow, bright and full color and luster and is sour and sweet and palatable in taste, the inside of the gluten is soft and fresh and tender, the texture of the gluten can be kept, and the gluten contains juice and has unique flavor, so the sugar and vinegar gluten is special food. In addition, the preparation method of the sugar and vinegar gluten is simple and the sugar and vinegar gluten has low cost.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Environment-friendly and energy-saving ecological wood and preparation method thereof

The invention discloses environment-friendly and energy-saving ecological wood and a preparation method thereof. The environment-friendly and energy-saving ecological wood comprises the following materials in parts by weight: 40-55 parts of PVC materials, 10-20 parts of wood powder materials, 20-30 parts of stone powder materials, 1-3 parts of a stabilizer YQ102, 0.2-0.5 part of a lubricating agent 1801, 1-2 parts of a foaming agent NH213, 4-6 parts of a foaming agent K278P, 0.5-1 part of a foaming additive 401K128P, 2-4 parts of a stabilizer CPE135A, 0.1-0.5 part of PE (Polyethylene) wax and 0.8-1.2 parts of soybean oil. The preparation method comprises the following steps: (1) mixing the PVC material, the wood powder material and the stone powder material in a mixing machine uniformly; (2) heating to 120 DEG C, adding the stabilizer YQ102, the lubricating agent1801, the foaming agent NH213, the foaming agent K278P, the foaming additive 401K128P and the stabilizer CPE135A, and stirring uniformly; (3) adding the PE wax and the soybean oil, stirring to be smooth and bright; and (4) adding into an extruder for molding. According to the environment-friendly and energy-saving ecological wood and the preparation method disclosed by the invention, the environment-friendly and energy-saving ecological wood has moisture-proof, anti-deformation and insect-resistant effects, is strong in acid-alkali resistance, flame retardance, weathering resistance and aging resistance, simple to manufacture and low in cost, and is environmentally friendly and nontoxic and harmless.

Owner:上海世旭塑木科技发展有限公司

Processing method of instant sea cucumbers

InactiveCN106538987AEasy to implementGood for promotion and applicationMeat/fish preservation by dryingPre treatmentFlavor

The present invention provides a processing method of instant sea cucumbers. The processing method comprises the following steps: raw material pretreating, rehydrating, seasoning, dehydrating, baking, cooling, vacuum packaging and sterilizing. The method can maximally preserve the texture, flavor and nutritional characteristics of the sea cucumbers, and is easy to implement and conducive to promotion and application.

Owner:威海红印食品有限公司

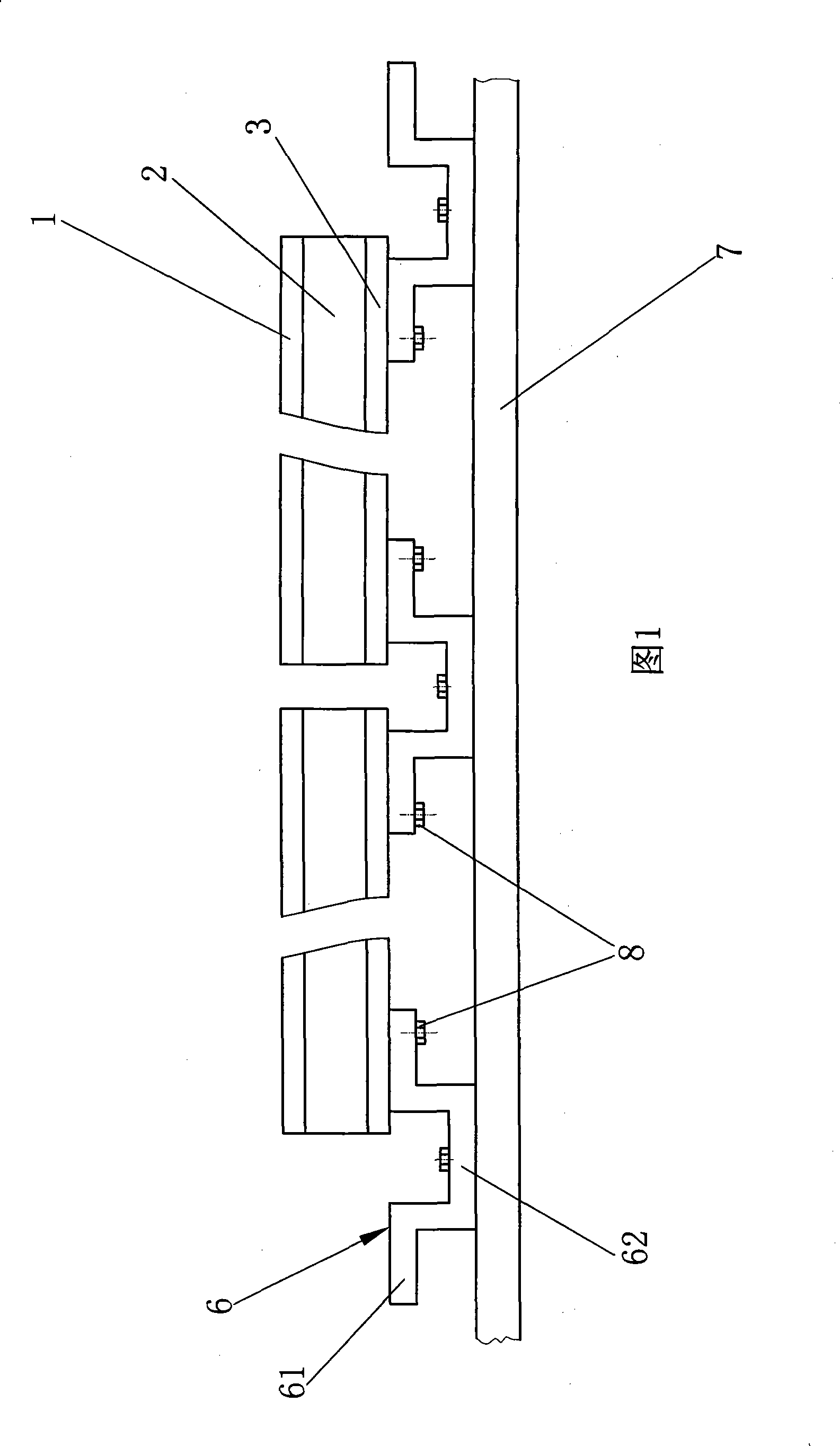

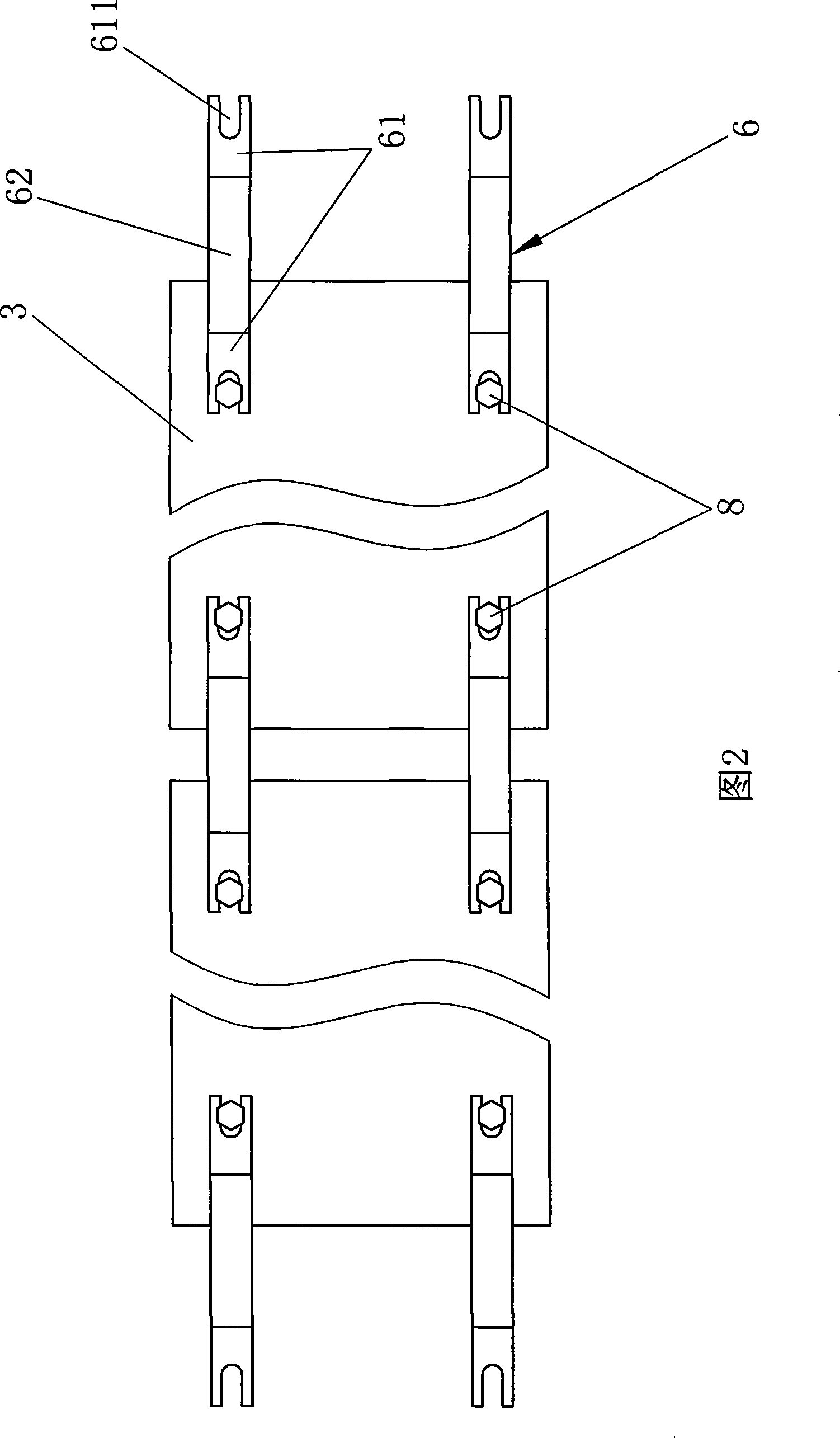

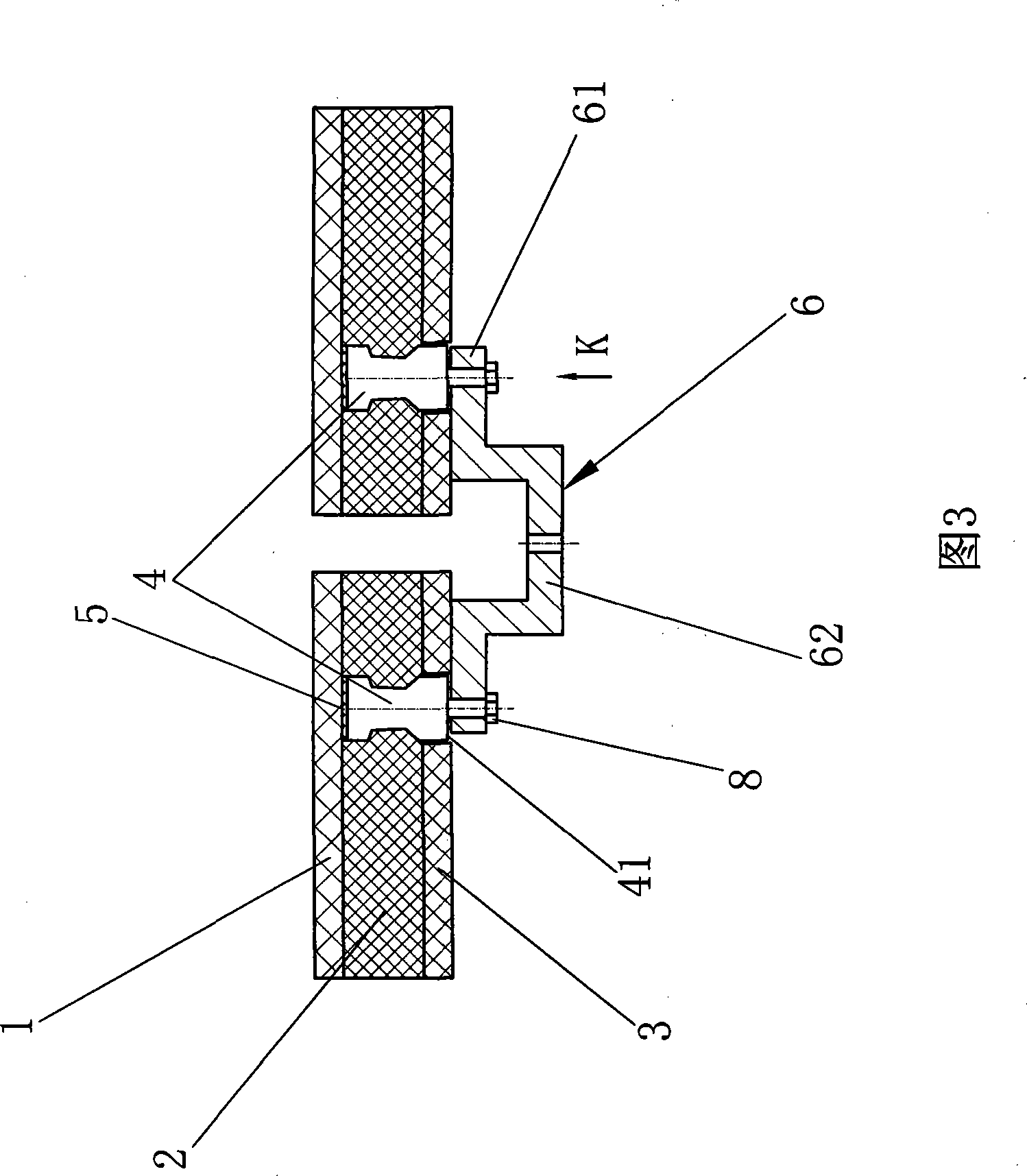

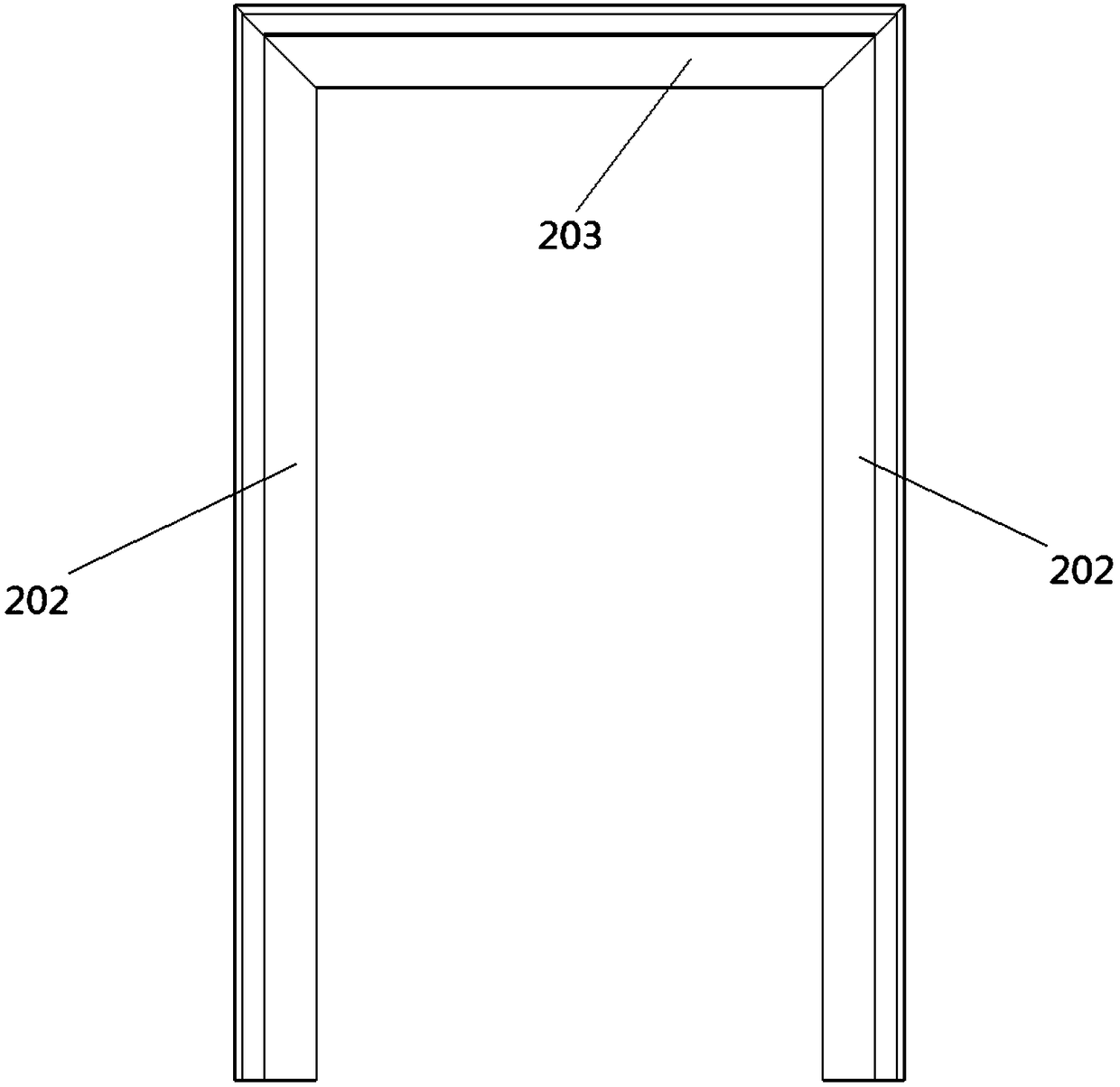

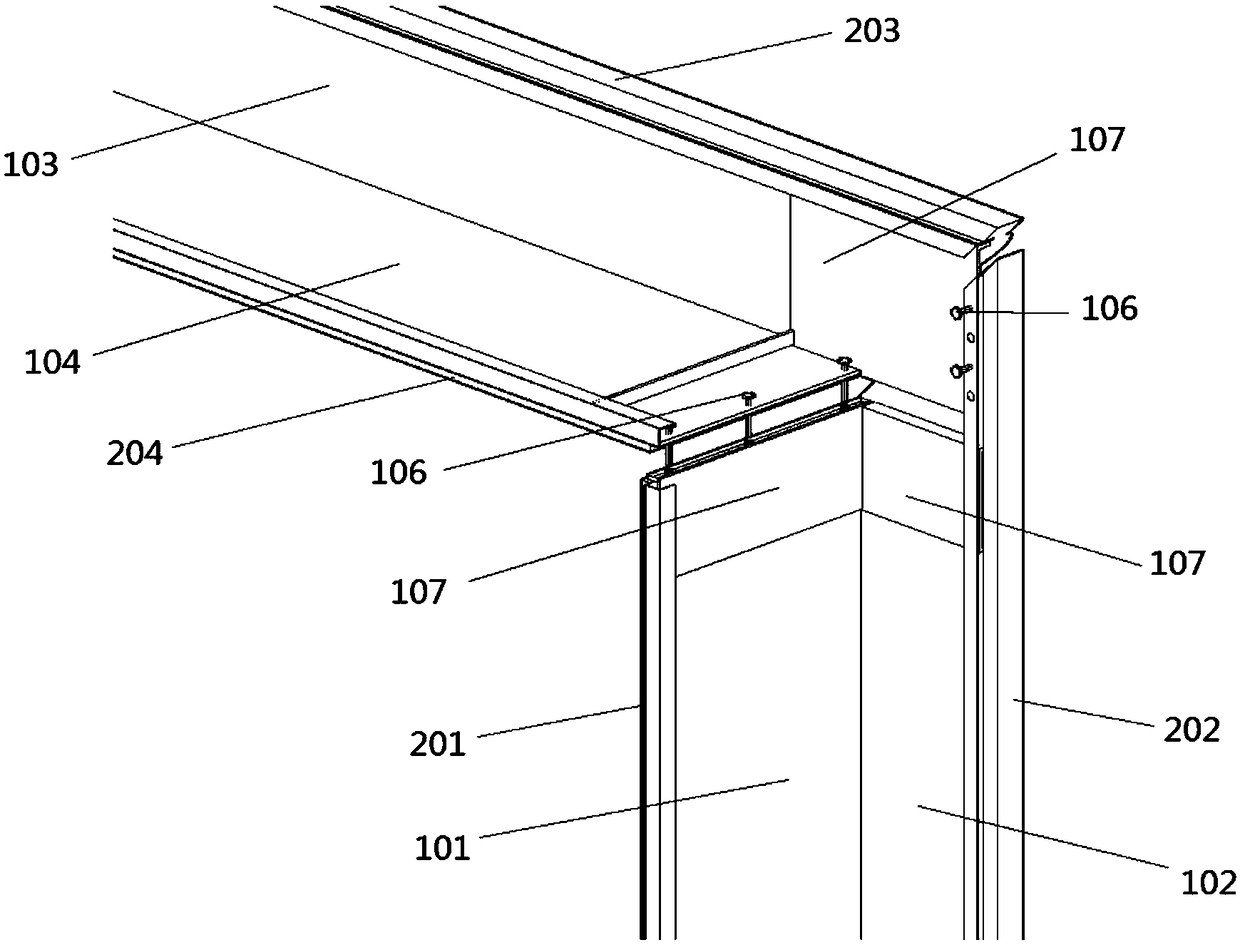

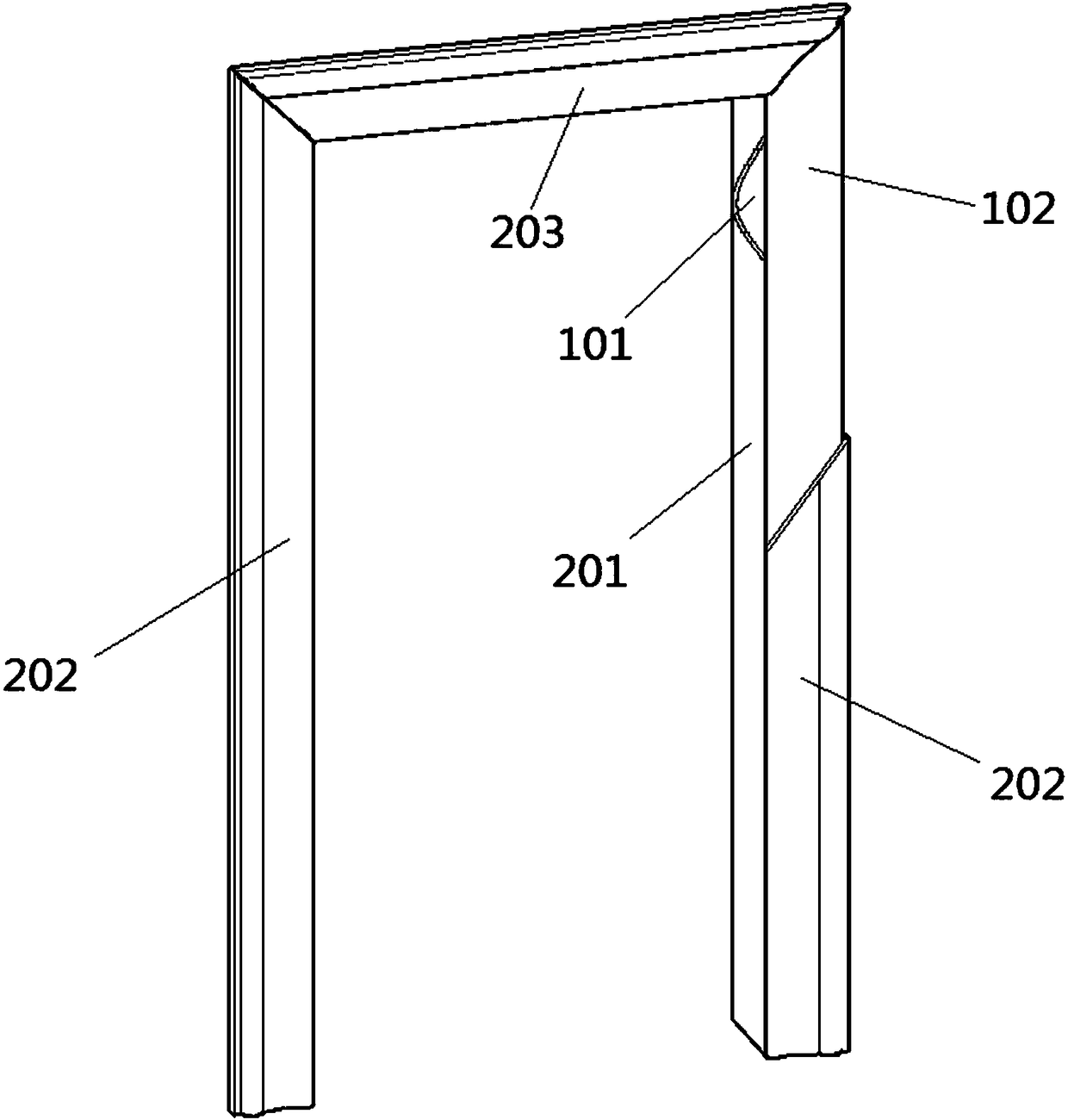

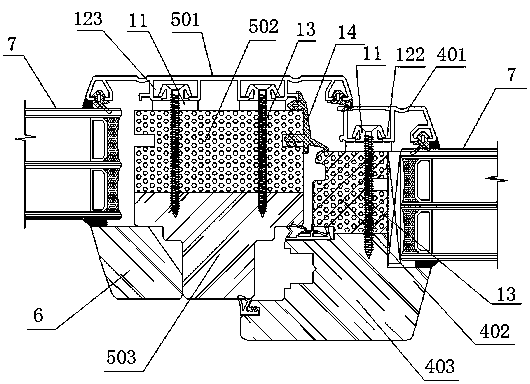

Elevator door pocket

PendingCN109081223AEasy to installRetain textureBuilding liftsMetallic materialsMechanical engineering

The invention provides an elevator door pocket, and particularly provides a steel-stone composite combined type elevator door pocket. At least a part of the skeleton portion of the elevator door pocket is made of a metal material, and the portion, capable of being observed by a user, of the elevator door pocket in a using state is made of a material other than the metal material. The elevator doorpocket retains the texture of an elevator door pocket made of stone materials, saves time and labor force required for processing, and has a longer service life.

Owner:LIAOCHENG GAOLI METAL MATERIALS

Method for producing chest moulding from eucalyptus cores

InactiveCN106272837AStrong resistanceAvoid deformationWood working apparatusEngineeringMaterial technology

The invention relates to the technical field of decoration materials, in particular to a method for producing a chest moulding from eucalyptus cores. The method comprises the process steps of first maintenance of the eucalyptus cores, drying, second maintenance of the eucalyptus cores, section shearing, splicing, cut molding, repairing, veneer adhering and the like. The chest moulding is produced from the eucalyptus cores, the eucalyptus cores are fully utilized, waste is turned into wealth, energy is saved, and the production cost of the chest moulding is greatly reduced. The chest moulding produced through the method is high in quality, good in stability, resistant to dampness, high in hitting resisting strength and not likely to deform.

Owner:GUANGXI BINWEI DECORATION MATERIAL

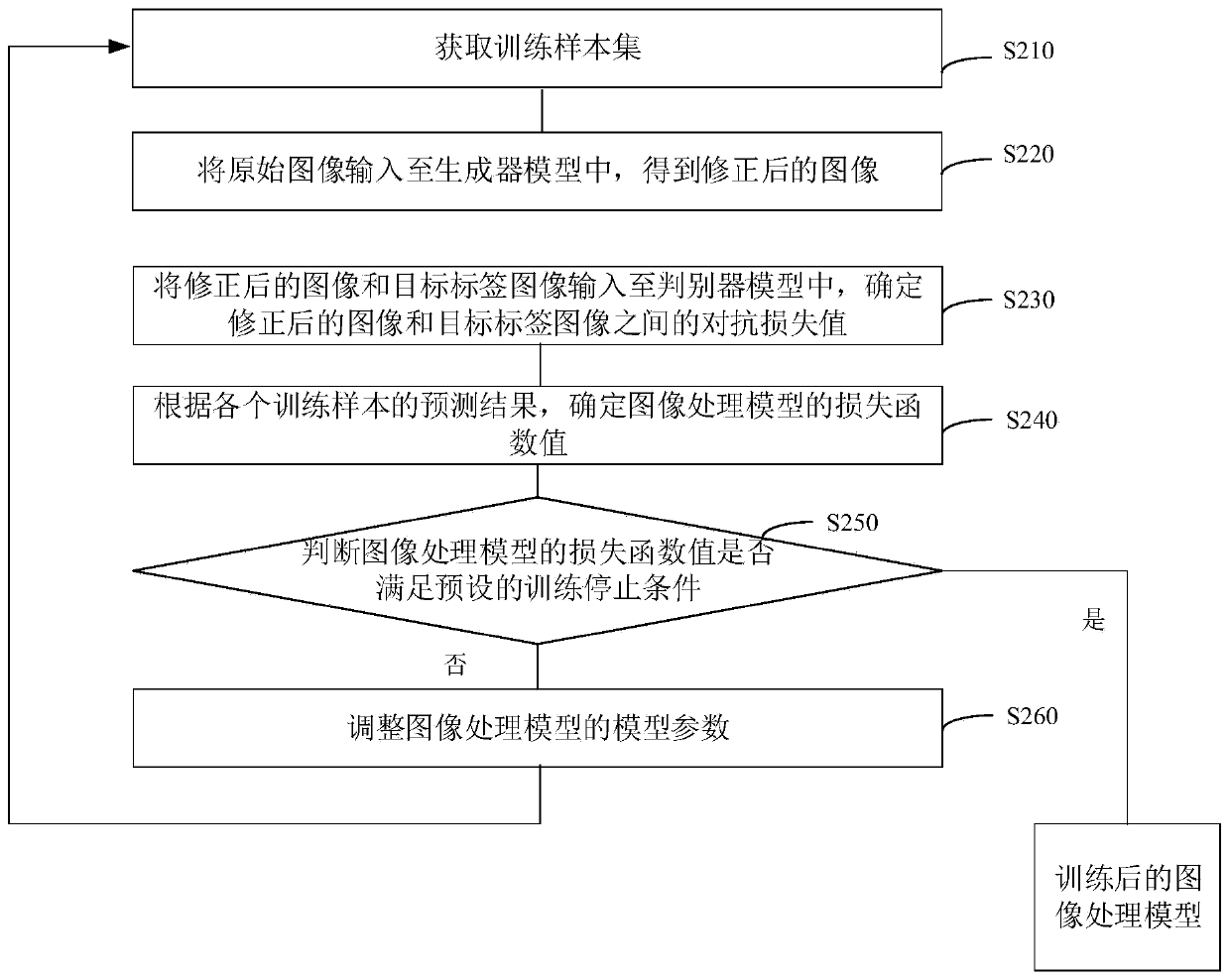

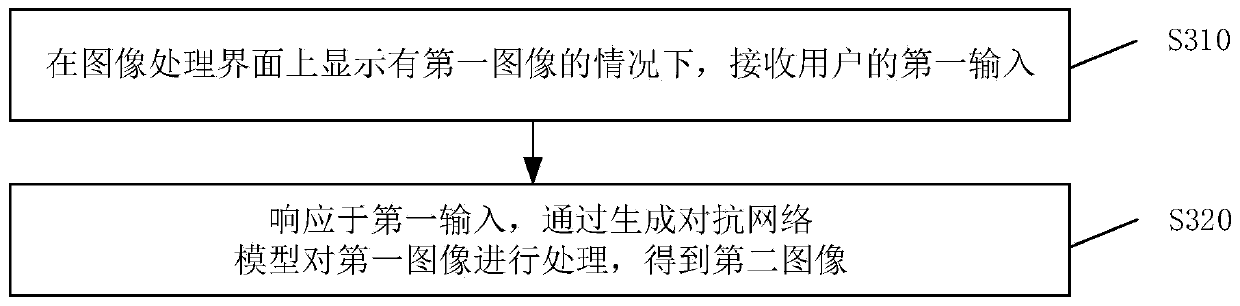

Image processing method and electronic equipment

PendingCN111553854AImprove user experienceImprove realismImage enhancementImage analysisImaging processingComputer graphics (images)

The embodiment of the invention discloses an image processing method and electronic equipment, and the method comprises the steps: receiving a first input of a user for an image processing interface under the condition that a first image is displayed on the image processing interface; in response to the first input, processing the first image through a generative adversarial network model to obtain a second image; wherein the generative adversarial network model comprises a generator and a discriminator. The invention aims to solve the problems of large image distortion and lack of sense of reality after image processing.

Owner:VIVO MOBILE COMM CO LTD

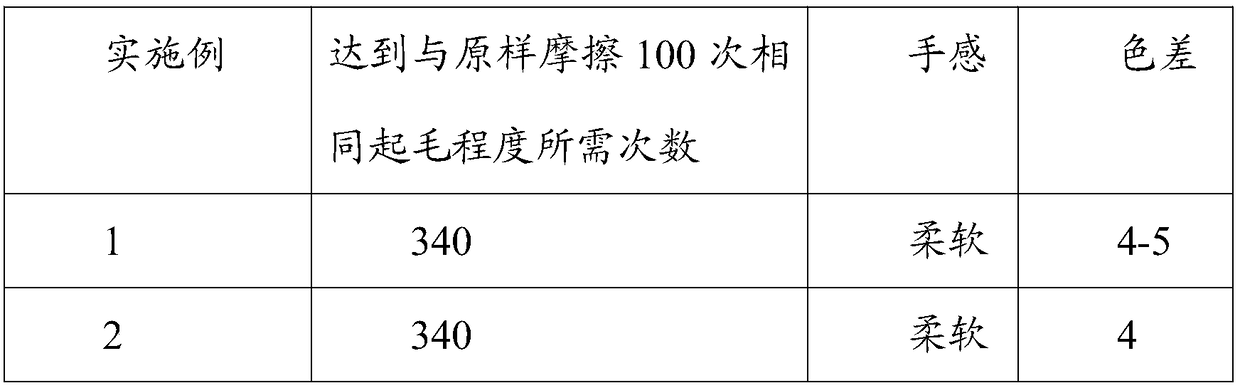

Finishing agent for preventing fluffiness of embroideries and preparation method and utilization method of finishing agent

ActiveCN109440467AImprove controllabilityAnti-pilling effect is obviousAbrasion resistant fibresCross-linkOperability

The invention discloses a finishing agent for preventing fluffiness of embroideries and a preparation method and a utilization method of the finishing agent. The finishing agent is prepared from, by weight, 2-5 parts of polyvinyl alcohol, 2-5 parts of polyacrylic acid, 0.2-0.5 part of cross-linking agent borax, 0.2-0.5 part of a colorless water-soluble penetrating agent, 0.2-0.5 part of a colorless water-soluble softening agent and deionized water added to obtain solution in total parts by weight of 100. The preparation method of the finishing agent for preventing fluffiness of the embroideries includes steps: weighing 2-5 parts by weight of polyvinyl alcohol, swelling in an appropriate amount of deionized water, heating to dissolve to obtain polyvinyl alcohol water solution. The preparation method of the finishing agent for preventing fluffiness of the embroideries is simple, and the utilization method of the finishing agent for preventing fluffiness of the embroideries is convenient,high in operability and controllability and free of pollution. The finishing agent for preventing fluffiness of the embroideries is evident in fluffiness resistance, the embroideries are low in colordifference after processing, and intrinsic color, pattern texture, hierarchical effect and soft handfeel of the embroideries are kept.

Owner:SUZHOU VOCATIONAL UNIV

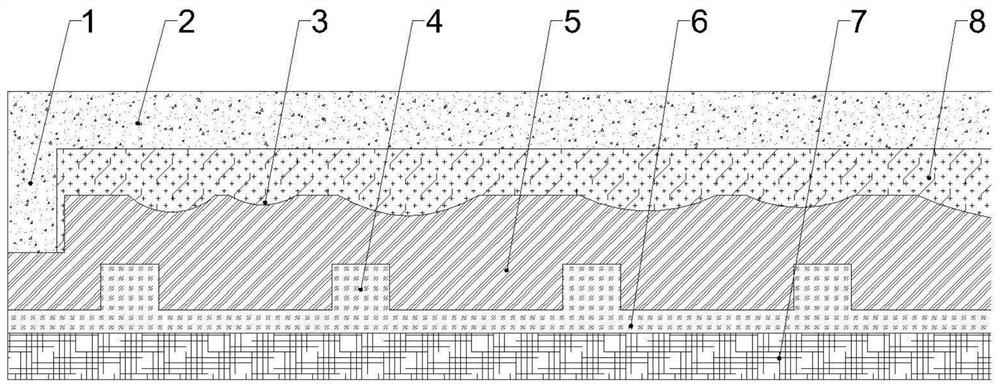

Bamboo-based floor tile with stone surface layer

ActiveCN113863615AReserve patternRetain textureConstructions elementsWood layered productsResin adhesiveComposite material

The invention discloses a bamboo-based floor tile with a stone surface layer. The bamboo-based floor tile comprises a bamboo base and the stone surface layer; the bamboo base is a two-layer composite bamboo-based material plate and comprises a heavy bamboo base plate and a nanmu spliced bottom plate, a round cambered surface groove is formed in the upper surface of the heavy bamboo base plate, a plurality of spaced blind grooves are formed in the lower surface of the heavy bamboo base plate, the nanmu spliced bottom plate and the bamboo base are bonded and formed through a first PVC resin adhesive layer, and the spaced blind grooves are filled with PVC resin filling strips integrally formed with the first PVC resin adhesive layer; and the stone surface layer is buckled on the surface of the outer edge of the bamboo base, the stone surface layer is provided with a rough lower surface, and the lower surface of the stone surface layer is adhered to the upper surface of the heavy bamboo base plate through the second PVC resin adhesive layer and is integrally formed with the upper surface of the heavy bamboo base plate. The bamboo-based floor tile has the advantages of a wood floor and a ceramic tile floor and has good strength, hand feeling and stability, and meanwhile bamboo serves as fast-growing wood, so that the floor tile structure is low in manufacturing cost.

Owner:怀化大隆农业科技有限公司

Eye shadow cream and making method thereof

InactiveCN110934756AImprove experienceRetain textureCosmetic preparationsMake-upSilicic acidHydroxystearic Acid

The invention relates to eye shadow cream comprising the following raw materials, by weight: 30 to 65% of pearly lustre material, 35 to 55 percent of isotridecyl isononanoate, 10.5% to 38% of a film-forming agent, 5 to 15 percent of isododecane, 5 to 10% of a colorant, 0.5 to 6 percent of ozocerite, 0.5 to 15 percent of trimethylsiloxy silicate, 1 to 18% of a thickening agent, 0.5 to 5% of silicondioxide, 0.2 to 3% of hydroxystearic acid, 0.5 to 6% of starch aluminum octenyl succinate, and 0.4% to 1.6% of a preservative. While the powder texture is reserved, the smearing feeling becomes softand fit. The eye shadow cream having advantages of great convenience in use and moderate price and the like is suitable for popularization and application.

Owner:广州市蔻萝生物科技有限公司

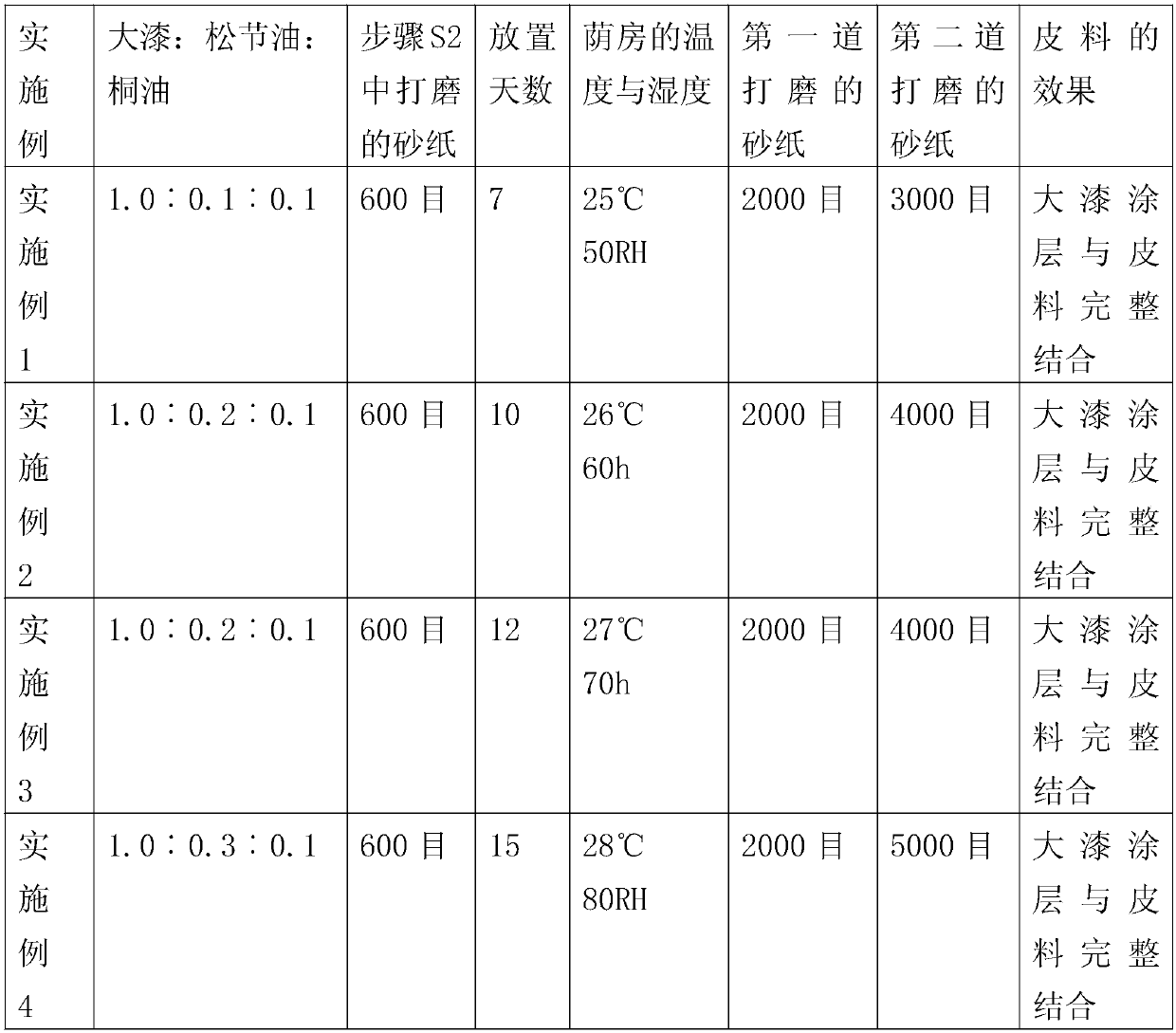

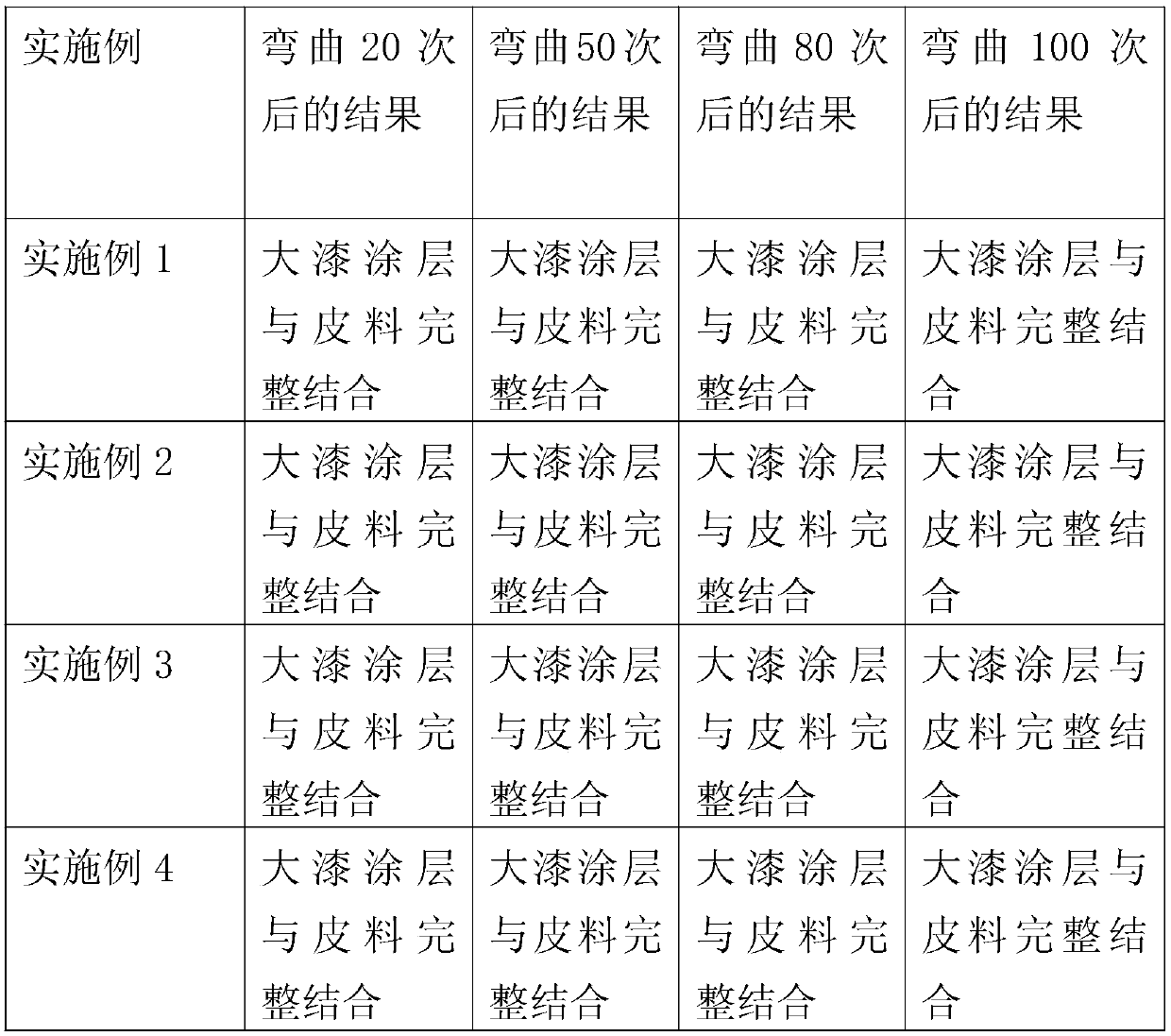

Rubbing polishing treatment method for Chinese lacquer on surface of leather

InactiveCN107828921ARetain textureEasy to solveFur mechanical treatmentLeather surface mechanical treatmentWaxLacquer

The invention relates to a rubbing polishing treatment method for Chinese lacquer on the surface of leather. The rubbing polishing treatment method comprises the following steps that S1, the Chinese lacquer, turpentine oil and tung oil are uniformly mixed proportionally, and Chinese lacquer paint is prepared; S2, wax or oil on the skin layer of the surface of the leather is polished with abrasivepaper, and the leather is pretreated; S3, the Chinese lacquer paint is completely smeared on the surface of the leather, and the leather is put at a cool and wet place to be naturally dried after sufficiently absorbs the Chinese lacquer paint; S4, after the leather is put at the place for some days, the Chinese lacquer paint is completely solidified on the surface of the leather and forms a Chinese lacquer coating layer, primary polishing is conducted on the solidified Chinese lacquer coating layer through the adhesive paper so that a lacquer film covering the surface can be removed, and then,secondary polishing is conducted the solidified Chinese lacquer coating layer through the adhesive paper; and S5, after the solidified Chinese lacquer coating layer is polished to be smooth, the leather is cleaned with clean cloth, and buffing is conducted. According to the rubbing polishing treatment method, the Chinese lacquer and the leather are combined, a lacquer-leather combining layer is formed on the surface of the leather, and the artistry and value of the leather are improved.

Owner:福州三分慵懒文化传播有限公司

Preparation method of minty sliced dried beef

InactiveCN105029454AReduce moisture contentReduced activityYeast food ingredientsNatural extract food ingredientsCooking & bakingFlavor

The invention discloses a preparation method of minty sliced dried beef. The minty sliced dried beef is matched with mint syrup and is fragrant, crispy and very delicious after being eaten. In the minty sliced dried beef, highland barley powder is added and comprises protein, fat, starch and vitamin B, so that the minty sliced dried beef has the effects of tonifying the spleen, nourishing the stomach, tonifying qi, preventing diarrhea, strengthening sinew, enhancing energy, removing humidification and sweating. According to the preparation method, a staged baking process is adopted, so that the content of water in the sliced dried beef and the water activity of the sliced dried beef can be fast reduced, sterilization and cooking functions can be realized, and further the minty sliced dried beef has roasting fragrance. Microorganisms are used for fermenting raw beef so as to obtain beef products which keep the original features of conventional beef and also have the obvious improvement on the aspects of quality, color, luster, taste, flavor and shelf life. In addition, a plurality of Chinese herbal medicines are added in the machining process, so that the minty sliced dried beef has the effects of improving eyesight, strengthening the brain, eliminating stagnant blood, stopping bleeding, removing swelling, relieving pain, clearing heat and inducing diuresis.

Owner:滁州市百年食品股份有限公司

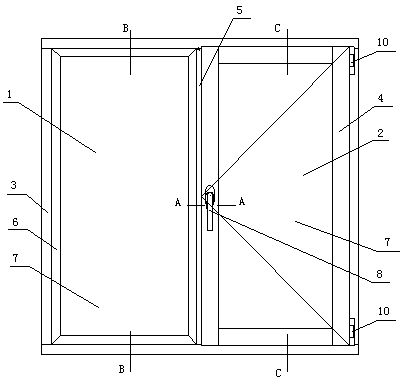

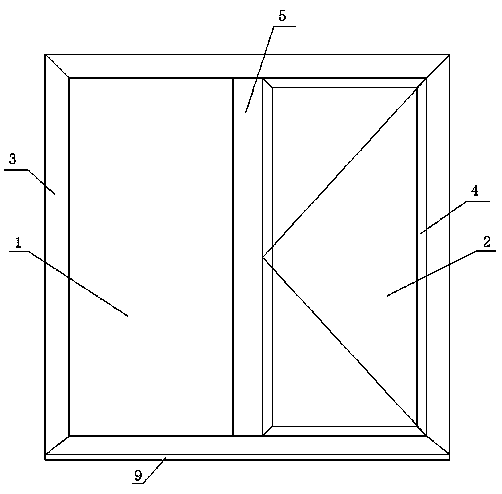

Energy-conservation and thermal-insulation aluminum wooden door and window with ultralow energy consumption

PendingCN111425111AImprove insulation effectMeet energy saving needsWing arrangementsUnits with parallel planesPolystyreneGraphite

The invention discloses an energy-conservation and thermal-insulation aluminum wooden door and window with ultralow energy consumption. A frame comprises an outdoor frame metal profile and an indoor frame compound profile which comprises an indoor frame wooden profile and a frame graphite polystyrene foaming plate spliced and fixed to the outside of the indoor frame wooden profile; a sash frame comprises an outdoor sash metal profile and an indoor sash compound profile which comprises an indoor sash wooden profile and a sash graphite polystyrene foaming plate spliced and fixed to the outside of the indoor sash wooden profile; a mullion comprises an outdoor mullion metal profile and an indoor mullion compound profile which comprises an indoor mullion wooden profile and a mullion graphite polystyrene foaming plate spliced and fixed to the outside of the indoor mullion wooden profile; and a false mullion comprises an outdoor false mullion metal profile and an indoor false mullion compoundprofile which comprises an indoor false mullion wooden profile and a false mullion graphite polystyrene foaming plate spliced and fixed to the outside of the indoor false mullion wooden profile. According to the energy-conservation and thermal-insulation aluminum wooden door and window, the thermal-insulation performance is significantly improved on the premise that the air tightness, water tightness and sound insulation properties are not influenced, and the heat transfer coefficient k is smaller than or equal to 0.8.

Owner:HEBEI ORIENT SUNDAR WINDOW

Furniture board and preparation method thereof

PendingCN111114051AEasy to prepareProcess stabilityLamination ancillary operationsSynthetic resin layered productsPolymer sciencePtru catalyst

The invention belongs to the field of furniture, and discloses a preparation method of a furniture board. The method comprises the following steps: adding nanometer silicon dioxide into ethylene glycol for dissolving; adding purified terephthalic acid, and carrying out an esterification reaction to obtain an esterified product; mixing diethylene glycol with dibasic acid, adding a titanium catalyst, and carrying out a polymerization reaction to obtain a prepolymer; adjusting temperature and pressure, and carrying out a hybrid reaction on the esterified product and the prepolymer to obtain a PETraw material with a melting point of 110-120 DEG C; carrying out melt extrusion on the PET raw material, and carrying out needling, hot bonding or spinning melting treatment to obtain a PET non-wovenfabric; pretreating the PET non-woven fabric with the melting point ranging from 110 DEG C to 120 DEG C and a PET non-woven fabric with a melting point ranging from 225 DEG C to 260 DEG C to obtain aPET non-woven fabric pre-material; and cutting, hot-pressing and cooling the pre-material to obtain the furniture board. The preparation method is simple and stable in process and suitable for large-scale industrial production.

Owner:广东顺德海一舸新材料有限公司

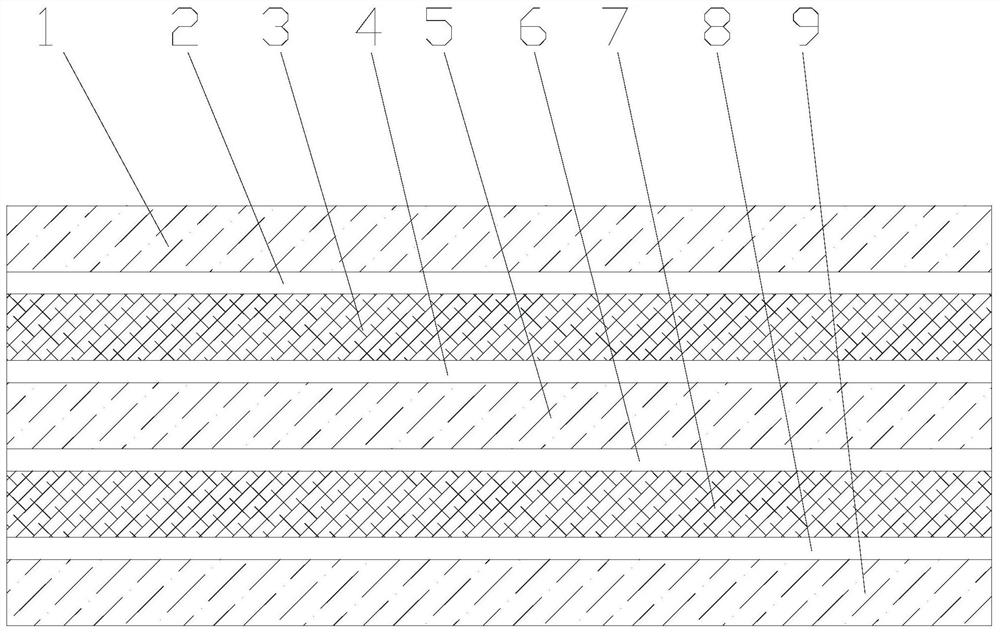

Multilayer aluminum-wood composite structure plate

PendingCN111959067AEasy to processEasy to installCovering/liningsWood veneer joiningSolid woodComposite structure

The invention discloses a multilayer aluminum-wood composite structure plate which comprises a base layer, a second bonding layer is arranged on the upper surface of the base layer, a first metal plate is bonded to the upper surface of the second bonding layer, a first bonding layer is bonded to the upper surface of the first metal plate, and a first solid wood layer is bonded to the upper surfaceof the first bonding layer, a third bonding layer is arranged on the lower surface of the base layer, a second metal plate is bonded to the lower surface of the third bonding layer, a fourth bondinglayer is bonded to the lower surface of the second metal plate, and a second solid wood layer is bonded to the lower surface of the fourth bonding layer. The upper surface and the lower surface are made of solid wood, the decorative effect of natural solid wood is achieved, and the texture of the natural solid wood is reserved.

Owner:上海西蒙铝业有限公司

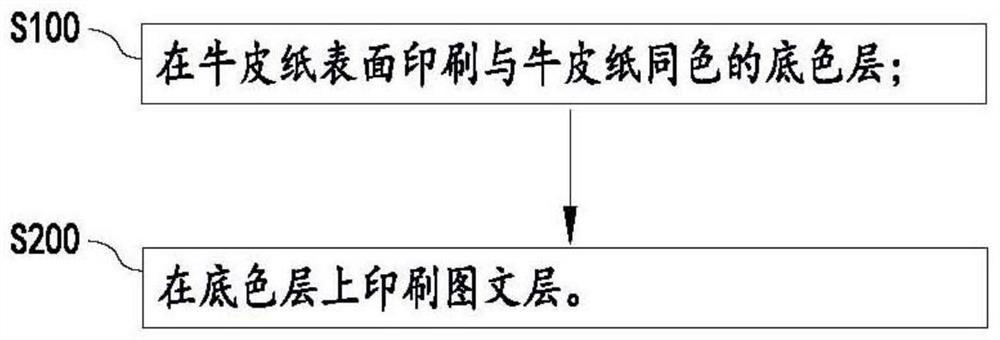

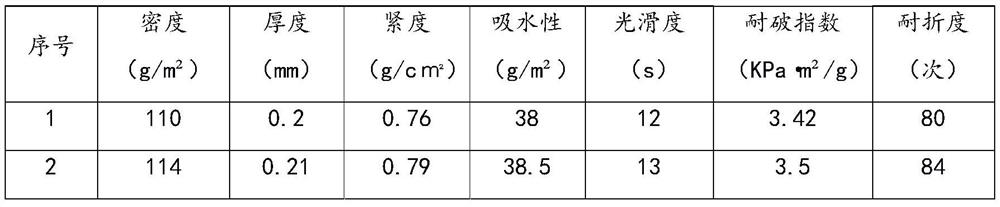

Kraft paper large ink position printing method and kraft paper for packaging

PendingCN114851730APreserve the original colorRetain textureBio-packagingInksMechanical engineeringKraft paper

The invention relates to the technical field of printing methods, and discloses a kraft paper large-ink-position printing method which comprises the following steps: printing a bottom color layer with the same color as kraft paper on the surface of the kraft paper; and printing the image-text layer on the ground color layer. And the bottom color layer is printed by spot color ink. And the image-text layer is printed by using spot color ink. The density of the adopted kraft paper is 110-120 g / m < 2 >, the thickness is 0.2-0.25 mm, the tightness of the kraft paper is 0.76-0.85 g / cm < 2 >, the water absorption is 38-40 g / m < 2 >, the smoothness is 12-15 s, the burst index is 3.42-3.6 KPa.m < 2 > / g, and the minimum folding strength in the transverse direction is 80 times. The kraft paper raw material is sulfate larch pulp. The invention also provides the kraft paper for packaging, which is prepared by using the kraft paper large ink position printing method. The kraft paper printing effect is smooth and clean in characters and patterns, clear and complete in edge, uniform in ink color, rich in layer, high in texture and saturated in color, and the kraft paper printing effect is greatly improved.

Owner:DONGGUAN MYS ENVIRONMENTAL PROTECTION TECH

Primate taxidermy coloring process

InactiveCN108823341BRetain textureGuaranteed color textureDyeing processLeather surface finishingPrimateSkin color

The invention provides a primate specimen coloring process. The process comprises the following steps: coloring the whole body skin of a specimen, and then performing partial coloring. The coloring process firstly treats the whole body skin into the same color, and the parts with different colors are further colored locally, thereby the situation that the texture of the specimen skin is affected due to direct applying of various pigments on the skin can be avoided, and at the same time, the discoloration of the hair due to pigment staining on the hair during direct application of various pigments to the skin can be avoided; original texture of the specimen can be kept, the natural and true specimen skin color can be provided, and the color texture of the specimen can be ensured.

Owner:KUNMING INST OF ZOOLOGY CHINESE ACAD OF SCI

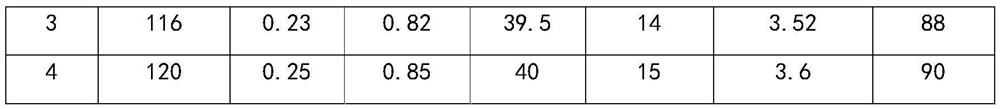

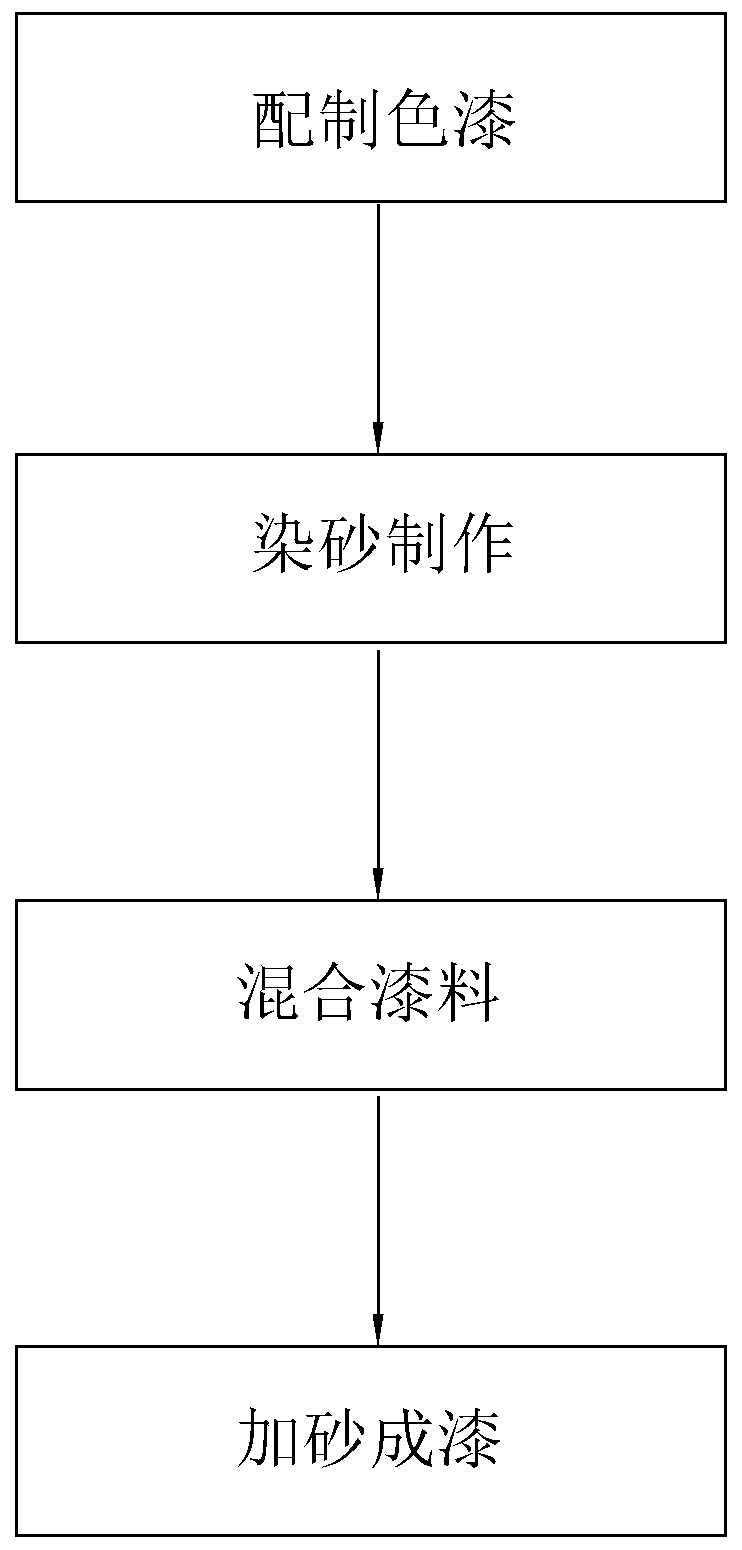

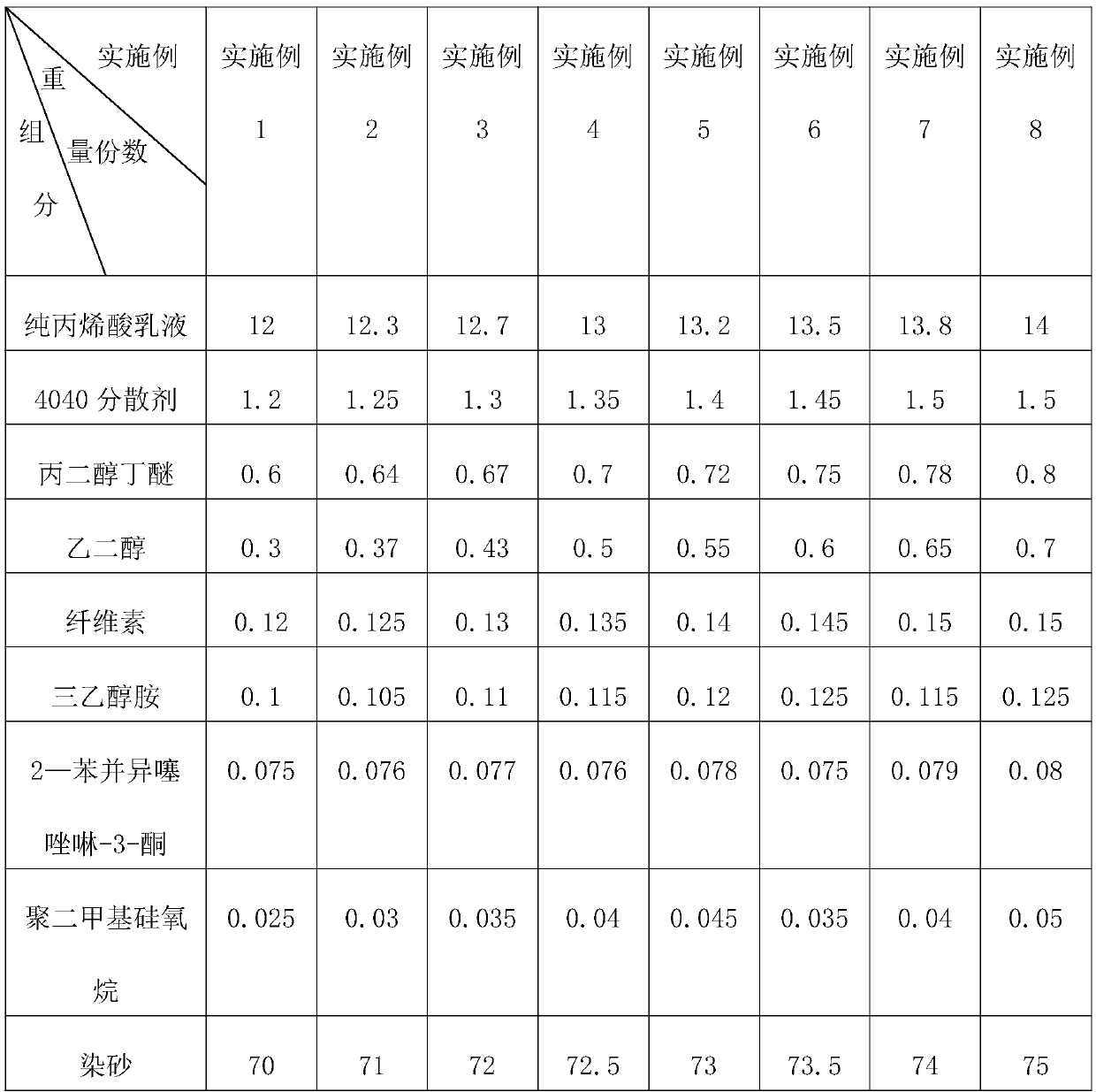

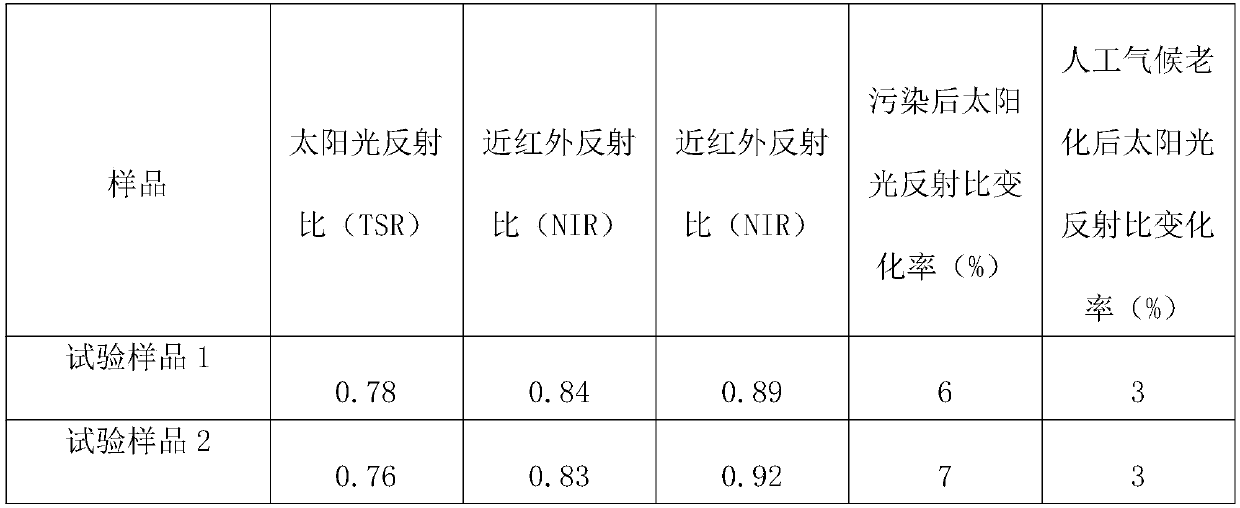

Reflective heat-insulating stone-like coating and preparation process thereof

InactiveCN110294607AGood reflection and heat insulation functionGood application effectCelluloseSolar light

The invention discloses a reflective heat-insulating stone-like coating and a preparation process thereof, relates to the technical field of building material coatings, and solves the problem of pooroverall application effect due to the fact that a coating film of the stone-like coating cannot effectively reflect visible light and near infrared light in solar light back into the atmosphere. The reflective heat-insulating stone-like coating comprises the following components in parts by weight: 12-14 parts of pure acrylic emulsion, 1.2-1.5 parts of 4040 dispersant, 0.6-0.8 part of a film forming additive, 0.3-0.7 part of ethylene glycol, 0.12-0.15 part of cellulose, 0.1-0.125 part of a pH regulator, 0.075-0.08 part of a preservative, 0.025-0.05 part of a defoaming agent and 70-75 parts ofdyed sand, wherein the dyed sand comprises the following components in percentage by weight: 75-80% of white quartz sand, 16-20% of polyurethane aqueous color paint for the dyed sand and 4-5% of a curing agent. A coating film formed by the reflective heat-insulating stone-like coating has a good reflection effect on THE visible light and near infrared light in solar light, can maintain good stability in the use process, and has a good application effect.

Owner:HUBAO NEW MATERIAL TECH SHANGHAI CO LTD

Surface treating process of multiple sheet alloy

The invention relates to a surface treatment method of a plurality of sorts of alloy boards, belonging to the material class. The surface treatment process comprises the following steps that: (a) a base material to be subject to surface treatment is selected; (b) a transparent film layer is formed through adopting a chemical method or an electrochemical method so as to reduce or terminate the chemical reaction of the base material and retain original conductive characteristics; and (c) surface dyeing of the base material is carried out through an electro deposition coating. The surface treatment process has the advantages that: the process ensures that a plurality of sorts of alloy boards represent three-dimensional appearance effect without adding other materials; moreover, the process retains the original texture of metal and does not pollute the environment, thereby having strong practicability.

Owner:上海达鑫电子有限公司 +1

Coloring formula and processing technology for surface color of bronze-based handicraft

InactiveCN112778801ARetain textureIncrease diversityAntifouling/underwater paintsPaints with biocidesLacquerSulfate

The invention discloses a coloring formula and a processing technology for surface color of a bronze-based handicraft. The prepared colored paint is prepared from the following raw materials in percentage by mass: 20-35% of nitric acid heavy metal salt, 5-10% of ethanol, 30-50% of a colored plant solution and the balance of water, wherein preferably, cochineal powder with a mass fraction of 1-4% is added when the nitric acid heavy metal salt is ferric nitrate, and when the nitric acid heavy metal salt is copper nitrate, ferrous sulfate with a mass fraction of 5-10% and castor oil with a mass fraction of 3-5% are added. The invention also provides a a processing technology for surface color of a bronze-based handicraft by adopting the formula. According to the invention, a relatively stable lacquer coating is formed on the surface of bronze ware, the coating is not easy to fall off, the artistic forms are diversified, the specific texture of the bronze ware is perfectly embodied, the characteristic of ancient color and charm of the surface of the bronze ware is embodied, and the diversity and ornamental value of the art are reflected.

Owner:湖南观互文化艺术发展有限公司

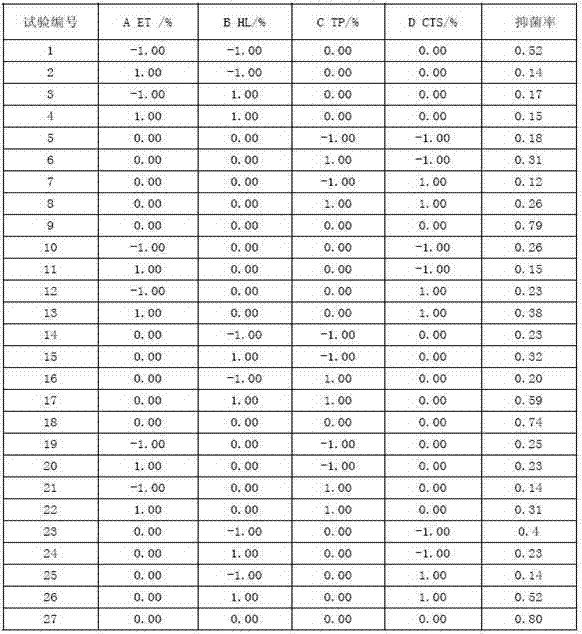

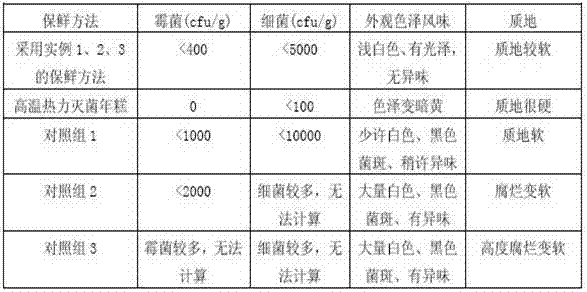

Compound New-Year-cake freshness preserving liquid and New-Year-cake freshness preservation method

The invention discloses compound New-Year-cake freshness preserving liquid and a New-Year-cake freshness preservation method. The compound New-Year-cake freshness preserving liquid is characterized by being composed of the following raw materials in the following formula: 61-79vt% of edible ethanol, 6-10mg / ml of chitosan, 10-20mg / ml of sodium lactate, 15-25mg / ml of tea polyphenols, and the balance sterile water. The New-Year-cake freshness preservation method comprises the following steps of preparing the compound New-Year-cake freshness preserving liquid; transferring the compound New-Year-cake freshness preserving liquid into a spray kettle, and carrying out spraying so as to coat surfaces of New-Year cakes with a protective membrane to obtain membrane-coated New-Year cakes; and then, putting the membrane-coated New-Year cakes with sustained-release ClO(2) agent in packing bags, and carrying out vacuum packaging. The compound New-Year-cake freshness preserving liquid and the New-Year-cake freshness preservation method have the advantages that original texture and taste of the New-Year cakes are preserved, and shelf lives of the New-Year cakes are prolonged.

Owner:NINGBO UNIV

A kind of large color paint formula and its paint coating process for the surface of copper ware

ActiveCN105694721BRetain textureIncrease diversityFireproof paintsNatural resin coatingsLacquerTurpentine

The invention discloses a formula of large-color paint for use on the surface of copperware. The prepared large-color paint is composed of the following raw materials and their mass percentages: raw paint: 65%; turpentine: 10%; colored ore powder: 25%; And the particle size of the non-ferrous ore powder after grinding is 600 mesh to 800 mesh; at the same time, a paint coating process for using this large-color paint to construct copperware was also announced. The purpose of the present invention is to provide a large-color paint formula for the surface of copperware and a paint coating process thereof. The surface of the copperware is coated with raw lacquer and retains the unique texture of the utensil part; at the same time, the single black color of the raw lacquer is changed and the restrained color is retained. , crystal clear, and antique; adding to the diversity and ornamental value of art products.

Owner:HIHEMA HUNAN CULTURAL IND DEV CO LTD

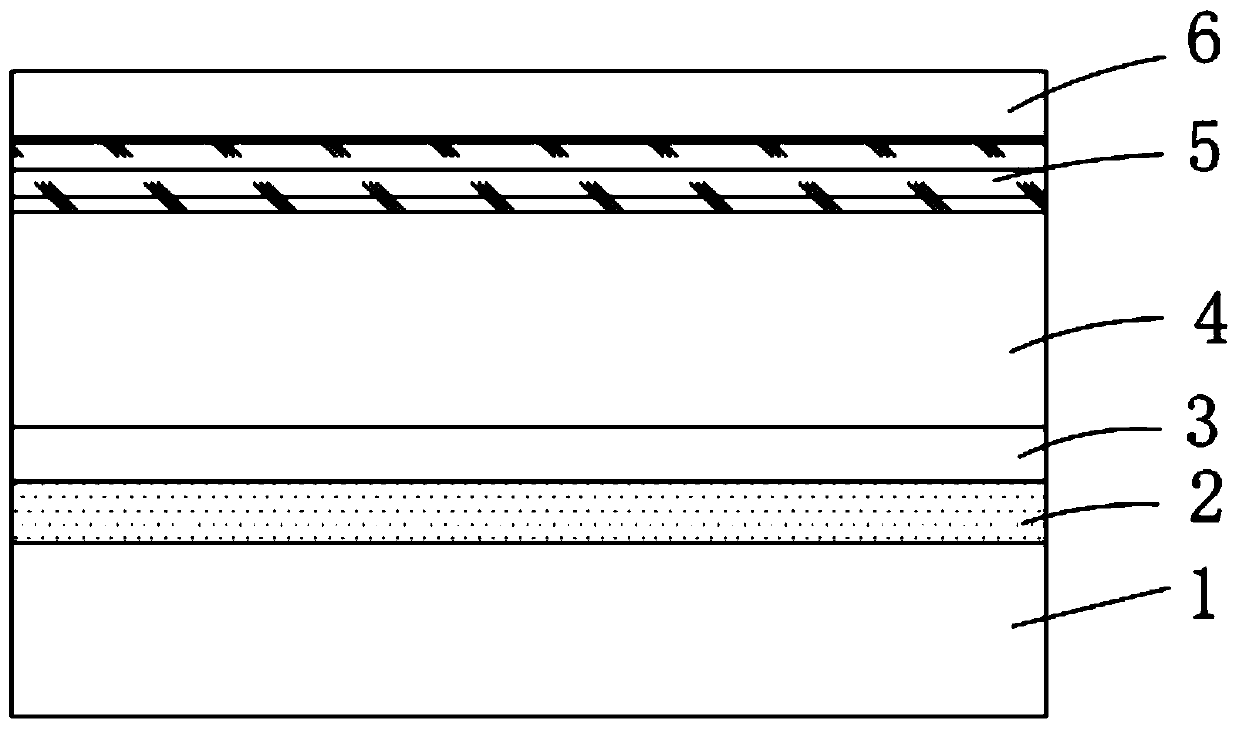

High-elasticity silicon rubber heat transfer film and preparation method thereof

InactiveCN110626088AStretch wellNot easily deformedPolyureas/polyurethane adhesivesSynthetic resin layered productsHot-melt adhesiveTear resistance

The invention discloses a high-elasticity silicon rubber heat transfer film and a preparation method thereof. The high-elasticity silicon rubber heat transfer film comprises a base substrate, whereina film removal layer is arranged on the base substrate, a scratch-resistant coating is arranged on the film removal layer, a rubber ink layer is arranged on the scratch-resistant coating, an adhesivelayer is arranged on the rubber ink layer, and a TPU hot melt adhesive film is adhered to the adhesive layer. According to the high-elasticity silicone rubber heat transfer film, by arranging the rubber ink layer in the preparation process, the heat transfer film has good stretchability and resilience, is resistant to water washing, is not prone to deform, and is high in softness. The TPU hot meltadhesive film is arranged so that the heat transfer film is good in elasticity and high in tear resistance, the used material is environment-friendly, odorless and non-toxic, the safety performance is good, and skin does not cause allergy after long-term contact with a silicone rubber surface. The arrangement of the scratch-resistant coating not only retains the texture of the TPU but also improves the scratch resistance and formability of resin.

Owner:安徽创研新材料有限公司

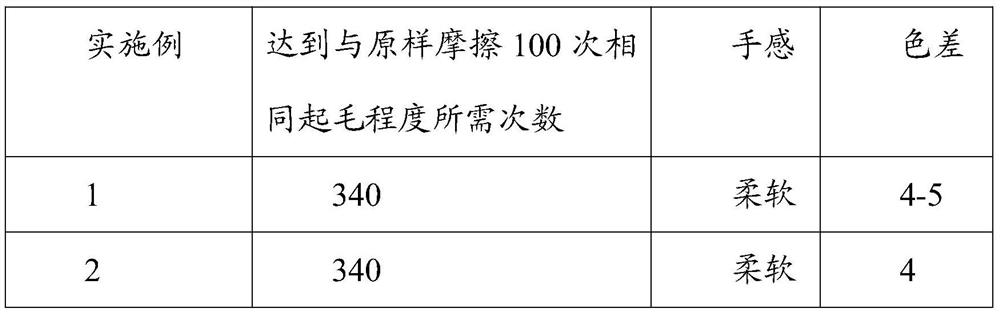

A finishing agent for preventing fluffing of embroidery and its preparation method and application method

ActiveCN109440467BImprove controllabilityAnti-pilling effect is obviousAbrasion resistant fibresMedicinePolyvinyl alcohol

The invention discloses a finishing agent for preventing fluffing of embroidery and its preparation method and application method. The finishing agent comprises the following proportions by weight: 2-5 parts of polyvinyl alcohol, 2-5 parts of polyacrylic acid, cross-linked 0.2-0.5 part of agent borax, 0.2-0.5 part of colorless water-soluble penetrating agent, 0.2-0.5 part of colorless water-soluble softener, add deionized water and be made into the solution of 100 parts of total amount; The preparation method of the agent comprises the steps of: weighing 2-5 parts of polyvinyl alcohol according to the ratio of parts by weight, and placing an appropriate amount of deionized water to swell, and then heating and dissolving to obtain an aqueous solution of polyvinyl alcohol; The preparation method of the finishing agent for preventing fluffing of embroidery is simple, and at the same time, the finishing agent for preventing fluffing of embroidery is convenient to use, has strong operability, good controllability, and no pollution; the finishing agent for preventing fluffing of embroidery The anti-pilling effect is obvious. At the same time, the color difference of embroidery after treatment is small, and its inherent color and pattern texture, layering and soft feel are retained.

Owner:SUZHOU VOCATIONAL UNIV

Bamboo chip painting and calligraphy production process

PendingCN113752741ARetain natural textureRetain textureCane mechanical workingReed/straw treatmentMechanical engineeringTemperature treatment

The invention discloses a bamboo chip painting and calligraphy production process. The bamboo chip painting and calligraphy production process comprises the following steps that: firstly, materials are selected; and 5-6 years old bamboos with straight, round and thicker rod shapes are selected; secondly, a hydraulic system is started to screw a hoop ring; after a tank door is closed, a vacuum valve is opened, all other valves are closed to start vacuum operation, and a vacuum state is kept; and after vacuum operation, negative pressure is used for liquid suction, and pressurization is conducted according to different materials and standards; and thirdly, the bamboo can be softened through high-temperature (160 DEG C) rapid heating; and meanwhile, due to the fact that the bamboo contains rich extracts, the durability of the bamboo is affected, and mildew is likely to be caused; and therefore, mildew-proof treatment can be conducted on the bamboo through high-temperature treatment, so that the durability and mildew-proof property of the bamboo are improved. According to the bamboo chip painting and calligraphy production process, by forming painting and calligraphy on the thin bamboo chips within 0.3 mm, the natural texture and texture of the bamboo chips are reserved, the natural faint yellow color is reserved, and the bamboo chips have the advantages of antique color and antique fragrance and can be preserved for a long time without fading through preservative treatment.

Owner:陈贵旭

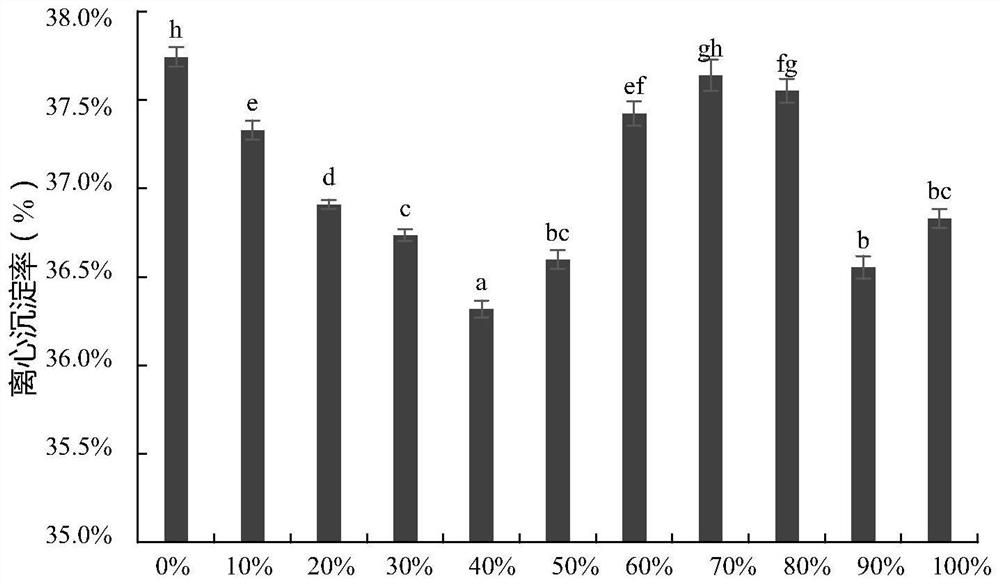

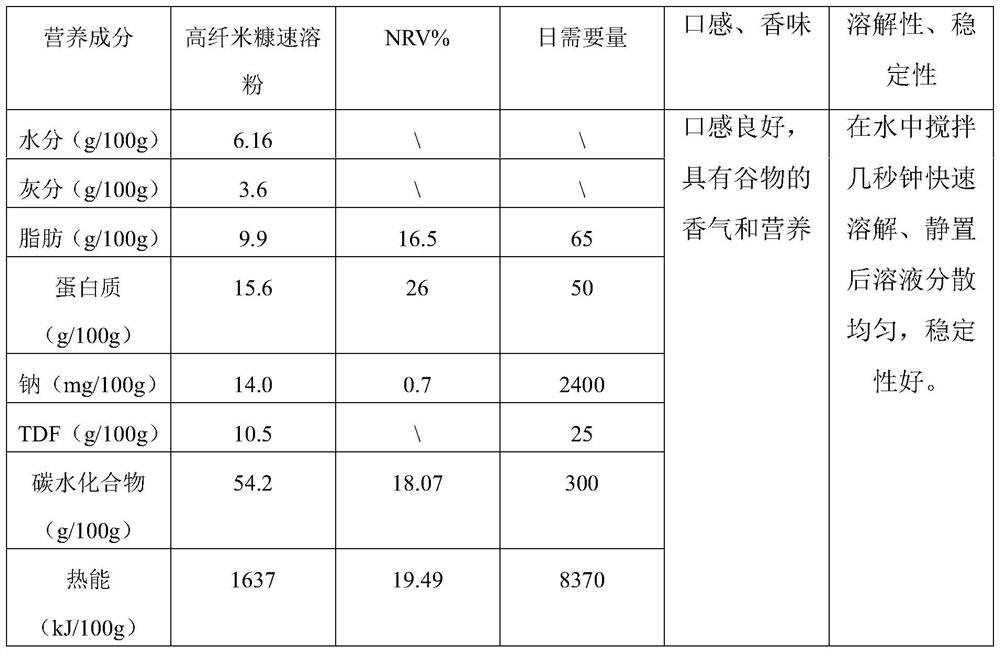

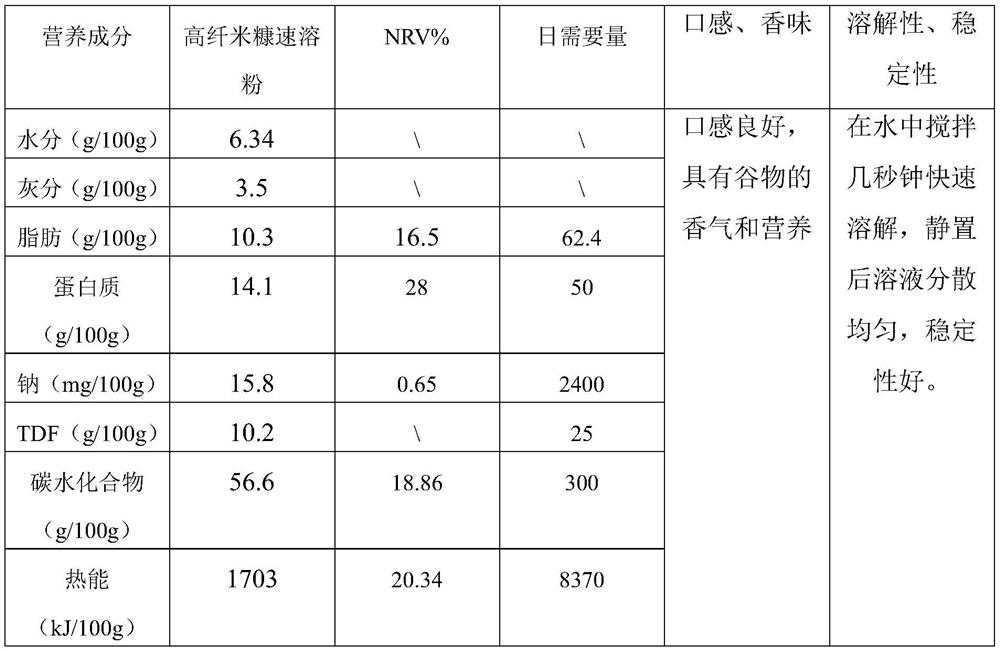

High-fiber rice bran instant powder and preparation method thereof

InactiveCN112369558AIncreased soluble polyphenol contentImprove bioavailabilityFood ingredient as thickening agentFood ingredient as mouthfeel improving agentBiotechnologySucrose

The invention relates to the food processing technology, in particular to a high-fiber rice bran instant powder and a preparation method thereof. The invention discloses the high-fiber rice bran instant powder which comprises the following raw materials: modified rice bran, puffed Avena sativa L. powder, puffed rice meal, semen sesami nigrum powder, sucrose ester, monoacylglyceride and konjak powder. The modified rice bran is a product obtained in a way that rice bran is subjected to degreasing, fermentation and enzymolysis. The high-fiber rice bran instant powder is prepared by the followingsteps of: (1) adding the puffed Avena sativa L. powder, the puffed rice meal and the semen sesami nigrum powder into the modified rice bran to obtain a compound; and (2) adding an emulsifying agent and a thickening agent into the compound, and carrying out even mixing and sterilization to obtain the high-fiber rice bran instant powder. The high-fiber rice bran instant powder obtained by the abovepreparation method has a good taste and has the fragrance and the nutrients of cereals.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

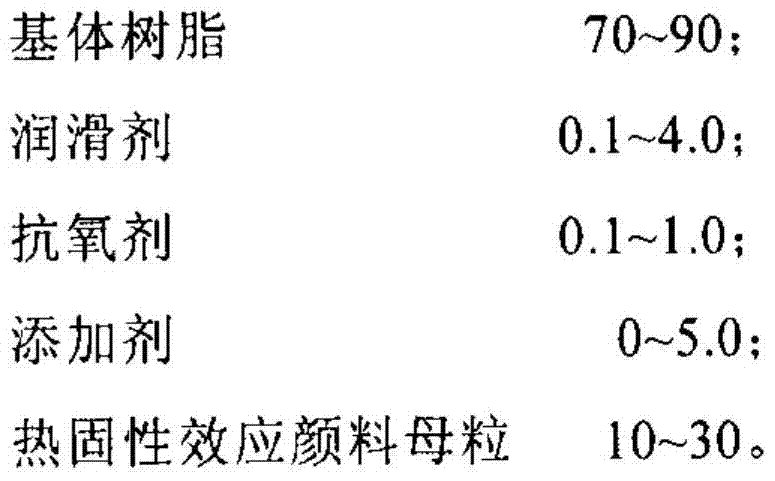

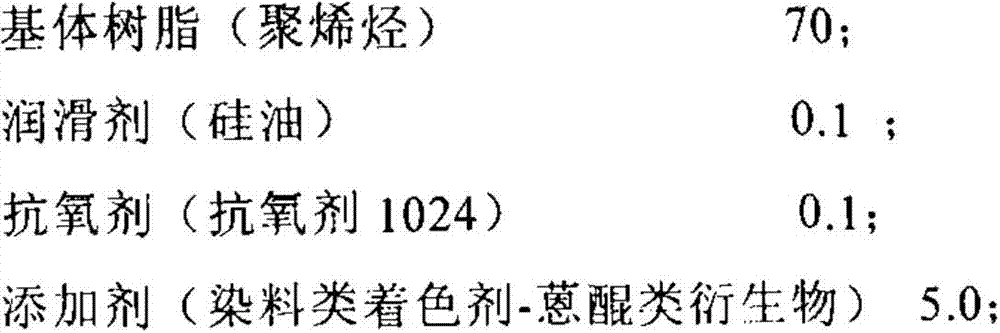

A kind of aesthetic resin composition with improved appearance and preparation method thereof

The invention relates to an aesthetic resin composition for improving appearance and a preparation method thereof, which is made of the following components and raw materials in parts by weight: matrix resin 70-90, lubricant 0.1-4.0, antioxidant 0.1-1.0, additive 0 ~5.0, thermosetting effect pigment masterbatch 10~30. Compared with the prior art, after the thermosetting resin and the effect pigment are mixed and cured in the present invention, the thermosetting resin has a covering effect on the effect pigment. Retain the texture of toner under the original particle size, so as to improve flow marks and weld lines with high surface quality. In addition, the cross-linked resin has a protective effect on the toner, which can improve the structure damage of the effect pigment during processing and improve the effect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

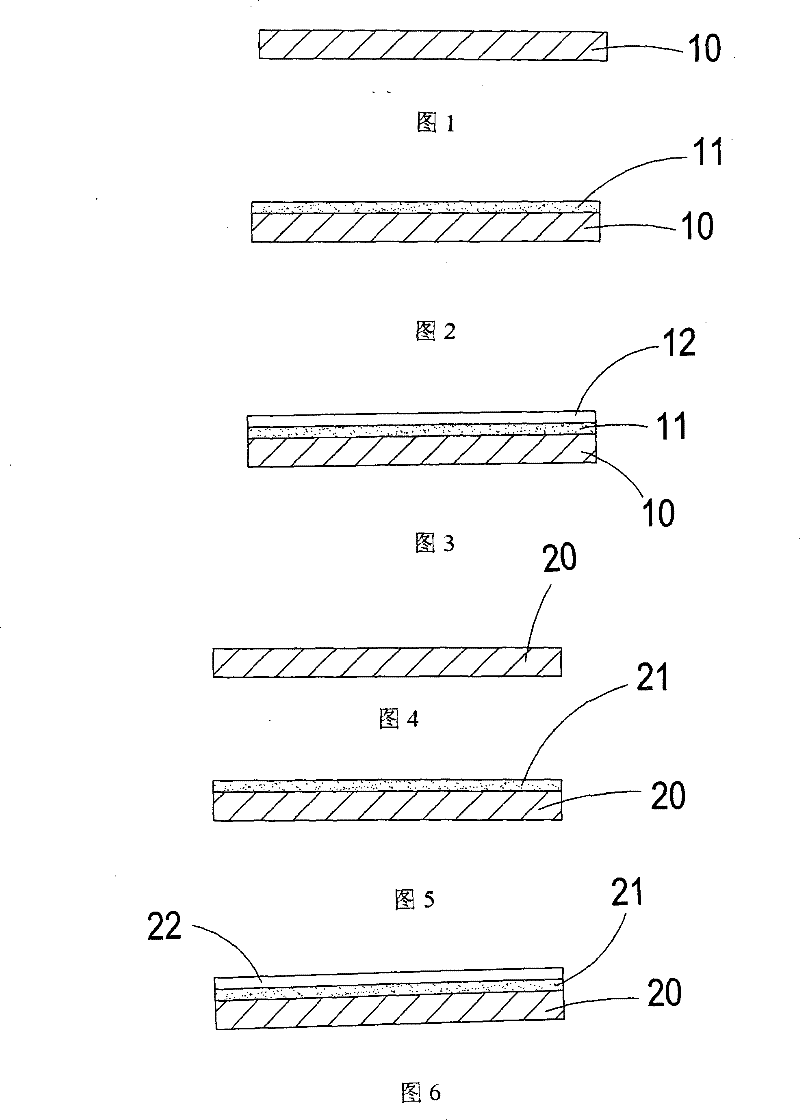

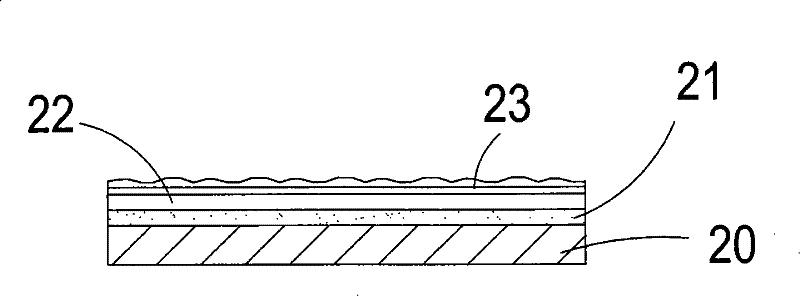

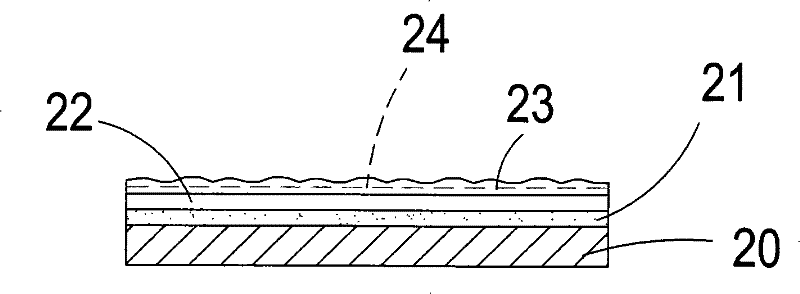

Novel processing technology for sandwich natural stone plate

InactiveCN110181926ARetain textureImprove expressivenessLaminationLamination apparatusFiberglass meshTextile

The invention provides a novel processing technology for a sandwich natural stone plate, and relates to the technical field of stone. The processing technology comprises the following steps: a glass fiber mesh is used as a substrate, the glass fiber mesh is bonded to single stone by using resin glue, another stone is bonded to the other side of the fiber mesh, and therefore the structure that themesh cloth is sandwiched between two stone is formed. The processing technology provided by the invention has the following beneficial effects: the thickness of the sandwich natural stone plate is notlimited, the physical structure of the stone is not changed by using the glue in the production process, the tensile and bending resistance of the plate is improved by the sandwich fiber mesh, the problem that a product is fragile during processing, transportation, installation and use of traditional stone is solved, scrapping is reduced, natural resources are utilized more environmentally and efficiently, reprocessing technologies such as cutting, grinding and polishing are the same as those of a traditional marble plate, characteristics such as original color and patterns of the natural stone are retained, and the expressive force of the natural stone is fully extended.

Owner:泉州薄石文化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com