Patents

Literature

68results about How to "Improve surface scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

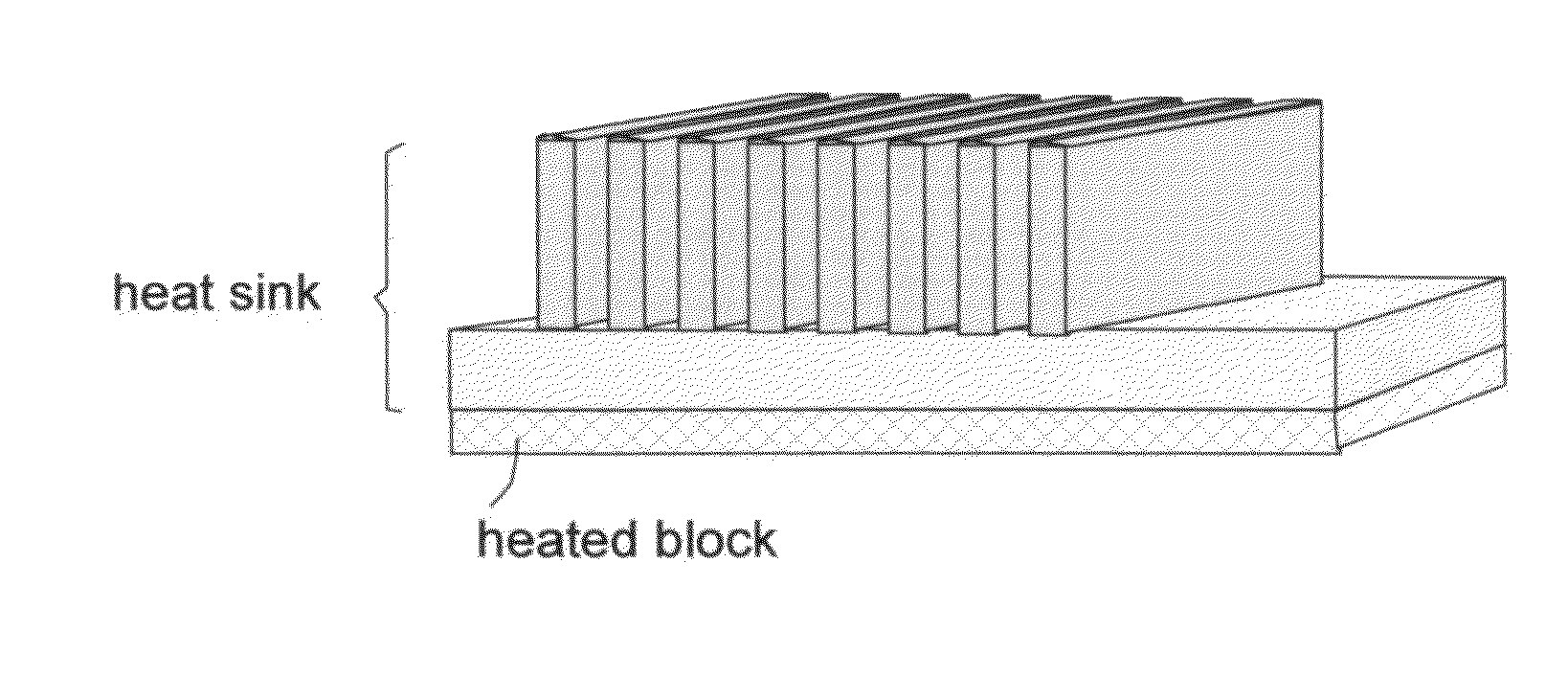

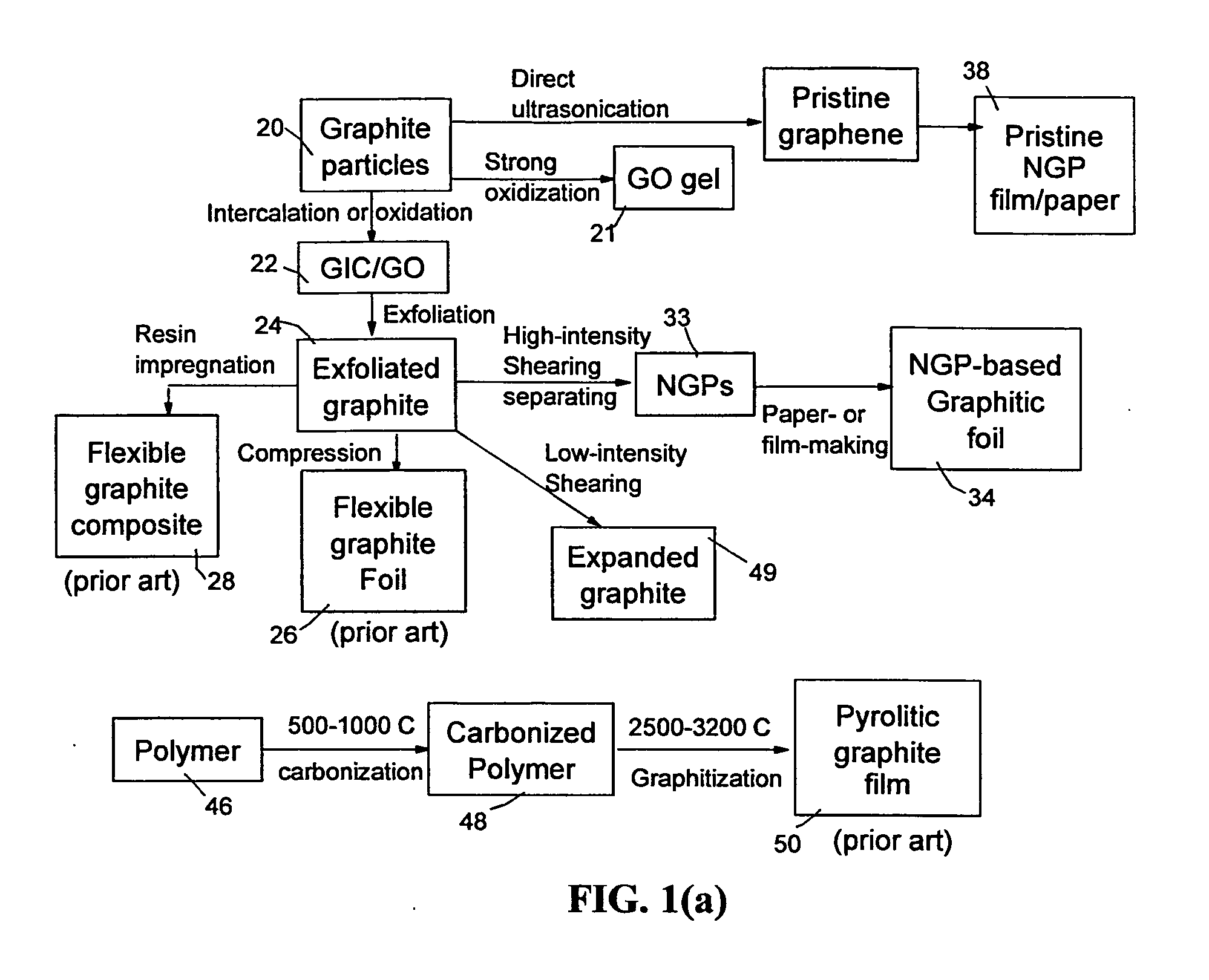

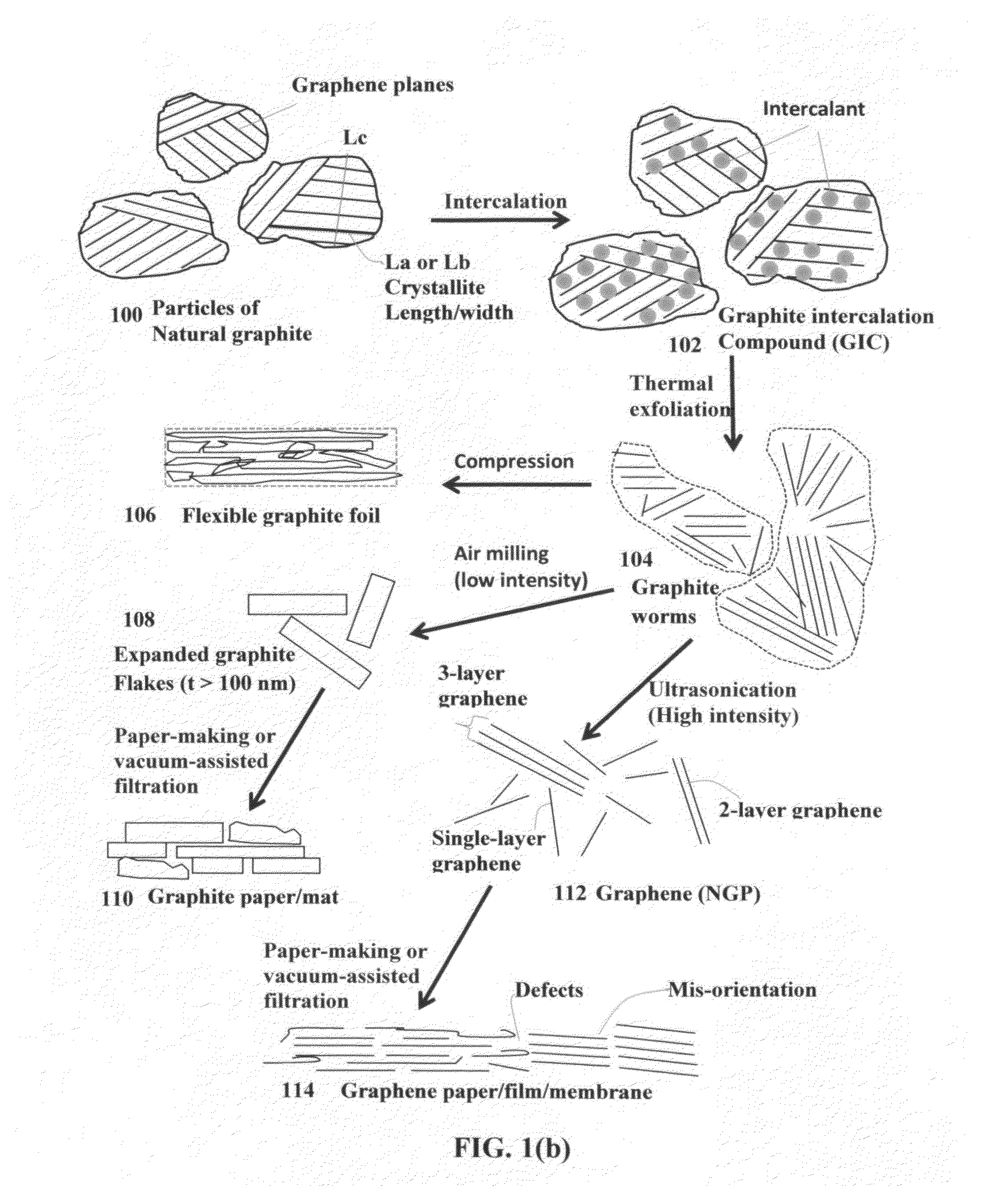

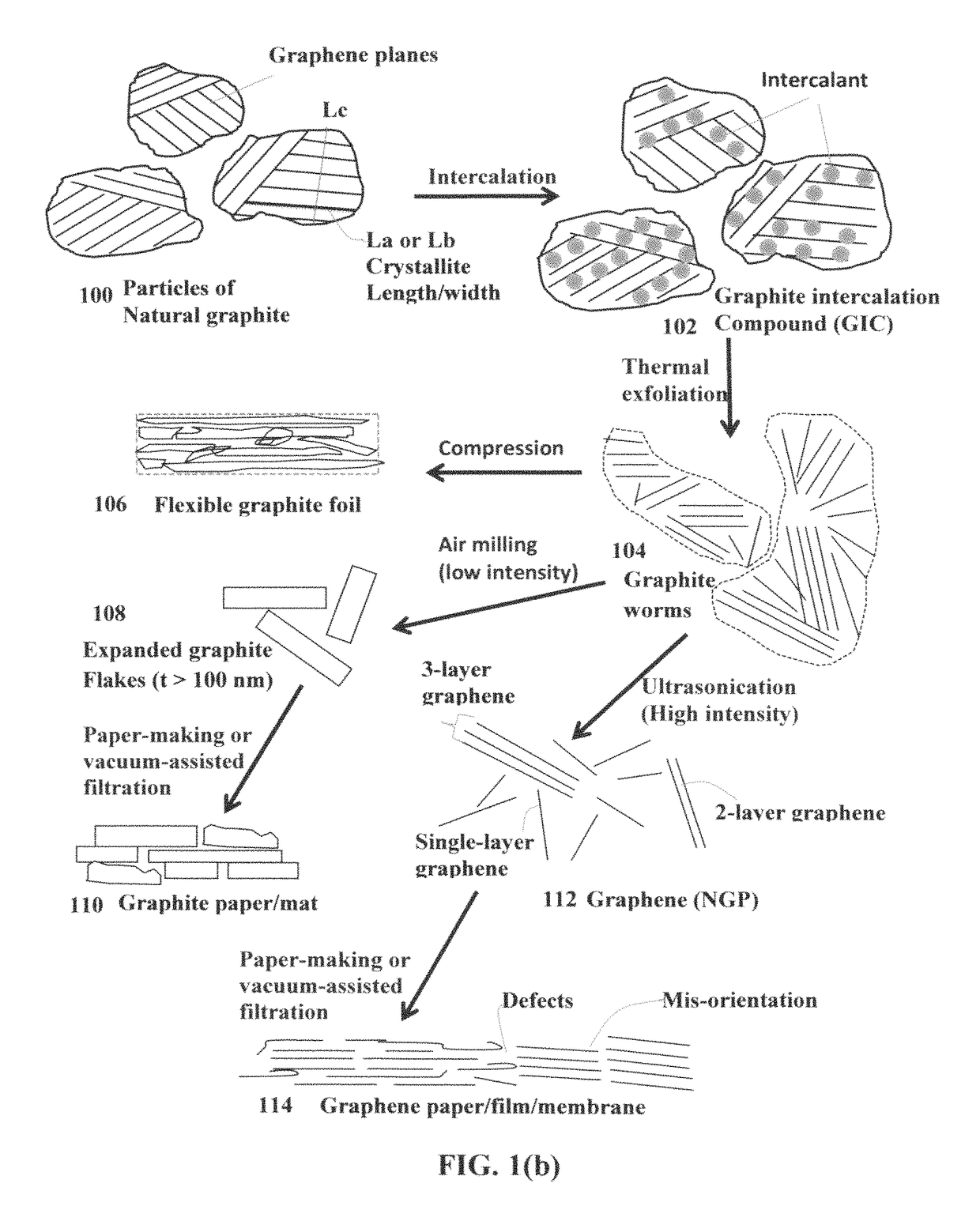

Nano graphene platelet-reinforced composite heat sinks and process for producing same

ActiveUS20140224466A1Improve surface scratch resistanceReduced/eliminated possibilityMaterial nanotechnologySemiconductor/solid-state device detailsEngineeringGraphite

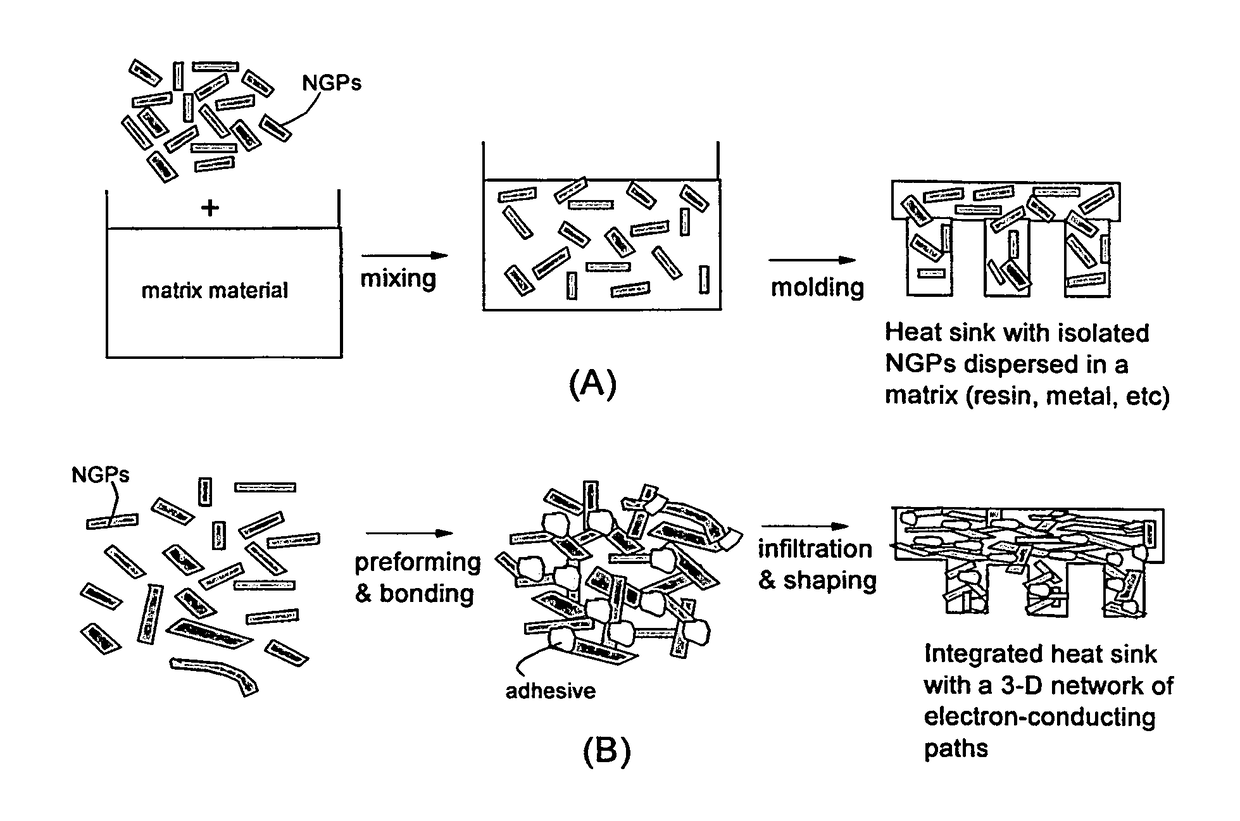

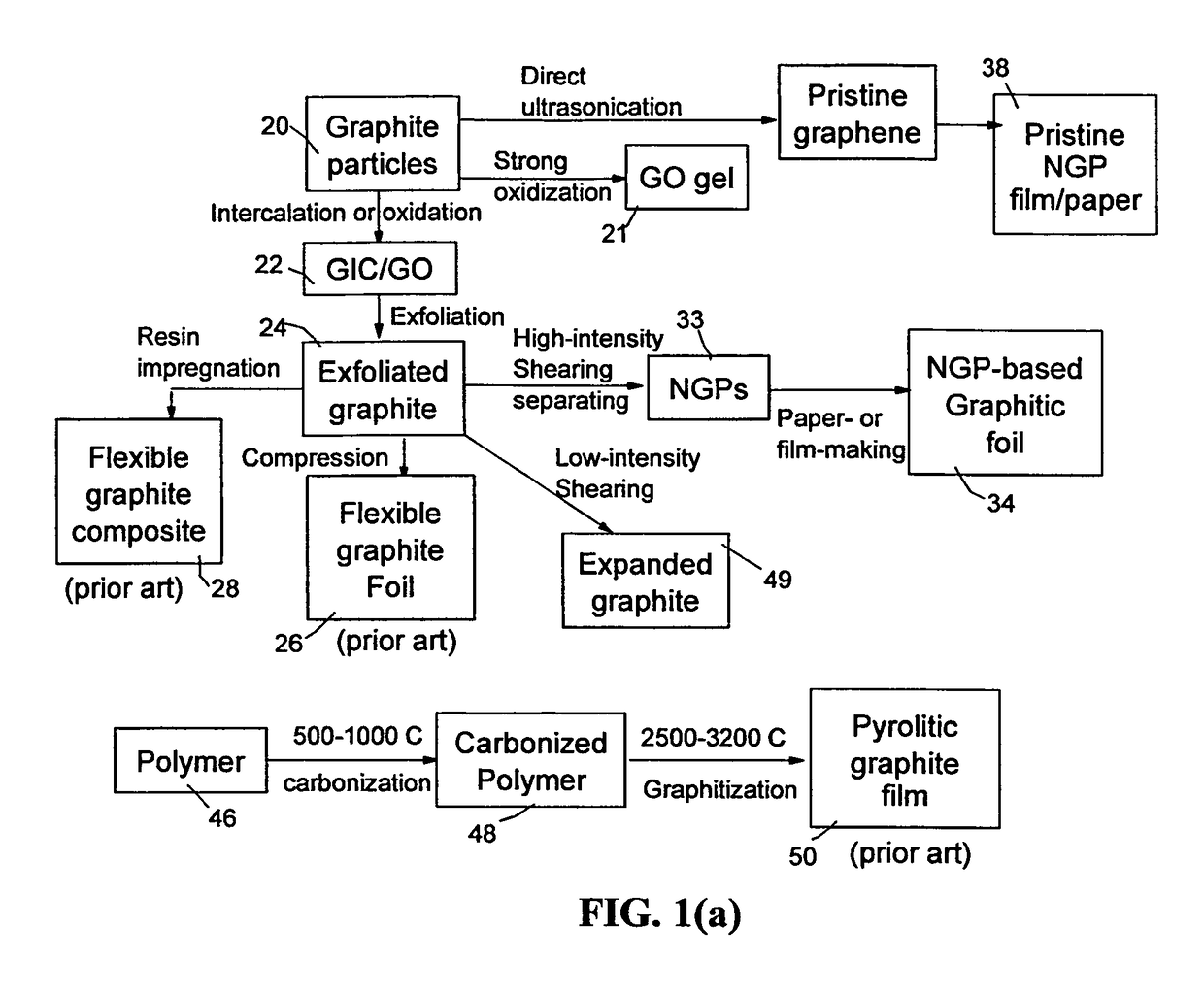

An integrated heat sink article composed of a heat collection member and at least one heat dissipation member integral to the heat collection member, wherein the heat collection member is configured to be in thermal contact with a heat source, collects heat from the heat source, and dissipates heat through the at least one heat dissipation member, and further wherein the heat sink is formed of a nano graphene platelet-reinforced composite having nano graphene platelets or sheets (NGPs) as a first reinforcement phase dispersed in a matrix material and the first reinforcement phase occupies a weight fraction of 1-90% based on the total composite weight. Preferably, these NGPs, alone or in combination with a second reinforcement phase, are bonded by an adhesive and constitute a continuous 3-D network of electron- and phonon-conducting paths.

Owner:GLOBAL GRAPHENE GRP INC

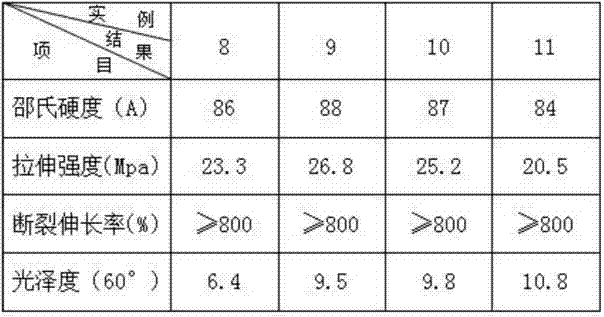

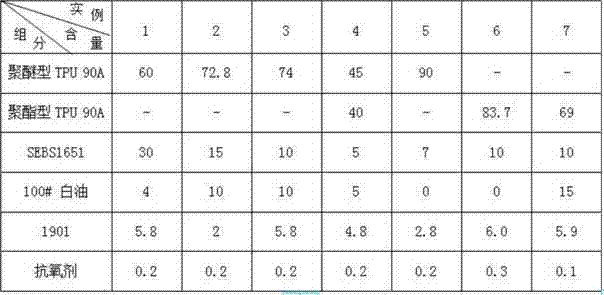

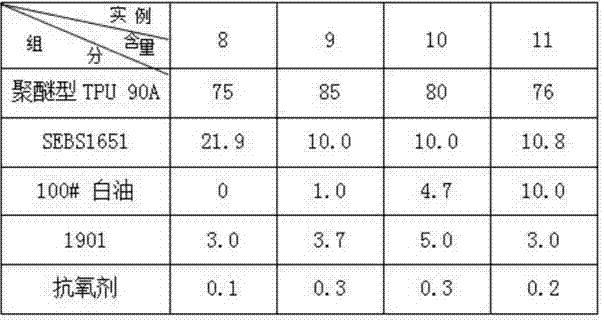

Dumb thermoplastic polyurethane elastomer composition and preparation method thereof

InactiveCN102199343AMatte effect and good surface scratch resistanceImprove processabilityBoiling pointAntioxidant

The invention relates to a dumb thermoplastic polyurethane elastomer composition and a preparation method thereof, belonging to the technical field of high polymer materials. The dumb thermoplastic polyurethane elastomer composition comprises the following components in percentage by weight: 60%-90% of thermoplastic polyurethane elastomer, 5%-30% of styrene block copolymer resin, 0%-15% of rubberprocessing oil, 2%-6% of compatilizer and 0.1%-0.3% of antioxidant. The invention also relates to the preparation method of the composition. Compared with the prior art, styrene-ethylene-butene-styrene (SEBS) is used as the fogging agent of the thermoplastic polyurethane (TPU) polymer, the obtained product has a dumb surface and a good surface scratch resistance effect, and the surface dumb degree of the product can be regulated at random according to the factual requirement; and simultaneously, by using the method, the problem that the viscosity of the TPU polymer is mutated at the vicinity of a boiling point along with the variation of the temperature in the course of processing is solved, thereby greatly improving the workability of the TPU polymer.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

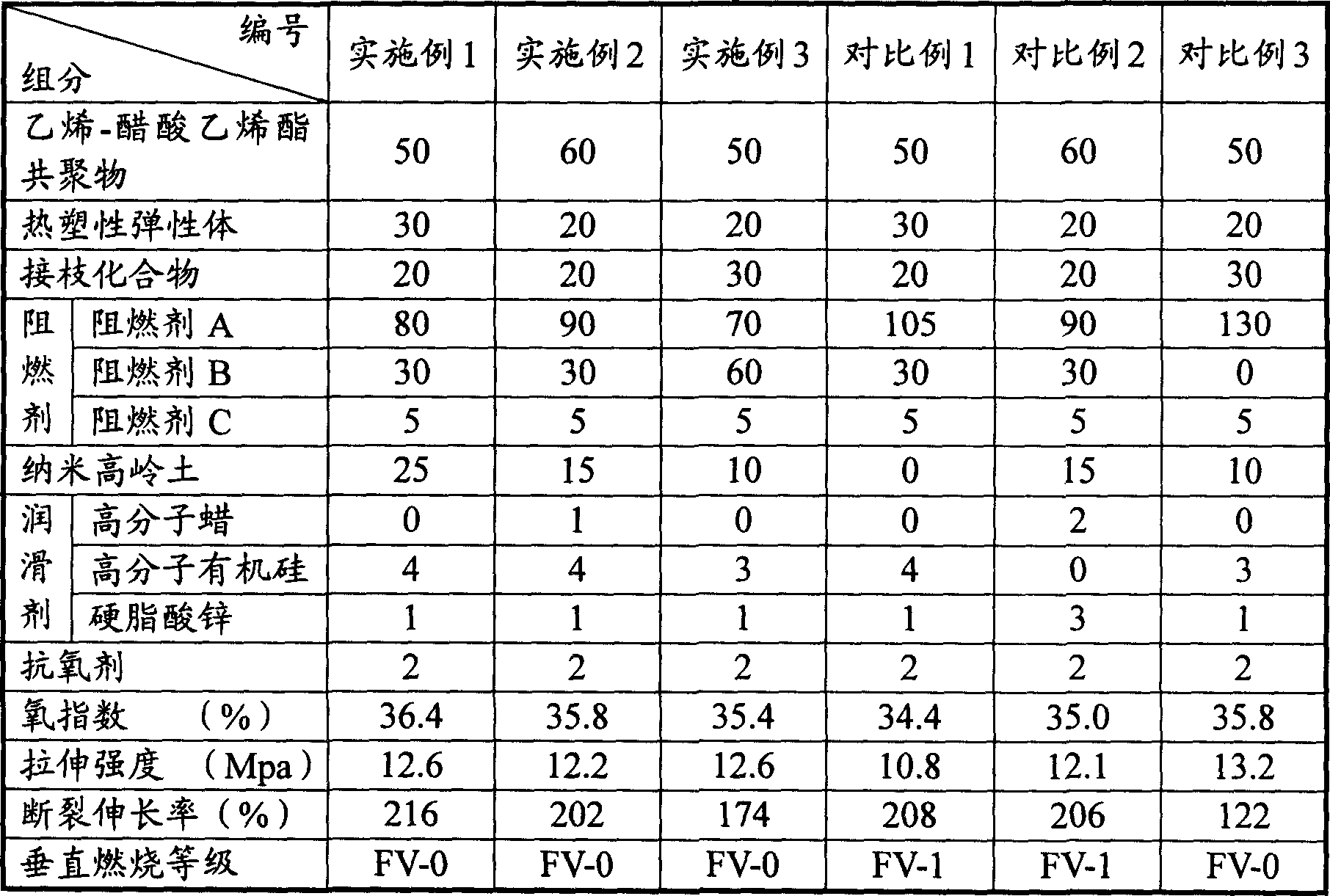

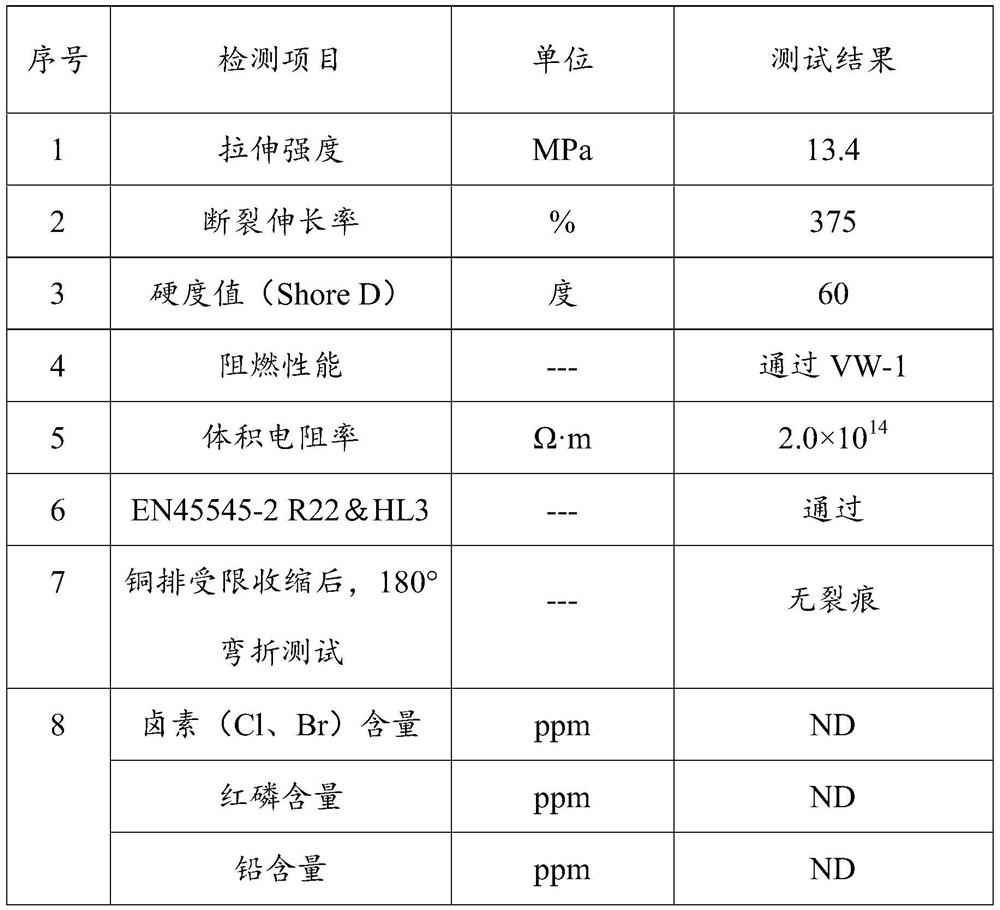

Nano kaoline fire-resistant synergistic halogen-free non-phosphor cable sheath material

InactiveCN1850899AHigh tensile strengthReduce spreadInsulated cablesInsulated conductorsPolymer chemistryEthylene-vinyl acetate

Owner:NINGBO SHIP PLASTIC CO LTD

Treatment method of black hard microarc oxidation ceramic membrane on surface of magnesium alloy

InactiveCN102021631AUniform colorImproved color stabilityAnodisationElectrolysisPlasma electrolytic oxidation

The invention belongs to the treatment technology of a black hard ceramic membrane on the surface of magnesium alloy, in particular relating to a treatment method of a black hard microarc oxidation ceramic membrane on the surface of magnesium alloy. The invention mainly solves the technical problems that the colour of a ceramic membrane treated by magnesium alloy microarc oxidation is white or grey white mostly and the deep colour and even black ceramic membranes can not be obtained in the prior art. The method provided by the invention comprises the steps that sodium phosphate, sodium fluoride, sodium hydroxide, sodium molybdate, potassium carbonate, sodium tungstate, copper sulphate and potassium dichromate are added into water and prepared into an alkaline electrolytic solution, and the solution is stirred for later use; and then magnesium alloy and a stainless steel plate are immersed into the alkaline electrolytic solution, the magnesium alloy is taken as an anode, the stainless steel plate is taken as a cathode, and microarc oxidation treatment is carried out until a compact black hard ceramic membrane grows in situ on the surface of the magnesium alloy.

Owner:杭州意来客电器设备有限公司

Thermoplastic elastomer composition and process for producing the same

InactiveUS20050038186A1Improve mechanical propertiesImprove scratch resistanceMeth-Thermoplastic elastomer

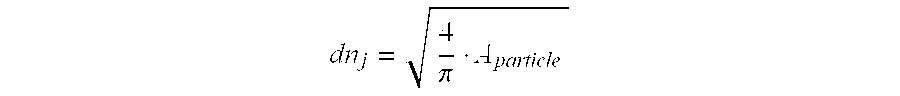

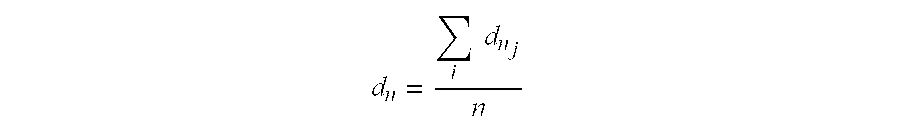

A thermoplastic elastomer composition of the invention, formed by dynamically crosslinking a polymer composition including a rubber and an olefinic resin and having an average particle size of rubber particles within a specific range, shows an excellent balance of mechanical properties such as flexibility and elastic recovery, and a moldability. Also an inclusion of a (meth)acrylate resin and a hydrogenated diene polymer provides a composition particularly excellent in scratch resistance. Also an inclusion of a maleimide compound provides a composition particularly excellent in injection fusibility. Also an inclusion of an undenatured organopolysiloxane of a specific viscosity and a denatured organopolysiloxane provides a composition particularly excellent in initial slidability and durable slidability.

Owner:ENEOS MATERIALS CORP

Window Material for Display

InactiveUS20080145632A1High transparencyHigh strengthSynthetic resin layered productsThin material handlingPolyesterDisplay device

The invention provides a window material for a display having at least two biaxially stretched polyester sheets, one of the sheets being disposed as an outer layer of a display surface. The window material for a display has a thickness of 0.3 to 5 mm and a light transmittance of 80 to 99.5%. The window material for a display preferably has a layer of a resin other than polyester, such as polycarbonate. Further, the window material for a display has a bending strength of 50 to 100 MPa, a bending modulus of elasticity of 3000 to 5500 MPa, and a maximum impact strength in a high-speed impact test of 1 kN or more. The window material for a display of the present invention is used as a window material for a display for devices such as liquid crystal display devices (LCDs), cathode-ray tube display devices (CRTs), EL display devices, plasma display devices (PDPs), and projection display devices.

Owner:MITSUI CHEM INC

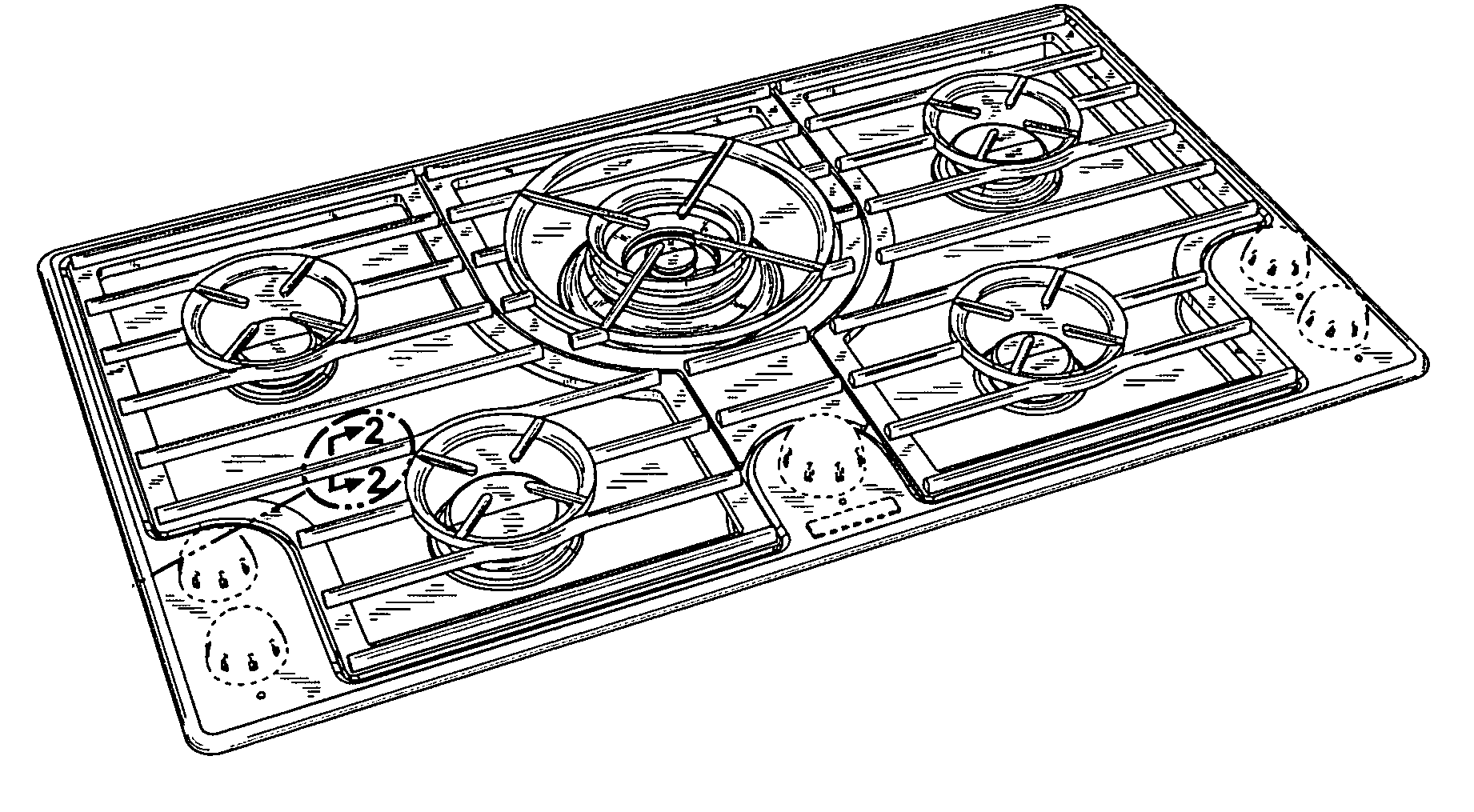

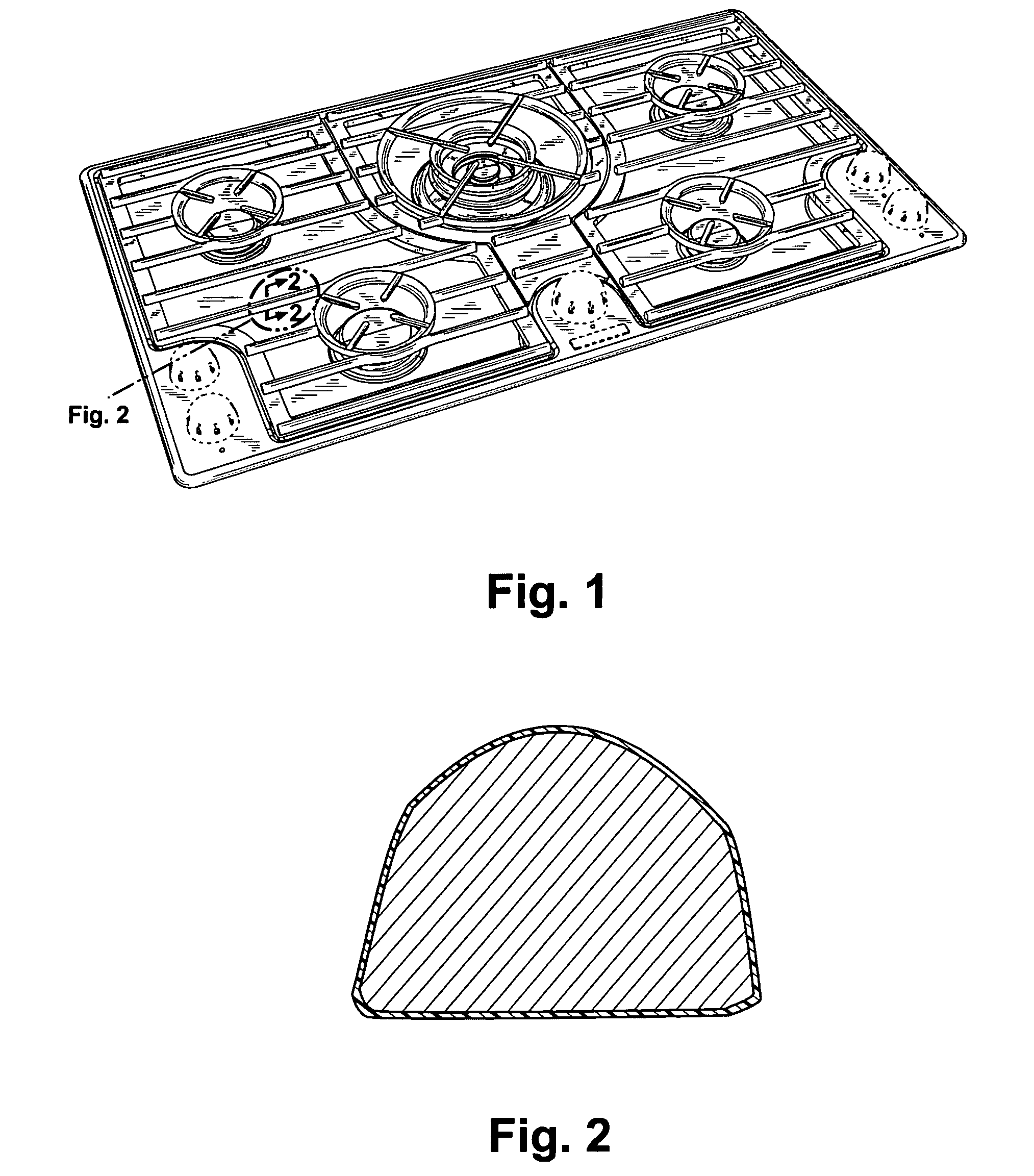

Transparent high temperature resistant and protective coating for domestic appliances and method for its deposition

ActiveUS7683293B2Good removal effectIncrease depositionLiquid surface applicatorsDomestic stoves or rangesSilicon oxideMetal

A domestic appliance, particularly a cooking appliance, having a metallic surface, is provided with a coating based on silicon oxide. Such coating is deposited on the metallic surface by plasma enhanced chemical vapor deposition (PECVD). The coating protects the metallic surface from scratching, staining and thermal yellowing.

Owner:WHIRLPOOL CORP

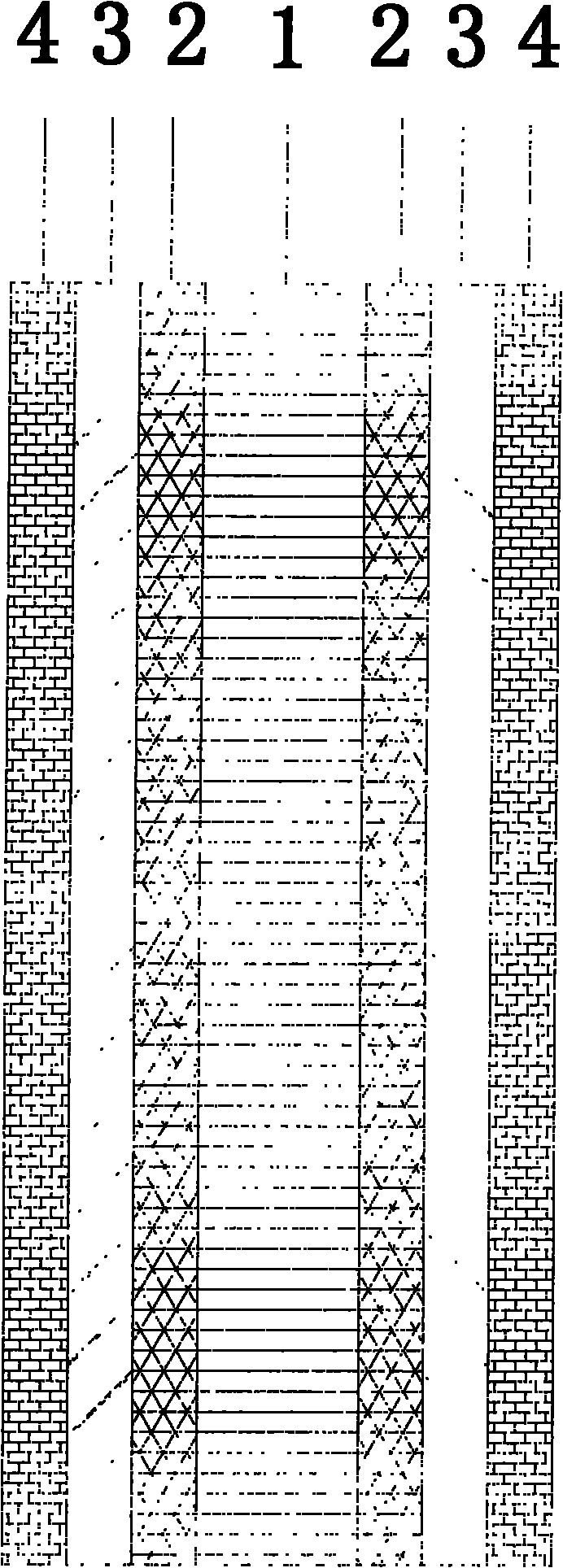

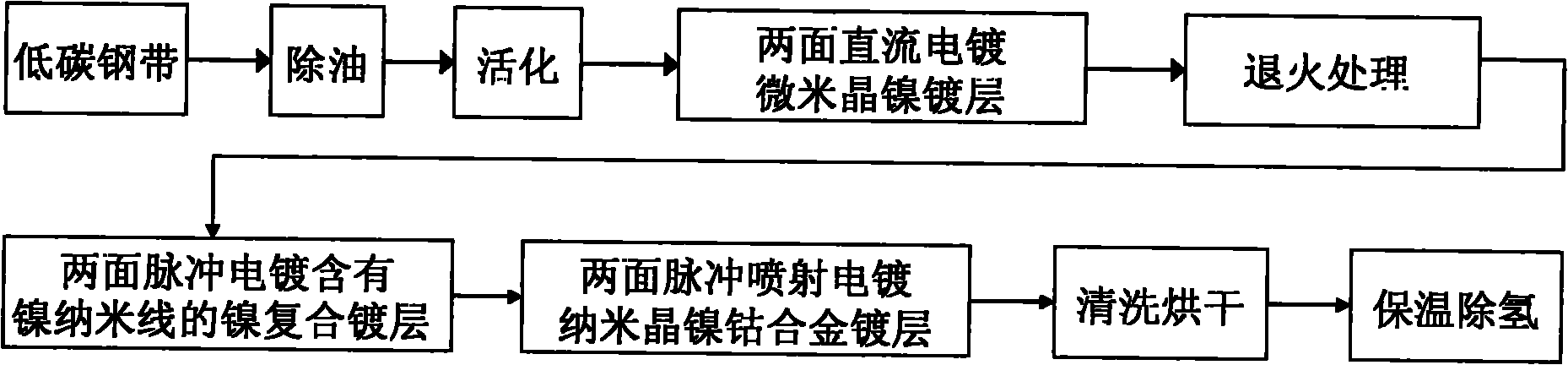

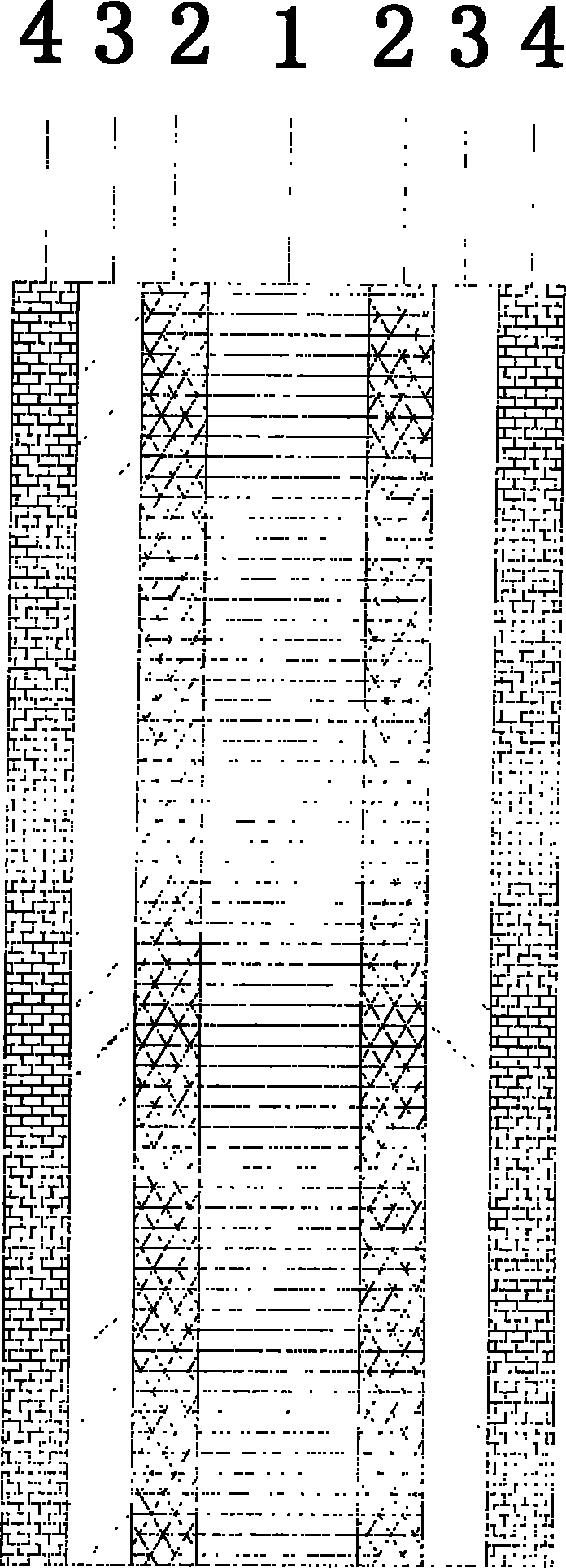

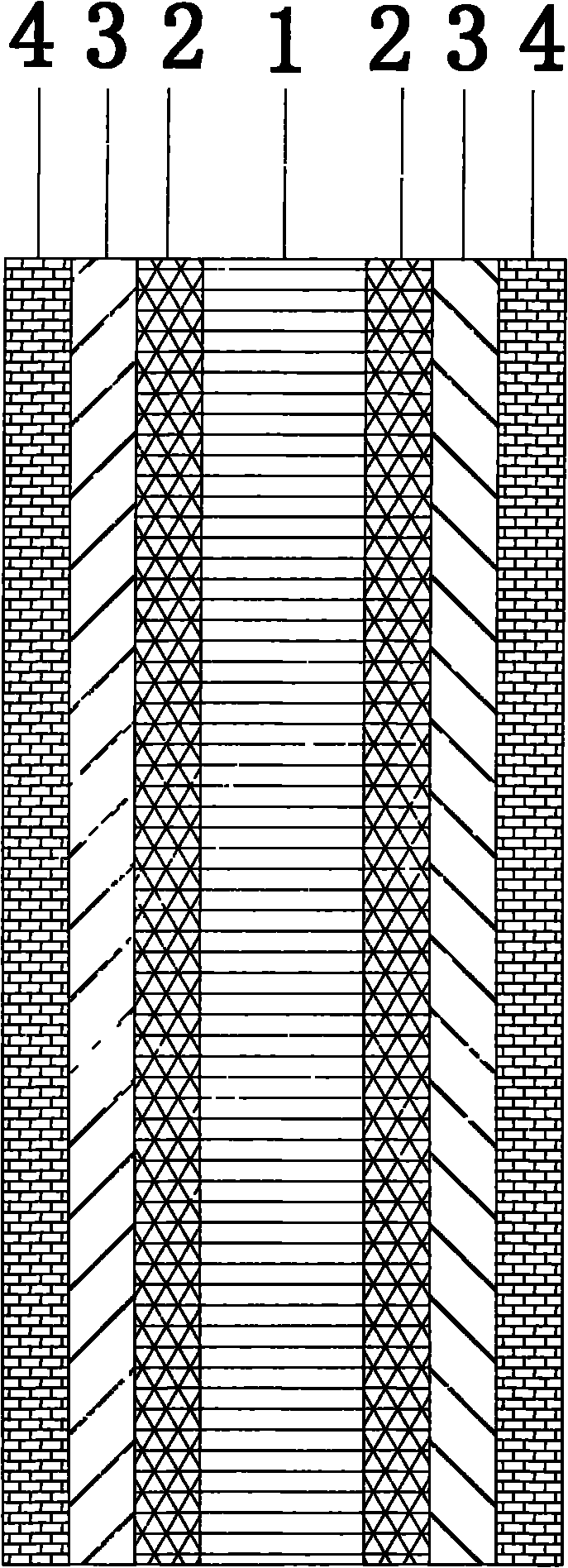

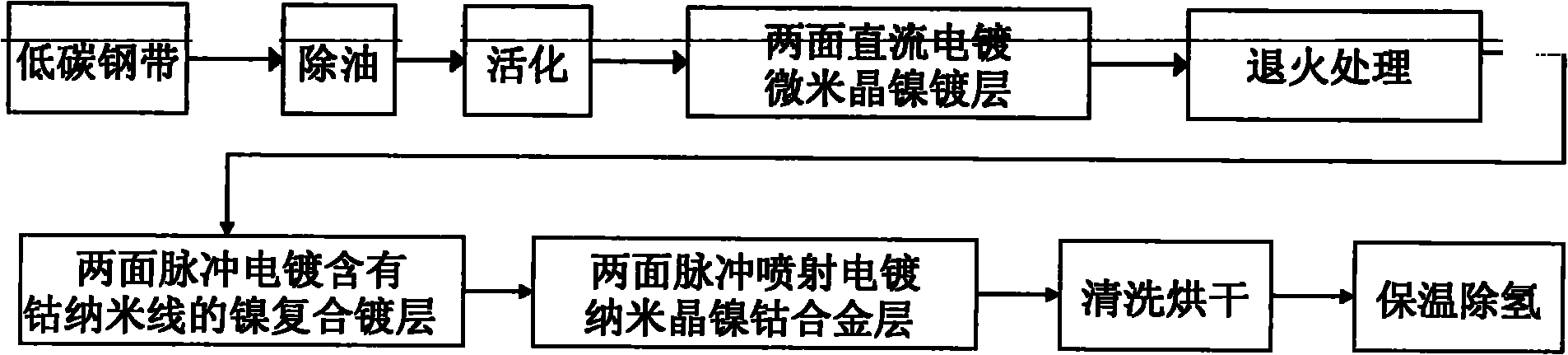

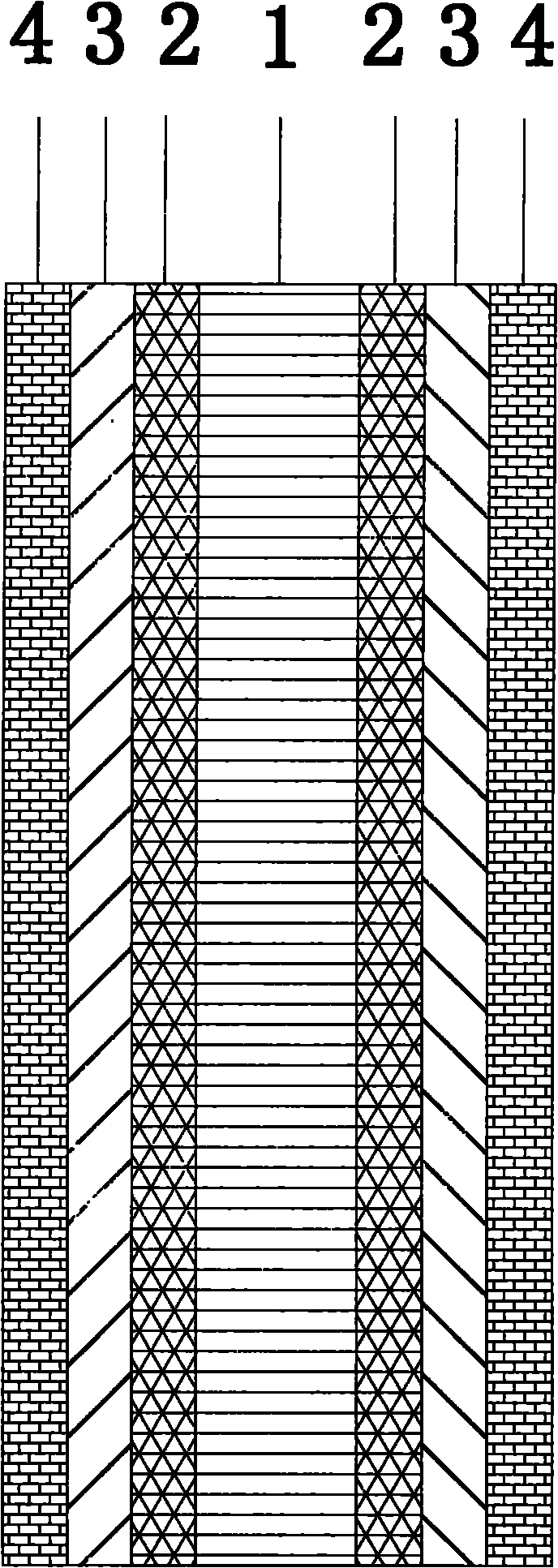

Nickeliferous nanowire laminated film plated steel belt and production method thereof

ActiveCN101954763AReduce corrosion rateHigh strengthElectrolytic coatingsCell component detailsNanowireMetallic Nickel

The invention discloses a nickeliferous nanowire laminated film plated steel belt and a production method thereof. A steel belt is used as a base, and both faces of the steel belt are respectively plated with a nickeliferous nanowire multilayer laminated film. The bottom layer of the nickeliferous nanowire multilayer laminated film is a micron-crystalline nickel plating layer, the middle layer isa nickeliferous nanowire nickel laminated plating layer, and the surface layer is a micron-crystalline nickel cobalt alloy plating layer. The invention also provides the production method of the steel belt, which comprises the following steps of: oiling and activating the base steel belt, and firstly preparing one micron-crystalline nickel plating layer on the base by using a DC electroplating mode; after annealing, preparing one nickeliferous nanowire nickel laminated plating layer on the nickel plating layer by using a pulse electroplating mode; then, preparing one micron-crystalline nickelcobalt alloy plating layer on the nickeliferous nanowire nickel laminated plating layer by using a pulse spraying mode, cleaning by using distilled water and drying; and finally, preserving temperature and removing hydrogen. The steel belt is formed by tightly combining the nickeliferous nanowire multilayer laminated film and a mild-carbon steel belt together, has good corrosion resistance, stamping performance and strong load resistance and can be applied to shell materials of lithium ion power batteries and high-performance alkaline manganese batteries.

Owner:XIANGTAN UNIV

Tactility-type non-primer BOPP pre-coating basement membrane and preparation method thereof

InactiveCN107351497AReduce investmentPrevent volatilizationFlexible coversWrappersSurface layerSolvent evaporation

The invention discloses a tactility-type non-primer BOPP pre-coating basement membrane and a preparation method thereof. The membrane is composed of a top surface layer, a bonding layer, a middle core layer and a bottom surface layer in sequence from top to bottom, the top surface layer is a tactility layer, the bonding layer is made from maleic anhydride grafted polypropylene, the middle core layer is a polypropylene layer, and the bottom surface layer is an EVA composite layer. According to the membrane, tactility resin, a special scuffing-resistant additive are subjected to directly participate in co-extruding two-way stretching film formation of polypropylene, subsequent coating processing is excluded, the equipment input of a coater is reduced, solvent evaporation in a coating process is avoided at the same time, and advantage of energy consumption and pollution reducing is provided. The tactility-type non-primer BOPP pre-coating basement membrane has the advantages that the haze is even, the light transmission, tensile strength and elongation at a break all meet national standard requirements; the tactility surface has the property of velvet-like hand feeling, and the surface scuffing-resistant performance is good when the basement membrane is produced or used.

Owner:ANHUI GUOFENG PLASTIC

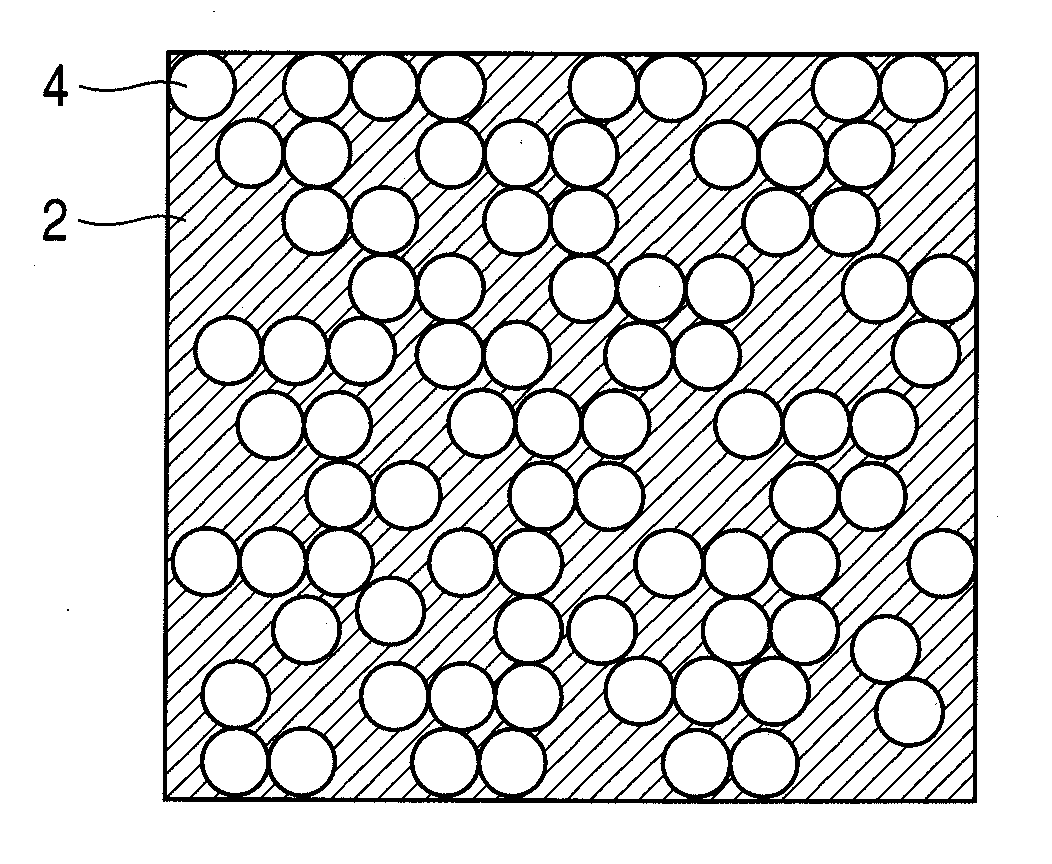

Steel strip plated with composite film containing cobalt nanowires and preparation method thereof

ActiveCN101954762AImprove toughnessDoes not reduce hardnessCell component detailsMetal layered productsLithiumPower battery

The invention discloses a steel strip plated with composite film containing cobalt nanowires and a preparation method thereof. the steel strip of the invention uses a steel strip as the substrate, and the both sides of the steel strip are respectively plated with a multilayer composite film containing cobalt nanowires. The bottom layer of each multilayer composite film containing cobalt nanowiresis a micron crystalline nickle plating, the middle layer is a nickle composite plating containing cobalt nanowires and the surface layer is nanocrystalline nickle-cobalt alloy plating. The invention also provides the preparation method of the steel strip. The preparation method comprises the following steps: degreasing and activating a steel strip, adopting the direct current electroplating mode to prepare a micron crystalline nickle plating on the substrate, annealing, adopting the pulse electroplating mode to prepare a nickle composite plating containing cobalt nanowires on the nickle plating and then adopting the pulse injection mode to prepare a nanocrystalline nickle-cobalt alloy plating on the nickle composite plating containing cobalt nanowires. The steel strip is closely combined by the multilayer composite film containing cobalt nanowires and the low carbon steel strip, has good corrosion resistance, punching property and high load resistance and can be used as the shell material of the lithium ion power battery and high-performance alkaline Zn / MnO2 battery.

Owner:HUNAN YONGSHENG NEW MATERIALS

Ink jet recording medium

InactiveUS20090324857A1Excellent characteristicsImprove resolutionThermographySilica particleColloidal silica

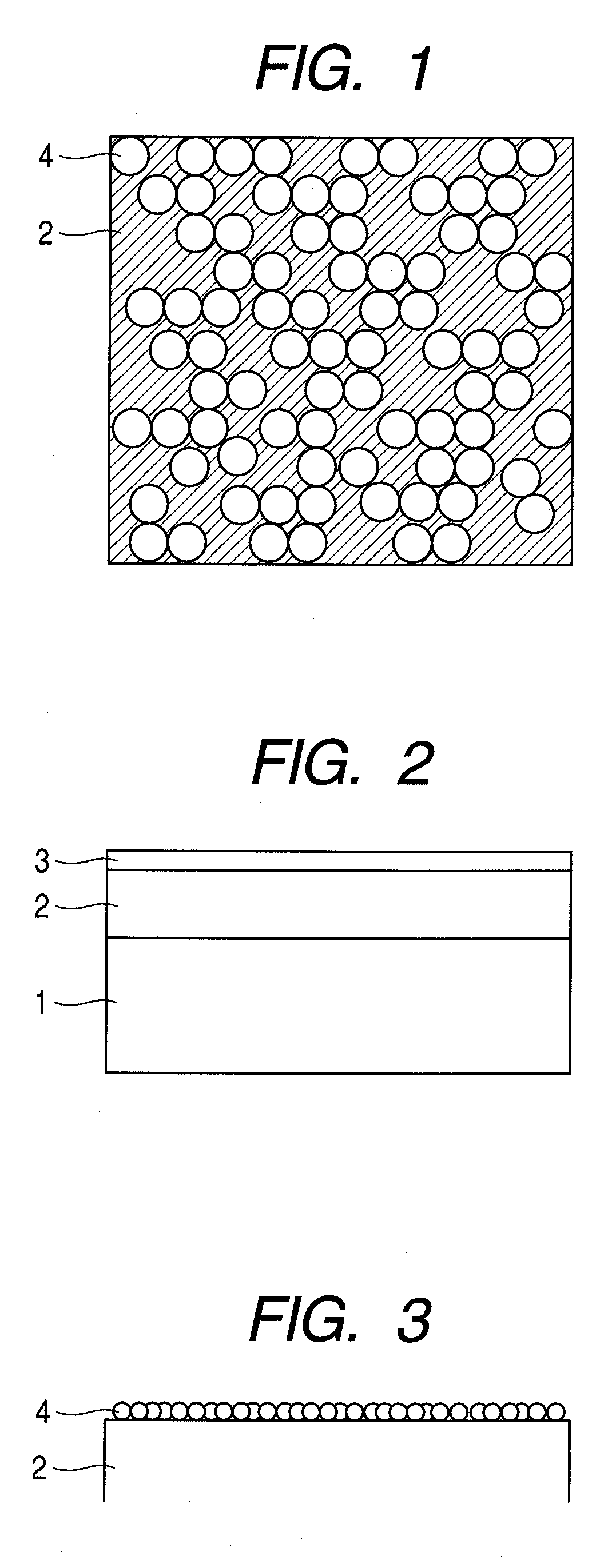

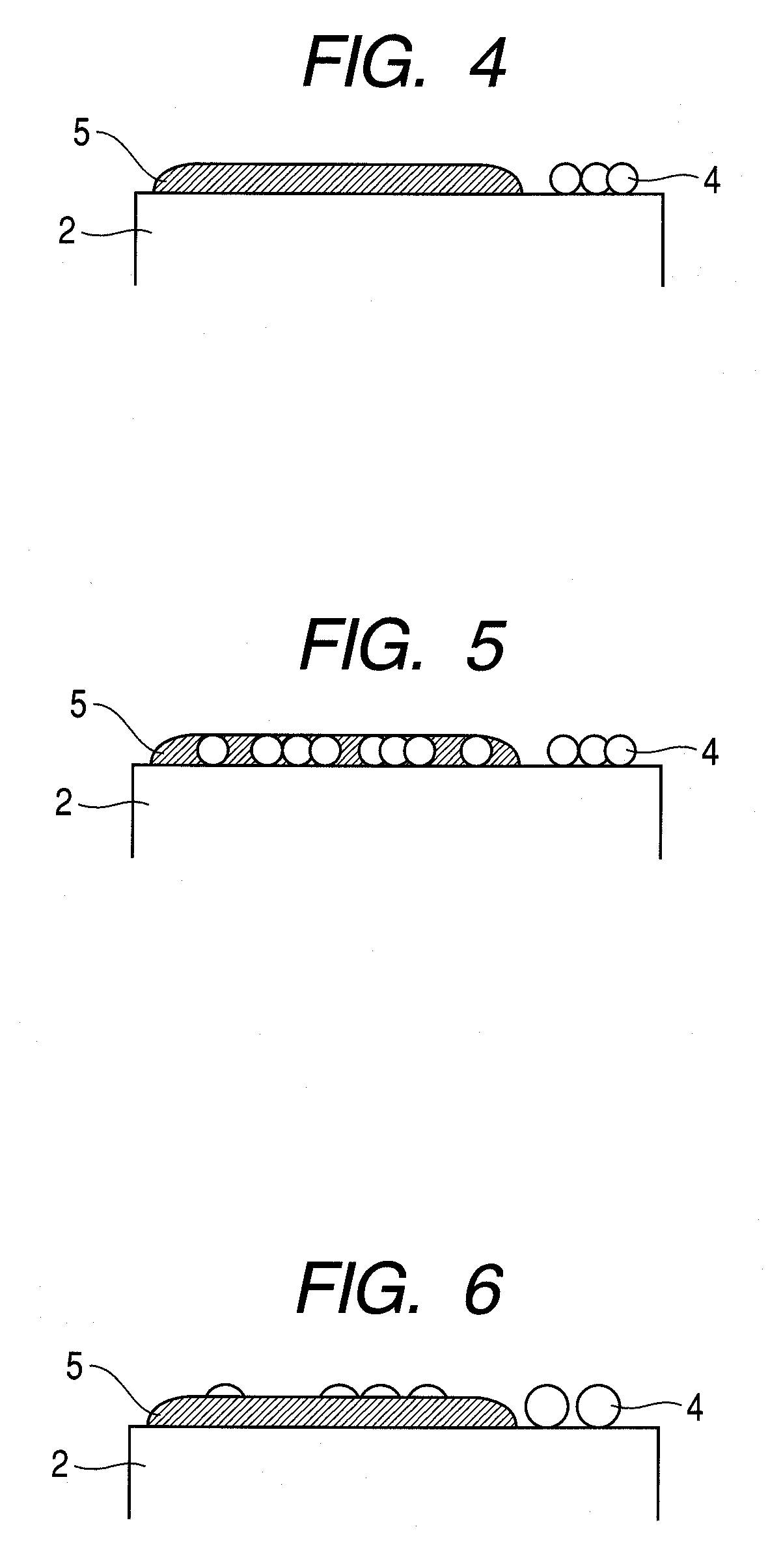

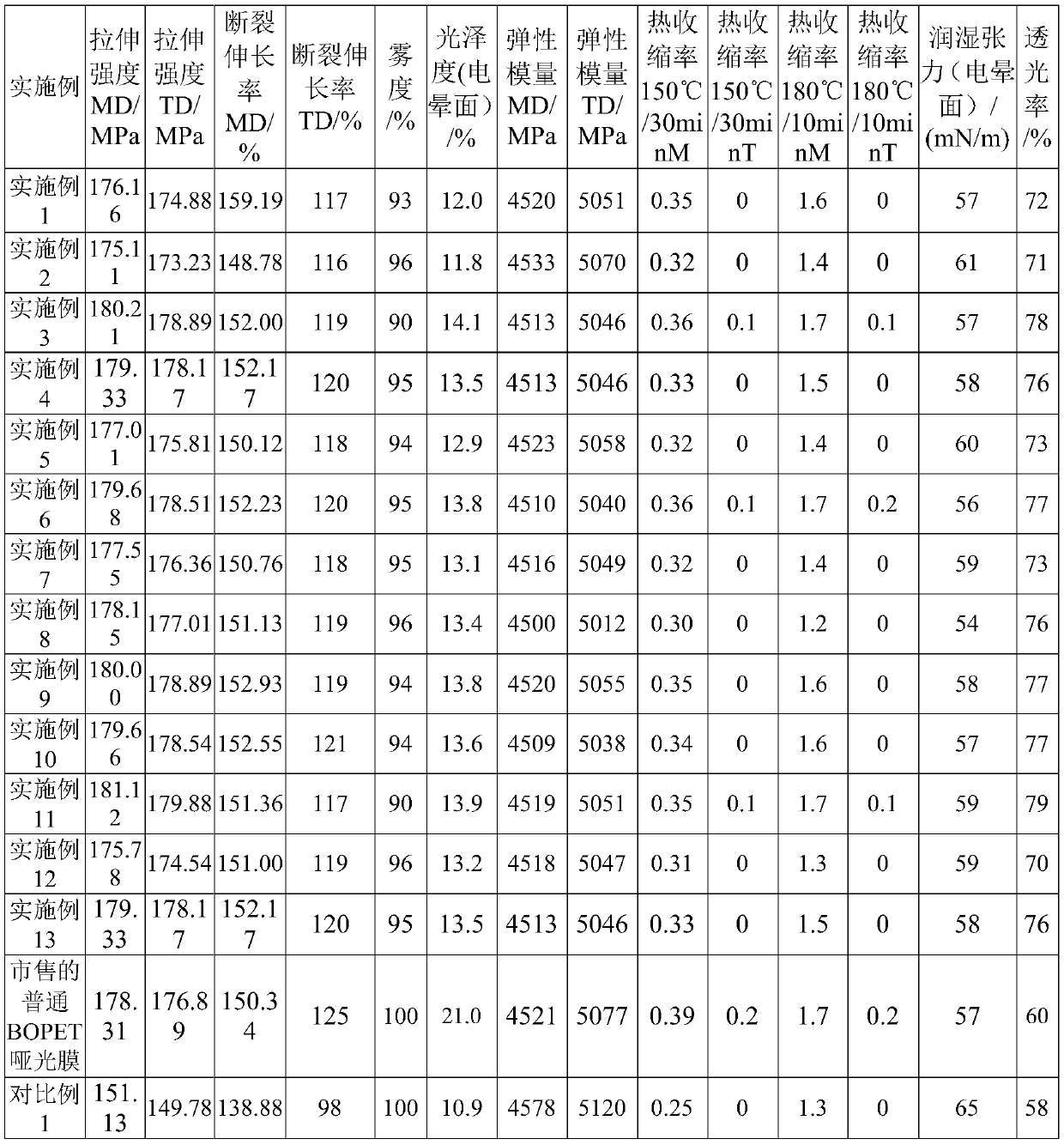

Provided is an ink jet recording medium including a substrate a porous layer containing one of a dry-process silica and an alumina hydrate and a silica layer containing spherical colloidal silica particles having a particle size of 105 nm or more and 200 nm or less. The porous layer and the silica layer are formed on the substrate in this order. The porous layer is covered by the spherical colloidal silica particles at a coverage of 40% or more and 75% or less.

Owner:CANON KK

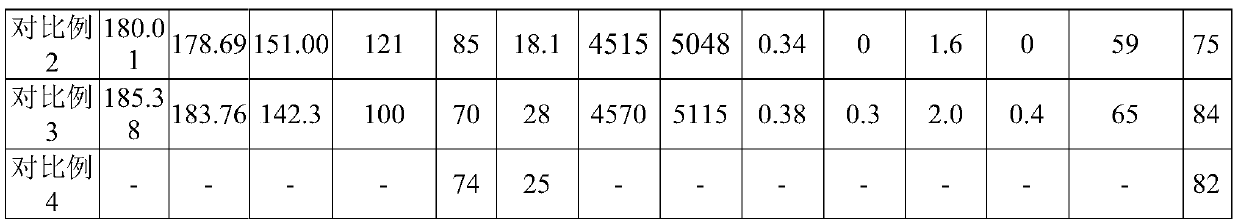

BOPET film high concentration matt masterbatch and preparation method thereof

The invention relates to the technical field of high molecular materials, more specifically, and relates to BOPET film high concentration matt masterbatch and a preparation method thereof. The main points of the technical schemes are as follows: the masterbatch includes, by weight ratio, 50-80 parts of PET, 5-25 parts of silicon dioxide, 1-3 parts of a hyper-dispersant, 3-15 parts of matting resin, 0.1-1 part of an anti-oxidant, and 3-15 parts of silicone microspheres. The masterbatch prepared through the above components and ratio is high in effective concentration, obvious in the cooperativeeffects of several matting components, good in matting effect and low in glossiness of matt BOPET films; and the masterbatch is only applied to the surface layers of the BOPET films, so that the advantage of costs can be obvious.

Owner:东莞市源丰高分子材料科技有限公司

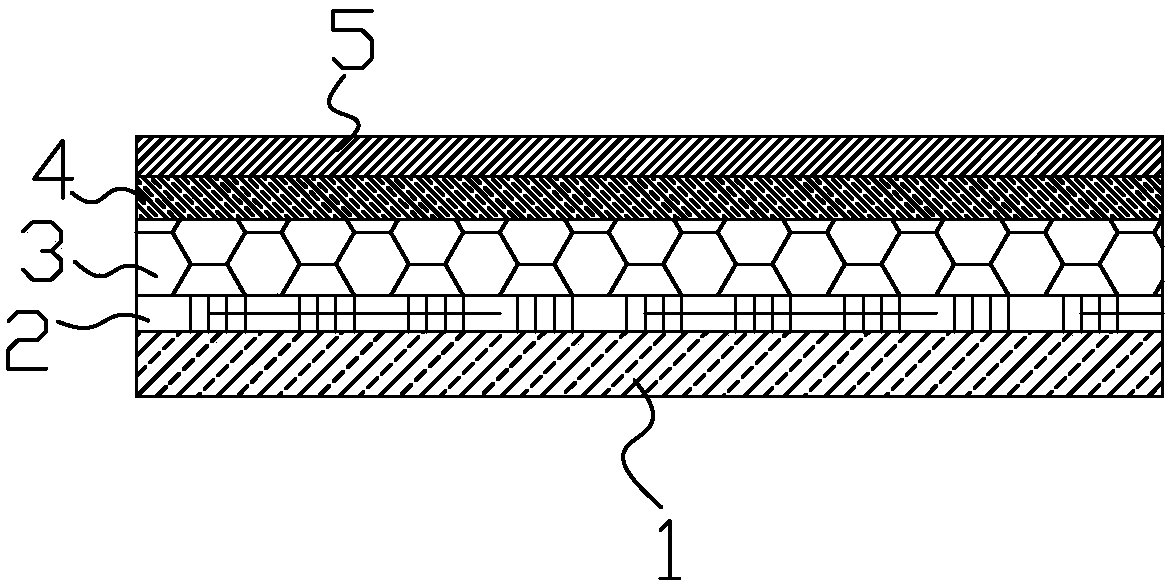

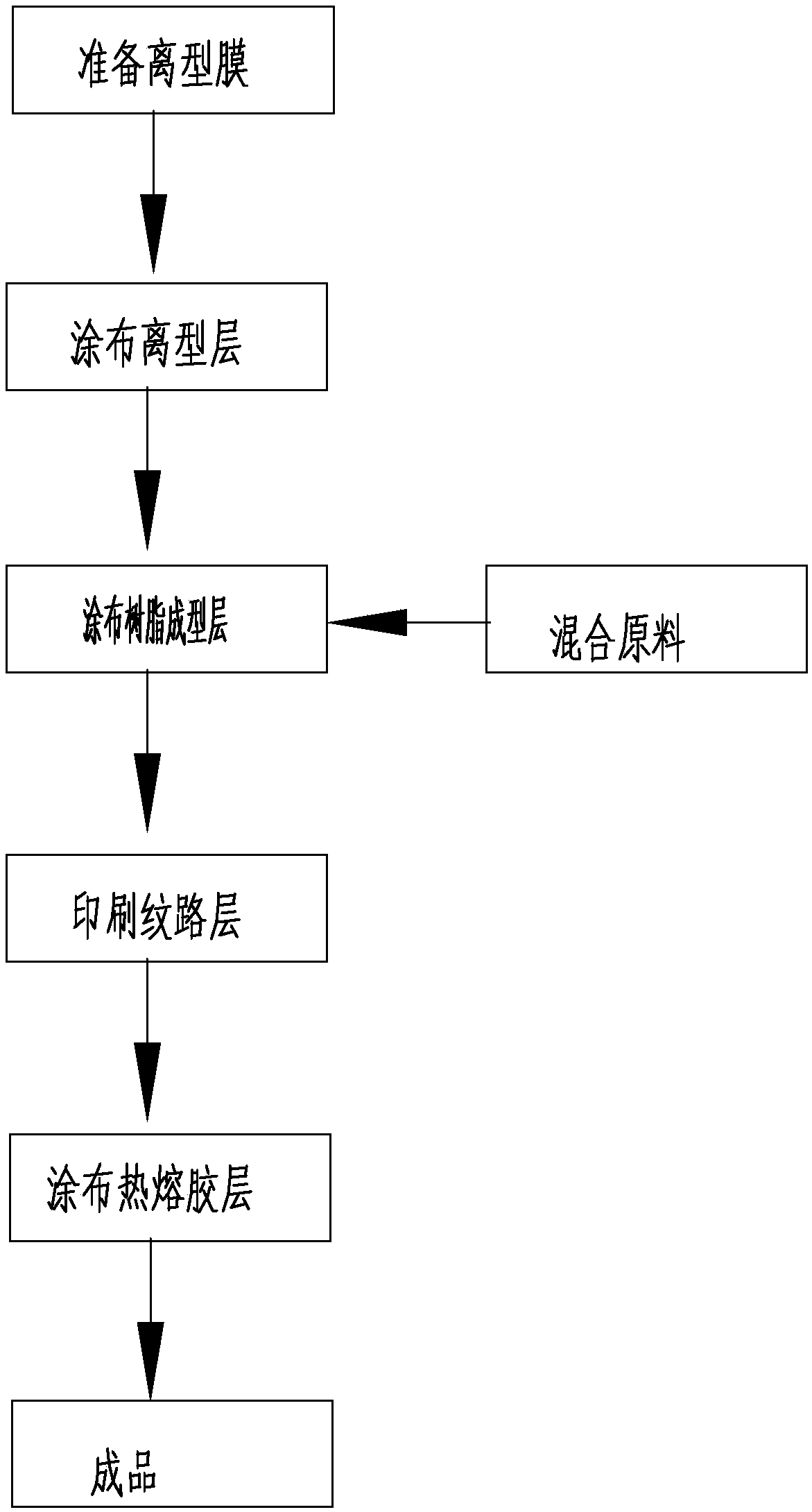

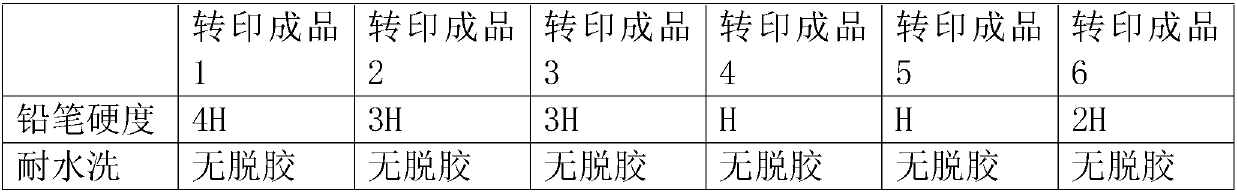

Scratch-resistant grain lettering film and manufacturing method thereof

The invention relates to the field of application of TPU materials, and provides a scratch-resistant grain lettering film and a manufacturing method thereof. The problem of poor scratch resistance ofa grain lettering film in the prior art is solved. The scratch-resistant grain lettering film comprises five parts, ie., a hot melt adhesive layer, a grain layer, a resin forming layer, a release layer and a release film, and the resin forming layer is prepared from, in percentages by weight, 60-70% of TPU, 5-15% of ABS, 10-20% of stearic acid-modified wollastonite powder, 1-5% of a compatibilizer, 1-5% of polysiloxane and 0-2% of a leveling agent. The scratch-resistant grain lettering film has strong scratch resistance, and can be applied to zipper film and a plurality of shoe and clothing thermal transfer products which need to have scratch resistance, and the shortcoming of the scratch irresistance of a grain lettering film on the existing market can be overcome.

Owner:福建新力元反光材料有限公司

Silver wear-resisting powder coating and manufacturing and using methods thereof

InactiveCN104962180AImprove surface scratch resistanceHigh glossPretreated surfacesPowdery paintsEpoxyPolyester resin

The invention discloses a silver wear-resisting powder coating. The silver wear-resisting powder coating comprises, by mass, 25-30 parts of epoxy resin, 40-50 parts of polyester resin, 0.5-1.5 parts of flatting agent, 0.5-0.8 part of wetting agent, 0.3-0.6 part of benzoin, 20-25 parts of barium sulfate, 0.3-0.5 part of hardening agent, 0.2-0.5 part of charging additive, 0.5-0.8 part of silver powder directional alignment agent, 2-3 parts of titanium dioxide and 0.01-0.03 part of carbon black. The surface of the silver wear-resisting powder coating can be as hard as Zhonghua pencils 5H in use, the scratch resistance of the surface is improved greatly, and meanwhile, surface glossiness is high.

Owner:苏州普勒新材料有限公司

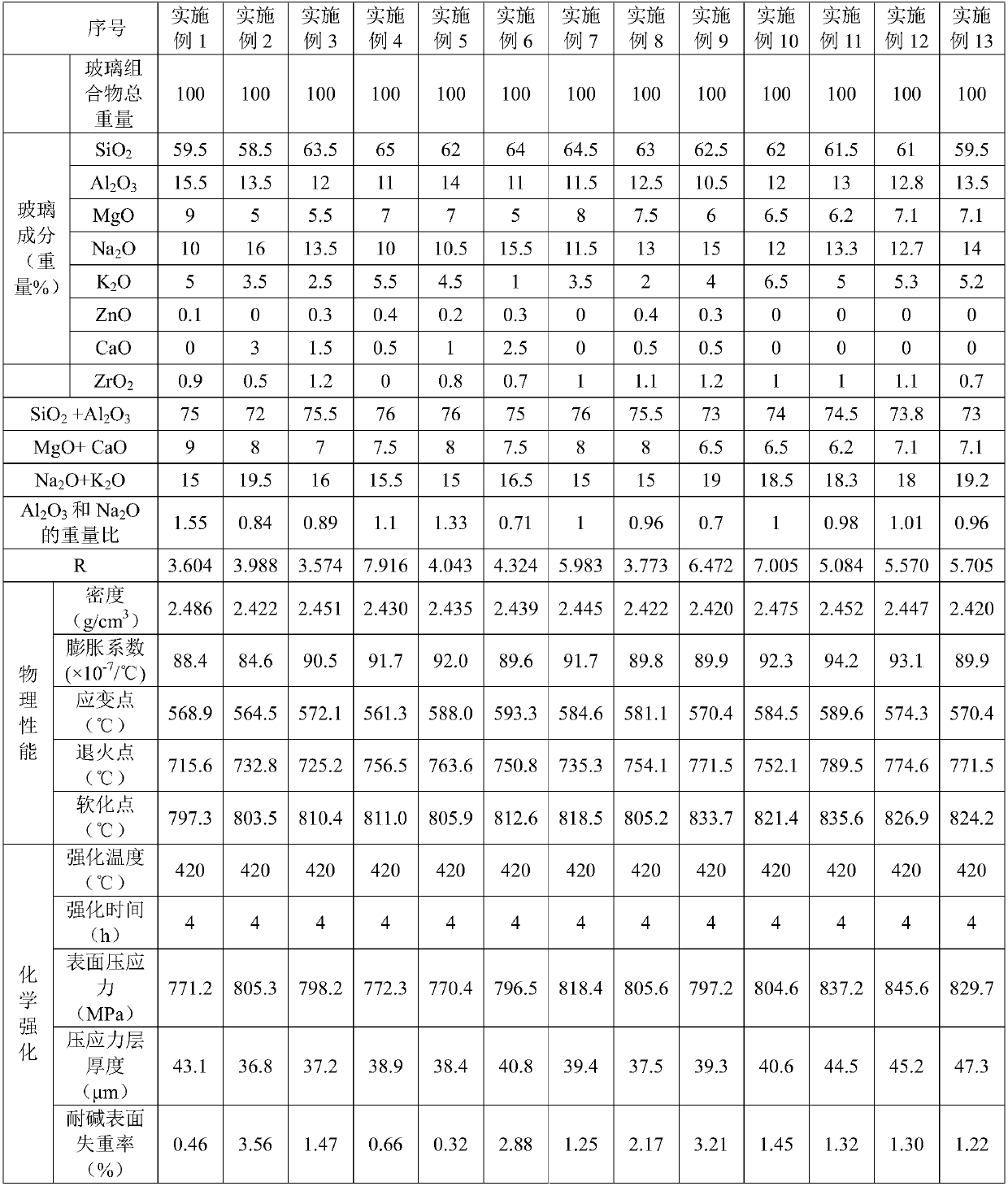

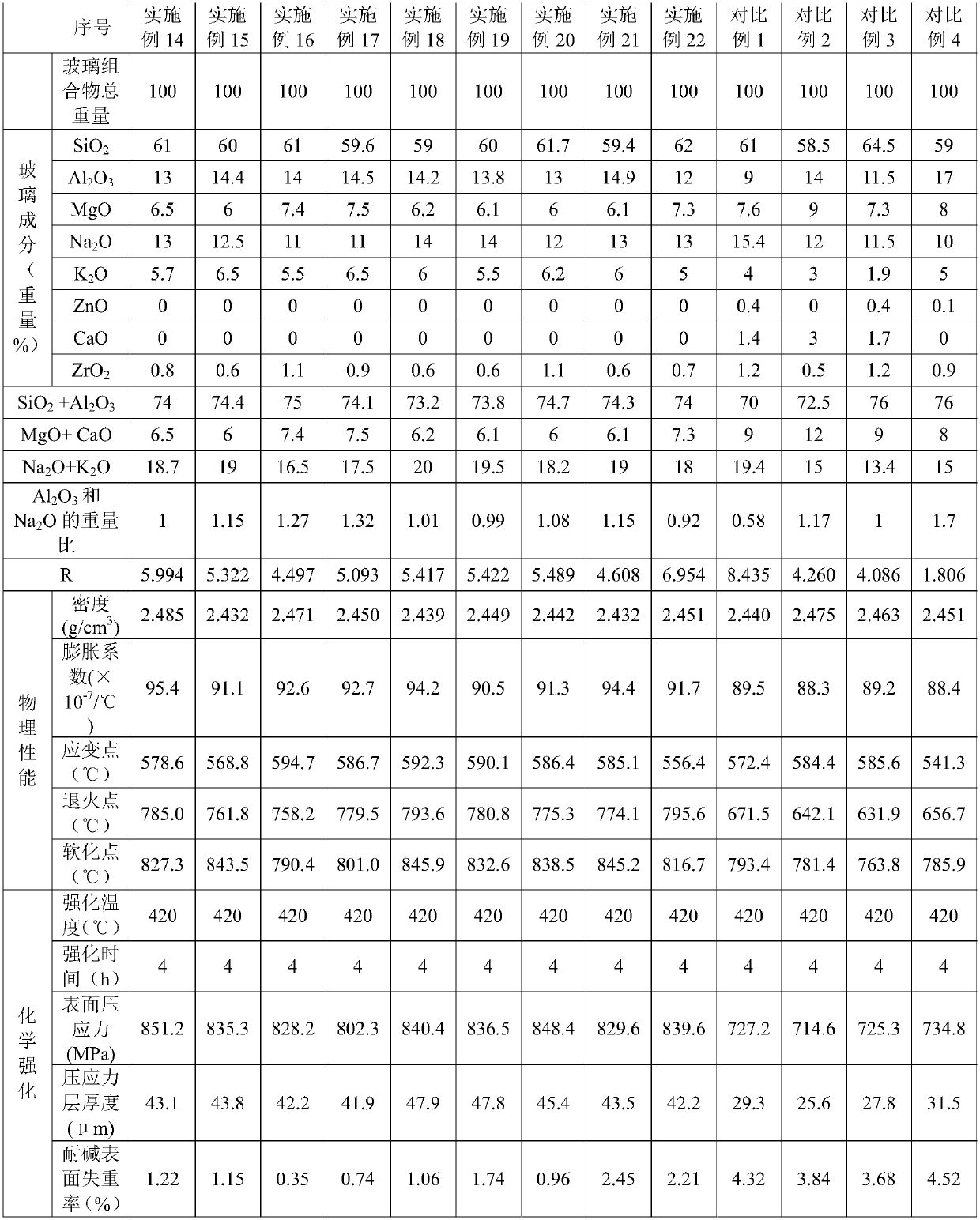

Chemically-reinforced cover plate glass, and preparation method thereof

The invention relates to a chemically-reinforced cover plate glass, and a preparation method thereof. According to the preparation method, under heating conditions, a glass composition is subjected tomelting homogenizing, moulding, and annealing so as to obtain cover plate glass; the cover plate glass is dipped into a molten salt containing potassium ions for ion exchange so as to obtain the chemically-reinforced cover plate glass. The surface compressive stress of the chemically-reinforced cover plate glass ranges from 770 to 860MPa, and the compressive stress layer thickness ranges from 36to 50<mu>m; the chemically-reinforced cover plate glass is subjected to boiling in a 1mol / L NaOH solution for 10h, glass surface weight loss ratio is equal to or lower than 3.56wt%. According to the preparation method, the specific composition and the weight range of the glass composition are limited, chemical reinforcing technology is adopted, so that the obtained chemically-reinforced cover plate glass is relatively high in surface stress and stress layer thickness, the surface scratch-proofness of glass substrate obtained via chemical tempering is improved, dropping resistance and wear resistance are improved, and the alkali resistance is excellent.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

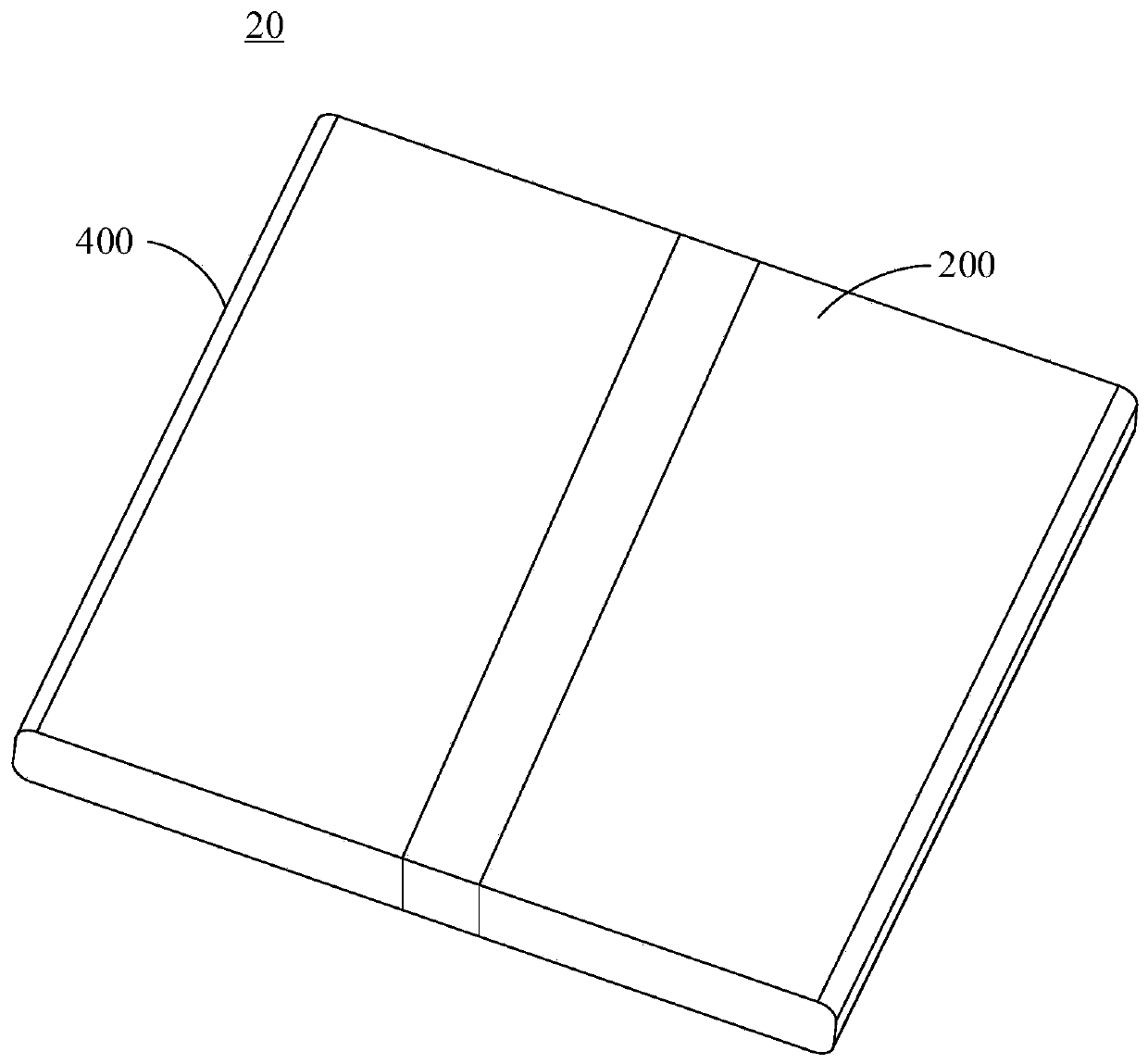

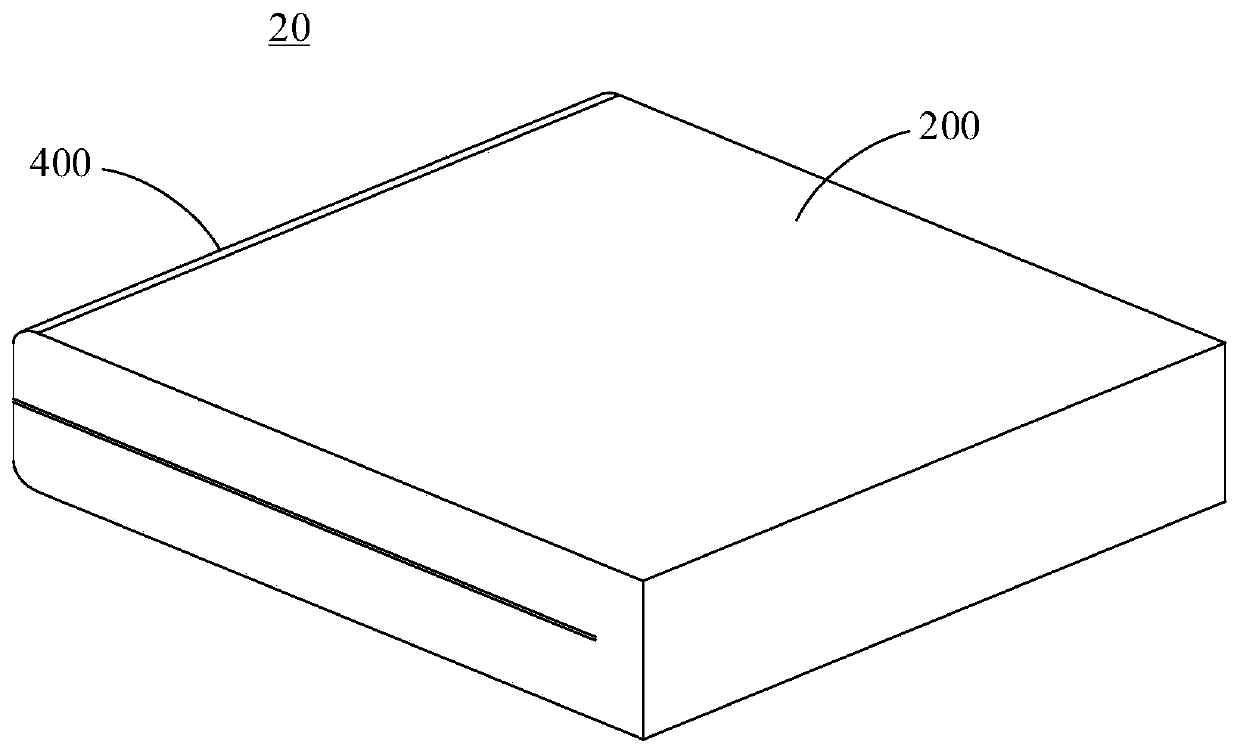

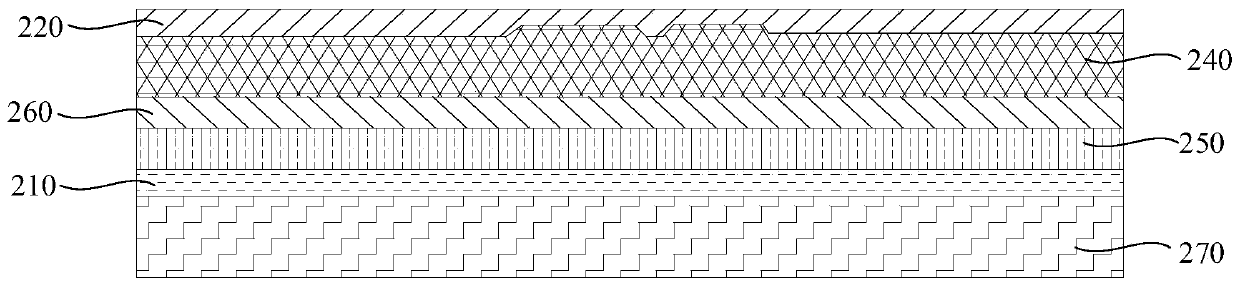

Foldable display screen and foldable electronic equipment

ActiveCN111369897AImprove impact resistanceImprove surface scratch resistanceIdentification meansEngineeringFlexible display

The embodiment of the invention provides a foldable display screen and foldable electronic equipment. The foldable electronic equipment comprises a shell and a foldable display screen arranged on theshell, the foldable display screen comprises a flexible display panel and a glass layer which are arranged in a stacked mode, the glass layer comprises a first sub-layer and a second sub-layer which are arranged in a stacked mode, at least one of the first sub-layer and the second sub-layer is provided with a gap, and the gap is located between the first sub-layer and the second sub-layer. According to the embodiment of the invention, the impact resistance and the surface scratch resistance of the foldable display screen can be improved on the premise that the bending activity of the foldabledisplay screen is not limited.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

UV (ultraviolet) high-wear-resistance curtaining finish

InactiveCN102660189AImprove wear resistanceBalanced Surface Scratch ResistancePolyurea/polyurethane coatingsEpoxy resin coatingsDefoamerPliability

The invention discloses UV (ultraviolet) high-wear-resistance curtaining finish which comprises, by weight, 60-70 parts of 100% UV resin, 0.4-0.7 part of defoamer, 0.5-1 part of dispersant, 4-8 parts of initiator, 0.5-1 part of leveling agent, 2-4 parts of wear-resisting agent, and 20-30 parts of monomers. The 100% UV resin is hexa-functional polyurethane acrylic resin, tri-functional modified epoxy acrylic resin, or mixture of the hexa-functional polyurethane acrylic resin and the tri-functional modified epoxy acrylic resin. The monomers are acrylates, modified acrylates, or mixture of the acrylates and the modified acrylates. The wear-resisting agent is made of modified high-purity high-hardness inorganic powders. The UV high-wear-resistance curtaining finish is high in wear resistance, high in surface scraping resistance and balanced in flexibility, and can be applied to wooden products such as wooden furniture and wooden flooring to protect the surface of the wooden furniture and wooden flooring for long.

Owner:JIANGSU HIMONIA TECH

Glass capable of effectively improving chemically strengthened warping performance

ActiveCN110655304AImproved chemically strengthened warpage propertiesChemically strengthened warpage performance controllableGlass tempering apparatusVitrificationEngineering

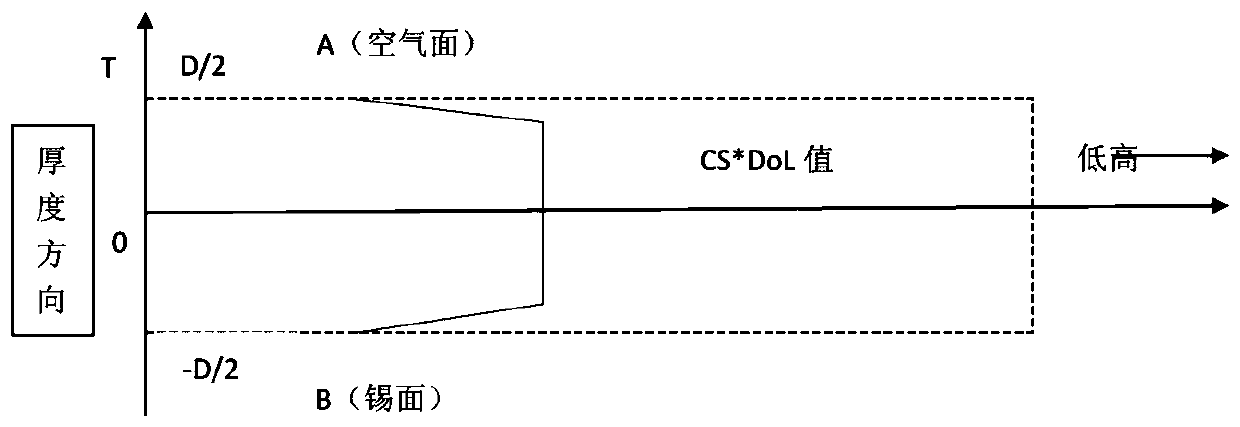

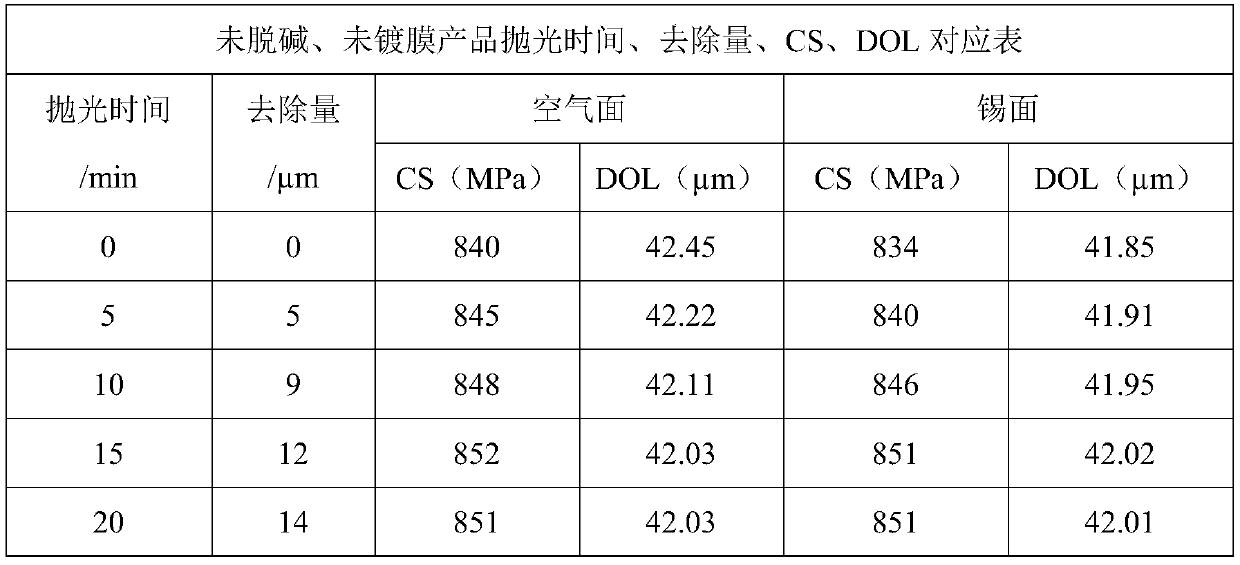

The invention discloses glass capable of effectively improving chemically strengthened warping performance. CS*DOL distribution of the side surface of the glass in the thickness direction satisfies |([sum]CS*DOLdT, 0<=T<=D / 2) / ([sum]CS*DOLdT, -D / 2<=T<=0)-1|<=10T%, wherein T is the corresponding thickness, the center of the glass is the origin of coordinates, the tin surface is -D / 2, and the air surface is D / 2; in addition, the central tensile stress (CT)=CS*DOl / (T-2DOL). The controllability of the chemically strengthened warping performance of the float glass is realized.

Owner:XIANNING NANBO PHOTOELECTRIC GLASS CO LTD +1

Nano graphene platelet-reinforced composite heat sinks and process for producing same

ActiveUS10087073B2Improves Structural IntegrityImprove surface scratch resistanceMaterial nanotechnologySemiconductor/solid-state device detailsGrapheneThermal contact

An integrated heat sink article composed of a heat collection member and at least one heat dissipation member integral to the heat collection member, wherein the heat collection member is configured to be in thermal contact with a heat source, collects heat from the heat source, and dissipates heat through the at least one heat dissipation member, and further wherein the heat sink is formed of a nano graphene platelet-reinforced composite having nano graphene platelets or sheets (NGPs) as a first reinforcement phase dispersed in a matrix material and the first reinforcement phase occupies a weight fraction of 1-90% based on the total composite weight. Preferably, these NGPs, alone or in combination with a second reinforcement phase, are bonded by an adhesive and constitute a continuous 3-D network of electron- and phonon-conducting paths.

Owner:GLOBAL GRAPHENE GRP INC

RF plasma transparent conductive film

InactiveCN102074281AImproved chemical composition and wetting propertiesReliable adhesionConductive layers on insulating-supportsRadio frequencyTouch panel

The invention provides a radio frequency (RF) plasma transparent conductive film. A base material is a polyethylene terephthalate (PET) film, the front face of the PET film is coated with a hardened coating, and the surface of the hardened coating is coated with a polyethylene (PE) protective film; and an RF plasma treatment layer is formed on the back face of the PET film, and a transparent conductive layer is sputtered on the RF plasma treatment layer and is coated with the PE protective film. In the transparent conductive film, one hardened coating is saved, and the RF plasma treatment layer is added, so that a reliable adhesion effect still exists between the transparent conductive layer and the PET film, the resistance value of the transparent conductive film still can keep high properties of uniformity and stability even if the transparent conductive film is subjected to high-temperature tempering, and the transparent conductive film can be widely applied to the aspects of touch panels, electronic games, child teaching machines, intelligent mobile phones, tablet personal computers (PCs) and the like.

Owner:SUZHOU HESHENG NEW MATERIALS

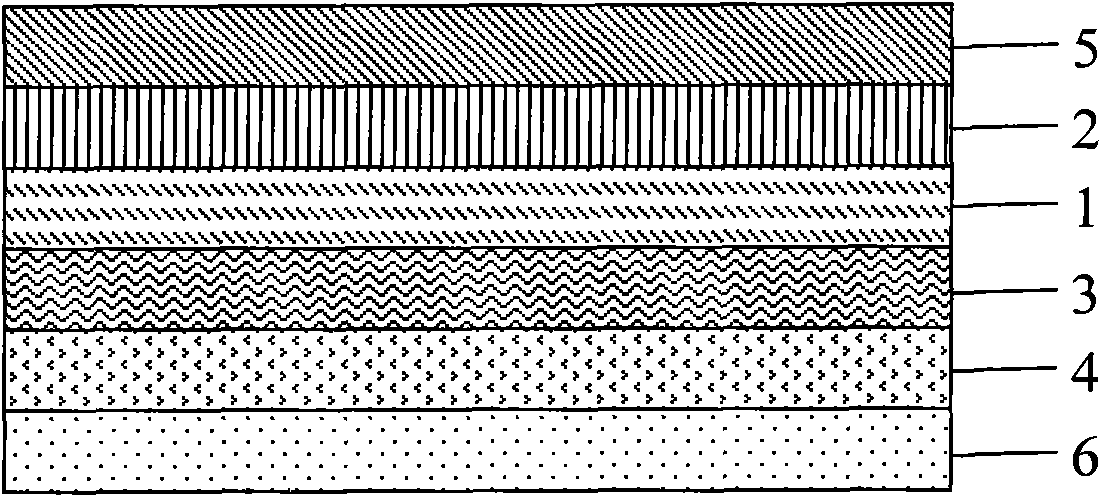

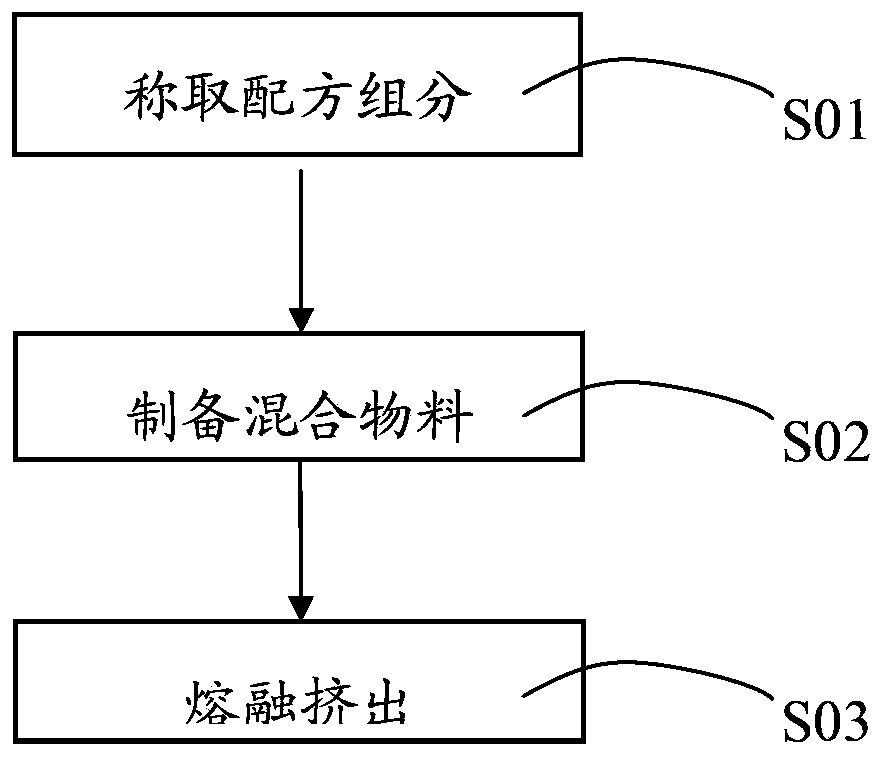

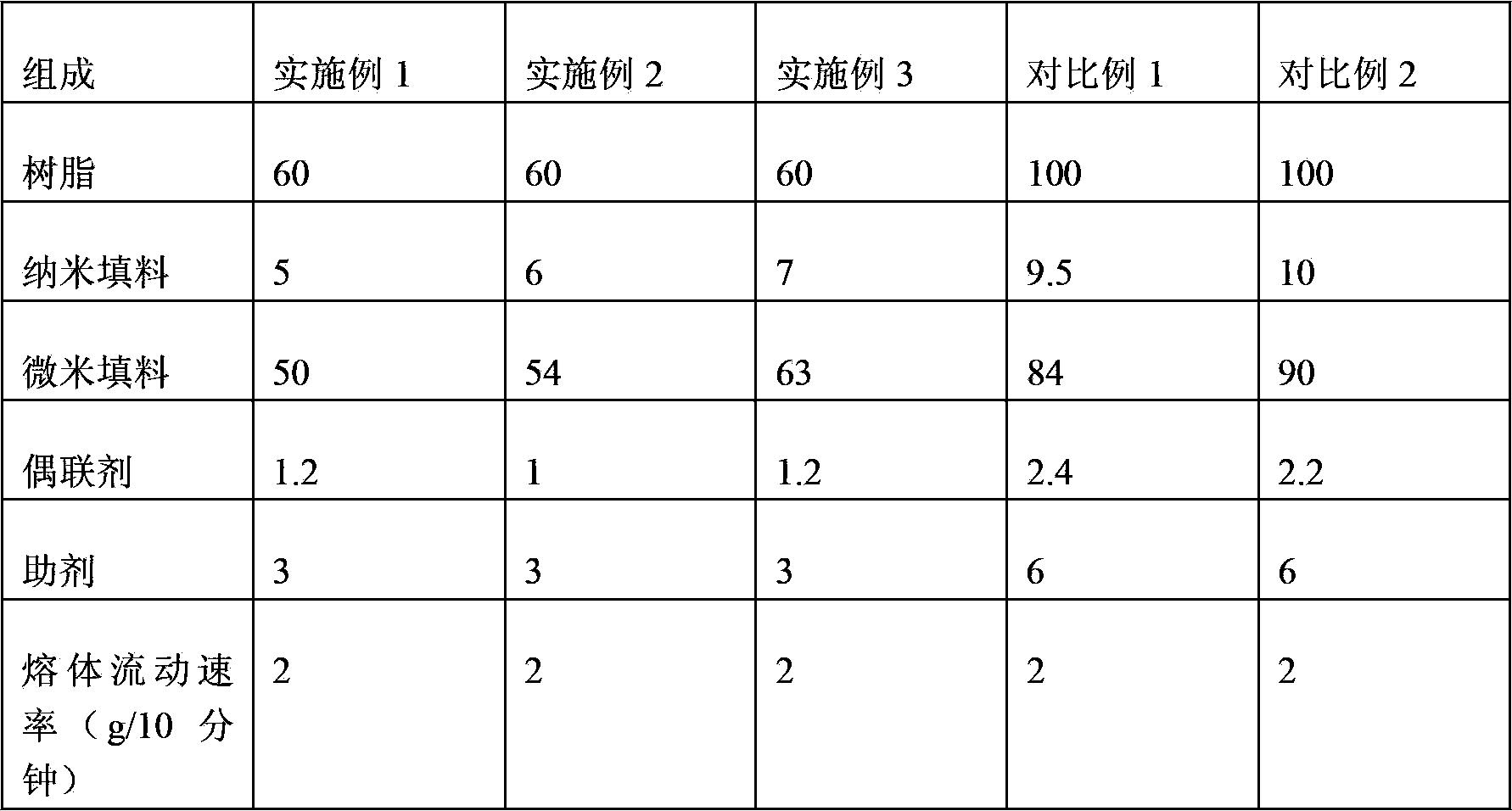

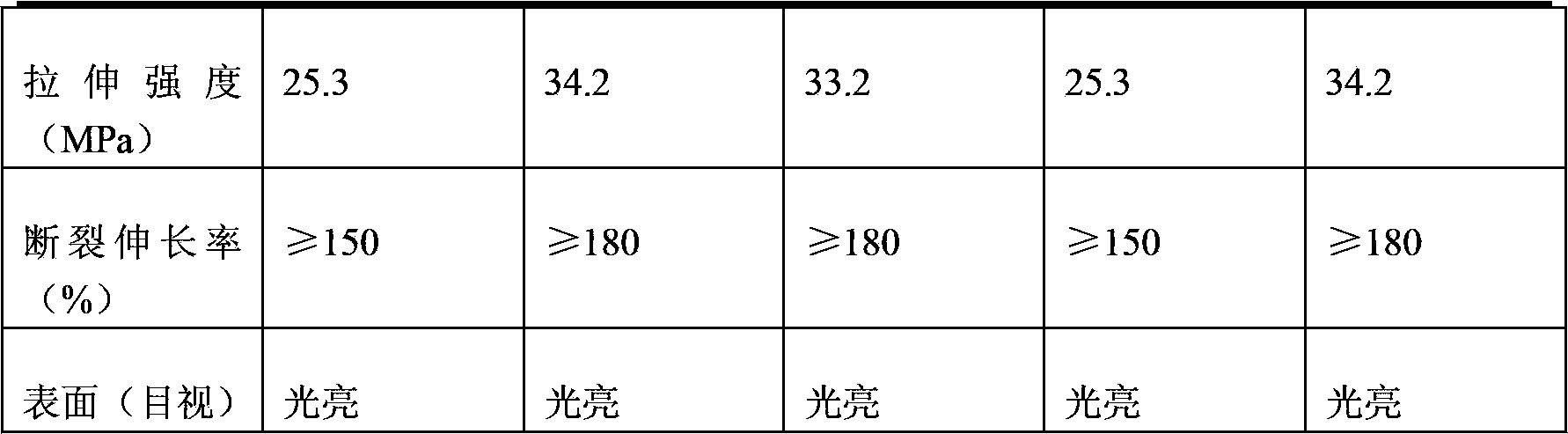

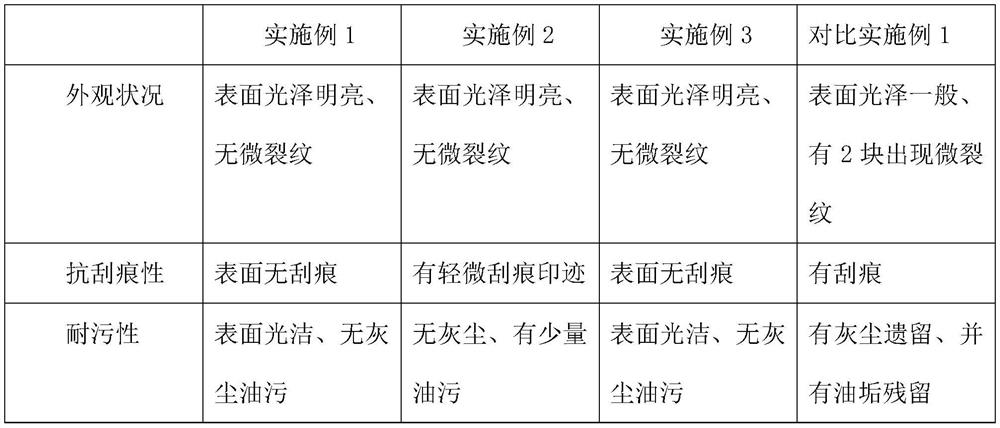

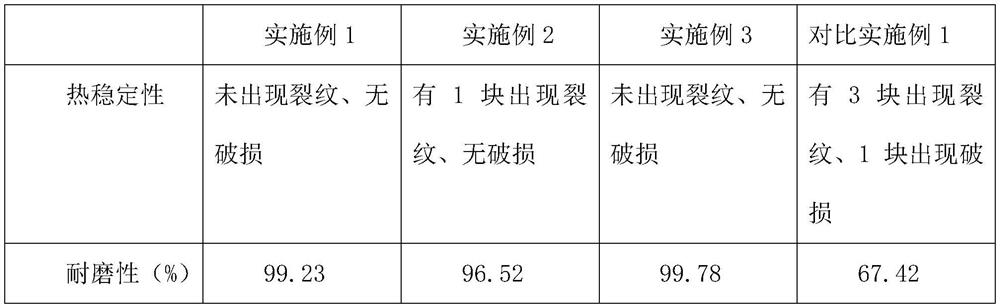

Compound resin material for cable and preparation method thereof

ActiveCN103509221AHigh impact strengthImprove surface scratch resistancePlastic/resin/waxes insulatorsInsulated cablesAging resistanceMicrometer

The invention discloses a compound resin material for a cable and a preparation method thereof. The compound resin material for the cable comprises the following formula components in parts by weight: 35-65 parts of resin, 30-90 parts of nanometer and micrometer composite fillers and 1-30 parts of auxiliary agents. The compound resin material for the cable takes the resin as a main material, is endued with the advantages of excellent impact strength, surface scratch resistant capacity, bending strength and electrical insulation property, ageing resistance and high smoothness through the synergetic effect of the nanometer and micrometer composite fillers and the auxiliary agents. By using the preparation method of the compound resin material for the cable, the product can be obtained by only mixing the components in two steps according to a formula and extruding for granulation at appropriate temperature and has the advantages of simple process, material property enhancement and low cost and is suitable for industrialized production, and conditions are easy to control.

Owner:SHENZHEN BENDAKANG CABLE

Metal powder, feeding and preparation process for preparing antibacterial stainless steel wearable products

InactiveCN111702165AHas bactericidal propertiesHigh hardnessTransportation and packagingMetal-working apparatusSS - Stainless steelAnti bacteria

The invention relates to a metal powder, feeding and preparation process for preparing antibacterial stainless steel wearable products. The mental powder is prepared from the components in percentageby mass: C: <=0.03%; Si: 0.4%-0.6%; Mn: 0.4%-0.8%; S: <=0.02%; P: <=0.02%; N: <=0.02%; Cr: 17%-19%; Ni: 7.5%-8.5%; Cu: 3.5%-4.5%; Cu: 1%-5%, and the balance of Fe. The preparation technology comprisesthe steps of S1: preparing powder; S2: preparing feed; S3: injecting: the feed is added to an injection machine, and the injection machine injects the feed into an internal cavity of an injection mold to form an injection blank; S4: sintering: the injection blank is sintered to form a sintered blank; and S5: heat treatment: the sintered blank is heat-treated to precipitate a copper-rich phase. Copper is added to stainless steel powder, and the copper makes the product have the characteristics of sterilization. The precipitation of copper in the form of the second phase can increase the hardness and strength of products and increase the scratch resistance of surfaces.

Owner:CHANGZHOU GIAN TECH

Stone-like glass mosaic and preparation method thereof

InactiveCN112266169APerformance is not affectedImprove performanceGlass furnace apparatusGlass productionCrazingStone dust

The invention relates to the technical field of decorative materials, and discloses a stone-like glass mosaic which comprises the following components, by weight: 20-30 parts of glass raw material, 10-15 parts of waste glass, 2-8 parts of borax, 2-5 parts of quartz powder, 2-7 parts of fluorite, 1-3 parts of a dispersing agent, 2-4 parts of zinc oxide and 5-10 parts of a surface treating agent. The surface treating agent is prepared from the following components, by weight: 10-15 parts of nano glass powder, 5-12 parts of pearl powder, 2-8 parts of chinastone powder, 2-5 parts of toughening agent, 1-3 parts of binder and the balance of water. The stone-like glass mosaic prepared by the invention has better wear resistance and hardness, reduces the probability of cracks in the preparation process, also reduces the glass viscosity and surface tension, improves the preparation efficiency, improves the scratch resistance and stain resistance of the surface of the stone-like glass mosaic byusing the cooperation of the surface treating agent, and enhances the quality of the stone-like glass mosaic. The stone-like glass mosaic has the advantages of no dust accumulation on the surface, self-cleaning in rainy days, durability, high novelty, hard texture and stable performance, can maintain the smoothness and glossiness of the surface for a long time, and the decorative effect can be enhanced.

Owner:广东伟祺艺术玻璃有限公司

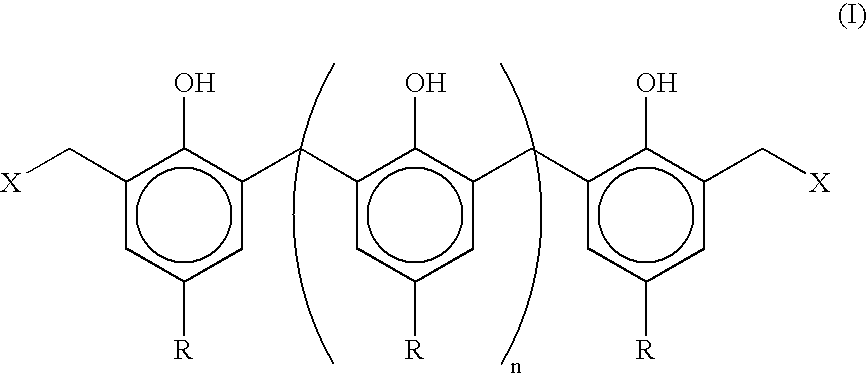

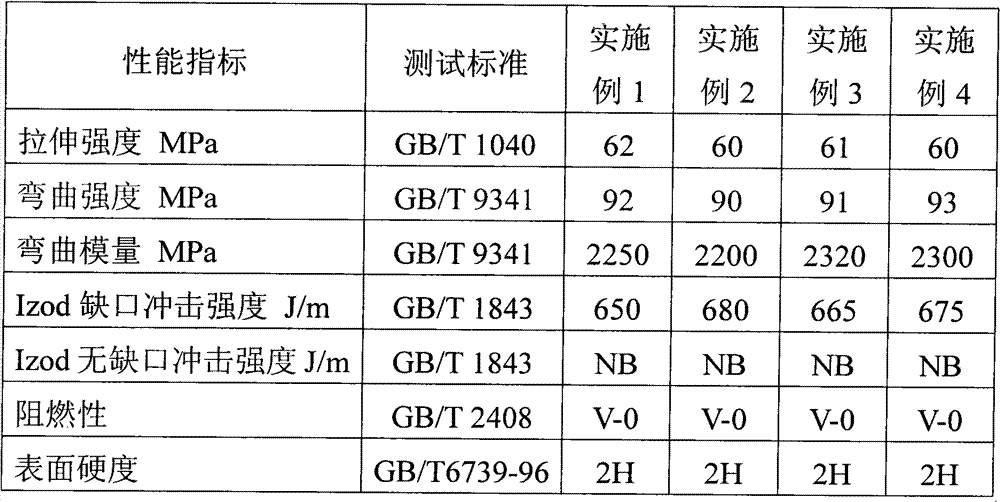

Environment-friendly flame-retardant scratch-resistant polycarbonate resin and preparation method thereof

ActiveCN102558808BGuaranteed performanceEnvironmentally friendly and bromine-freeEnvironmental resistancePlasticizer

The invention discloses an environment-friendly flame-retardant scratch-resistant polycarbonate resin, which comprises the following ingredients in part by weight: 90-95 parts of polycarbonate resin, 2-5 parts of flame retardant, 2-5 parts of plasticizer, 03-1 part of anti-dripping agent, 0.5-1 part of antioxidant additive and 0.5-1 part of processing additive. A preparation method of the environment-friendly flame-retardant scratch-resistant polycarbonate resin adopts a twin-screw extrusion process and has the advantages of simple and continuous technological process, high production efficiency and stable product quality; the flame-retardant and fireproofing performance and the surface scratch resistance of a product are increased at the same time that the properties of the polycarbonate resin are maintained, so that the serviceable range of the product is enlarged, and the environment-friendly flame-retardant scratch-resistant polycarbonate resin can be applied to occasions with harsher fireproofing and scratch-resistant requirements on polycarbonate products and has broad application prospects.

Owner:滁州格美特科技有限公司

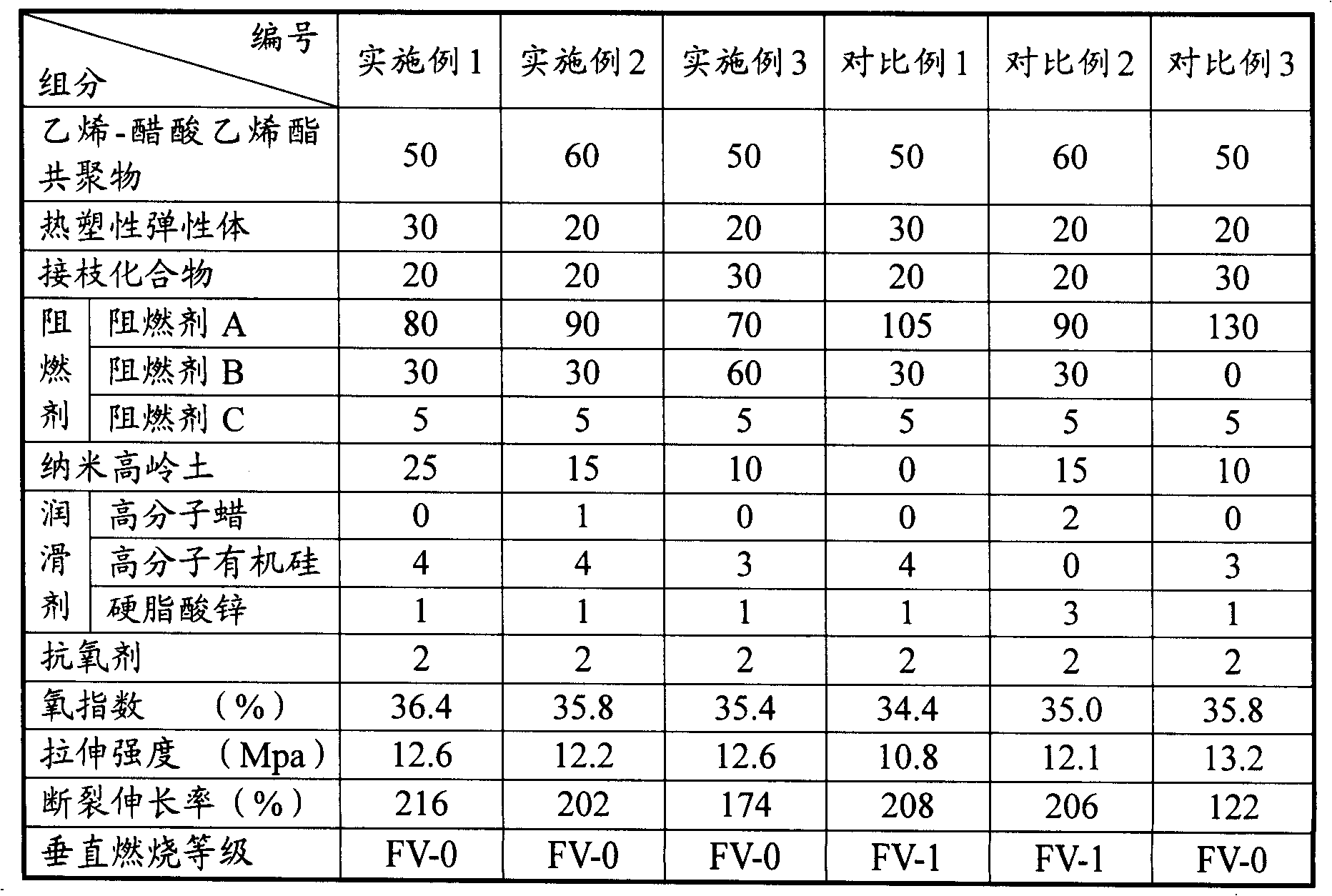

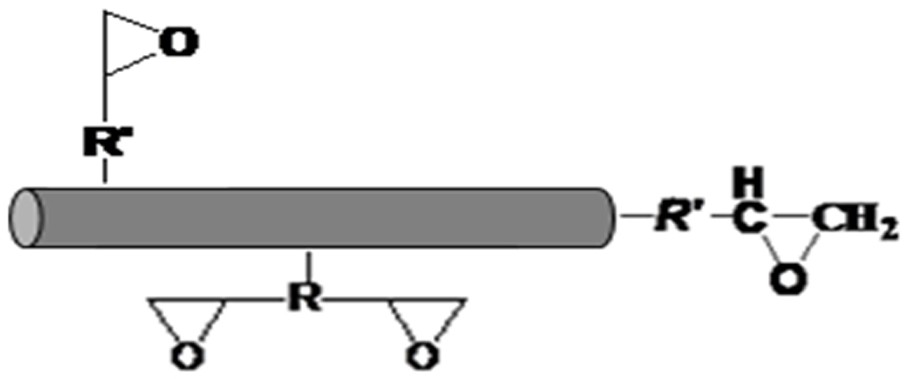

Nano kaoline fire-resistant synergistic halogen-free non-phosphor cable sheath material

InactiveCN100445329CReduce the rate of mass lossAvoid drippingInsulated cablesInsulated conductorsManufacturing technologyPhosphor

The invention discloses a compound material manufacture technology that uses modified nanometer kaolin to take place of nanometer montorillonite clay as antiflaming synergic action bulking agent. It contains matrix resin, fire retardant, antiflaming synergic action bulking agent, lubricant, and antioxidant; the matrix resin is the mixture of ethylene vinyl acetate copolymer, thermoplastic elastomer and grafting compound. The fire retardant contains three type fire retardants; and the antiflaming synergic action bulking agent is kaolin. The weight portions of the constituents are: 100 portions matrix resin, 100-140 portions fire retardant, 10-30 portions, 1-5 portions lubricant, 1-3 portions antioxidant. The invention has the advantages of low cost, easy technology, and excellent flame retardant property.

Owner:NINGBO SHIP PLASTIC CO LTD

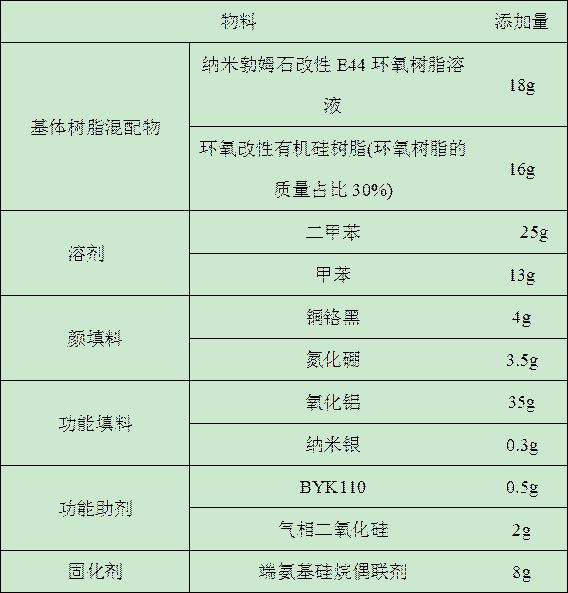

High-performance ceramic-based epoxy modified organic silicon coating material, preparation method and application method thereof

ActiveCN113388312AHigh hardnessImprove wear resistanceFireproof paintsChemical industryFirming agentEconomic benefits

The invention relates to a high-performance ceramic-based epoxy modified organic silicon coating material, which is characterized in that a boehmite modified epoxy resin, an epoxy modified organic silicon resin and a curing agent are selected as main components, and a ceramic-based resin is gradually formed in a resin curing and cross-linking process, so that high hardness and wear resistance of the epoxy modified organic silicon coating material are realized, and the coating material has excellent oil resistance and high-temperature resistance. According to the invention, the ceramic-based epoxy modified organic silicon coating material has the advantages of simple construction, no need of complex equipment, good film-forming property of the prepared material, and high adhesive force; and by applying the ceramic-based epoxy modified organic silicon coating material, the scratch-resistant protection and corrosion protection effects on equipment can be realized, and the coating can also be widely applied to high-temperature protection of facilities such as chimneys, hot pipelines and the like, and has relatively high economic benefits.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

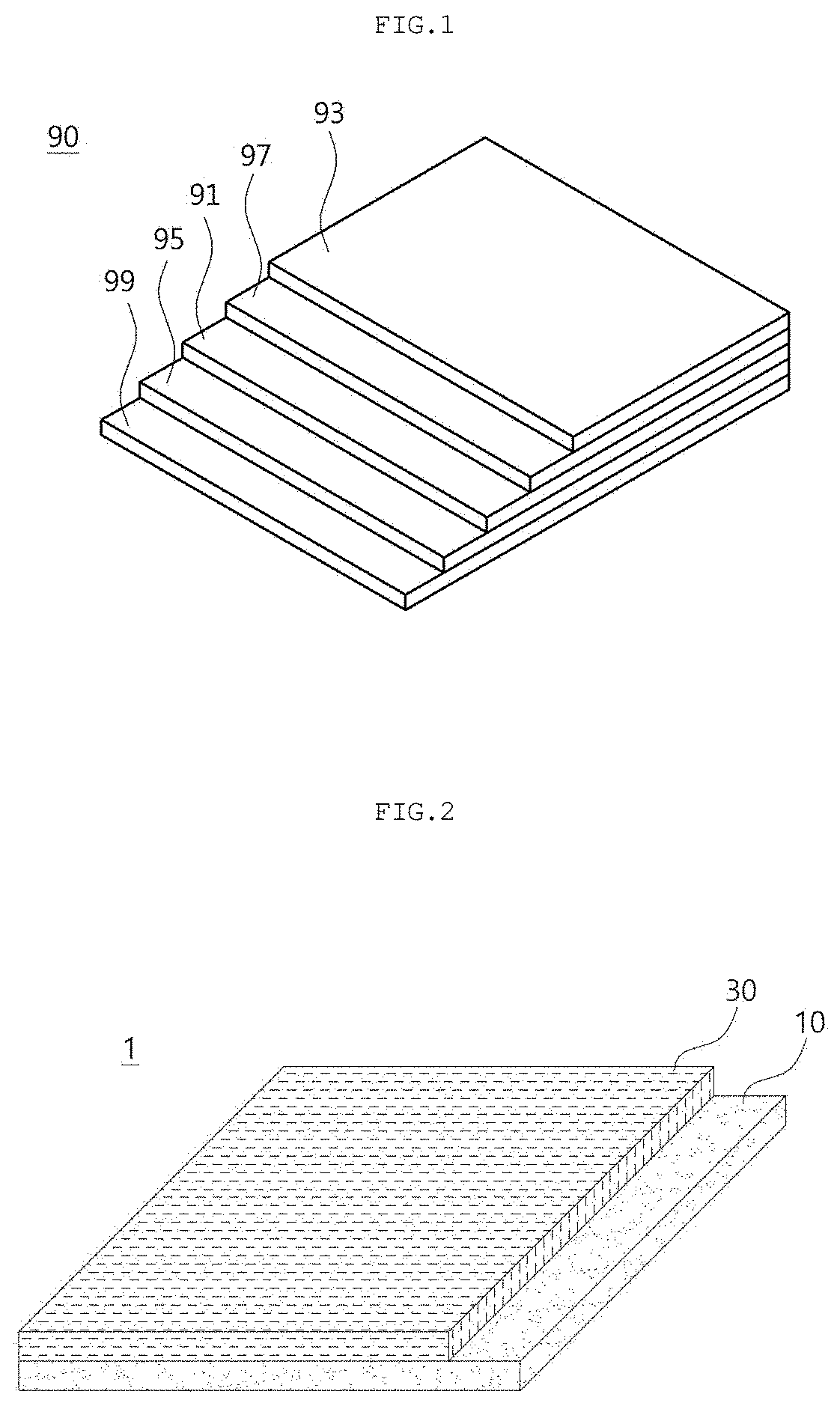

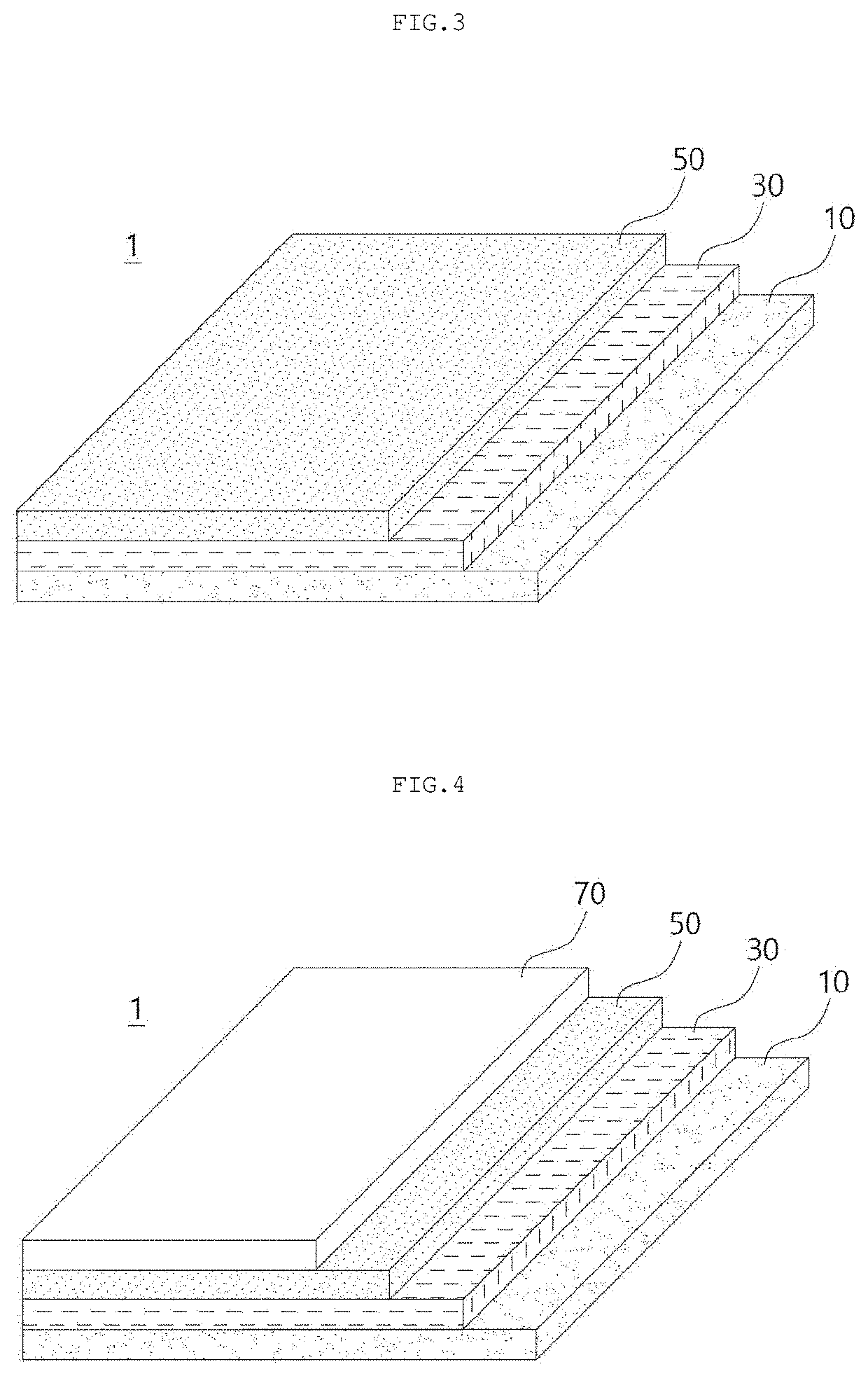

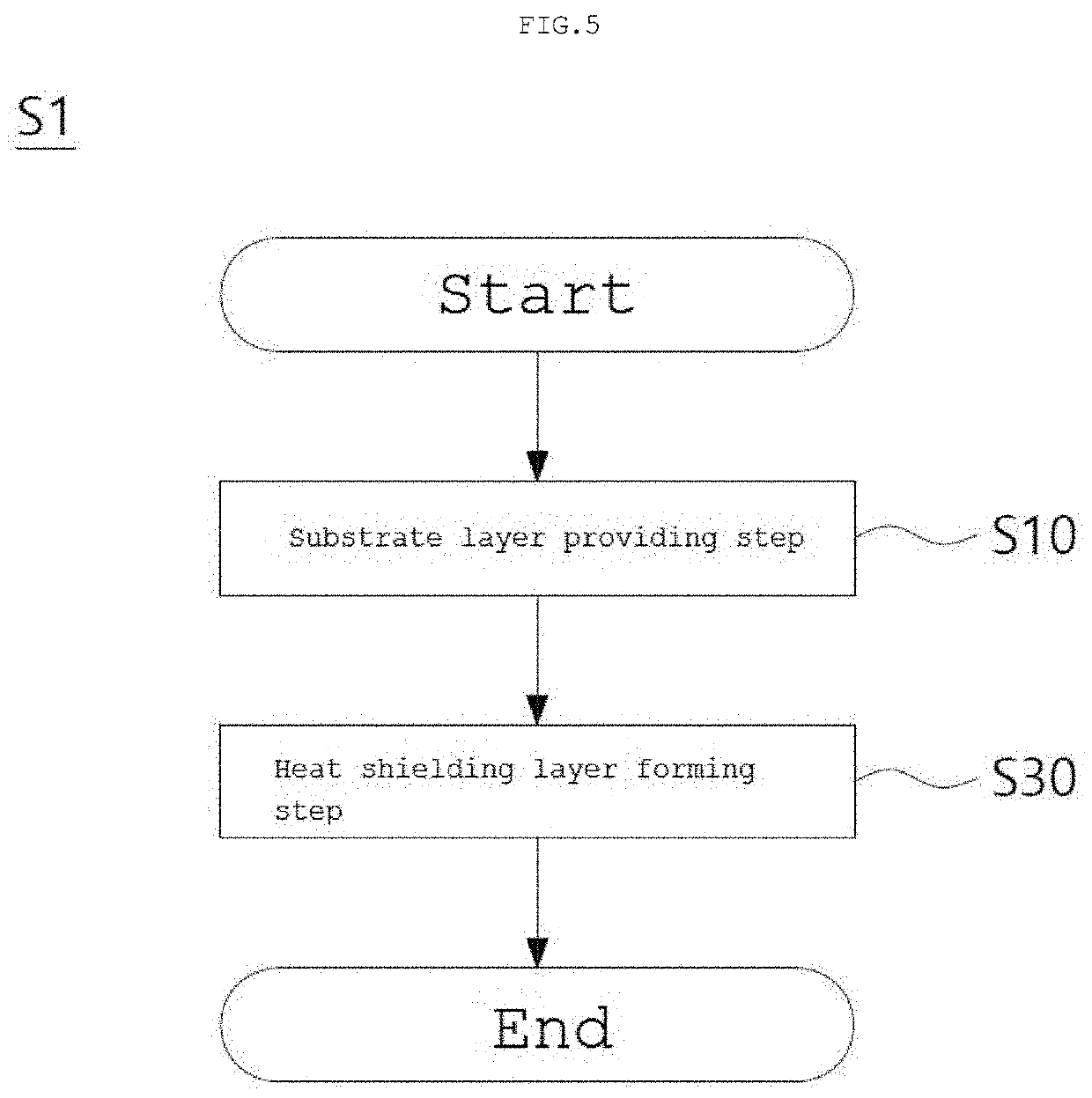

Environment-Friendly Heat Shielding Film Using Non-radioactive Stable Isotope and Manufacturing Method Thereof

ActiveUS20210246278A1Easy to disperseConveniently formedTungsten oxides/hydroxidesPretreated surfacesRadioactive agentHeat resistance

Disclosed are an environment-friendly heat shielding film using a non-radioactive stable isotope and a manufacturing method therefor and, more specifically, an environment-friendly heat shielding film using a non-radioactive stable isotope and a manufacturing method therefor, wherein a heat shielding layer is formed on one surface of a substrate layer; the heat shielding layer is composed of stable isotopes as elements constituting a precursor and contains a non-radioactive stable isotope tungsten bronze compound having an oxygen-deficient (Y)Ax(182,183,184,186)W1O(3-n) type hexagonal structure, thereby preventing the generation of radioactive materials, fundamentally blocking haze, and improving the visible light transmittance and the infrared light blocking rate; and the heat resistance and durability problems that may occur when the heat shielding layer is formed of the non-radioactive stable isotope tungsten bronze compound are solved by a passivation film.

Owner:HWANG TAI GYEONG

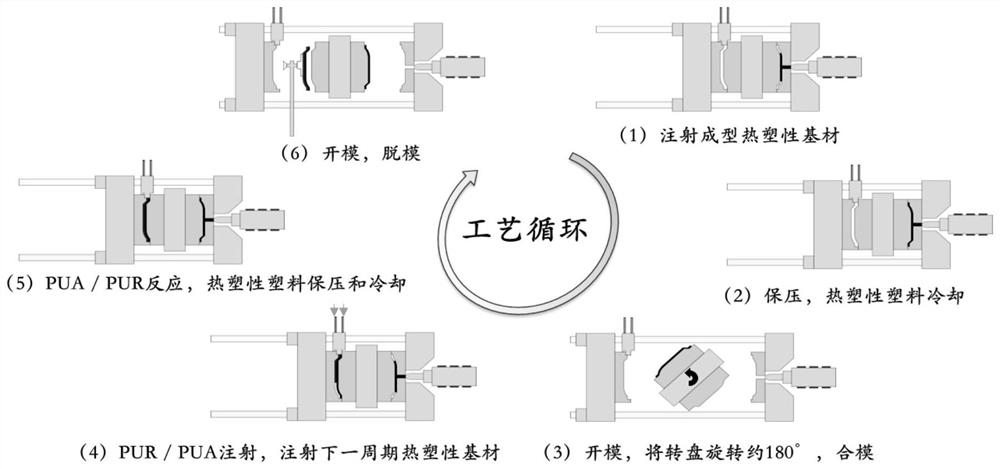

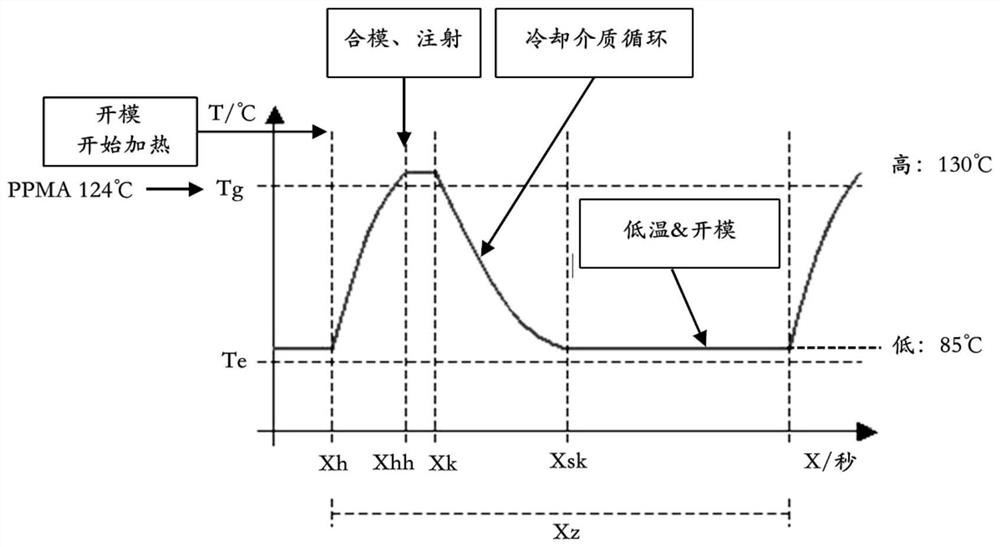

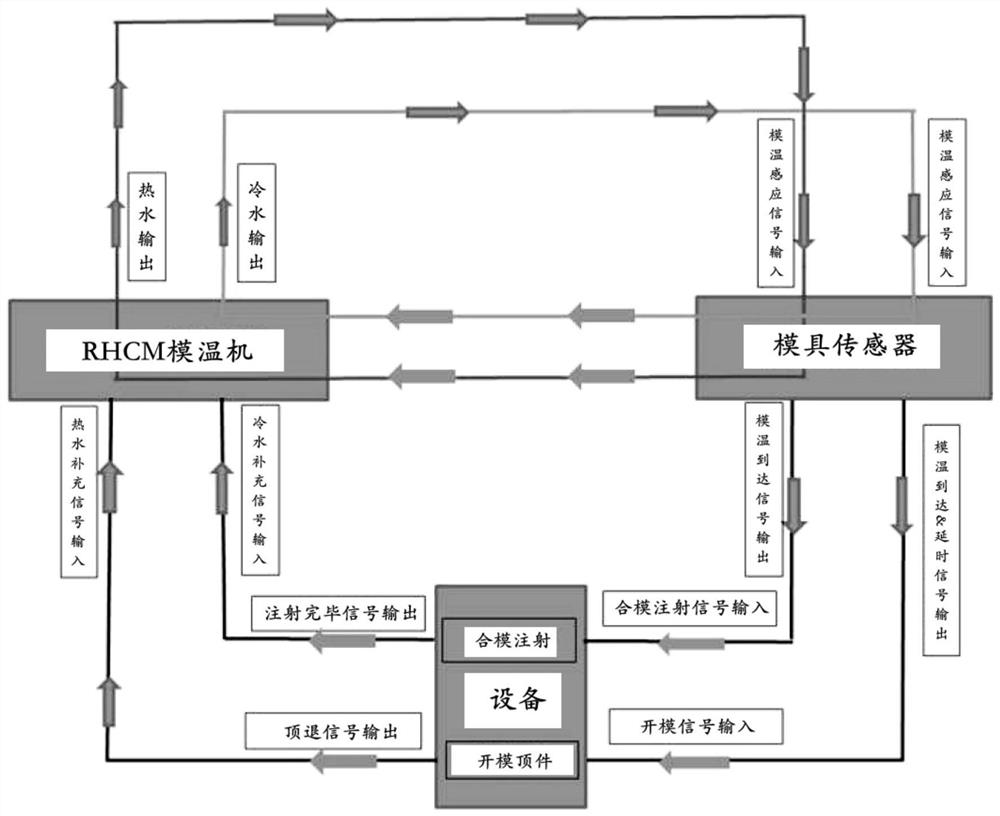

Rapid in-mold simulation surface decoration process

The invention belongs to the field of automobile part manufacturing processes, and particularly relates to a rapid in-mold simulation surface decoration process. The forming process of an injection molding part comprises the following steps that a thermoplastic base material is subjected to injection molding in a first mold cavity through a rapid cooling and rapid heating process to form the highlight injection molding part, wherein nanometer or femtosecond laser textures are pre-machined on the inner surface of the first mold cavity so that the highlight injection molding part can have a nanometer or femtosecond laser texture structure; the first mold cavity is quenched and opened, a rotary table is approximately rotated by 180 degrees, and a second mold cavity is closed; the highlight injection molding part is directly cast and coated with a two-component coating in the second mold cavity, and the two-component coating reacts and is cured in the second mold cavity, so that a transparent coating is formed on the surface of the highlight injection molding part; and the second mold cavity is cooled and opened, and the highlight injection molding part with the nanometer or femtosecond laser texture structure and the scratch-resistant surface is formed. The rapid in-mold simulation surface decoration process has the obvious cost advantage, and the surface coating of the formed highlight injection molding part is attractive, ideal in hardness and good in scratch resistance; and in addition, due to the combination of the nanometer or femtosecond laser texture structure and the external transparent coating, the highlight injection molding part has a three-dimensional decorative effect on the whole, and the product has more advantages and competitiveness.

Owner:长春恒兴集团有限公司

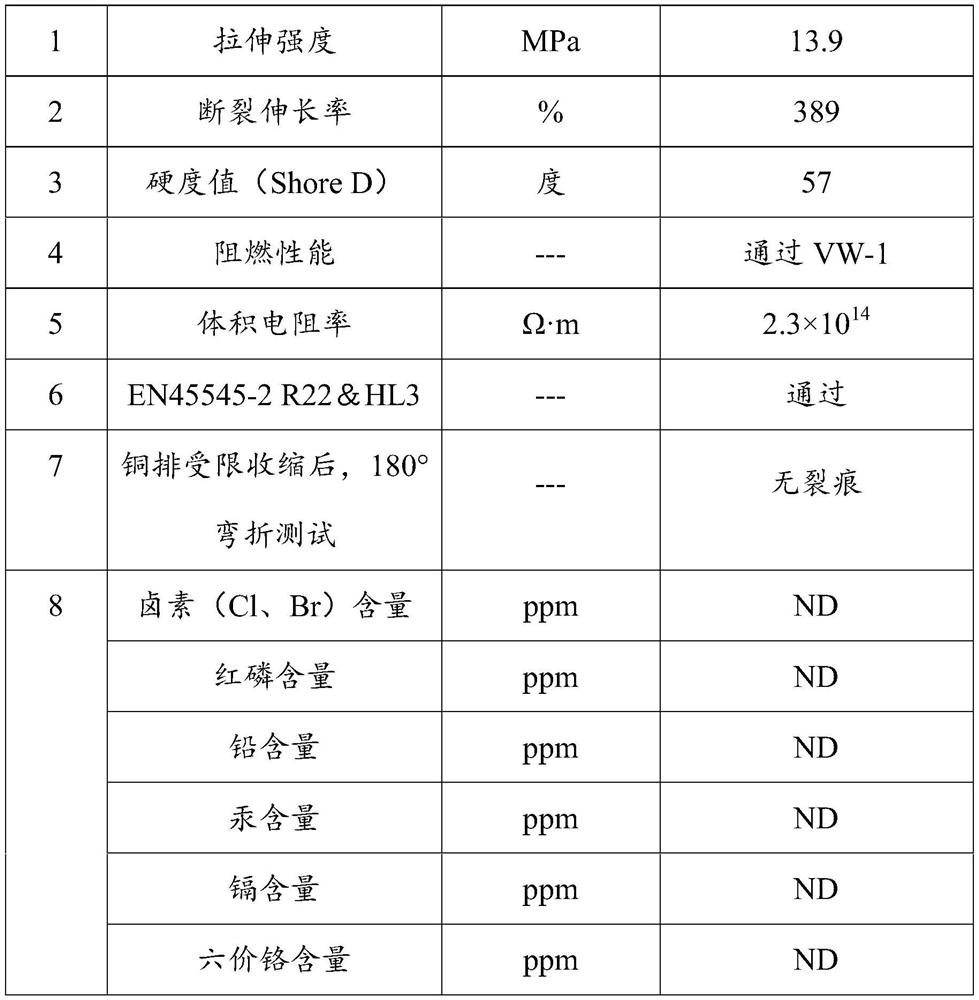

Semi-hard halogen-free red phosphorus-free flame-retardant heat-shrinkable tubing and preparation method thereof

InactiveCN112812416AGood environmental stress cracking resistanceImprove flame retardant performancePolyolefinRaw material

The invention is suitable for the technical field of heat-shrinkable sleeves, and provides a semi-hard halogen-free red phosphorus-free flame-retardant heat-shrinkable sleeve and a preparation method thereof. The heat-shrinkable sleeve is prepared from the following components in parts by weight: 60-80 parts of an ethylene-vinyl acetate copolymer, 20-30 parts of a vinyl polymer, 40-60 parts of a phosphorus-nitrogen flame retardant, 40-60 parts of an inorganic flame retardant, 2-6 parts of a compatilizer, 1-2 parts of an antioxidant, 1.5-3 parts of a lubricant, 4-8 parts of silicone master batch and 6-10 parts of color master batch. The polyolefin base material adopted by the invention has good environmental stress cracking resistance, tear resistance, puncture resistance and the like, and the silicone master batch can improve the scratch resistance of the product and play a role in synergistic flame retardance; the compound flame retardant does not contain halogen and red phosphorus, meets the environmental protection requirement, and has good flame retardance; in the method, the raw materials are subjected to melt blending, extrusion, irradiation crosslinking and expansion shaping to obtain the heat-shrinkable sleeve with good environmental stress cracking resistance, scratch resistance, flame retardance and environmental protection performance.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +2

Scratch-resistant modified PP material and preparation method thereof

PendingCN111793273AImprove scratch resistanceStrong scratch resistancePolymer scienceMelt flow index

The invention discloses a scratch-resistant modified PP material, which is prepared from the following components in parts by weight: 65 to 85 parts of PP resin, 5 to 20 parts of a toughening agent, 0.1 to 3 parts of an antioxidant, 0.5 to 5 parts of a compatilizer, 2 to 4 parts of a scratch-resistant agent, 5 to 20 parts of talcum powder and 0 to 4 parts of color master batch, wherein the PP resin is one or more of homo-polymerized PP and copolymerized PP, the melt indexes of the homo-polymerized PP and the copolymerized PP are 20-25g / 10min under the test conditions of 230 DEG C and 2.16 Kg,the crystallinity of the homo-polymerized PP and the copolymerized PP is greater than 60%; and the scratch-resistant agent is a polysiloxane substance. The scratch-resistant modified PP material has the advantages of better scratch resistance, low odor, good comprehensive performance, simple production process and low cost.

Owner:上海奉坤新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com