Stone-like glass mosaic and preparation method thereof

A glass mosaic and stone imitation technology, applied in the field of decorative materials, can solve the problems of the imitation stone glass mosaic use performance, the thermal stability is not perfect, the surface stain resistance is not good enough, etc. The effect of reducing glass viscosity and surface tension and shortening melting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

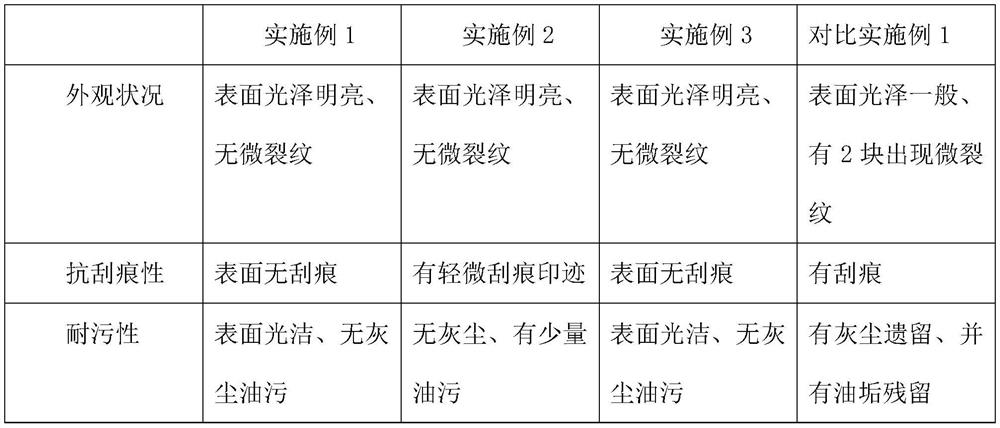

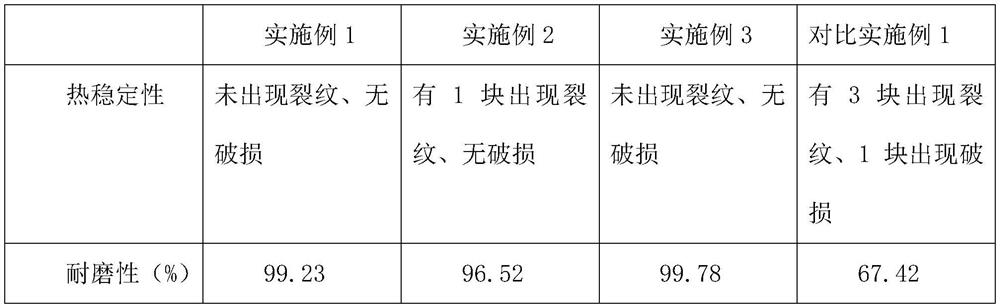

Examples

preparation example Construction

[0022] In an embodiment of the present invention, a stone-like glass mosaic and a preparation method thereof, the preparation method of the stone-like glass mosaic comprises the following steps:

[0023] S1. After cleaning and drying a certain amount of waste glass, use a ball mill to grind it into powder. After screening, add it to a mixing tank, and add glass raw materials, borax, quartz powder and fluorite to it in turn, and stir evenly for 10-20 minutes. The stirring speed is 500-100r / min to obtain the mixture;

[0024] S2. Then add a certain amount of dispersant, zinc oxide and surface treatment agent into the above-mentioned mixture, continue mixing for 20-30min, and control the temperature at 60-90°C to obtain a glass blank;

[0025] S3. Place the glass blank in a kiln for high-temperature melting. The temperature of the furnace is 1200-1500° C., then place the melted glass blank in a mold, and press and form it to obtain a shaped glass body;

[0026] S4, annealing and...

Embodiment 1

[0031] A stone-like glass mosaic, the stone-like glass mosaic is composed of: 20 parts of glass raw materials, 10 parts of waste glass, 2 parts of borax, 2 parts of quartz powder, 3 parts of fluorite, 1 part of dispersant, 3 parts of zinc oxide parts, 5 parts of surface treatment agent;

[0032] The surface treatment agent is composed by weight: 10 parts of nano-glass powder, 5 parts of pearl powder, 2 parts of porcelain stone powder, 3 parts of toughening agent, 1 part of binder, and the balance is water;

[0033] Further, the preparation method of surface treatment agent is the following steps:

[0034] A1. Add a certain amount of nano-glass powder and porcelain stone powder into the mixing tank, and add an appropriate amount of water, and mix and stir for 15-30 minutes;

[0035] A2. After stirring evenly, add pearl powder, binder and toughening agent into it, and continue stirring for 20-30 minutes until the stirring is uniform, and then the surface treatment agent can be ...

Embodiment 2

[0038] A stone-like glass mosaic, the stone-like glass mosaic is composed of: 30 parts of glass raw materials, 15 parts of waste glass, 8 parts of borax, 5 parts of quartz powder, 7 parts of fluorite, 3 parts of dispersant, zinc oxide 4 parts, 10 parts of surface treatment agent;

[0039] The surface treatment agent is composed of 15 parts by weight of nano-glass powder, 12 parts of pearl powder, 8 parts of porcelain stone powder, 5 parts of toughening agent, 3 parts of binder, and the balance is water;

[0040] Further, the preparation method of surface treatment agent is the following steps:

[0041] A1. Add a certain amount of nano-glass powder and porcelain stone powder into the mixing tank, and add an appropriate amount of water, and mix and stir for 15-30 minutes;

[0042] A2. After stirring evenly, add pearl powder, binder and toughening agent into it, and continue stirring for 20-30 minutes until the stirring is uniform, and then the surface treatment agent can be pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com