Compound resin material for cable and preparation method thereof

A composite resin and composite filler technology, applied in the direction of insulating cables, plastic/resin/wax insulators, cables, etc., can solve the problems of affecting the strength of polymers, high proportion of coupling agent, insufficient mixing of coupling agent and inorganic filler, etc. , to achieve the effect of improving impact strength and gloss, excellent impact strength and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

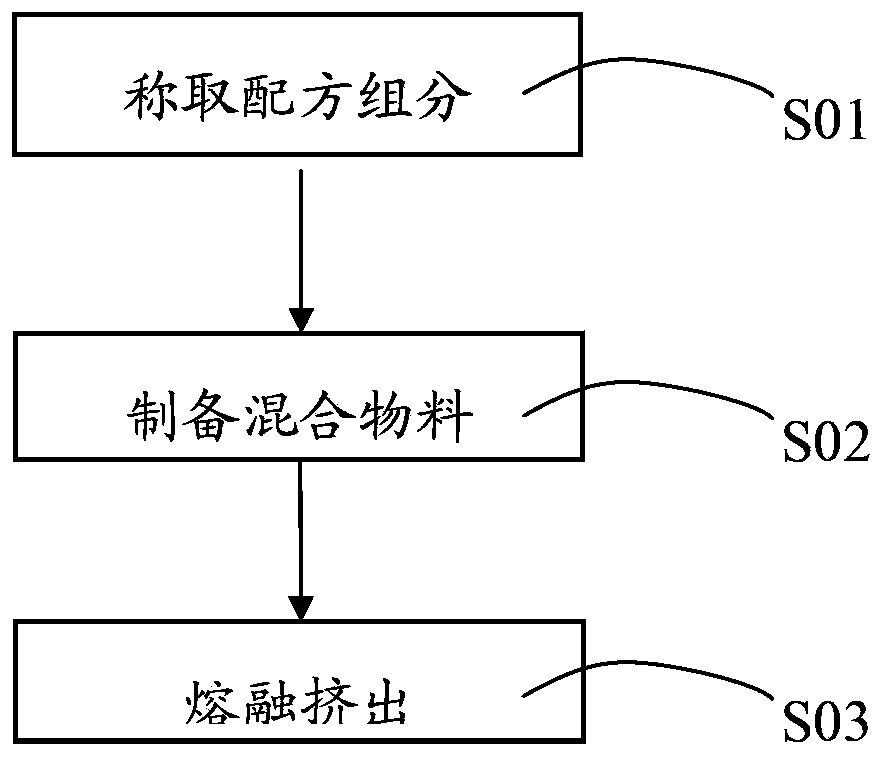

[0063] The present embodiment also provides the preparation method of above-mentioned cable composite resin material, and its technical process is as follows figure 1 shown. The method comprises the steps of:

[0064] S01. Weighing the formula components: Weighing each component according to the formula of the above-mentioned composite resin material for cables;

[0065] S02. Preparation of mixed material: Divide the nanometer and micron composite filler into two parts, and melt extrude one part with the above resin to form a mixed material.

[0066] S03. Melt extrusion: Melt and extrude the mixed material prepared in step S02 with another part of nanometer and micrometer composite filler and auxiliary agent to obtain the above-mentioned composite resin material for cables; the weight of the above nanometer and micrometer composite filler and resin The part ratio is 1:2~3, and the above-mentioned melt extrusion temperature is 190°C-210°C.

[0067] Specifically, in the above...

Embodiment 1

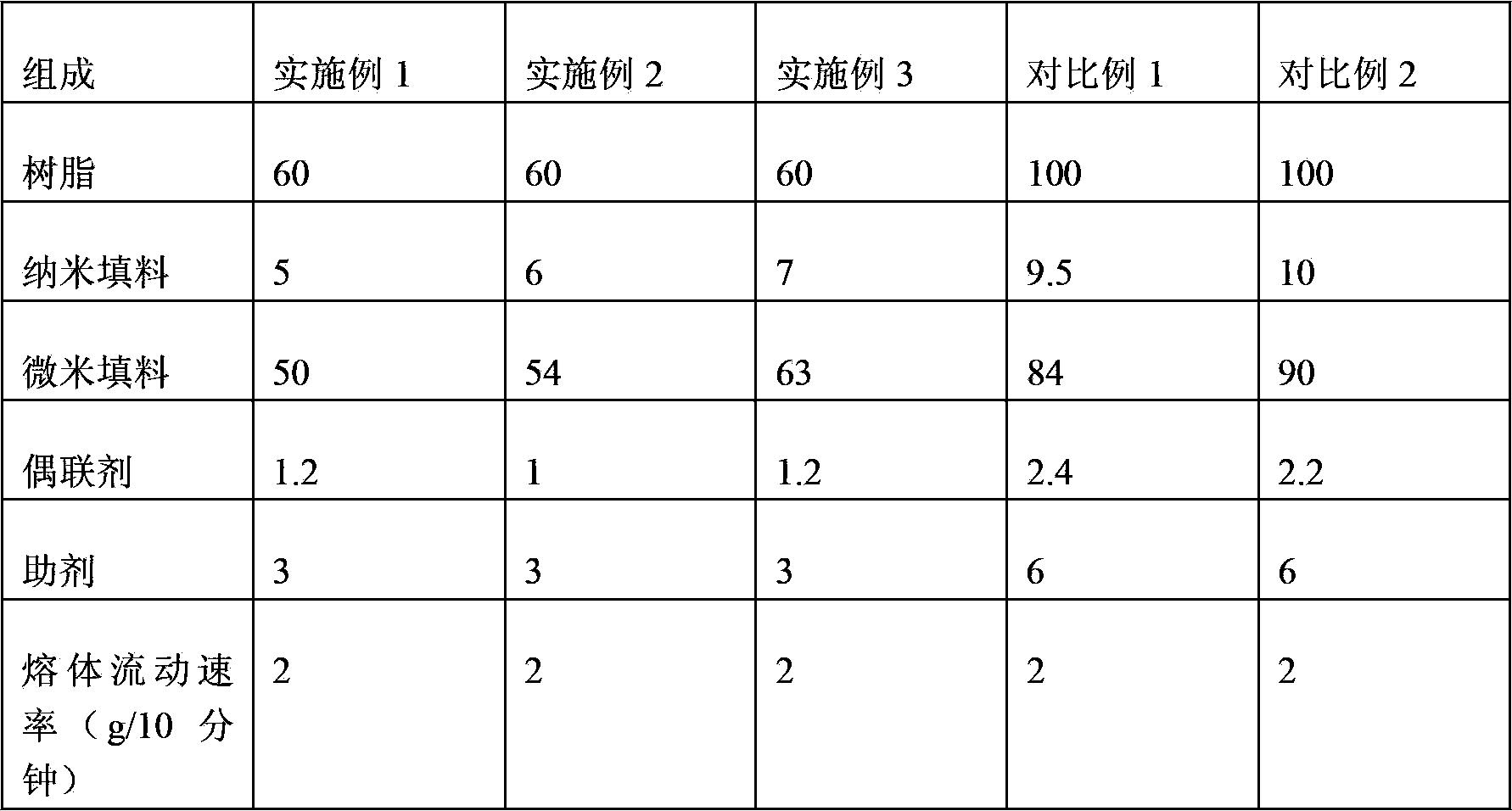

[0080] The percentage by weight of the composite resin material for cables in this embodiment is as follows, and the formulation components are shown in Table 1 below.

[0081] Resin 60 parts

[0082] Nano and micro composite filler 55 parts

[0083] 3 parts of auxiliary agent;

[0084] Wherein, the nano and micro composite fillers include the following components by weight:

[0085] Nano filler 5 parts

[0086] Micron filler 50 parts

[0087] 1.2 parts of coupling agent.

[0088] Among them, the resin is polyethylene, the nanometer filler is G-101 nanometer calcium carbonate, the micrometer filler is heavy calcium carbonate, the coupling agent is a zirconium coupling agent, and the auxiliary agent is an antioxidant.

[0089] The preparation method of the cable composite resin material is as follows:

[0090] S11: Weighing the formula components: Weighing each component of the formula of the above-mentioned composite resin material for cables;

[0091] S12: Preparation of...

Embodiment 2

[0099] The percentage by weight of the composite resin material for cables in this embodiment is as follows, and the formulation components are shown in Table 1 below.

[0100] Resin 60 parts

[0101] Nano and micro composite filler 60 parts

[0102] 3 parts of auxiliary agent;

[0103] Wherein, the nano and micro composite fillers include the following components by weight:

[0104] Nano filler 6 parts

[0105] Micron filler 54 parts

[0106] 1 part of coupling agent.

[0107] Among them, the resin is polyvinyl chloride, the nano filler is G-101 nano calcium carbonate, the micron filler is ceramic powder, the coupling agent is a zirconium coupling agent, and the auxiliary agent is a stabilizer.

[0108] Refer to Example 1 for the preparation method of the composite resin material for cables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com