Environment-friendly flame-retardant scratch-resistant polycarbonate resin and preparation method thereof

A technology of polycarbonate resin and polycarbonate, which is applied in the field of engineering plastics, can solve the problems of polycarbonate being not environmentally friendly and not resistant to scratches, and achieve the effects of stable product quality, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

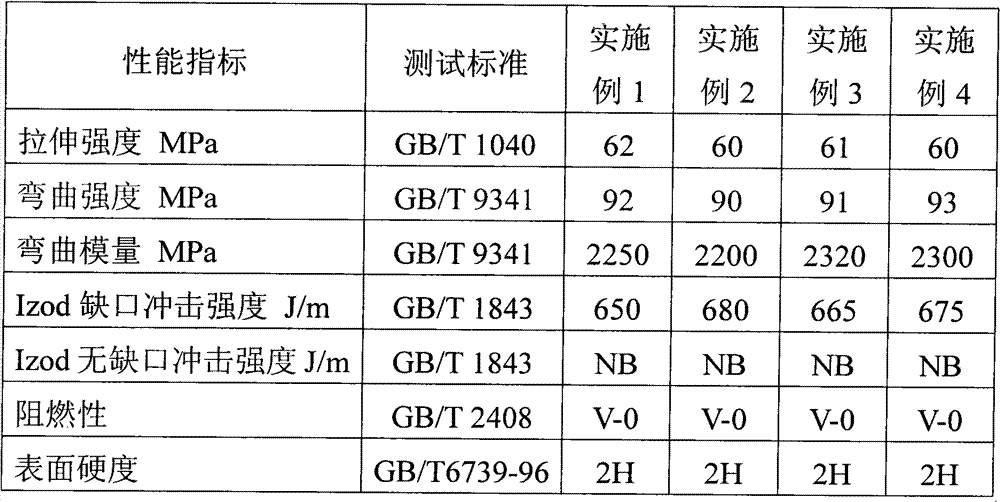

Examples

Embodiment 5

[0034] A method for preparing an environmentally friendly flame-retardant and scratch-resistant polycarbonate resin, comprising the following steps:

[0035] Weigh 90 parts by weight of medium molecular weight bisphenol A type polycarbonate resin with molecular weight between 25000-80000, 5 parts by weight of flame retardant dimethyl siloxane polymer, toughening agent core-shell class A 5 parts by weight of methyl acrylate, 1 part by weight of polytetrafluoroethylene (fluorine content is 60%) of anti-dripping agent, 1 part by weight of alkylated monophenol of antioxidant auxiliary agent, 1 part by weight of processing aid fatty acid amide, add Fully mix in the high-speed mixer; use the metering and conveying device to send the mixed material into the twin-screw extruder. Finished product; Among them, the twin-screw extruder adopts vacuum exhaust when mixing materials, the aspect ratio of the twin-screw extruder is greater than 40, the screw speed is 300 rpm, and the working te...

Embodiment 6

[0037] A method for preparing an environmentally friendly flame-retardant and scratch-resistant polycarbonate resin, comprising the following steps:

[0038] Weigh 95 parts by weight of low molecular weight bisphenol A type polycarbonate resin with molecular weight between 10000-25000, 2 parts by weight of flame retardant silicone polymer, toughening agent butadiene and styrene 2 parts by weight of terpolymer, 0.3 part by weight of tetrafluoroethylene copolymer (fluorine content is 75%) of anti-dripping agent copolymerizable unsaturated monomer, 0.5 part by weight of antioxidant auxiliary agent hindered phenol, processing aid Add 0.3 parts by weight of titanate coupling agent and 0.2 parts by weight of stearic acid amide into a high-speed mixer and mix them uniformly; After shearing and mixing, extrude, pull, cool, pelletize, and pack into finished products; among them, the twin-screw extruder adopts vacuum exhaust when mixing materials, and the aspect ratio of the twin-screw ...

Embodiment 7

[0040] A method for preparing an environmentally friendly flame-retardant and scratch-resistant polycarbonate resin, comprising the following steps:

[0041] Weigh 92 parts by weight of polycarbonate resin, 2 parts by weight of flame retardant dimethyl siloxane polymer, 2 parts by weight of silicone polymer, 4 parts by weight of toughening agent methyl methacrylate, Anti-dripping agent polytetrafluoroethylene (fluorine content is 70%) 0.8 parts by weight, antioxidant auxiliary agent diphenyl phosphite 0.5 parts by weight, triphenyl phosphite 0.3 parts by weight, processing aid aluminate coupling agent 0.4 parts by weight, 0.4 parts by weight of ethylene bis stearic acid amide, add in the high-speed mixer and fully mix; With the metering and conveying device, the mixed material is sent into the twin-screw extruder, through the shearing of the screw, After mixing, extrude, draw, cool, pelletize, and pack into finished products; among them, the twin-screw extruder adopts vacuum e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com