Patents

Literature

44results about How to "Increase surface stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemically toughened glasses

InactiveUS6518211B1Promote meltingNot affecting strain pointGlass/slag layered productsThin material handlingToughened glass

A glass composition capable of being chemically strengthened by ion-exchange within 100 hours to provide a glass with a surface compressive stress of greater then 400 MPa and an ion-exchange depth greater then 200 microns comprising: SiO2 58% to 70% (by weight), Al2O3 5% to 15%, Na2O 12% to 18%, K2O 0.1% to 5%, MgO 4% to 10%, CaO 0% to 1% with the provisos that the total of the Al2O3 and MgO is in excess of 13%, the total of the amounts of Al2O3 plus MgO divided by the amount of K2O is at least 3 and that the sum of the amounts of Na2O, K2O and MgO is at least 22%.

Owner:GKN AEROSPACE SERVICES LTD

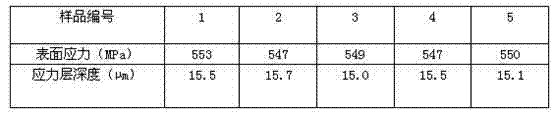

Dual-phase ion exchange method for glass enhancement

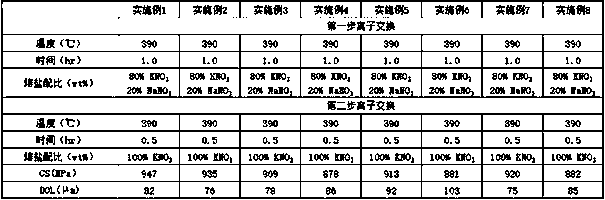

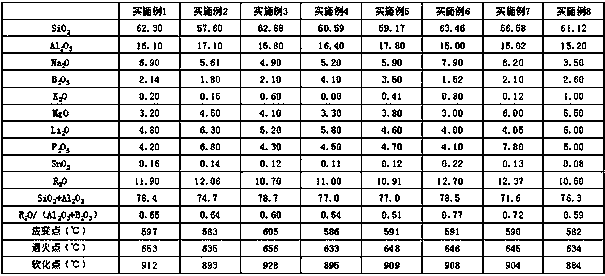

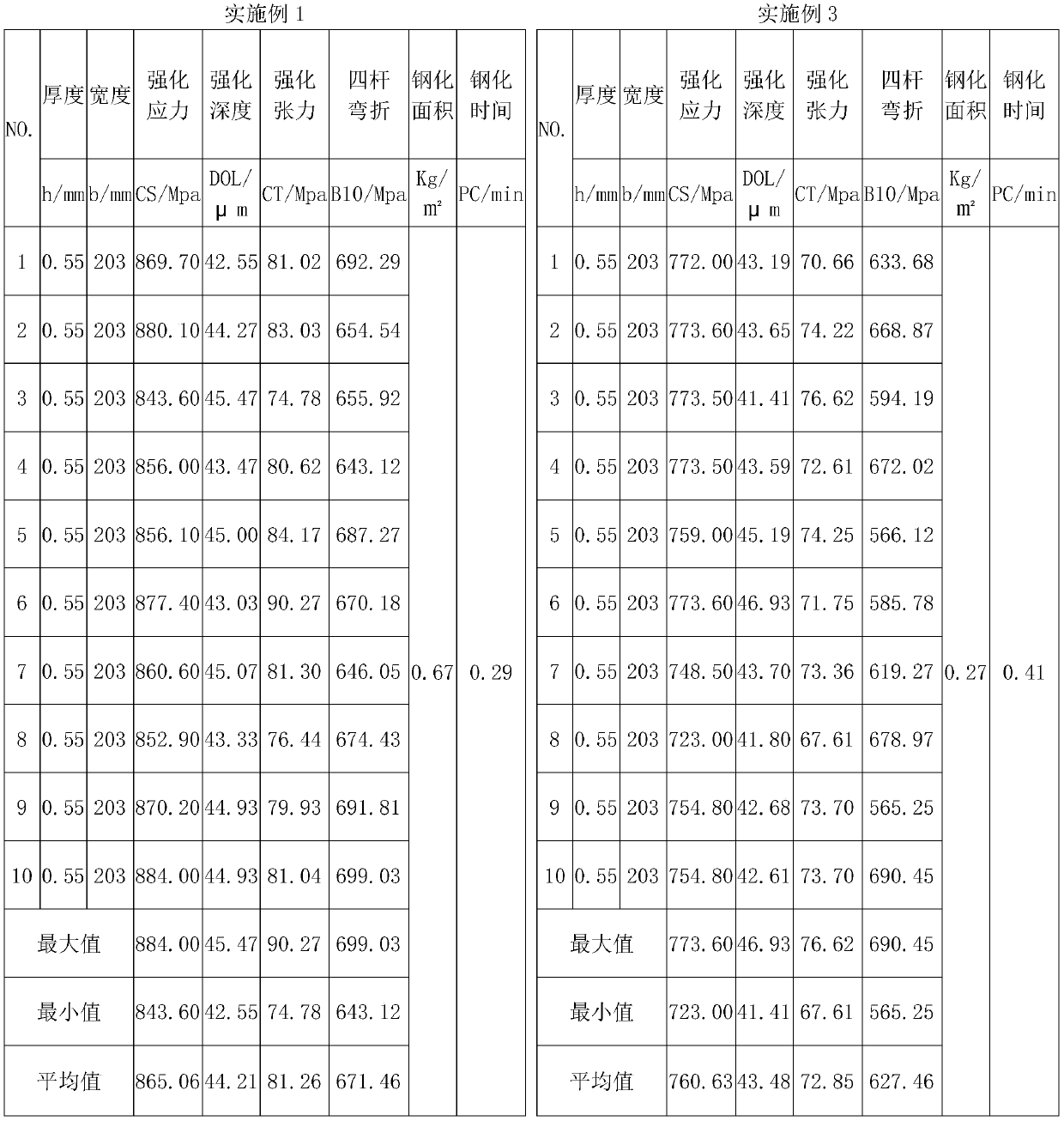

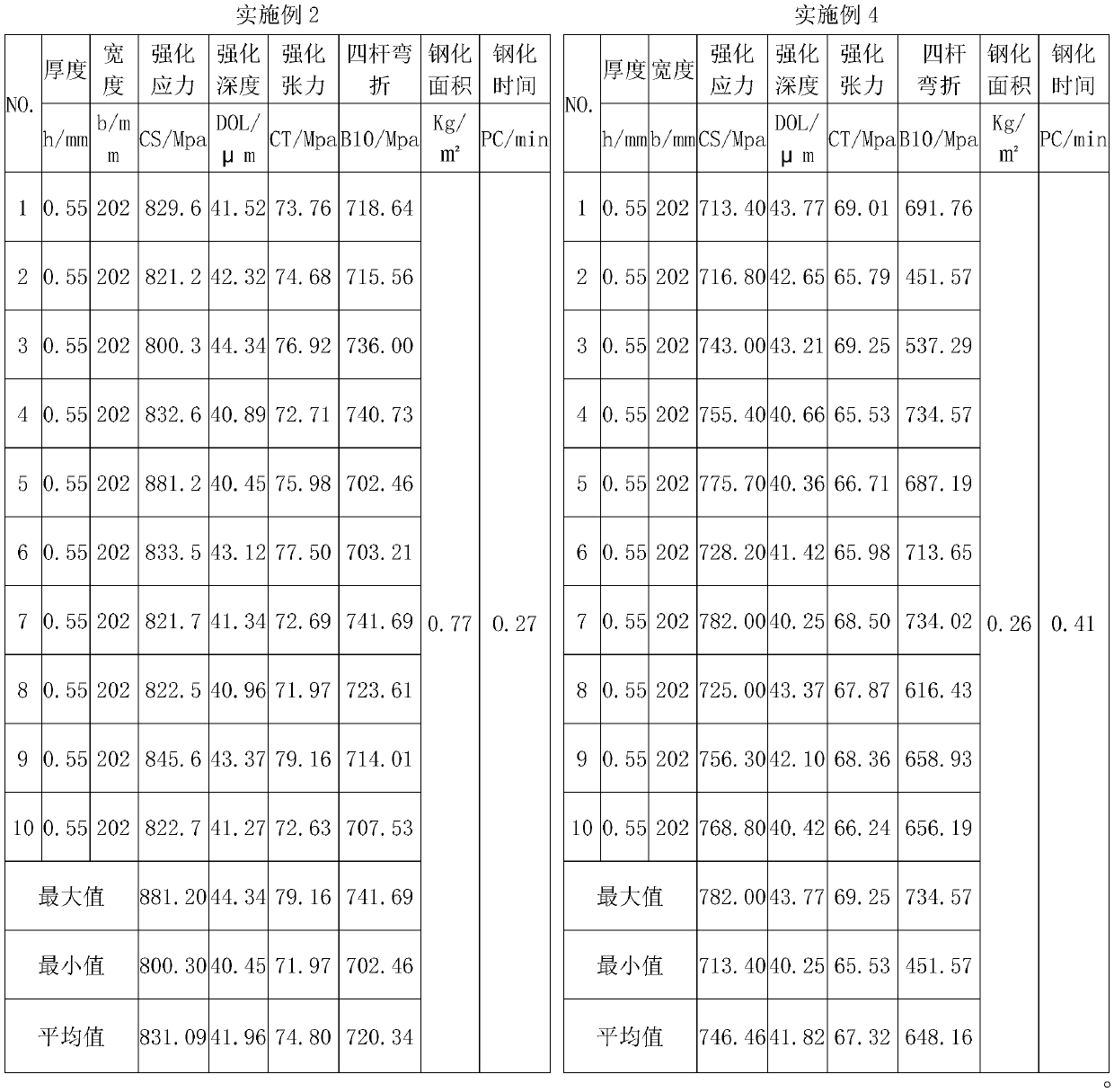

The invention belongs to the technical field of glass reinforced treatment and proposes a dual-phase ion exchange method for glass enhancement. According to the proposed dual-phase ion exchange method for glass enhancement, in an area lower than the glass transition temperature, two stages of ion exchange processes are carried out in the same fused salt at two different temperatures; the ion exchange temperature of the first stage is higher than that of the second stage; the ion exchange time of the first stage is greater than that of the second stage; the glass with a deep enough stress layer is obtained after the first stage of ion exchange in the fused salt; the glass with the deep enough stress layer is subjected to the second-stage ion exchange inside the same fused salt, so as to obtain the glass with large enough surface stress and the deep enough stress layer. By adopting the dual-phase ion exchange method for glass enhancement, the surface stress and the stress layer depth of thin glass are greatly improved, and the dual-phase ion exchange method has a simple process.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

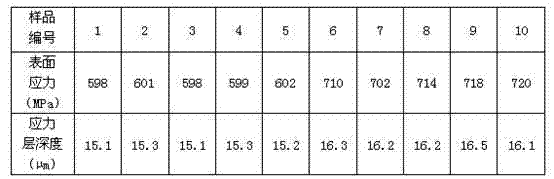

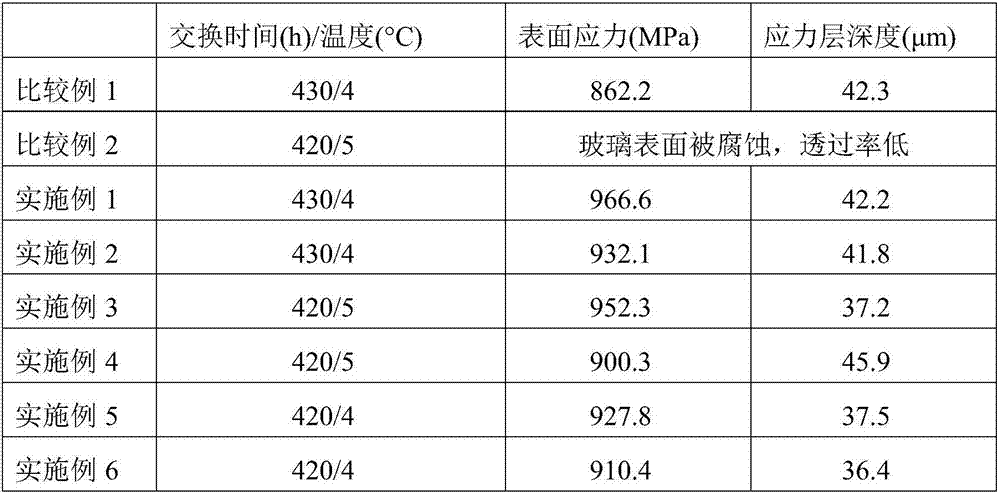

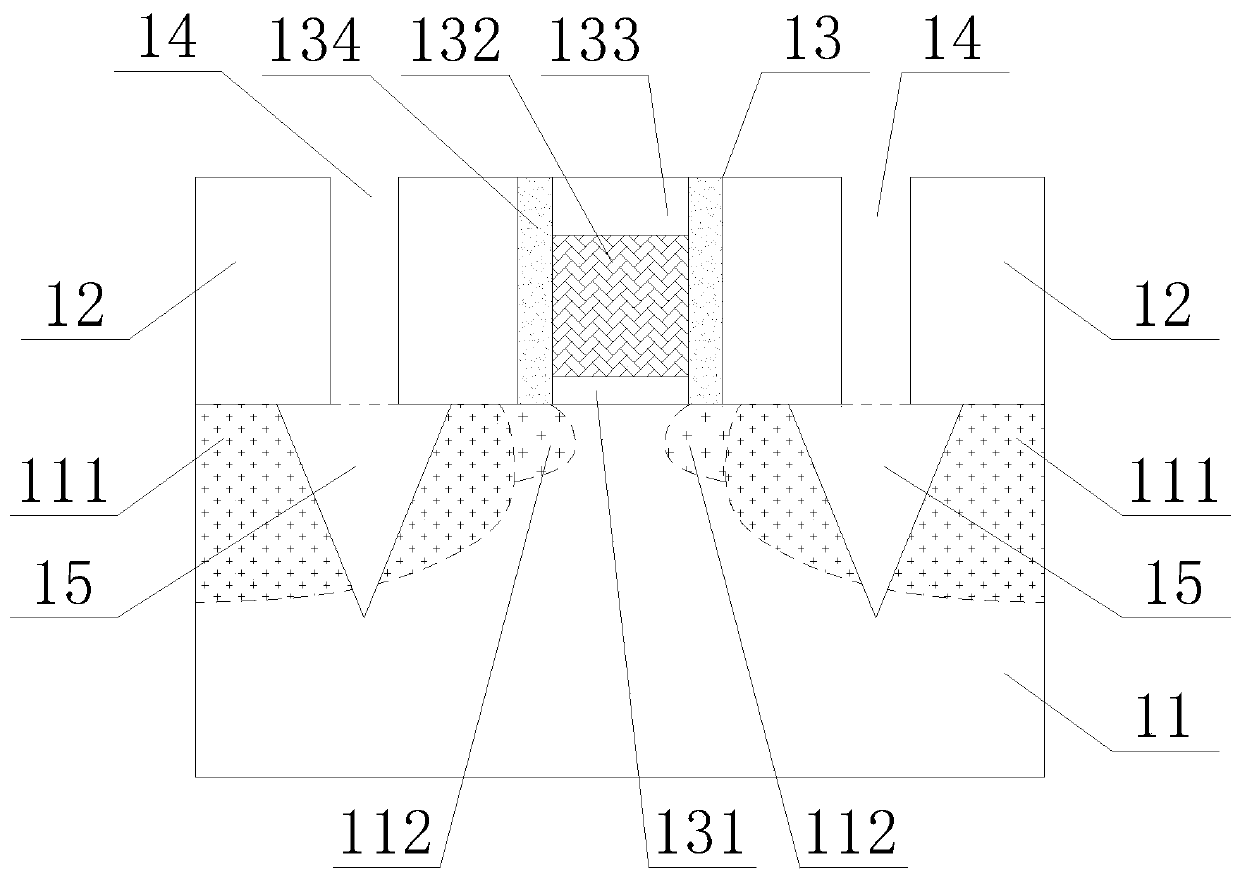

Fused salt for chemically enhancing medium-aluminum and high-aluminum silicate glass and method for performing chemically-toughened enhancement by using fused salt

The invention provides a fused salt for chemically enhancing medium-aluminum and high-aluminum silicate glass. The fused salt comprises the following compositions: KNO3, KOH, KCl and K2CO3, wherein a mass ratio of KOH to K2CO3 in the fused salt is 0.05-0.4; a mass ratio of KCl to K2CO3 is 0.075-1.0; and a mass ratio of KNO3 to K2CO3 is 100:(1.0-4.0). The invention further provides a method for performing chemically toughened enhancement by using the fused salt for chemical enhancing of medium-aluminum and high-aluminum silicate glass. The fused salt formula disclosed by the invention indicates a formula composition range suitable for chemical enhancing of the medium-aluminum and high-aluminum glass. According to the formula, corrosion on the glass surface can be avoided, and the chemically enhanced glass has high transmittance; and meanwhile, due to the formula disclosed by the invention, the surface stress and stress layer depth of the chemically enhanced glass can be greatly improved.

Owner:WUHAN UNIV OF TECH

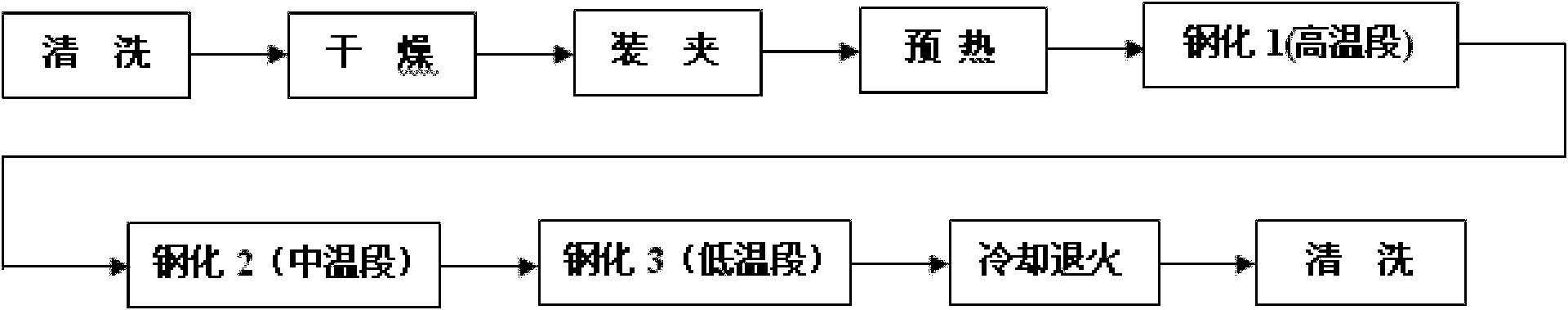

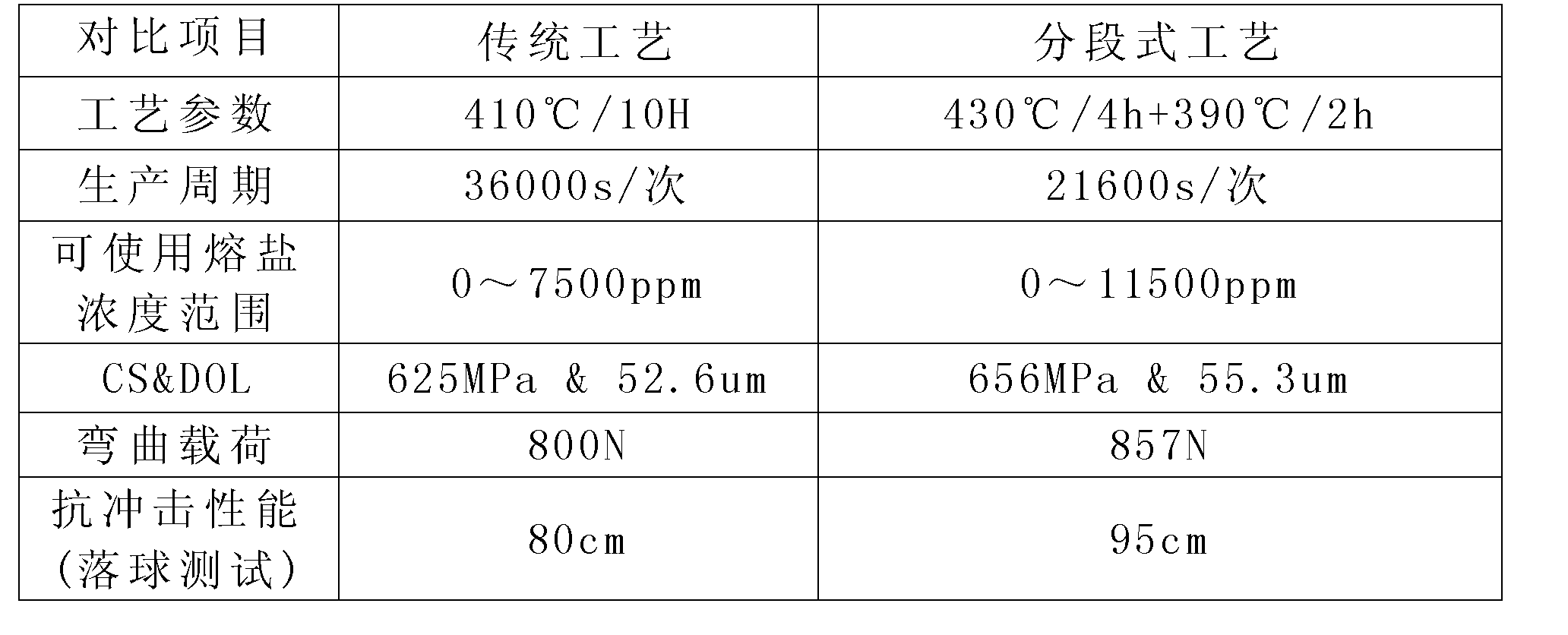

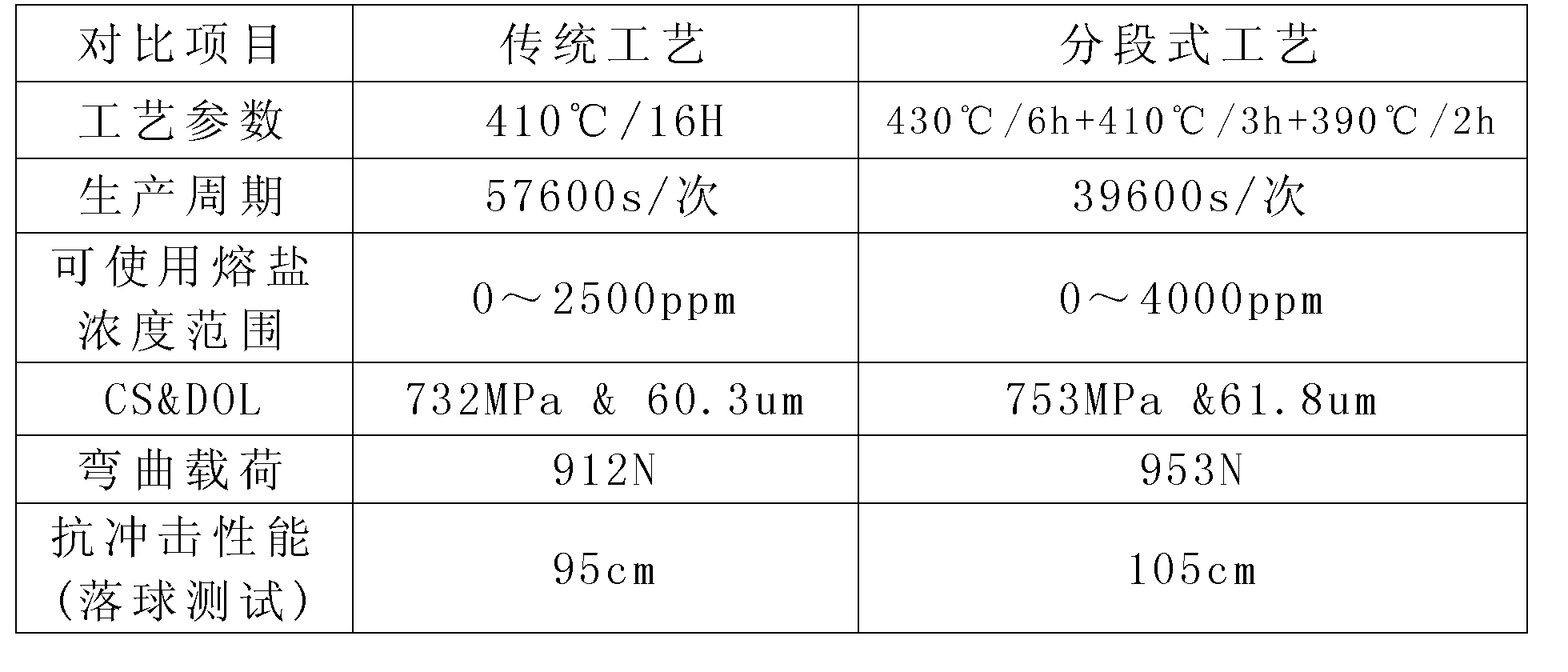

Segmented chemical toughening process

InactiveCN102030465AAdd depthHigh hardnessGlass tempering apparatusGlass productionMolten saltHigh surface

The invention discloses a segmented chemical toughening process comprising a cleaning step, a drying step, a clamping step, a preheating step, a toughening step, a cooling annealing step and a cleaning step. The toughening process comprises the process parameters: 430 DEG C / 4 h + 390 DEG C / 2h or 430 DEG C / 6h + 410 DEG C / 3h + 390 DEG C / 2h. The invention can effectively combine various chemical toughening process parameters and effectively improve the reinforcing layer depth and the surface hardness of a product. Meanwhile, the process can effectively improve the production efficiency of chemically toughening glass lenses, shorten the production period thereof, effectively prolong the service life of molten salt and achieve the aim of decreasing the production cost. The toughened product has high surface stress and good smoothness and can fully meet various performance requirements of general special safe glass.

Owner:LENS TECH

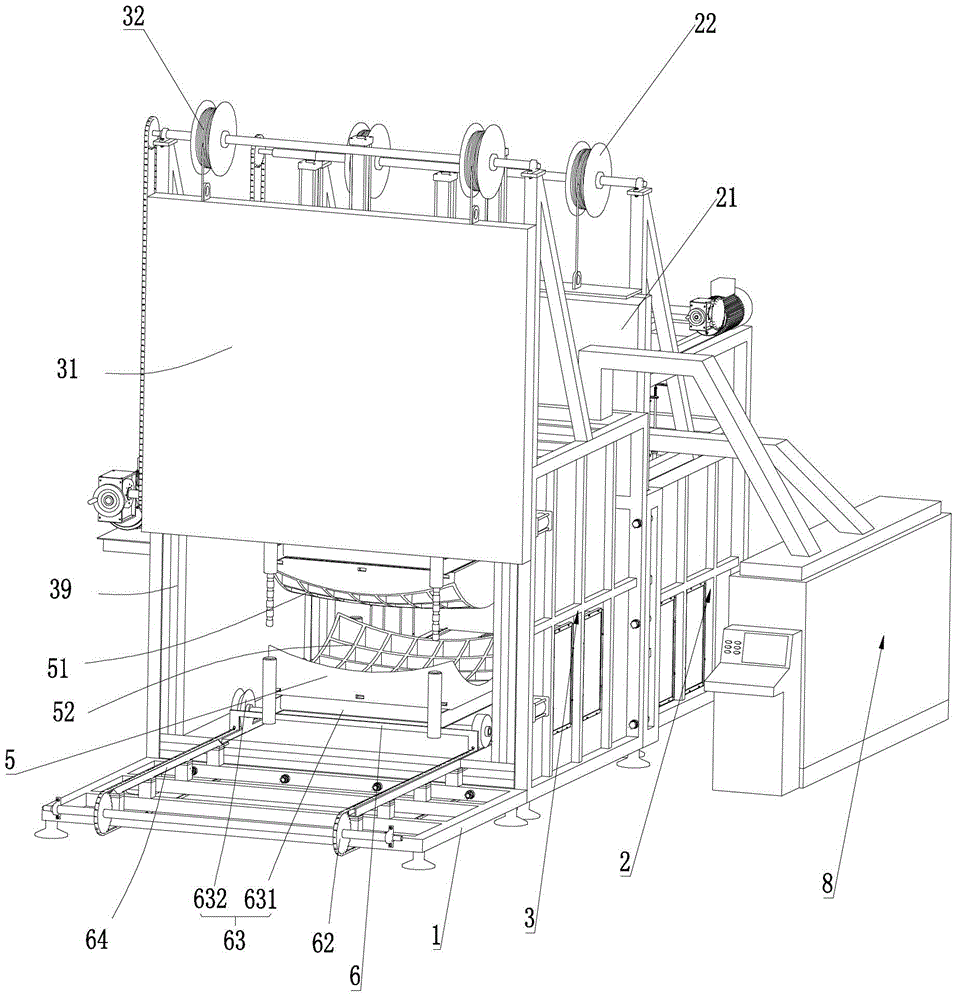

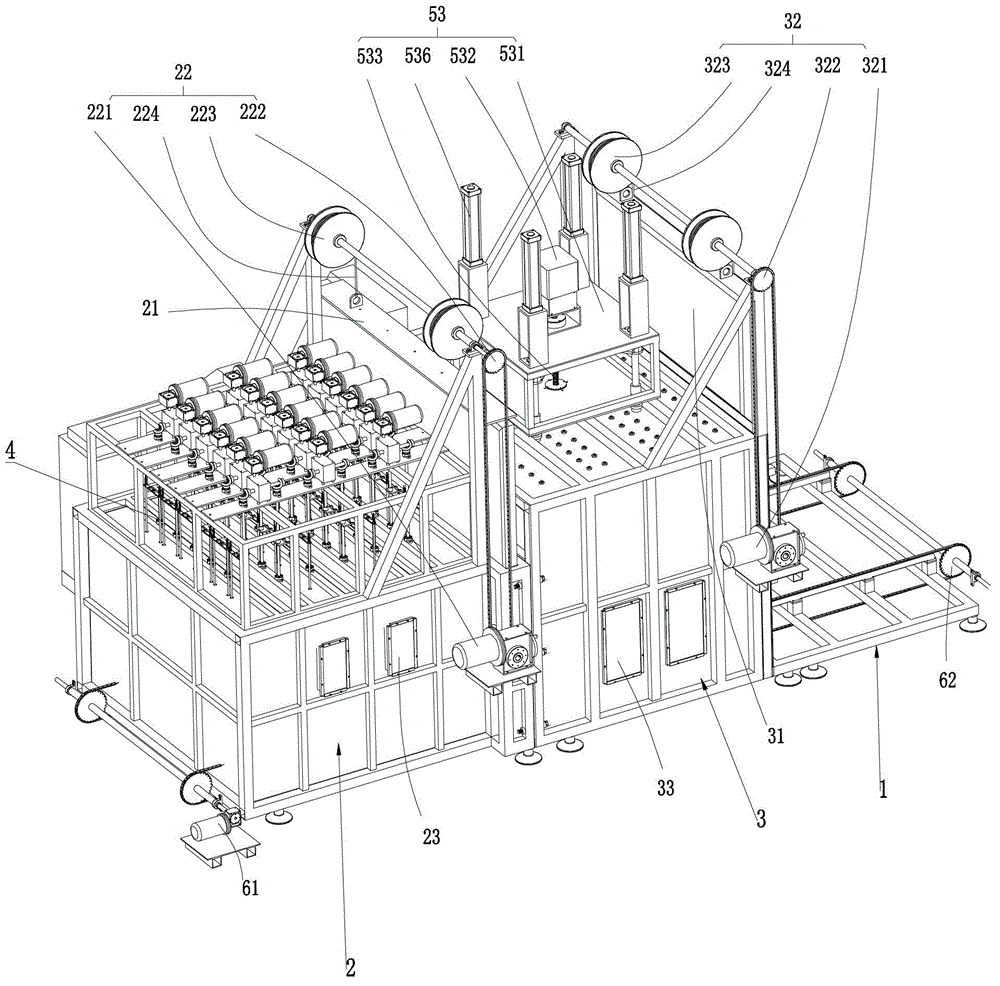

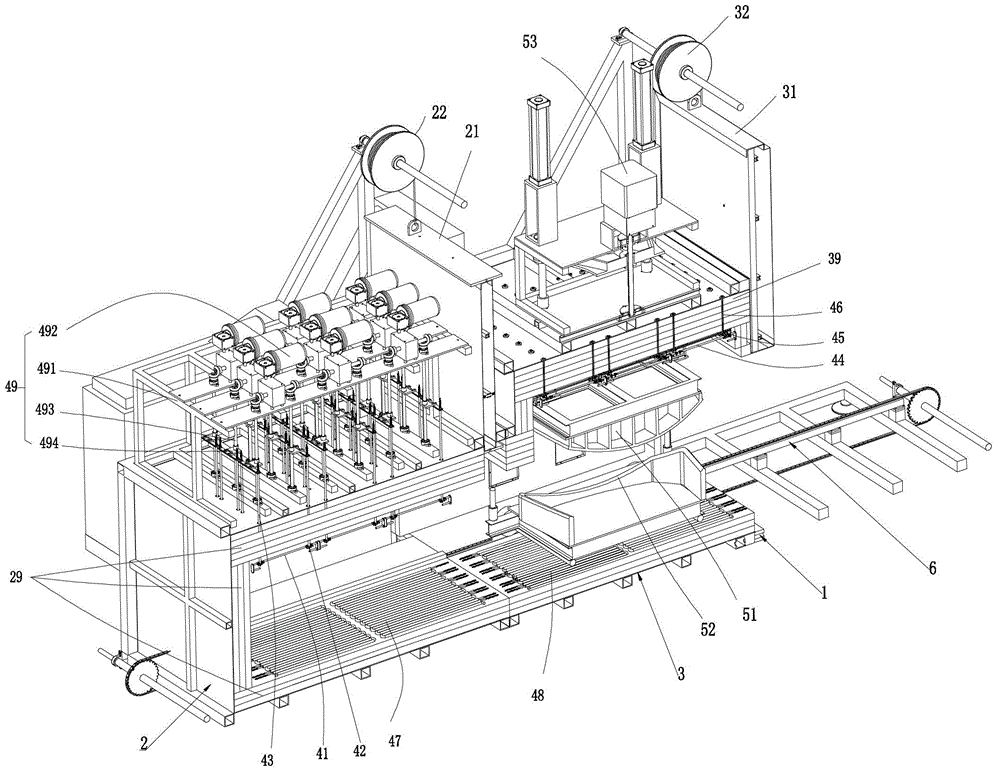

Compression molding device and process of multi-curved-surface inorganic glass

ActiveCN102745885AGuaranteed curvature accuracyGuaranteed bending temperatureGlass reforming apparatusInternal temperatureTemperature control

The invention relates to a compression molding device and process of multi curved surface inorganic glass. The compression molding device comprises a heating box, a molding box and a heating device, wherein the heating box and the molding box are arranged adjacently and are isolated by an inner door; the molding box is internally provided with a molding mold and a mold carrier; the mold carrier can move forwards and backwards between the molding box and the heating box; the molding mold comprises a female mold arranged on the mold carrier, a male mold movably arranged on the molding box, and a male mold driving device which is used for driving the male mode to stamp relative to the female mold; the compression molding device further comprises a control box; the control box is internally provided with a molding control module which is used for controlling the molding mold to do molding action, a mold moving control mold which is used for controlling the movement and the positioning of the mold carrier, and a temperature control module which is used for controlling the internal temperature of the molding box and the heating box. The compression molding device is applicable for multi curved surface molding of inorganic glass; the curvature precision of the multi curved surface inorganic glass after being molded can be improved; and moreover a proper bending temperature of the inorganic glass and the optical property and the quality of the surface of the glass after being bent and transformed can be ensured.

Owner:SHENZHEN SANXIN JMT GLASS

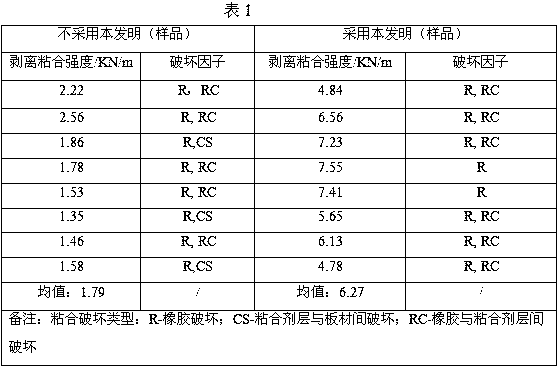

Stainless steel surface treatment method, silica gel and stainless steel bonding technology and product

InactiveCN108393805AImprove coating adhesionIncrease surface stressPretreated surfacesSpecial surfacesSand blastingSilica gel

The invention discloses a stainless steel surface treatment method. The stainless steel surface treatment method is characterized by comprising the following steps that degreasing, oil stains and impurities on the surface of a base material are removed by using a degreasing liquid; sand blasting, shot blasting treatment or sand blasting treatment is carried out on the surface of the base material,so that the surface state of the base material is uniform and consistent; dust removing, dust which is left on the surface of the base material after the sand blasting is carried out is removed; gluing, glue mucus uniformly coats the surface of the base material; and drying, a dried adhesive layer is formed on the surface of the base material. The stainless steel surface treatment method is usedfor carrying out surface treatment on stainless steel before bonding the silica gel with the stainless steel to change the characteristics of the surface of the stainless steel, good adhesion betweentwo inert materials of the silica gel and the stainless steel is realized, so that the bonding strength between the two inert materials of the silica gel and the stainless steel is greatly improved. The invention further provides the silica gel and stainless steel bonding technology and a product.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

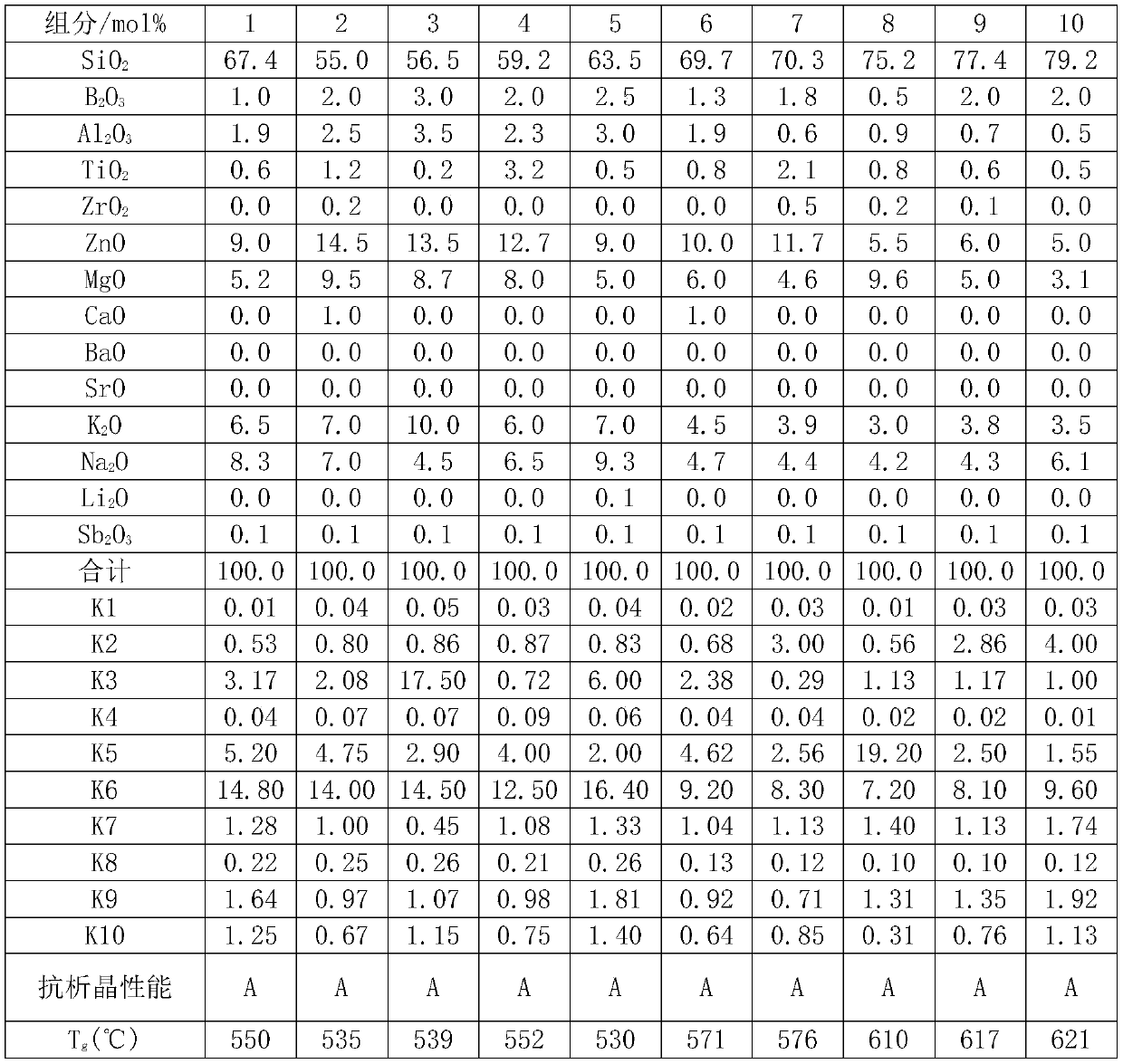

Glass and glass product

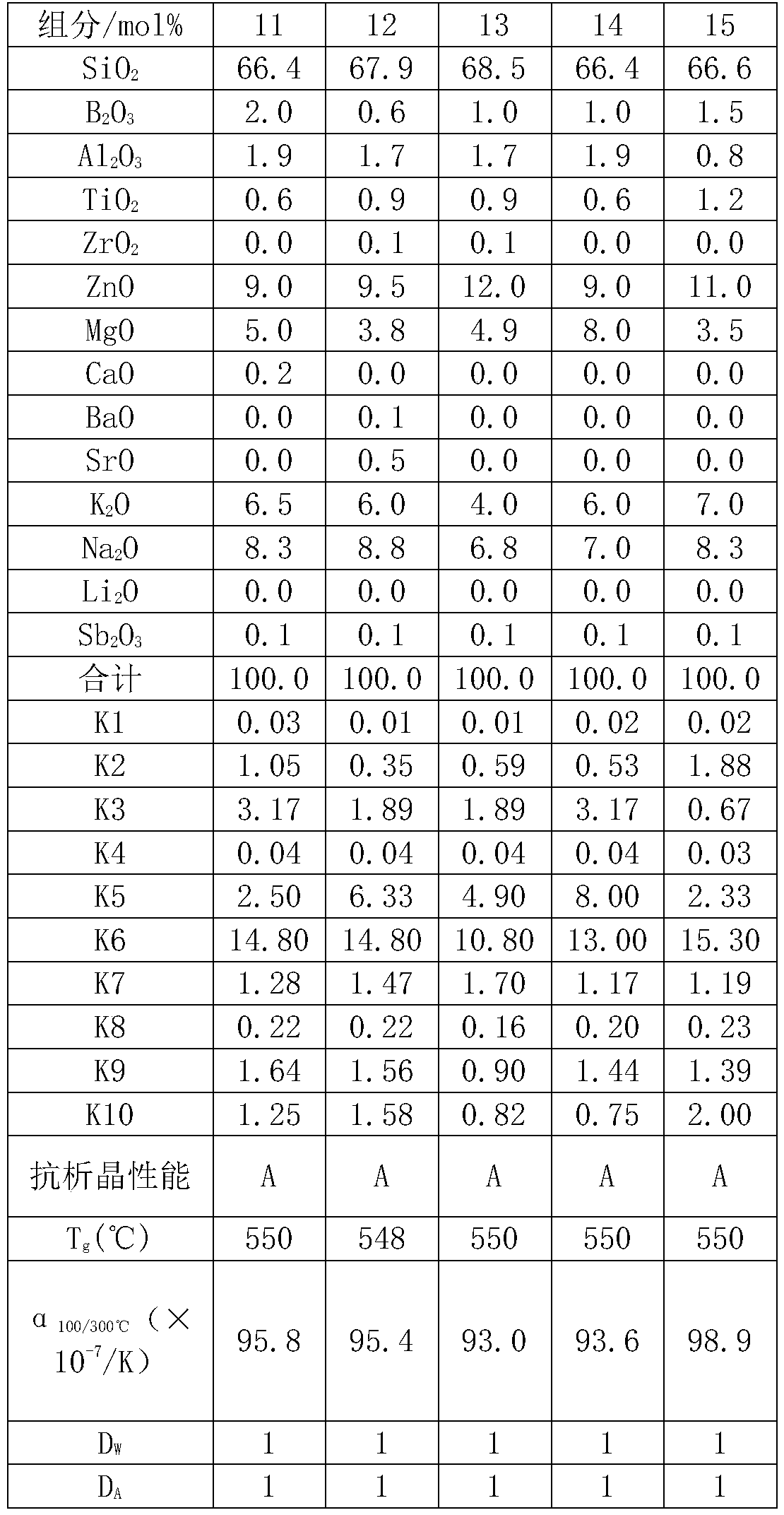

PendingCN109987839AImprove thermal shock resistanceHigh coefficient of thermal expansionOptical articlesGlass shaping apparatusSurface stressThermal expansion

A glass having a high coefficient of thermal expansion and excellent thermal shock resistance is prepared from the following raw materials in mole percentage: SiO2: 55-80%; B2O3: 0-10%; Al2O3: 0-10%;ZnO: 2-20%; MgO: 0-15%; Li2O+Na2O+K2O: not more than 30%. The glass obtained by the invention has higher thermal expansion coefficient and excellent thermal shock resistance through reasonable proportion of components. The glass of the invention is suitable for chemical strengthening, and the glass product obtained after chemical strengthening has larger surface stress and deeper stress layer depth.

Owner:CDGM OPTICAL GLASS

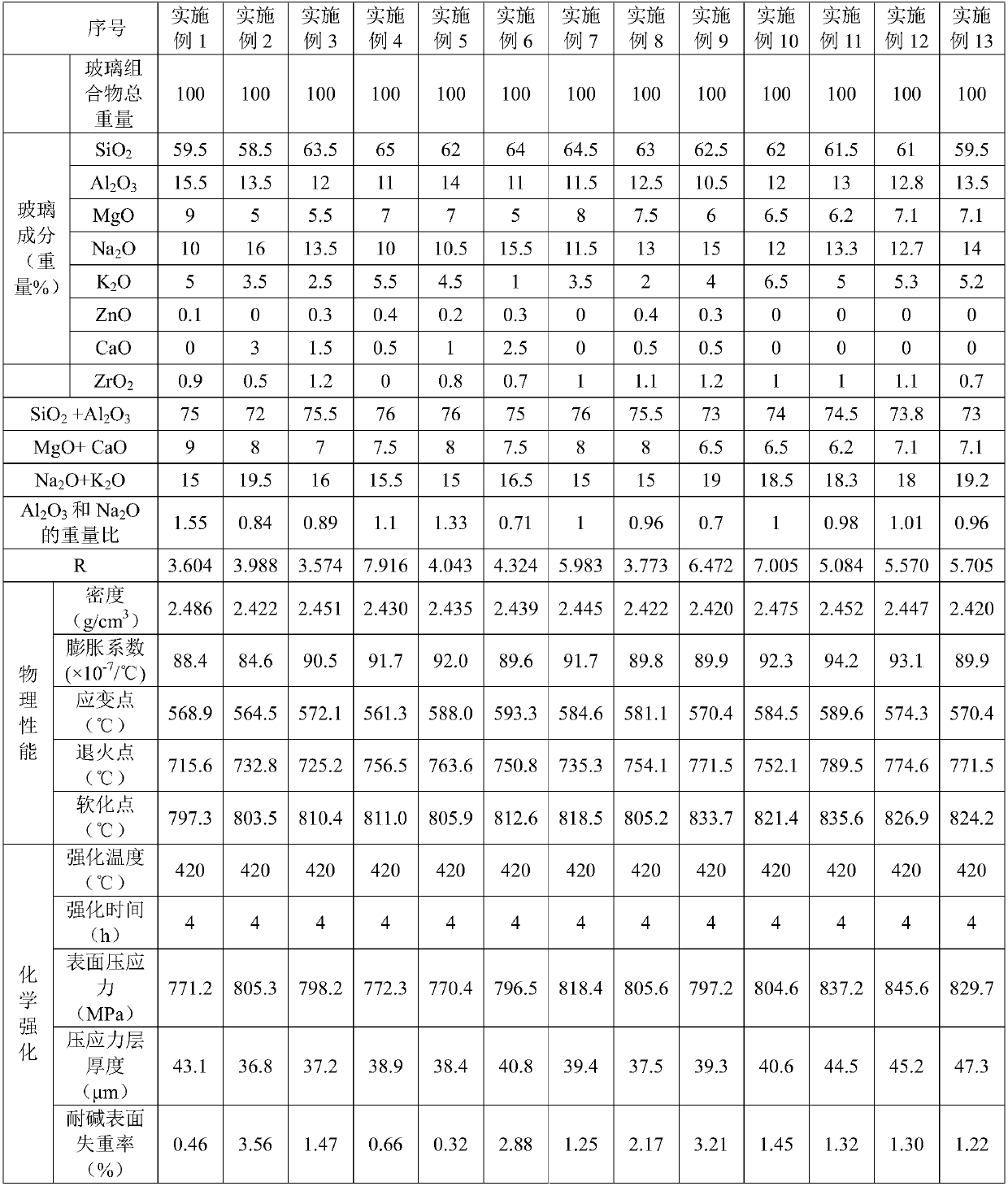

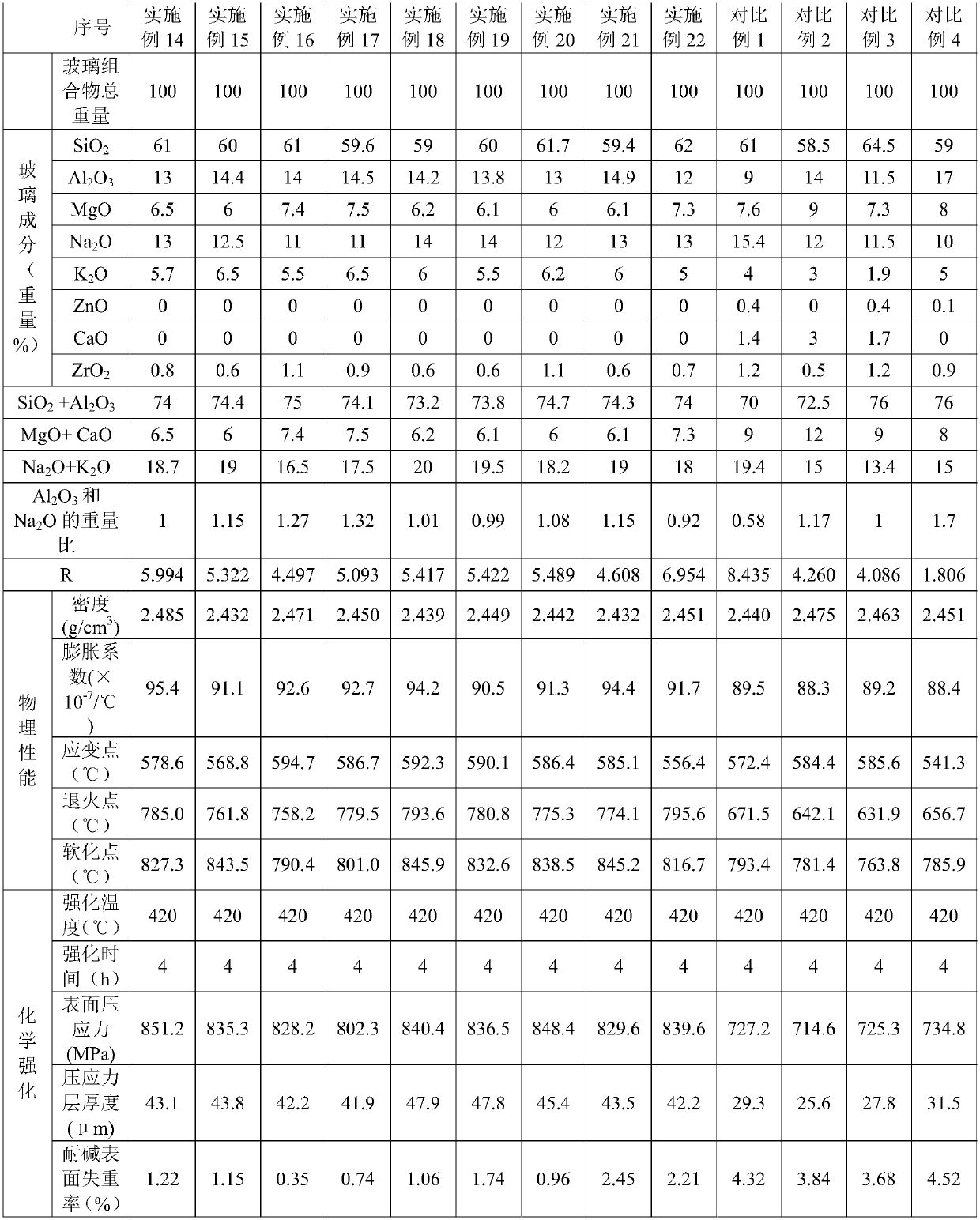

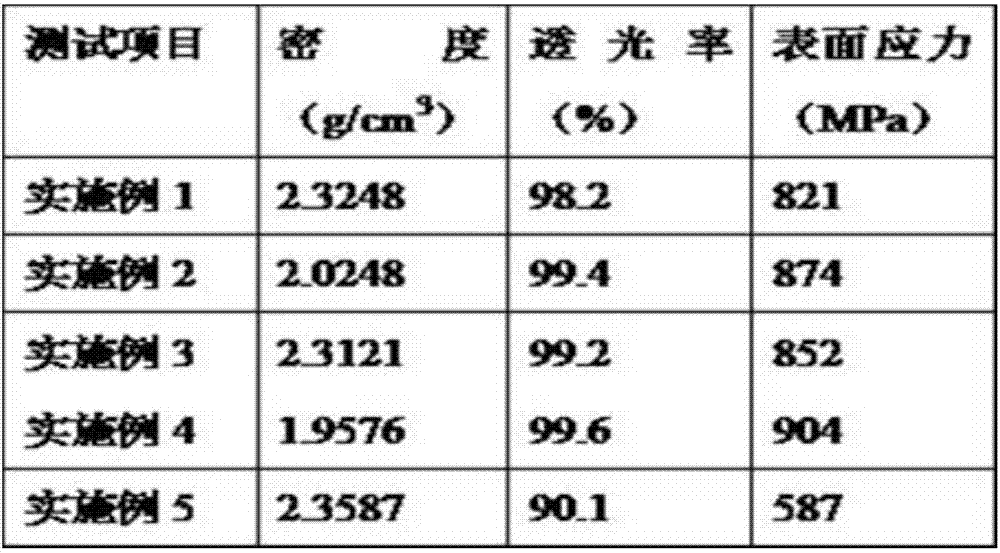

Chemically-reinforced cover plate glass, and preparation method thereof

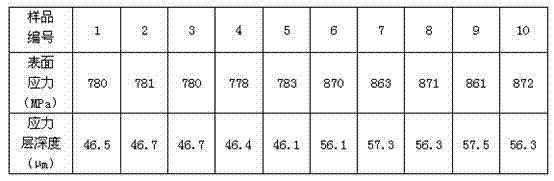

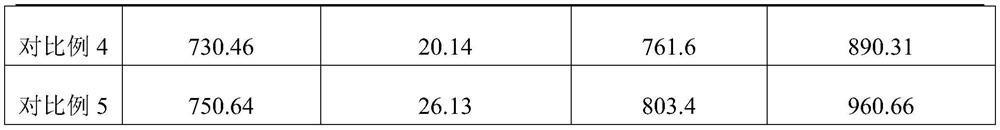

The invention relates to a chemically-reinforced cover plate glass, and a preparation method thereof. According to the preparation method, under heating conditions, a glass composition is subjected tomelting homogenizing, moulding, and annealing so as to obtain cover plate glass; the cover plate glass is dipped into a molten salt containing potassium ions for ion exchange so as to obtain the chemically-reinforced cover plate glass. The surface compressive stress of the chemically-reinforced cover plate glass ranges from 770 to 860MPa, and the compressive stress layer thickness ranges from 36to 50<mu>m; the chemically-reinforced cover plate glass is subjected to boiling in a 1mol / L NaOH solution for 10h, glass surface weight loss ratio is equal to or lower than 3.56wt%. According to the preparation method, the specific composition and the weight range of the glass composition are limited, chemical reinforcing technology is adopted, so that the obtained chemically-reinforced cover plate glass is relatively high in surface stress and stress layer thickness, the surface scratch-proofness of glass substrate obtained via chemical tempering is improved, dropping resistance and wear resistance are improved, and the alkali resistance is excellent.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

High-alumina glass with rapid ion exchange

InactiveCN109279787AIncrease intrinsic strengthImprove melting effectSurface stressChemical composition

The invention discloses high-alumina glass with rapid ion exchange. The high-alumina glass with rapid ion exchange comprises, in percent by molar, 55-65% of SiO2, 15-19% of Al2O3, 3-10% of Na2O, 1.5-5% of B2O3, 4-10% of P2O5, 4-7% of Li2O, 3-7% of MgO, 20-50% of SnO and the balance K2O. The intrinsic strength of the glass is improved through increase of the content of Al2O3 in the glass, and meanwhile the chemical tempering property and melting property of the glass are further improved through reasonably adjustment of the content of Li2O and P2O5 in the glass, so that surface stress and a deeper stress layer of the glass are obtained in a short time; and meanwhile a double stress layer on the glass surface can be obtained through chemical reinforcement, and the glass can be used as protective glass for mobile phones and other touch screen-containing electronic products.

Owner:KORNERSTONE MATERIALS TECH

Tempered glass processing technology

InactiveCN105948472AIncrease surface stressImprove toughnessGlass tempering apparatusGlass productionSurface cleaningFree cooling

The invention discloses a tempered glass processing technology. The processing technology mainly comprises the following steps of glass surface cleaning, glass preheating, silicon dioxide powder spraying on the glass surface, high power heating on glass, cooling liquid spraying for cooling and natural cooling. According to the tempered glass processing technology, the production technology is simple, the made tempered glass has high surface stress and toughness, and the yield is increased; meanwhile, cooling is conducted by adopting a cooling liquid, the cooling speed can be increased, and the tempered glass cannot burst.

Owner:HENAN HUANYU GLASS TECH CO LTD

Chemical tempering method for glass

The invention discloses a chemical tempering method for glass. The chemical tempering method mainly comprises the following steps: preheating aluminosilicate glass at 100-300 DEG C for 1-3 hours; immersing a first preheated part into a first molten salt, and carrying out primary ion exchange for 5-6 hours at the temperature of 410-420 DEG C; rising an obtained first tempered part for dripping saltfor 10-20 minutes; annealing the first tempered part for 2-3 hours to reduce the temperature to be lower than 100 DEG C; standing an obtained first annealed part for 10-30 min, and preheating the first annealed part for 1-3 h at the temperature of 100-300 DEG C; immersing a second preheated part into a second molten salt, and carrying out primary ion exchange for 10-20 minutes at the temperatureof 380-400 DEG C; rising a second tempered part for dripping salt for 10-20 minutes; and carrying out direct drop annealing on the second tempered part to finish tempering. According to the chemical tempering method, the thickness of a stress layer is increased by adopting a relatively high temperature in the first tempering process, and the surface stress is increased by adopting a relatively lowtemperature and an annealing direct drop mode in the second tempering, so that the strength is ensured, the time required by tempering is greatly shortened, frequent replacement of molten salt is avoided, the cost is reduced, and the efficiency is improved.

Owner:北海市龙浩光电科技有限公司

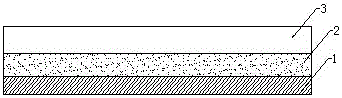

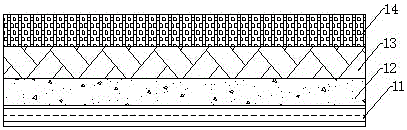

Decoration panel with concealed touch control display function, and preparation method thereof

ActiveCN106066734AWith invisible touch display functionImprove consistencyInput/output processes for data processingPrinting inkEngineering

The invention relates to a decoration panel with a concealed touch control display function. The decoration panel comprises a decoration glass panel which is provided with a concealed window and is disposed at a bottom layer, a touch control membrane arranged on the decoration glass panel, and a display module which is arranged on the touch control membrane and is provided with a decoding deck, wherein the decoration glass panel comprises a toughened glass panel, a high-transmittance decoration film layer, a high-transmission high-reflection nonconductive plated film layer and a printing ink layer with a window, which are successively arranged from bottom to top. The decoration panel with the concealed touch control display function is mainly realized through an attaching mode. The decoration panel with the concealed touch control display function has the following advantages: the decoration panel with the concealed touch control display function is composed of the decoration glass panel, the touch control membrane and the display module, the decoration panel is enabled to have the concealed touch control display function, and while needed functions can be used through concealed touch control, the decoration effect is good.

Owner:JIANGSU FANHUA GLASS CO LTD

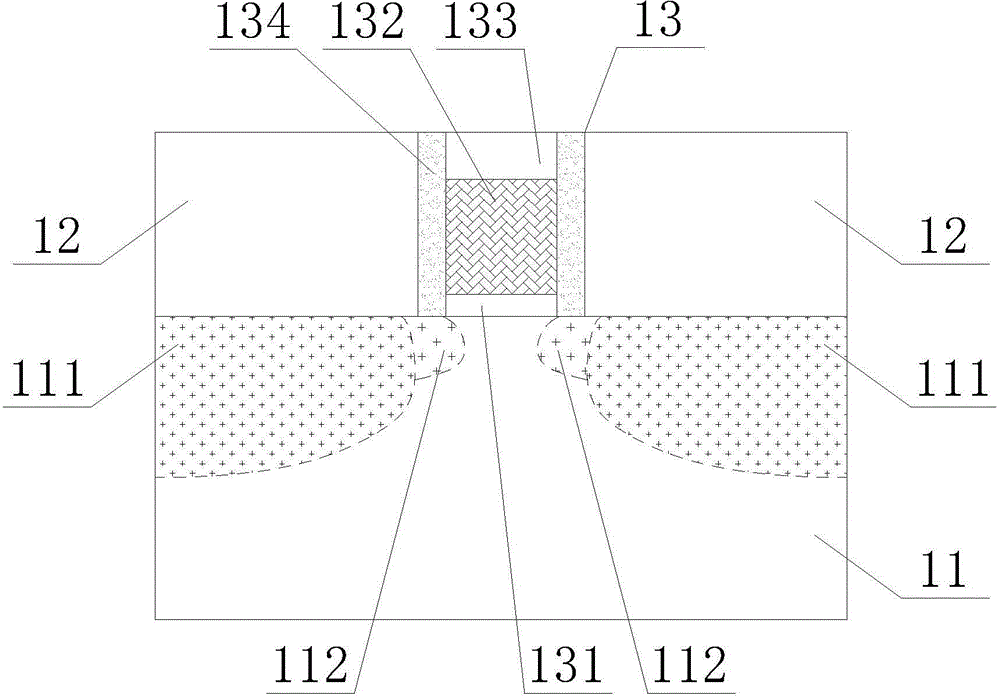

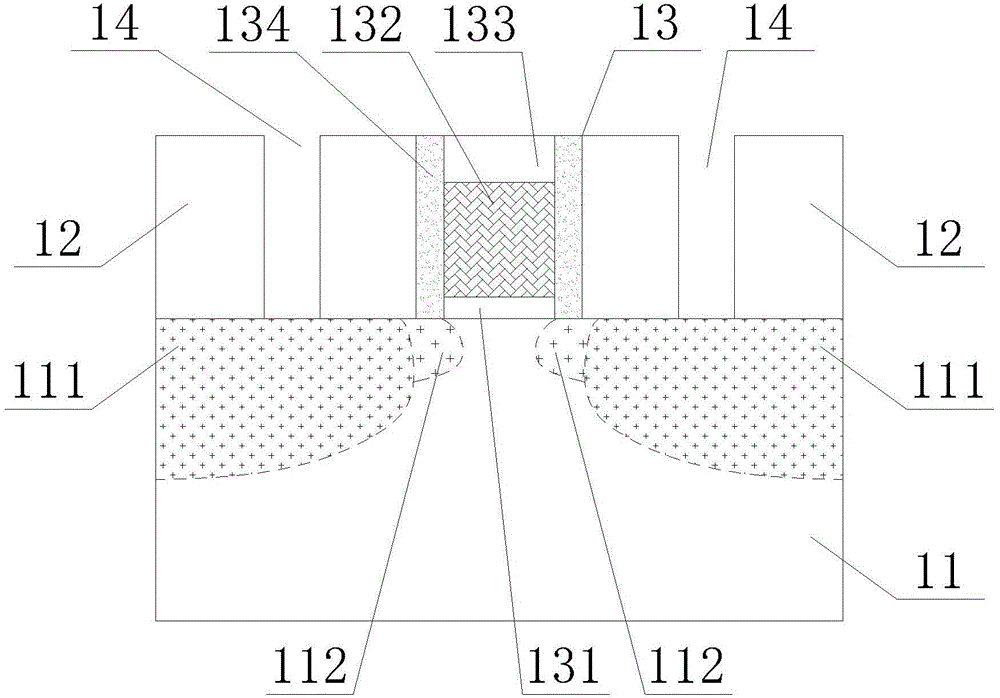

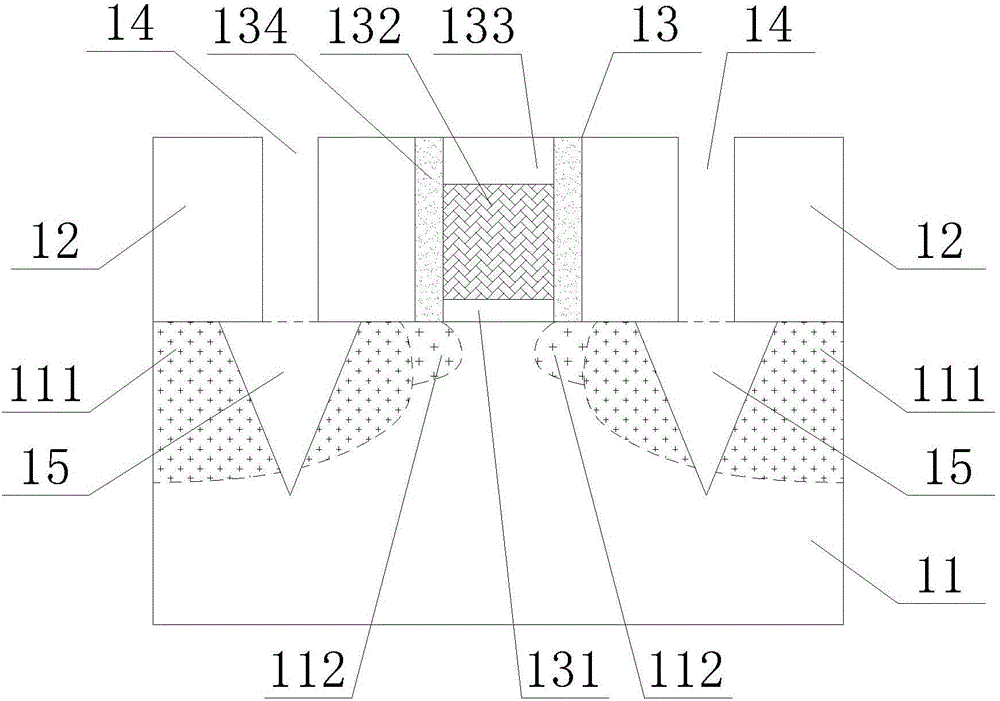

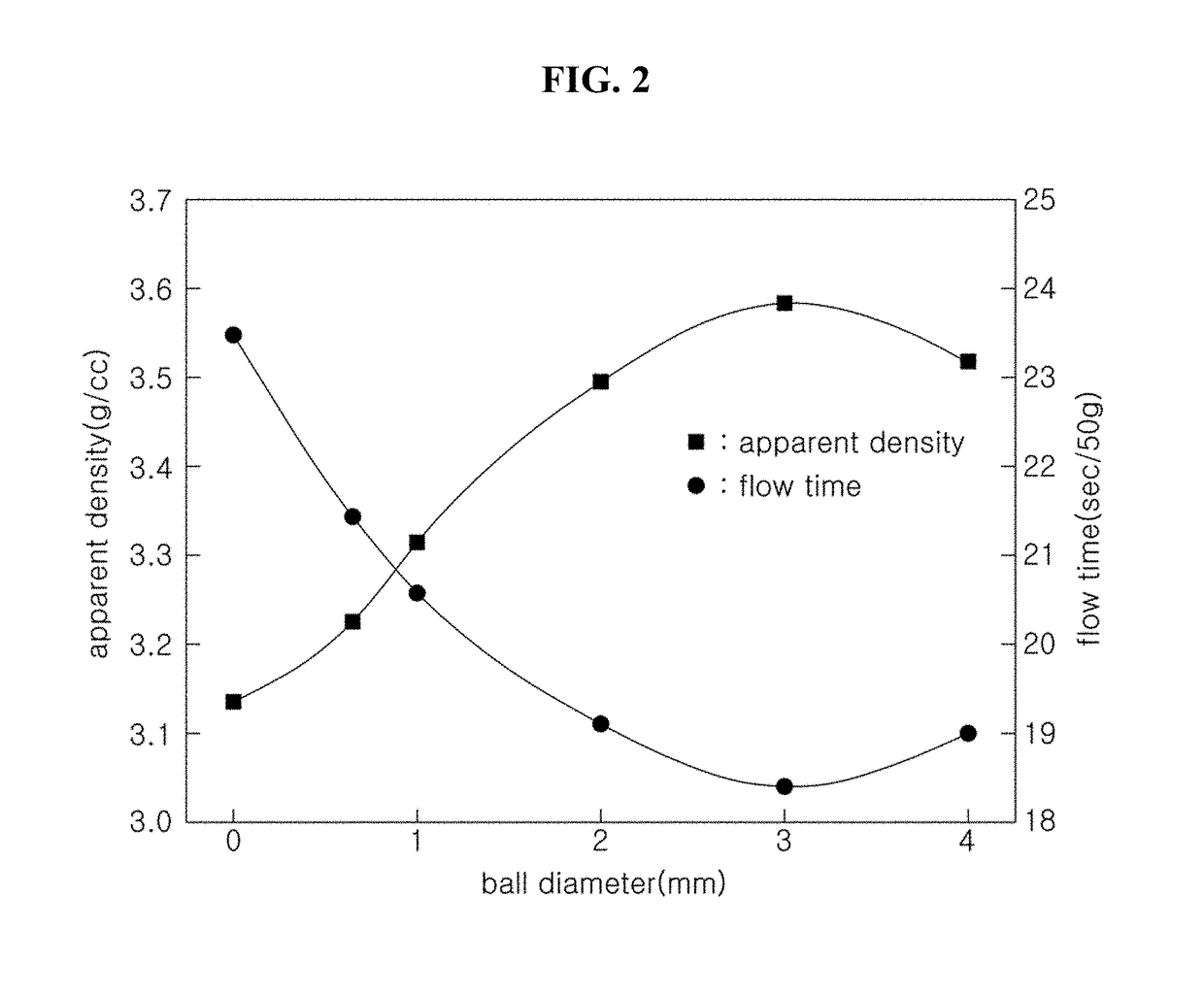

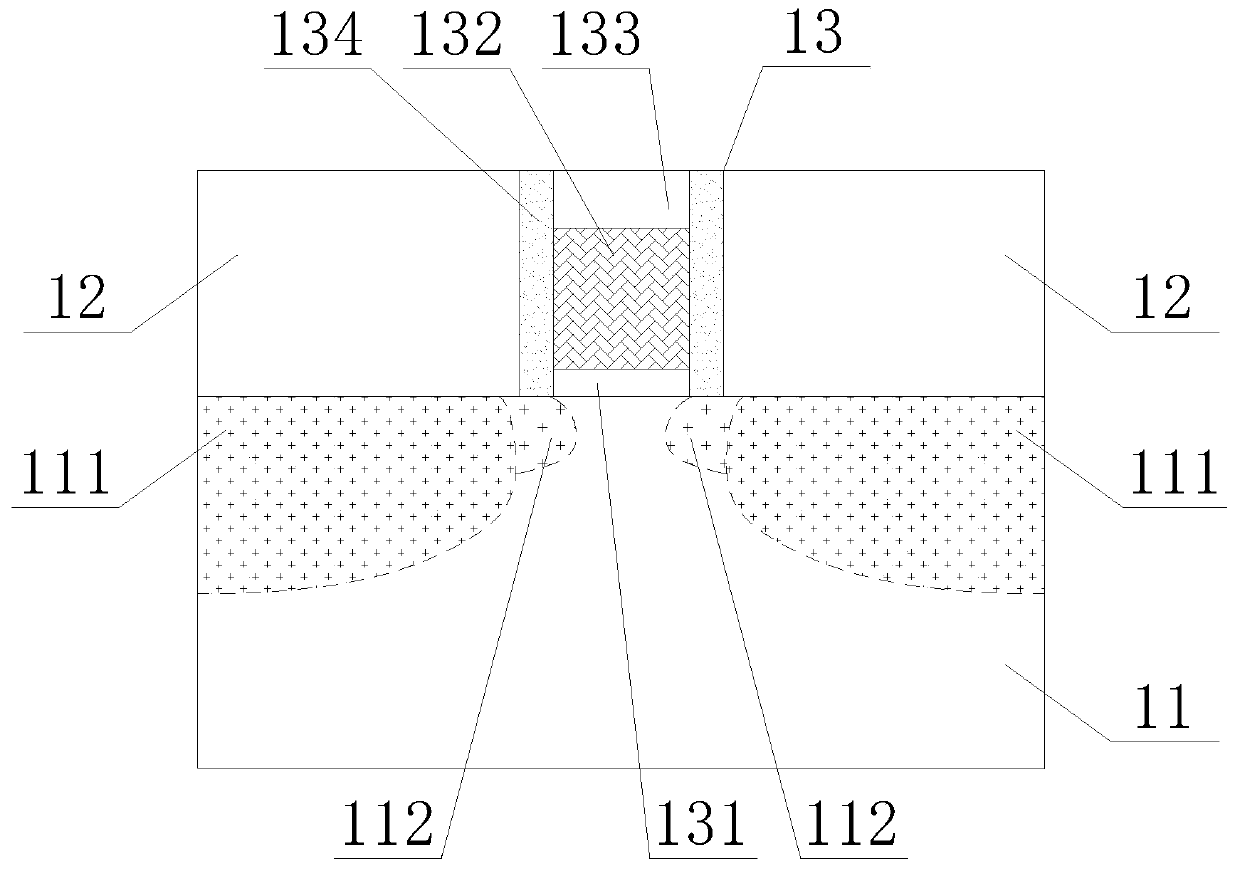

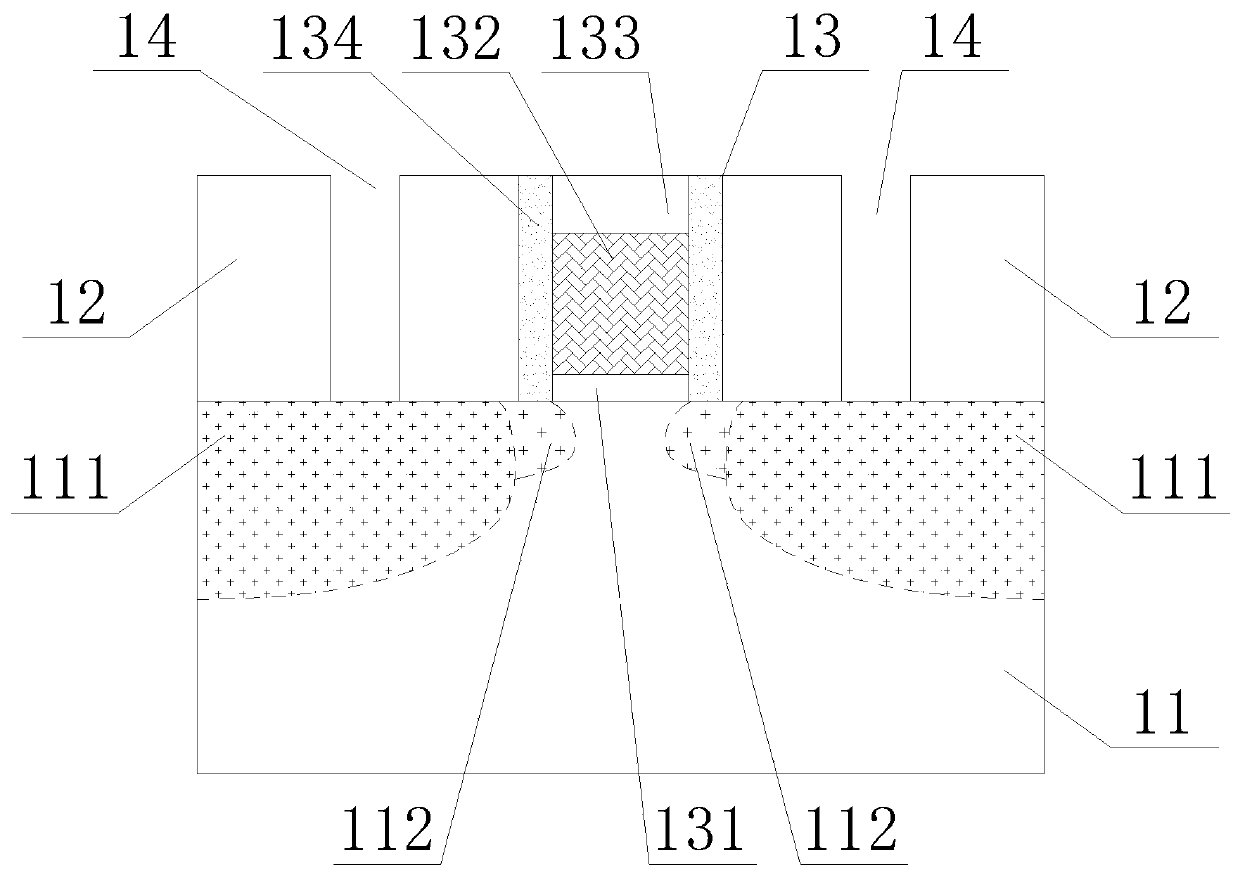

Method of preparing ESD device, and ESD device

ActiveCN105990230AOptimizing trigger voltageImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingEtchingShort-channel effect

The invention relates to the technical field of semiconductor manufacturing, and specifically relates to a method of preparing an ESD (Electro-Static Discharge) device and an ESD device. The method of preparing an ESD device comprises the steps: based on a traditional method of preparing an MOS device (such as a PMOS or EMOS device), implanting ESD ions into a mask to open a dielectric layer above a source / drain area; utilizing a wet etching process to form a wide-top and narrow-bottom V type groove in a silicon substrate; and generating two epitaxial layers with different ion doping concentration in the V type groove continuously to form a triangular epitaxial stress layer (namely, a bottom epitaxial layer) in the source / drain area so as to realize the aim of enhancing the channel surface stress and optimizing the ESD trigger voltage on the premise of not performing the ESD ion implantation process and to greatly improve the performance of the ESD device while the device SEC (Short-Channel Effect) can be effectively improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Preparation method of flexible ultrathin glass

InactiveCN110156320AHigh strengthImprove toughnessGlass shaping apparatusGlass tempering apparatusUltimate tensile strengthToughness

The invention discloses a preparation method of flexible ultrathin glass. The glass is prepared from SiO2, Al2O3, Na2O, K2O, MgO, P2O5, B2O3, Sb2O3, Er2O3 and SrF. The above substances are melted at ahigh temperature to form homogeneous and synergistic effects, so the excellent characteristics of the substances are effectively reflected, and the strength and the toughness of the flexible ultrathin glass is effectively enhanced.

Owner:KAYMAO TECH SHENZHEN

Shaft machining technology capable of reducing heat treatment bend amount

InactiveCN107127532AReduce heat treatment warpageImprove surface roughnessSurface roughnessEngineering

The invention provides a shaft machining technology capable of reducing the heat treatment bend amount. The machining technology at least comprises the following steps of blanking, turning, heat treatment and grinding. The surface roughness of a semi-finished shaft prepared during turning is smaller than or equal to 6.3. By the adoption of the machining technology, shaft bend and deformation which is 0.35 MAX originally is reduced to 0.10 MAX after heat treatment, accordingly, grinding time is shortened, the working efficiency is improved, and the material utilization rate is also improved.

Owner:SHANGHAI XIANGMING BEARING

Processing technique of glass for sightseeing train

InactiveCN106477865AHigh strengthImprove flatnessCoatingsGlass tempering apparatusSurface stressToughened glass

The invention discloses a processing technique of glass for a sightseeing train. The processing technique comprises the following several steps of (1), cutting and edge grinding: cutting the glass, and then carrying out edge grinding treatment, (2), cleaning: cleaning the glass until a surface has no smirch and no water stain; (3), tempering. By using the processing technique provided by the invention, through carrying out preheating in advance before the tempering, and adopting the high-temperature quick tempering at the same time, the strength of tempered glass is improved, the time of the technique is shortened; the production efficiency is improved; after being tempered, the glass is soaked in a protective solution; the smoothness of the surface of the tempered glass is improved; meanwhile, the surface stress of the tempered glass is improved; the glass is suitably used for a train.

Owner:SUZHOU DACHENG ELECTRIC TECH CO LTD

Anti-impact tempered glass, preparation method of anti-impact tempered glass and display terminal

ActiveCN107793039AHigh impact strengthReduce warpageCoatingsInput/output processes for data processingToughened glassLight transmission

The invention relates to the field of glass processing, and discloses anti-impact tempered glass, a preparation method of the anti-impact tempered glass and a display terminal. The preparation methodof the anti-impact tempered glass comprises the following steps of enabling tempered glass to be in contact with silicon oil; then, cleaning glass by a solution; performing drying. The anti-impact glass prepared by using the method has the advantages that on the basis of not influencing the light transmission rate of the glass, the tempering performance and the anti-impact performance of the glasscan be improved; the preparation method is simple and convenient; the raw material cost is low.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Modified glass for thin-film solar cells, and preparation method of modified glass

InactiveCN107151102AHigh light transmittanceLight in massPhotovoltaic energy generationSemiconductor devicesFiberAntioxidant

The invention discloses modified glass for thin-film solar cells, and a preparation method of the modified glass. The modified glass is prepared from the following components: silicon dioxide, aluminum oxide, sodium oxide, potassium carbonate, zinc oxide, borax, sodium borate, cobalt oxide, sodium chloride, graphite, manganese powder, quartz sand, nickel oxide, calcium oxide, chromium oxide, bamboo fibers, sodium hydroxide and an antioxidant. The preparation method comprises the steps of putting the silicon dioxide, the aluminum oxide, the sodium oxide, the potassium carbonate, the zinc oxide, the borax, the sodium borate, the cobalt oxide, the sodium chloride, the graphite, the manganese powder, the quartz sand, the nickel oxide, the calcium oxide and the chromium oxide into a reaction kettle, heating up to 500-700 DEG C, and then carrying out plasma treatment to obtain a first mixture; mixing the bamboo fibers with the sodium hydroxide, soaking the obtained mixture at low temperature for 24-34h, then adding the soaked mixture into the first mixture, adding the antioxidant, and evenly stirring to obtain a second mixture; sintering the second mixture at high temperature. After being modified, the glass is good in mechanical properties and high in surface stress, thus being suitable for serving as components of the thin-film solar cells.

Owner:JURONG GCL SYST INTEGRATION TECH CO LTD

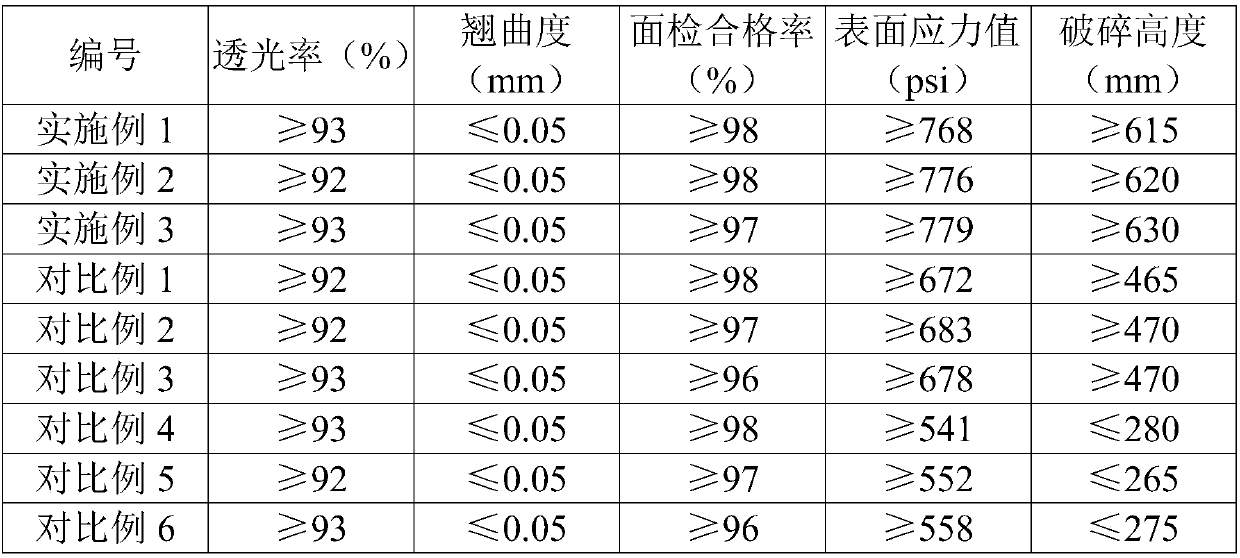

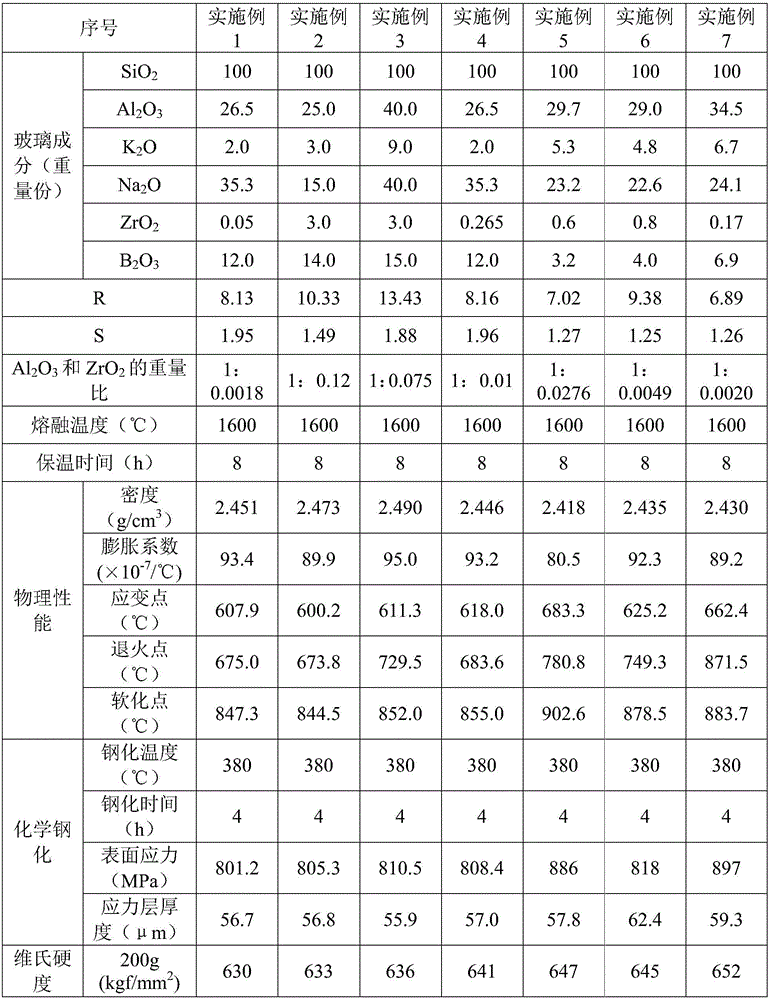

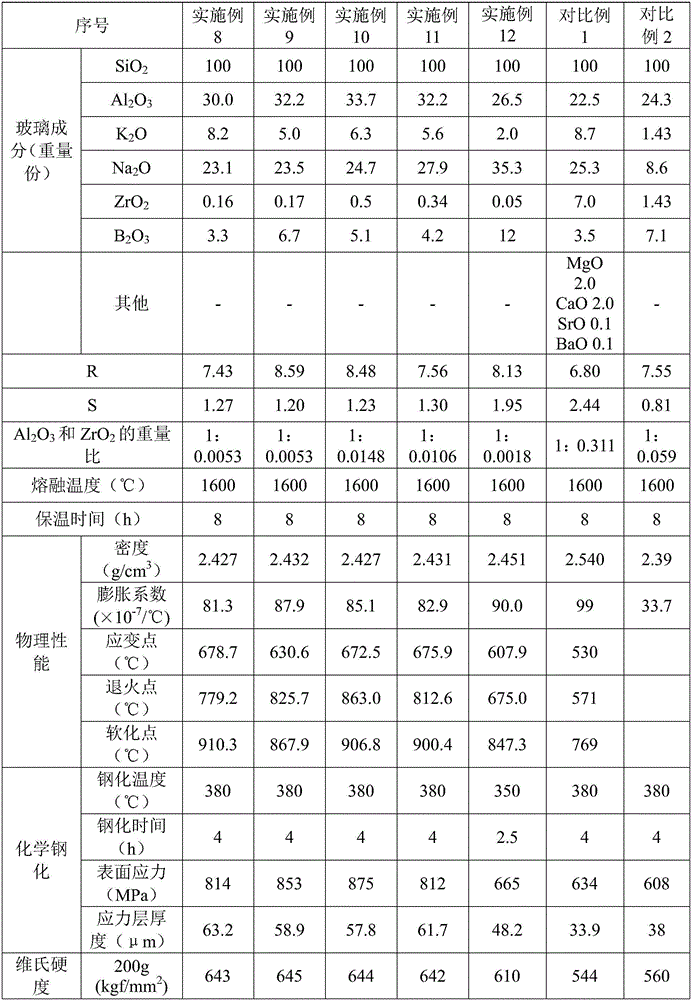

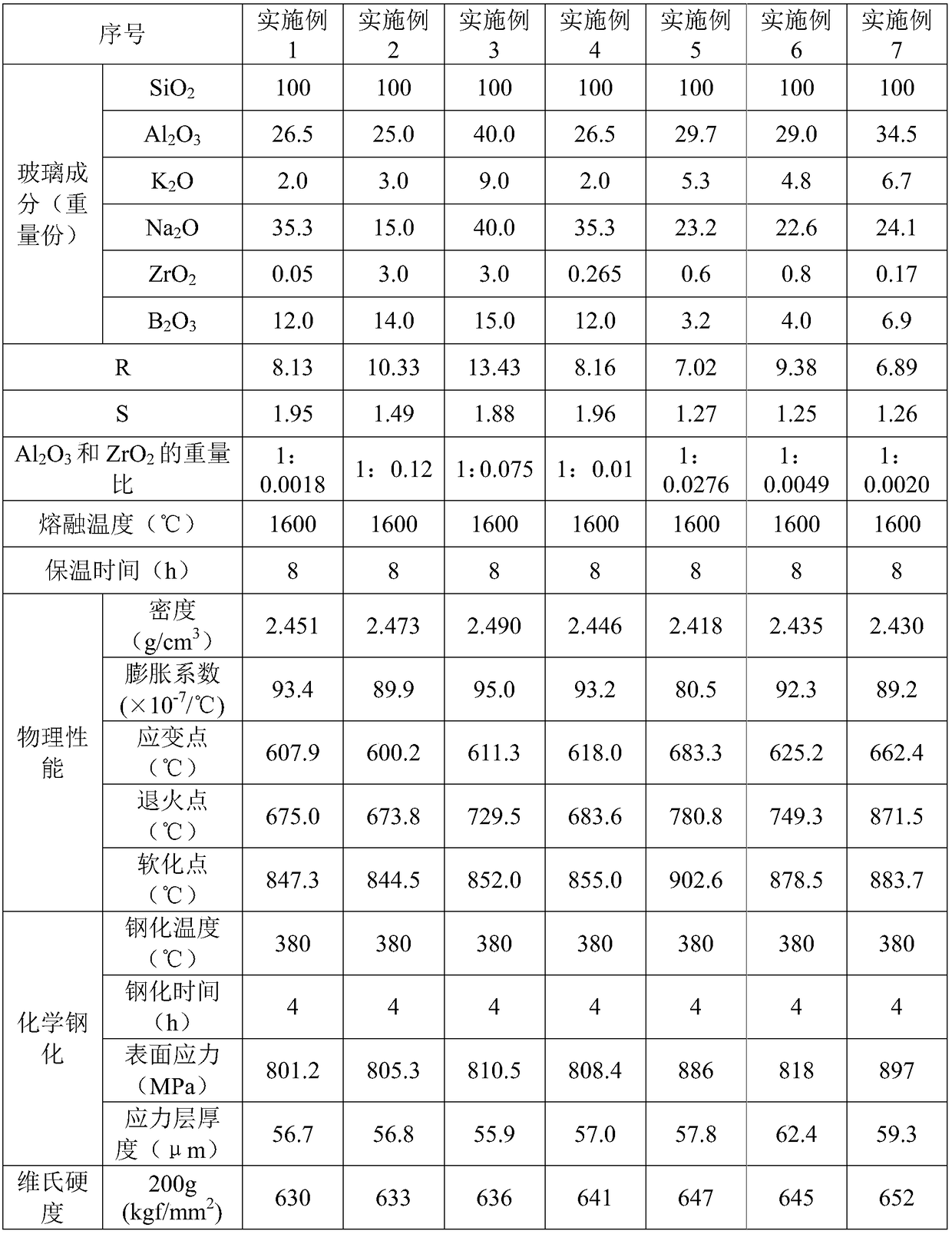

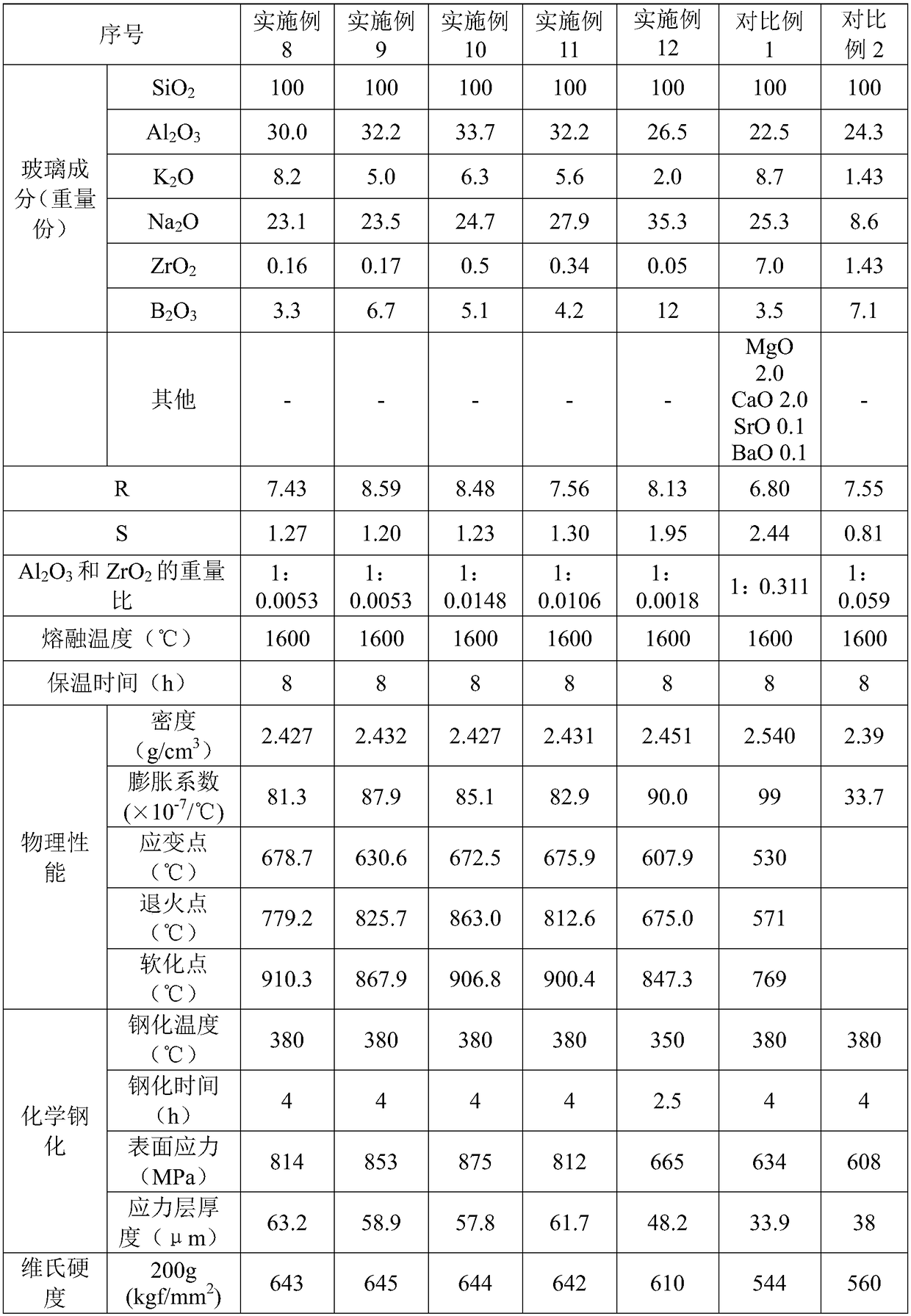

Glass composition, glass substrate and chemical strengthening method thereof

ActiveCN106517770AIncrease surface stressImprove surface scratch resistanceHardnessMelting temperature

The invention relates to a glass composition, a glass substrate and a chemical strengthening method thereof. The composition contains SiO2, Al2O3, K2O, Na2O, ZrO2 and B2O3, wherein relative to 100 parts by weight of SiO2, the Al2O3 content is 25-40 parts by weight, the K2O content is 1-9 parts by weight, the Na2O content is 15-40 parts by weight, the ZrO2 content is 0.05-3 parts by weight, and the B2O3 content is 1-15 parts by weight; and R is calculated to be 6.87-13.89 according to the formula below: R=0.206w(Al2O3)+0.17w(K2O)-0.006w(Na2O)+0.13w(ZrO2)+0.37w(B2O3).Since the disclosed composition has the defined specific components and content ranges thereof, glass prepared from the composition has high strain point and softening point and low melting temperature, has excellent chemical strengthening property, and can be used for preparing the chemically-strengthened glass substrate. The surface of the chemically-strengthened glass substrate prepared according to the method has high surface stress and hardness, so that the surface scratch resistance of the chemically-strengthened glass substrate is improved, thereby ensuring that the chemically-strengthened glass substrate can resist the effect of external forces such as fall, abrasion and the like.

Owner:TUNGHSU GRP

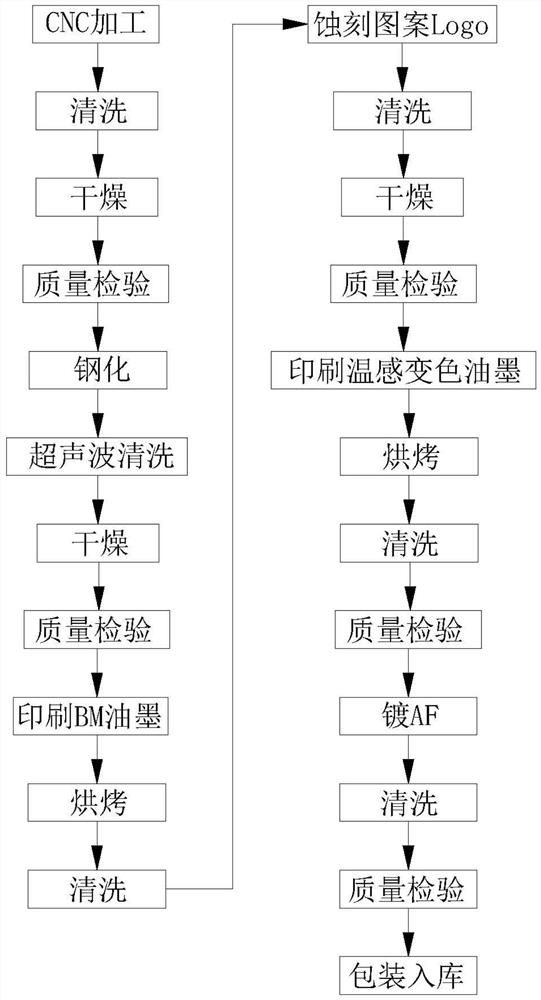

Manufacturing method of temperature sensing computer keyboard touchpad glass

The invention discloses a manufacturing method of temperature sensing computer keyboard touchpad glass. The method comprises the following steps: step 1, putting a touch panel glass raw material on a numerical control machine tool for CNC (Computer Numerical Control) processing; step 2, putting the glass substrate into a toughening furnace for toughening treatment; step 3, sequentially immersing the glass substrate into a chemical washing tank I and a chemical washing tank II for ultrasonic cleaning, rinsing the glass substrate subjected to ultrasonic cleaning by a countercurrent method, washing off the cleaning agent attached to the glass substrate, and then drying and inspecting the quality of the glass substrate which is rinsed to be clean; step 4, screen printing of BM ink and etching of a pattern Logo are carried out; step 5, silk-screen printing of temperature-sensitive color-changing ink; step 6, coating the surface of the glass substrate by using AF liquid medicine to form a touch panel glass finished product; and step 7, performing final quality inspection on the touch panel glass finished product, and packaging and warehousing the touch panel glass finished product. The touch panel glass has the beneficial effect that the surface color of the touch panel glass can be changed along with the change of temperature.

Owner:杭州万程科技有限公司

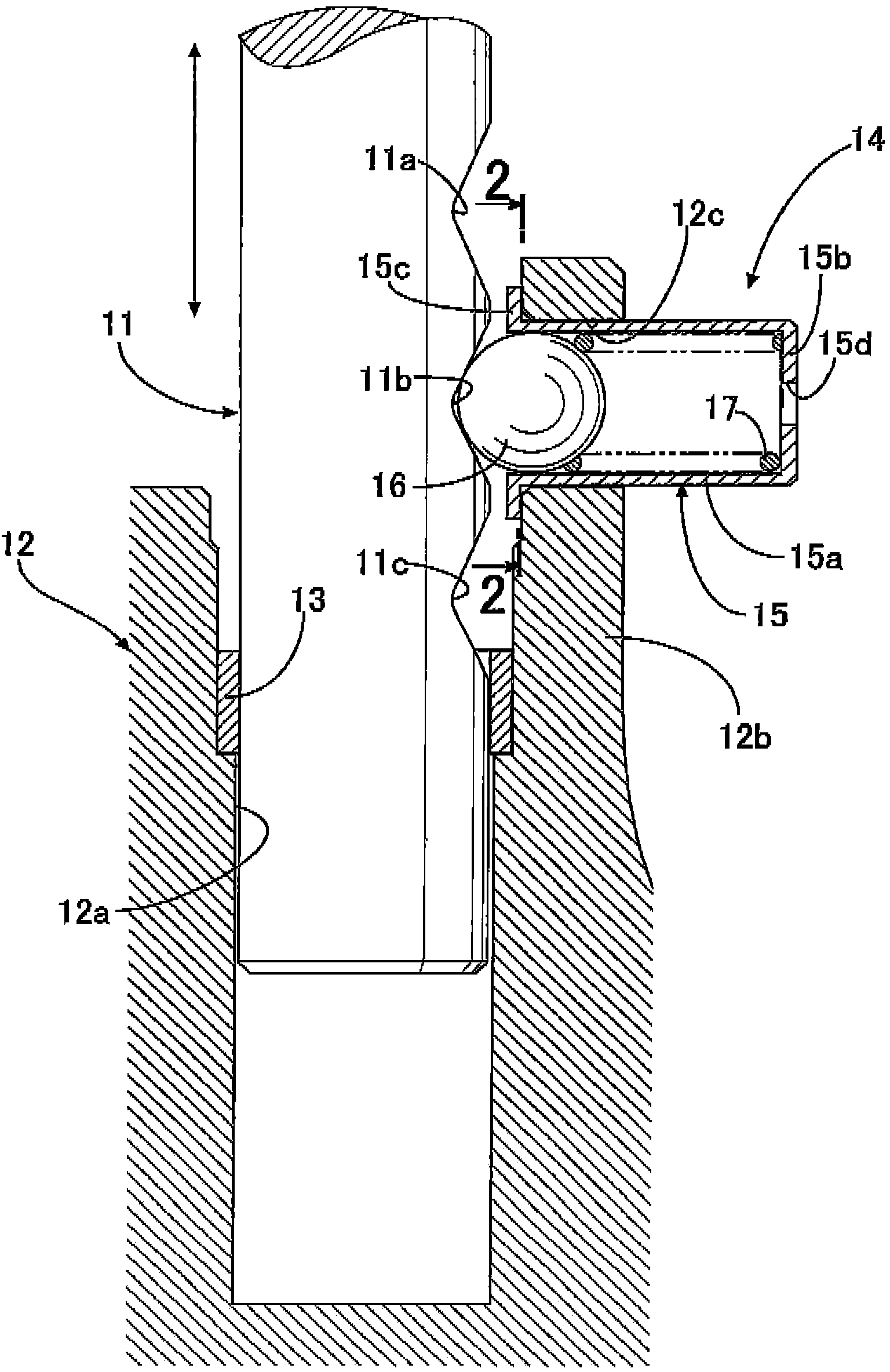

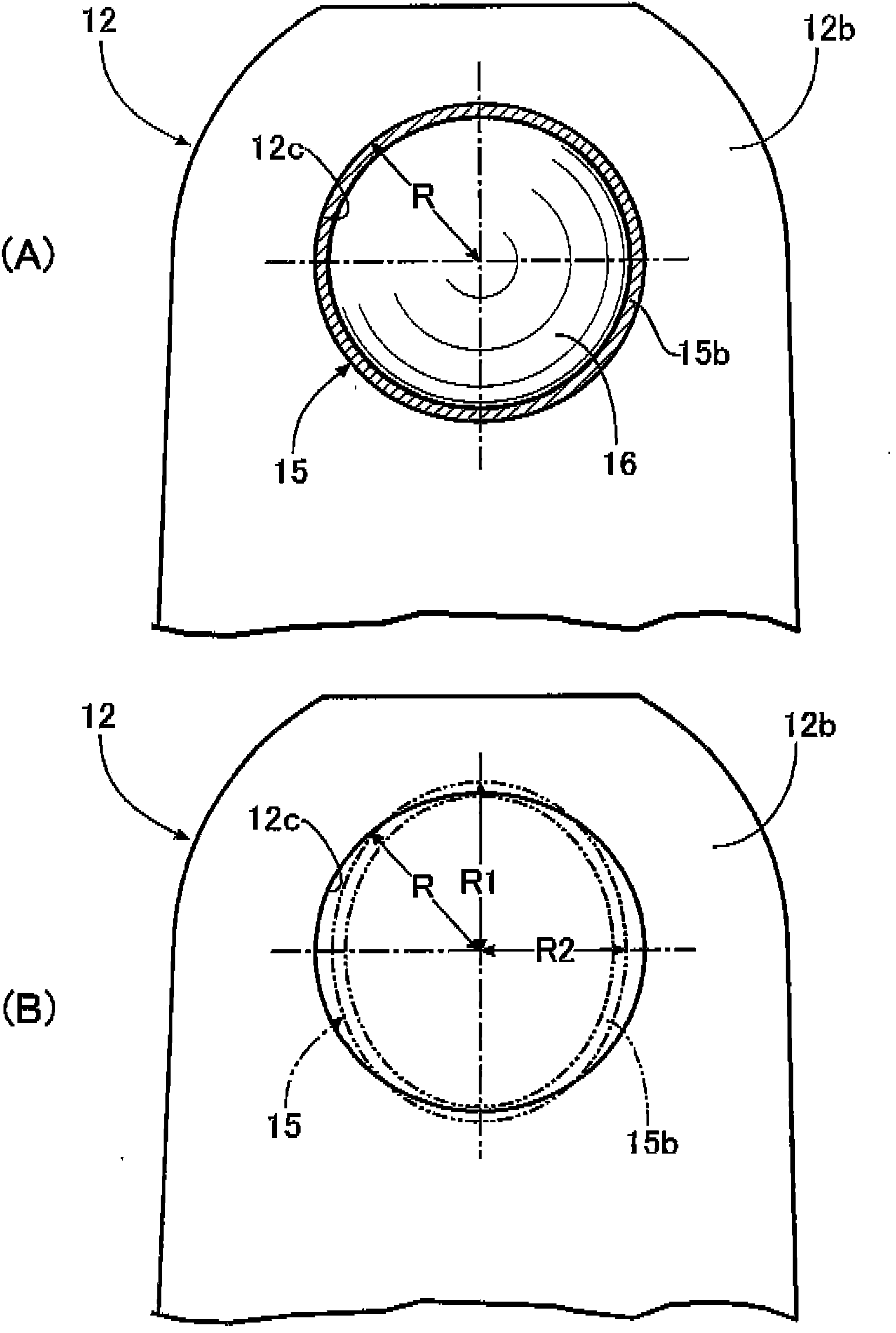

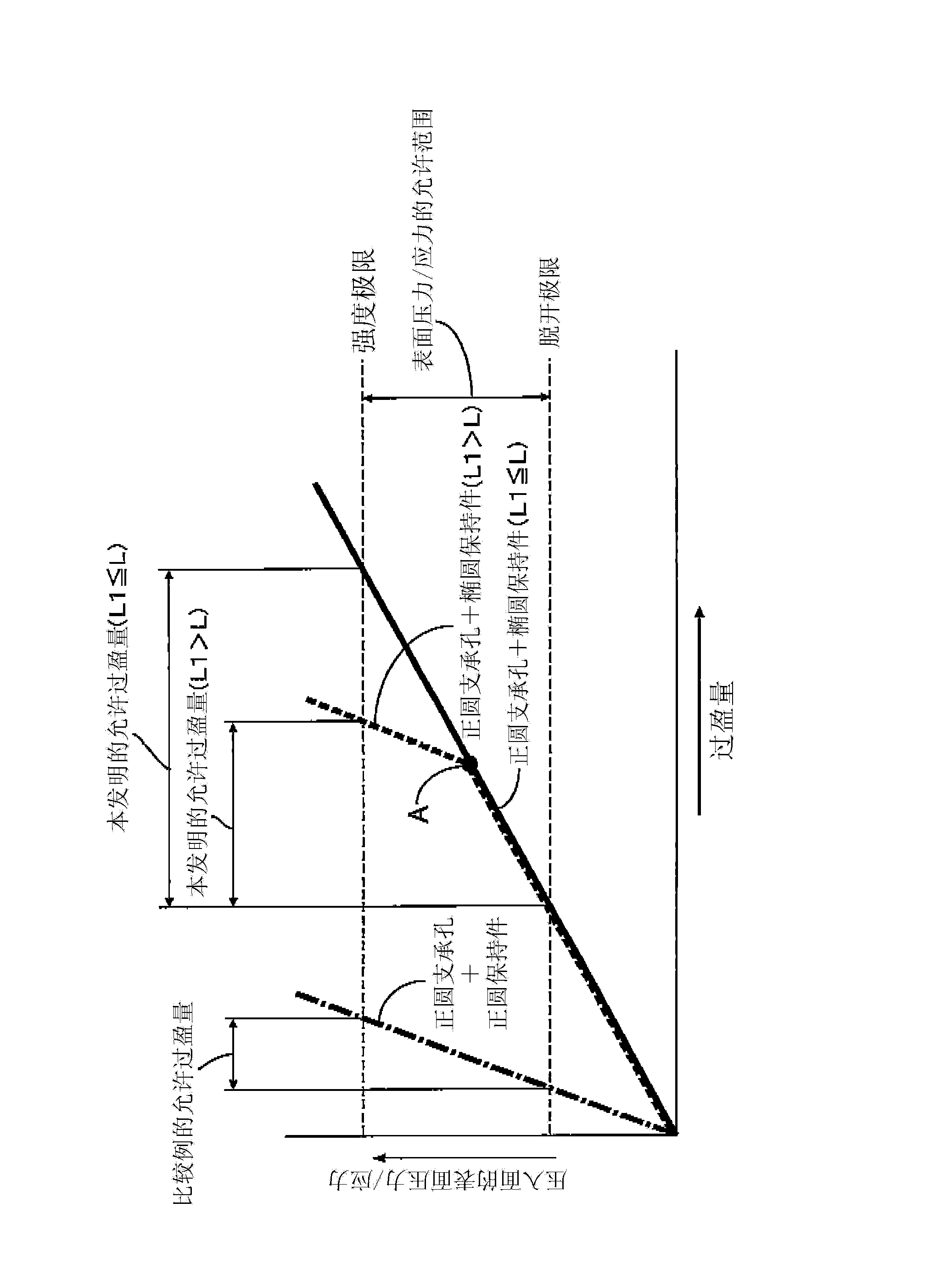

Locking device

ActiveCN103513696AAvoid breakingInhibit sheddingGearing controlLimiting/preventing/returning movement of partsSurface pressureEngineering

The invention provides a locking device which can enable the degree of freedom of setting of the magnitude of interference between a retainer of the locking device and a support hole of a housing to be increased. When the section shape of an internal circumference surface of the support hole (12c) of the housing (12) coincides with the section shape of a peripheral surface of the retainer (15) of the locking device (14) with centers being coincident, the section shape of the inner circumference surface passes through an inner side and an outer side of the section shape of the periphery surface, thus, in the process of pressing-in, the section shape of the periphery surface of the retainer (15) deforms to adapt to the section shape of the internal circumference surface of the support hole (12c), thus proper surface pressure (stress) is generated on a pressing-in surface, and the housing (12) can be prevented from cracking and the retainer (15) can be prevented from dropping. Thus, even if the housing (12) is made of aluminium material and the retainer (15) is made of iron material and difference exists in thermal expansivity, the degree of freedom of setting of the magnitude of interference between the two can be increased.

Owner:HONDA MOTOR CO LTD

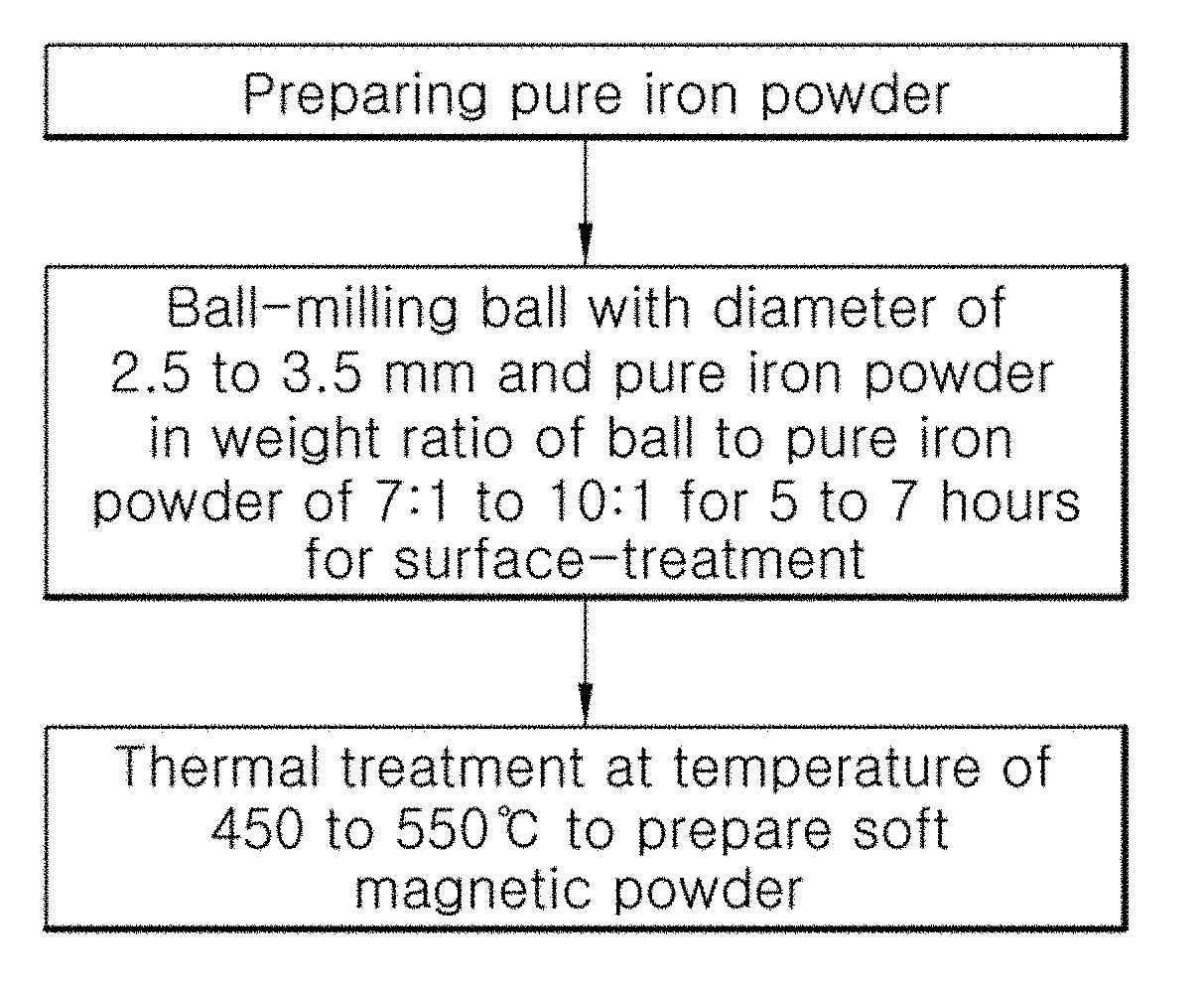

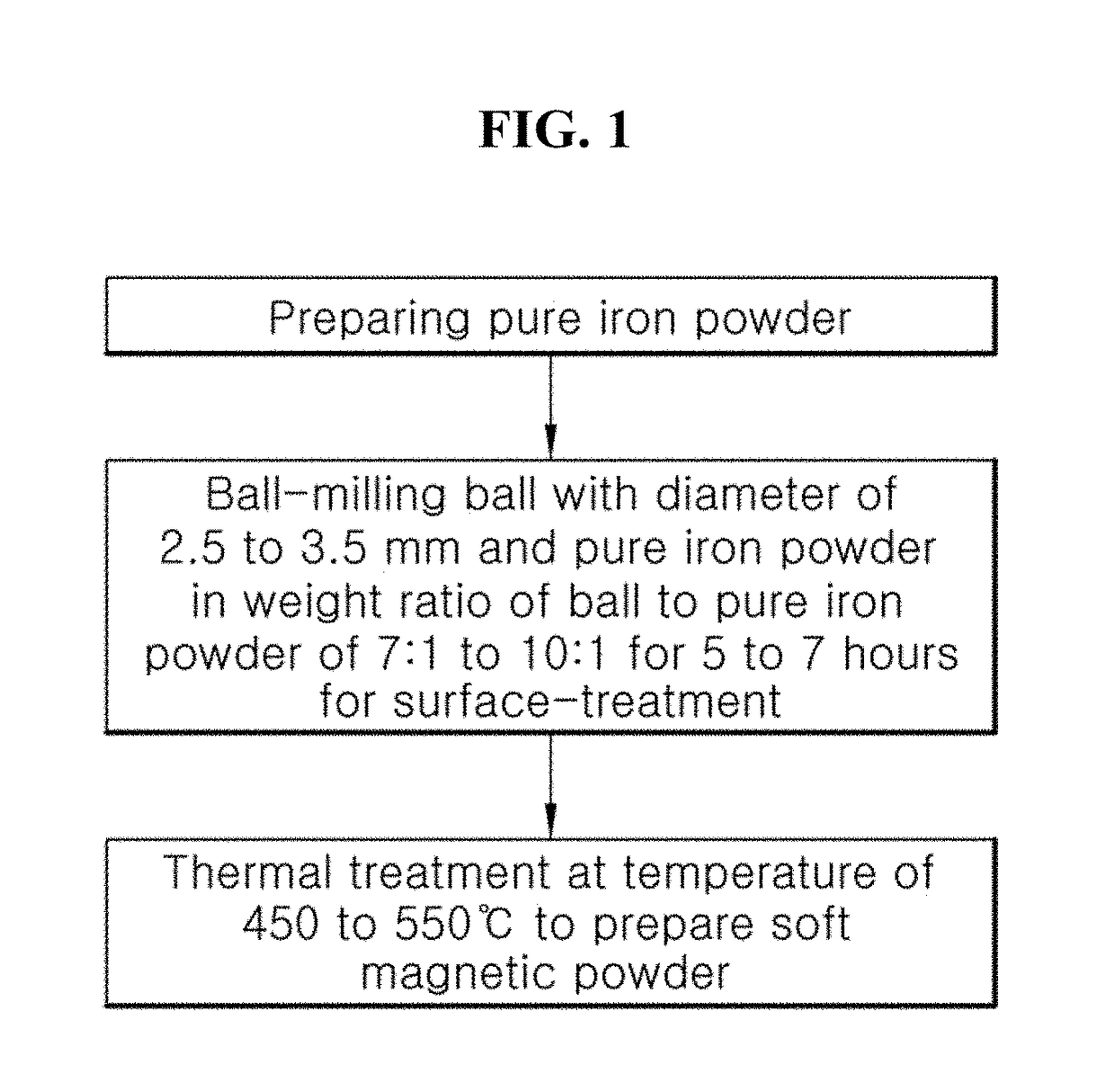

Method of producing soft magnetic powder

InactiveUS20180151294A1Excellent saturation flux densityLess core lossTransportation and packagingMetal-working apparatusSurface stressIron powder

Disclosed is a method of producing a soft magnetic powder including spraying gas or water into a pure iron bath to prepare a pure iron powder, surface-treating the pure iron powder by milling to increase surface stress of the pure iron powder and make the pure iron powder spherical, and subjecting the surface-treated pure iron powder to reducing thermal treatment to grow surface crystal grains of the pure iron powder and to prepare a soft magnetic powder.

Owner:HYUNDAI MOTOR CO LTD +2

Preparation process of tempered glass for gas stove panel

The invention discloses a preparation process of tempered glass for a gas stove panel, which comprises the following steps: 1) preparing a modified acrylic resin emulsion; 2) preparing the modified acrylic resin emulsion, polyurethane resin, lithium sulfate, nano titanium oxide, and polyalphaolefin , white carbon black, polyethylene glycol and curing agent are mixed to obtain a coating composition; 3) Take flat glass and put it into a tempering furnace for heating. ℃, take it out, spray the coating composition evenly on the surface of the flat glass, and wait until it cools down to room temperature. The preparation method of tempered glass provided by the present invention is to modify the acrylic resin, adjust the coating composition with the modified acrylic resin as the base material, and improve the adhesion of the coating composition to the surface layer of the tempered glass, so that the tempered glass surface It has high flatness and also improves the surface stress of tempered glass.

Owner:QINGDAO TIANDI CASTING CO LTD

Method for preparing esd device, esd device

ActiveCN105990230BOptimizing trigger voltageImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingSurface stressEtching

The invention relates to the technical field of semiconductor manufacturing, and specifically relates to a method of preparing an ESD (Electro-Static Discharge) device and an ESD device. The method of preparing an ESD device comprises the steps: based on a traditional method of preparing an MOS device (such as a PMOS or EMOS device), implanting ESD ions into a mask to open a dielectric layer above a source / drain area; utilizing a wet etching process to form a wide-top and narrow-bottom V type groove in a silicon substrate; and generating two epitaxial layers with different ion doping concentration in the V type groove continuously to form a triangular epitaxial stress layer (namely, a bottom epitaxial layer) in the source / drain area so as to realize the aim of enhancing the channel surface stress and optimizing the ESD trigger voltage on the premise of not performing the ESD ion implantation process and to greatly improve the performance of the ESD device while the device SEC (Short-Channel Effect) can be effectively improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Molten salt for chemical strengthening of medium-aluminum and high-alumina silicate glass and method for chemical strengthening using it

The invention provides a fused salt for chemically enhancing medium-aluminum and high-aluminum silicate glass. The fused salt comprises the following compositions: KNO3, KOH, KCl and K2CO3, wherein a mass ratio of KOH to K2CO3 in the fused salt is 0.05-0.4; a mass ratio of KCl to K2CO3 is 0.075-1.0; and a mass ratio of KNO3 to K2CO3 is 100:(1.0-4.0). The invention further provides a method for performing chemically toughened enhancement by using the fused salt for chemical enhancing of medium-aluminum and high-aluminum silicate glass. The fused salt formula disclosed by the invention indicates a formula composition range suitable for chemical enhancing of the medium-aluminum and high-aluminum glass. According to the formula, corrosion on the glass surface can be avoided, and the chemically enhanced glass has high transmittance; and meanwhile, due to the formula disclosed by the invention, the surface stress and stress layer depth of the chemically enhanced glass can be greatly improved.

Owner:WUHAN UNIV OF TECH

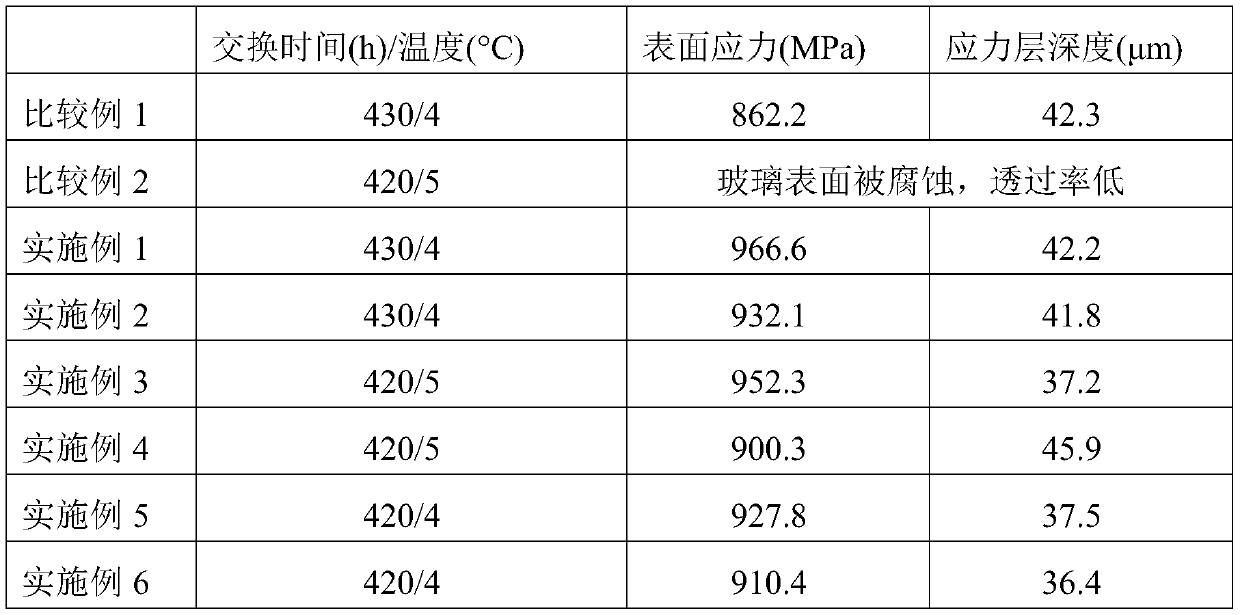

Ultrathin high-aluminum glass chemical strengthening and film-covering strengthening process

ActiveCN113501670AIncrease surface stressHigh hardnessCoatingsGlass productionOXALIC ACID DIHYDRATEPotassium fluoride

The invention provides an ultrathin high-aluminum glass chemical strengthening and film-covering strengthening process which comprises the steps: (1) cleaning: soaking a glass substrate in a cleaning agent which comprises tetrabutylammonium fluoride, oxalic acid, sodium gluconate and polyacrylic acid, ultrasonically washing the soaked glass substrate, putting the glass substrate in a drying oven after ultrasonic treatment, and drying; (2) preheating: putting the cleaned glass substrate into a muffle furnace for heating and preheating; (3) chemical strengthening: placing the preheated glass substrate in molten salt, wherein the molten salt is prepared from potassium nitrate, sodium nitrate, sodium silicate, potassium fluoride, potassium carbonate and diatomite; and (4) film-covering and strengthening: spin-coating a protective film coating on the surface of the chemically strengthened glass substrate, wherein the protective film coating comprises polydimethylsiloxane, silicon oxide, zirconium oxide and polyvinyl chloride. According to the preparation process, the surface stress, the stress layer depth, the hardness and the bending strength of the ultrathin high-aluminum glass are improved.

Owner:海南海控特玻科技有限公司

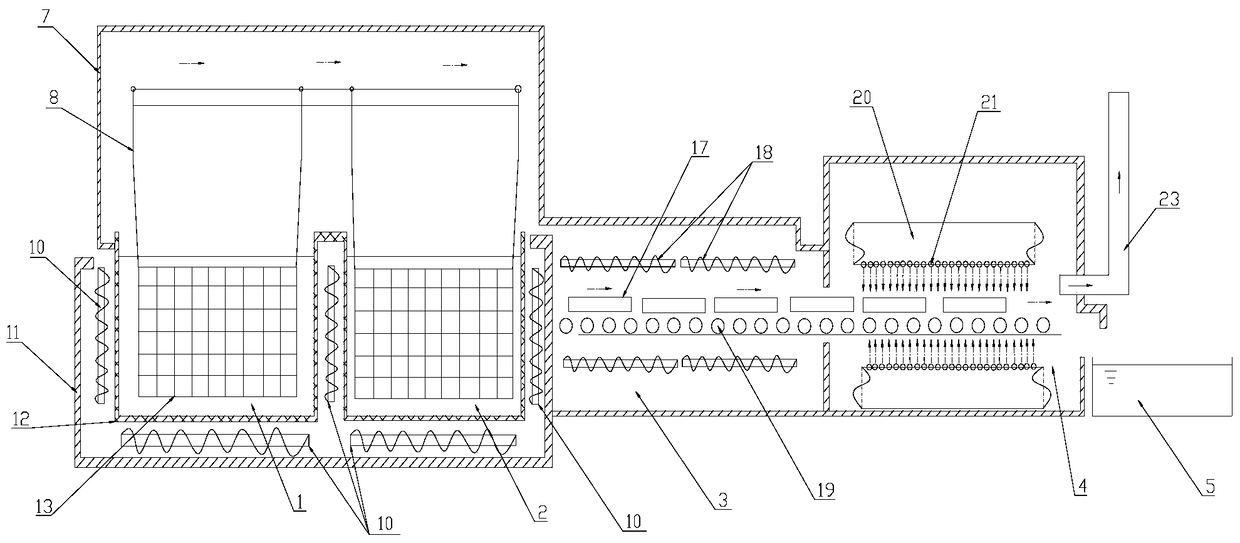

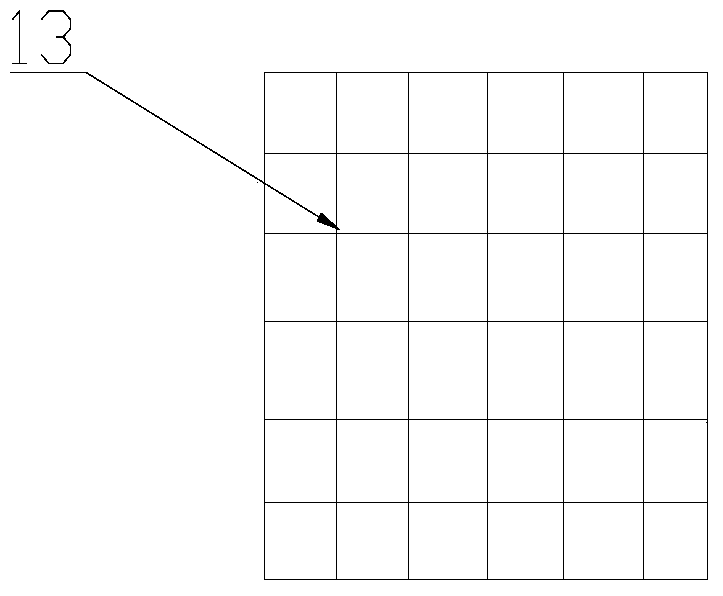

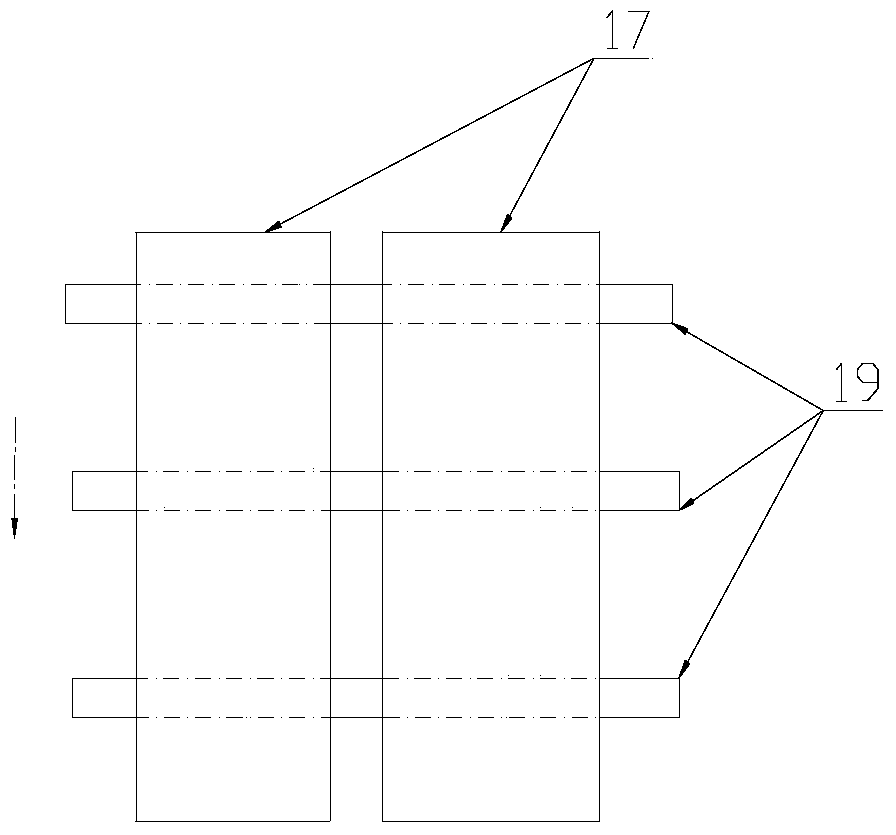

Tempering equipment and tempering method for display cover glass

ActiveCN105236767BImprove performanceIncrease surface stressGlass tempering apparatusSurface stressHardness

The invention discloses a tempering equipment and a tempering method for display screen cover glass. The tempering equipment includes a first-level chemical toughening zone, a second-level chemical toughening zone, a first-level physical toughening zone and a rapid cooling zone connected in sequence; the tempering method includes First-level chemical toughening, second-level chemical toughening, first-level physical toughening and rapid cooling. The tempering equipment and tempering method for the display screen cover glass of the present invention adopt two-stage chemical tempering and one-stage physical tempering, so that the physical properties such as surface stress, compressive strength, and surface Vickers hardness of the display screen cover glass are greatly improved, satisfying The use requirements of the cover glass are met; and the three areas are isolated from each other and do not interfere with each other. The parameters of the three areas can be adjusted at the same time according to different needs to meet the use requirements of the display cover glass for different occasions and requirements.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

Nanometer transparent heat-protecting glass and manufacturing technology thereof

InactiveCN106746639AGood heat insulationGood surface stressStrontium titanateManufacturing technology

The invention provides nanometer transparent heat-protecting glass and a manufacturing technology thereof and relates to the technical field of glass manufacturing. The nanometer transparent heat-protecting glass is mainly prepared from the following ingredients in parts by weight: 50 to 60 parts of silicon dioxide, 12 to 15 parts of sodium silicate, 7 to 13 parts of borax, 3 to 5 parts of calcium metasilicate, 0.05 to 0.2 part of arsenious oxide, 0.3 to 0.7 part of zinc oxide, 1 to 3 parts of magnesium carbonate, 0.2 to 0.4 part of zirconium sulfate, 0.2 to 0.4 part of calcium fluoride, 0.5 to 1 part of potassium feldspar, 0.3 to 0.5 part of ethylchlorosilane, 0.03 to 0.05 part of tungsten trioxide and 0.02 to 0.08 part of cobaltous oxide. The nanometer transparent heat-protecting glass is further prepared from the following ingredients in parts by weight: 0.2 to 1 part of nanometer strontium titanate, 0.05 to 1 part of 3,4-dimethylpyrazole phosphate and 0.02 to 0.08 part of yttrium oxide. The nanometer transparent heat-protecting glass provided by the invention has better thermal insulation capacity and higher light transmittance.

Owner:张眙宁

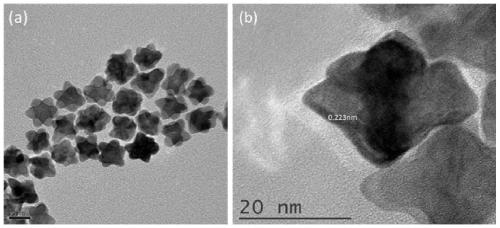

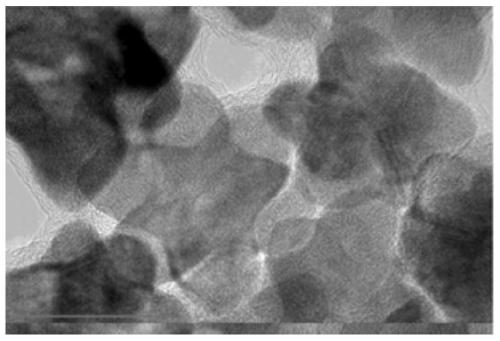

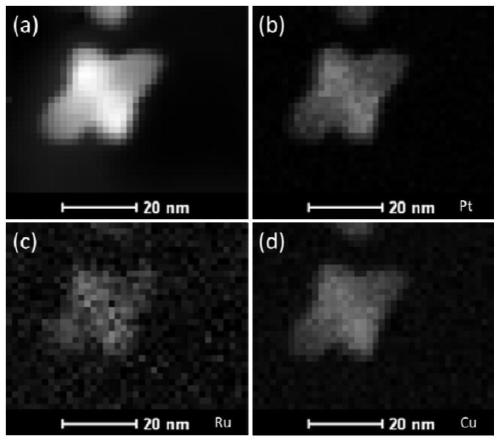

A petal-shaped Cu-doped Ptru alloy catalyst and preparation method thereof

InactiveCN107123818BIncrease surface stressImprove stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFuel cells

The invention relates to a petal-shaped Cu-doped PtRu alloy catalyst and a preparation method thereof. The petal-shaped Cu-doped PtRu alloy catalyst has a petal-shaped morphology. The three elements Pt, Ru and Cu all exist in the form of alloys, and Pt and Ru atoms are distributed at the active sites. The mass activity of the prepared petal-shaped PtRu / Cu catalyst in the methanol oxidation reaction is at least 3.1 times that of commercial Pt / C. The preparation method is simple and the operation is easy. The excellent methanol oxidation performance makes it widely used in many fields such as methanol fuel cell catalysts.

Owner:WUHAN UNIV OF TECH

A glass composition, glass substrate and chemical strengthening method thereof

The invention relates to a glass composition, a glass substrate and a chemical strengthening method thereof. The composition contains SiO2, Al2O3, K2O, Na2O, ZrO2 and B2O3, wherein relative to 100 parts by weight of SiO2, the Al2O3 content is 25-40 parts by weight, the K2O content is 1-9 parts by weight, the Na2O content is 15-40 parts by weight, the ZrO2 content is 0.05-3 parts by weight, and the B2O3 content is 1-15 parts by weight; and R is calculated to be 6.87-13.89 according to the formula below: R=0.206w(Al2O3)+0.17w(K2O)-0.006w(Na2O)+0.13w(ZrO2)+0.37w(B2O3).Since the disclosed composition has the defined specific components and content ranges thereof, glass prepared from the composition has high strain point and softening point and low melting temperature, has excellent chemical strengthening property, and can be used for preparing the chemically-strengthened glass substrate. The surface of the chemically-strengthened glass substrate prepared according to the method has high surface stress and hardness, so that the surface scratch resistance of the chemically-strengthened glass substrate is improved, thereby ensuring that the chemically-strengthened glass substrate can resist the effect of external forces such as fall, abrasion and the like.

Owner:TUNGHSU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com