Ultrathin high-aluminum glass chemical strengthening and film-covering strengthening process

A high-alumina glass, ultra-thin technology, applied in glass production, coating and other directions, can solve the problems of limiting the application range and practical performance of glass, low flexural strength, high glass brittleness, etc., to improve scratch resistance, The effect of increasing surface stress and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

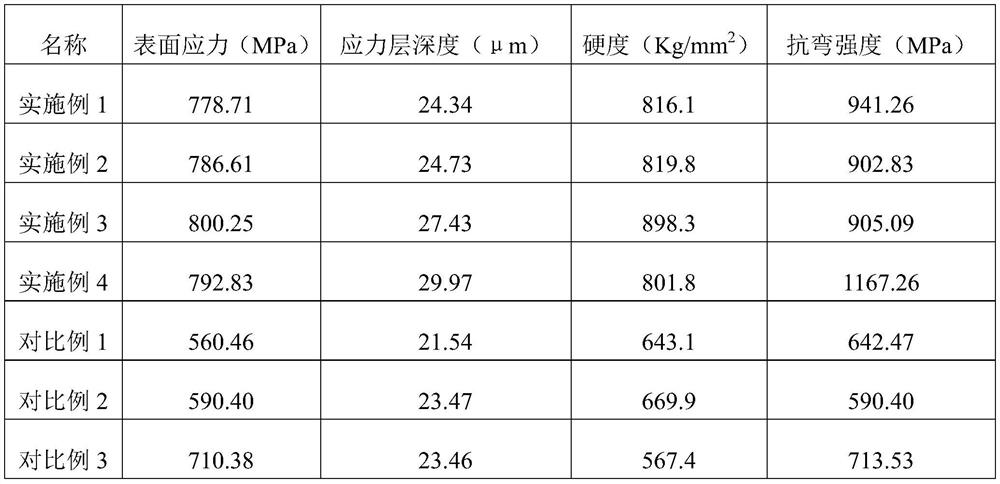

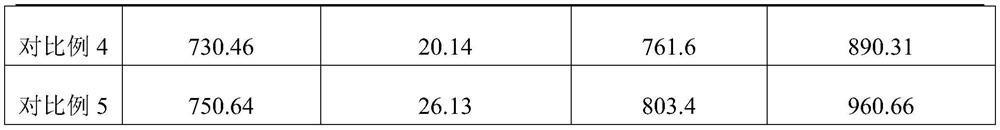

Examples

Embodiment 1

[0026] Embodiment 1 Ultra-thin high-alumina glass chemical strengthening and coating strengthening process

[0027] (1) Cleaning: Put the glass substrate with a thickness of 0.07mm into a cleaning agent and soak for 20 minutes. The cleaning agent consists of 1% tetrabutylammonium fluoride, 6% oxalic acid, 30% sodium gluconate, 20% made of polyacrylic acid and the rest of water. After soaking, the glass substrate is placed in an ultrasonic liquid for ultrasonic washing for 10 minutes. The ultrasonic frequency is 20kHz and the output power is 250W. The ultrasonic liquid consists of 2% detergent, 20% Prepared with ethanol solution with a mass fraction of 60% and the rest of water, put it into an oven for drying after ultrasonication, the drying time is 2 hours, and the drying temperature is 60°C;

[0028] (2) Preheating: put the cleaned glass substrate into the muffle furnace and slowly raise the temperature to the corresponding tempering temperature of 200°C. The speed is 10°C / ...

Embodiment 2

[0031] Embodiment 2 Ultra-thin high-alumina glass chemical strengthening and coating strengthening process

[0032] (1) Cleaning: Put the glass substrate with a thickness of 0.07 mm into a cleaning agent and soak for 40 minutes. The cleaning agent consists of 5% tetrabutylammonium fluoride, 10% oxalic acid, 40% sodium gluconate, 40% made of polyacrylic acid and the rest of water. After soaking, the glass substrate is placed in an ultrasonic liquid for ultrasonic washing for 20 minutes. The ultrasonic frequency is 25kHz and the output power is 250W. The ultrasonic liquid consists of 3% detergent, 45% Prepared with ethanol solution with a mass fraction of 60% and the rest of water, put it into an oven for drying after ultrasonication, the drying time is 2 hours, and the drying temperature is 70°C;

[0033] (2) Preheating: put the cleaned glass substrate into the muffle furnace and slowly raise the temperature to the corresponding tempering temperature of 250°C. The rate is 15°C...

Embodiment 3

[0036] Example 3 Ultra-thin high-alumina glass chemical strengthening and coating strengthening process

[0037] (1) Cleaning: Put the glass substrate with a thickness of 0.07mm into a cleaning agent and soak for 30 minutes. The cleaning agent consists of 3% tetrabutylammonium fluoride, 8% oxalic acid, 35% sodium gluconate, 23% made of polyacrylic acid and the rest of water. After soaking, the glass substrate is placed in an ultrasonic liquid for ultrasonic washing for 15 minutes. The ultrasonic frequency is 30kHz and the output power is 250W. The ultrasonic liquid consists of 2.5% detergent, 30% Prepared with ethanol solution with a mass fraction of 60% and the rest of water, put it into an oven for drying after ultrasonication, the drying time is 3 hours, and the drying temperature is 60°C;

[0038] (2) Preheating: put the cleaned glass substrate into the muffle furnace and slowly raise the temperature to the corresponding tempering temperature of 225°C, the heating rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com