Molten salt for chemical strengthening of medium-aluminum and high-alumina silicate glass and method for chemical strengthening using it

A high-alumina silicate and glass technology, which is used in the field of molten salt for chemical strengthening of aluminum and high-alumina silicate glass, and chemical tempering strengthening field The effect of increasing exchange rate, avoiding corrosion, and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

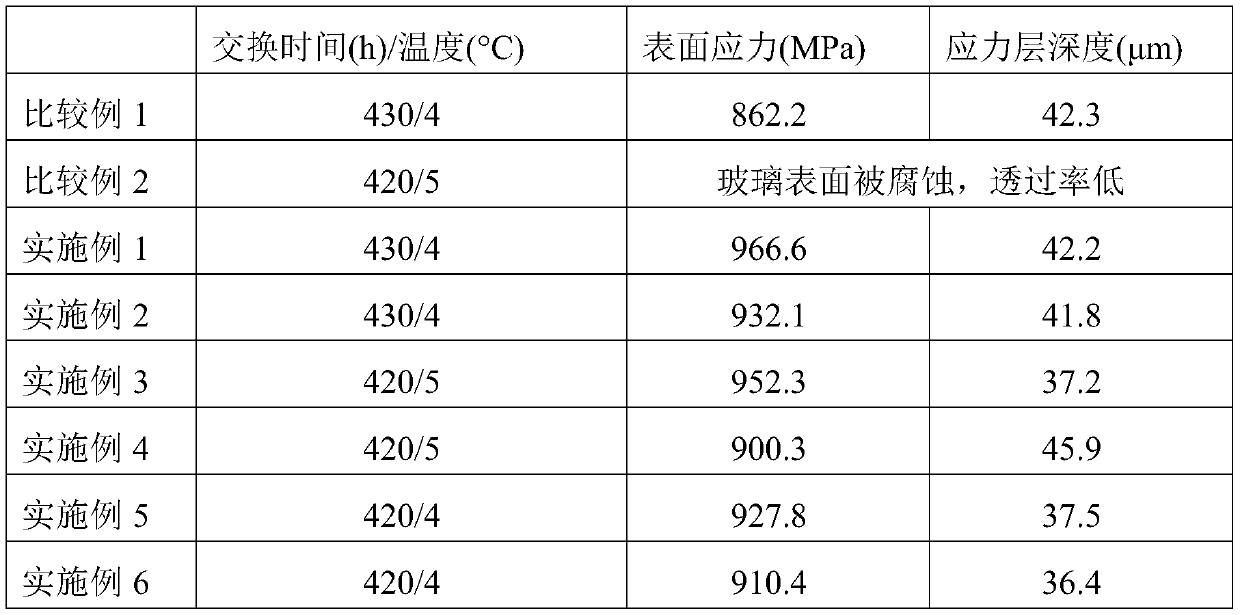

Embodiment 1

[0024] The above-mentioned original glass sheet is cut and edged, cleaned and placed in a preheating furnace for preheating treatment. The preheating temperature is 380°C, and the temperature is raised with the furnace and kept for half an hour, and then quickly transferred to the molten molten salt. The temperature of the molten salt is 430°C, the ion exchange time is 4 hours, after the exchange is completed, take it out to cool naturally, and use a stress tester to test the stress and stress layer depth of the glass.

[0025] Molten salt composition is 100 parts by weight KNO 3 , 0.4 parts by weight KOH, 0.3 parts by weight KCl and 1 parts by weight K 2 CO 3 . where m(KCl) / m(K 2 CO 3 )=0.3, m(KOH) / m(K 2 CO 3 )=0.4, satisfying 0.075≤m(KCl) / m(K 2 CO 3 )≤0.35, 0.075≤m(KOH) / m(K 2 CO 3 )≤0.4.

Embodiment 2

[0027] The difference between this embodiment and embodiment 1 is:

[0028] Molten salt composition is 100 parts by weight KNO 3 , 0.4 parts by weight KOH, 0.3 parts by weight KCl and 2 parts by weight K 2 CO 3 , the molten salt temperature is 430°C, and the exchange time is 4h. where m(KOH) / m(K 2 CO 3 )=0.4, m(KCl) / m(K 2 CO 3 )=0.15, m(KOH) / m(K 2 CO 3 )=0.4, satisfying 0.075≤m(KCl) / m(K 2 CO 3 )≤0.35, 0.075≤m(KOH) / m(K 2 CO 3 )≤0.4.

Embodiment 3

[0030] The difference between this embodiment and embodiment 1 is:

[0031] Molten salt composition is 100 parts by weight KNO 3 , 0.4 parts by weight KOH, 0.3 parts by weight KCl and 4 parts by weight K 2 CO 3, the molten salt temperature is 420°C, and the exchange time is 5h. where m(KCl) / m(K 2 CO 3 )=0.075, m(KOH) / m(K 2 CO 3 )=0.1, satisfying 0.075≤m(KCl) / m(K 2 CO 3 )≤0.35, 0.075≤m(KOH) / m(K 2 CO 3 )≤0.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface stress | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com