Patents

Literature

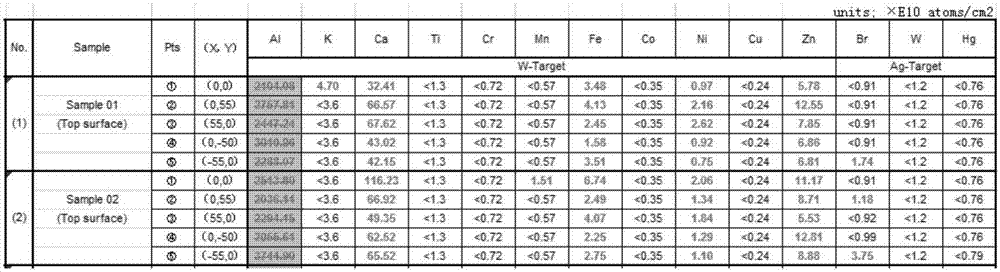

83results about How to "Avoid secondary contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

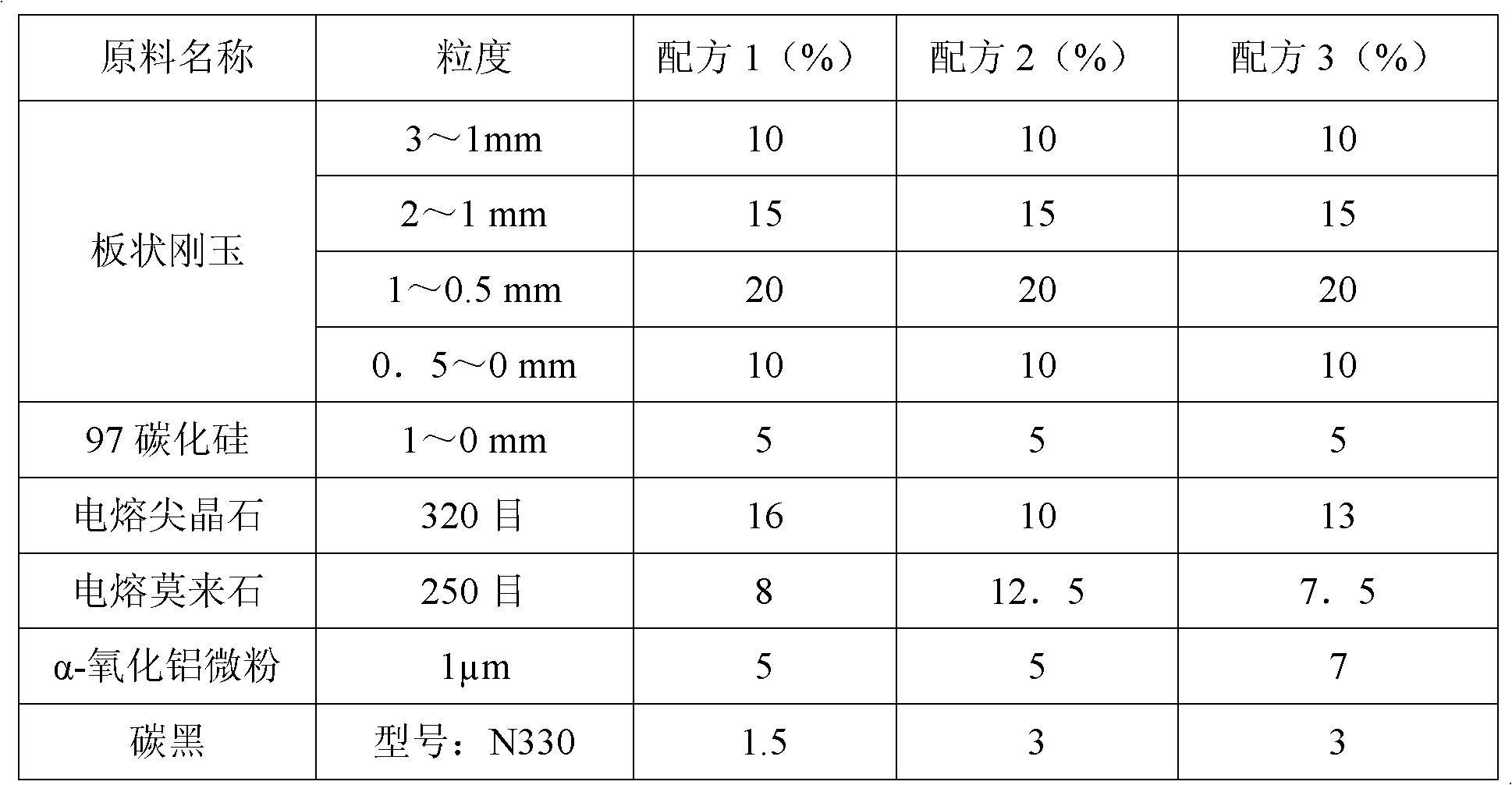

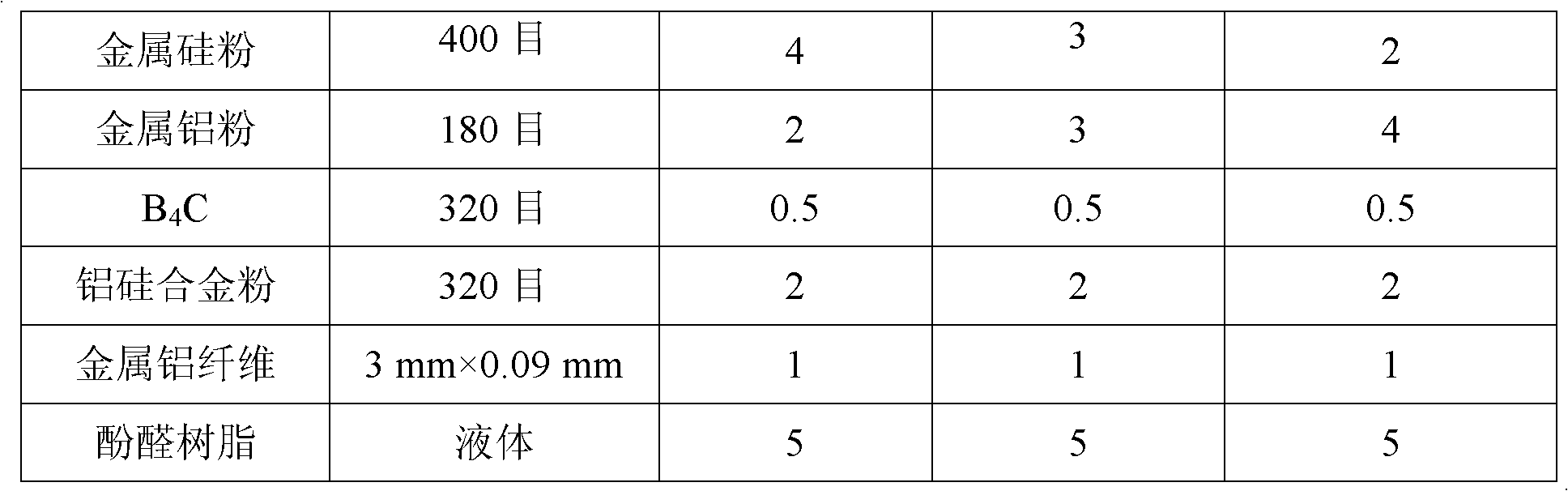

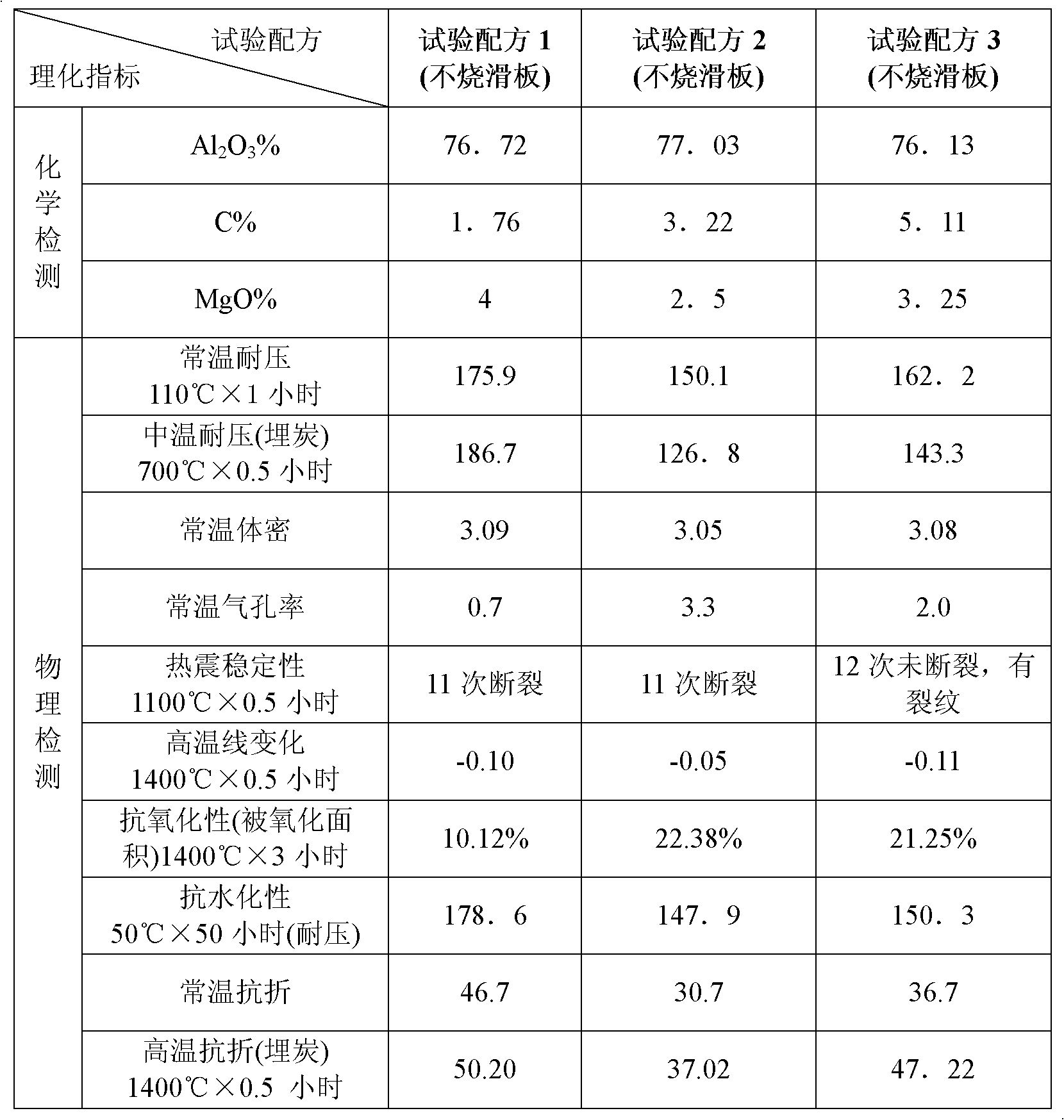

Metal ceramic combination sintering free low carbon sliding plate brick and preparation method thereof

The invention discloses a metal ceramic combination sintering free low carbon sliding plate brick and a preparation method thereof. The sliding plate brick comprises the following components according to weight percentage: 50%-60% of sintered plate shape alundum, 10%-25% of electric melting akerite, 5%-15% of electric melting mullite, 1%-3% of soot carbon, 3%-8% of Alpha- aluminum oxide micropowder, 5%-10% of silicon carbide, 2%-5% of metallic silicon powder,1%-5% of metallic aluminium powder, 0.5%-1% of boron carbide, 1%-3% of aluminum-silicon alloy powder, and 0.5%-2% of metallic aluminium fiber. In the invention, the product has low carbon, high thermal state strength, thermal shock resistance and good oxidation resistance, hole reaming is uniform, galling is less and the crack is verysmall; the process of the invention is characterized in that drying is carried out at a low temperature, the production cycle is shortened from 30 days originally to 7 days, the natural gas consumption is reduced to 2.5% of original technology, and the sintering free low carbon sliding plate brick is indeed belongs to the environmental protective and energy-saving and environmental material resistance product.

Owner:无锡市南方耐材有限公司

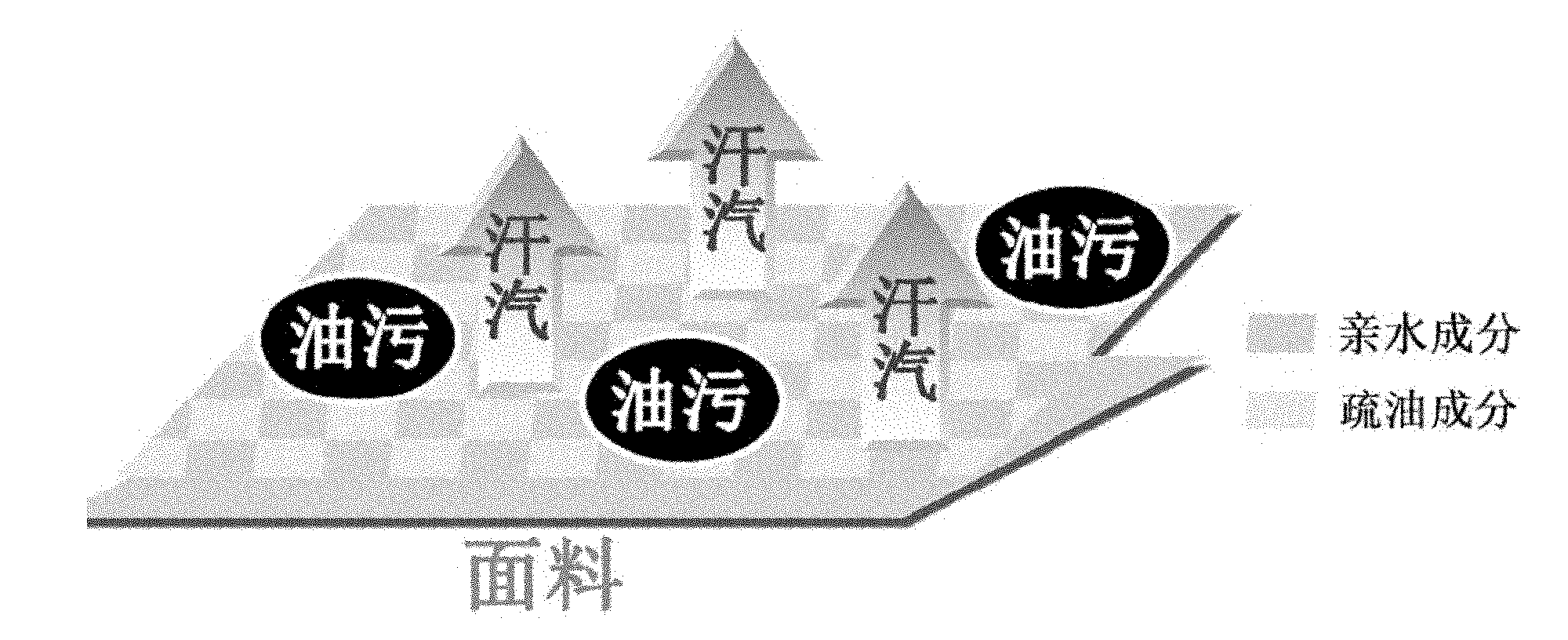

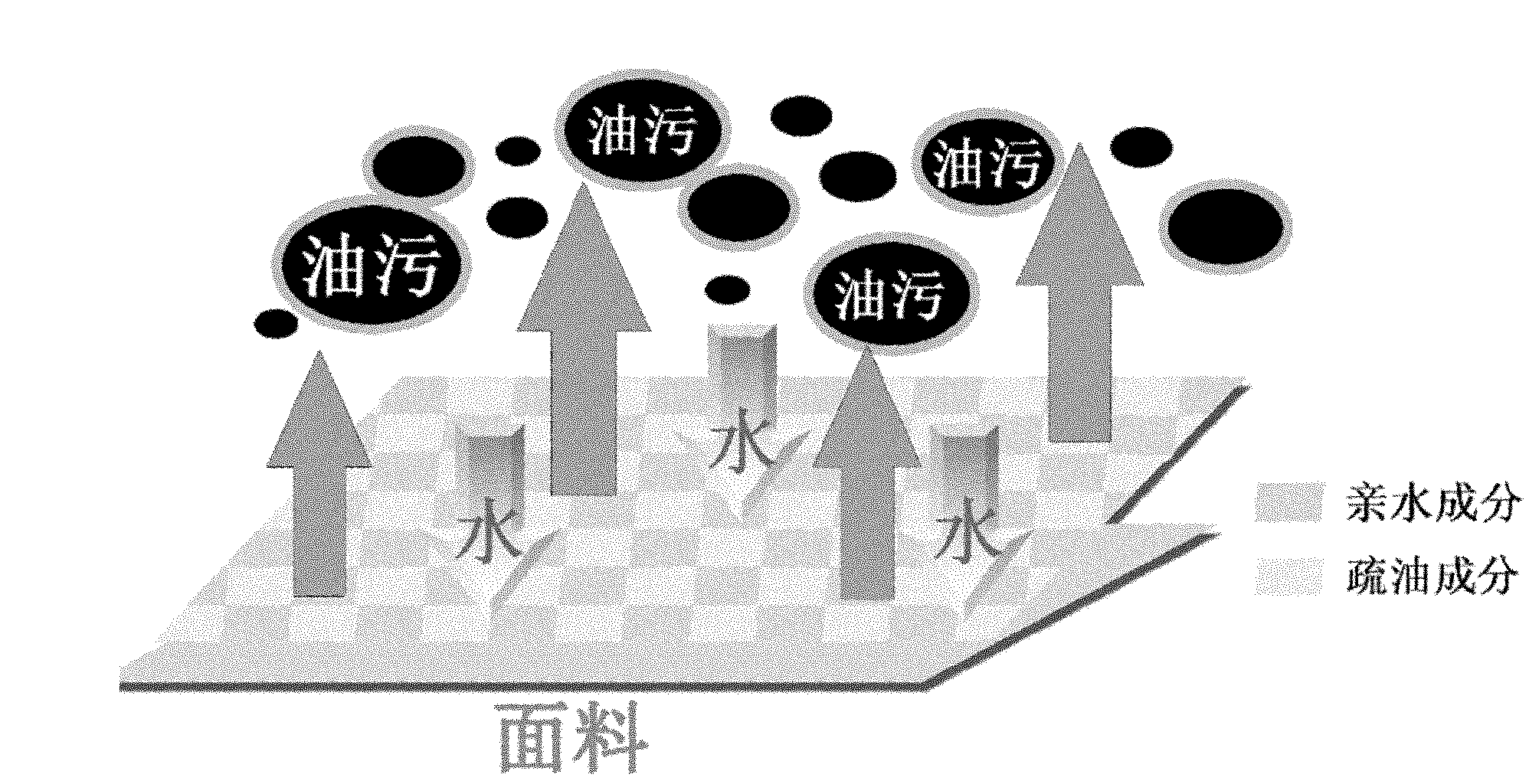

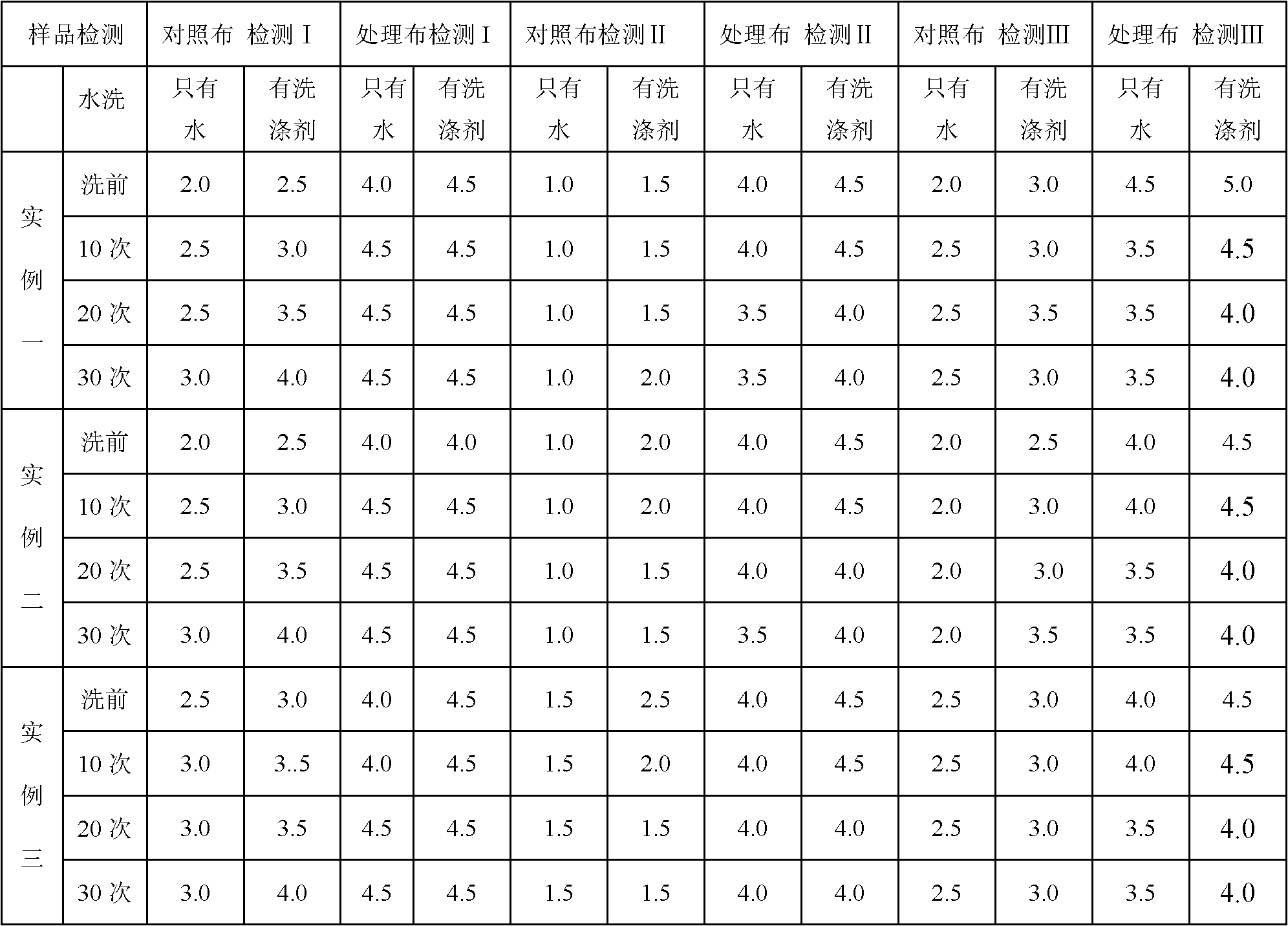

Finishing method of fiber product free of cleaning by detergent

InactiveCN102041685AImprove wettabilityReduce interfacial energyBiochemical fibre treatmentSingeingFiberPre treatment

The invention provides a finishing method of a fiber product free of cleaning by a detergent. The technical process comprises singeing, desizing, mercerizing, tentering and preshrinking. The finishing method is characterized in that enzyme piling is added between the singeing and the desizing; a high-efficiency desizing technique is adopted in desizing; liquid ammonia finish and pretreatment are added between the mercerizing and tentering; baking finish is added between the tentering and preshrinking so as to lead the whole technical process to be singeing, enzyme piling, desizing, mercerizing, liquid ammonia finish, pretreatment, tentering, baking and preshrinking. Textiles manufactured by adopting the technique is not cleaned by using the detergent for cleaning, has basically the same cleaning effect with that of cleaning during which the detergent is added, also can not generate secondary dirt in cleaning; and simultaneously, the textile manufactured by using the method has the functions of fouling resistance and easy decontamination, proper oil-proof function, excellent multiple functions of water absorption, air permeability, washing resistance and electrostatic resistance, meets the requirements of people and belongs to an ideal high-grade textile which is energy-saving, environment-friendly and low-carbon.

Owner:LUTAI TEXTILE

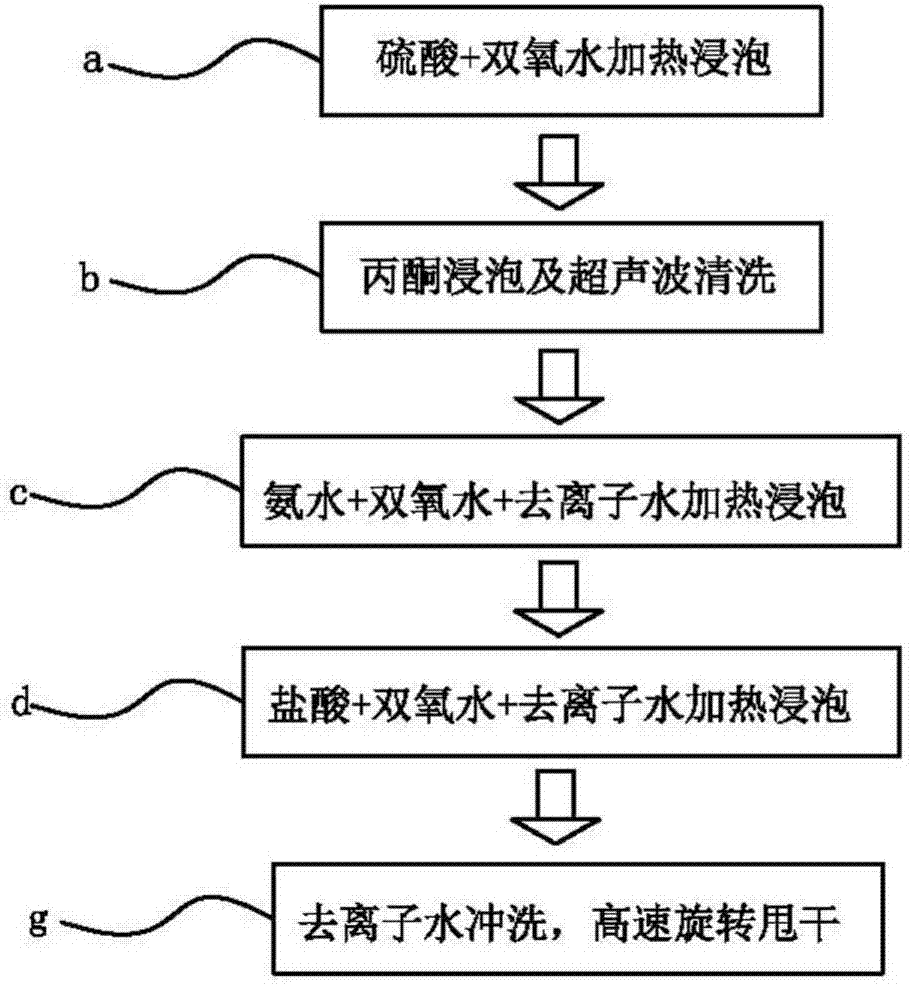

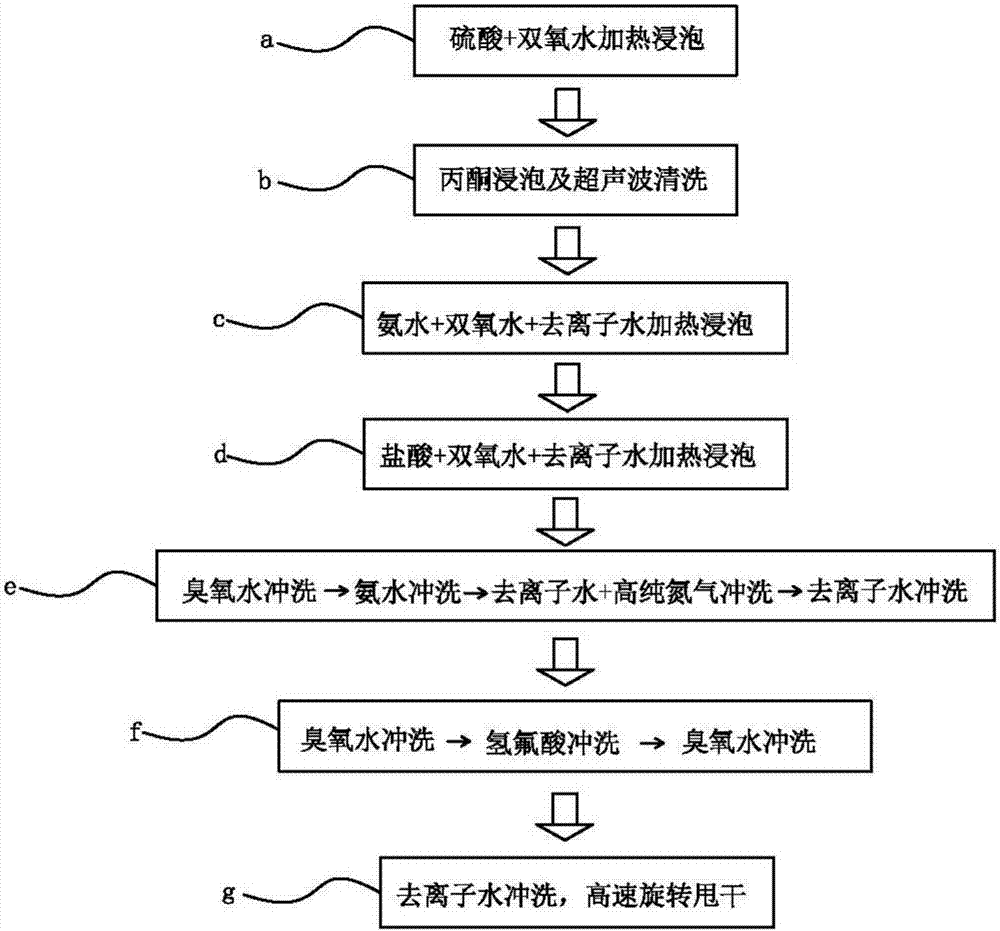

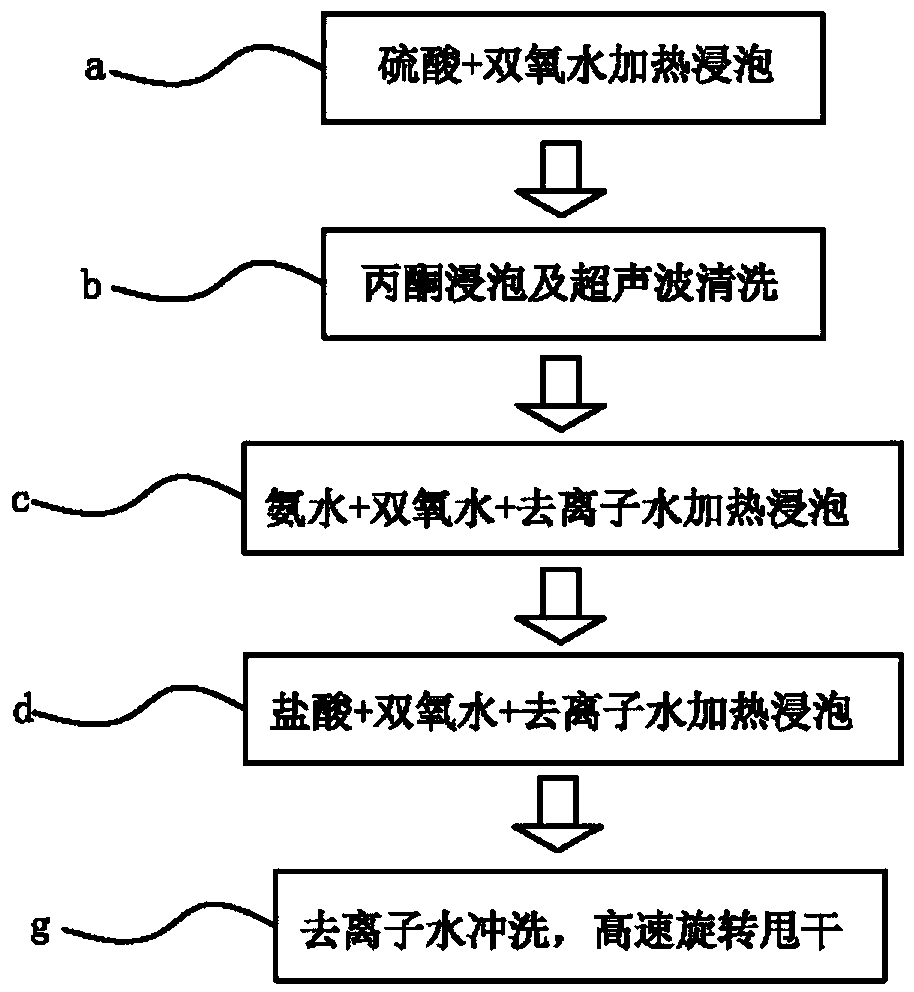

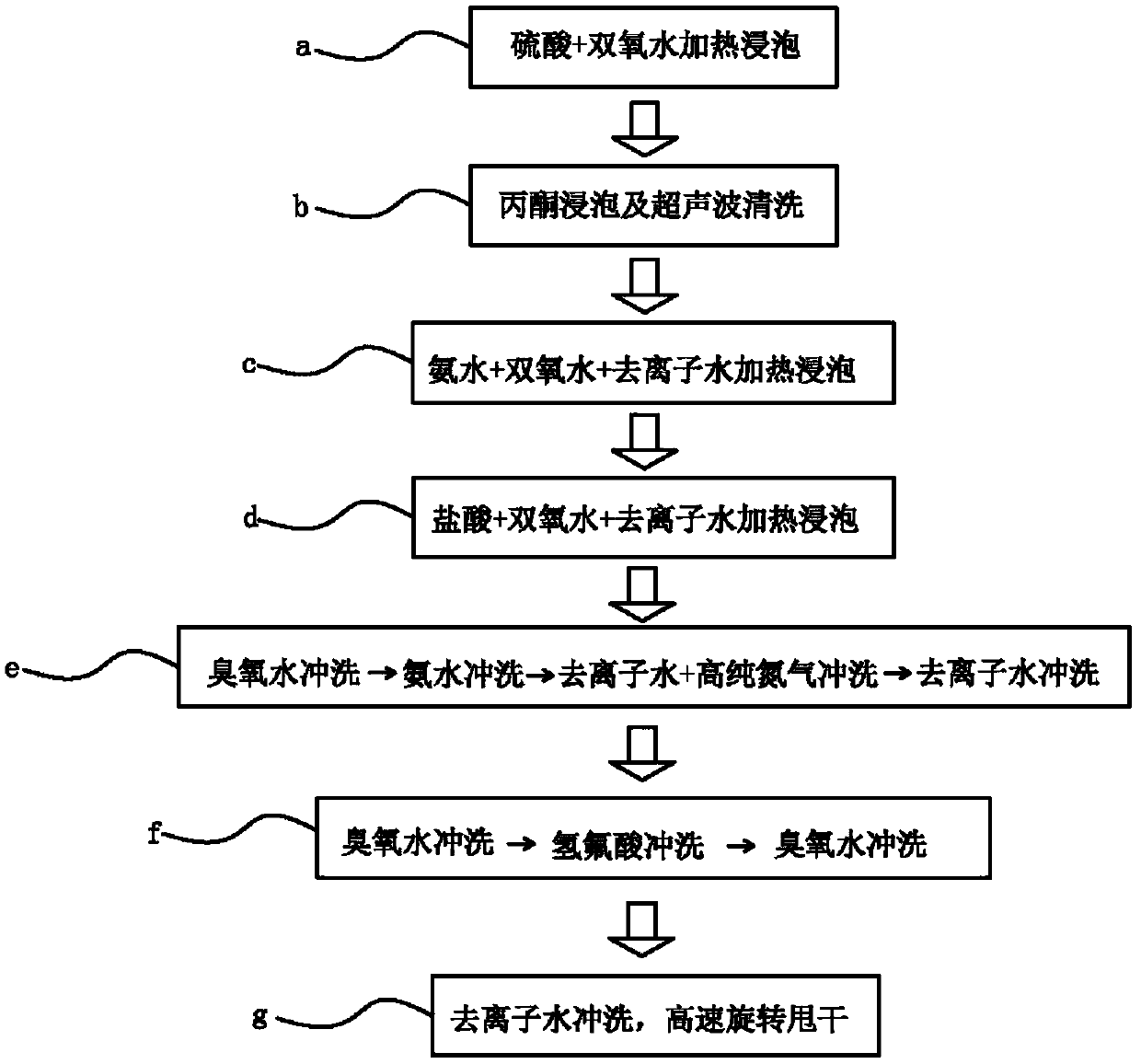

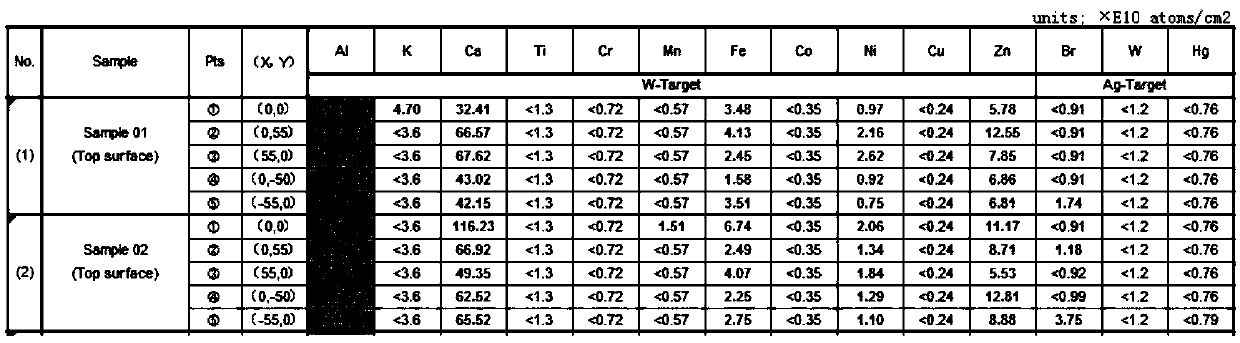

Cleaning method for removing metal pollution or residuals of SiC epitaxial wafer

ActiveCN106910674AEfficient removalAvoid adsorptionSemiconductor/solid-state device manufacturingChemistryHydrogen peroxide

The invention discloses a cleaning method for removing metal pollution or residuals of a SiC epitaxial wafer, and the method comprises the following steps: a, putting the SiC epitaxial wafer in mixed washing liquor, formed by the mixing of sulfuric acid and hydrogen peroxide, for immersing; b, cleaning the surface of the SiC epitaxial wafer through deionized water, and then putting the SiC epitaxial wafer in acetone for ultrasonic cleaning; c, cleaning the surface of the SiC epitaxial wafer through deionized water, and then putting the SiC epitaxial wafer in heated mixed washing liquor, formed by the mixing of ammonia water, hydrogen peroxide and deionized water, for immersing; d, , cleaning the surface of the SiC epitaxial wafer through deionized water, and then putting the SiC epitaxial wafer in heated mixed washing liquor, formed by the mixing of hydrochloric acid, hydrogen peroxide and deionized water, for immersing; e, sequentially cleaning the surface of the SiC epitaxial wafer through ozone water, ammonia water, high-purity nitrogen and deionized water; f, sequentially cleaning the surface of the SiC epitaxial wafer through ozone water, hydrofluoric acid liquor and ozone water; g, cleaning the surface of the SiC epitaxial wafer through deionized water, and rotating the SiC epitaxial wafer at a high speed for drying.

Owner:DONGGUAN TIANYU SEMICON TECH

Broad-sense garbage collection and transportation method and device

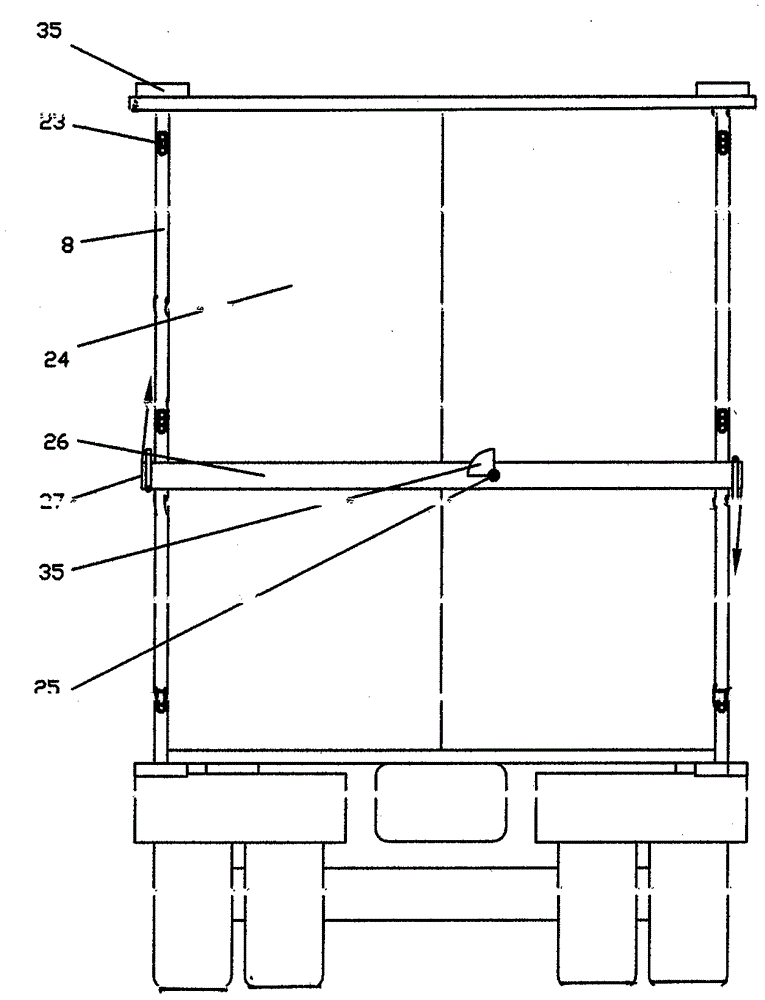

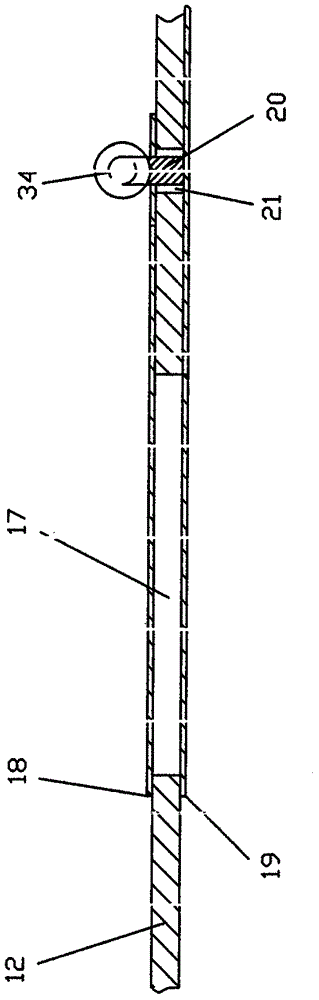

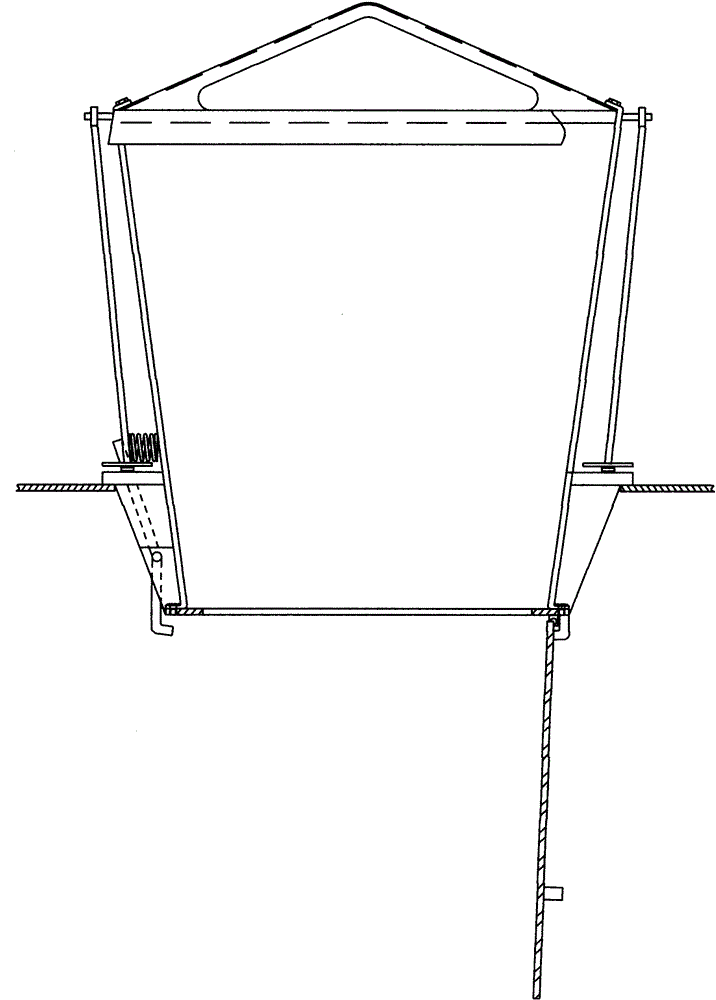

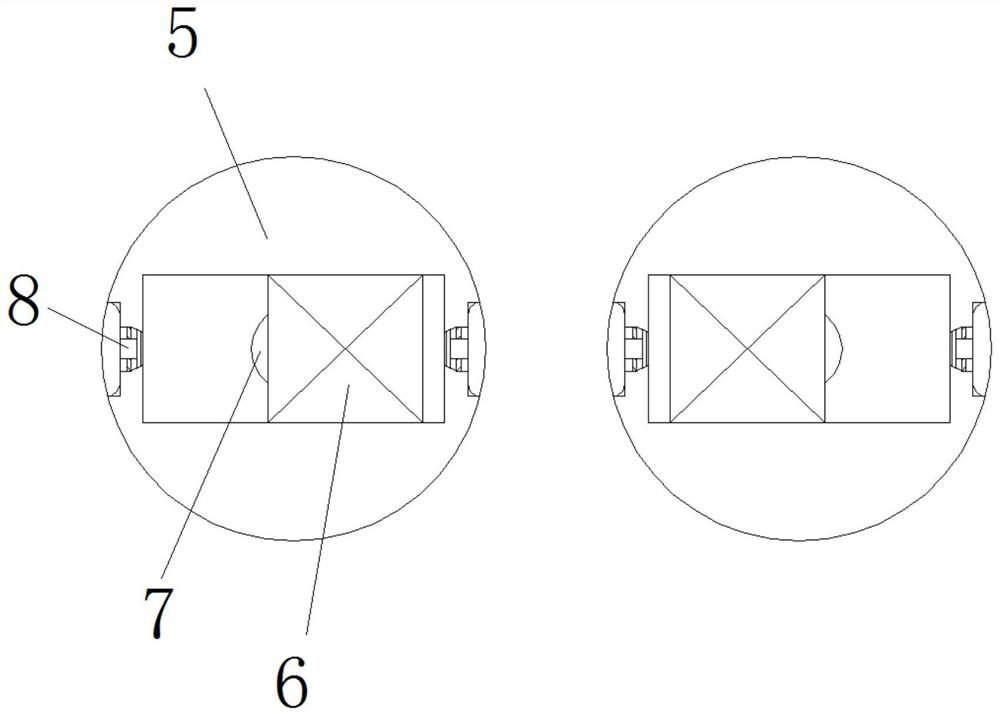

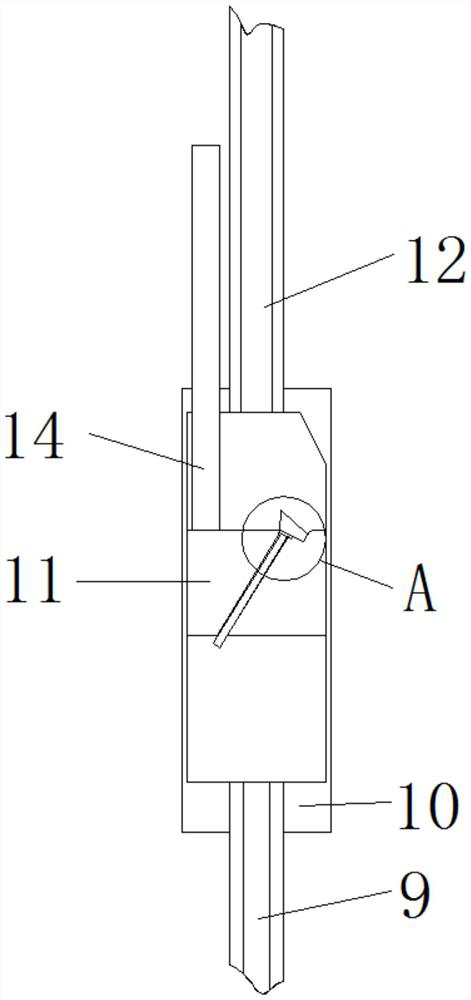

InactiveCN103832756ASolve collection and transportation proceduresReduce collection and transportation proceduresRefuse receptaclesRefuse vehiclesBulky wasteEngineering

The invention provides a broad-sense garbage collection and transportation method and device, and belongs to the technical field of urban environmental sanitation equipment. Broad-sense garbage is a general item of household garbage, construction waste and bulky waste. At present, urban environmental sanitation equipment can only realize collection and transportation of the household garbage and can not realize collection and transportation of the construction waste and the bulky waste. To solve the technical problem, the technical schemes of a tipping bucket with a bi-directional open / close cover, an uncovered tipping bucket, a crane trolley, a dump truck provided with a lifting device and a compacting device, a dump truck provided with a lifting device and an open cover and other devices are provided, and therefore not only the household garbage by also the construction waste and the bulky waste can be collected and transported by the urban environmental sanitation department.

Owner:浙江长大建设技术有限公司

Preparation method of hot pot for instant salty and dried food

The invention relates to a preparation method of a hot pot for instant salty and dried food. The preparation method comprises the following steps of: cleaning various salty and dried products; cutting the products into regular small pieces, and mixing the small pieces and seasoner and adding water; placing the mixture into a can, and heating; and braising and warming up for sterilization to obtain an instant hot pot. By the method, salty and dried food can be processed into a canned cooked food hot pot and sold in markets to meet the requirements of people in non-productive areas on the salty and dried food; the added values of the products are improved, the quality guarantee periods of the products are long, edible seasons are prolonged, and the products can be instantly eaten conveniently and fast when opened; the products are cooked by high-quality natural mineral water which is rich in various trace elements beneficial to human bodies, and have mellow mouthfeel and unique flavor; hot pot materials are canned and then cooked to avoid secondary contamination to cooked food caused by canning; the hot pot materials are canned, then braised until medium rare, and cooked until well finished, so that the secondary destruction to nutrients in the food can be avoided and the quality guarantee effect is better.

Owner:廖全斌

Environment-friendly brick and production method thereof

InactiveCN106365592AHigh compressive strengthImprove bending resistanceEnvironmental resistanceBrick

The invention discloses an environment-friendly brick and a production method thereof, which belong to the technical field of building materials. The environment-friendly brick is prepared from the following raw materials in parts by weight: 5 to 10 parts of waste tile, 6 to 12 parts of river sand, 6 to 12 parts of building rubbish, 6 to 12 parts of coal ash, 5 to 15 parts of andalusite powder, 5 to 15 parts of zirconium oxide powder, and 8 to 16 parts of kaolin tail mineral powder. The environment-friendly brick provided by the invention is high in compressive strength, good in breaking resistance and low in cost, the resource is effectively saved, and the secondary pollution on the environment is avoided.

Owner:广西塔锡科技有限公司

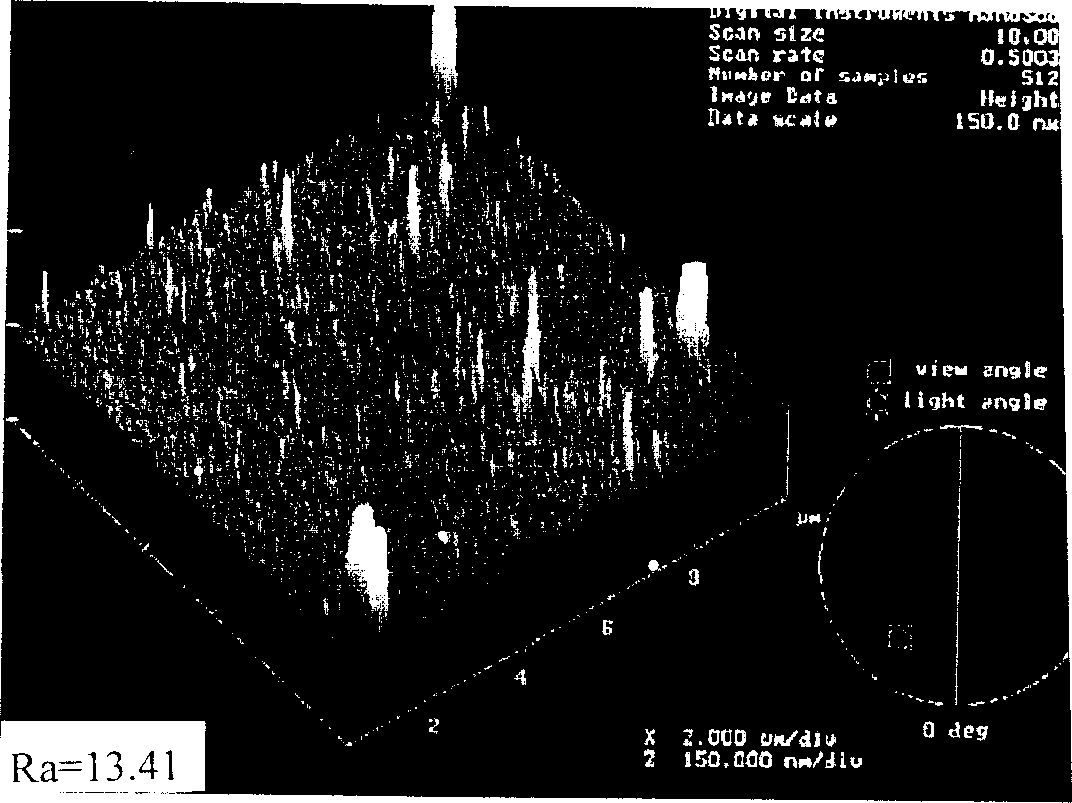

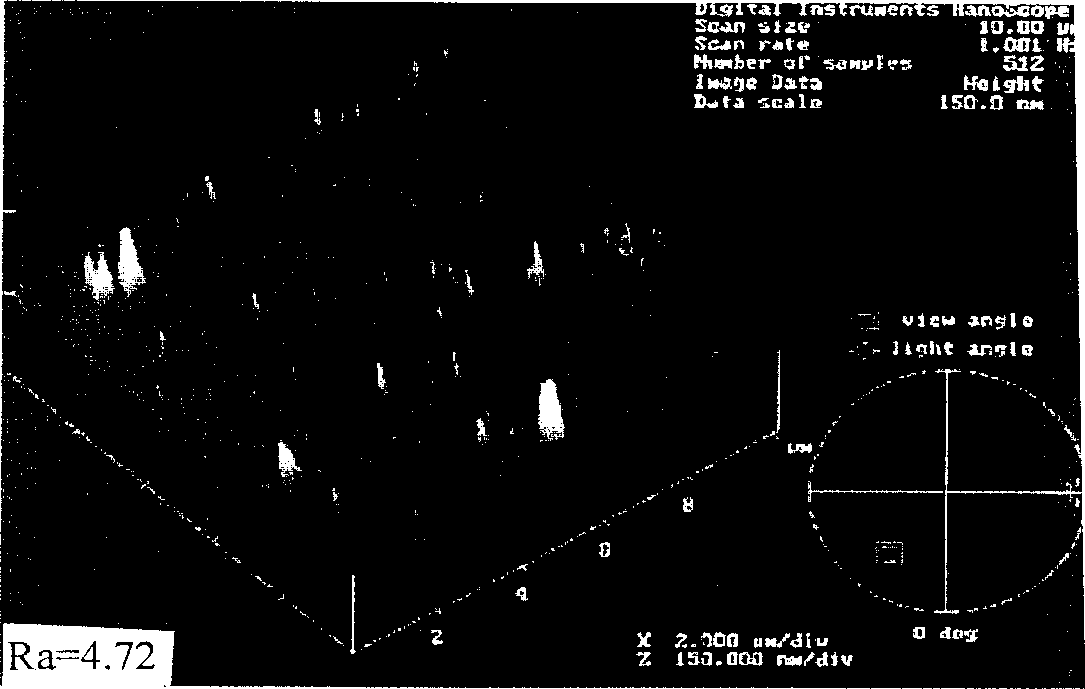

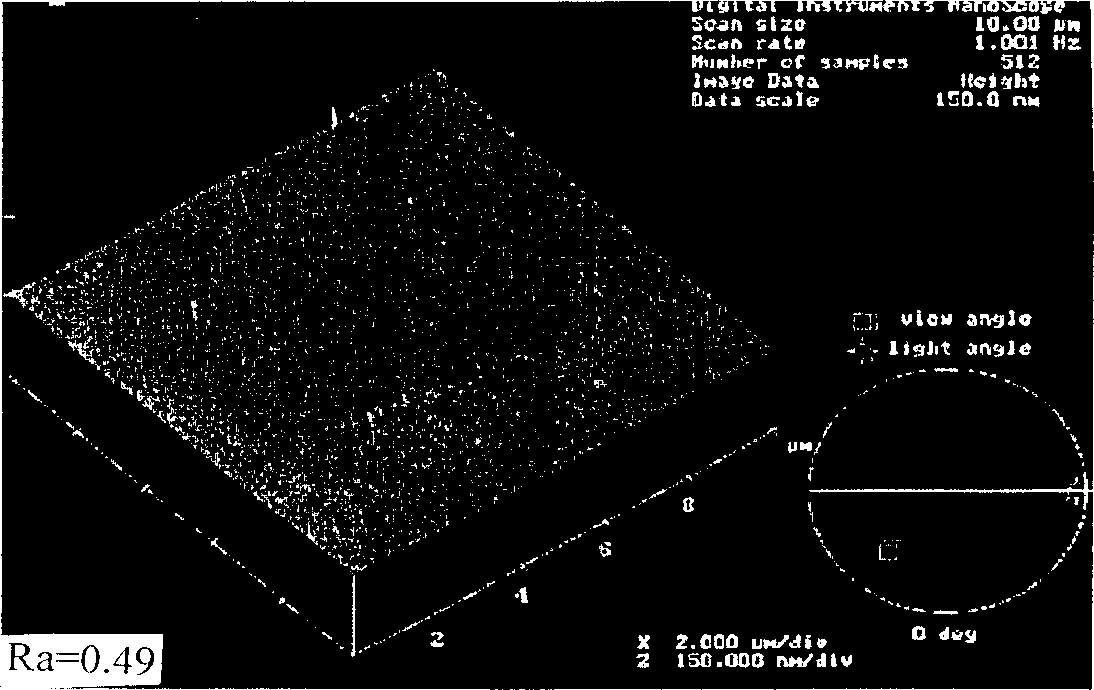

Method for controlling roughness in ULSI multi-layer copper metallization chemico-mechanical polishing

InactiveCN1864925AMeet the requirements of wiring CMP precision machiningAvoid secondary contaminationPolishing machinesAqueous dispersionsCopper wireSurface roughness

The invention relates to a method for controlling mechanically polished surface roughness of ULSI multilayer copper wire. It is characterized in that: it uses SiO2 hydrosol at small diameter as abrasive; uses organic alkali as the pH adjuster and complex builder; adds non-ionic surface activator to prepare the polish liquid; the preparation comprises following steps that first, preparing the polish liquid that a, diluting the SiO2 abrasive whose diameter is 15-20nm with the 1-5 times of deionized water; b, using pH adjuster organic alkali to adjust said solution, to make the pH value between 10-12; c, mixing and adding 0.5-10% (volume percentage) aether mellow activator to prepare the polish liquid; then, polishing form 3-5mins, while the flux is 3-5L / min, the temperature is 15-25Deg. C, the rotation speed is 30-120rpm, and the external pressure is zero that there is only the weight of carrier; the invention can effectively reduce the roughness of copper, baffle material and tantalum surface, via the strong complex function and accelerating the surface quantity transmission at alkali condition, with simple process and significant effect.

Owner:HEBEI UNIV OF TECH

Novel environment-friendly bricks and production method thereof

InactiveCN106316340AHigh compressive strengthImprove bending resistanceSolid waste managementCeramic shaping apparatusBrickCompressive strength

The invention discloses novel environment-friendly bricks and a production method thereof and belongs to the technical field of building materials. The novel environment-friendly bricks are prepared from, by weight, 10-20 parts of coal gangue powder, 5-15 parts of quick lime, 10-20 parts of building rubbish, 5-15 parts of granite tailings, 10-20 parts of coal slime and 10-20 parts of kaolin tailing powder. The novel environment-friendly bricks are high in compressive strength, good in breaking resistance and low in cost, resources are effectively saved, and secondary pollution to the environment is avoided.

Owner:广西塔锡科技有限公司

Nano-silicon dioxide modified environment-friendly waterborne paint remover and preparation method thereof

InactiveCN106752291AImprove stabilityImprove antioxidant capacityChemical paints/ink removersMicrocrystalline waxSilicon dioxide

The invention discloses a nano-silicon dioxide modified environment-friendly waterborne paint remover and a preparation method thereof. The nano-silicon dioxide modified environment-friendly waterborne paint remover is prepared from the following raw materials in parts by weight: 1.2-1.4 parts of nanometer montmorillonite, 1.5-2 parts of a penetrating agent T, 42-46 parts of benzyl alcohol, 11-12 parts of acetone, 10-11 parts of hydrogen peroxide, 3-3.5 parts of methylcellulose, 2-2.4 parts of urotropine, 1.3-1.5 parts of dodecylbenzenesulfonic acid, 1.6-1.9 parts of microporous starch, 2.2-2.5 parts of microcrystalline wax, 0.8-1 part of tetrabutyl titanate, a proper amount of ammonia water, a proper amount of ethyl alcohol, 50-55 parts of water, 1.2-1.5 parts of boronic acid, 0.4-0.6 part of sodium dichloro isocyanurate and 0.9-1.3 parts of nano-silicon dioxide. With using of the boronic acid and the sodium dichloro isocyanurate, the nano-silicon dioxide modified environment-friendly waterborne paint remover has the bacterium resistance and the corrosion resistance, is good in permeability and promotes peeling of a paint film; and by using the nano-silicon dioxide, peeling is formed at an interface, the peeling speed is increased, secondary pollution is prevented, and metal corrosion is retarded.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

Industrial detergent

InactiveCN103937619AReduce stimulationReduce pollutionOrganic detergent compounding agentsSurface-active detergent compositionsHazardous substanceGlycerol

The invention relates to the technical field of mechanical equipment cleaning, and discloses an industrial detergent. The industrial detergent is characterized by comprising the following raw materials by weight percent: 10% to 18% of non-ionic surface active agent, 5% to 15% of diglycolamide oleate borate, 3% to 7% of glycerol, 3% to 10% of defoaming agent, 1% to 10% of dispersing agent, 1% to 5% of anti-staining agent, 5% to 10% of cyclodextrin, 1% to 5% of emulsifying agent, 1% to 5% of kieselguhr and 15% to 70% of deionized water. Compared with the prior art, the industrial detergent disclosed by the invention has the advantages that the stimulation of the surface active agent to skin is reduced due to the addition of the cyclodextrin, i.e., the cyclodextrin and contaminants can form stable inclusion complexes, so that the environmental contamination is reduced; oil dirt is prevented from floating on the water surface due to the addition of the anti-staining agent and the emulsifying agent, so that the secondary staining is avoided; the dirt cleaning speed is rapid, the dirt can be completely dissolved and insoluble substances cannot remain on the surface of a cleaned object in a cleaning process, so that new dirty stains are not generated; the production cost is low; toxic and harmful substances cannot be generated.

Owner:杨文礼

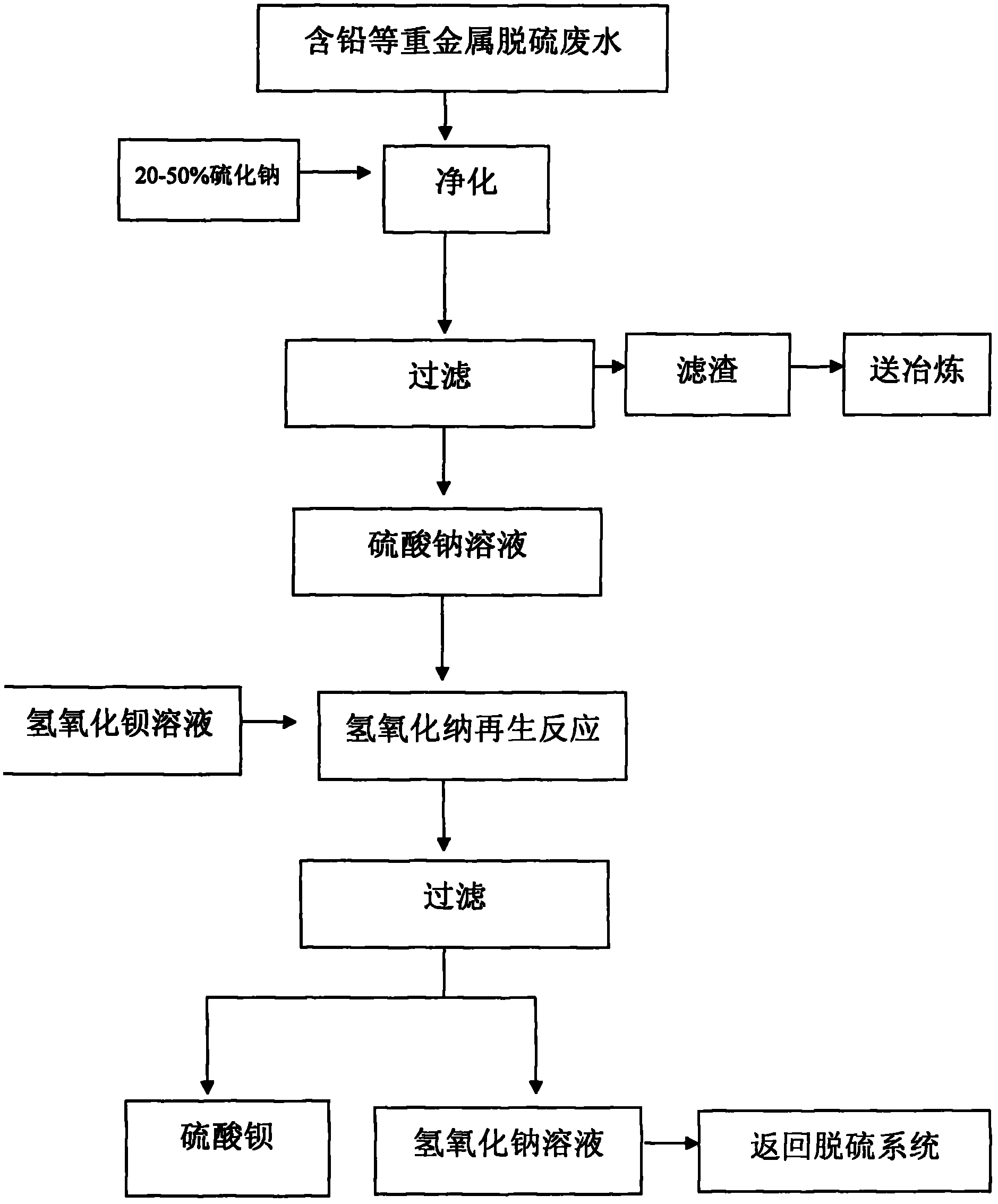

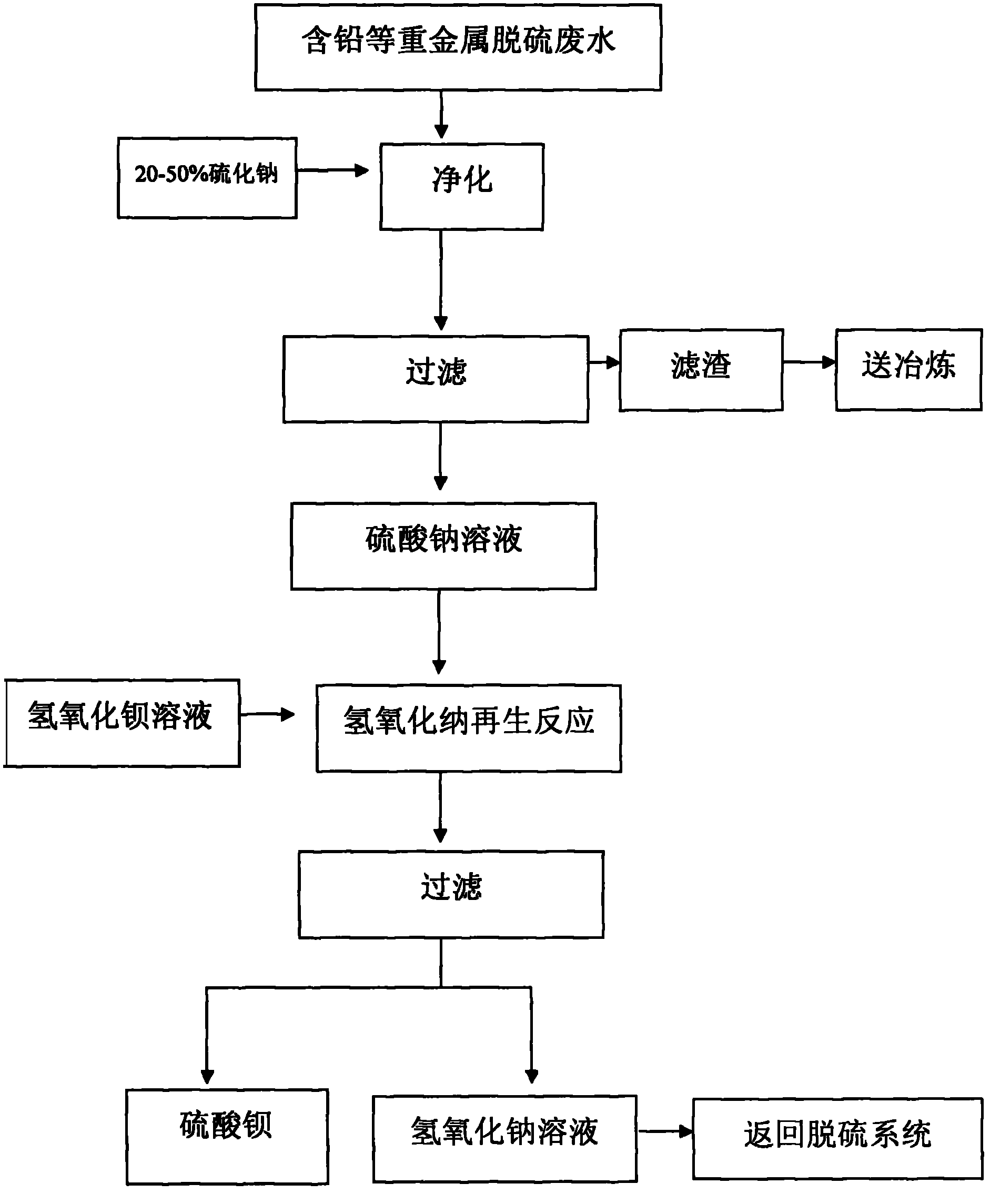

Desulfurized lead-containing wastewater recycling processing method

InactiveCN102424489ANo emissionsAvoid secondary contaminationWater contaminantsWaste water treatment from metallurgical processSOLUTION/DROPSHeavy metals

The invention which discloses a desulfurized lead-containing wastewater recycling processing method relates to the technical field of lead ore smelting. The method is characterized in that the method comprises the following steps: adding a 20-50% sodium sulfide solution with the weight required by a theoretical reaction at normal temperature according to the content of heavy metals in the wastewater, stirring to fully react, taking a quantitative amount of the obtained solution, adding the sodium sulfide solution drop by drop to inspect until no deposition appears, that is, the reaction is completed, filtering out filter residues, slowly adding the filtered solution to a theoretic amount of barium hydroxide, reacting for 20-60min under stirring, and filtering to obtain barium sulfate which can be applied to the storage battery manufacturing operation and a sodium hydroxide solution which returns to a desulfurization system. According to the method of the invention, the heavy metals of lead, copper, cadmium and the like can be removed from the desulfurized lead-containing wastewater, and the wastewater is regenerated into the sodium hydroxide solution which returns to the desulphurization operation with above barium salt, so a problem of secondary pollution of traditional technologies is fundamentally and scientifically avoided, no pollutants are discharged, and energy saving and environmental protection are realized.

Owner:JIESHOU CITY JUNMA IND & TRADE

Dyeing method of cotton type polyester staple fibers produced from PET bottom cut pieces

InactiveCN104894889ASolve the problem of uneven dyeingImprove cleanlinessDry-cleaning apparatus for textilesDyeing processDisperse dyeSOAP

The invention discloses a dyeing method of cotton type polyester staple fibers produced from PET bottom cut pieces. The dyeing method is characterized by specifically comprising the following steps: a, selecting an alkali-resisting disperse dye and grinding until the fineness reaches 2 microns, b, adopting a pretreatment dyeing one-bath-one-step process, firstly, adding regenerated polyester staple fibers to a dye jar, dissolving a pure alkali agent, an even penetrating agent GL and a chelating dispersant DF101 according to a dyeing bath ratio of 1: (5-7) and putting into the dye jar, and adding the alkali-resisting disperse dye to obtain mixed dye liquor; C, regulating the pH value to the range of 13-14, gradually increasing the temperature to the range of 128-132 DEG C and preserving heat for 1 hour; and D, performing water washing, soap boiling and water washing on the dyed fibers, thereby finishing dyeing. The dyeing method is used for solving the problem of uneven dyeing of the cotton type polyester staple fibers produced from the PET bottom cut pieces; small-batch and multi-variety production is realized, the requirements of market variety diversification are met, the process time is greatly shortened, the yield is improved, the environment can be protected, the dye-uptake can be above 90%, the color fastness is high and the usability of the products is improved.

Owner:微山县南四湖再生资源利用有限公司

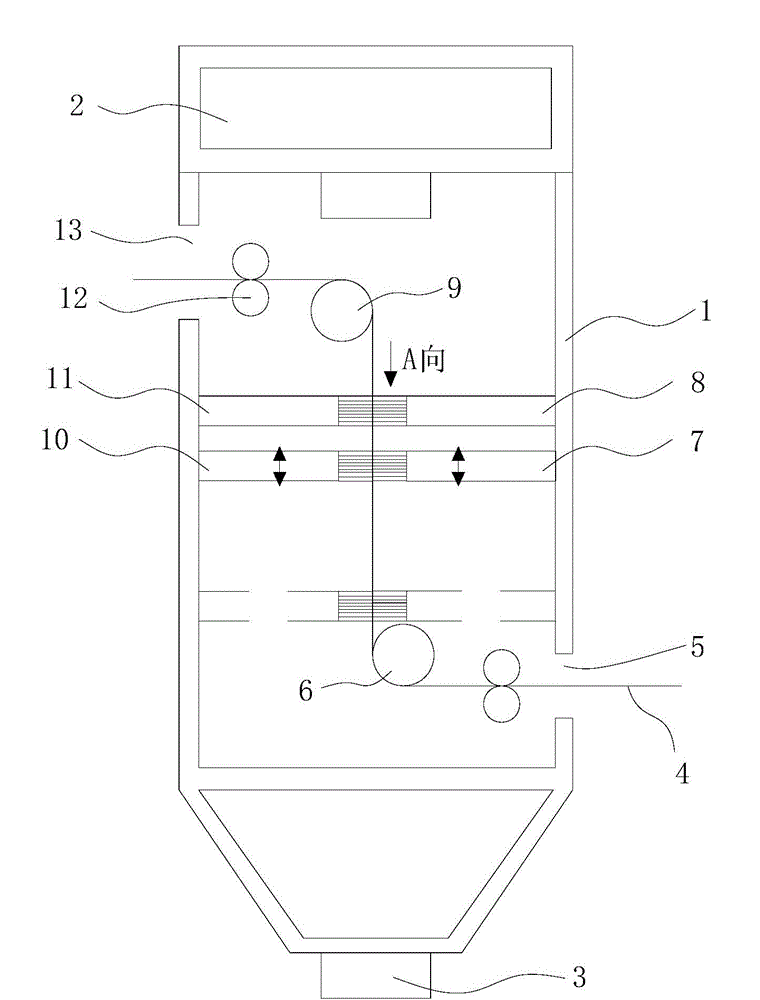

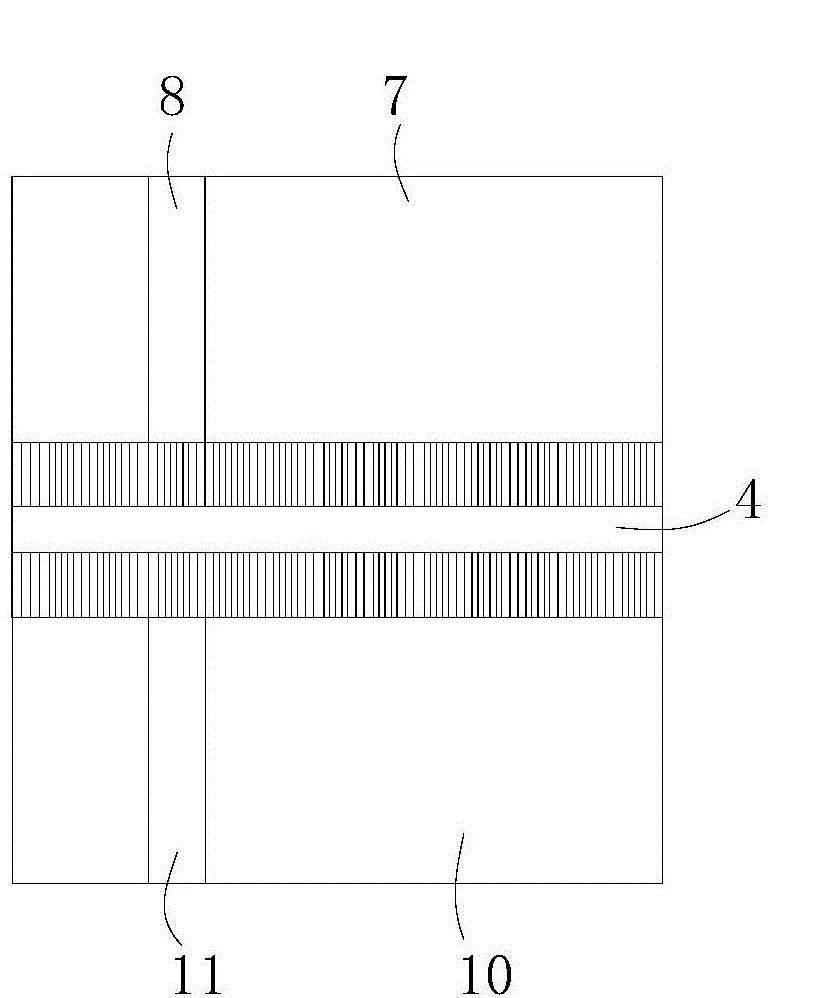

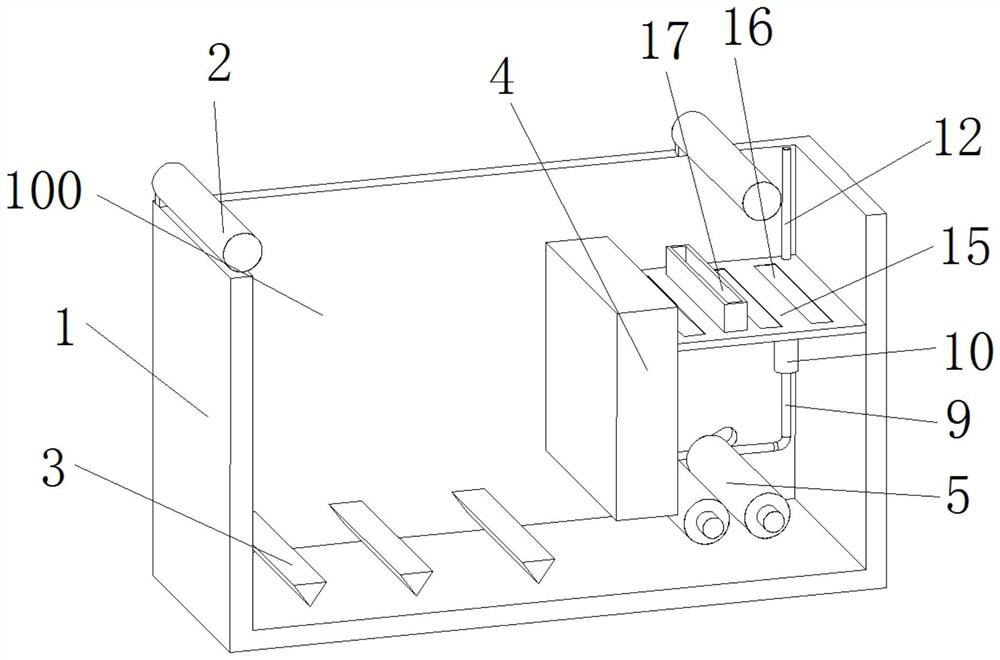

De-dusting device capable of rapidly cleaning fabric dust

InactiveCN105583171AEffective scatterTake it away in timeCleaning using toolsCleaning using gasesArchitectural engineeringAir blower

The invention discloses a de-dusting device capable of rapidly cleaning fabric dust. The de-dusting device comprises a box body, the top of which is provided with an air blower. The bottom of the box body is provided with an induced draft fan. The bottom on one side of the box body is provided with a cloth inlet. The top on the other side of the box body is provided with a cloth outlet. A first driving roller and a second driving roller are arranged in the middle of the inside of the box body. The first driving roller and the cloth inlet are located on the same height. The second driving roller and the cloth outlet are located on the same height. The inside of the side wall, provided with the cloth inlet, of the box body is provided with a first transverse hairbrush, and a first vertical hairbrush located below the first transverse hairbrush. The inside of the side wall, provided with the cloth outlet, of the box body is provided with a second transverse hairbrush and a second vertical hairbrush located below the second transverse hairbrush. The widths of the first vertical hairbrush and the second vertical hairbrush are the same as the fabric width so that surface dust of the fabric can be effectively cleaned and dust is prevented from adhering to fabric or dispersing to the environment.

Owner:WUXI HONGFEN MACHINERY FACTORY

Environment-friendly brick and preparation method thereof

The invention discloses an environment-friendly brick and a preparation method thereof, which belong to the technical field of building materials. The environment-friendly brick is prepared from the following raw materials in parts by weight: 10 to 20 parts of coal ash, 10 to 20 parts of river sand, 10 to 20 parts of building rubbish, 10 to 20 parts of coal gangue, 10 to 20 parts of straw and 10 to 20 parts of kaolin tail mineral powder. The environment-friendly brick provided by the invention is high in compressive strength, good in breaking resistance and low in cost, the resource is effectively saved, and the secondary pollution on the environment is avoided.

Owner:广西塔锡科技有限公司

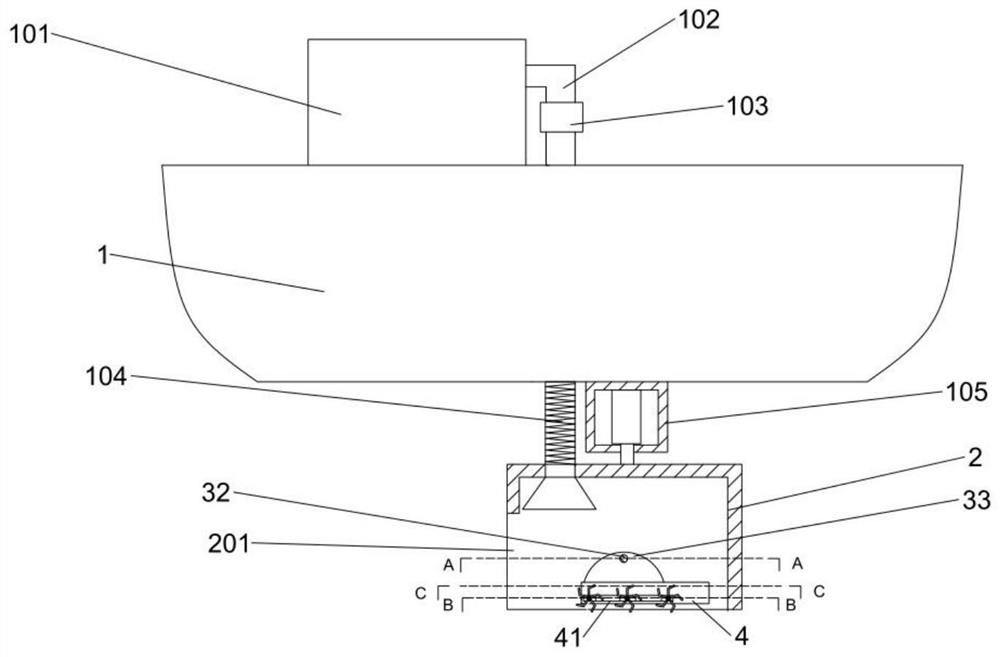

Water conservancy construction rapid desilting equipment

InactiveCN112343114AImprove crushing efficiencyCompletely brokenMechanical machines/dredgersSludgeHull

The invention discloses water conservancy construction rapid desilting equipment. The rapid desilting equipment comprises a ship body, wherein a silt storage tank is arranged on the ship body, and thesilt storage tank is internally provided with a silt-water separator; and the rapid desilting equipment further comprises a silt pumping device, a lifting device, a box body and a sludge crushing device, wherein the silt pumping device is arranged on the ship body and used for pumping silt, the lifting device is arranged at the bottom of the ship body, the box body arranged below the ship body, the top of the box body is fixedly connected with the movable end of the lifting device, a silt inlet is formed in one side wall of the box body, and the sludge crushing device is arranged on the box body. According to the rapid desilting equipment, the sludge crushing device is high in sludge crushing efficiency, sludge can be selected to be crushed horizontally or vertically through a turnover device, sludge crushing is more thorough and efficient during horizontal crushing, sludge of different thicknesses can be crushed at the same time during vertical crushing, the crushing area is increased, sludge diffusion can be prevented through the box body, and secondary pollution of the scattered sludge to a river is prevented.

Owner:张民录

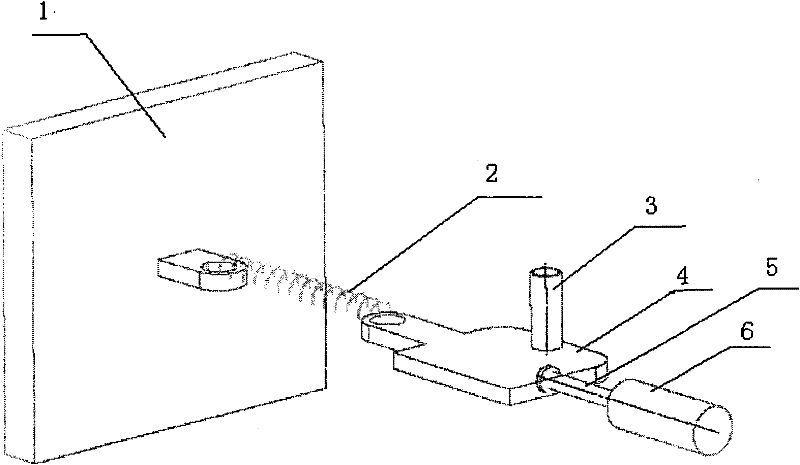

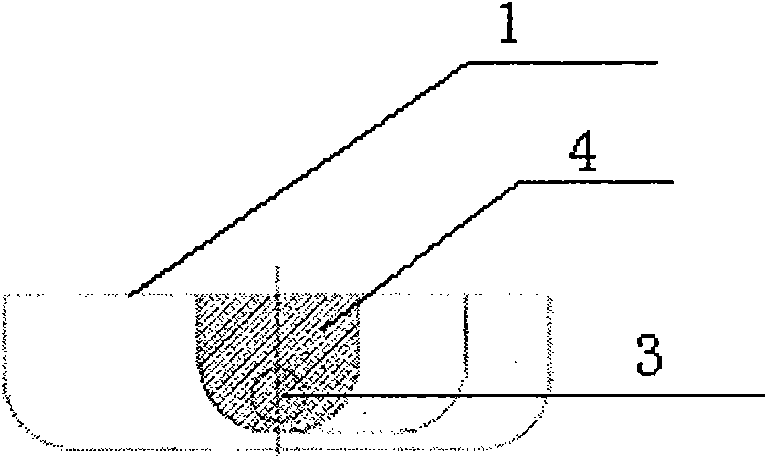

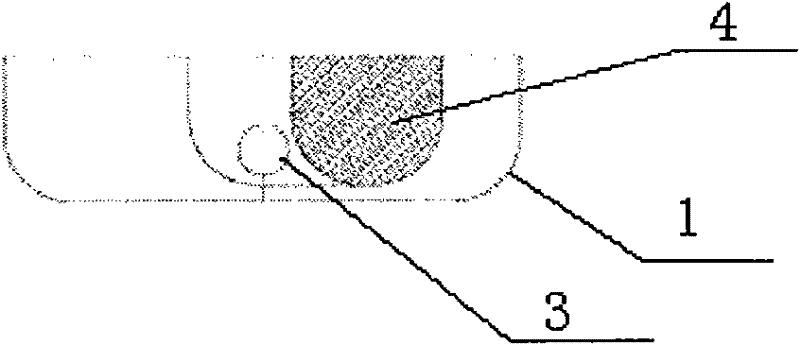

Dustproof device for water outlet of water dispenser

The invention provides a dustproof device for a water outlet of a water dispenser. The dustproof device comprises a dustproof shell, a dustproof slip sheet and a dustproof slip sheet control system, wherein the dustproof slip sheet control system consists of an iron core, a spring and a controller; the controller comprises an optical coupler, a singlechip, a driving chip, a relay and an electromagnetic solenoid; one end of the dustproof slip sheet is directly connected with the iron core, the other end of the dustproof slip sheet is connected with the dustproof shell through the spring, and the iron core is connected with the electromagnetic solenoid; and the controller is controlled by a water dispenser switch. The dustproof device can effectively prevent dust and bacteria in the air from being adsorbed on the water outlet and ensure cleanness and sanitation of the water outlet; and because the dustproof slip sheet in the dustproof device can automatically slip according to on and off of the water dispenser switch, the dustproof device is more convenient and sanitary in practical application.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

High-pressure water jet electric dirt brushing and stain removing three-linkage clean-keeping device

ActiveCN104707820AAvoid secondary contaminationFast dripping and peeling off stainsCleaning using toolsCleaning using liquidsSewageEngineering

The invention discloses a high-pressure water jet electric dirt brushing and stain removing three-linkage clean-keeping device. The device comprises a stain scraping device, a dirt removing device and a water spraying device, all of which are erected on a vertical wall support. The stain scraping device comprises a rotating scraping roll used for scraping waste water on a wall face, the dirt removing device comprises a rotating wiping roll used for removing the stain on the wall face, and the water spraying device comprises a water spraying pipeline. The rotating scraping roll, a water spraying port of the water spraying pipeline and the rotating wiping roll are arranged from top to bottom in sequence. The working face of the rotating scraping roll and the working face of the rotating wiping roll are the same vertical face, and the vertical face is opposite to the water spraying port of the water spraying pipeline. When a high-rise building outer wall face is cleaned, operation is convenient, the cleaning effect is good, the speed is high, labor and time can be saved, cost is reduced, and construction is safe and efficient.

Owner:浙江嘉苑园艺景观有限公司

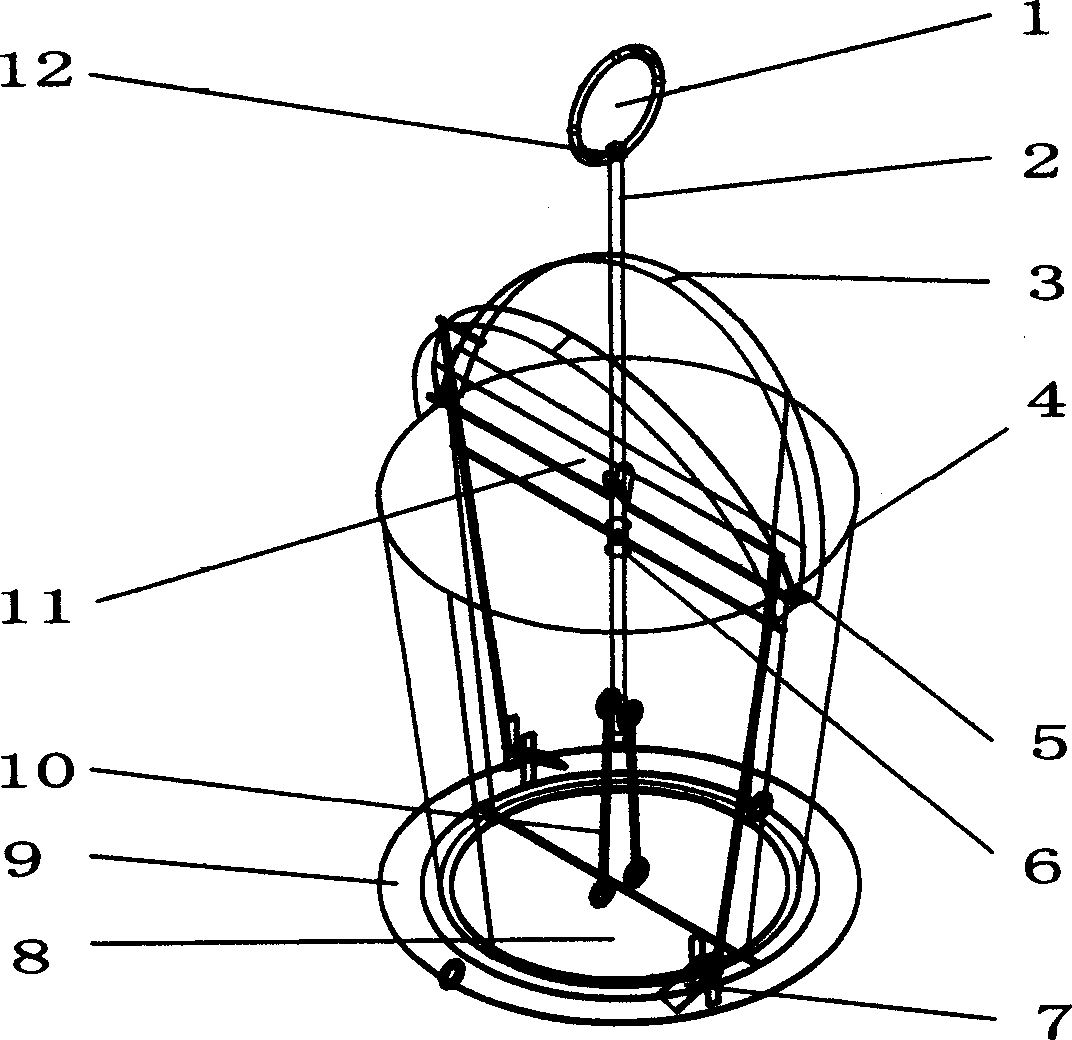

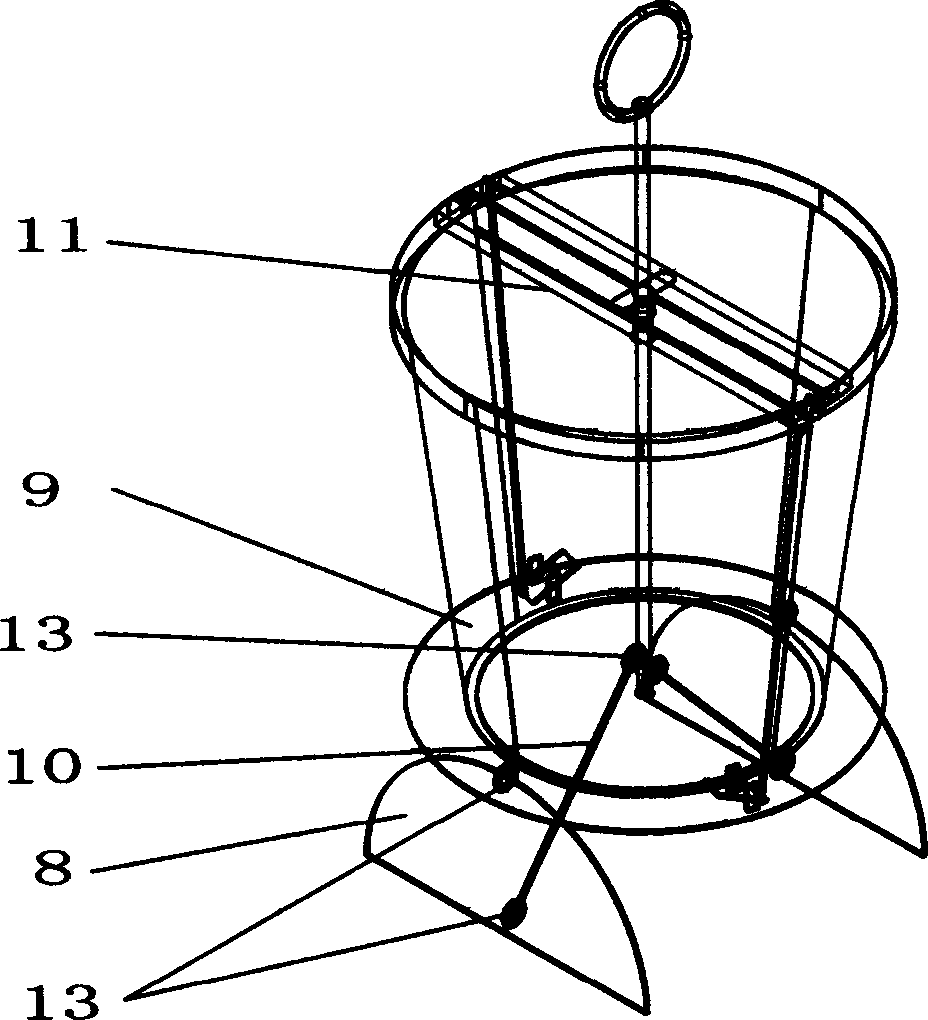

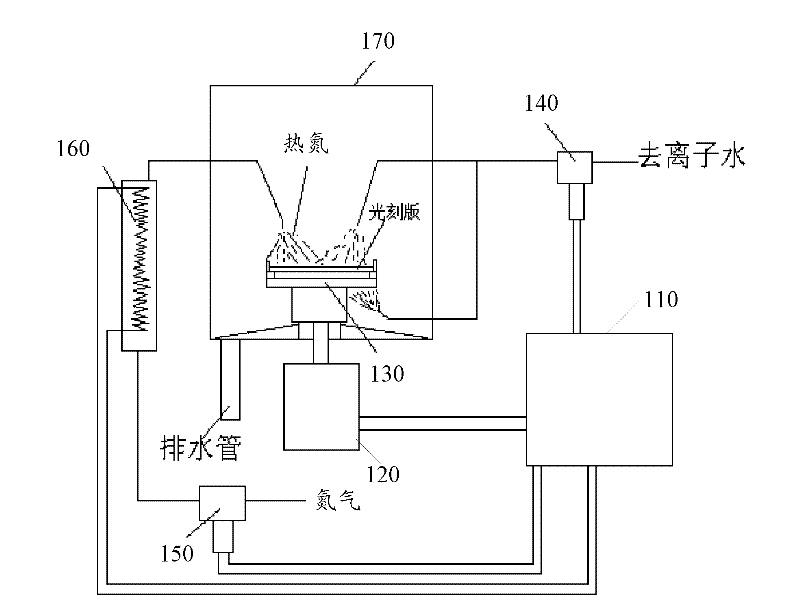

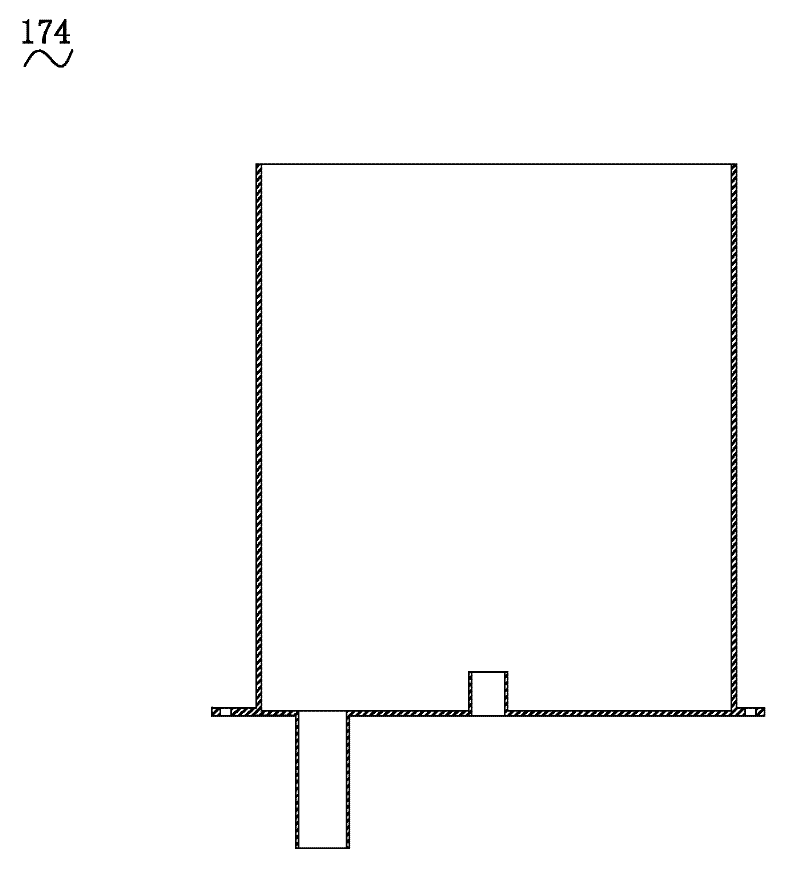

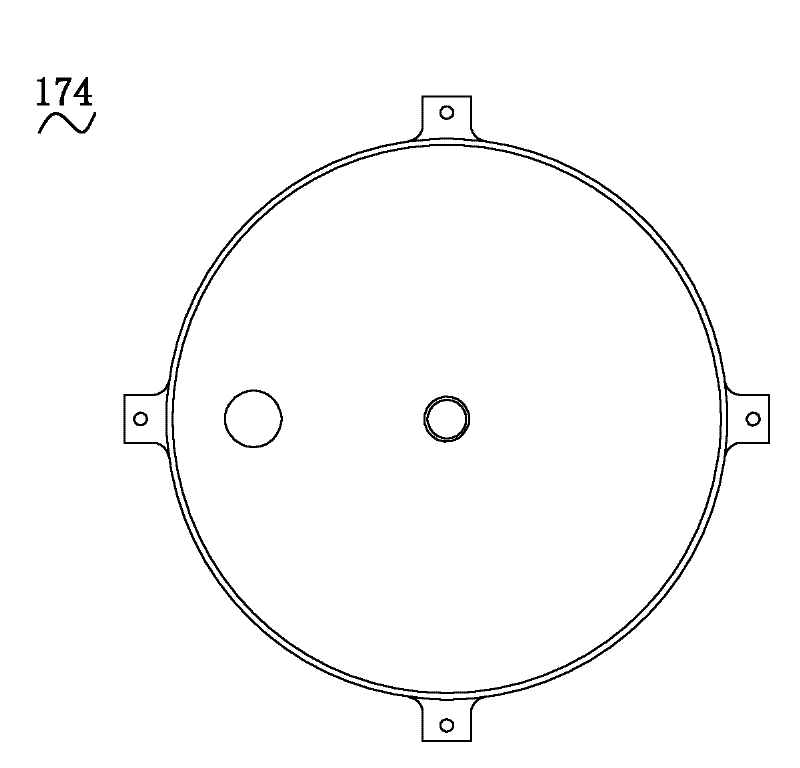

Mask spinning cleaning machine and cleaning method of mask

InactiveCN102357481AAvoid scratchesAvoid secondary contaminationDrying gas arrangementsCleaning using liquidsMachine controlEngineering

The invention relates to a mask spinning cleaning machine. The machine comprises a mask spinning cleaning machine control circuit, a driving device, a mask clamping device, an outlet valve, a sprinkler head, a gas outlet valve, a jet head, a heating device and a pipeline, wherein the mask spinning cleaning machine control circuit is electrically connected with the driving device, the outlet valve, the gas outlet valve and the heating device and is used for controlling the driving device to drive the mask clamping device to rotate around a rotating shaft, controlling on / off of the outlet valve and the gas outlet valve and controlling the heating device to carry out heating; the outlet valve is connected with the sprinkler head by a water pipe to spray deionized water onto a mask; the gas outlet valve is connected with the heating device and the jet head by a gas pipe in sequence; and the jet head is used for jetting the heated gas onto the mask. The invention also relates to a cleaning method of the mask. The machine and the cleaning method have the following beneficial effects: as the surface of the mask is dried while being spun during cleaning, the mask cleaning efficiency is much higher than that of the traditional technology and watermarks can no longer appear on the surface of the mask; and the mask is directly put into a mask box after being cleaned, thus avoiding secondary contamination.

Owner:深圳深爱半导体股份有限公司

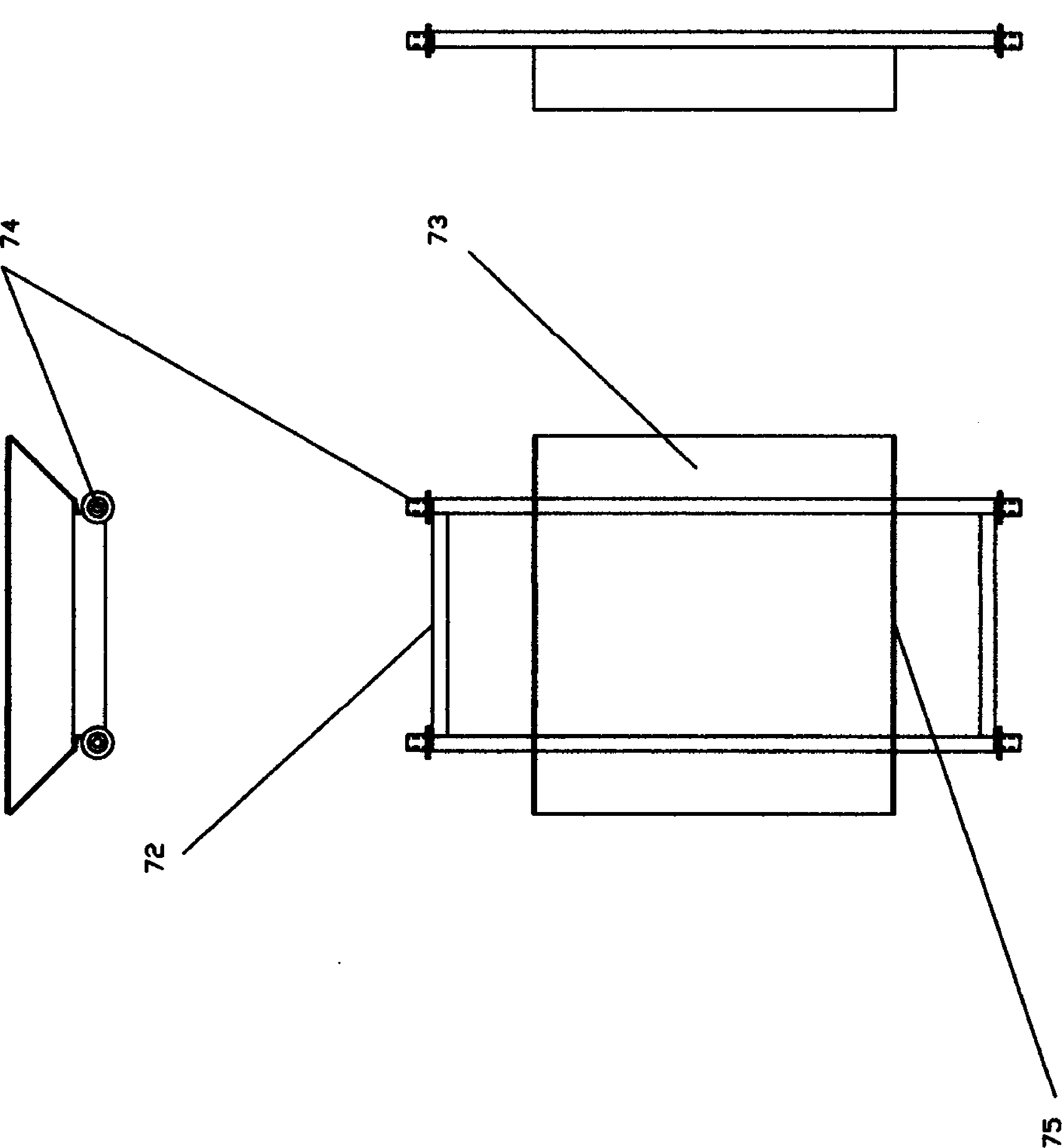

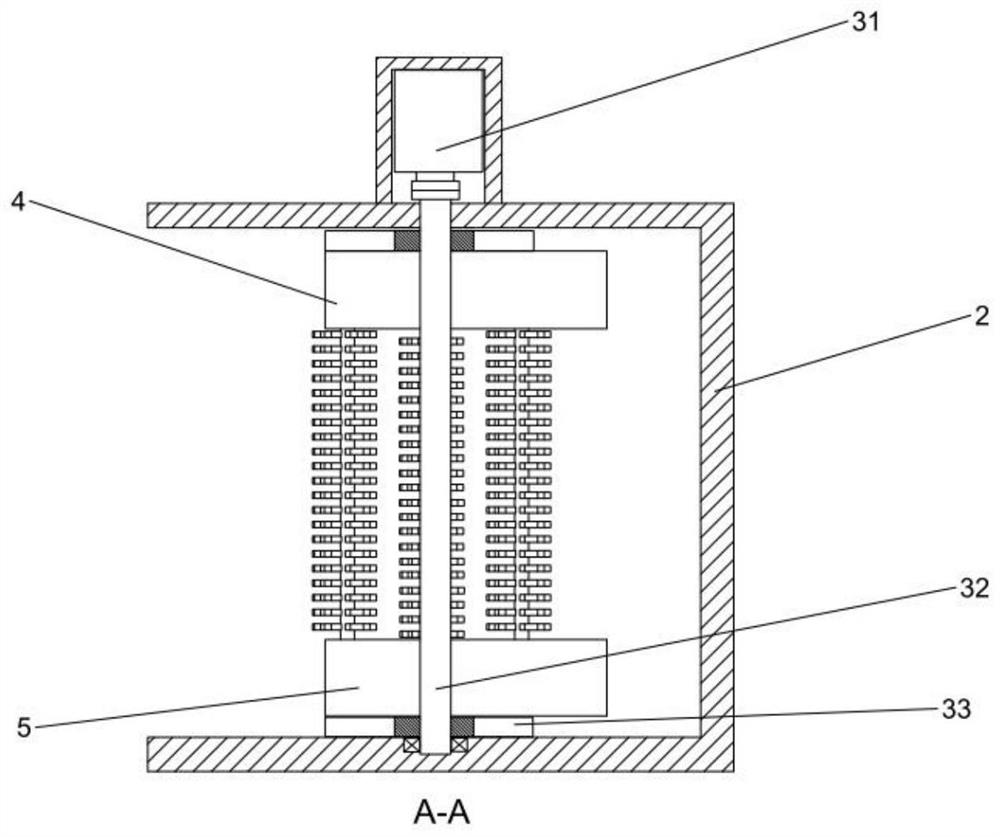

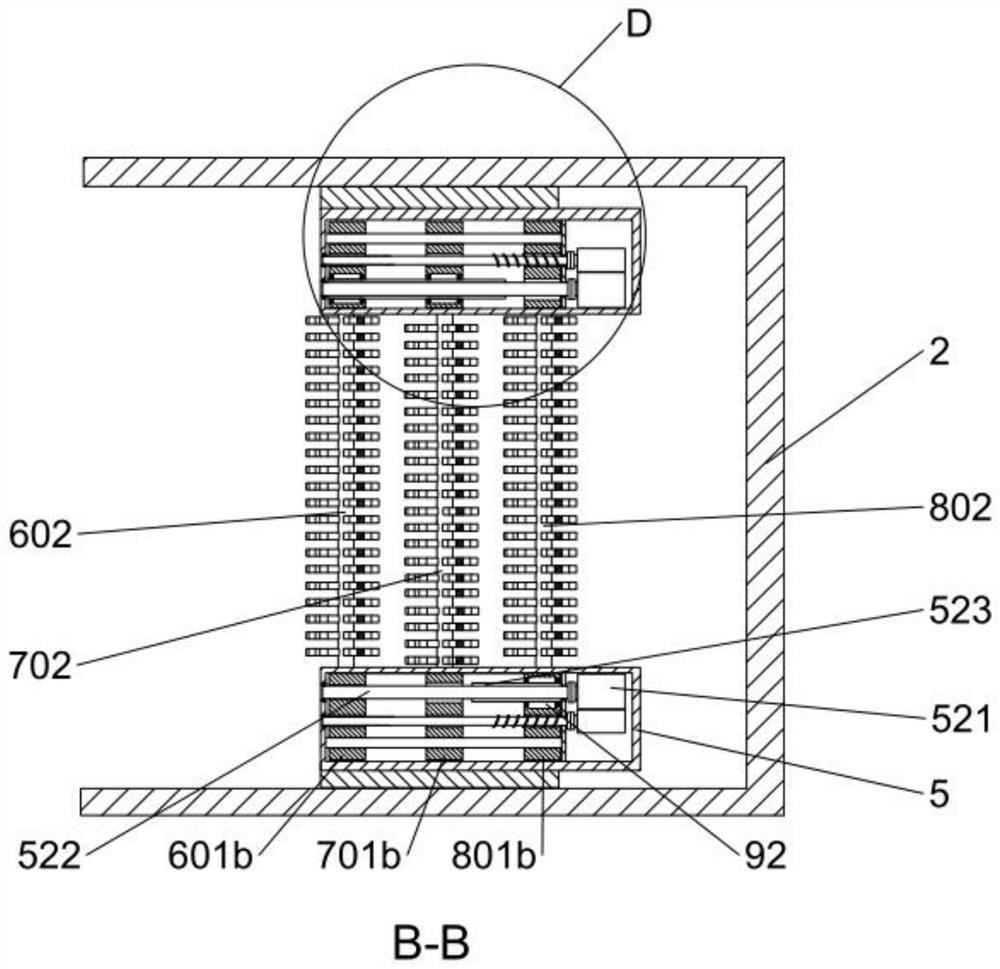

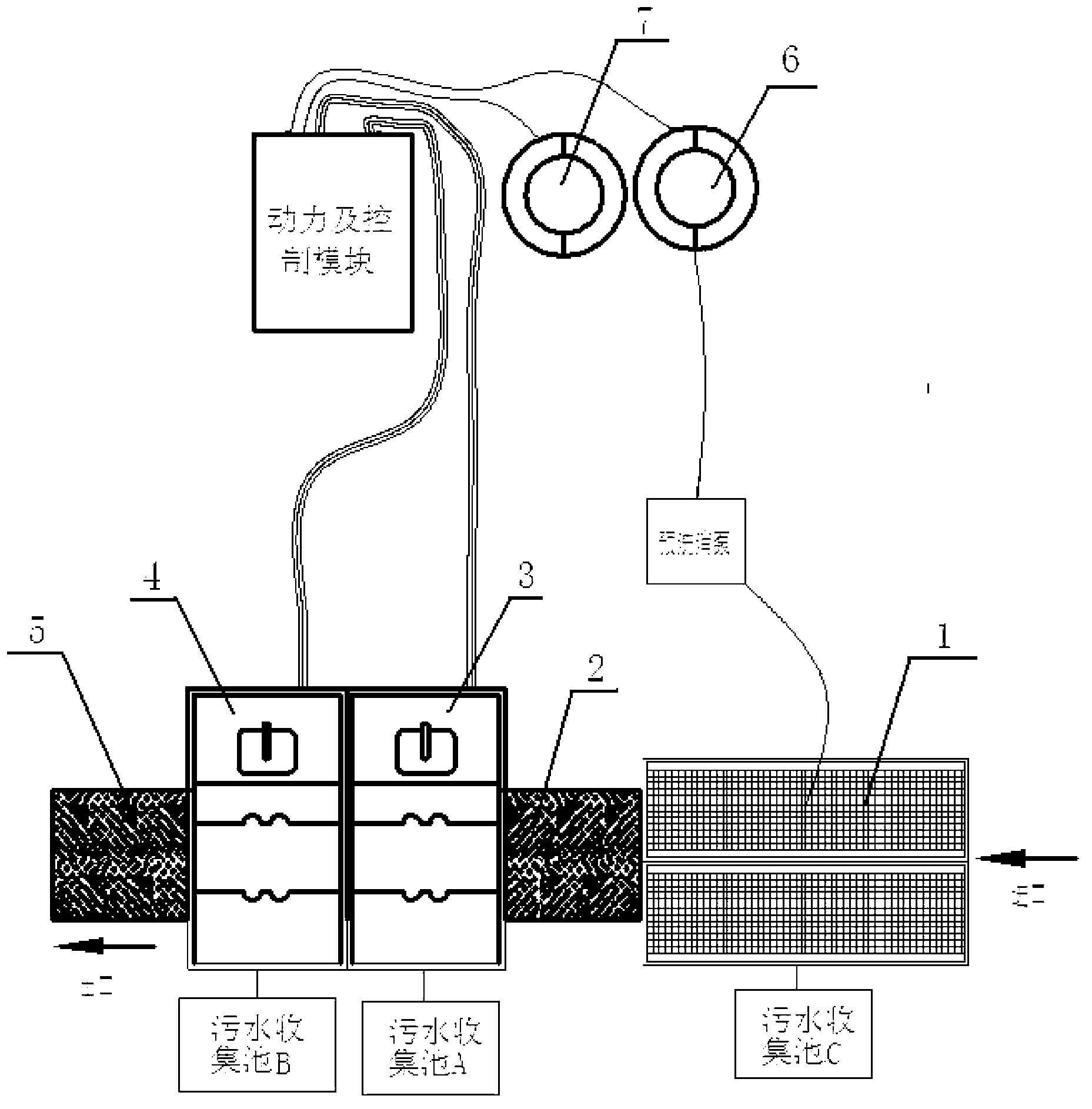

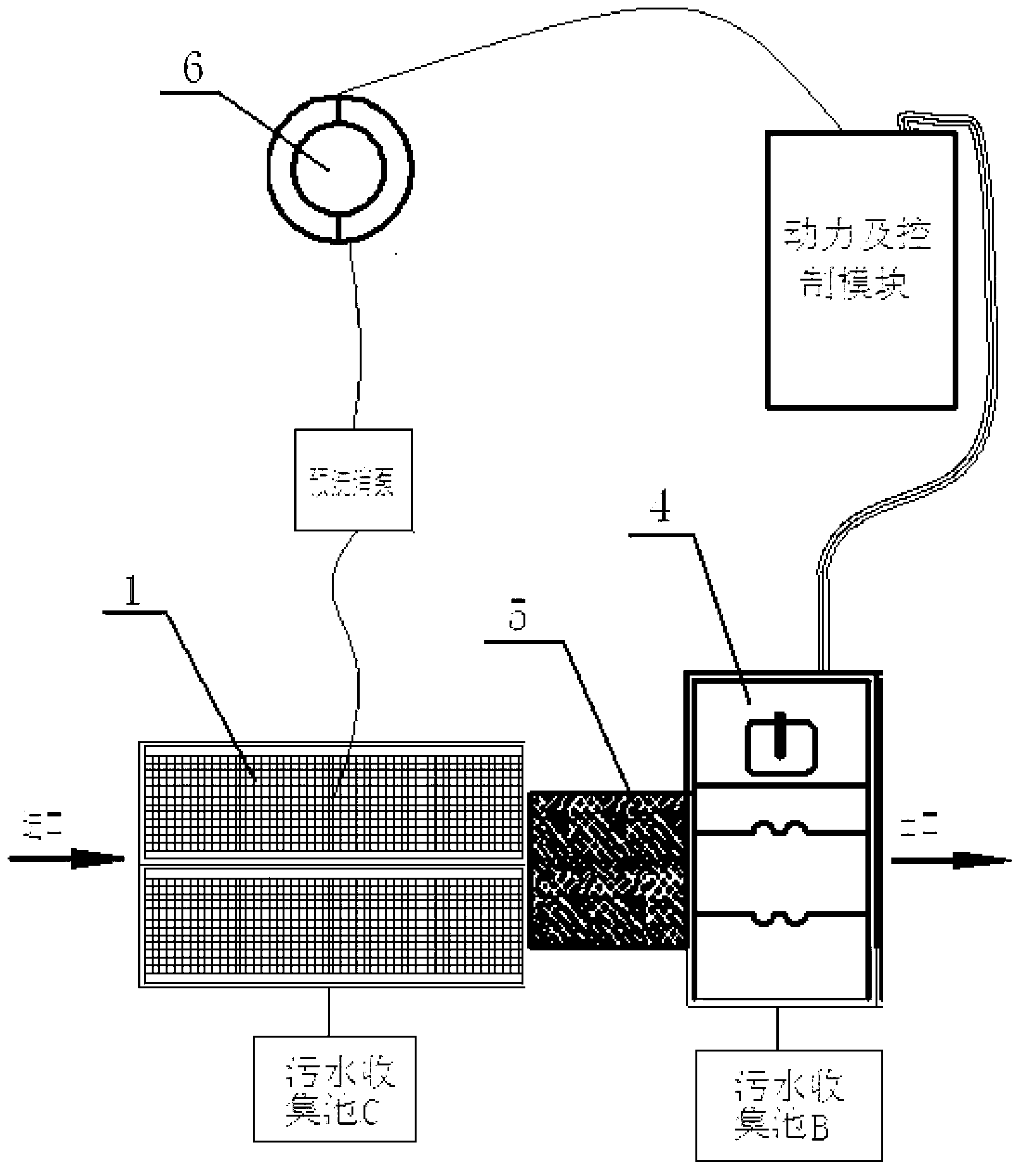

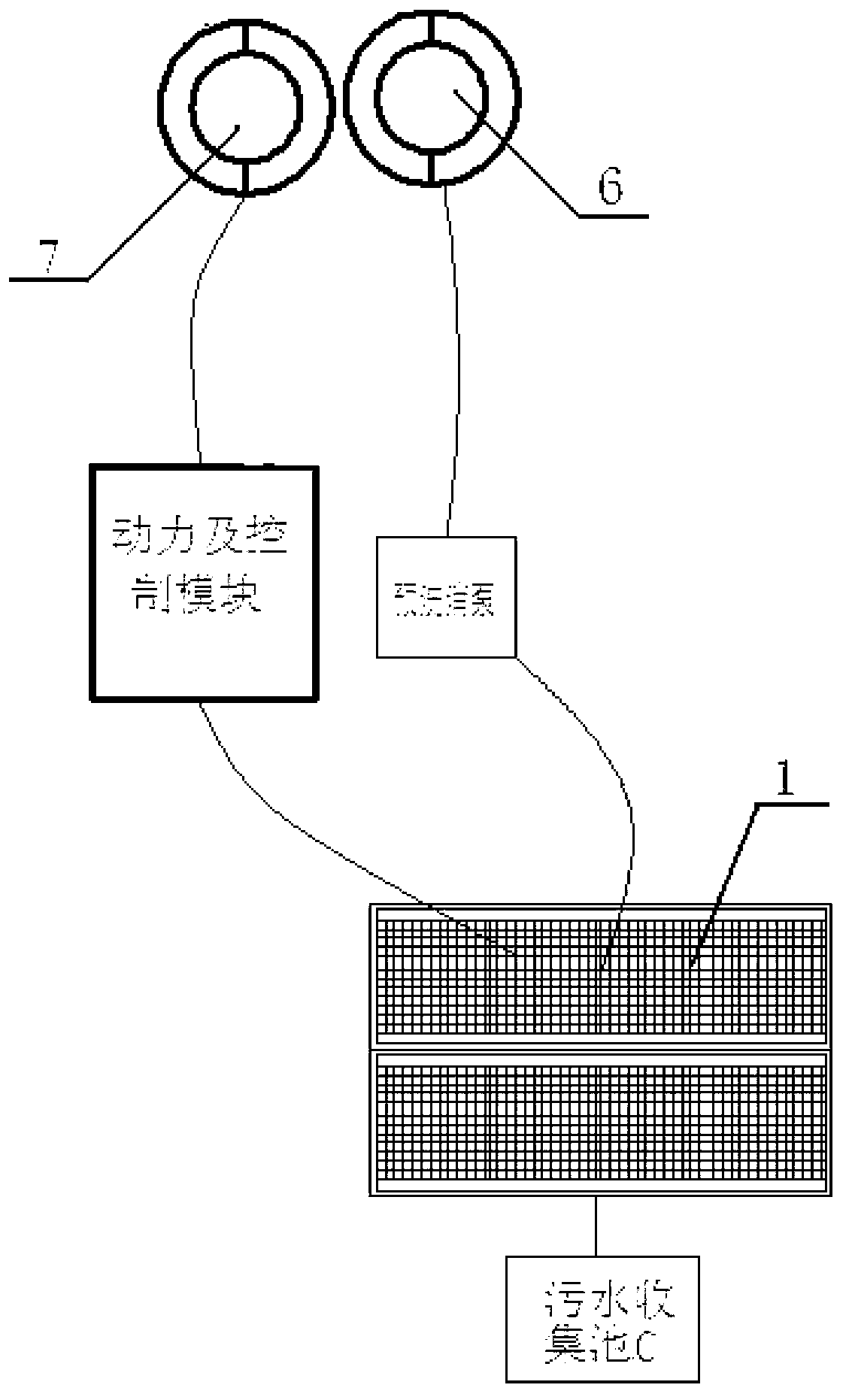

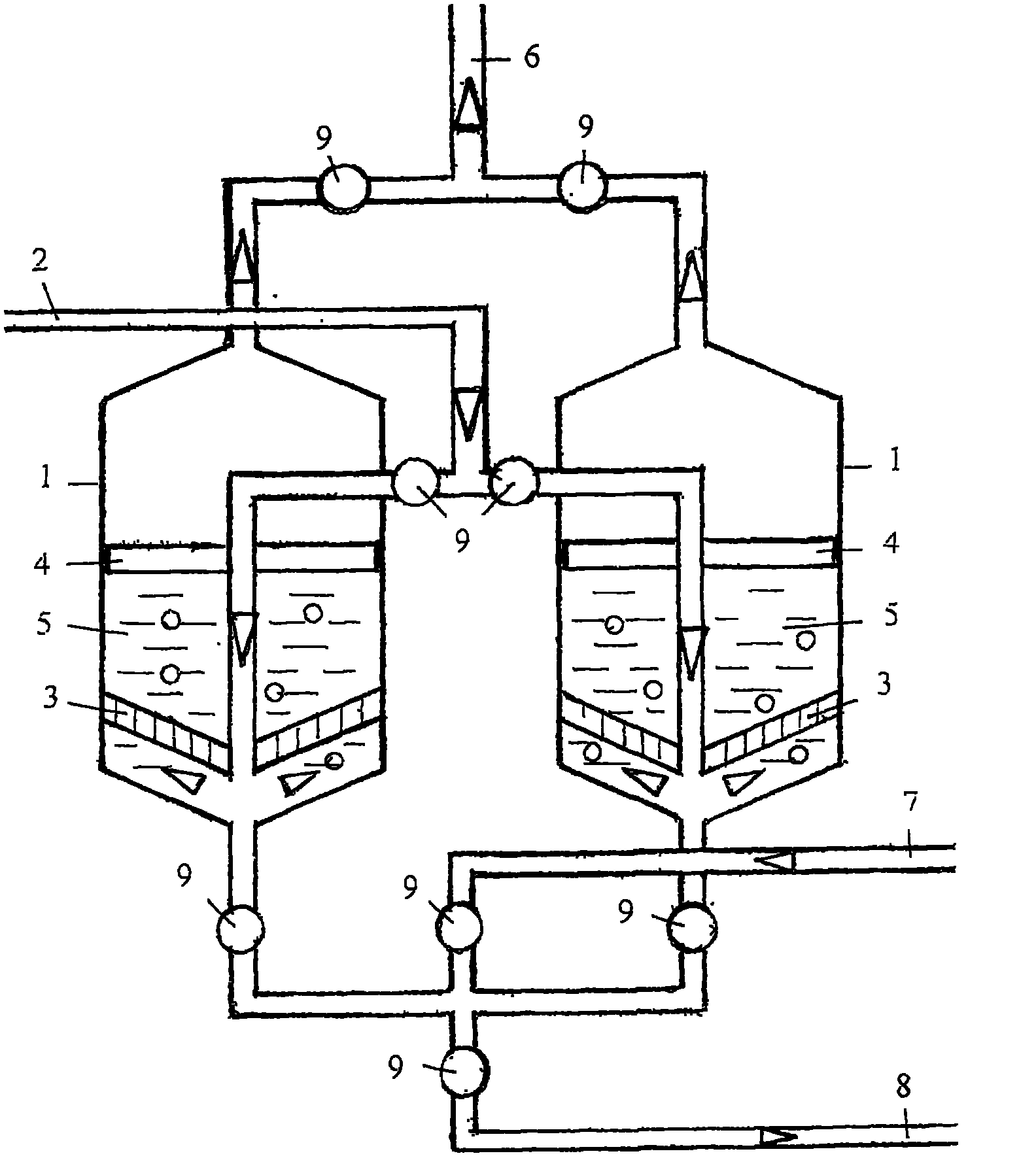

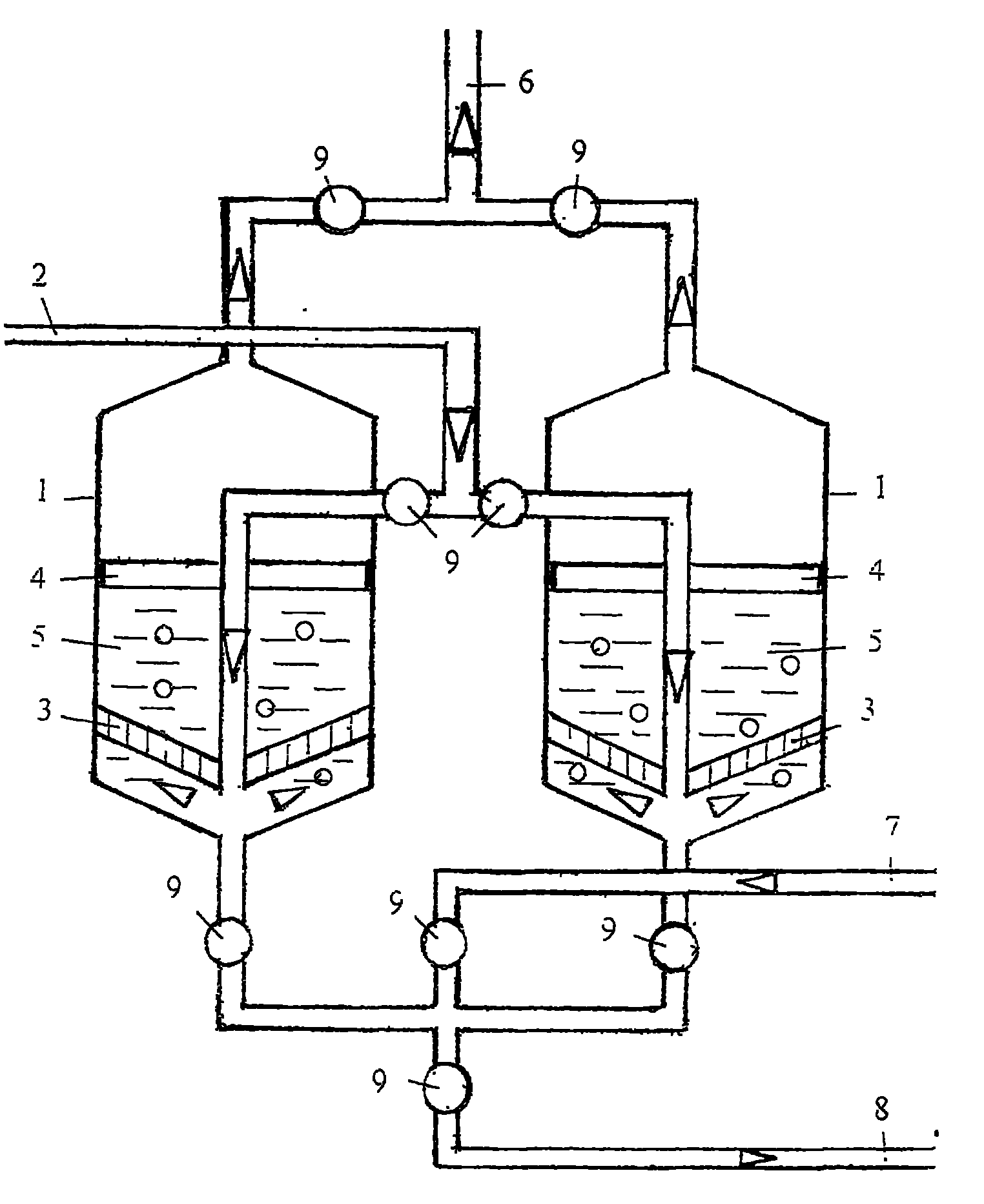

Nuclear biochemical pollution box group decontamination system

InactiveCN102909189ASame dimensionsEasy to transportCleaning using liquidsEnvironmental engineeringPollution

The invention provides a nuclear biochemical pollution box group decontamination system. The system comprises a pre-decontamination box group, a drug decontamination box group, a clear water decontamination box group and an equipment and accessory box group; the appearance sizes of the four box groups are the same; the pre-decontamination box group internally comprises a pre-decontamination channel, an external decontamination pump and two spray guns with different lengths; the drug decontamination box group internally comprises a drug decontamination module and a netty wall board A; the clear water decontamination box group comprises a clear water decontamination module and a netty wall board B; the equipment and accessory box group internally comprises a power and control module; and the power and control module comprises a clear water pump, a drug pump and a control module. The decontamination system has three different combining forms for respectively aiming at different pollution conditions and different decontaminated objects in the use field, is flexible to combine and has a strong field adaptability; and the decontamination process adopts the streamlined operation, so that the nuclear biochemical pollution box group decontamination system is complete to decontaminate and has a high efficiency.

Owner:中国人民解放军防化学院 +1

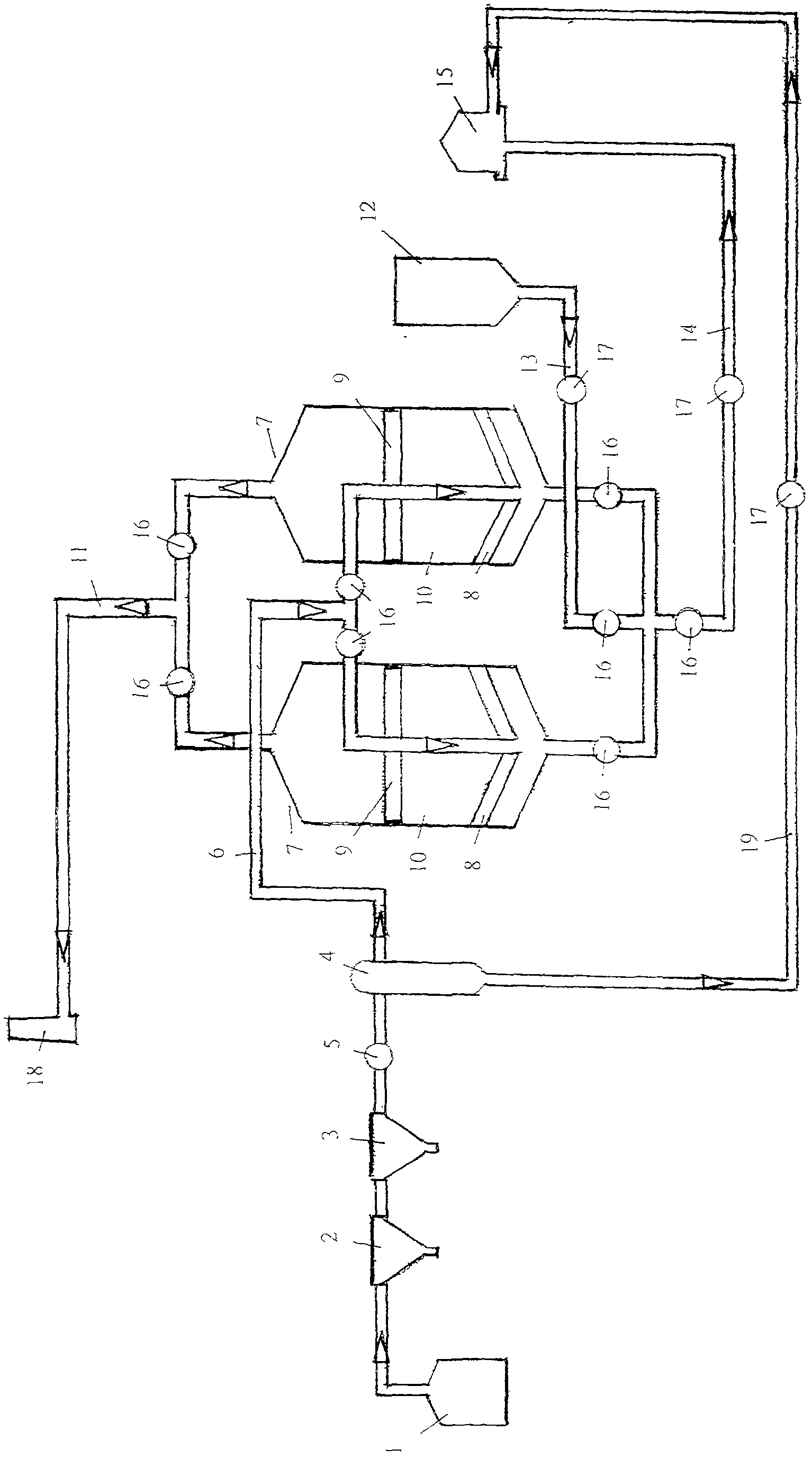

Coal-fired power plant flue gas sulfur dioxide catalytic desulfurization production and technical flow

ActiveCN102218264AAvoid secondary contaminationImportant industrial useDispersed particle separationSulfateControl system

The invention discloses a coal-fired power plant flue gas sulfur dioxide catalytic desulfurization production and technical flow and application of catalyst for coal-fired power plant flue gas sulfur dioxide catalytic desulfurization. The invention has high desulfurization rate, is stable and is easy to grasp, can recycle and use the sulfur dioxide and turn the harm into benefit to create huge economic benefits for coal power enterprises. The catalytic desulfurization production and technical flow are applications of the catalyst in practice. A catalytic desulfurization device comprises a supply system for producing catalyst and a catalyst distributing tank, a raw gas processing system consisting of a secondary dedusting and pressurizing fan and a heat exchanger, and dual-body catalytic towers arranged in a core device and mutually switched through an appliance and control system and a transfer switch, and the uniformity of a catalytic system and a cycling system is formed by shifting operation; and after desulfurization, a sulfur dioxide saturated sulphate liquid becomes an industrial material, thus achieving the purpose of changing wastes into values. The technology is applicable for the environmental protection of various coal-fired enterprises.

Owner:叶汉华 +2

High-strength environmental protection brick and preparation method thereof

The invention discloses a high-strength environmental protection brick and a preparation method thereof and belongs to the technical field of building materials. The raw materials of the high-strengthenvironmental protection brick comprises, by weight, 5-15 parts of fly ash, 15-25 parts of shale mine, 4-16 parts of attapulgite, 5-15 parts of coal gangue, 5-15 parts of perlite and 5-15 parts of kaolin tailings powder. The high-strength environmental protection brick has the advantages of strong in compressive strength, good in flex resistance, low in cost, effective in saving resources, and avoidable in second pollution to the environment.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

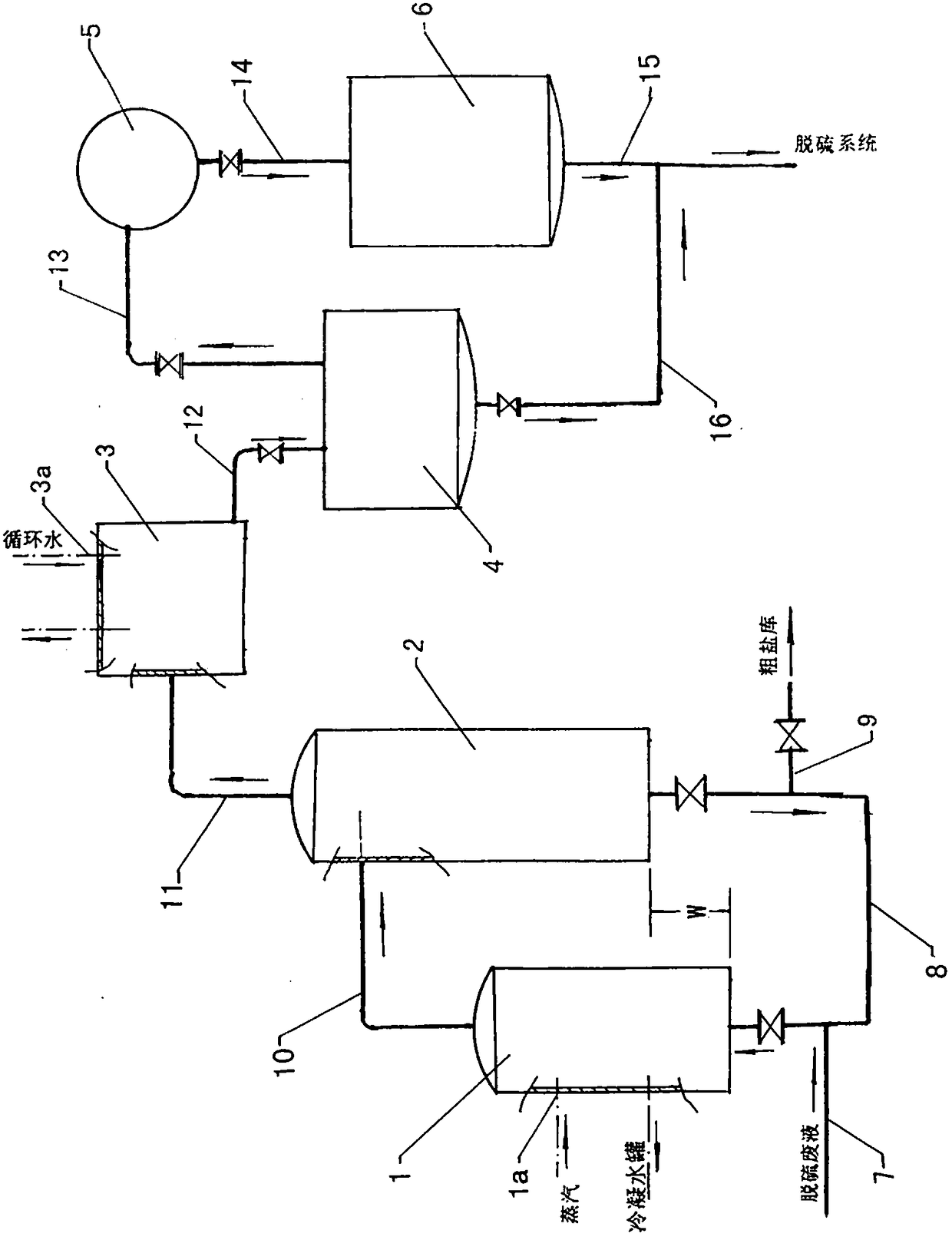

Process for extracting secondary salt from desulfurization waste liquid

PendingCN108217690AImprove desulfurization effectImprove desulfurization efficiencyThiosulfates/dithionites/polythionitesThiocyanic acidLiquid wasteInternal pressure

The invention discloses a process for extracting secondary salt from desulfurization waste liquid. An input quantity of the desulfurization waste liquid in a desulfurization waste liquid conveying pipe connected with a concentrated liquid conveying pipe is controlled at 0-5 t / h; a steam pipeline with a heat exchange area of 120-140 m<2> is mounted in an evaporator; a steam input pipe on the steampipeline has a steam temperature of 120-160 DEG C and a steam pressure of 0.2-0.5 MPa; a gas-liquid mixture conveying pipe is connected with a top end of the evaporator and an upper side wall of an evaporation chamber; the evaporation chamber has a volume of 12-14 m<3>, an internal pressure of 0.05 MPa and a top temperature of 90-100 DEG C; the concentrated liquid conveying pipe with a switch is connected with lower parts of the evaporator and the evaporation chamber, wherein bottom ends of the evaporator and the evaporation chamber has a position difference W; an ammonia-containing steam conveying pipe is connected between the evaporation chamber and a condensation cooler; a circulation cooling water pipeline is arranged in the condensation cooler; a water flow rate in a circulated waterinlet pipe is 25-35 t / h; cooled ammonia water is returned to a desulfurization system; the desulfurization waste liquid is subjected to two-stage evaporation and is separated and crystallized to extract the secondary salt. The process provided by the invention has excellent economic and environmental protection benefits.

Owner:湖南华菱涟源钢铁有限公司 +1

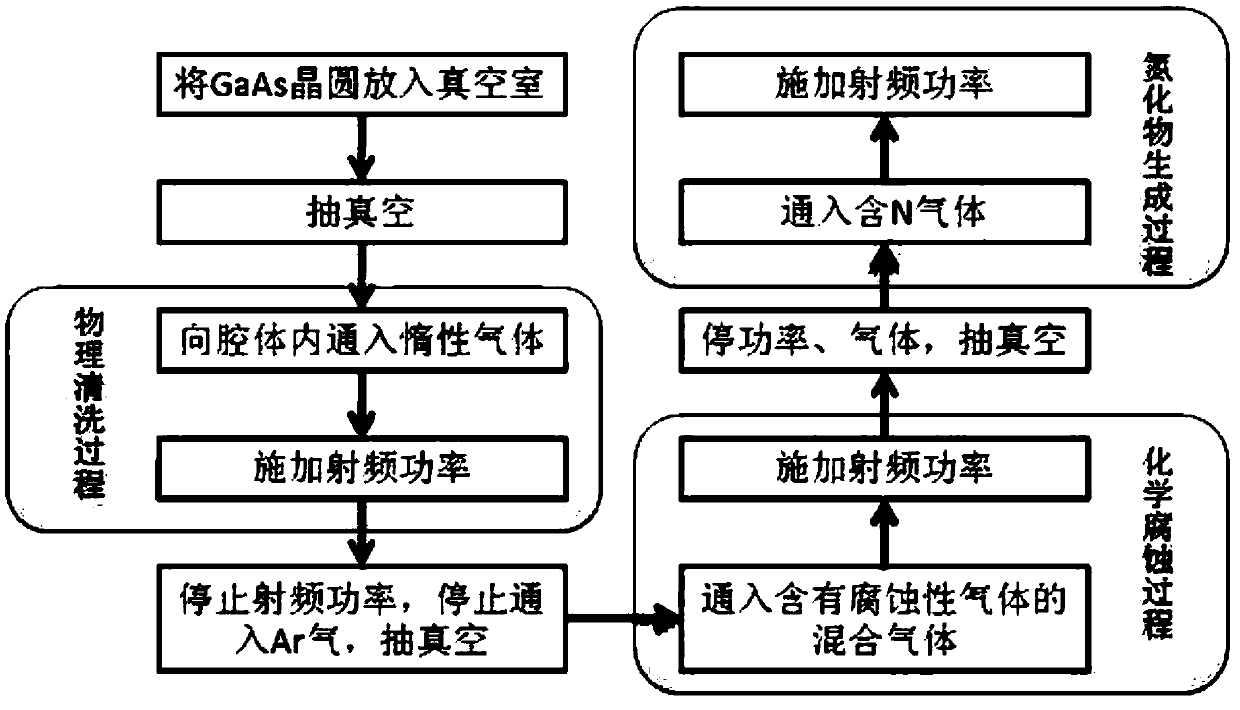

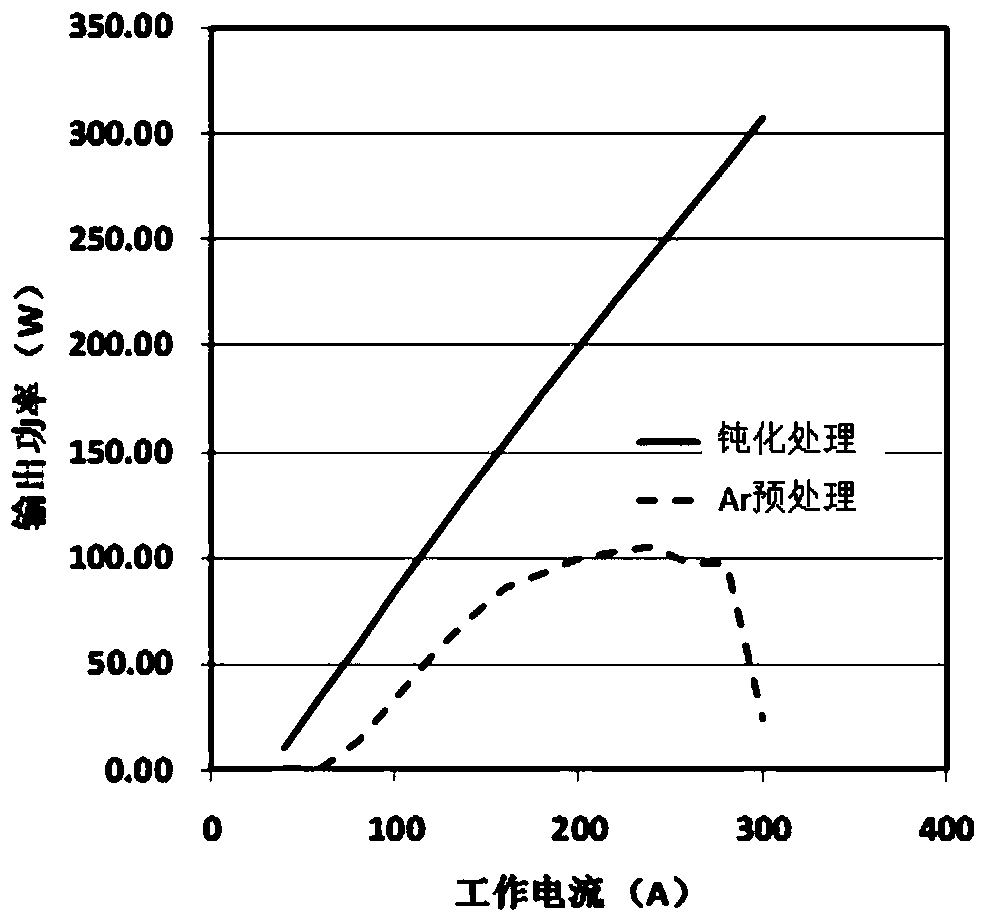

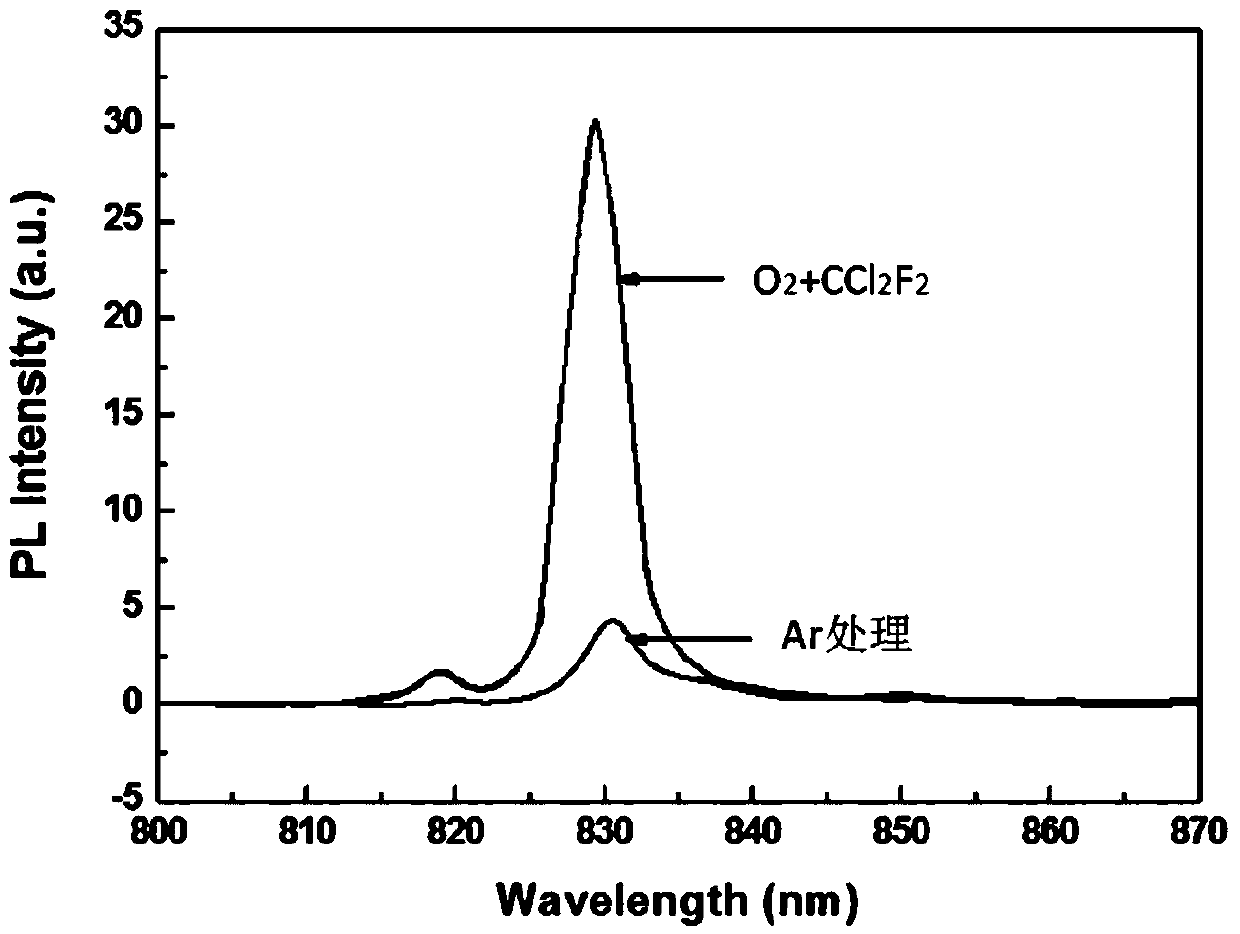

Novel method for modifying GaAs material surface

ActiveCN105513948AAvoid secondary contaminationAchieve seamless connectionSemiconductor/solid-state device manufacturingChemical reactionSurface oxidation

The invention provides a novel method for modifying a GaAs material surface. The method may stably and reliably reduce defects on the GaAs material surface, decreases a possibility of surface oxidation, and simplifies processing steps. The method comprises steps of: (1) placing a GaAs material to be processed in a vacuum chamber, adding inert gas into the vacuum chamber after the vacuum chamber is made vacuum , and forming stable plasma under the effect of a radiofrequency source to perform physical cleaning; (2) making the vacuum chamber vacuum, adding corrosive gas into the vacuum chamber, and forming stable plasma under the effect of the radiofrequency source, and enabling the plasma to react with an oxide layer on the surface of the material so as to chemically clean the surface of the GaAs material for removing the original oxide layer and impurities on the surface of the GaAs material and forming a Ga-enriched material surface; and (3) making the vacuum chamber vacuum, adding nitrogen into the chamber vacuum, and forming the stable plasma under the effect of the radiofrequency source in order to enable the plasma to react with Ga-enriched material surface to generate a GaN material passivation layer.

Owner:XIAN LIXIN PHOTOELECTRIC SCI & TECH

Energy-saving environment-friendly building brick and production method thereof

InactiveCN107673672AHigh compressive strengthImprove bending resistanceSolid waste managementBrickSlag

The invention discloses an energy-saving environment-friendly building brick and a production method thereof, and belongs to the technical field of building materials. The energy-saving environment-friendly building brick comprises the following raw materials in parts by weight: 10 to 20 parts of clay, 5 to 15 parts of river sand, 4 to 10 parts of construction waste, 10 to 20 parts of colliery powder, 5 to 15 parts of andalusite powder, 5 to 15 parts of steel slag, 10 to 20 parts of zirconium oxide powder, and 10 to 20 parts of stone tailings. The energy-saving environment-friendly building brick is high in compressive strength, good in breaking resistance and low in cost, effectively saves resources, and avoids secondary pollution to the environment.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

Environment-friendly energy-saving brick and production method thereof

InactiveCN107857518AHigh compressive strengthImprove bending resistanceSolid waste managementCeramic shaping apparatusTO-18Brick

The invention discloses an environment-friendly energy-saving brick and a production method thereof, and belongs to the technical field of a building material. The environment-friendly energy-saving brick is prepared from the following raw materials in parts by weight: 10 to 20 parts of gangue powder, 8 to 20 parts of river sand, 10 to 20 parts of building rubbish, 10 to 18 parts of zirconium oxide powder, 10 to 20 parts of andalusite powder, 8 to 18 parts of kaolin tailing powder and 8 to 16 parts of attapulgite. The environment-friendly energy-saving brick has the advantages that the compressive strength is high; the fracture resistance is high; the cost is low; resources are effectively saved; the secondary pollution on environment is avoided.

Owner:桂林市晟博科技服务有限公司

A cleaning method for removing metal contamination or residues of sic epitaxial wafers

ActiveCN106910674BEfficient removalAvoid adsorptionSemiconductor/solid-state device manufacturingMetal contaminationAcetone

Owner:DONGGUAN TIANYU SEMICON TECH

Environment-friendly brick and production method thereof

InactiveCN107777945AHigh compressive strengthImprove bending resistanceEnvironmental resistanceBrick

The invention discloses an environment-friendly brick and a production method thereof, and belongs to the technical field of building materials. The environment-friendly brick comprises, by weight, 6-12 parts of slags, 4-10 parts of river sand, 3-9 parts of building rubbish, 5-15 parts of coal gangue powder, 4-10 parts of andalusite powder, 5-9 parts of granite tailings, 8-16 parts of zirconium oxide powder and 3-9 parts of kaolin tailing powder. The environment-friendly brick has high compressive strength, high breaking resistance and low cost, resources are saved effectively, and secondary pollution to the environment is avoided.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

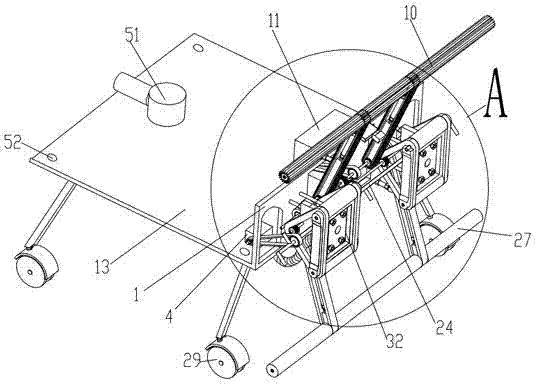

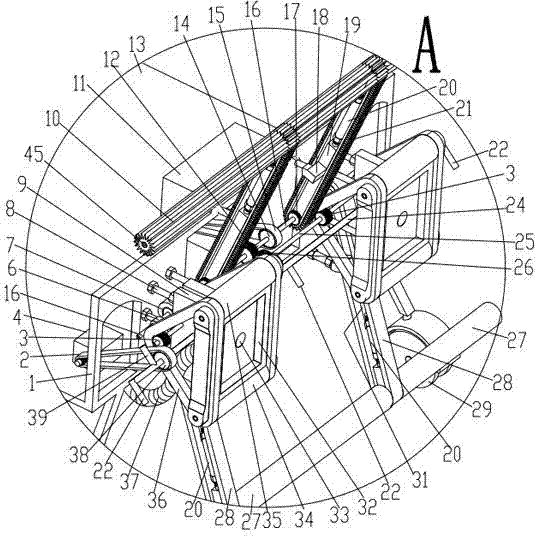

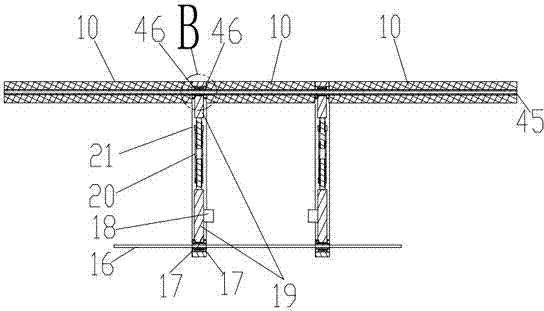

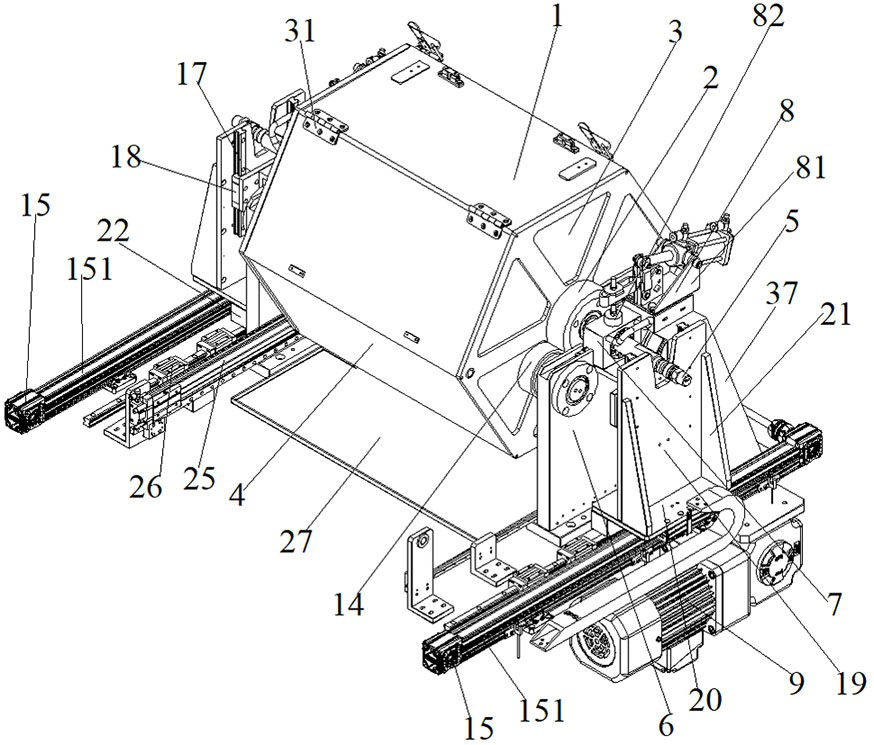

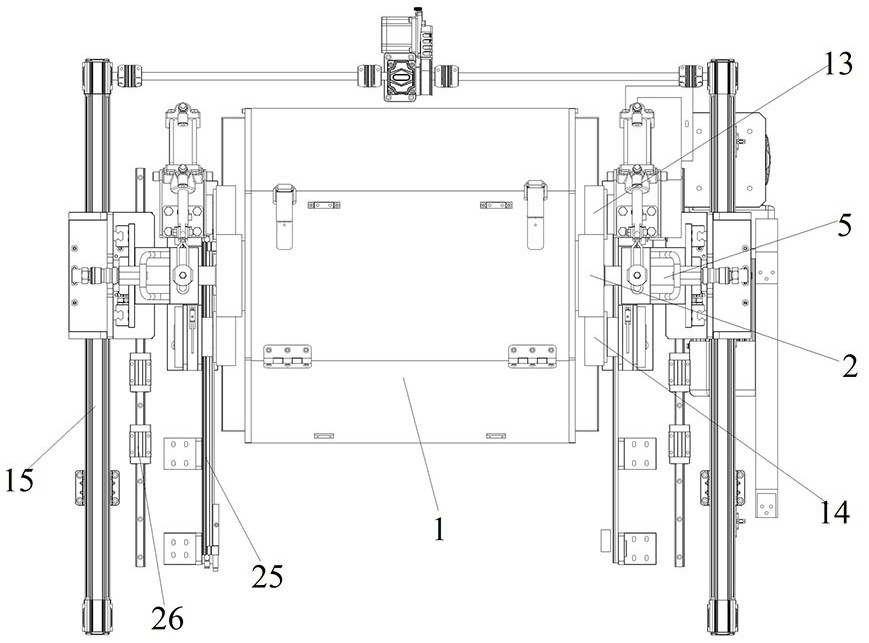

A set of equipment for collecting and transporting garbage

ActiveCN104309971BReduce volumeIncrease in sizeRefuse vehiclesManufacturing technologyWaste collection

The invention discloses garbage collecting and conveying equipment, belongs to the technical field of environmental sanitation production and expands and improves the conventional garbage collecting, hoisting, compressing and conveying methods and equipment. The conventional environmental sanitation can only collect and convey household garbage through waster transfer stations and fails to solve small-scale construction garbage, made during house decoration and reconstruction and the like, and large-piece garbage including abandoned large old furniture which are required to be conveyed by owners themselves. According to the arrangement, the conventional garbage collecting and conveying process is simplified, the waste transfer stations are omitted, fewer sanitation workers are required, and household garbage, construction garbage and large-piece garbage are collected and conveyed in the rapid manner.

Owner:江苏乐尔环境科技股份有限公司

Desizing device for textile fabric production

InactiveCN112813613AAvoid contaminationClean thoroughlyMechanical cleaningPressure cleaningSlurryMechanical engineering

The invention relates to the technical field related to textile fabric production, and discloses a desizing device for textile fabric production. The desizing device comprises a washing tank; reversing wheels are movably mounted on two sides of the top of the washing tank respectively; a cleaning brush is fixedly mounted at the bottom of an inner cavity of the washing tank; a partition plate is fixedly mounted in the middle of the inner wall of the washing tank; and a washing cavity is formed in the inner wall of the washing tank. According to the invention, the partition plate is arranged in the washing tank, so that a large amount of slurry floats to one side in the washing cavity in a fabric treatment process; meanwhile, movable magnetic blocks are arranged in a cleaning wheel, the movable magnetic blocks attract each other through rotation of the cleaning wheel, and a fabric is blown by airflow, so that cleaning is achieved; and the airflow in liquid is upward and acts on the part near the fabric, and when the fabric leaves from the liquid, slurry blocks are pushed away through the airflow, so that the phenomenon of secondary contamination after cleaning is avoided, and finally the purpose of avoiding secondary slurry contamination is achieved.

Owner:王骏

Rolling type high-pressure gas dust removal equipment

ActiveCN114453341AImprove dust removal efficiencyGood effectCleaning using gasesDust controlProcess engineering

The invention relates to rolling type high-pressure gas dust removal equipment. The rolling type high-pressure gas dust removal equipment comprises a roller assembly, a gas supply assembly, a rotary driving assembly, a supporting assembly and a carrying assembly. The air supply assembly partially penetrates through the roller assembly, it can be guaranteed that high-pressure air is in direct contact with products after being blown out, and the dust removal efficiency is improved. The carrying assembly is connected with the roller assembly and used for driving the roller assembly to move and switch between the dust removal station and the product collection station. The roller assembly can be directly moved to the product collecting station for one-time discharging after dust removal is completed, manual one-by-one discharging is avoided, the automation degree of the dust removal equipment is improved, and the situation that products are contaminated with chippings for the second time can be effectively avoided. The rotary driving assembly drives the roller assembly to rotate through friction transmission, and the roller assembly is detachably connected with the supporting assembly, so that the roller assembly can be separated from the rotary driving assembly and the supporting assembly at the same time after dust removal is completed, and free switching between a dust removal station and a product collection station is achieved under driving of the carrying assembly.

Owner:HANGZHOU RISHE MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com