Rolling type high-pressure gas dust removal equipment

A dust removal equipment and high-pressure gas technology, applied in the field of tumbling high-pressure gas dust removal equipment, can solve the problems of low automation, poor dust removal effect, and secondary contamination of products, achieving good results, avoiding secondary contamination of debris, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

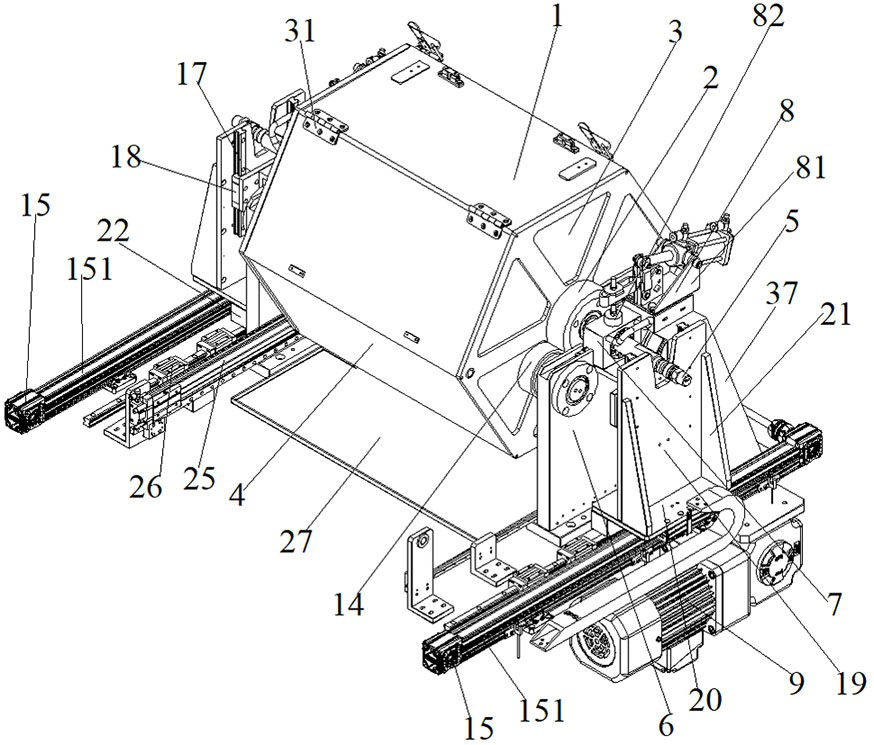

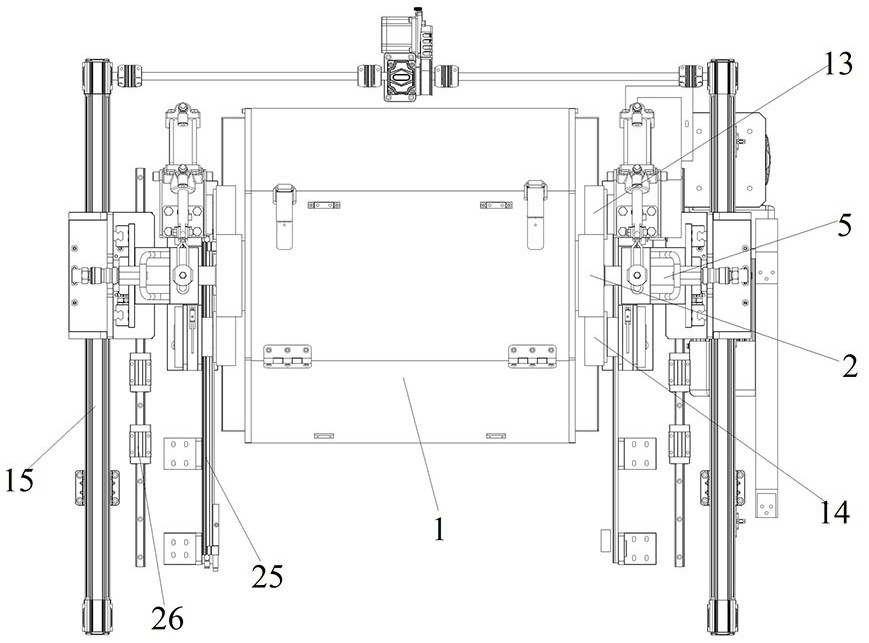

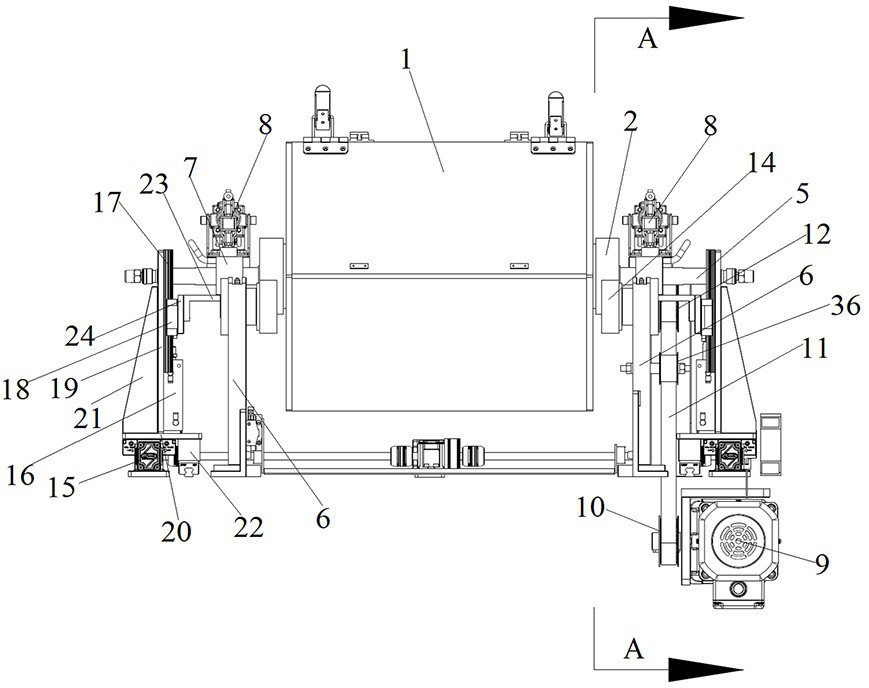

[0064] Such as Figure 1-7 As shown, this embodiment provides a tumbling high-pressure gas dedusting device for dedusting rubber and plastic products, including a drum assembly, an air supply assembly, a rotary drive assembly, a support assembly, and a handling assembly.

[0065] The air supply assembly is passed through the drum assembly, part of which is arranged inside the drum assembly, and the other part is arranged outside the drum assembly.

[0066] The rotary drive assembly drives the drum assembly to rotate through friction transmission, and the drum assembly is detachably connected to the support assembly. The handling component is connected with the drum component, and is used to drive the drum component to move and switch between the dust removal station and the product collection station.

[0067] After the roller assembly completes dust removal on the dust removal station, the conveying assembly drives the roller assembly to rise, so that the roller assembly is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com