Multistage cyclone separation device of dust collector

A technology of cyclone separation device and vacuum cleaner, which is applied in the direction of suction filter, etc., can solve the problems of restricting the separation efficiency of the secondary separation device and reducing the dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, specifically illustrate the utility model:

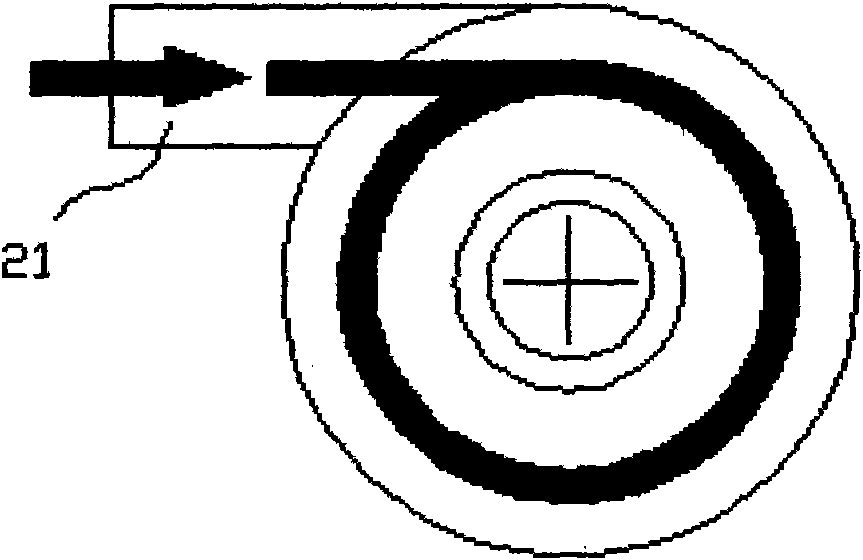

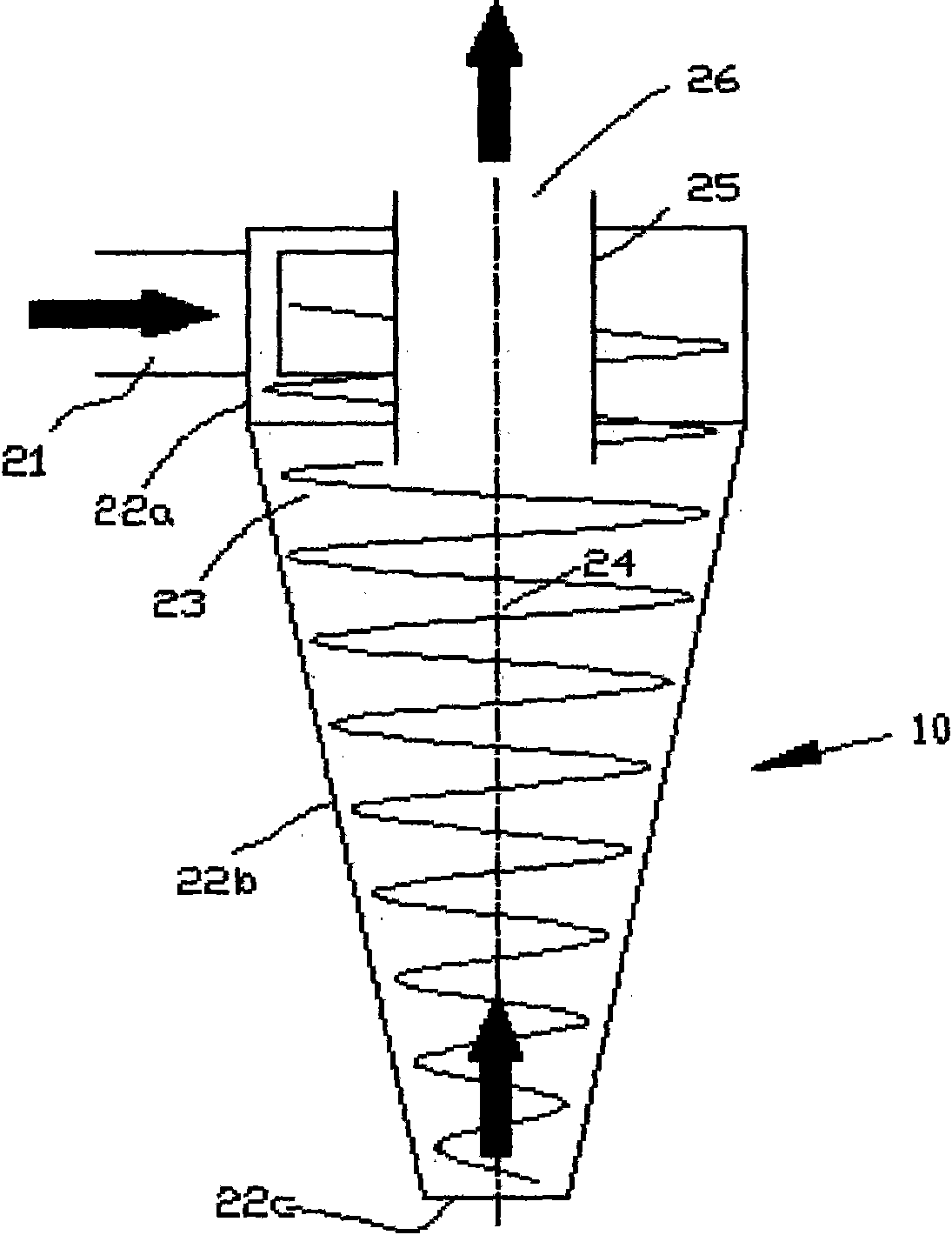

[0026] Such as figure 1 and figure 2 What is shown is a structural schematic diagram of a cyclone cylinder in a multi-stage cyclone separation device for a vacuum cleaner in the prior art. The cylinder (22a) of the cyclone body (20) is provided with a tangential air inlet (21) and an exhaust port (505), and the inner cavity (23) of the cyclone body (20) forms a cyclone separation chamber. The separated small particle ash enters the dust collection chamber (not shown in the figure) through the terminal ash discharge port (22c), and the clean air is discharged from the exhaust port (505) through the exhaust pipe (504).

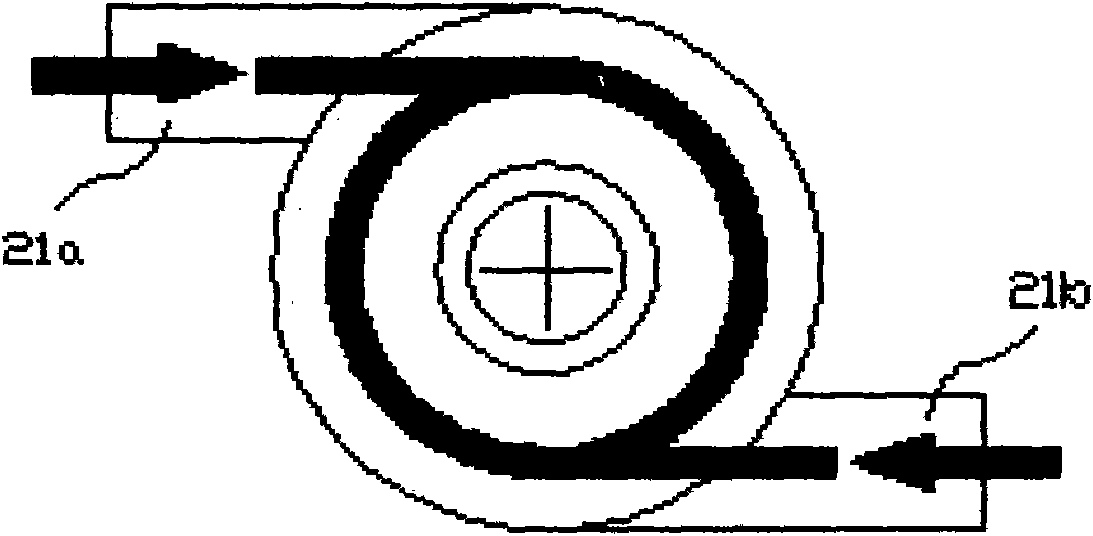

[0027] image 3 and Figure 4 Shown is a schematic diagram of the structure of the cyclone cylinder in the multi-stage cyclone separation device for the vacuum cleaner used in the present invention. The cyclone cylinder (20) is frusto-conical and consists of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com