Coal-fired power plant flue gas sulfur dioxide catalytic desulfurization production and technical flow

A technology for sulfur dioxide and coal-fired power plants, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as secondary pollution, serious scaling problems, and difficult operation of enterprises, and achieve recycling and utilization. , high utilization rate of catalyst, and the effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

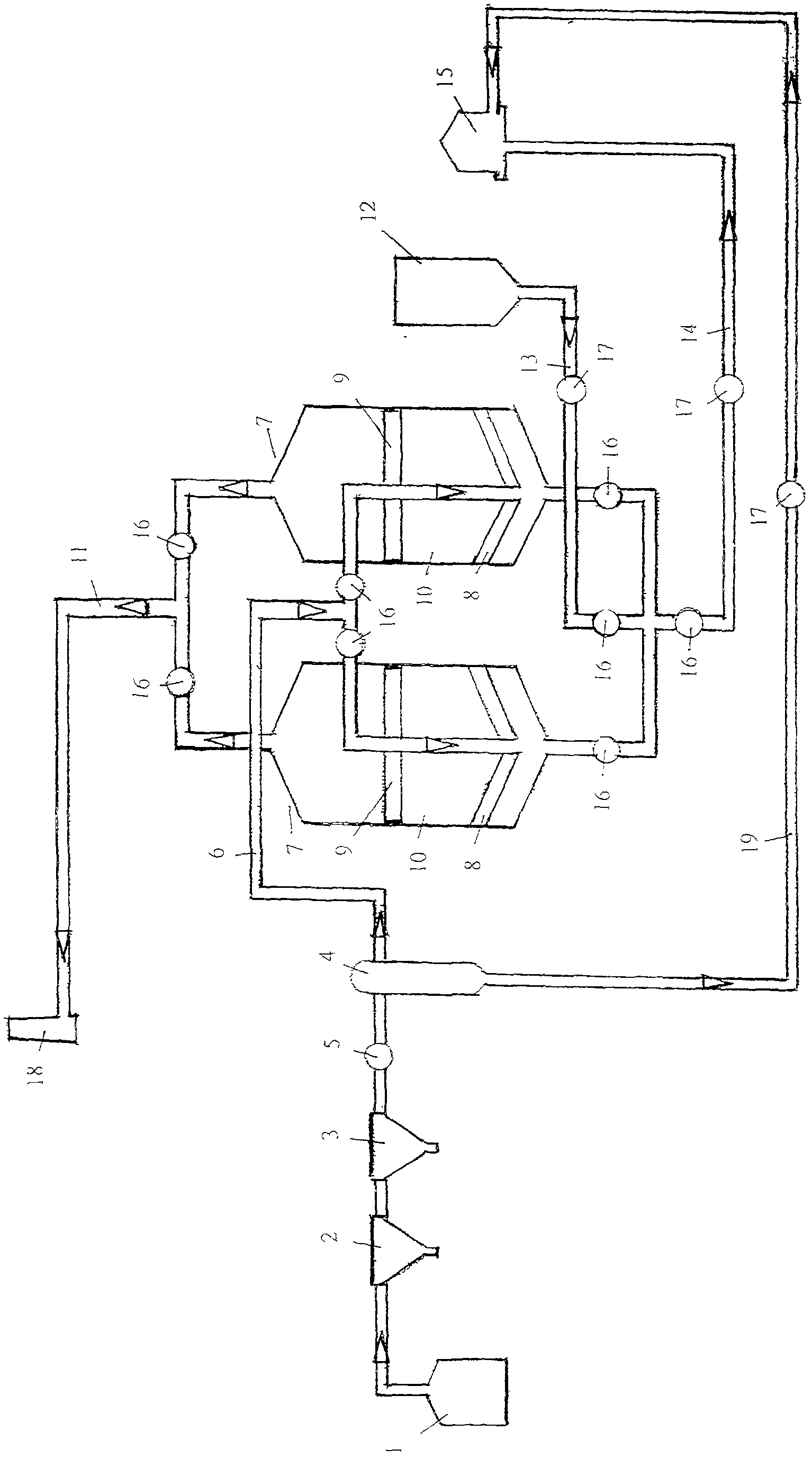

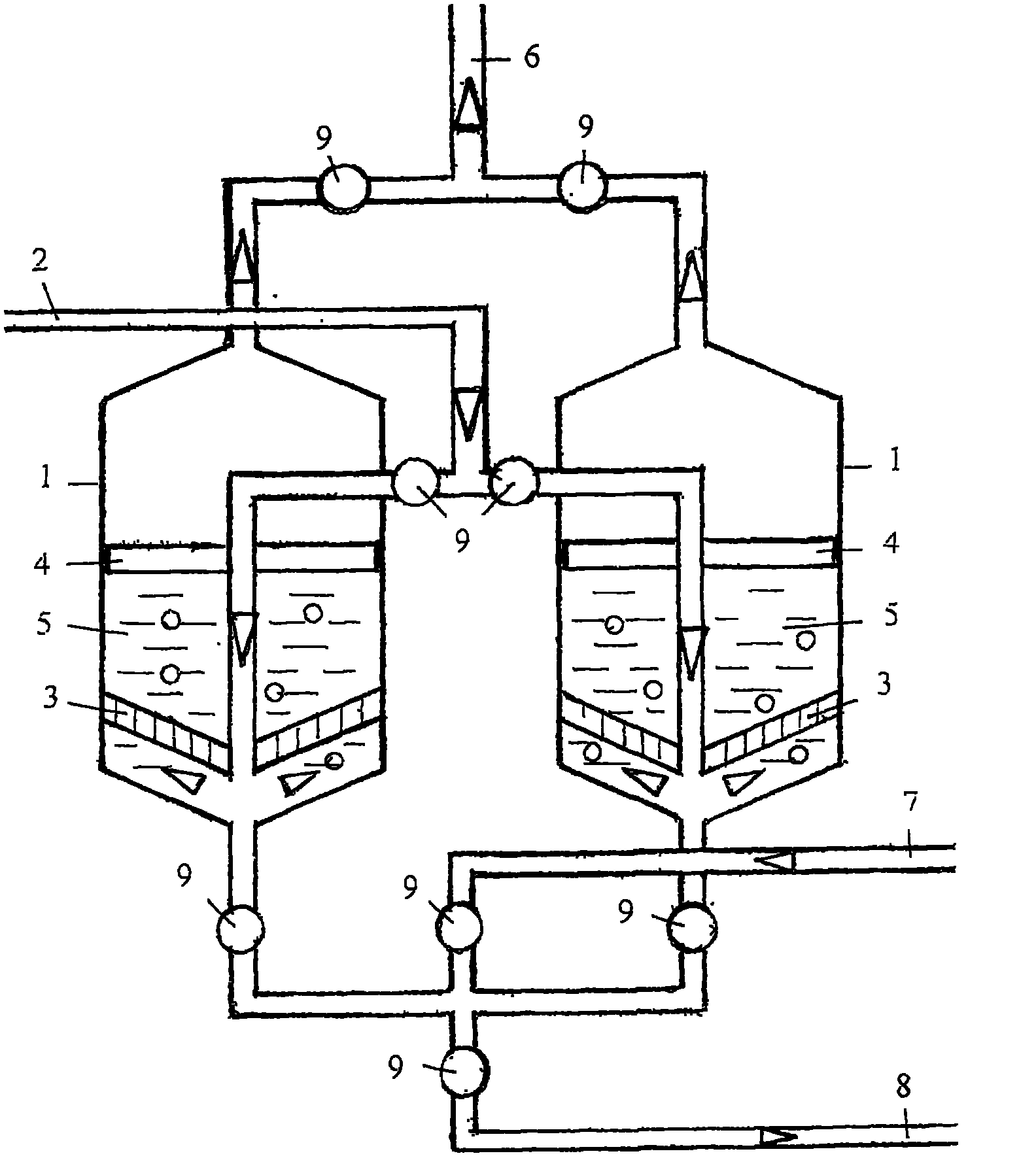

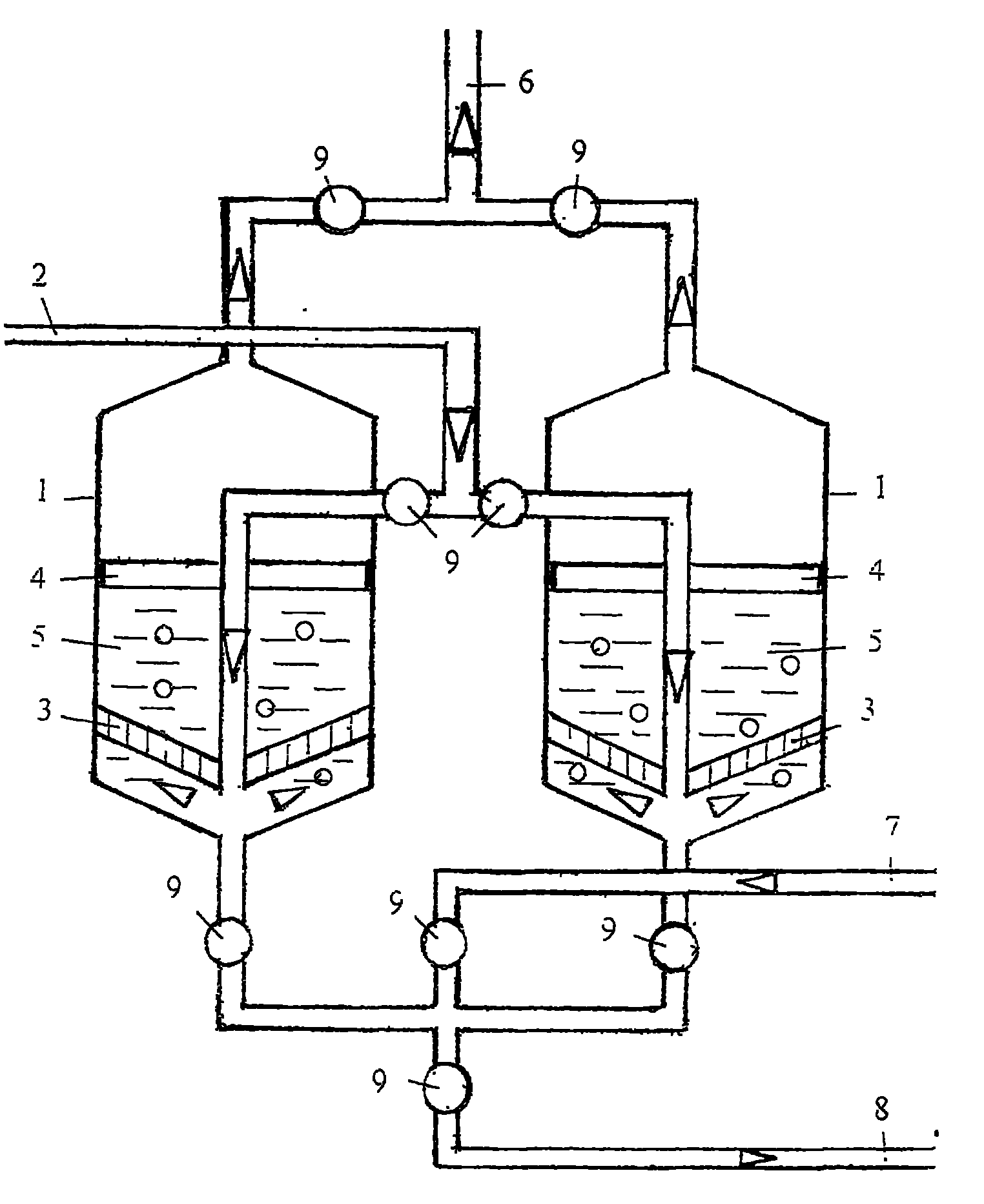

[0145] "Coal-fired power plant flue gas sulfur dioxide SO2, catalytic desulfurization production and process flow" is the application of catalysts in coal-fired power plant flue gas sulfur dioxide SO2 catalytic desulfurization, the specific implementation method is that coal-fired flue gas sulfur dioxide SO2 passes through the catalytic tower , Catalyst to achieve filtration, complete desulfurization method, catalytic filtration method, suitable for flue gas desulfurization of coal-fired enterprises of different scales, regardless of large, medium, or small coal-fired power plant desulfurization, have a wide range of adaptability.

[0146] (1) One-time investment can be realized, and economic, social and environmental benefits can be seen immediately:

[0147] (2) Make the enterprise's coal-fired power plant, sulfur dioxide SO 2 The desulfurization rate is much higher than the national standard;

[0148] (3) Make the surrounding environment of the enterprise's coal-fired powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com