A cleaning method for removing metal contamination or residues of sic epitaxial wafers

An epitaxial wafer and metal technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of reducing breakdown voltage, reliability device yield that affects the performance of semiconductor devices, shortening the life of minority carriers, etc., to prevent The effect of secondary contamination, prevention of adsorption of secondary pollutants, and reduction of re-contamination by metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

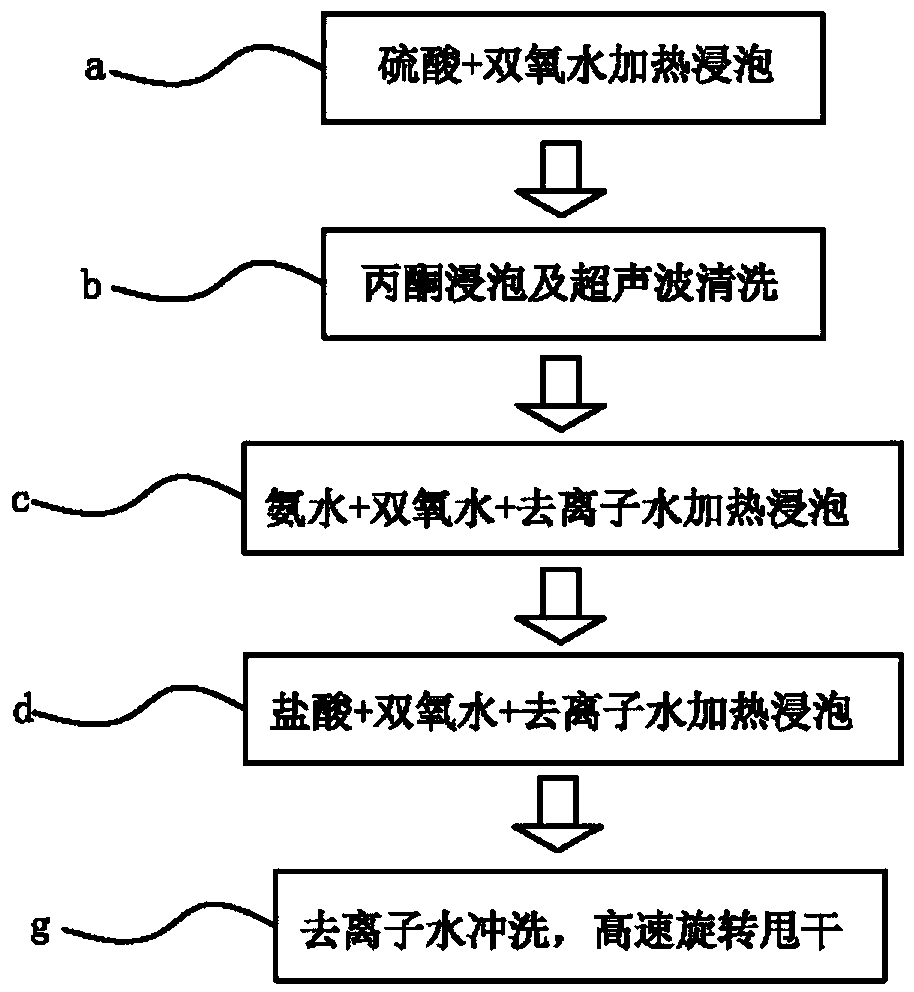

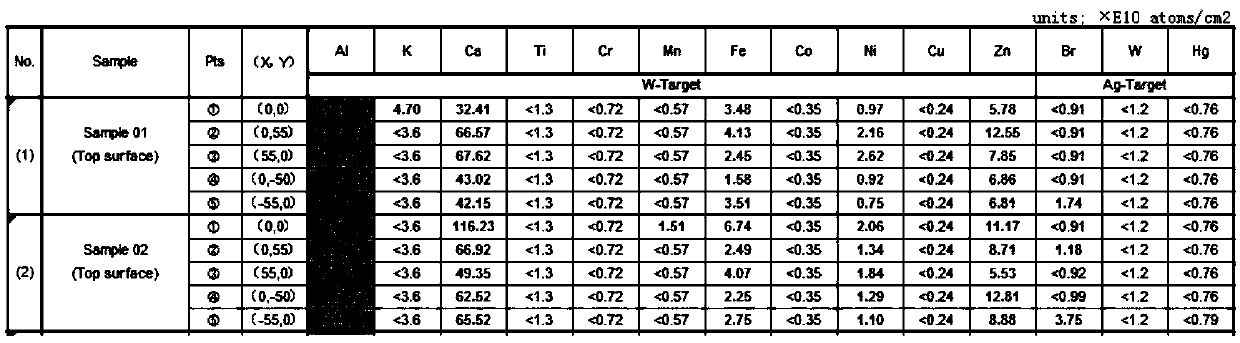

[0036] combine figure 1 As shown, this embodiment one uses steps a, b, c, d, and g in the above-mentioned cleaning method for removing metal contamination or residues on SiC epitaxial wafers, and the test results of two samples in this embodiment one show: Calcium (Ca) residue The minimum value is 3.241E+11atom / cm 2 , the maximum value is 1.1623E+12atom / cm 2 ; The minimum iron (Fe) residue is 1.58E+10atom / cm 2 , the maximum value is 6.74E+10atom / cm 2 ; The minimum zinc (Zn) residue is 5.53E+10atom / cm 2 , the maximum value is 1.281E+11atom / cm 2 ;The residual content of other metal elements is less than 5E+10atom / cm 2 , see the test value image 3 .

Embodiment 2

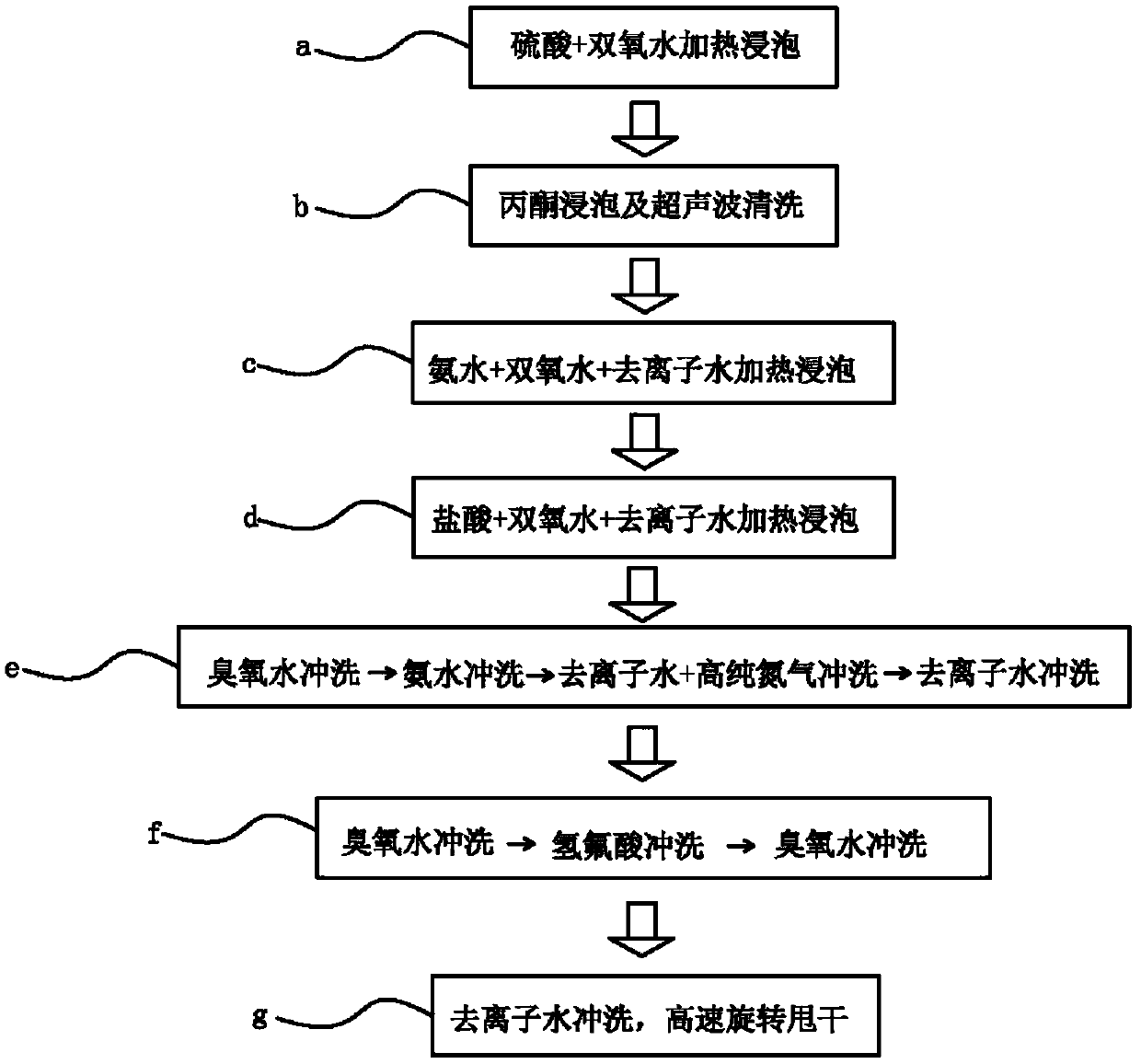

[0038] combine figure 2 As shown, the present embodiment 2 uses steps a, b, c, d, e, f, and g in the above-mentioned cleaning method for removing metal contamination or residue on SiC epitaxial wafers. The test results of the two samples in the present embodiment 2 show: the sample 04 (Sample 04) The content of potassium (K) and calcium (Ca) in the central point is relatively high, and the other test points are all less than 5E+10atom / cm 2 ; The minimum iron (Fe) residue is less than 0.45E+10atom / cm 2 , the maximum value is 0.88E+10atom / cm 2 ; The minimum residual amount of zinc (Zn) is less than 0.21E+10atom / cm 2 , the maximum value is 1.41E+10atom / cm 2 ;The residual content of other metal elements is less than 2E+10atom / cm 2 , see the test value Figure 4 .

[0039] Embodiment 2 has a better effect of removing metal pollution or residue, and the result meets the material requirements of the semiconductor industry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com