Finishing method of fiber product free of cleaning by detergent

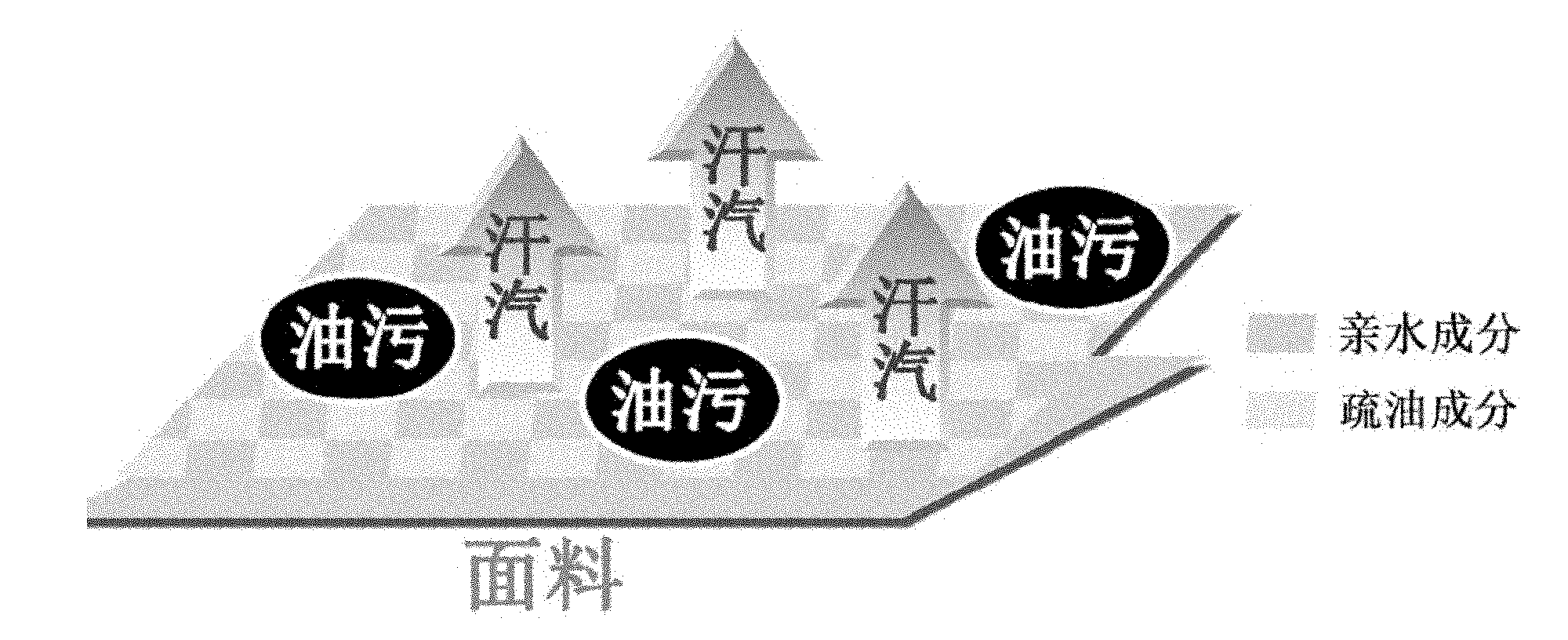

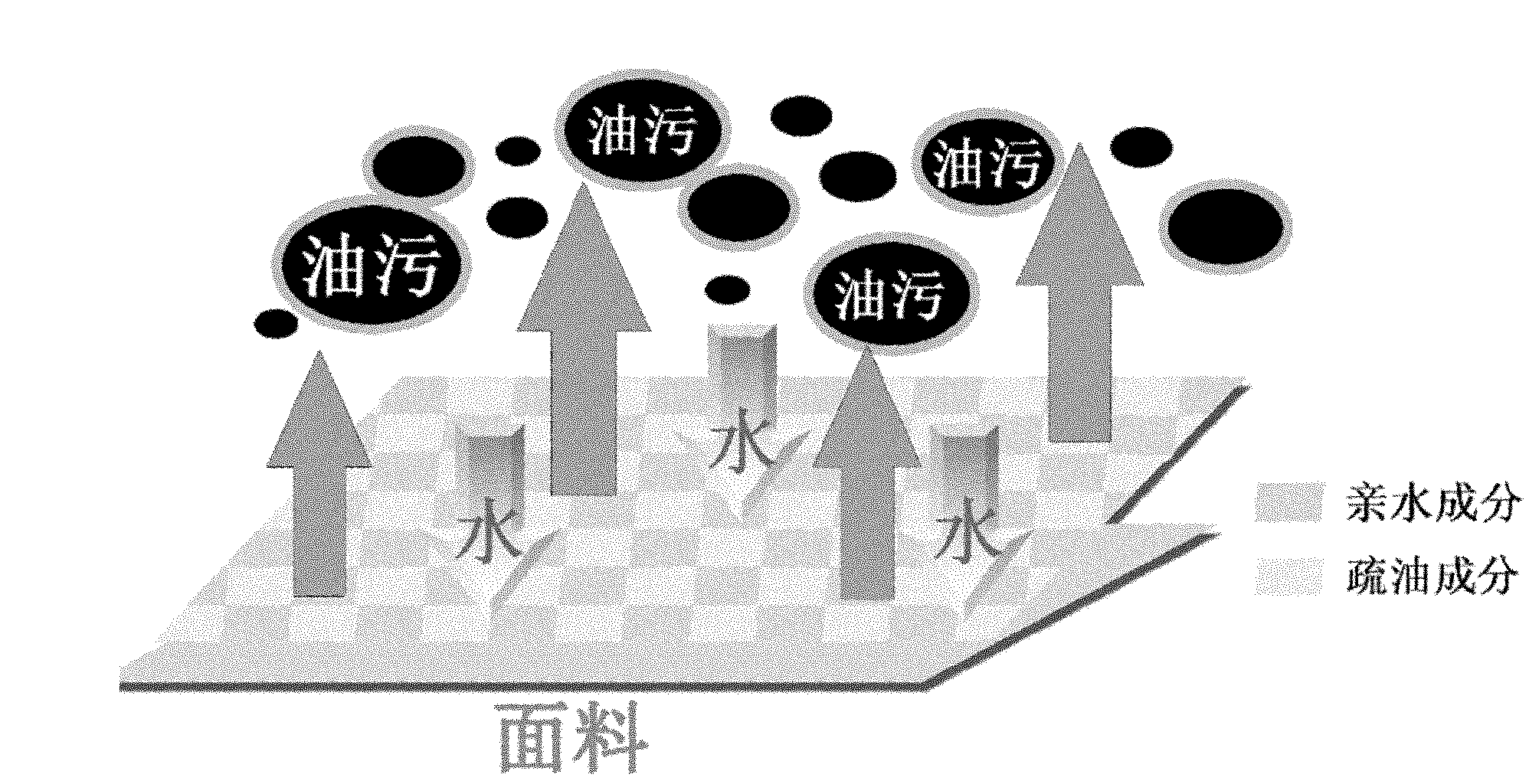

A technology for fiber products and detergents, used in dry cleaning fiber products, fiber treatment, biochemical fiber treatment, etc., can solve problems such as uncomfortable wearing, poor air permeability, environmental impact, etc., and achieve enhanced gloss, clear texture, and improved washability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

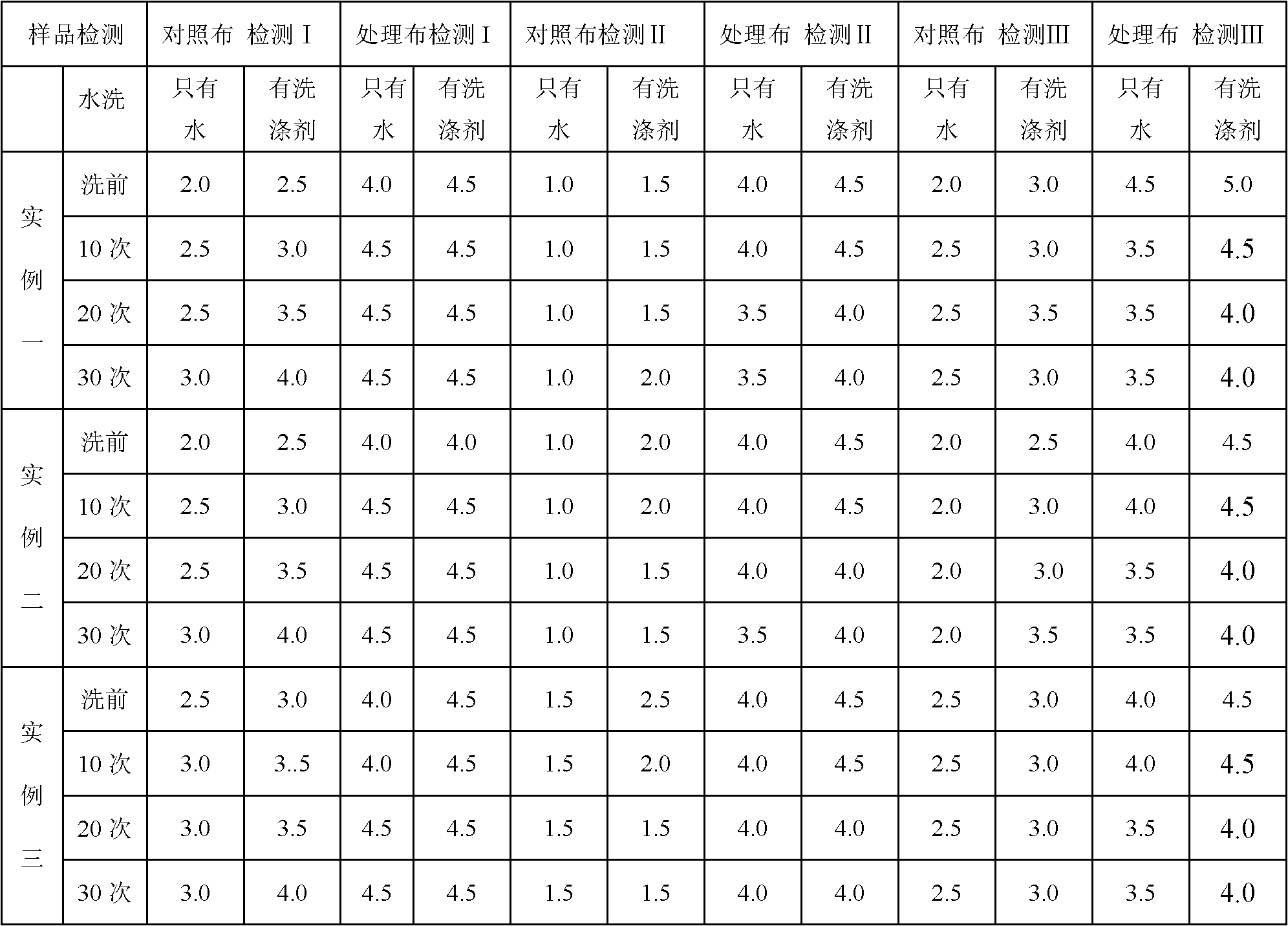

Embodiment 1

[0021] Embodiment 1: Using cpt40*40*120*70*58″, the specific steps are:

[0022] 1. Fabric singeing: the singeing speed is 90m / min, the burner position is 2#, and the flame intensity is 14.

[0023] 2. Enzyme stack: In the cold stack stacking process, 8g / l of desizing enzyme, 5g / l of penetrant, and 5g / l of wax removal agent are added, and the cold stack stacks at room temperature for 6 hours.

[0024] 3. Desizing: Add 4g / l desizing enzyme, 3g / l penetrant and 3g / l refining agent to the trough of the desizing machine. ℃ processing and desizing.

[0025] 4. Mercerizing: alkali concentration is 23Be 0 , carried out on a cloth clip mercerizing machine, the vehicle speed is 50m / min, the penetrating agent is 5g / l, the temperature of the washing tank is 80°C, and the pH value of the falling cloth is 6.0.

[0026] 5. Liquid ammonia: vehicle speed 30m / min, pH value 5.8, washing temperature 60°C.

[0027] 6. Pretreatment: The cellulose-reactive N-methylol compound is selected from di...

Embodiment 2

[0032] Embodiment two: adopt CVC45*CVC45*130*80*57 ", concrete steps are:

[0033] 1. Fabric singeing: the singeing speed is 110m / min, the burner position is 2#, and the flame intensity is 12.

[0034] 2. Enzyme pile: In the cold pile stacking process, add desizing enzyme 6g / l, penetrant 4g / l, dewaxing agent 4g / l, and put it in a cold pile at room temperature for 10 hours.

[0035] 3. Desizing: add desizing enzyme 6g / l, penetrant 5g / l, refining agent 5g / l respectively in the trough of the desizing machine, the temperature of the trough is 60°C, the saturated steam is steamed for 20min, and the temperature of the washing tank is 95 ℃ processing and desizing.

[0036] 4. Mercerizing: alkali concentration is 20Be 0 , carried out on a straight roller mercerizing machine with a speed of 70m / min, a penetrating agent of 5g / l, a washing tank temperature of 75°C, and a pH value of 6.5.

[0037] 5. Liquid ammonia: the vehicle speed is 40m / min, the pH value is 6.0, and the washing tem...

Embodiment 3

[0043] Example Three: Using CM80 / 2*80 / 2*160*72*60″

[0044] 1. Fabric singeing: the singeing speed is 80m / min, the burner position is 2, and the flame intensity is 14.

[0045] 2. Enzyme stack: In the cold stack stacking process, add 12g / l of desizing enzyme, 8g / l of penetrant, and 6g / l of wax removal agent, and stack in cold stack at room temperature for 12 hours.

[0046] 3. Desizing: Add 12g / l desizing enzyme, 8g / l penetrant, and 8g / l refining agent to the trough of the desizing machine. ℃ processing and desizing.

[0047] 4. Mercerizing: alkali concentration is 28Be 0 , carried out on the cloth clip mercerizing machine, the speed of the machine is 65m / min, the penetrating agent is 6g / L, the temperature of the washing tank is 85°C, and the pH value of the falling cloth is 7.0.

[0048] 5. Liquid ammonia: the vehicle speed is 30m / min, the pH value is 6.5, and the washing temperature is 70°C.

[0049] 6. Pretreatment: The cellulose-reactive N-methylol compound is selected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com