Patents

Literature

458results about How to "Antifouling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

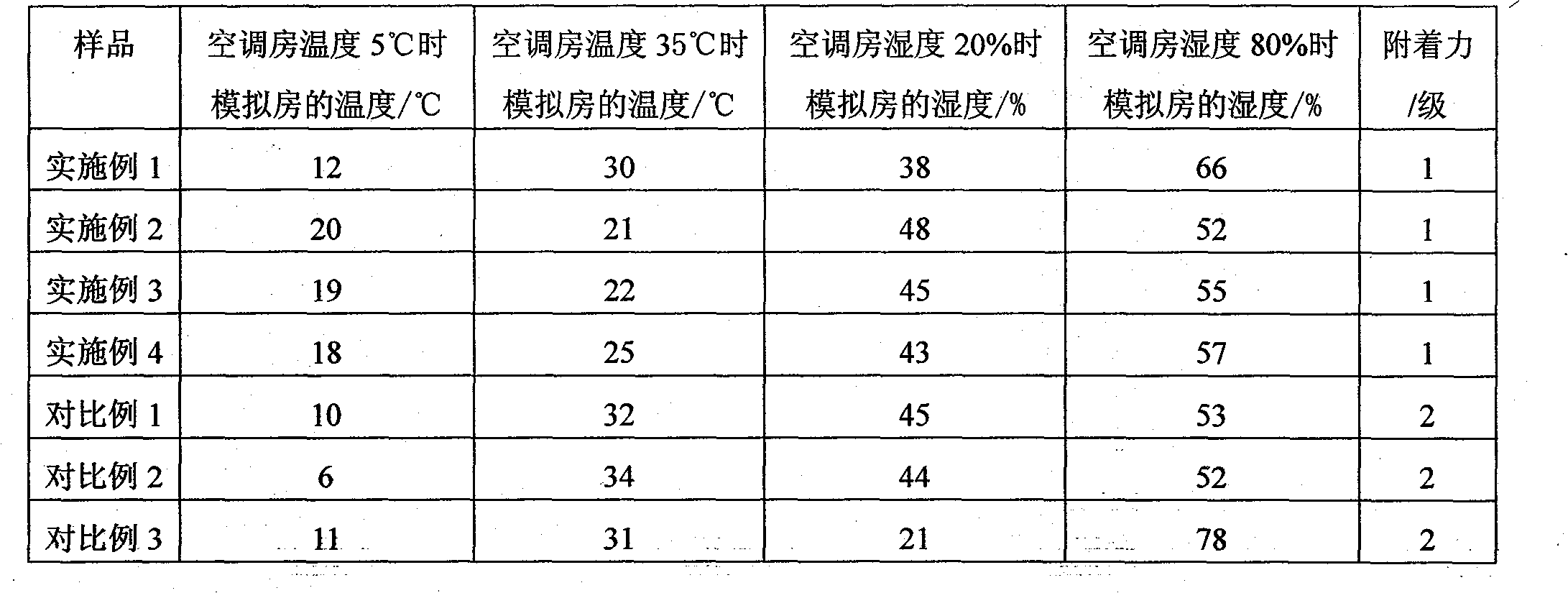

Temperature adjusting humidity adjusting coating and preparation method thereof

InactiveCN103159437ALower room temperatureTurn up the room temperatureEnvironmental resistanceThermal insulation

The invention relates to temperature adjusting humidity adjusting coating and a preparation method thereof. The temperature adjusting and humidity adjusting coating comprises thermal insulation undercoat, phase transition energy storage intermediate coat and heat conduction humidity adjusting finish. The undercoat insulates heat, and the phase transition energy storage intermediate coat transmits indoor energy through the finish and stores energy through the phase transition, and thereby effectively adjusting indoor temperature. The phase transition energy storage intermediate coat and the humidity adjusting function of the finish impart the whole coating temperature adjusting and humidity adjusting function. In addition, the temperature adjusting and humidity adjusting coating has the advantages of being fireproof, waterproof, antifouling, mechanical, capable of eliminating peculiar smell, sterilizing, insulating heat, removing sound, protecting environment and the like. The temperature adjusting and humidity adjusting coating is applicable to various kinds of constructional coating.

Owner:LUNAN RES INST OF COAL CHEM

Preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and product thereof

The invention relates to a preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and a product thereof. The method comprises the following steps that raw materials are prepared; polyester glycol dehydration pretreatment is carried out; polyester glycol obtained after dehydration pretreatment is subjected to a prepolymerization reaction with an end alkyl polysiloxane linear body, a nonionic chain extender, a functionality chain extender and diisocyanate under catalyzing of a polymerization catalyst so that a prepolymer can be obtained; the prepolymer reacts with a nonionic chain extender and a part diluent to prepare an intermediate; the intermediate reacts with a silane coupling agent, and is emulsified to prepare the modified cation waterborne polyurethane emulsion. The product is a polyester type cation waterborne polyurethane high-polymer material containing hydrophilic and hydrophobic side long chains, wherein polysiloxane is embedded into a main chain of the material, a side chain is grafted with long-chain polyether and long-chain alkyl, and the silane coupling agent is connected into the tail end of the material; the film-forming ability is high, and serving as a film, the emulsion has obvious water-repellent, antifouling and easy dirt-removing abilities, is excellent in compatibility with a cation softening agent, and has an excellent low-temperature soft feature; the product is safe, environmentally friendly and convenient to use.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

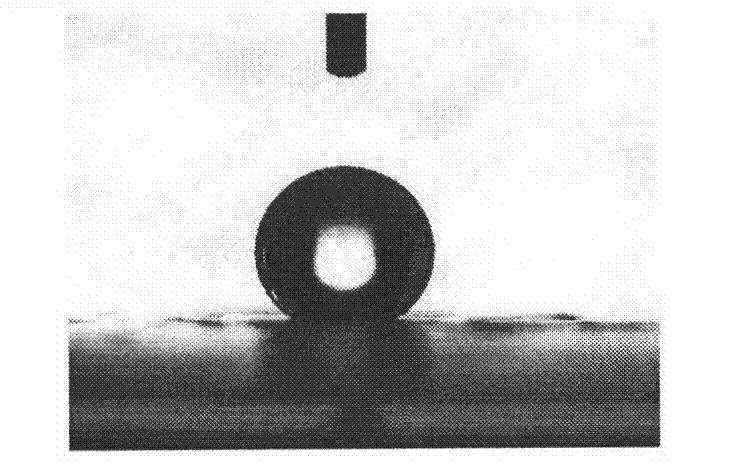

Super-hydrophobic self-cleaning paint

InactiveCN101205439ASuperhydrophobicSelf-cleaningPolyurea/polyurethane coatingsPolyether coatingsEngineeringSolvent

The invention relates to super-hydrophobic self-cleaning paint suitable to be used in various surfaces. The paint comprises the following components: 100 portions of filler, 30 to 50 portions of polyurethane, 300 to 500 portions of mixed solvent and 1 to 5 portions of Gamma-aminopropyltrimethoxysilane. The invented paint has the advantages of super-hydrophoby, self cleaning, antifouling, antisticking, denoise and drag reduction, etc.; meanwhile, the paint has low price cost, convenient construction and less environmental pollution.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Self-cleaning film and preparation thereof

InactiveCN101280155AGood self-cleaning propertiesHigh mechanical strengthPretreated surfacesSpecial surfacesSilanesPolymer chemistry

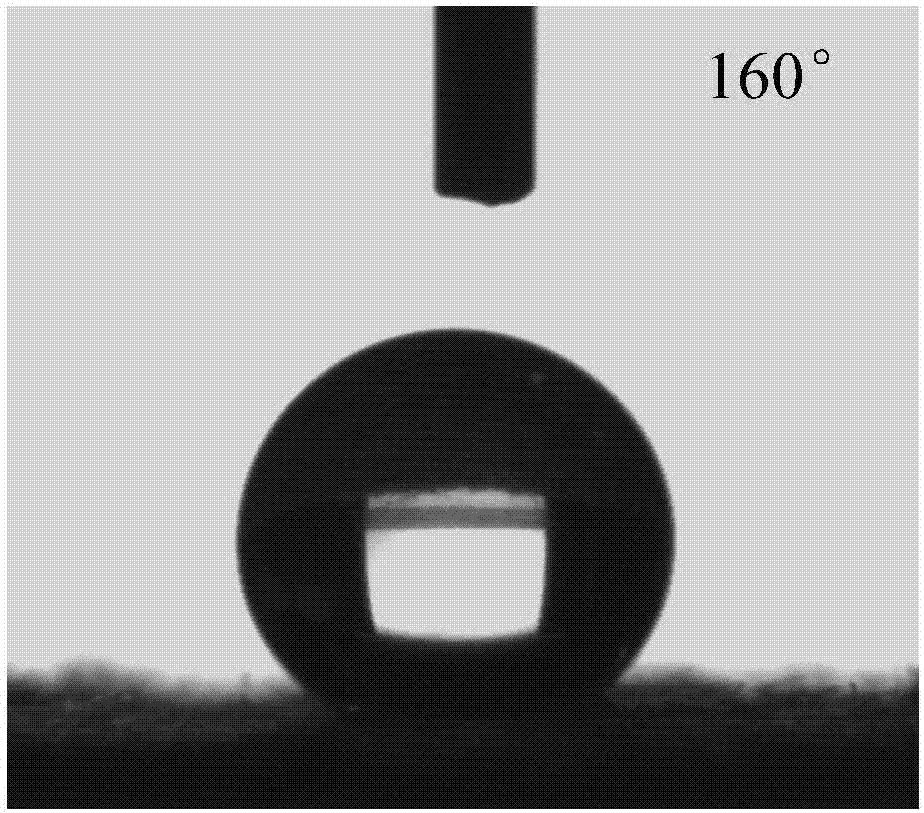

The invention discloses self-cleaning film and the preparation method; the method provided by the invention and used for preparing the self-cleaning film is that the raw material mixtures are mixed, stirred and put into chlorosilane, alkoxy silane or fluoro-alkyl silanes solutions for self-assembly after film forming and drying; and then the self-cleaning film is obtained. The self-cleaning film and the preparation method are the break through in preparing the self-cleaning coating; the water contact angle of the film is above 150 degrees and the lag angle is less than 20 degrees; meanwhile, the mechanical intensity difference problem of the ultra-hydrophobic coating is effectively solved. The self-cleaning film in the invention has wide application range and can be coated on the surfaces of the materials including vehicle glasses, rearview mirrors, buildings and clothes, ensuring the surfaces of the materials to have the self-cleaning functions of waterproof, antifouling, frost prevention and snow cover prevention.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Superhydrophobic acrylic resin paint

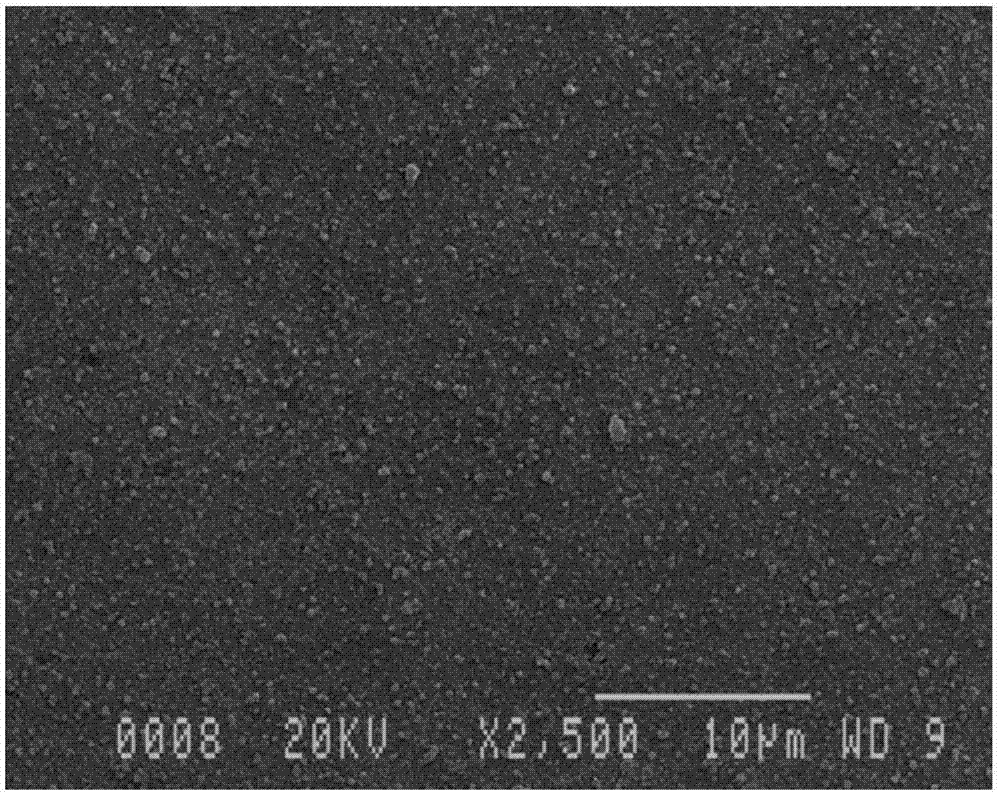

InactiveCN102417773AStable superhydrophobic propertiesChanges in superhydrophobic propertiesCoatingsAcrylic resinNanoparticle

The invention provides a superhydrophobic acrylic resin paint. The paint comprises a nanoparticle, an acrylic resin, a mixed solvent, and heptadecafluoro trimethoxy ethoxy silane, wherein the ratio of the nanoparticle to the acrylic resin to the mixed solvent to heptadecafluoro trimethoxy ethoxy silane is 100:20-60:20-600:3-10. When the paint is sprayed on the surface of a solid, the contact angle of water drops on the surface is 150-160DEG, and the roll angle of the water drops on the surface is less than 10DEG. The superhydrophobic acrylic resin paint of the invention, which has the advantages of low cost, simple construction technology and small pollution to environment, has a good industrialized application prospect.

Owner:袁志庆 +2

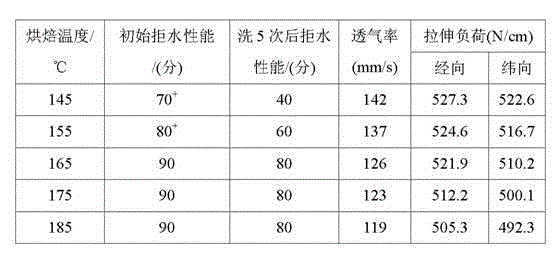

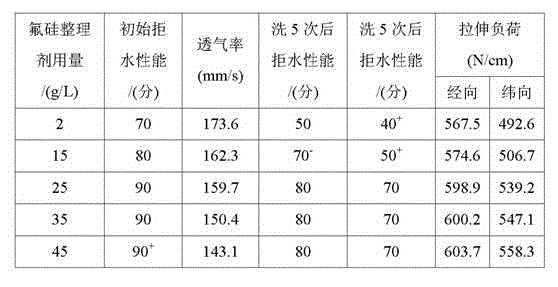

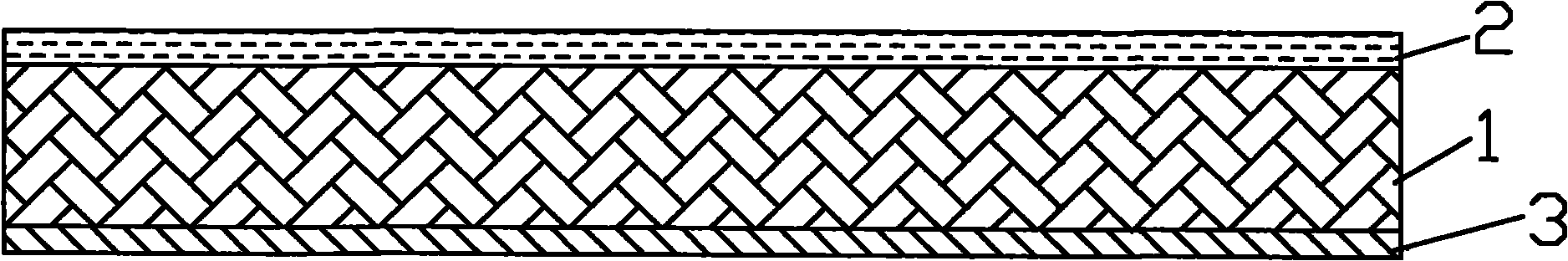

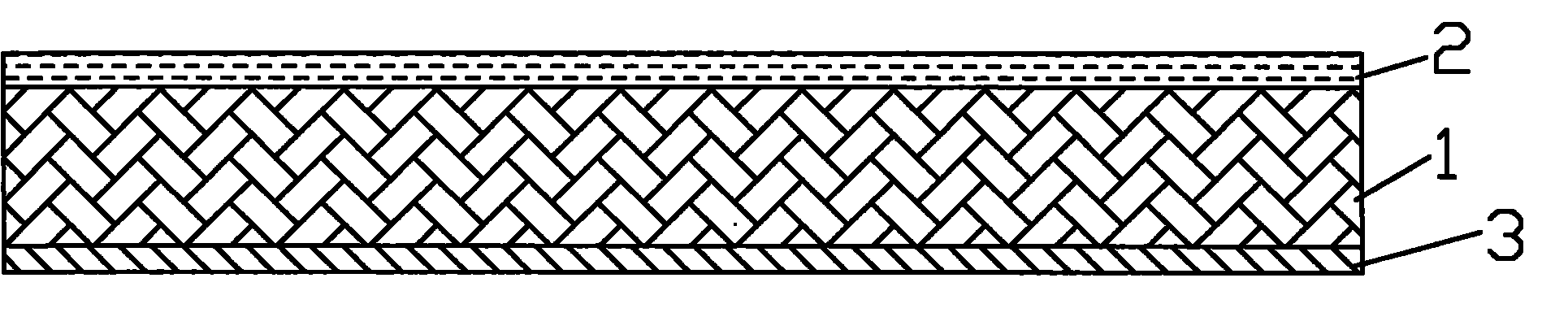

Matte flame-retardant cold-resistant covering cloth

ActiveCN104401084AImprove flame retardant performanceGood mechanical propertiesFibre typesSynthetic resin layered productsEngineeringFire retardant

The invention relates to matte flame-retardant cold-resistant covering cloth. The covering cloth is prepared by performing gumming dipping and drying on base cloth, employing a PVC surface membrane and a PVC bottom membrane to bond with two faces of the base cloth, performing cooling fixing, then employing a fluorosilicone finishing agent to perform surface function processing, and then performing drying and reeling. A double-face bonding production technology of plain base cloth and the PVC surface membrane and the PVC bottom membrane is employed, also a flame retardant and a cold-resisting agent are added into the formula of the PVC membrane, so that the flame retardation performance and the cold resistant performance of the product are improved. The covering cloth possess good flame retardation performance, mechanical properties, cold resistance and the like, and also is greatly improved in applicability and added value by coating the covering cloth surface with a layer of the fluorosilicone finishing agent.

Owner:ZHEJIANG BOTAI PLASTIC

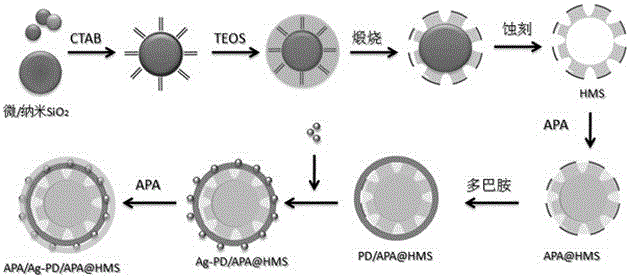

Self-repairing super-hydrophobic composite material, preparation method and application thereof

ActiveCN105949861ASuperhydrophobicAntifoulingAntifouling/underwater paintsPaints with biocidesMicrosphereCarbon chain

The invention discloses a self-repairing super-hydrophobic composite material, a preparation method and application thereof. The composite material has a structural general formula of: APA / M-PD / APA@HMS, wherein, APA is alkyl primary amine having a long carbon chain with C greater than or equal to 12, PD is polydopamine, HMS is hollow mesoporous SiO2 microsphere, APA@HMS refers to HMS loaded with APA, and the M refers to an antifouling able to stick on PD. The preparation method provided by the invention has the advantages of simple operation, and rich raw material sources, and is suitable for mass production. The prepared APA / M-PD / APA@HMS can be used as a paint additive, can endow a coating with super-hydrophobicity, antifouling property, self-repairability, and durability, and can be used for protective coatings of marine materials.

Owner:SHANGHAI MARITIME UNIVERSITY

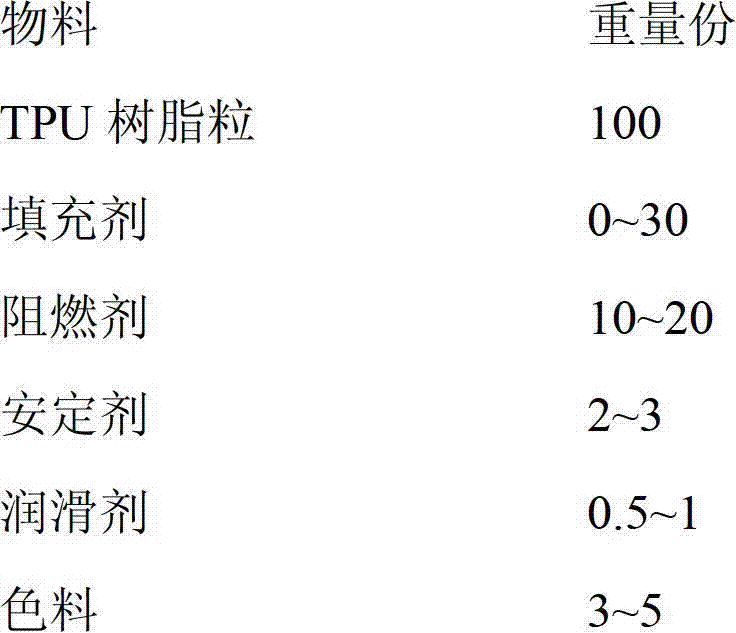

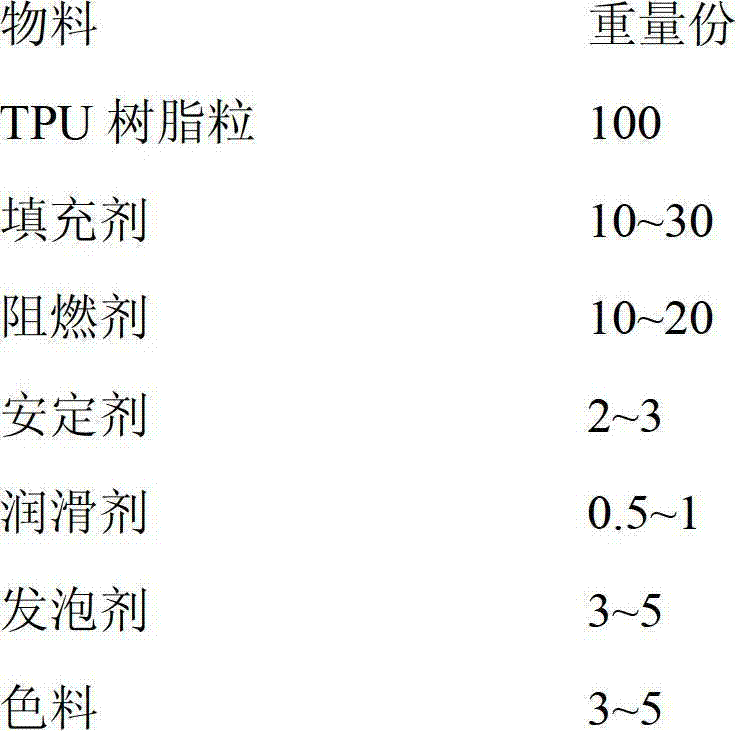

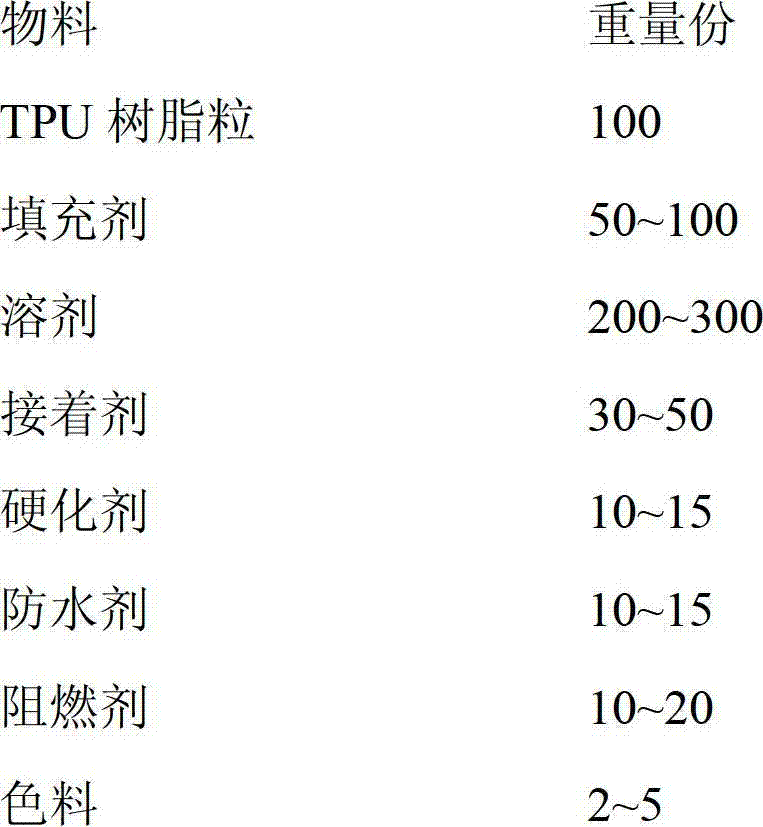

Thermoplastic foaming polyurethane fiber board, production method and uses thereof

ActiveCN103072346AAntifoulingWaterproofCovering/liningsSynthetic resin layered productsFiberThermoplastic

The present invention relates to a thermoplastic foaming polyurethane fiber board, a production method and uses thereof. The thermoplastic foaming polyurethane fiber board comprises an A surface layer, a B middle layer and a C bottom layer, wherein the A surface layer, the B middle layer and the C bottom layer are integratedly compounded from top to bottom, the A surface layer is a sheet material prepared by carrying out mixing calendaring on a TPU resin, a filler, a fire retardation agent, a stabilizer, a lubricant and a colorant according to a certain ratio, the B middle layer is a layer prepared by foaming the sheet material prepared by carrying out mixing calendaring on a TPU resin, a filler, a fire retardation agent, a stabilizer, a lubricant and a colorant according to a certain ratio, and the C bottom layer is a layer prepared by drying a fiber cloth impregnated with a TPU composition. The thermoplastic foaming polyurethane fiber board can be used as flooring boards, wall panels, roof hanging plates and indoor partition boards, and can be used for production of furniture materials and various building materials.

Owner:JIANGSU BIDE SCI & TECH CO LTD

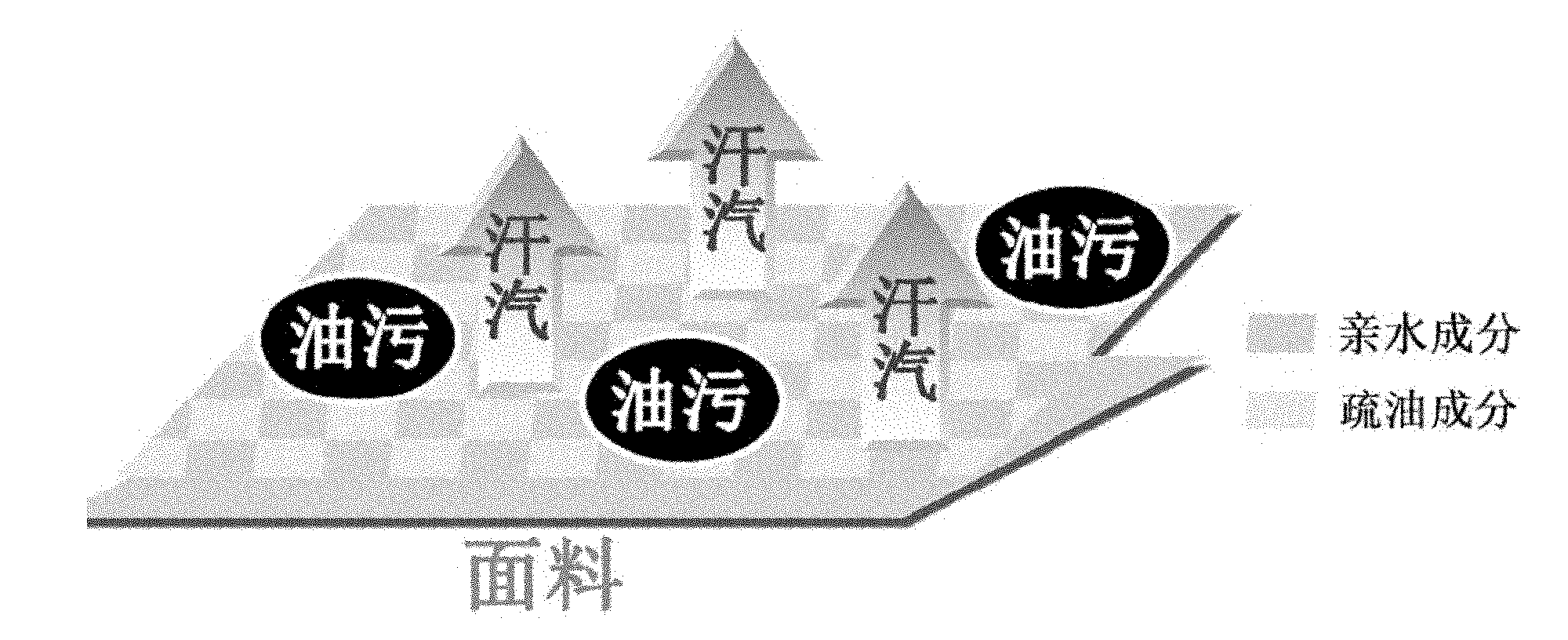

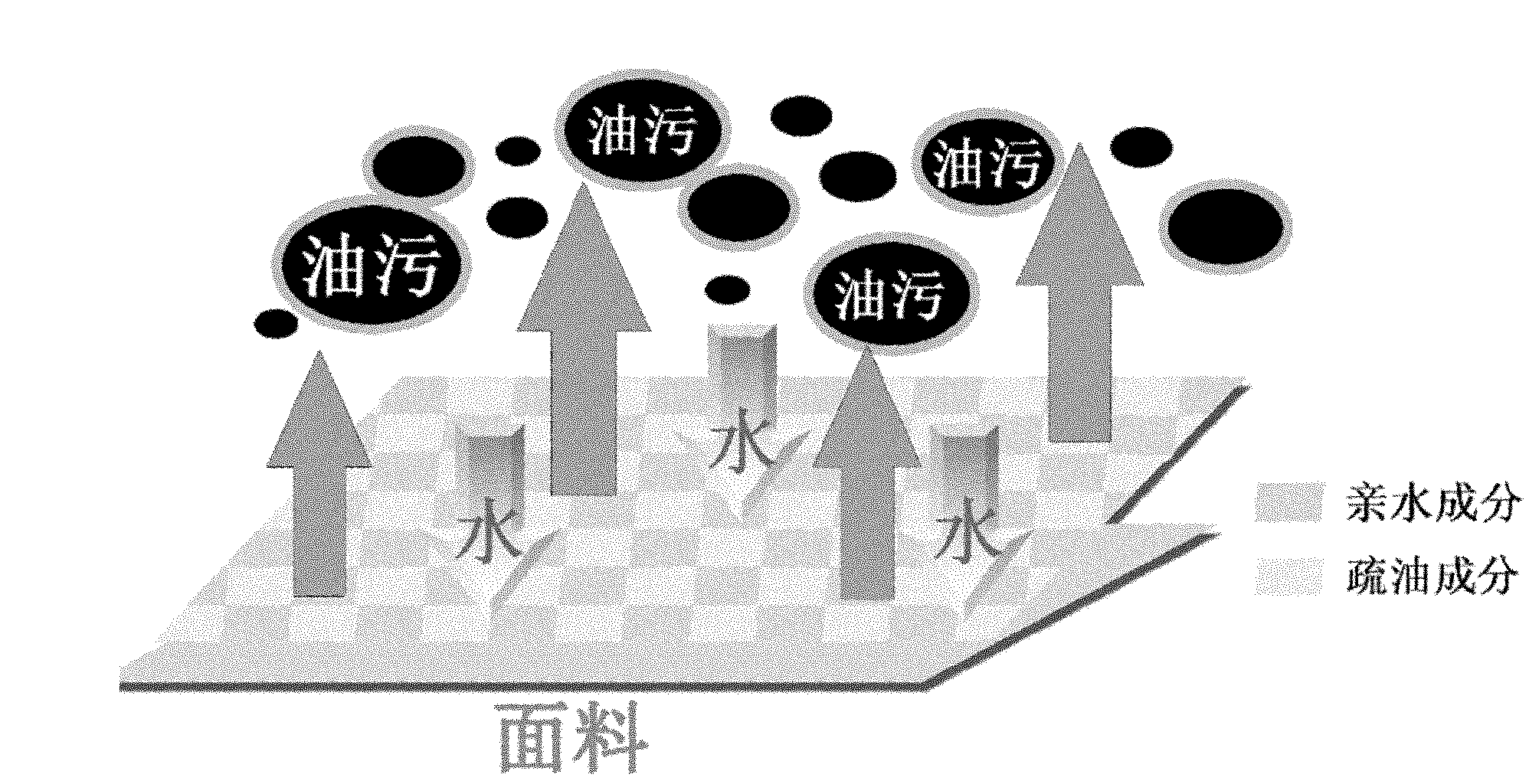

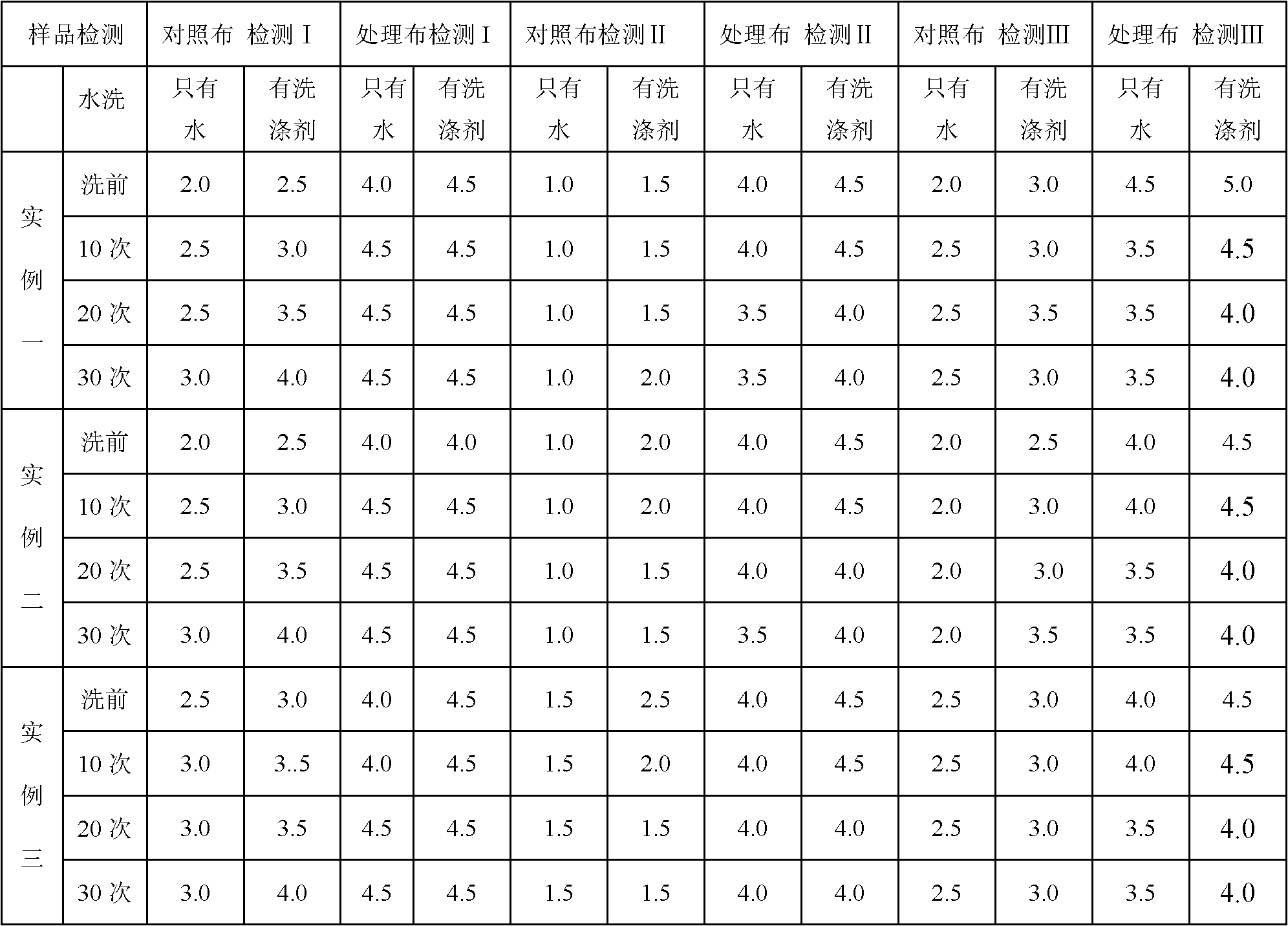

Finishing method of fiber product free of cleaning by detergent

InactiveCN102041685AImprove wettabilityReduce interfacial energyBiochemical fibre treatmentSingeingFiberPre treatment

The invention provides a finishing method of a fiber product free of cleaning by a detergent. The technical process comprises singeing, desizing, mercerizing, tentering and preshrinking. The finishing method is characterized in that enzyme piling is added between the singeing and the desizing; a high-efficiency desizing technique is adopted in desizing; liquid ammonia finish and pretreatment are added between the mercerizing and tentering; baking finish is added between the tentering and preshrinking so as to lead the whole technical process to be singeing, enzyme piling, desizing, mercerizing, liquid ammonia finish, pretreatment, tentering, baking and preshrinking. Textiles manufactured by adopting the technique is not cleaned by using the detergent for cleaning, has basically the same cleaning effect with that of cleaning during which the detergent is added, also can not generate secondary dirt in cleaning; and simultaneously, the textile manufactured by using the method has the functions of fouling resistance and easy decontamination, proper oil-proof function, excellent multiple functions of water absorption, air permeability, washing resistance and electrostatic resistance, meets the requirements of people and belongs to an ideal high-grade textile which is energy-saving, environment-friendly and low-carbon.

Owner:LUTAI TEXTILE

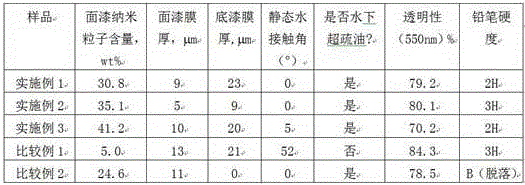

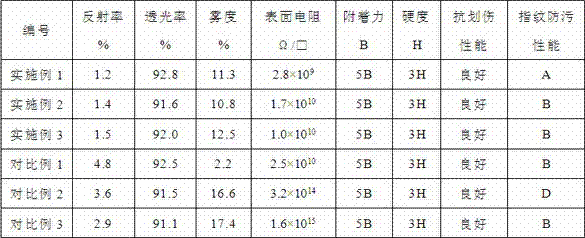

Superhydrophilic/underwater superoleophobic coating material and preparation method thereof

ActiveCN106634275AImprove mechanical propertiesHigh transparencyAntifouling/underwater paintsPretreated surfacesNano structuringAcrylic resin

The invention relates to a superhydrophilic / underwater superoleophobic coating material and a preparation method thereof. The coating material is composed of a primer layer and a finish coat layer, wherein the primer layer is mainly composed of a hydroxy acrylic resin and a curing agent thereof; the finish coat layer is composed of polyvinyl alcohol and nanoparticles; and the curing agent in the primer can produce chemical crosslinking reaction with the polyvinyl alcohol. The preparation method comprises the following steps: applying the primer layer on the substrate surface; applying the finish coat layer, and precrosslinking by drying at room temperature or low temperature to initiate the chemical bonding between the primer layer finish coat layer; soaking the coating in a crosslinking agent water solution for some time; and taking the coating out of the crosslinking agent water solution, and sufficiently curing the primer layer by drying at room temperature or high-heat treatment. The coating material obtained by the method has a gradient micro / nano structure surface, and has the advantages of outstanding superhydrophilicity and underwater superoleophobicity, high binding force with the substrate and favorable transparency. The coating material can be used as an antifogging coating, and can also be used as a self-cleaning antifouling coating on the surface of an underwater facility.

Owner:FUDAN UNIV

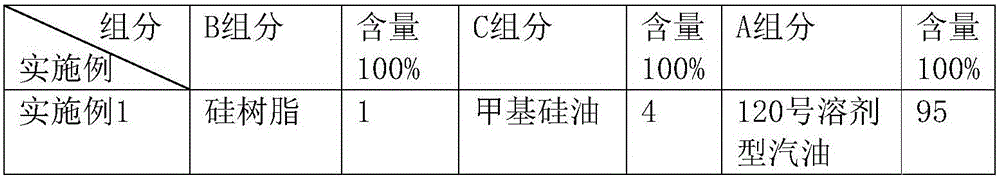

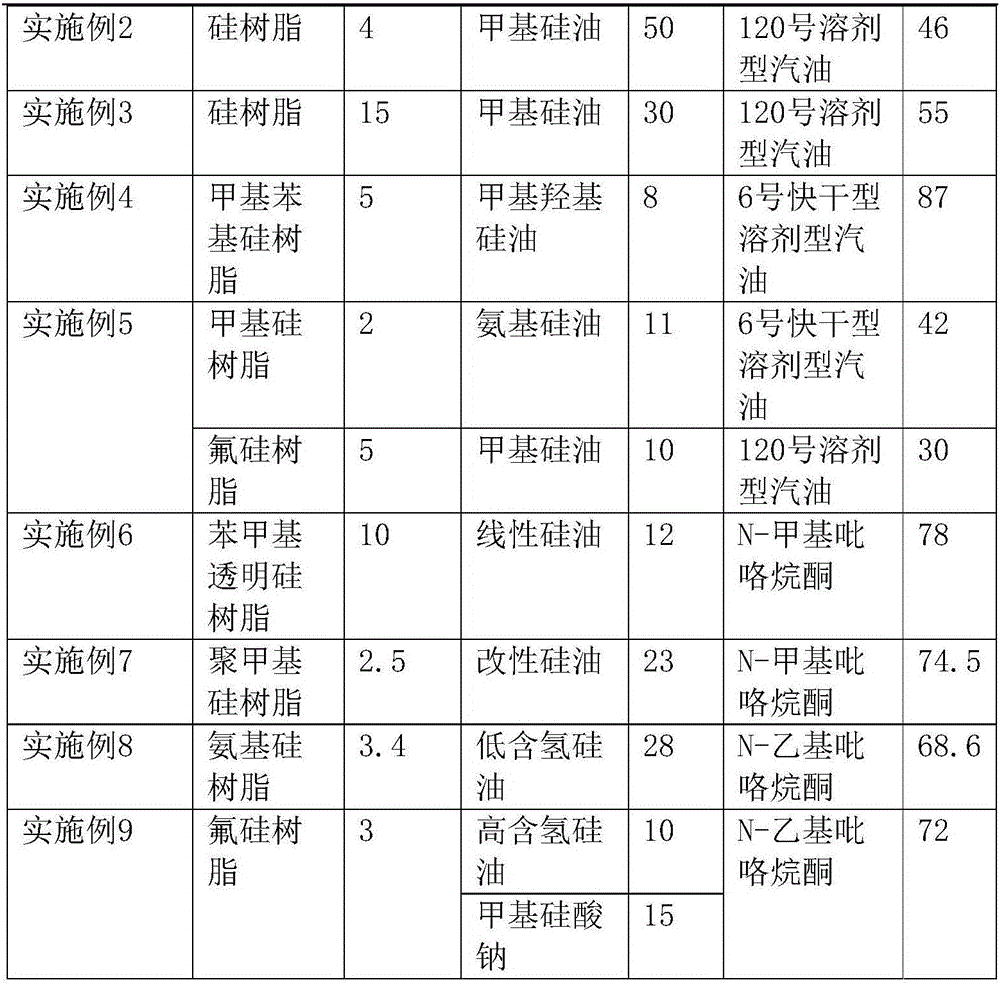

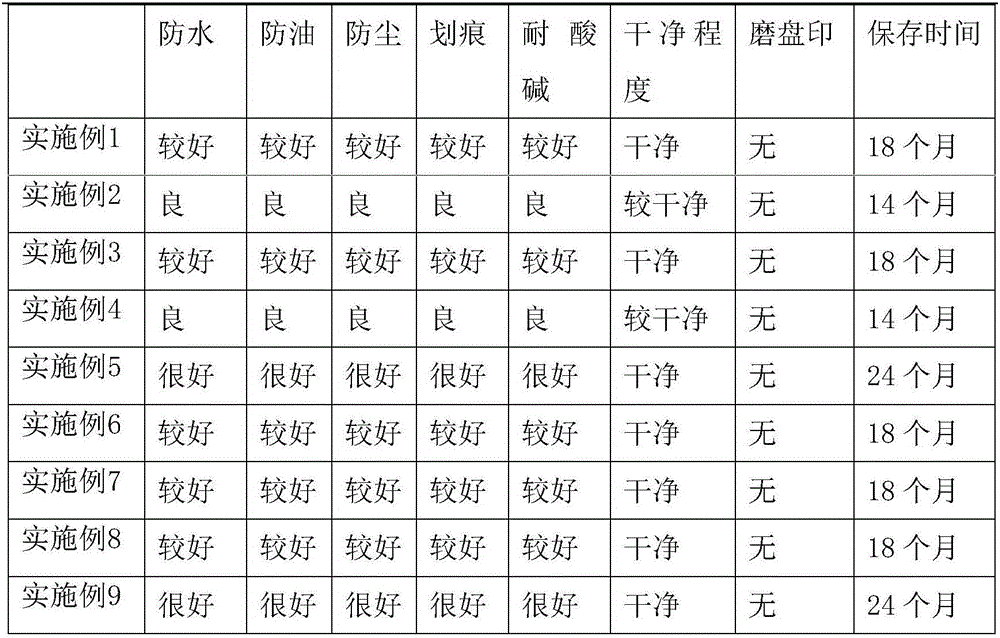

Matte brick stain-proofing agent and preparation method thereof

ActiveCN105860831AAntifoulingExtended service lifeAntifouling/underwater paintsPaints with biocidesOrganic solventBrick

The invention discloses a matte brick stain-proofing agent. The matte brick stain-proofing agent is prepared from a component A, a component B and a component C, wherein the component A is an organic solvent, the component B is silicon resin, and the component C is at least one of silicone oil and organosiloxane monomers. The invention further provides a preparation method of the matte brick stain-proofing agent. By compounding the components, the matte brick stain-proofing agent can achieve a good stain-proofing effect when used for performing stain-proofing treatment on the surfaces of matte bricks in follow-up application; besides, the matte brick stain-proofing agent has a very long shelf life and service life; moreover, the preparation technology is simple and easy to implement and can be conveniently applied to industrial production.

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

Super-hydrophilic coating with long-acting antibacterial property and preparation method thereof

ActiveCN108816689AResistance adhesionGood antibacterial propertiesSurgeryPharmaceutical delivery mechanismIonNitrogen gas

The invention provides a super-hydrophilic coating with a long-acting antibacterial property and a preparation method thereof. The preparation method comprises the following steps that the surface ofa substrate material is pretreated; the pretreated substrate material is put into a slight acidic buffer solution, then a polyphenolic substance, a multi-amine compound, an antibacterial agent and anoxidizing agent are added to react; a reaction product is immersed in deionized water, ultrasonic cleaning is carried out, then drying is carried out under a nitrogen condition to prepare the coating.The super-hydrophilic coating with the long-acting antibacterial property and the preparation method thereof have the advantages that the operation is simple, the reaction condition is mild; the prepared coating material contains the polyphenolic substance, and a large number of carboxyl, phenolic hydroxyl group, quinonyl, amidogen and other functional groups and metal ions or agents which has the antibacterial property, so that the metal ions and the antibacterial agents achieve the long-term existence of the antibacterial agent through the mutual effect with the phenolic hydroxyl group function group or the accumulation of a pi-pi system. The coating can be applied to the preparation of wound dressing materials in the field of medical materials.

Owner:JILIN VENUS HAOYUE MEDICAL LTD

Knife-scrapping coating tent cloth and preparation process thereof

ActiveCN103317805AWaterproofAntifoulingNon-macromolecular adhesive additivesSynthetic resin layered productsUltravioletPolyvinyl chloride

The invention discloses knife-scrapping coating tent cloth. The knife-scrapping coating tent cloth sequentially comprises a basic cloth layer, an adhesion layer, a shading layer and a surface layer from inside to outside, wherein the adhesion layer is prepared from polyvinyl chloride paste resins, plasticizers, stabilizers, inorganic flame retardant and mould inhibitors; the shading layer is prepared from polyvinyl chloride of which the k value is 80, plasticizers, stabilizers, inorganic flame retardant, carbon black pigment color pastes, ultraviolet absorbent and mould inhibitors; the surface layer is prepared from polyvinyl chloride of which the k value is 85, plasticizers, acrylic ester, inorganic flame retardant and methylbenzene. The knife-scrapping coating tent cloth has the excellent performances of waterproofing, antifouling, inflame retardance, anti-aging and the like, is high in tearing resistant performance and extremely high in peeling strength, and has high self-cleaning and excellent uvioresistant functions. The knife-scrapping coating tent cloth is high in product performance and long in service life, and the requirement of clients is met.

Owner:GUANGDONG UPAL DISPLAY TECH CO LTD

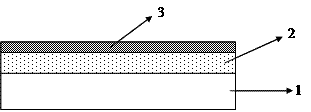

Antistatic, anti-dazzle and anti-reflection optical film and manufacture method for the same and application thereof

InactiveCN107203013AWith anti-reflection propertiesAntifoulingOptical elementsCoated surfaceAntistatic agent

The invention discloses an antistatic, anti-dazzle and anti-reflection optical film and a manufacture method for the same and an application thereof. The antistatic, anti-dazzle and anti-reflection optical film comprises a transparent film base material, an antistatic and anti-dazzle hard coating which is at least coated on the transparent film base material and an anti-reflection coating on the surface of the antistatic and anti-dazzle hard coating; the antistatic and anti-dazzle hard coating comprises a medium the refractive rate UV solidified resin with a refractive index ranging from 1.45-1.53, an active diluent, transparent anti-dazzle particles, a photoinitiator, an antistatic agent and a diluent; the anti-reflection coating consists of a low refractive rate material with a refractive index lower than 1.45 and a high refractive rate material with a refractive index higher than 1.52; the anti-reflection coating is formed through coating the antistatic and anti-dazzle hard coating on the surface of the transparent film base material and then performing one-time coating on the antistatic and anti-dazzle film after the film is formed. The antistatic, anti-dazzle and anti-reflection optical film and the manufacture method for the same and the application thereof can have functions of preventing static electricity, preventing dazzling, preventing scratching and fouling and can be applied to polarized plates of various kinds of flat displayers and display screen surface protection.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Superfine fiber synthetic leather and preparation method thereof

InactiveCN102425070AImprove product qualityWaterproofSynthetic resin layered productsTextiles and paperPolymer scienceEngineering

The invention relates to superfine fiber synthetic leather and a preparation method thereof, and belongs to the technical field of synthetic leather. The superfine fiber synthetic leather consists of a superfine fiber synthetic leather base fabric, a foamed bottom sealing filling layer, a coating top layer, a coating bonding layer and a surface treatment layer, wherein the foamed bottom sealing filling layer comprises the following components in part by weight: 10 to 30 parts of water-borne comprehensive resin, 30 to 40 parts of water-borne foamed resin and 1 to 5 parts of waterproof agent; the coating top layer comprises the following components in part by weight: 70 to 90 parts of water-borne polyurethane, 3 to 10 parts of water-borne color paste, 1 to 5 parts of flatting agent and 1 to5 parts of handfeel agent; the coating bonding layer comprises the following components in part by weight: 70 to 90 parts of water-borne polyurethane bonding agent, 3 to 10 parts of water-borne colorpaste and 1 to 5 parts of flatting agent; and the surface treatment layer comprises the following components in part by weight: 1 to 5 parts of waterproof agent and 1 to 5 parts of handfeel agent. The superfine fiber synthetic leather has good properties of scratch resistance, pollution resistance and water resistance, and has wide application prospect; and by adoption of the superfine fiber synthetic leather, clean production can be realized.

Owner:深圳市天之一科技开发有限公司

Radiation proof fabric

InactiveCN102059835AImprove conductivityImprove antistatic performanceSynthetic resin layered productsCeramic layered productsEquipment OperatorMetallurgy

The invention relates to a radiation proof fabric comprising a base fabric weaved by warp yarns and weft yarns, the warp yarns and the weft yarns are formed by blending stainless steel fibers and terylene fibers, wherein the stainless steel fibers account for 20-30% of total weight of the fabric, the terylene fibers account for 70-80% of total weight of the fabric; nanometer coating liquid is coated on the surface of the base fabric and has the thickness of 0.05-0.2mm; and a far infrared coating is coated on the other surface of the base fabric and contains far infrared ceramic powder. Because the stainless steel fibers are utilized in the invention, the damage of electromagnetic waves, in particular microwave radiation to a human body can be effectively avoided, the radiation proof fabric is suitable for the dressing requirements on high frequency equipment operators, communication equipment operators and women of childbearing age in the fields of industry, medical treatment, and the like; the stainless steel fibers have excellent conductive property and anti-static property; and the coated nanometer coating liquid has antifouling and antibacterial effects.

Owner:WUJIANG TONGLONG TEXTILE

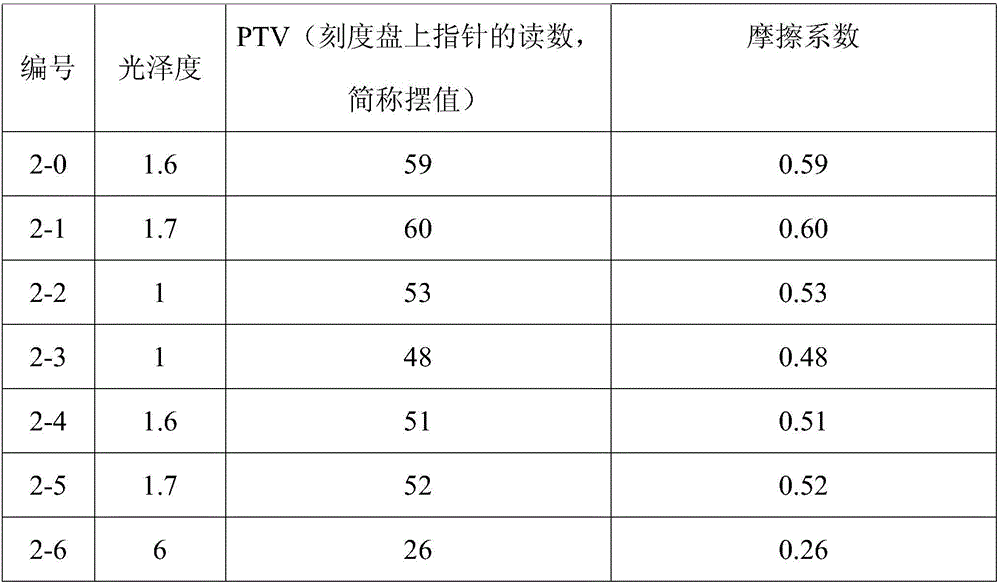

Surface skid resistance enhancing glazed tile adobe and preparation method thereof

A surface skid resistance enhancing glazed tile adobe and preparation method thereof, the preparation method comprises the steps of A, preparing rough glaze: weighing by mass 60-100 parts of bright transparent frit powder, 25-35 parts of kaolin, 1-2 parts of alumina, then the above raw materials being added with water to prepare into glaze pulp with specific weight less than 1.3; B, preparing and sintering the product: spreading antifouling finish on the surface of adobe, then spreading the rough glaze obtained from step A, the glazing amount of the rough glaze being ,<=0.5 kg / m2, sintering ready after drying, and finally obtaining the finished product after polishing treatment. The proposed surface skid resistance enhancing glazed tile adobe and preparation method thereof, carries out improvements from glaze material formula, through the performance combination of two kinds of glaze materials, enabling the coefficients of the product skid resistance to be stabilized on a relatively higher value, and achieving the goal of increasing the performances of skid resistance and ant fouling.

Owner:FOSHAN DONGPENG CERAMIC +2

Preparation method of environment-friendly type three-prevention automobile needling finishing material

InactiveCN101694056AWaterproofOil-resistantPhysical treatmentDry-cleaning apparatus for textilesEngineeringSewage

The invention discloses a preparation method of environment-friendly type three-prevention automobile needling finishing material, which comprises the following steps: firstly, cleaning blankets, namely placing automobile finishing base blankets into dissolvent to clean for a certain period, flushing by deionized water, and drying for stand-by, secondly, low-temperature plasma treatment, namely placing automobile finishing base blankets after cleaning in a low-temperature plasma treatment instrument to conduct electro discharge treatment, improving the reactivity of subsequent finishing agent and materials, and improving durability, thirdly, slop padding method treatment, namely, immersing automobile finishing base blankets after plasma treatment into fluorine-containing organic finishing agent solution to conduct two-leaching and two-rolling treatment, conducting baking and thermal treatment in a baking box, and preparing to get environment-friendly type three-prevention automobile needling finishing material. The automobile needling finishing material is a clean and environemt-friendly vehicle-used textile material with 'three-prevention' functions of preventing water, oil and sewage.

Owner:ANHUI NANAO CARPET +1

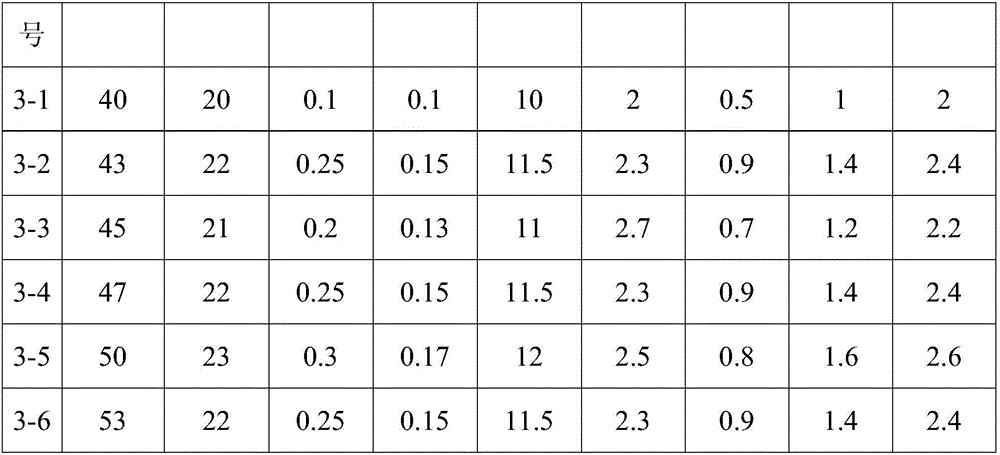

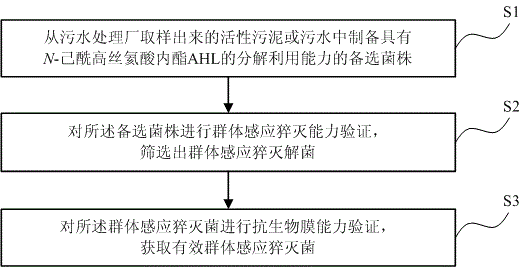

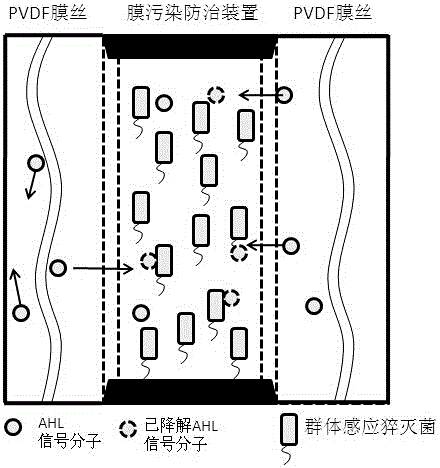

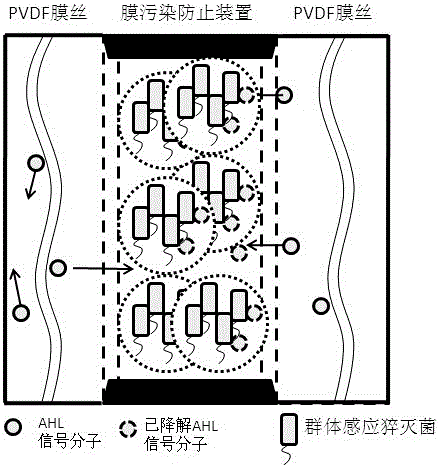

Quorum sensing quenching bacteria preparation method, MBR membrane pollution prevention and control method, and MBR membrane pollution prevention and control apparatus

InactiveCN106399140AAntifoulingReduce energy consumptionBacteriaMicroorganism based processesHomoserineSignalling molecules

The invention provides a quorum sensing quenching bacteria preparation method, a MBR membrane pollution prevention and control method, and a MBR membrane pollution prevention and control apparatus. The preparation method comprises: preparing an alternative strain having N-hexanoyl-homoserine lactone AHL decomposition and utilization capability from active sludge or sewage sampled from a sewage treatment plant; verifying the quorum sensing quenching ability of the alternative strain to screen quorum sensing quenching bacteria; and verifying the anti-bio-film ability of the quorum sensing quenching bacteria to obtain the effective quorum sensing quenching bacteria. According to the present invention, the prepared quorum sensing quenching bacteria uses the pollutants in the sewage as the nutrition to decompose other microorganisms during the growth process to generate the signal molecules, such that the concentration of the AHL signal molecules produced by other microorganisms in the membrane pool cannot achieve the concentration threshold required by the quorum sensing and the signal loop conduction cannot be formed so as to inhibit the bio-film formation of the membrane pool microorganisms on the MBR membrane assembly surface and achieve the effects of pollution prevention and energy consumption saving.

Owner:福瑞莱环保科技(深圳)股份有限公司

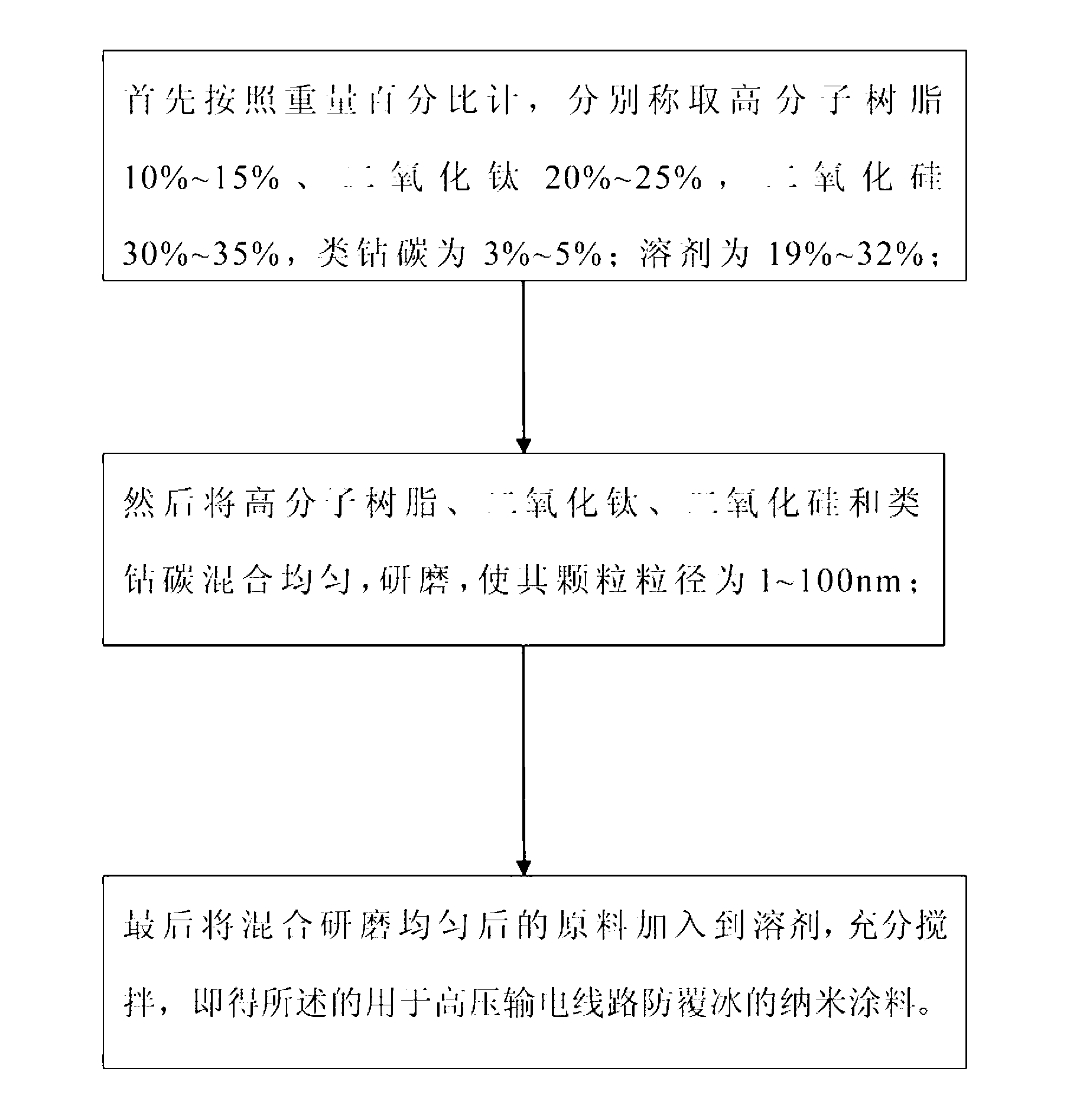

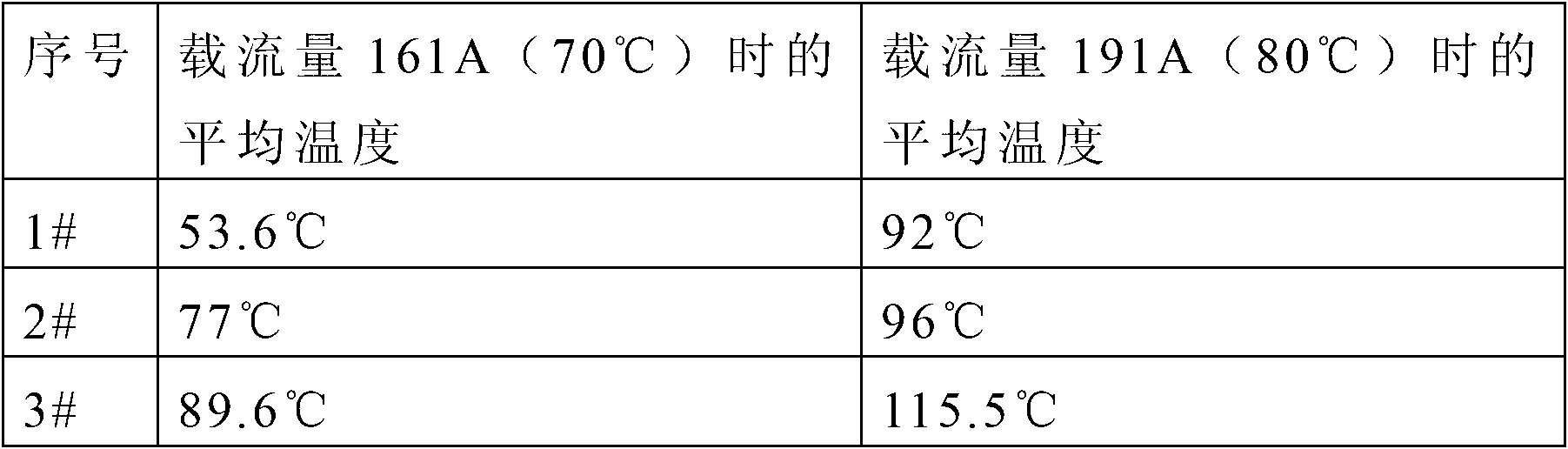

Nanometer coating used for preventing icing of high tension transmission line and application thereof

InactiveCN103059650AAntifoulingAnti-icingOther chemical processesPolycarbonate coatingsDiamond-like carbonSolvent

The invention relates to a nanometer coating used for preventing icing of a high tension transmission line and application thereof. The nanometer coating is prepared through the following steps: weighing, by weight, 10 to 15% of a high-molecular resin, 20 to 25% of titanium dioxide, 30 to 35% of silica, 3 to 5% of diamond-like carbon and 19 to 32% of a solvent; then compounding and uniformly mixing the high-molecular resin, titanium dioxide, silica and diamond-like carbon and carrying out grinding to obtain a particle with a particle size of 1 to 100 nm; and finally, adding the raw materials uniformly mixed and ground into the solvent and carrying out full stirring so as to obtain the nanometer coating used for preventing icing of the high tension transmission line. The coating provided by the invention allows the high tension transmission line to have the advantages of fouling resistance, icing resistance, high wear resistance and the like, provides a long-acting, high-efficiency, convenient, economic and feasible approach for active resistance to ice and snow disasters, realizes delaying and prevention of icing of super-cooled droplets on the high tension transmission line and enables no icing or little icing to be generated on the high tension transmission line in snowy weather.

Owner:STATE GRID CORP OF CHINA +2

Preparation method of nano multifunctional assistant and application thereof

ActiveCN101559917AFlame retardantWith sterilizationNanostructure manufactureFibre treatmentAluminium hydroxideSlurry

The invention relates to a preparation method of a nano multifunctional assistant and an application thereof. The method comprises the steps of (1) preparing nano-scale titanium dioxide, zinc oxide, magnesium hydroxide and aluminum hydroxide respectively; (2) mixing materials according to a certain proportion, adding deionized water, stirring to prepare slurry with the concentration of 40 percent-60 percent, and carrying out the modification to obtain modified slurry; (3) adding deionized water to dilute to the concentration of 10 percent-20 percent, pouring 2-6kg of nano silver-silicon compound and a dispersant in a kettle and stirring to react; (4) slowly dripping 6-12kg of fluorine-containing resin in the kettle under specific conditions, adding a coupling agent and the dispersant to react, keeping the temperature for 50-250 minutes and finally cooling and discharging. The product produced by the method has a plurality of functions of flame-retardant, anti-bacteria, anti-fungus, anti-water, anti-oil, anti-fouling and the like. The prepared nano multifunctional assistant can be applied in a variety of textiles.

Owner:江苏常泰纳米材料有限公司

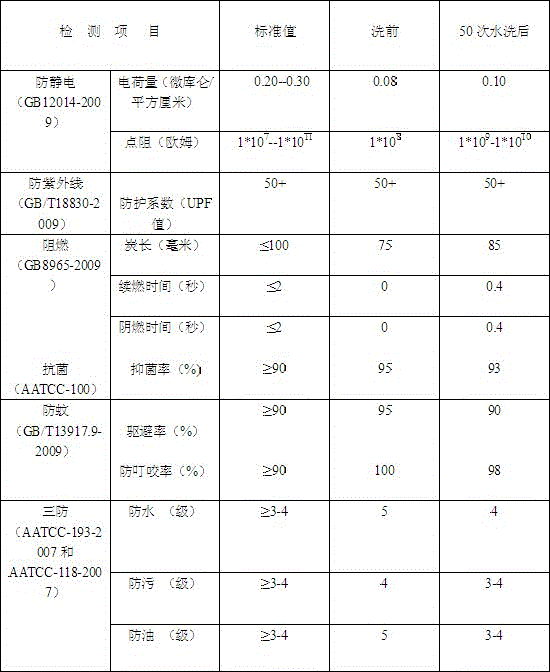

Production method of multi-functional composite fabric

InactiveCN106400259AFlame retardantWith anti-staticWoven fabricsVegetal fibresEngineeringSoil resistance

The invention discloses a production method of multi-functional composite fabric and belongs to the technical field of production methods and technologies of special clothes processed fabric. To solve the technical problem above, the following technical scheme is adopted. Provided is the production method of composite multi-functional fabric. The method comprises the steps of A, spinning and weaving; B, dyeing and conducting ultraviolet-proof arrangement; C; conducting flame-retardant arrangement; D, conducting antibacterial and anti-mosquito treatment; E, conducting three-anti treatment, namely oil-proof, waterproof and soil resistant treatment. The multi-functional composite fabric meanwhile has all the following 8 functions: flame retardancy, destaticization, oilproofness, soil resistance, waterproofness, antibacterial and mosquito repellence. Actual demands are basically met, and a safe and reliable guarantee for users of special environment is provided.

Owner:新乡市新科防护科技有限公司

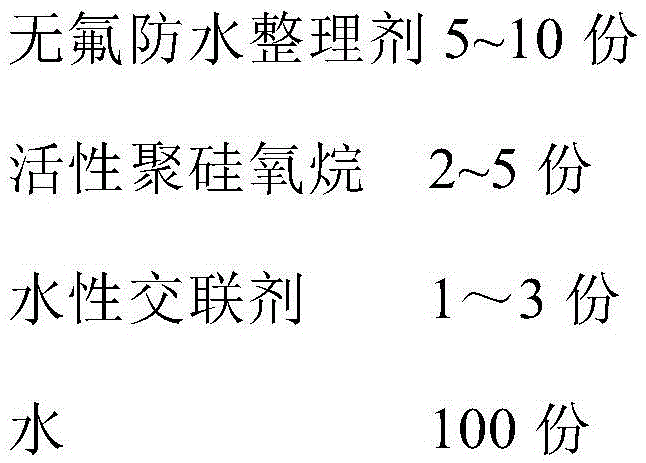

Environmentally friendly anti-siphon afterfinishing method for suede microfiber synthetic leather

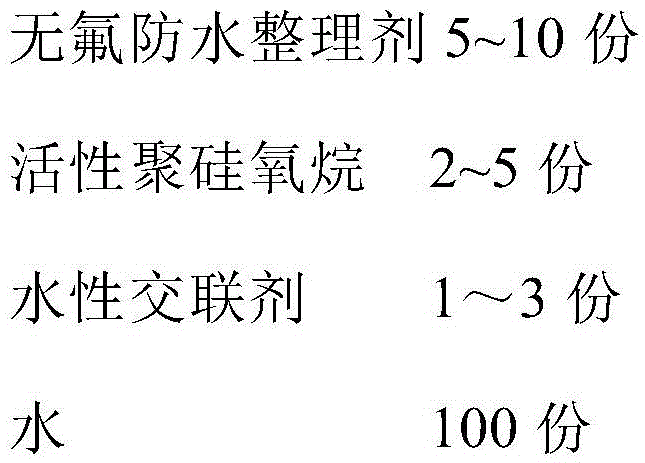

ActiveCN105463857AImprove the anti-siphon effectSpeed up penetrationFibre treatmentFluorine freeMicrofiber

The present invention discloses an environmentally friendly anti-siphon afterfinishing method for a suede microfiber synthetic leather. The method is as below: (1) immersing the dyed microfiber synthetic leather into an anti-siphon treatment solution, and padding; (2) then drying the product obtained in the step (1), cooling, rolling and crumpling to obtain the anti-siphon suede microfiber synthetic leather. The anti-siphon treatment solution for suede microfiber synthetic leather has a pH value of 4-6, and comprises the following components by weight: 5-10 parts of a fluorine-free waterproof finishing agent, 2-5 parts of reactive polysiloxane, 1-3 parts of an aqueous crosslinking agent and 100 parts of water. The agent of the invention uses the fluorine-free environment-friendly waterproof finishing agent without APEO, PFOA or PFOS, and the ultrasonic technology; and the obtained microfiber synthetic leather achieves anti-siphon effect of rise of impregnating solution of less than 1cm after 2h immersion, and has good creases and velvety sense, so as to improve the grade of the suede microfiber synthetic leather.

Owner:HUAFON MICROFIBER SHANGHAI

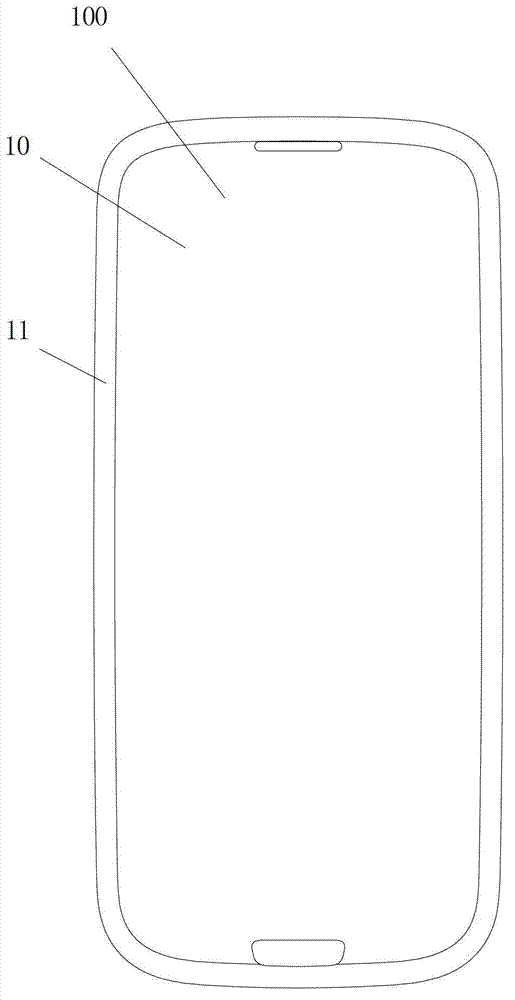

Electronic product screen protection glass film and manufacturing method thereof

InactiveCN102896839AAntifoulingAnti-fingerprintGlass/slag layered productsGlass reforming apparatusDisplay deviceEngineering

The invention discloses an electronic product screen protection glass film and a manufacturing method thereof. The glass film comprises a glass film planar part which is matched with a planar part of an electronic product screen, and a glass film curved surface part which extends out of the glass film planar part and is matched with a curved surface part of the electronic product screen. The manufacturing method comprises the following steps of: blanking, coating a glass demolding agent onto a mold, loading a blanked material onto the mold, heating the blanked material and the mold and preserving heat, pressurizing and assembling the mold, taking out for standing, reinforcing, performing vapor deposition and the like. The electronic product screen protection glass film disclosed by the invention has the functions of preventing stains, preventing fingerprints, preventing collision and the like, can be up to 7-8 H Moh's hardness on the aspect of the surface hardness, and can be widely applied to screen protection of electronic equipment such as mobile phones and electronic instrument displays; and due to the adoption of the manufacturing method of the electronic product screen protection glass film, the problem of easiness in breaking of thin glass during machining is solved, the rate of graded product is high, and the production and manufacturing costs are lowered.

Owner:蒋兰波

Multifunctional super-hydrophobic textile finishing agent, and preparation method and applications thereof

ActiveCN107326651AReduce usageSimple manufacturing processStain/soil resistant fibresBiochemical fibre treatmentHydrolysisSkin protection

The invention discloses a multifunctional super-hydrophobic textile finishing agent, and a preparation method and applications thereof. The preparation method comprises following steps: a precursor of an oxide sol and a graphite oxide aqueous dispersion are dispersed in deionized water, an anionic surfactant is added, a catalyst is added for hydrolysis and condensation reaction after uniform dispersion so as to obtain a mixed reaction system, and the mixed reaction system is heated to 30 to 50 DEG C for 3 to 12h of reaction so as to obtain a hydrosol; a functional agent is added into the hydrosol so as to obtain the multifunctional super-hydrophobic textile finishing agent. The multifunctional super-hydrophobic textile finishing agent is safe, is friendly to the environment, is excellent in effect, is used for super hydrophobic and multifunctional finishing of textile, is capable of providing textile with six functions including super-hydrophobic property, flame resistance, antibacterial property, stain resistance, ultraviolet resistance, and skin protection performance, is capable of eliminating adverse effect of the plurality of functions, improving the synergistic effect; the preparation method is simple and convenient, is easy to control, and is suitable for large scale production.

Owner:石狮市杰立纺织科技有限公司

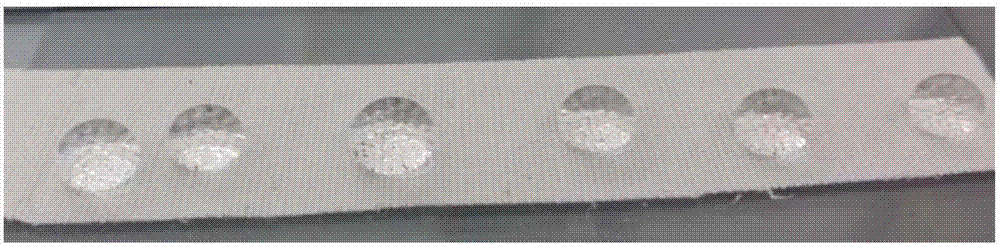

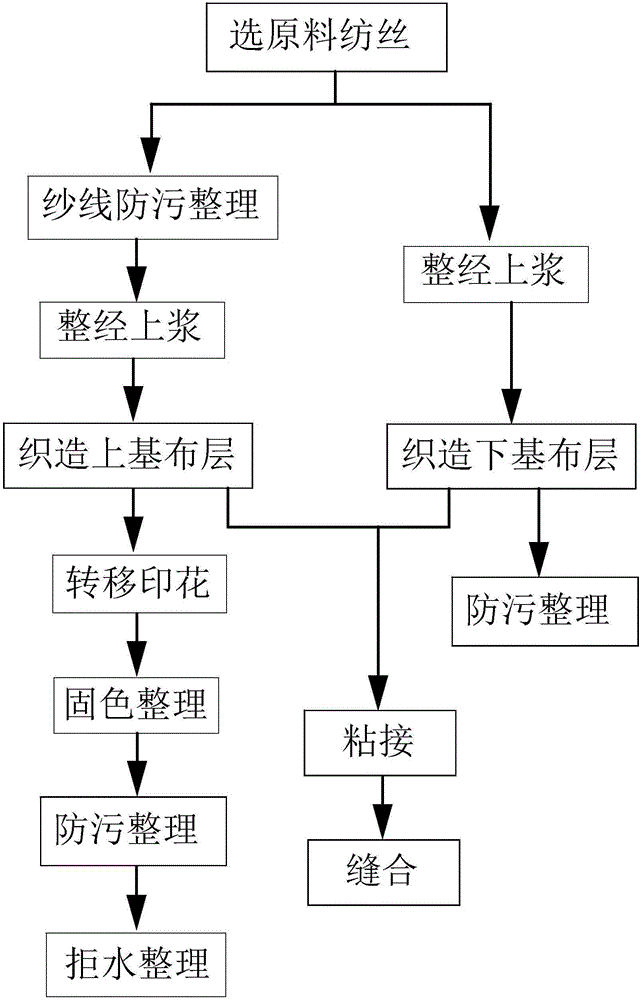

Production method of antifouling sofa fabric

ActiveCN106283340AIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnAdhesive

The invention provides a production method of an antifouling sofa fabric, belonging to the technical field of home textiles. The production method comprises the following steps: (1) selecting raw materials and spinning; (2) performing anti-pollution finishing of yarns; (3) warping and sizing; (4) weaving: weaving an upper base cloth layer and a lower base cloth layer; (5) transferring and printing; (6) fixing color and finishing; (7) performing anti-pollution finishing; (8) conducting water repellent finishing; (9) adhering: coating adhesives on the upper side and the lower side of a sponge respectively, applying pressure to the upper base cloth layer, the sponge and the lower base cloth layer which are superposed vertically, so as to enable the three to be adhered as a whole; and (10) sewing. The yarns treated by a warping and sizing machine are high in sizing rate, and fewer in feathers, so that static electricity generated due to friction among yarns can be reduced, the static electricity of the fabric can be effectively reduced, and the woven fabric is difficult to generate static electricity, thus being relatively difficult to adsorb dust; and the sofa fabric produced by utilizing the method has multiple antifouling capabilities, and has obvious antifouling effect.

Owner:海宁宝祥布业有限公司

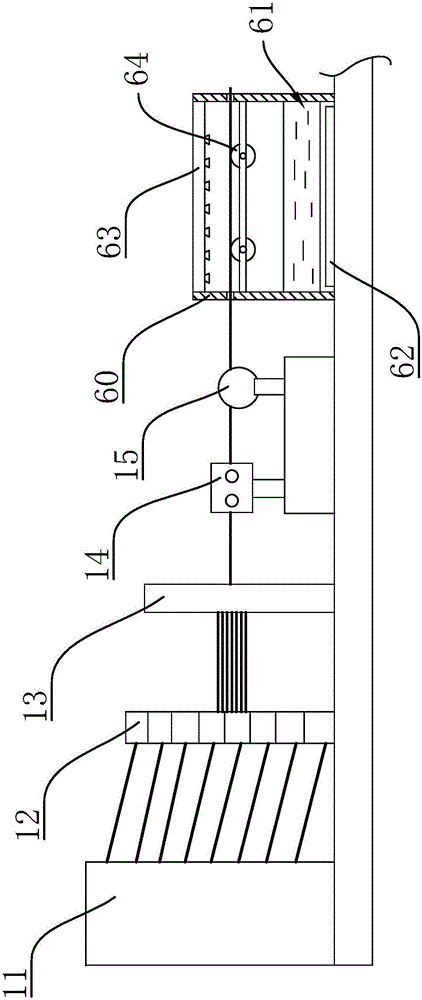

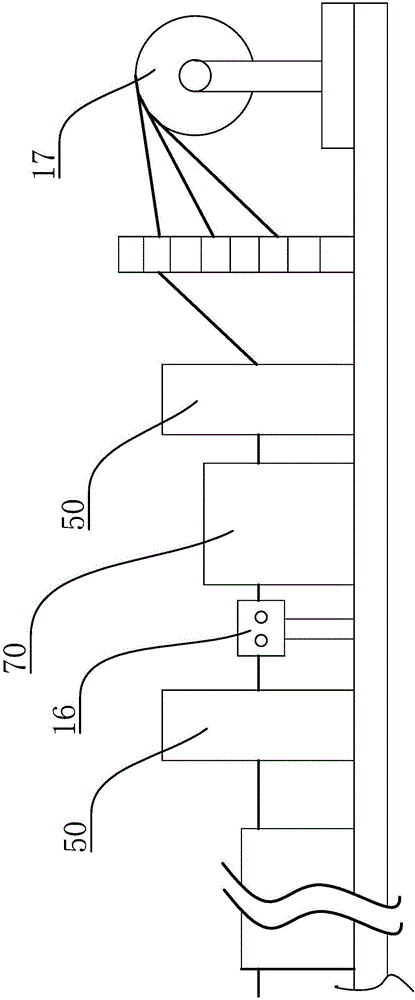

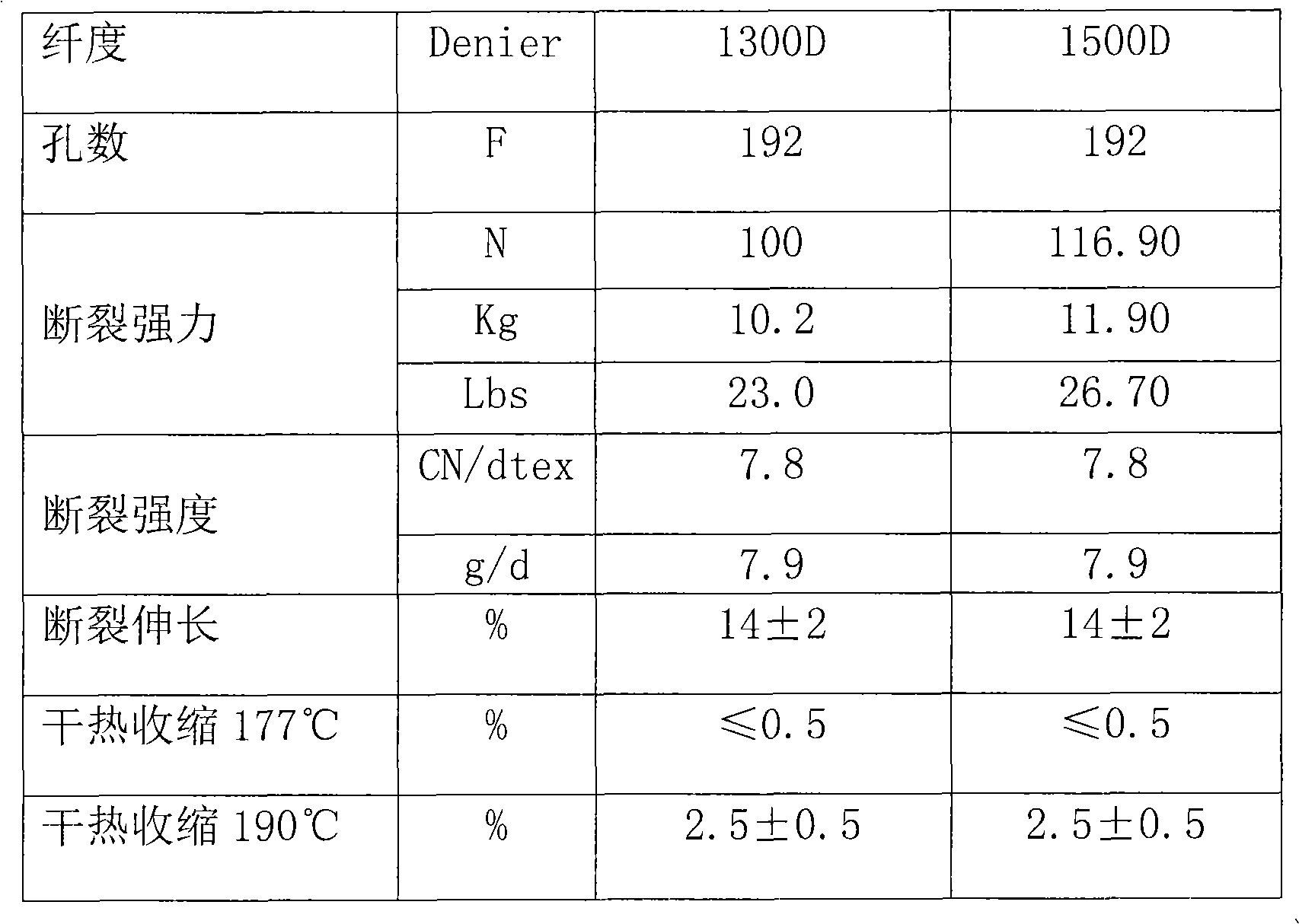

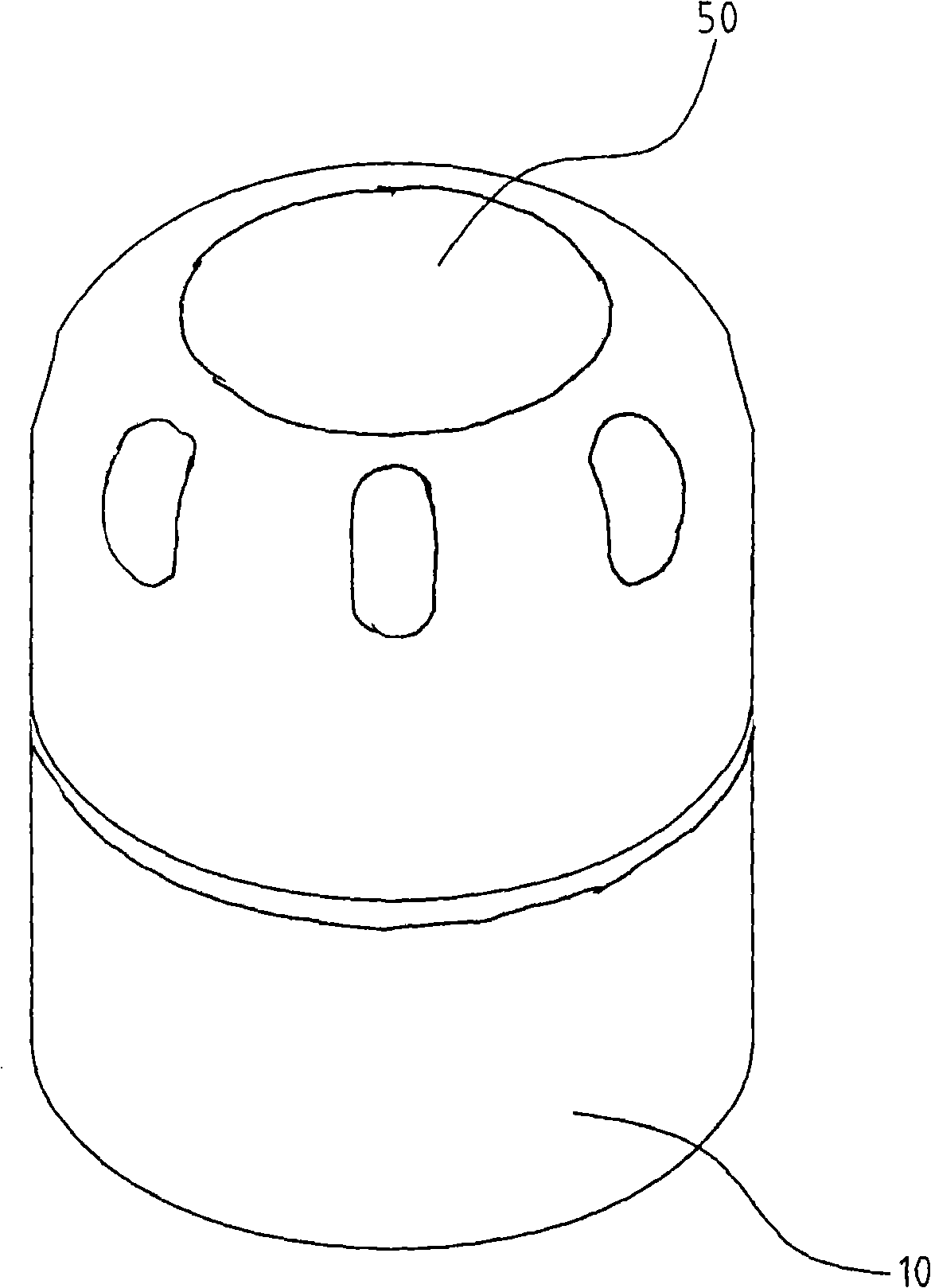

Coal mine air cylinder and manufacturing method thereof

InactiveCN101644164AGood abrasion and tear resistanceReduce weightTunnel/mines ventillationTextiles and paperPlasticizerAntistatic agent

The invention relates to a coal mine air cylinder which comprises gridding base cloth and a PVC calendered coating covered on the base cloth, wherein the PVC calendered coating is coated with antistatic agent, and the gridding base cloth is spun by taking twisting polyester fiber filament yarn as warp and weft; the PVC calendered coating comprises the components based on the parts by weight: 100 parts of SG-70 resin, 73-112 parts of plasticizer, 8-12 parts of inorganic fire retardant, 60-65 parts of inorganic filler, 0.2-1 part of anti-aging agent, 0.1 part of antiseptic, 20-25 parts of pigment and 6-12 parts of coupling agent. The coal mine air cylinder has the advantages of good abrasive resistance, tear resistance, light weight, water resistance, pollution and mould prevention, inflaming retarding, good antistatic effect, ageing resistance, long service life and single-width formation.

Owner:浙江天地塑业有限公司

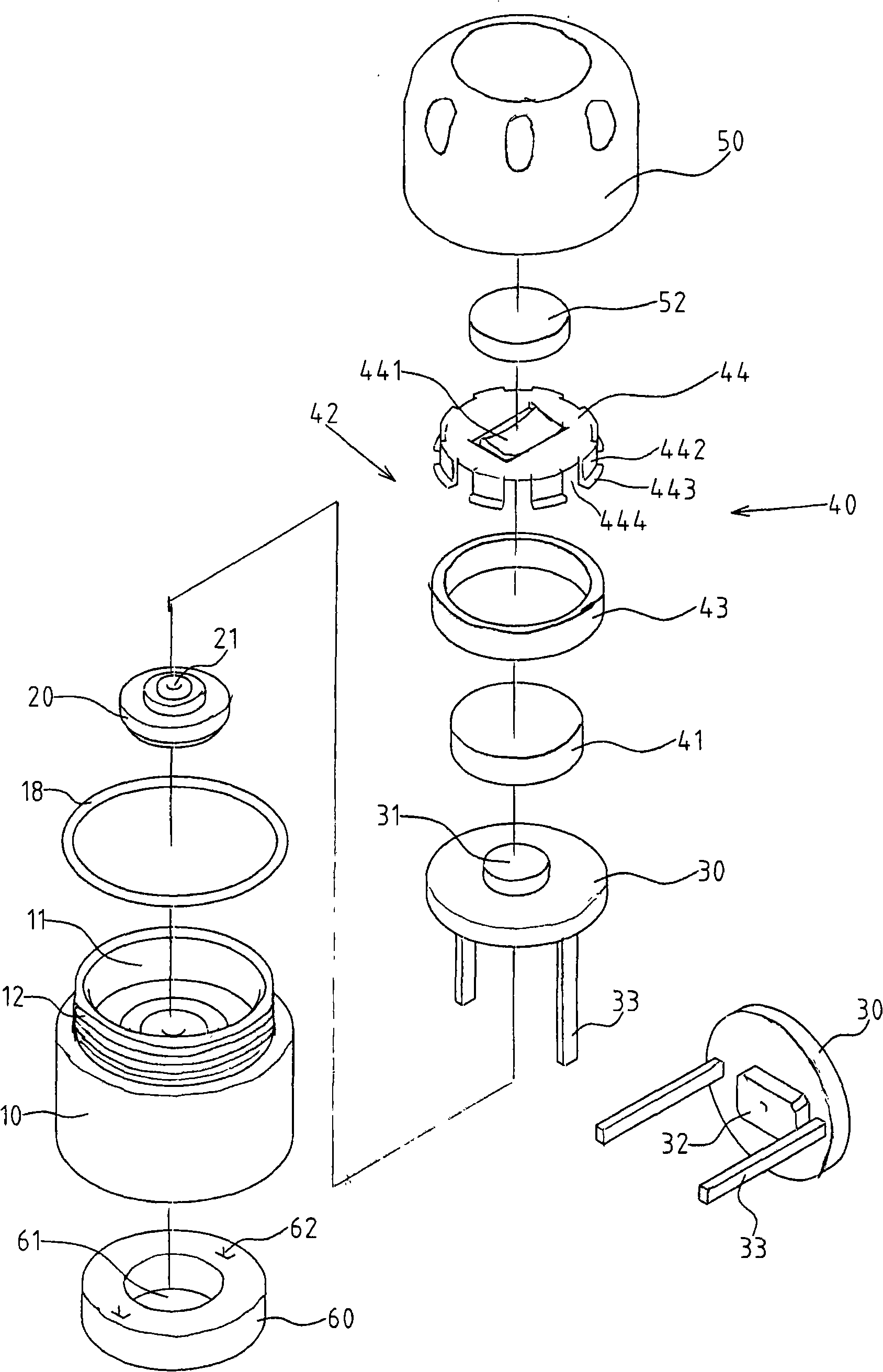

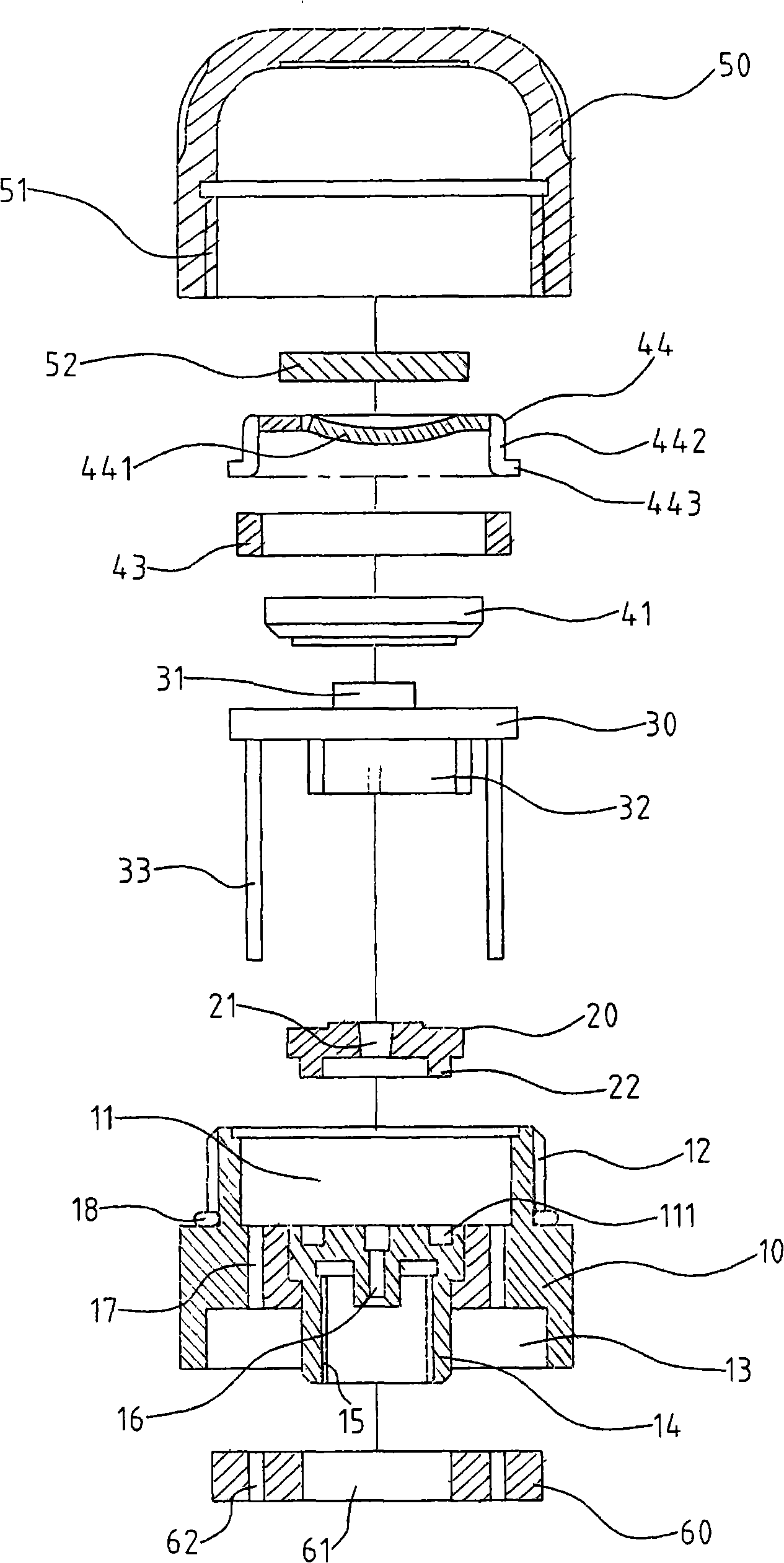

Air valve cap type tire pressure detecting device

InactiveCN101293467AShortened height volumeAchieve collision avoidanceInflated body pressure measurementAntenna adaptation in movable bodiesEngineeringNozzle

The invention provides an air nozzle hood type tyre pressure detector which mainly consists of a base body, a signal transmitting unit, a hood and an antenna; the invention is mainly characterized in that the antenna is assembled at the bottom of the base body and the antenna is arranged at the periphery part of the connection end of the base body, thus leading the antenna to be in a concealed state so as to be convenient for achieving the practical advancements of shortening the height and size of the tyre pressure detector as well as preventing collision and pollution.

Owner:MOBILETRON ELECTRONICS NINGBO

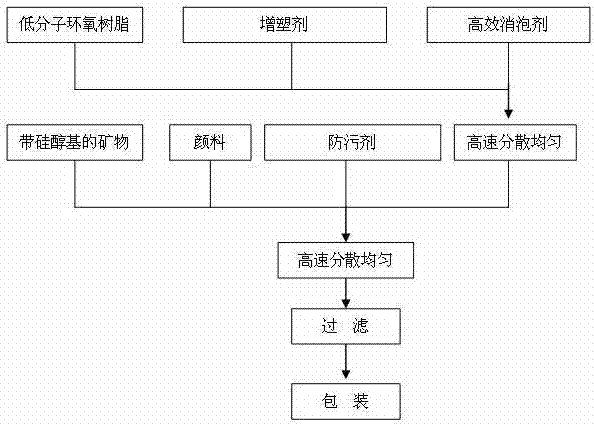

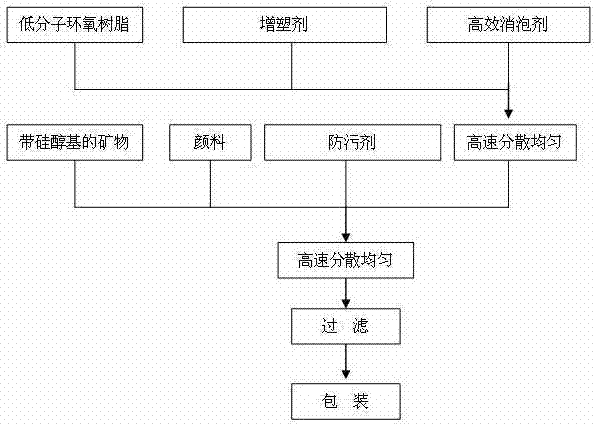

Antifouling paint for underwater coating construction

ActiveCN102363688AGood construction performanceSave resourcesAntifouling/underwater paintsPaints with biocidesEpoxyOyster

The invention discloses an antifouling paint for the underwater coating construction. The antifouling paint comprises a component A and a component B, wherein the component A comprises 20-50 parts of a low molecular epoxy resin, 5-20 parts of a plasticizer, 0.05-1 part of an antifoaming agent, 10-25 parts of silicate mineral powder, 15-40 parts of a broad spectrum antifouling agent, 3-15 parts ofan auxiliary antifouling agent, 0.5-5 parts of a pigment, and 0.5-5 parts of a thixotroping assistant; and the component B is a curing agent which is a Mannich base curing agent, and the mass of the curing agent accounts for 10-30% of the mass of the component A. According to the invention, the antifouling paint is an environmentally friendly resource conserving paint; the coating construction performance is good; the antifouling paint which allows the coating antifouling performance to be improved has a score of more than 85 when the coating is subjected to shallow sea hanging for six monthsin Xiamen seas; the underwater coating construction can be carried out through the antifouling paint; the antifouling paint has an antifouling effect on animal sea creatures of barnacle, oyster and mussel, and botanical algae; and the antifouling paint can be brush-coated, scrape-coated, and roll-coated during underwater coating, the paint cannot be scattered, and the coating does not contract after curing.

Owner:XIAMEN SUNRUI SHIP COATING

Double-ingredient epoxy seam beautifying glue

InactiveCN106381117AEasy to operateSafe and non-toxicNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyCrack resistance

The invention relates to seam beautifying glue, in particular to double-ingredient epoxy seam beautifying glue. An ingredient A is prepared from the following ingredients in percentage by weight: 60 to 90 percent of epoxy resin, 0 to 30 percent of plasticizers, 0 to 3 percent of anti-freezing agents, 0 to 15 percent of glitter powder, 1 to 10 percent of thixotropic agents, 0.01 to 1 percent of antifoaming agents and 0 to 20 percent of filling materials; an ingredient B is prepared from the following ingredients in percentage by mass: 65 to 95 percent of curing agents, 1 to 20 percent of thixotropic agents, 0 to 30 percent of plasticizers and 0 to 15 percent of glitter powder. The ingredient A and the ingreeinet B are respectively packaged after the preparation; the ingredient A and the ingredient B can be used after being uniformly mixed according to the weight ratio of 1:1. The construction operation is convenient; the advantages of safety, non-toxicity, wear resistance, waterproof performance, mildewproof performance, stain prevention, chemical medicine resistance, anti-cracking performance, fine crack resistance, yellowing resistance, rich color and the like are realized; the seam beautifying glue can be used as the seam beautifying glue by replacing the existing cement and can be used for performing color matching on ceramic tiles in different colors so as to achieve the decoration effect.

Owner:三友(天津)高分子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com