Antifouling paint for underwater coating construction

An antifouling coating and coating technology, applied in the field of coatings, can solve problems such as antifouling performance not mentioned, achieve the effect of improving antifouling performance, ensuring antifouling performance, and improving construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

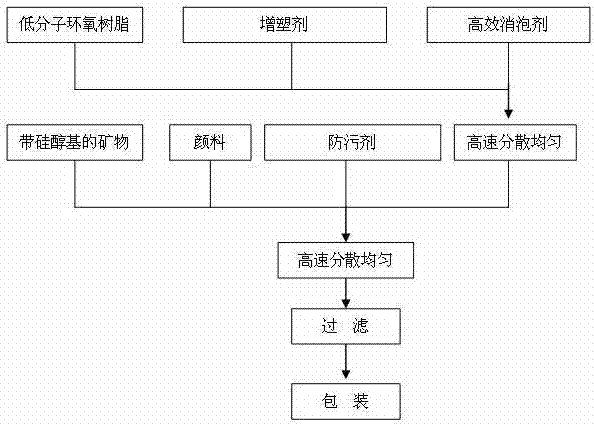

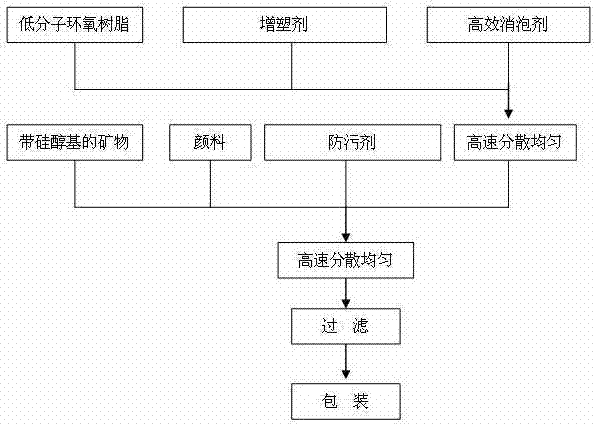

Method used

Image

Examples

Embodiment Construction

[0049] Examples of the present invention are shown in Table 3, all in parts by mass.

[0050] Table 3, embodiment

[0051] A component Example 1 Example 2 Example 3 618 epoxy resin 0 35 25 6101 epoxy resin 25 0 17 Dibutyl phthalate 5 7 10 BYK-A530 defoamer 0.05 0.5 1 Cuprous oxide 26.95 10 0 Cuprous thiocyanate 0 10 14 zinc pyrithione 9 5 3 polyamide wax 1 2 2 calcium silicate 20 15 5 Iron Oxide Red 3 2 5 B component Example 1 Example 2 Example 3 Mannich base curing agent 10 13.5 18

[0052] Table 4. Main technical indicators of coatings

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com