Matte flame-retardant cold-resistant covering cloth

A canopy, cold-resistant technology, applied in the field of canopy, can solve the problems of poor flame retardant performance, low peel strength, cracking and contamination, achieve the best cold resistance, improve product quality and production efficiency, and increase additional effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A matte flame-retardant and cold-resistant tarpaulin. After the tarpaulin is soaked in glue and dried on the base fabric, the base fabric, PVC mask and PVC base film are laminated on both sides, and then finished with fluorine silicon after cooling and shaping. The surface functional treatment is carried out with the agent, and then it is made by drying and coiling process;

[0029] Wherein, the calendering formula of the PVC mask and the PVC bottom film is: 100 parts by weight of PVC resin powder, 3 parts by weight of antimony trioxide, 50 parts by weight of dioctyl phthalate, 3 parts by weight of dioctyl adipate , 3 parts by weight of titanium dioxide, 3 parts by weight of stabilizer, 2 parts by weight of soybean oil, and 20 parts by weight of calcium carbonate.

[0030] The surface of the PVC mask and the PVC bottom film has been matte treated, and the matte surface can greatly improve the sticking phenomenon between the film and the pressure roller; the base fabric ...

Embodiment 2

[0037] With reference to Example 1, change the calendering formula of PVC facial film, PVC base film, the calendering formula of described PVC facial film, PVC base film is: PVC resin powder 100 weight parts, antimony trioxide 4 weight parts, dioctyl phthalate 60 parts by weight of ester, 4 parts by weight of dioctyl adipate, 5 parts by weight of titanium dioxide, 6 parts by weight of stabilizer, 4 parts by weight of soybean oil, and 20 parts by weight of calcium carbonate.

[0038] The flame retardancy of the covering cloth obtained by the present invention meets the requirements of grade B2 of decorative fabrics in GB / T 17591, the tensile load is ≥2450N / 5cm in the warp direction, and ≥1800N / 5cm in the transverse direction, and the tear load is ≥260N in the warp direction, and ≥260N in the transverse direction. 195N, cold resistance performance: placed at -30°C for 2 hours and folded in half without cracks.

Embodiment 3

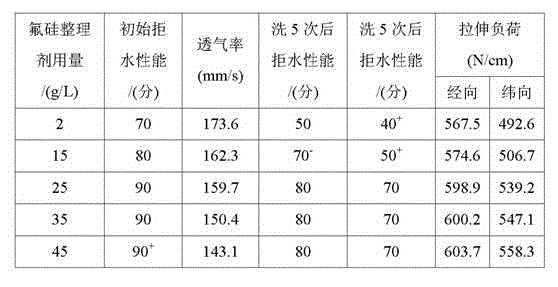

[0040] The fluorosilicone finishing agent utilizes the internal C=C and Si-H in its molecule to cross-link to form a film under the action of a catalyst, thereby providing low surface energy on the surface of the fiber. The influence of different process parameters on the finishing effect is investigated. The specific steps refer to Example 1 .

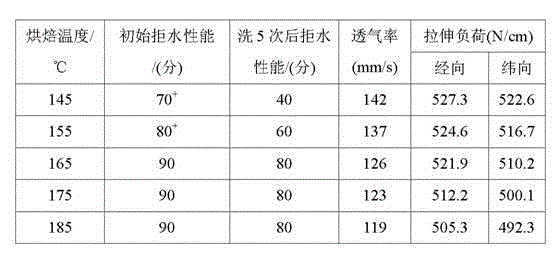

[0041] 1. Effect of baking temperature on finishing effect

[0042] Since the process of fluorine-containing silicone oil cross-linking itself to form a film or reacting with the hydroxyl functional group on the fiber is mainly completed during the baking process, the selection of the baking temperature is very important. The fabrics finished with 25g / L fluorosilicone finishing agent were baked at different baking temperatures, and the effects of the baking temperatures on the water repellency, washability, and mechanical strength of the finished fabrics were tested. The results are shown in Table 1. Show:

[0043] Table 1

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com