Patents

Literature

222 results about "Surface membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pancreatic cancer associated antigen, antibody thereto, and diagnostic and treatment methods

The present invention is directed to an antigen found on the surface of rat and human pancreatic cancer cells and provides antibodies of high specificity and selectivity to this antigen as well as hybridomas secreting the subject antibodies. Methods for both the diagnosis and treatment of pancreatic cancer are also provided. This tissue marker of pancreatic adenocarcinoma, an approximately 43.5 kD surface membrane protein designated PaCa-Ag1, is completely unexpressed in normal pancreas but abundantly expressed in pancreatic carcinoma cells. Moreover, a soluble form of PaCa-Ag1 exists, having a molecular weight about 36 to about 38 kD, that is readily identified in sera and other body fluids of pancreatic cancer patients, using a subject antibody.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

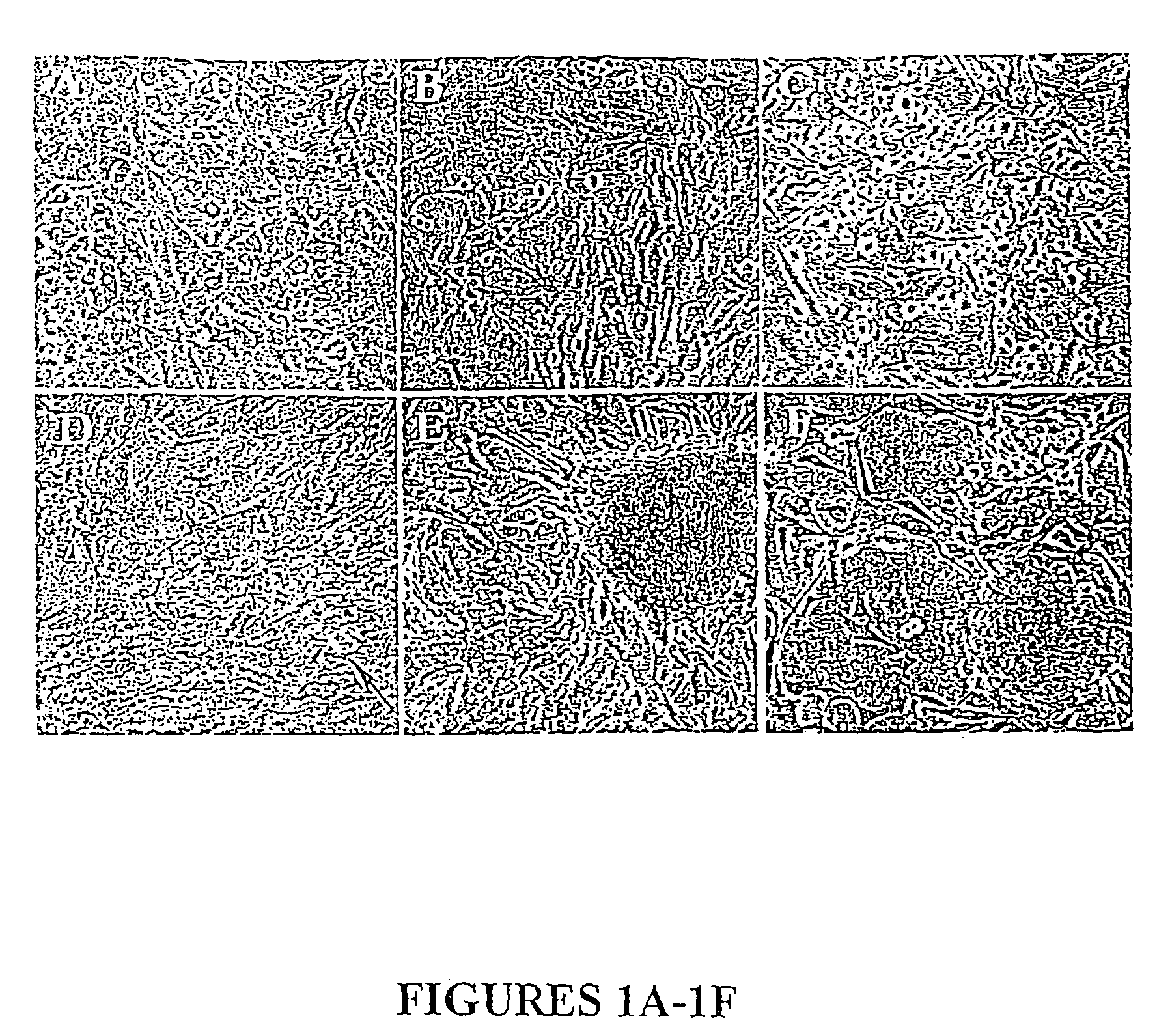

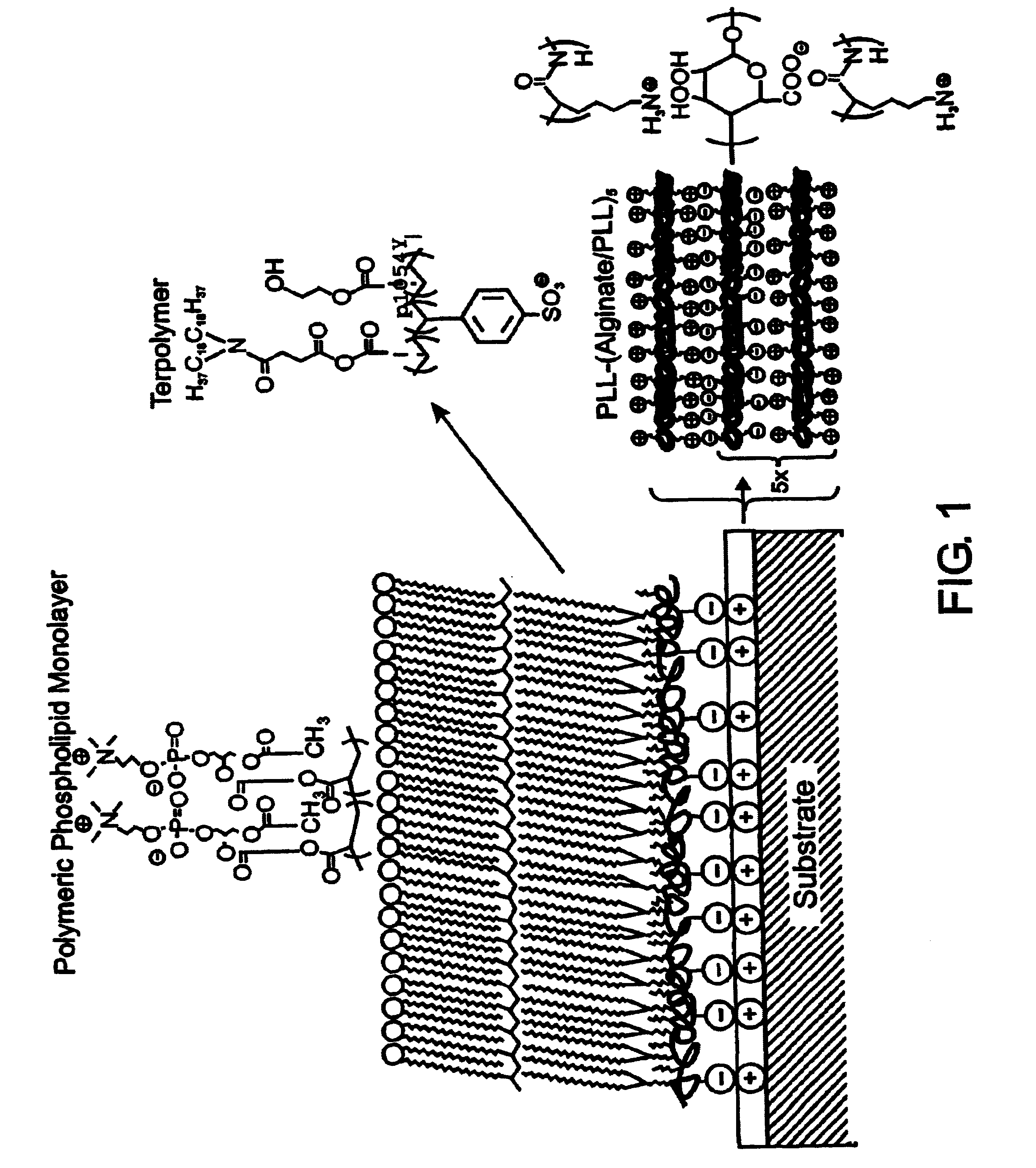

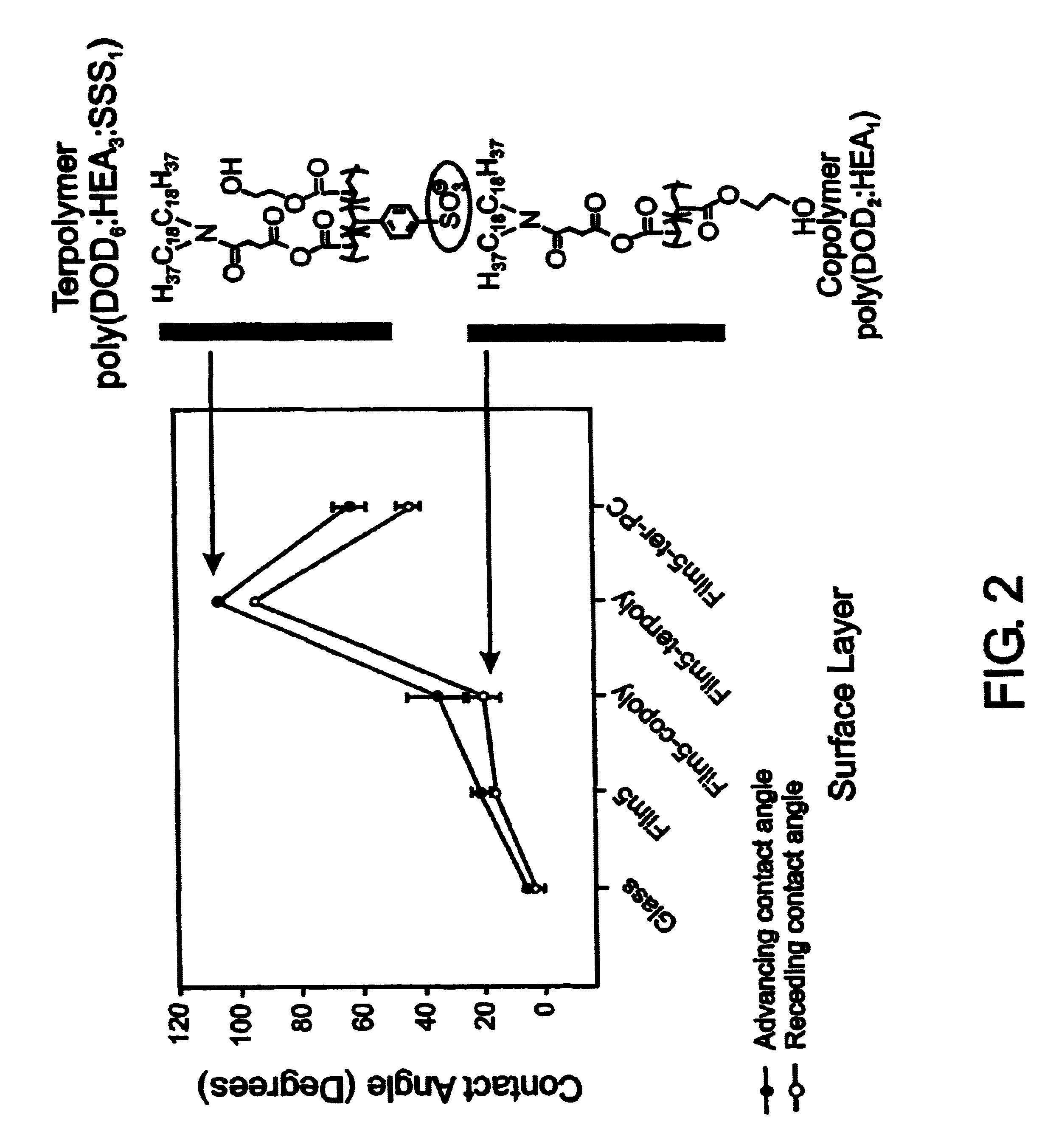

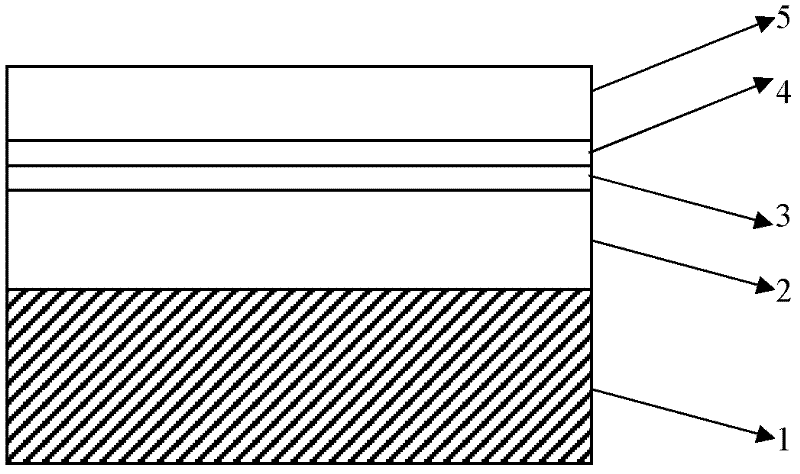

Biological component comprising artificial membrane

InactiveUS7713544B2Improved performance characteristicsMinimize adhesionMaterial nanotechnologyMicroorganismsAmount of substanceMembrane mimetic

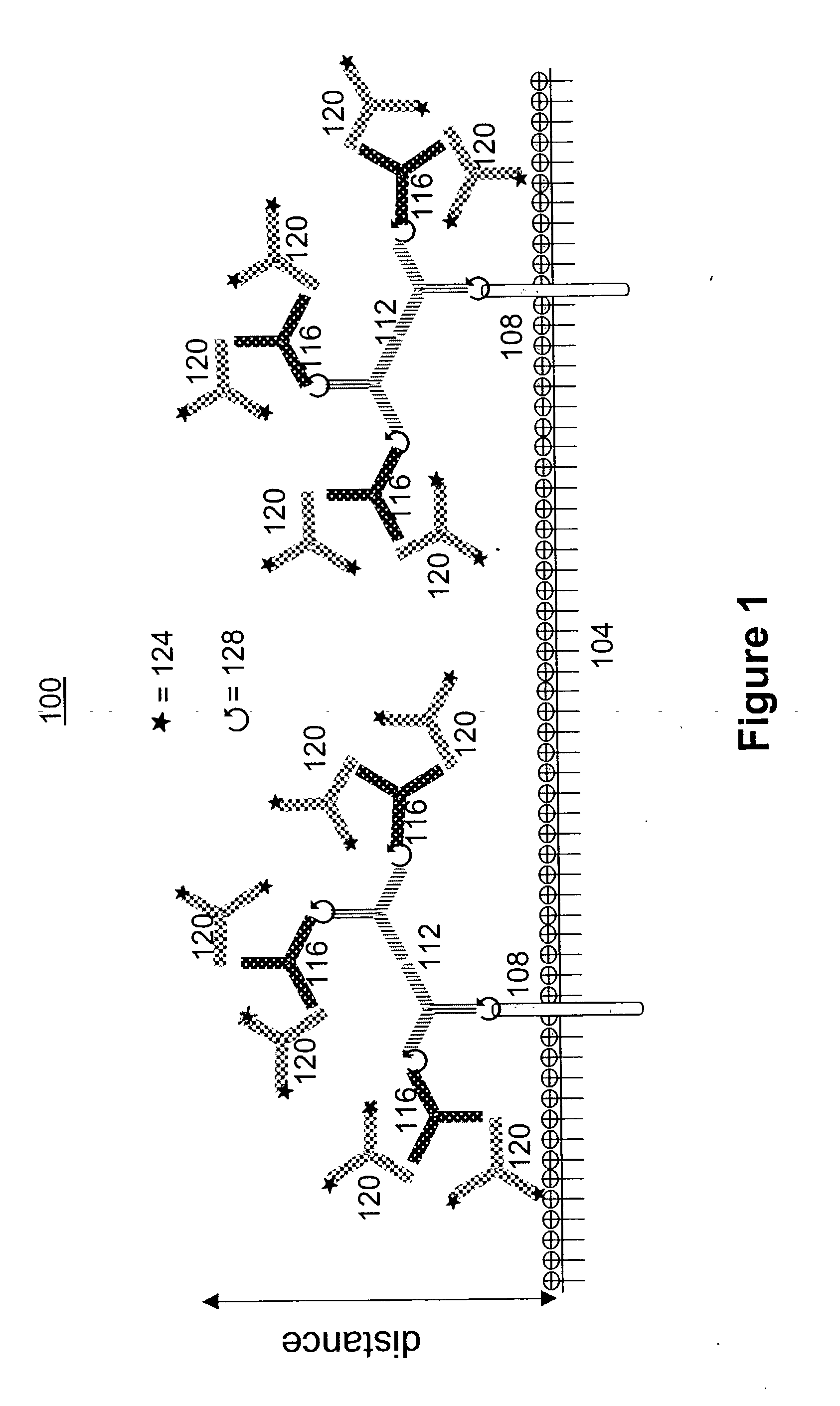

A biocompatible biological component is provided comprising a membrane-mimetic surface film covering a substrate. Suitable substrates include hydrated substrates, e.g. hydrogels which may contain drugs for delivery to a patient through the membrane-mimetic film, or may be made up of cells, such as islet cells, for transplantation. The surface may present exposed bioactive molecules or moieties for binding to target molecules in vivo, for modulating host response when implanted into a patient (e.g. the surface may be antithrombogenic or antiinflammatory) and the surface may have pores of selected sizes to facilitate transport of substances therethrough. An optional hydrophilic cushion or spacer between the substrate and the membrane-mimetic surface allows transmembrane proteins to extend from the surface through the hydrophilic cushion, mimicking the structure of naturally-occurring cells. An alkylated layer directly beneath the membrane-mimetic surface facilates bonding of the surface to the remainder of the biological component. Alkyl chains may extend entirely through the hydrophilic cushion when present. To facilitate binding, the substrate may optionally be treated with a polyelectrolyte or alternating layers of oppositely-charged polyelectrolytes to facilitate charged binding of the membrane-mimetic film or alkylated layer beneath the membrane-mimetic film to the substrate. The membrane-mimetic film is preferably made by in situ polymerization of phospholipid vesicles.

Owner:EMORY UNIVERSITY

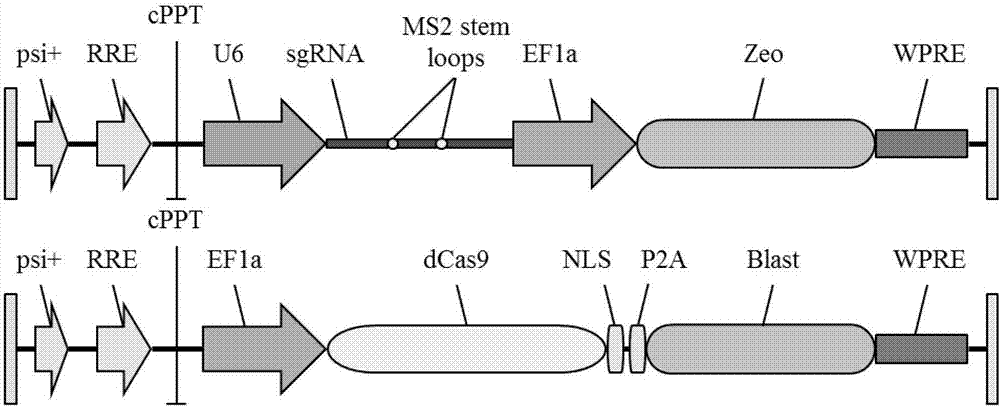

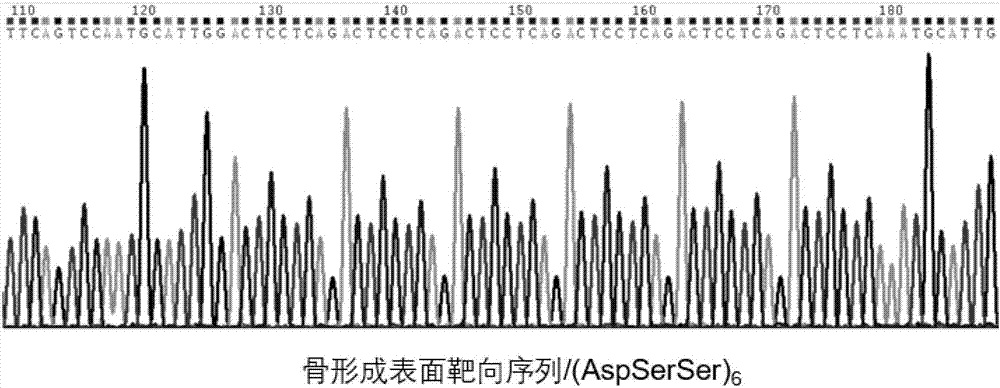

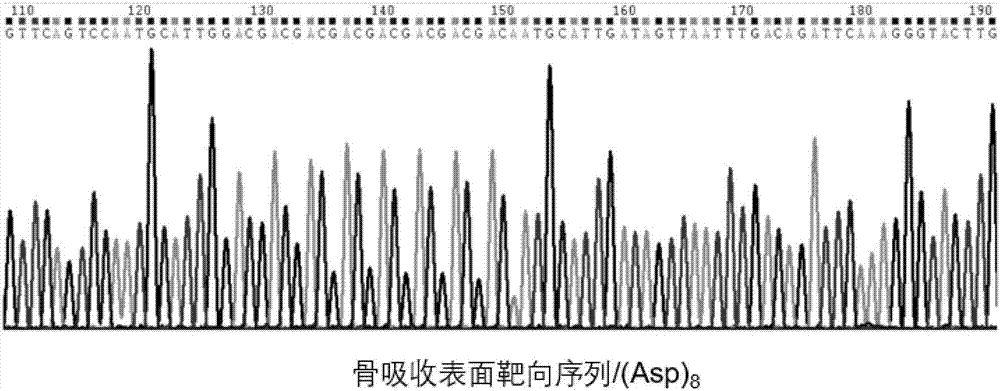

Exosome carrier of targeted bone, CRISPR/Cas9 gene editing system and application

ActiveCN107034188APlay gene editingFunctionHydrolasesStable introduction of DNATarget peptideExosome

The invention relates to an exosome carrier of a targeted bone, a CRISPR / Cas9 gene editing system and application. The exosome carrier comprises a targeted peptide of any one of a targeted bone forming surface, a bone absorbing surface and an endothelial cell. The exosome carrier can be fused with (AspSerSer)6, (Asp)8 and a CREDVW oligopeptide respectively by transforming an exosome surface membrane protein lamp2b, so that an exosome can be fused with the targeted bone forming surface, the bone absorbing surface and the endothelial cell. Therefore, the bone targeting exosome is developed as the carrier, a CRISPR / Cas9 system serves as a gene editing and controlling tool, and the two parts are combined to play the important significance on the treatment of various bone diseases.

Owner:HOSPITAL OF STOMATOLOGY SUN YAT SEN UNIV

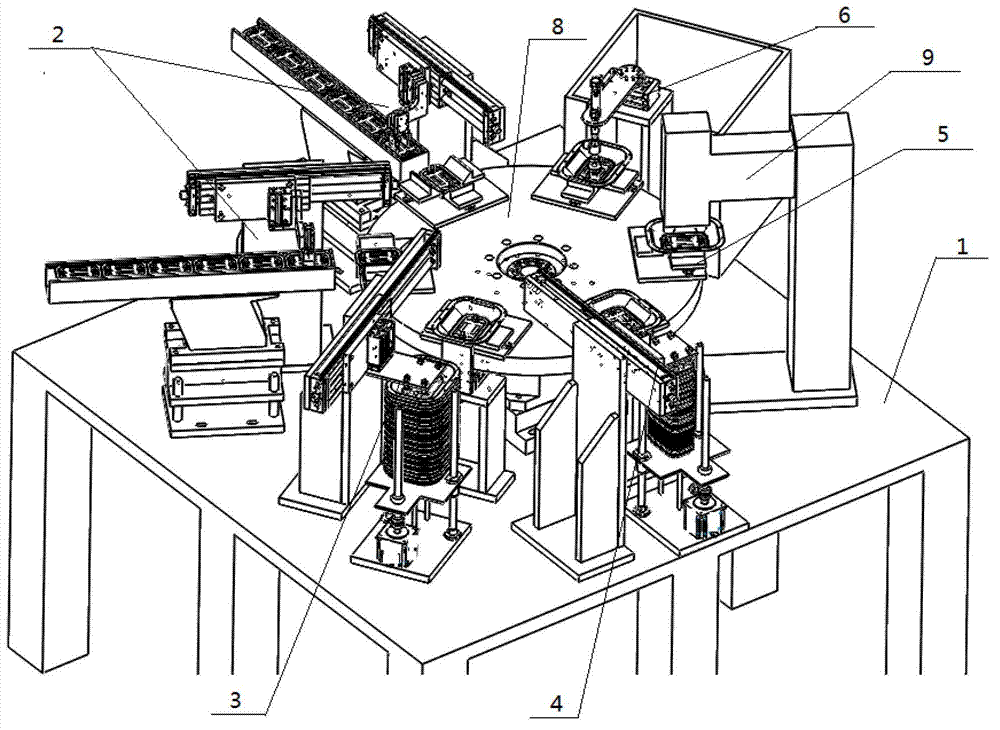

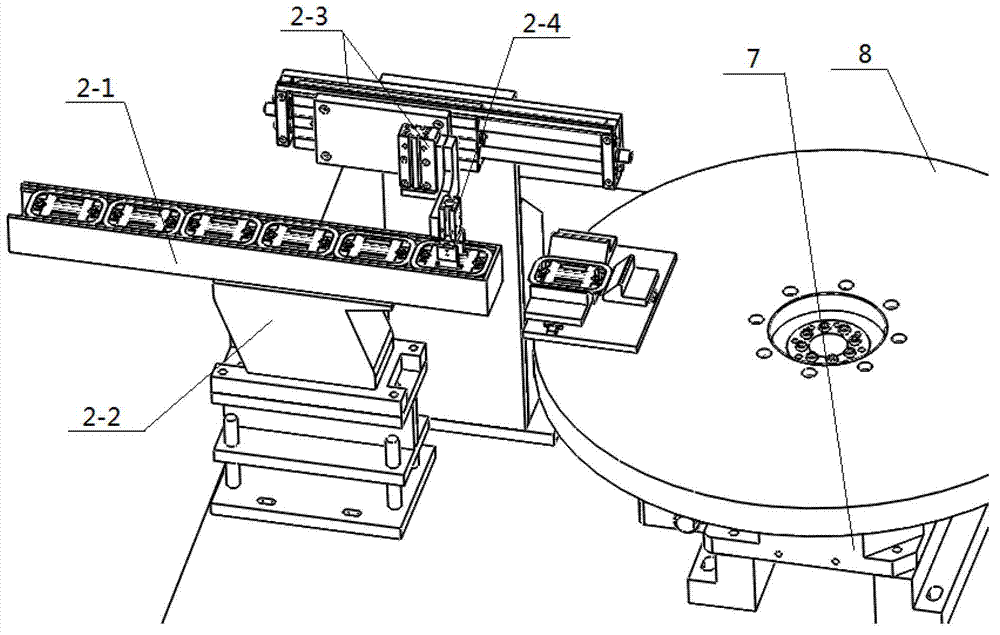

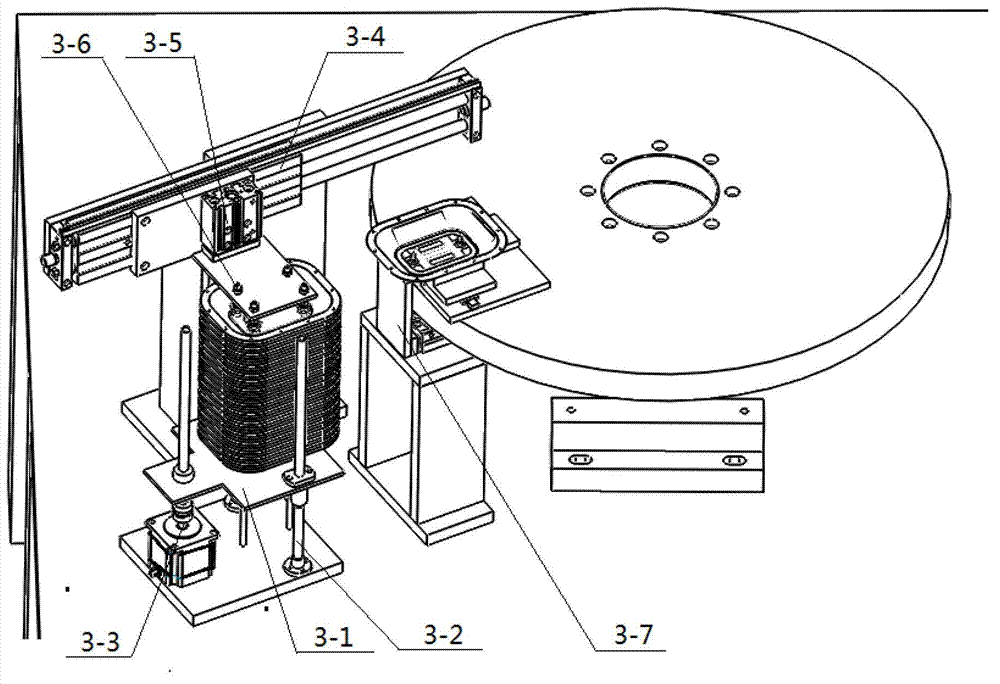

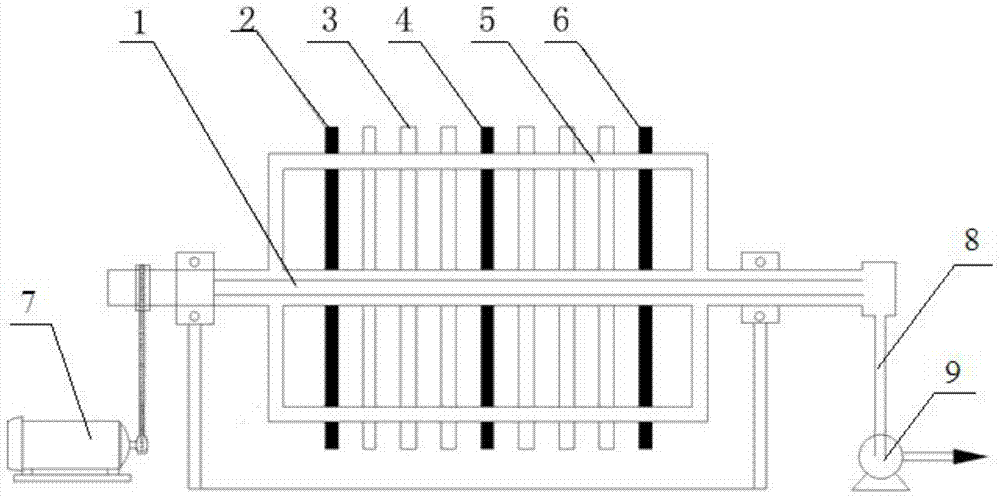

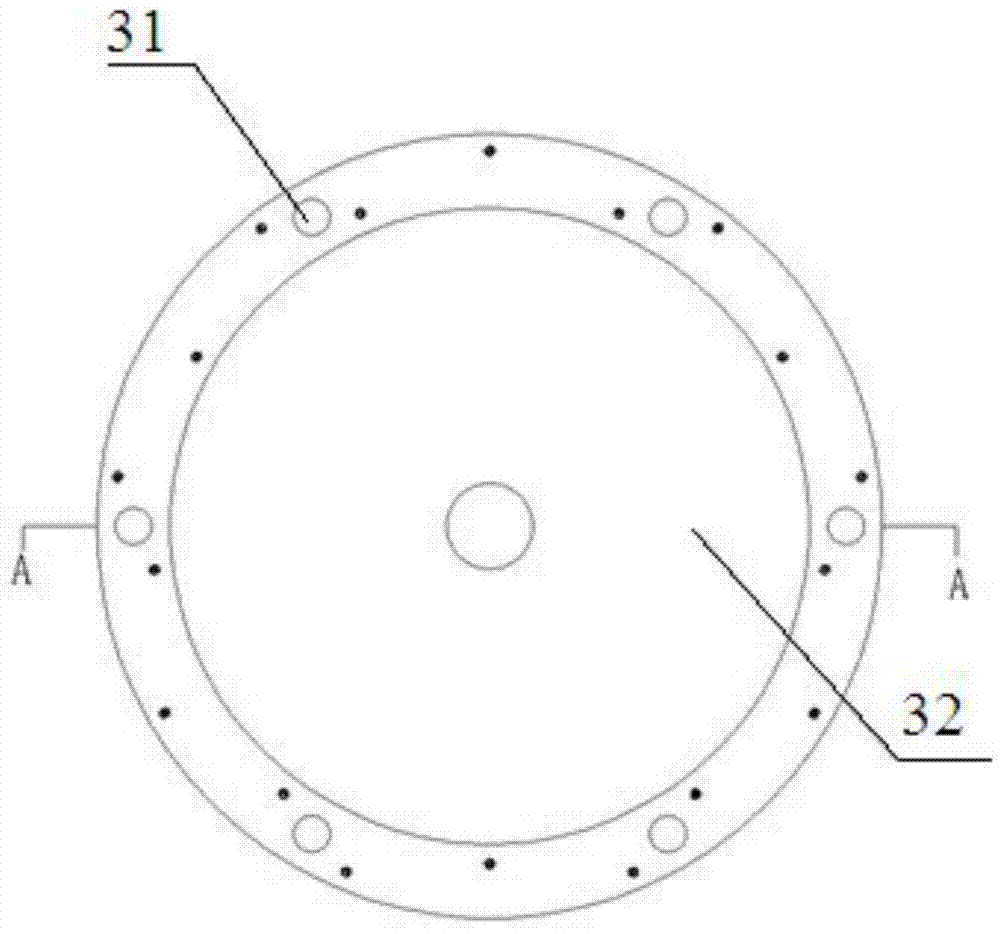

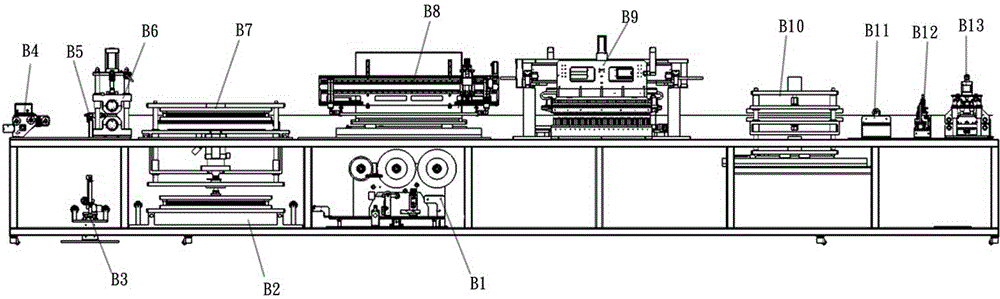

Assembly machine for gas surface membrane component

InactiveCN102814650AExpand the scope of workImprove qualityAssembly machinesDrive motorSurface membrane

An assembly machine for a gas surface membrane component comprises a rack and a turntable indexing drive device, wherein the turntable indexing drive device is fixed on the rack, and comprises a turntable, a drive motor and a divider for converting the continuous rotation of the drive motor into indexing rotation, the drive motor is connected with the divider, and the turntable is fixed on an output flange of the divider; and six groups of adjustable clamps are uniformly distributed on the turntable, and six station working areas are uniformly distributed arranged at the outer part of the turntable indexing drive device, and are sequentially a plastic clamping box assembling station, a membrane assembling station, an aluminum clamping box assembling station, a hot weld station and an unloading station. According to assembly machine for the gas surface membrane component disclosed by the invention, the assembling efficiency can be greatly increased, the employment requirement is lowered, the production cost of an enterprise is reduced, and the production quality of a product is ensured.

Owner:ZHEJIANG UNIV

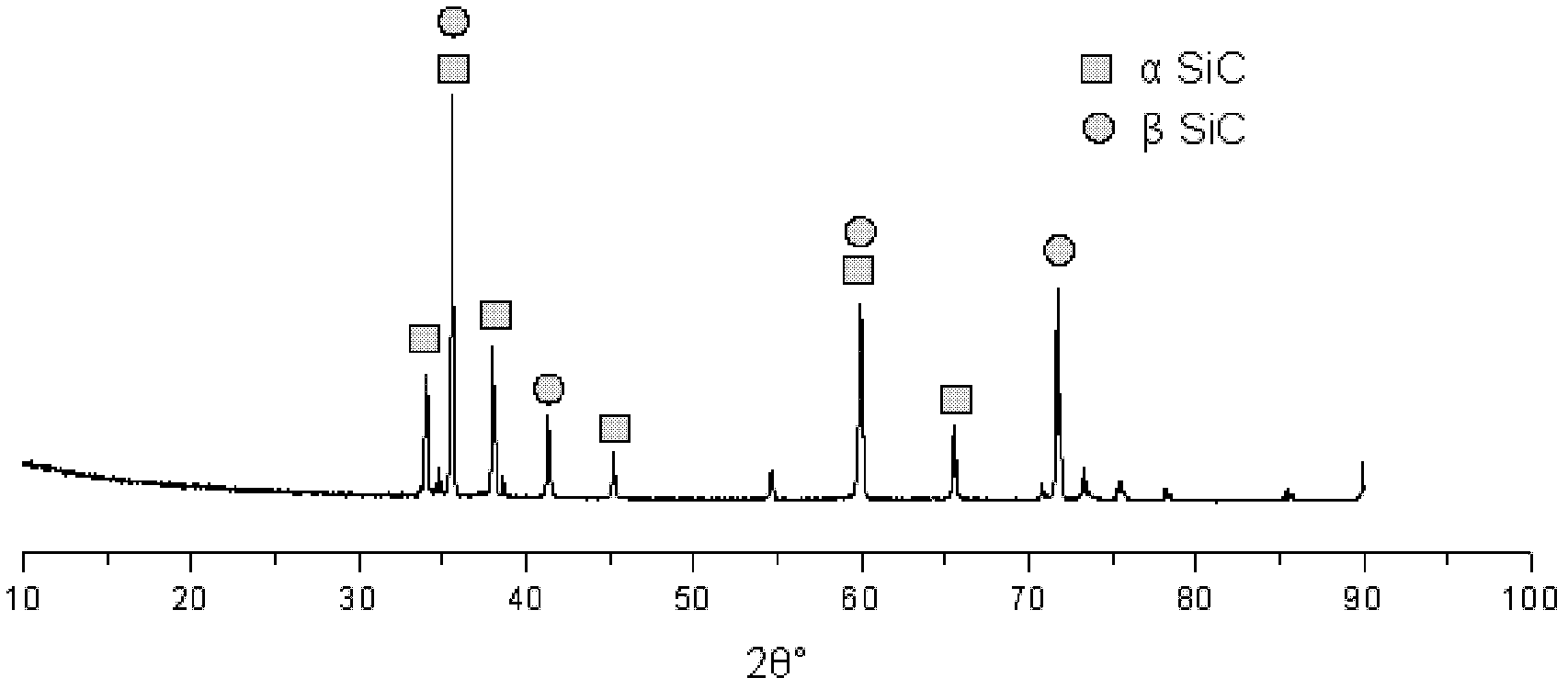

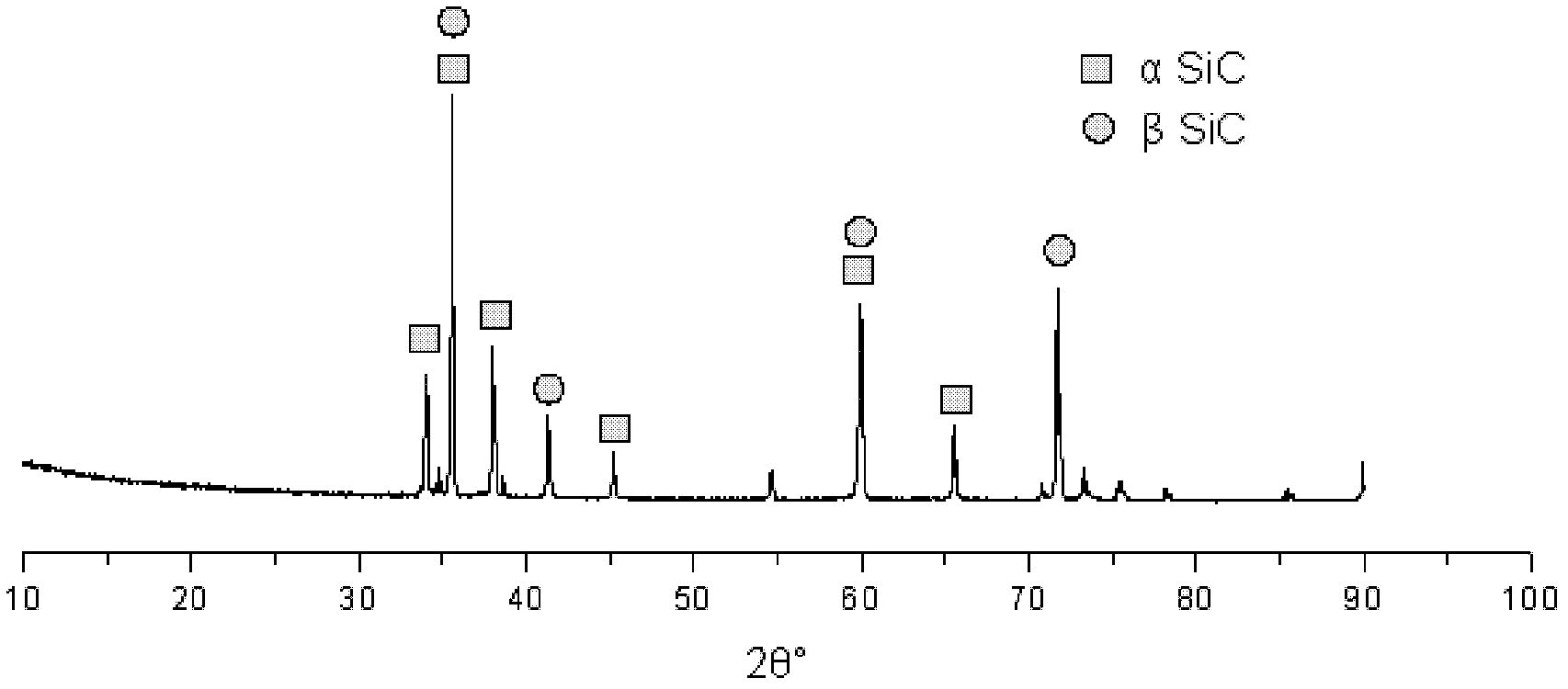

Pure silicon carbide filtering membrane and preparation method thereof

ActiveCN102659447AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareStrong acidsThermal shock

The invention belongs to the technical field of porous ceramic materials and their preparation and especially discloses a pure silicon carbide filtering membrane and a preparation method thereof. The pure silicon carbide filtering membrane has a high porosity, a low pressure drop, high strength, good thermal shock resistance and a high use temperature. The preparation method can be realized easily and can guarantee product performances. The pure silicon carbide filtering membrane comprises pure SiC, is a surface membrane layer obtained by pile-up and binding of fine SiC particles and has aperture sizes of 0.1 to 20 microns and membrane porosity of 25 to 50%. Fine SiC particles, silicon powder, a pore-forming additive and one or more organic resins as raw materials are prepared into a surface membrane layer by spraying or dipping and the surface membrane layer is dried and sintered to form the pure silicon carbide filtering membrane. The pure silicon carbide filtering membrane can be used in an oxidation atmosphere and in a reducing atmosphere, has strong acid corrosion and alkaline corrosion resistance, and can be used for various high / low temperature fluid filtering purification fields such as coal gasification chemical engineering, integrated gasification combined cycle (IGCC) and pressurized fluidized bed combustion (PFBC) coal gasification power generation, and high temperature flue gas, automobile exhaust and water purification.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

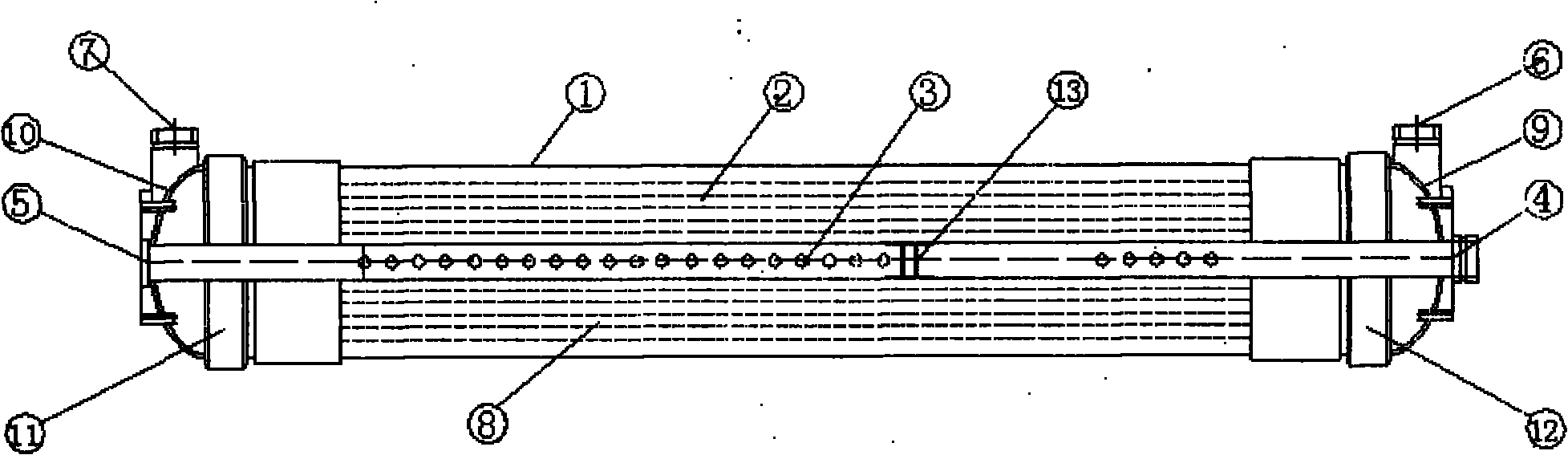

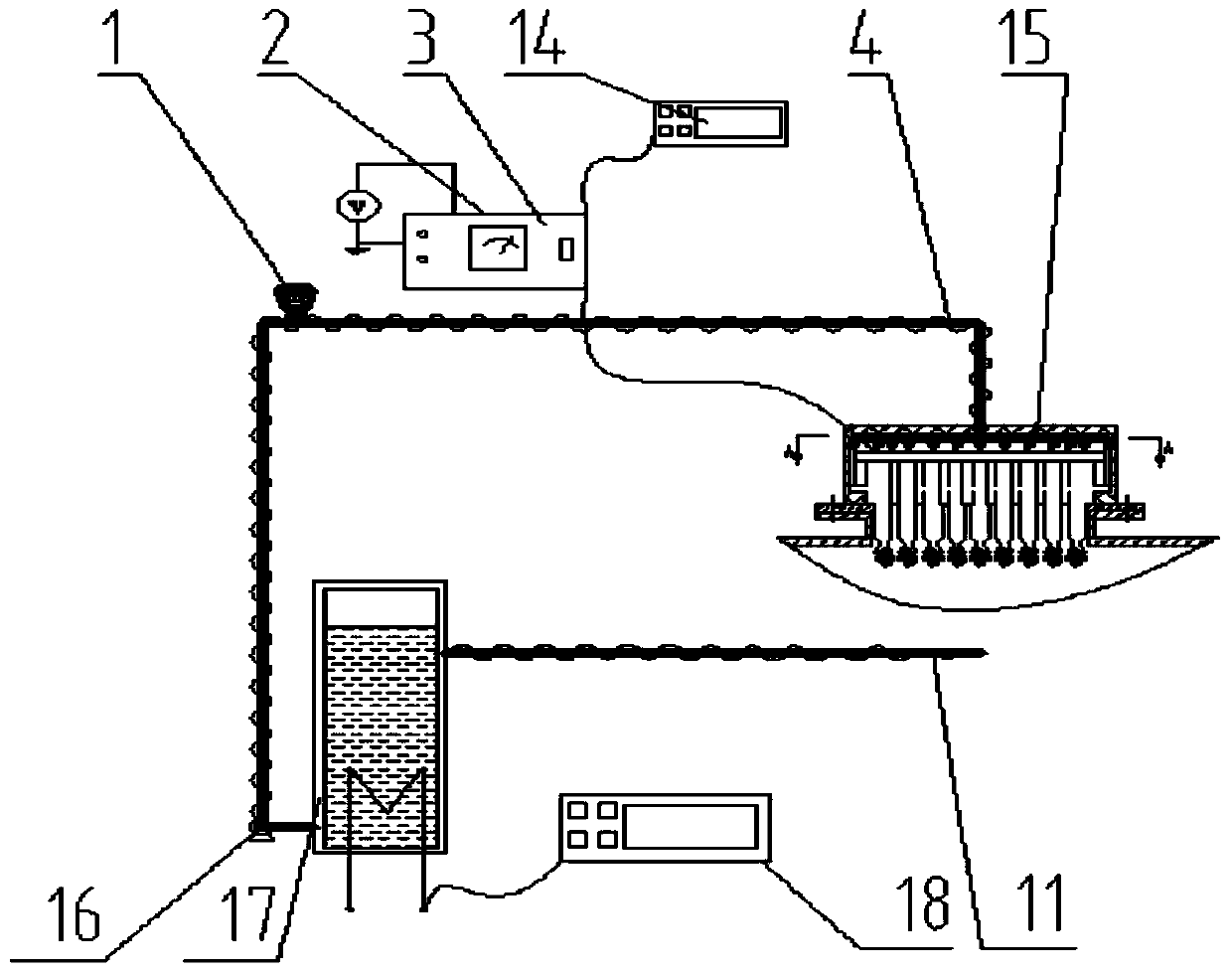

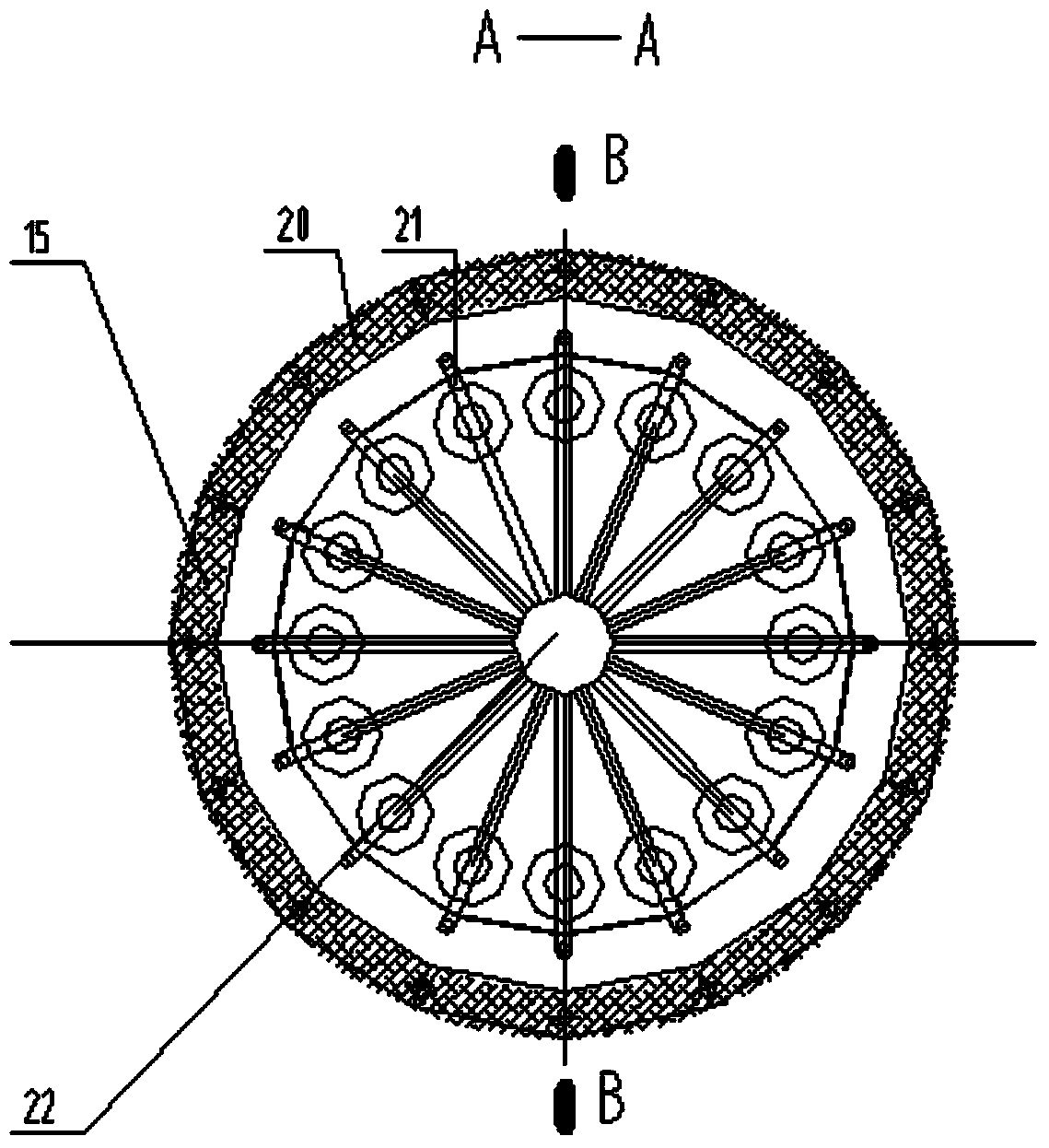

Multi-channel metal palladium or palladium alloy composite membrane hydrogen separator

InactiveCN101642684AHigh separation area/volume ratioEasy to achieve airtight connectionsSemi-permeable membranesHydrogen separationHydrogenGraphite

The invention discloses a multi-channel metal palladium or a palladium alloy composite membrane hydrogen separator. A graphite sealing ring is adopted to connect and seal the multi-channel metal palladium or the palladium alloy composite membrane and a metal joint at any position in a section of an outer surface membrane. In order to better realize sealing connection, any position in a section where the outer surface and one end have a 3-50mm distance on the adopted multi-channel metal palladium or palladium alloy composite membrane is provided with a groove or a gradient exists along the outer surface membrane and is formed at a position having a 10-80mm distance from the end through concaving, so that the multi-channel metal palladium or the palladium alloy and the metal joint can be insealing connection more closely. The metal joint and a separator shell are connected to form the hydrogen separator. When the metal joint and the separator shell are connected to form the hydrogen separator, at least one metal joint at one end of the two ends is connected with a metal pipe capable of buffering the stress of expansion caused by heat and contraction caused by cold so as to release the stress in the heating and cooling processes. The hydrogen separator has the advantages of obviously low device investment and separation cost for medium and small-scale hydrogen separation.

Owner:大连华海制氢设备有限公司

Nanoelectroablation control and vaccination

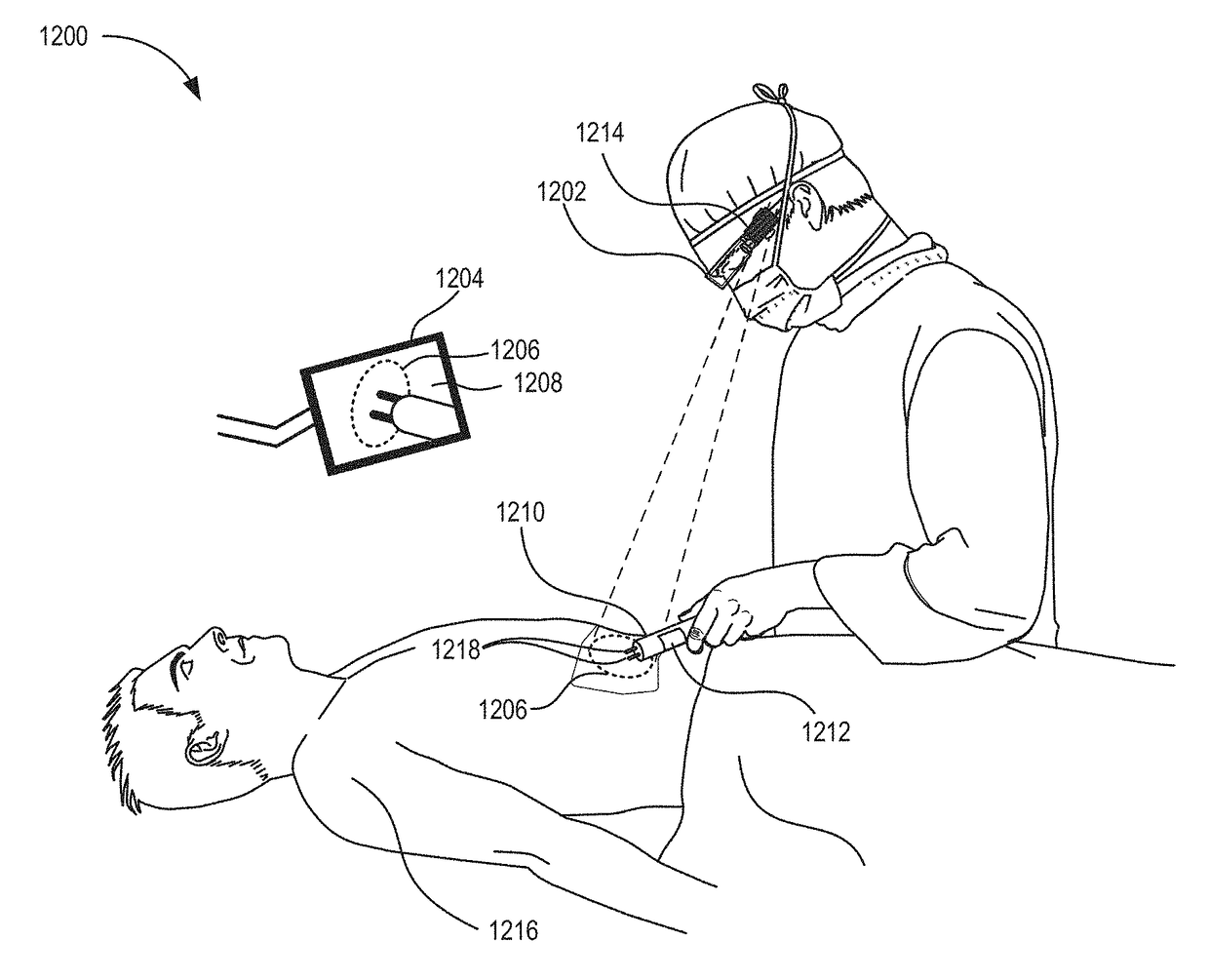

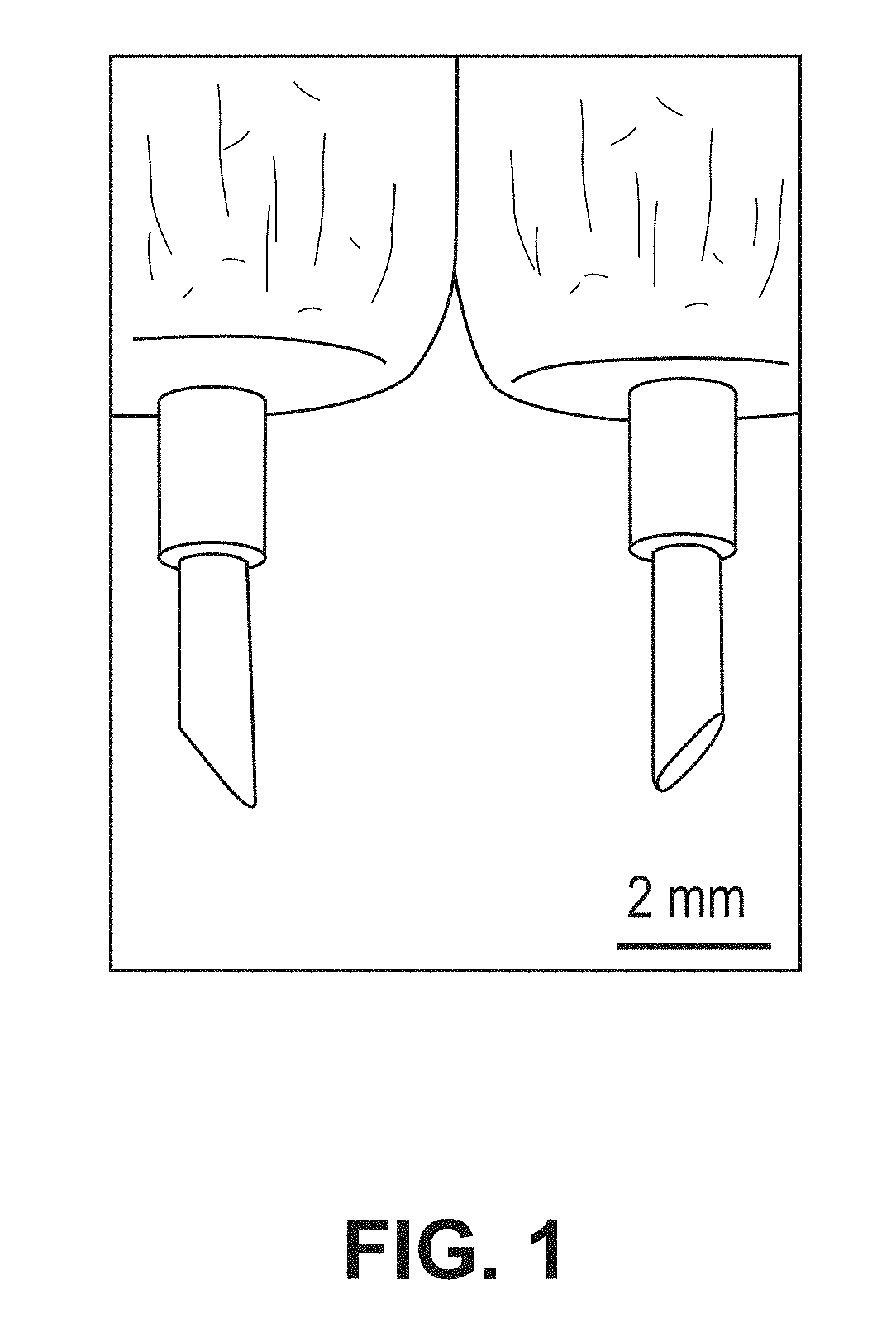

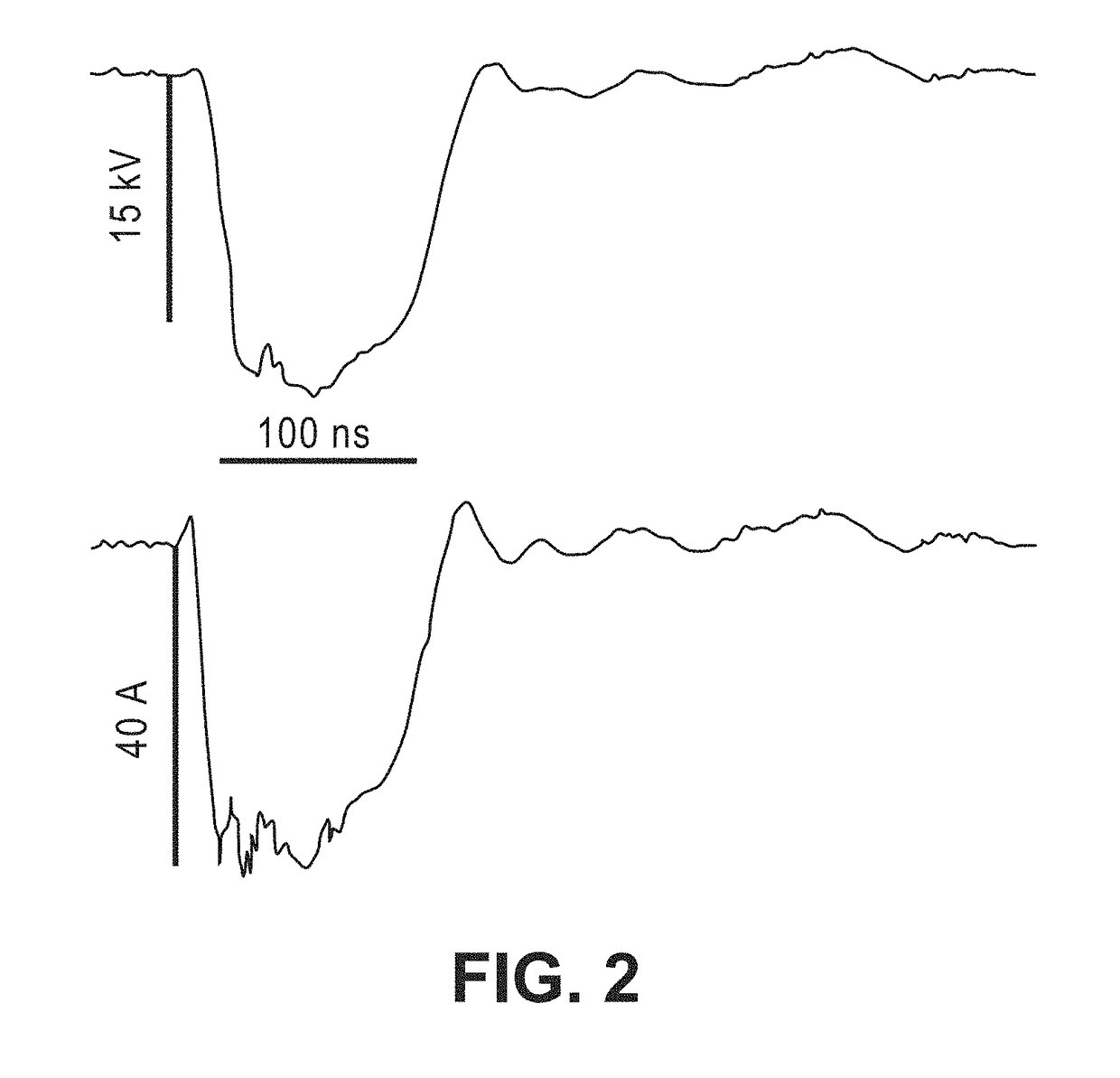

ActiveUS9724155B2Promote phagocytosisFacilitates presentation of antigenElectrotherapySurgical needlesVaccinationCalreticulin

Techniques for treating a tumor and vaccinating against cancer are described. The techniques include treating the tumor by positioning electrodes over an interface between the tumor and non-tumor tissue and applying sub-microsecond pulsed electric fields. The positioning is facilitated by an imaginary contour line of a threshold value of the electric field. In an example, the imaginary contour line is overlaid over images that include the tumor such that the electrodes are properly positioned over the tumor. The techniques also include vaccinating against cancer by passing sub-microsecond pulsed electric fields through tumor cells of a subject sufficient to cause the tumor cells to express calreticulin on surface membranes. The tumor cells are extracted and introduced with the expressed calreticulin into the subject or another subject, thereby providing a vaccination.

Owner:PULSE BIOSCI INC

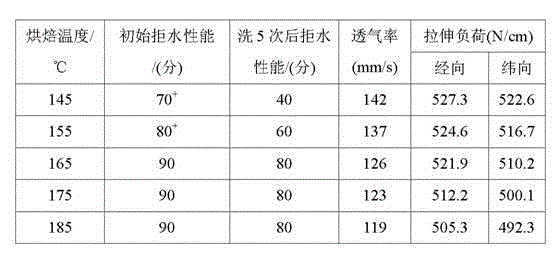

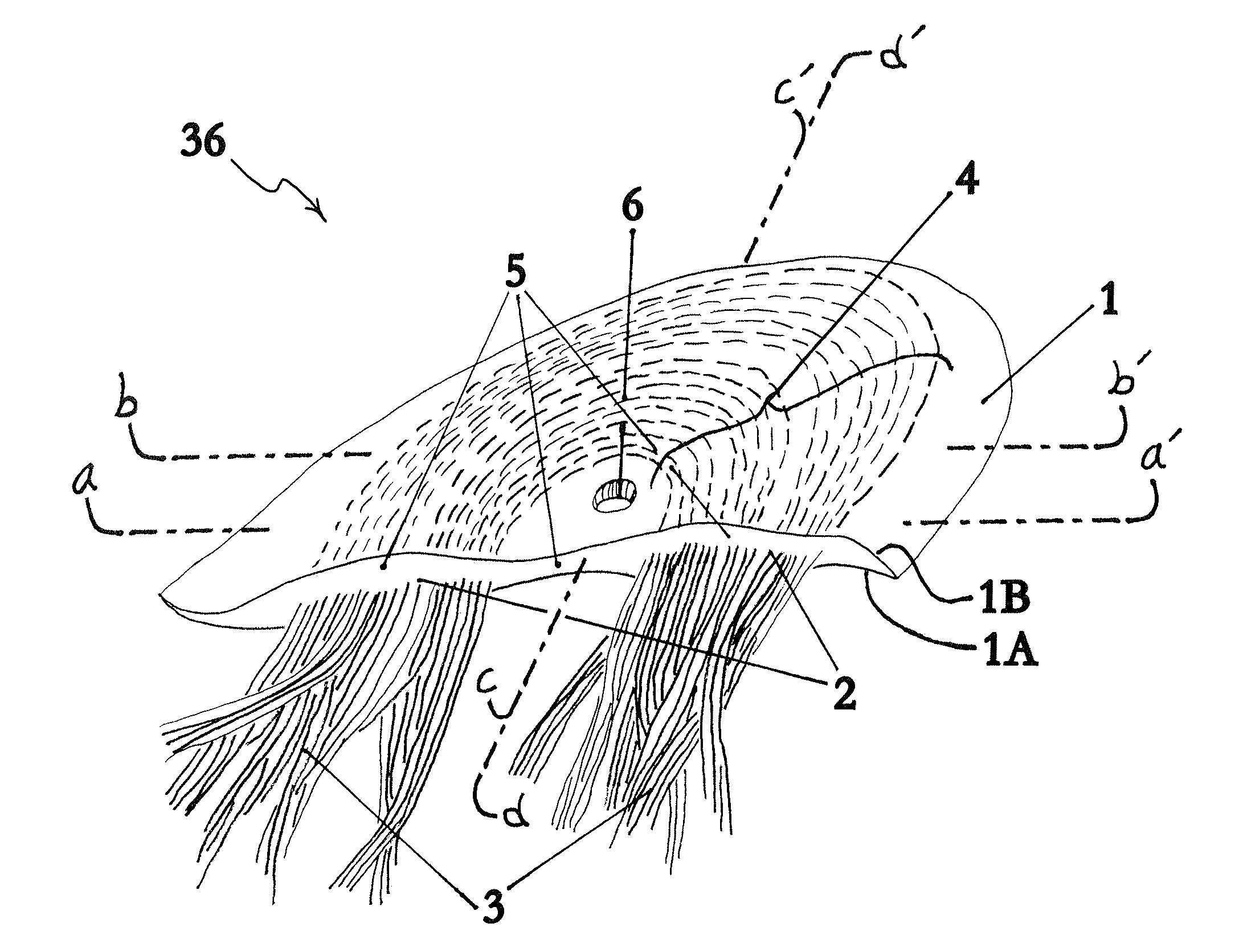

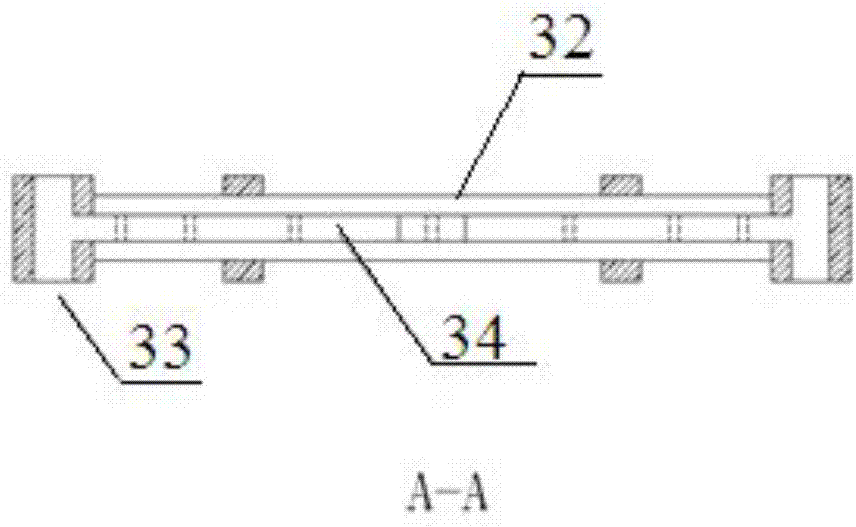

Matte flame-retardant cold-resistant covering cloth

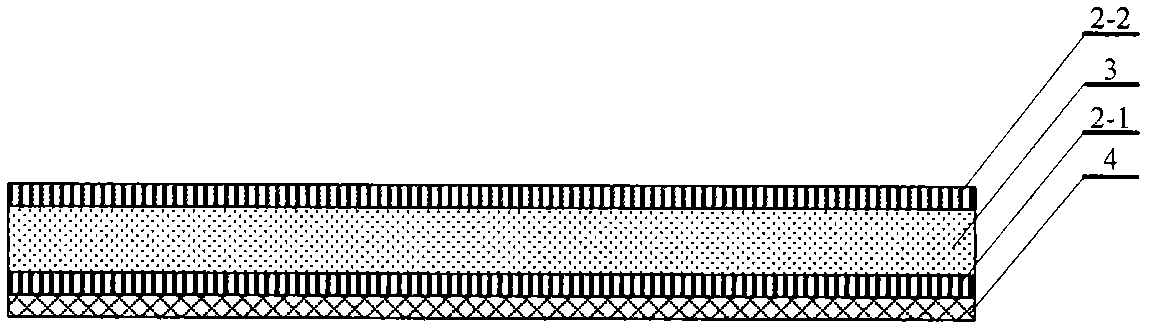

ActiveCN104401084AImprove flame retardant performanceGood mechanical propertiesFibre typesSynthetic resin layered productsEngineeringFire retardant

The invention relates to matte flame-retardant cold-resistant covering cloth. The covering cloth is prepared by performing gumming dipping and drying on base cloth, employing a PVC surface membrane and a PVC bottom membrane to bond with two faces of the base cloth, performing cooling fixing, then employing a fluorosilicone finishing agent to perform surface function processing, and then performing drying and reeling. A double-face bonding production technology of plain base cloth and the PVC surface membrane and the PVC bottom membrane is employed, also a flame retardant and a cold-resisting agent are added into the formula of the PVC membrane, so that the flame retardation performance and the cold resistant performance of the product are improved. The covering cloth possess good flame retardation performance, mechanical properties, cold resistance and the like, and also is greatly improved in applicability and added value by coating the covering cloth surface with a layer of the fluorosilicone finishing agent.

Owner:ZHEJIANG BOTAI PLASTIC

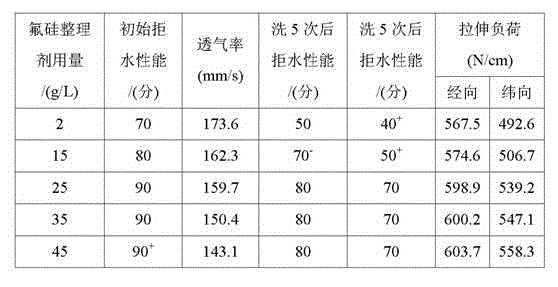

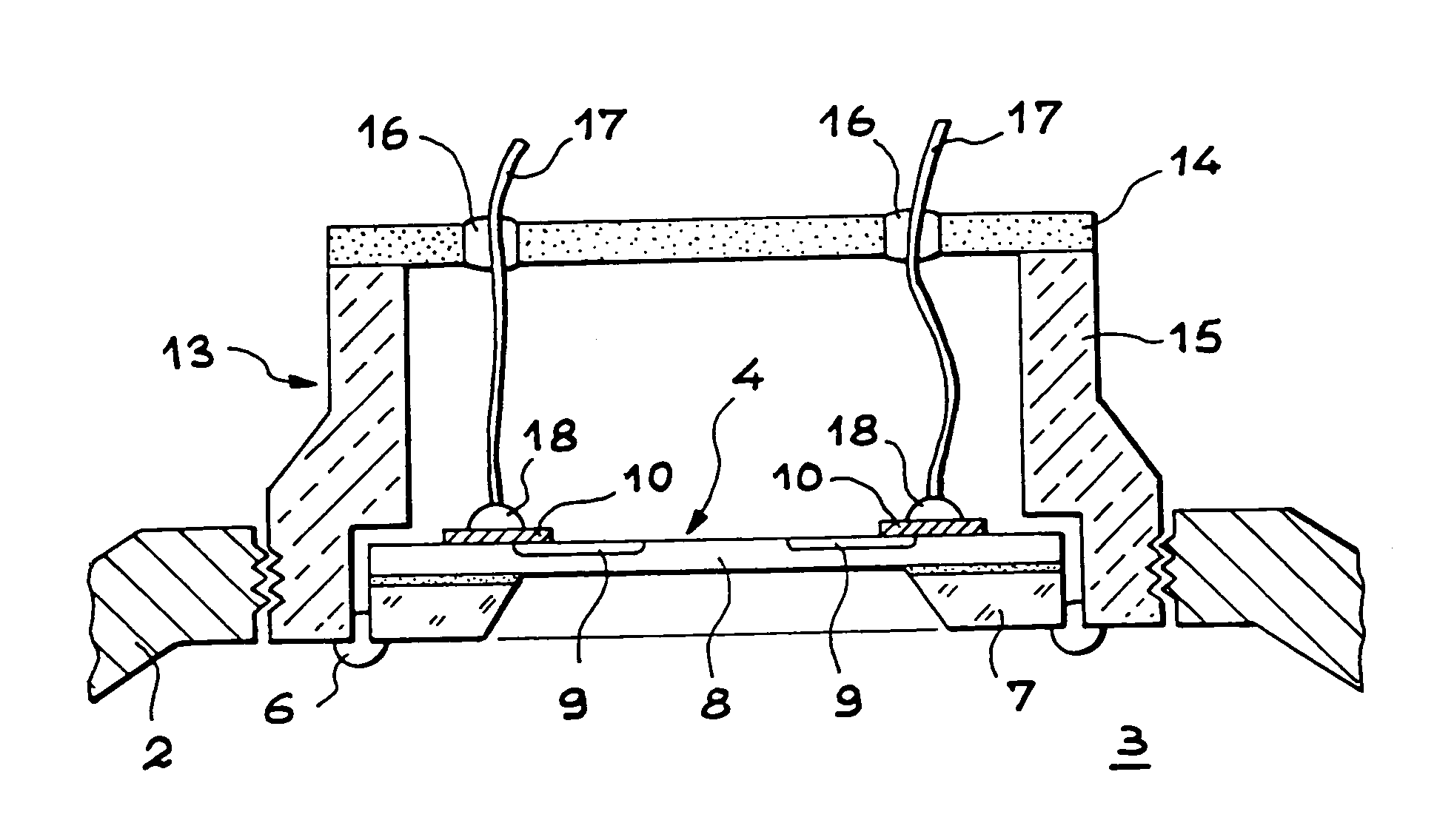

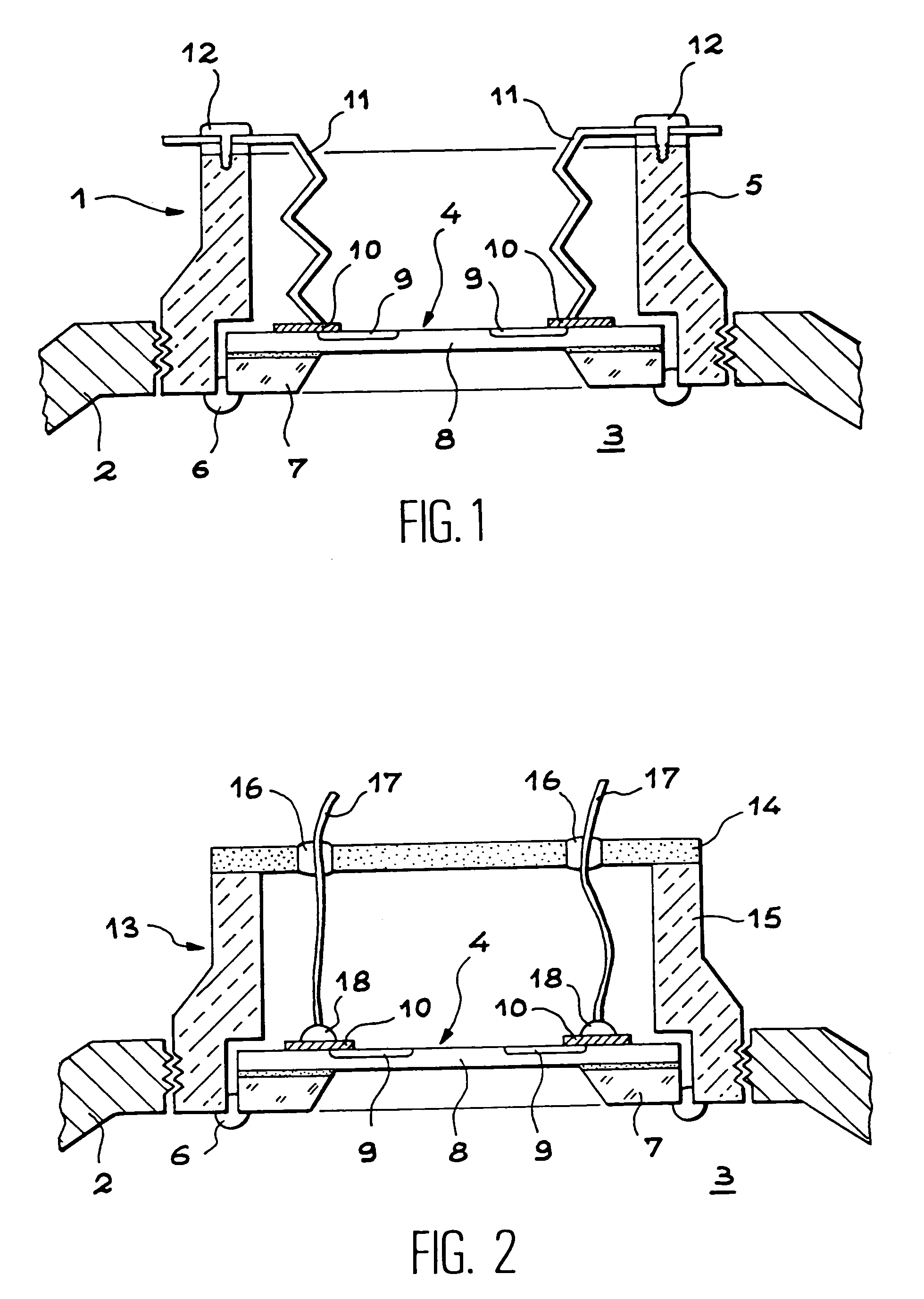

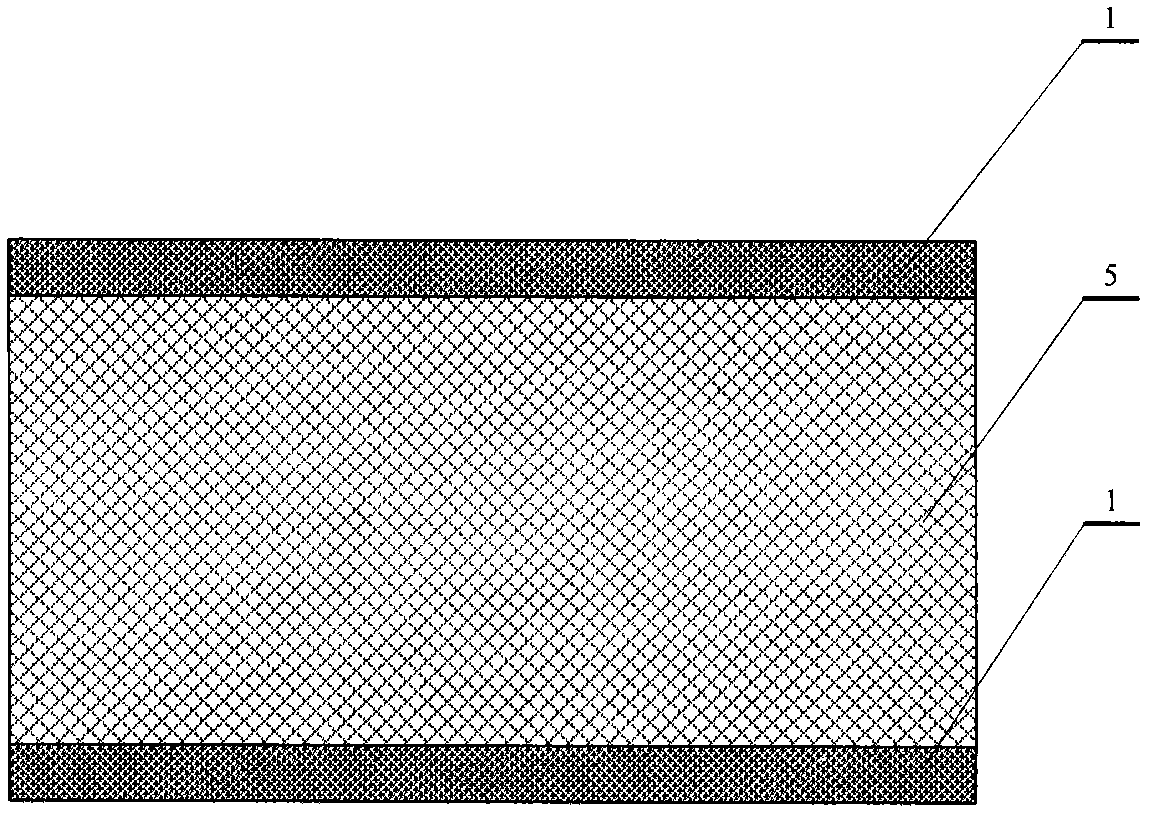

Prosthetic anchor and method of making same

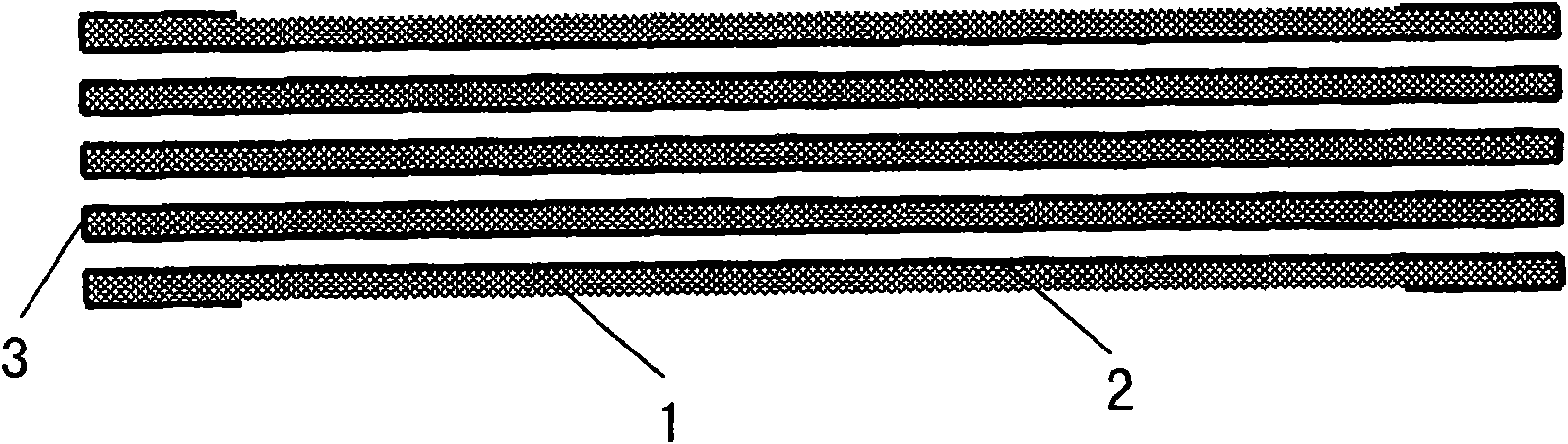

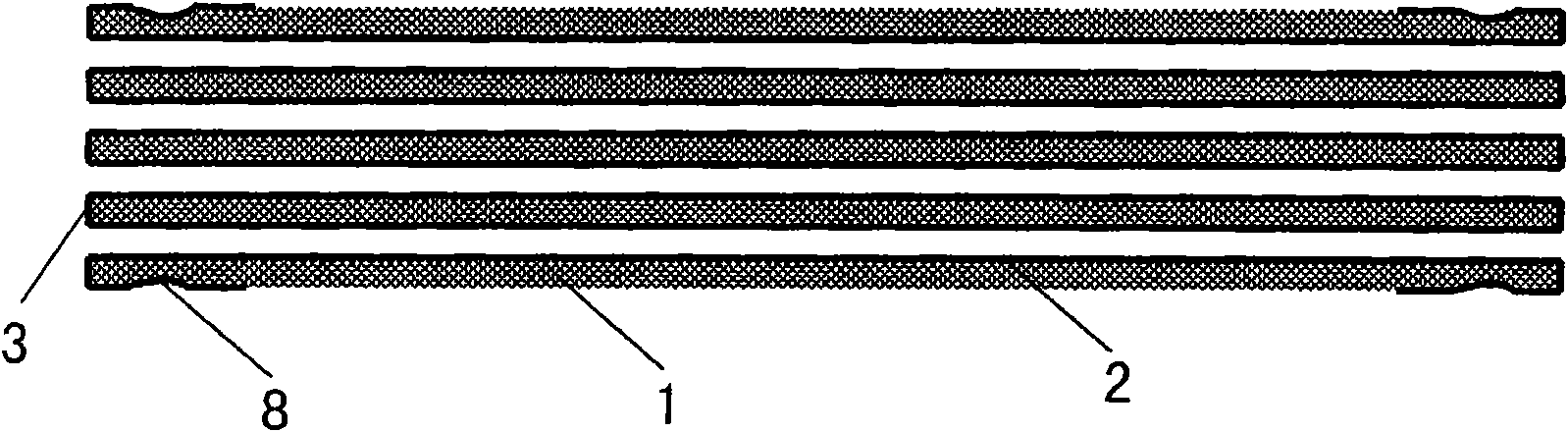

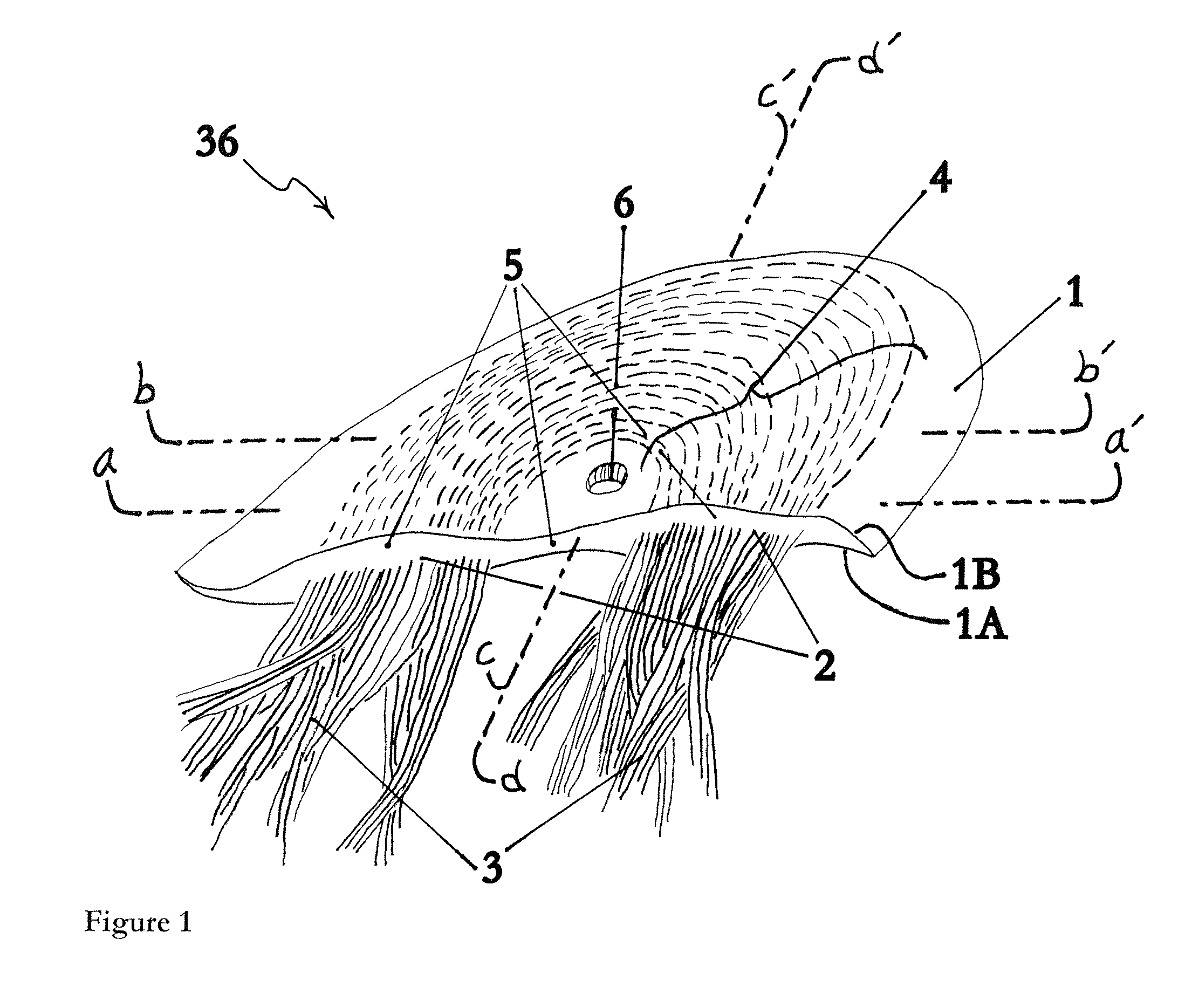

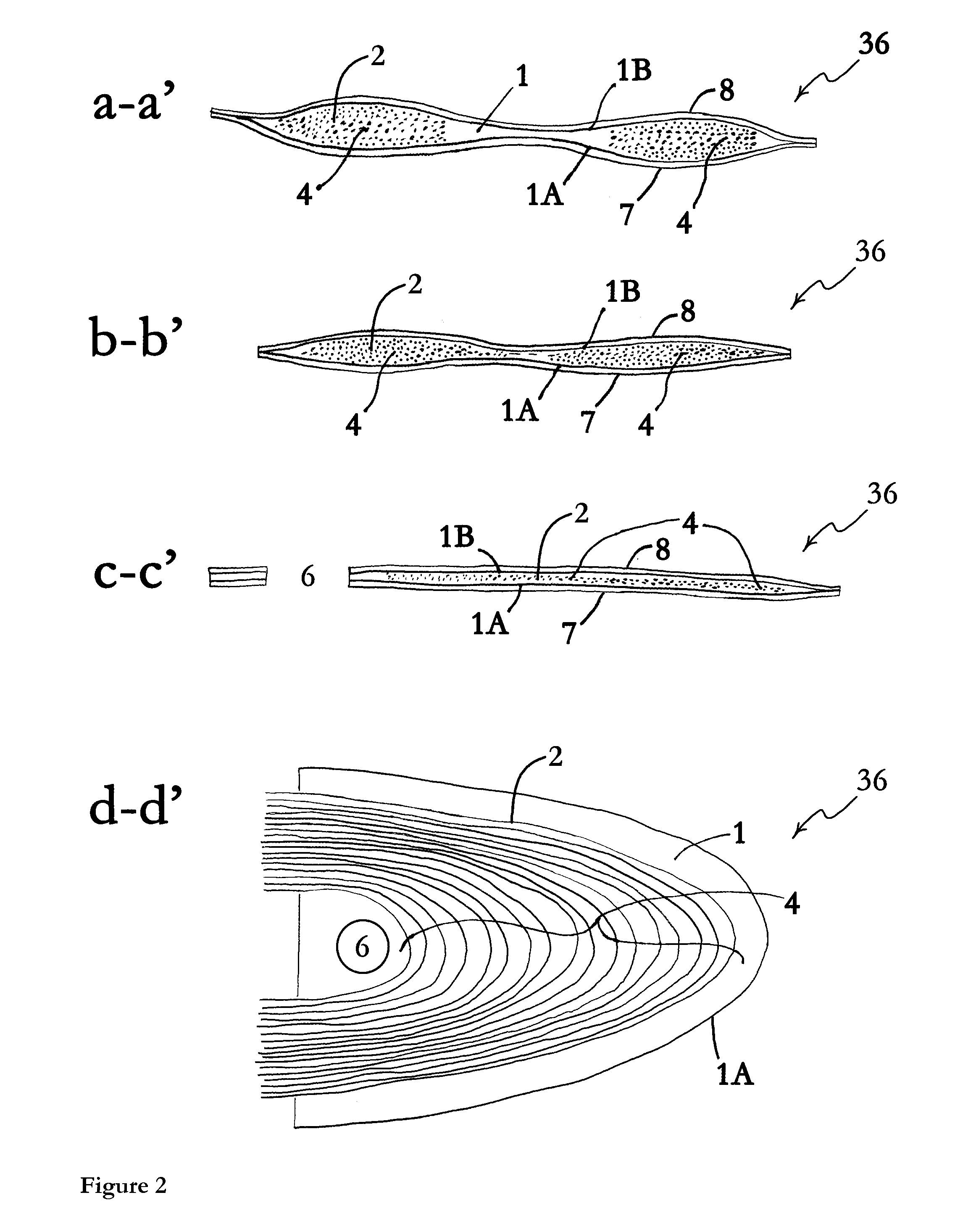

The present invention is directed towards a prosthetic anchor (36) including a central layer (1) through which embedded fibers (2), such as artificial tendons, pass in defined pathways (4), a ‘deep’ surface membrane (7) which interfaces with a hard structure, whether that is a prosthesis, a bone, or other hard tissue, and a ‘superficial’ surface membrane (8) which interfaces adjacent tissue and may be configured to adhere or not to adhere to that tissue. The central layer (1) is positioned intermediate the surface membranes (7, 8) which are mechanically and / or adherently attached thereto. Also, non-limiting examples of methods of fabrication and of affixing the anchor (36) to a relatively rigid structure, natural or prosthetic, in a human or animal body with improved stress distribution in the fixed tension member end are taught.

Owner:UNIVERSITY OF CINCINNATI

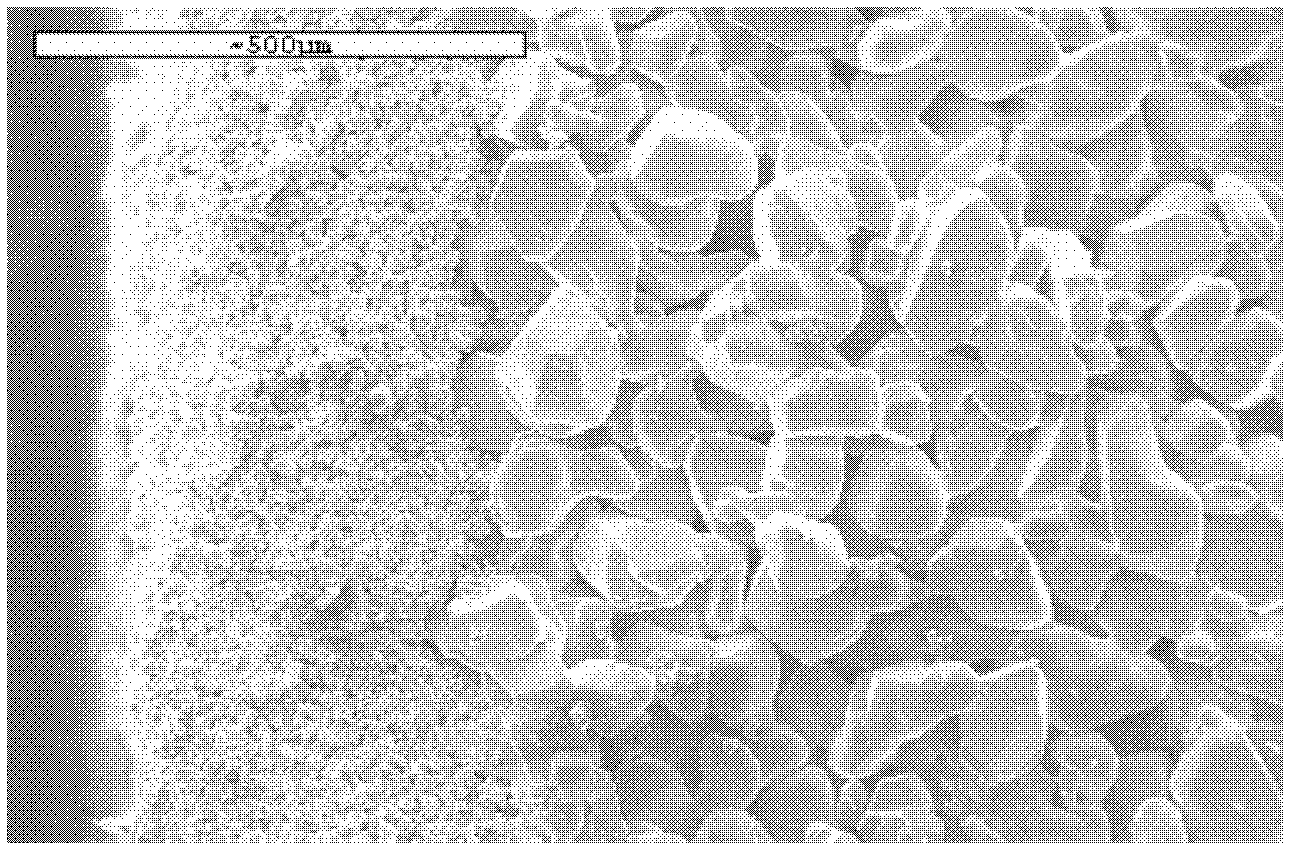

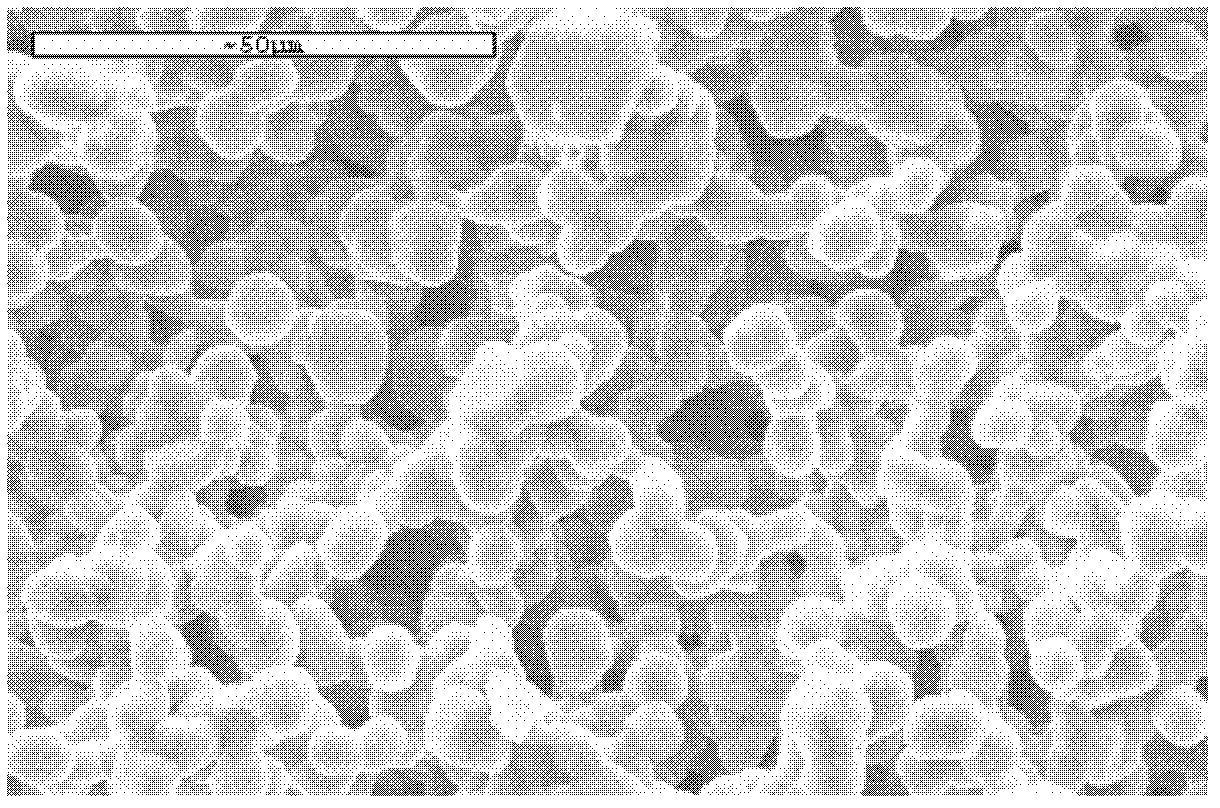

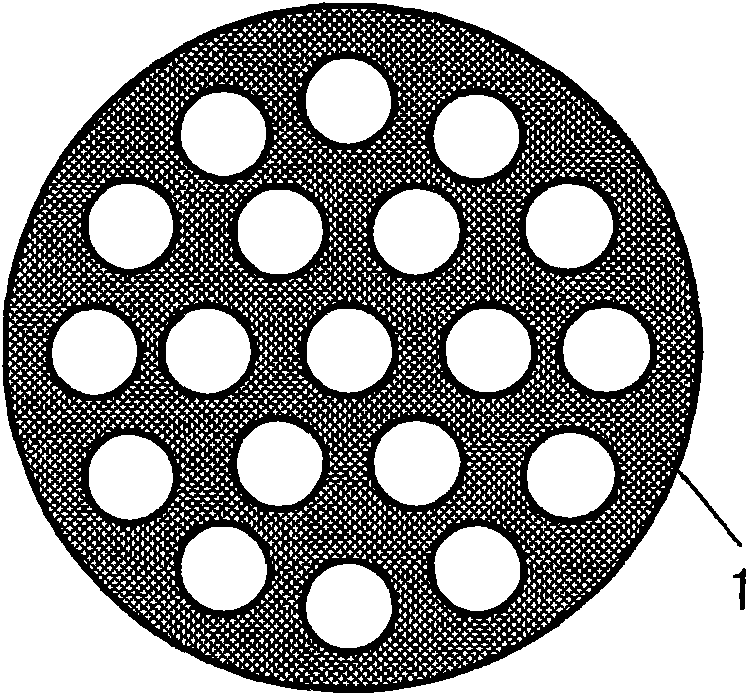

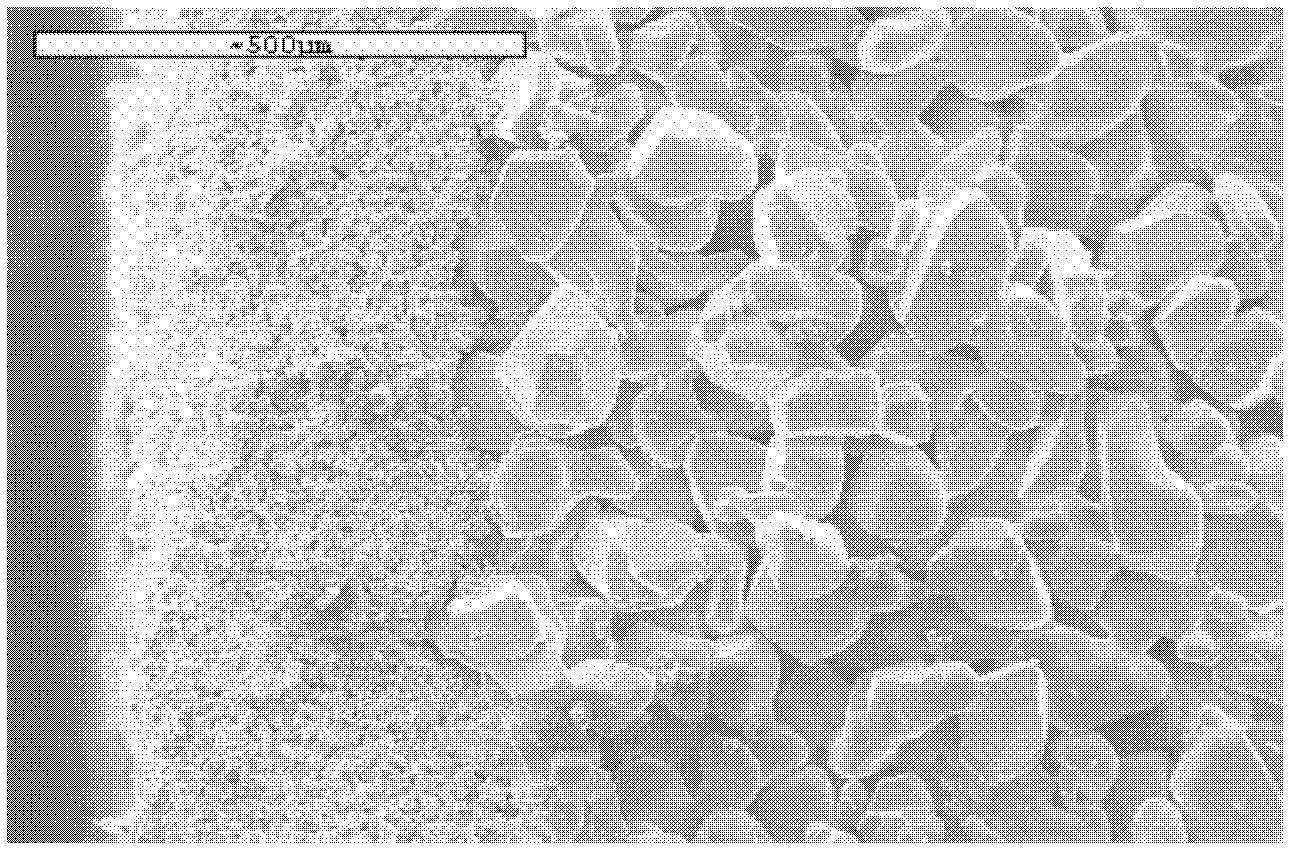

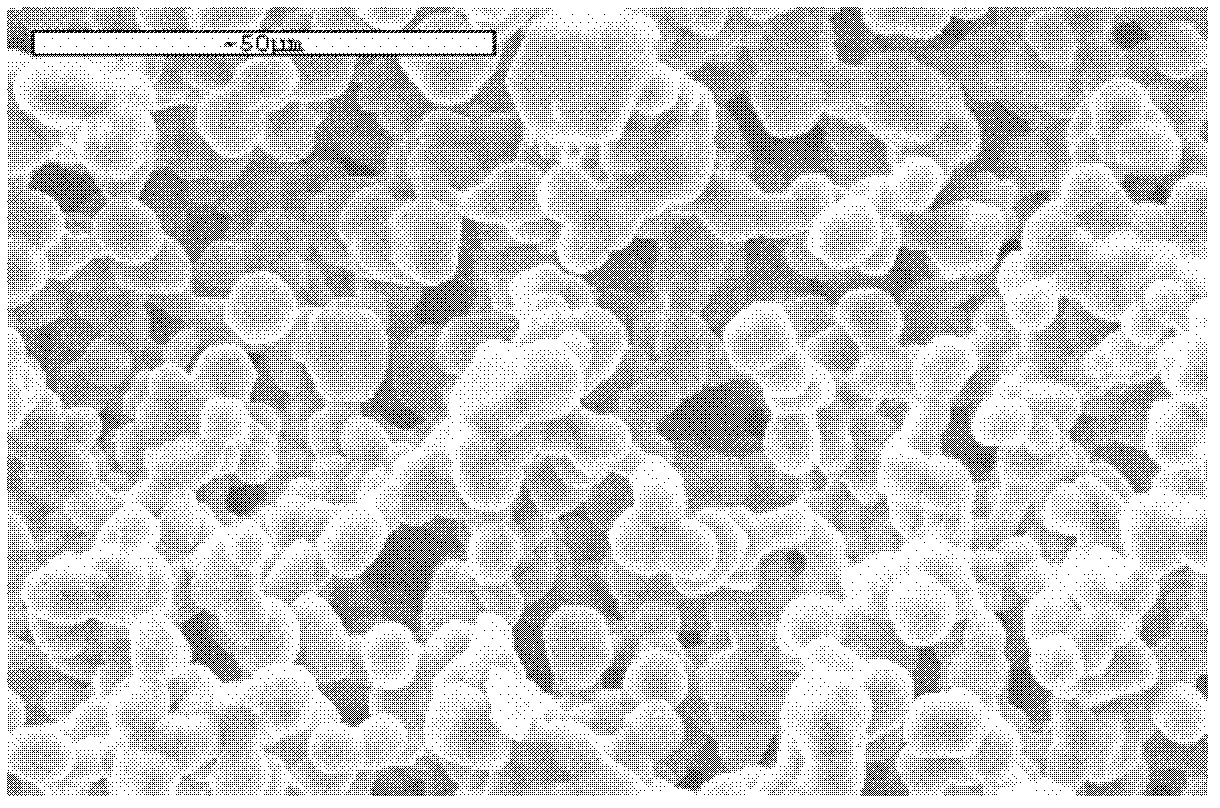

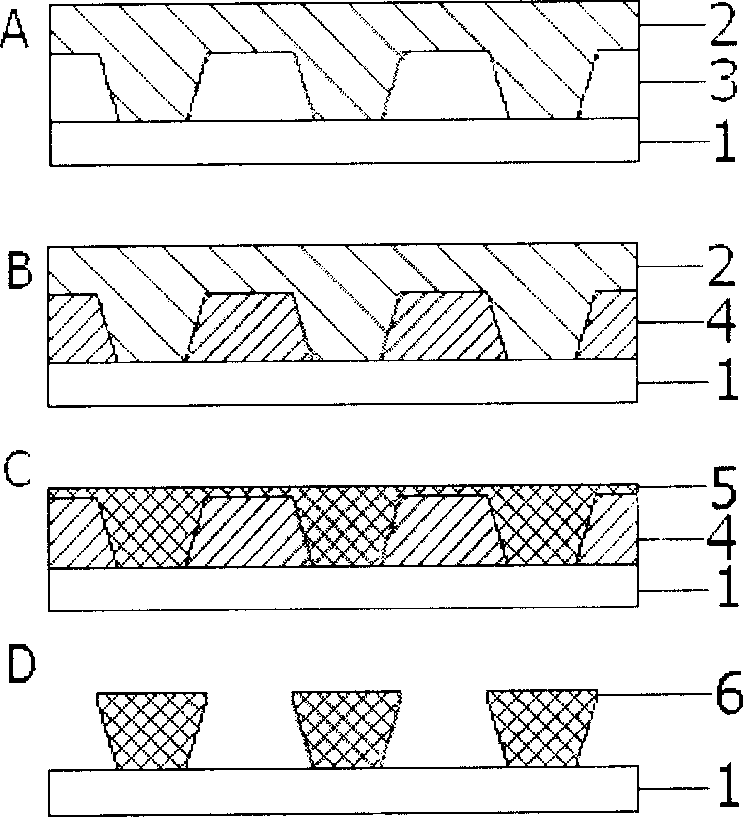

Gradient-porosity pure silicon carbide membrane tube and preparation method thereof

ActiveCN102633531AGuaranteed corrosion resistanceExtended service lifeSemi-permeable membranesCeramicwareCorrosionSurface membrane

The invention belongs to the technical field of multipore ceramic materials and preparation thereof, and particularly relates to a gradient-porosity pure silicon carbide membrane tube and a preparation method thereof. The gradient-porosity pure silicon carbide membrane tube consists of pure SiC; a gradient filter structure consists of a supporting body layer and a surface membrane layer, wherein the supporting body is formed by stacking and combining roughly granular SiC, and the average aperture is 5-120 mu m; the surface membrane layer is formed by stacking and combining finely granular SiC, and the aperture is 0.1-20 mu m; and the whole porosity of the membrane tube is 25-50%. The preparation method comprises burdening, forming the supporting body, preparing the membrane layer and sintering, wherein forming is performed under equal static pressure; the forming pressure is controlled between 40 and 150MPa; the sintering temperature is controlled between 1,500 and 2,400 DEG C; and heat is preserved for 0.5-5 hours. The method is easy to implement, and the performance of a product can be guaranteed. The gradient-porosity pure silicon carbide membrane tube can be used under an oxidization atmosphere and a reduction atmosphere, is high in acid and alkaline corrosion resistance and can be applied to gas chemical engineering and integrated gasification combined cycle (IGCC) and pressurized fluidized bed combustion (PFBC) power generation and used for filtering and purifying various types of high- and low- temperature fluid, such as high-temperature flue, automobile tail gas, water and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

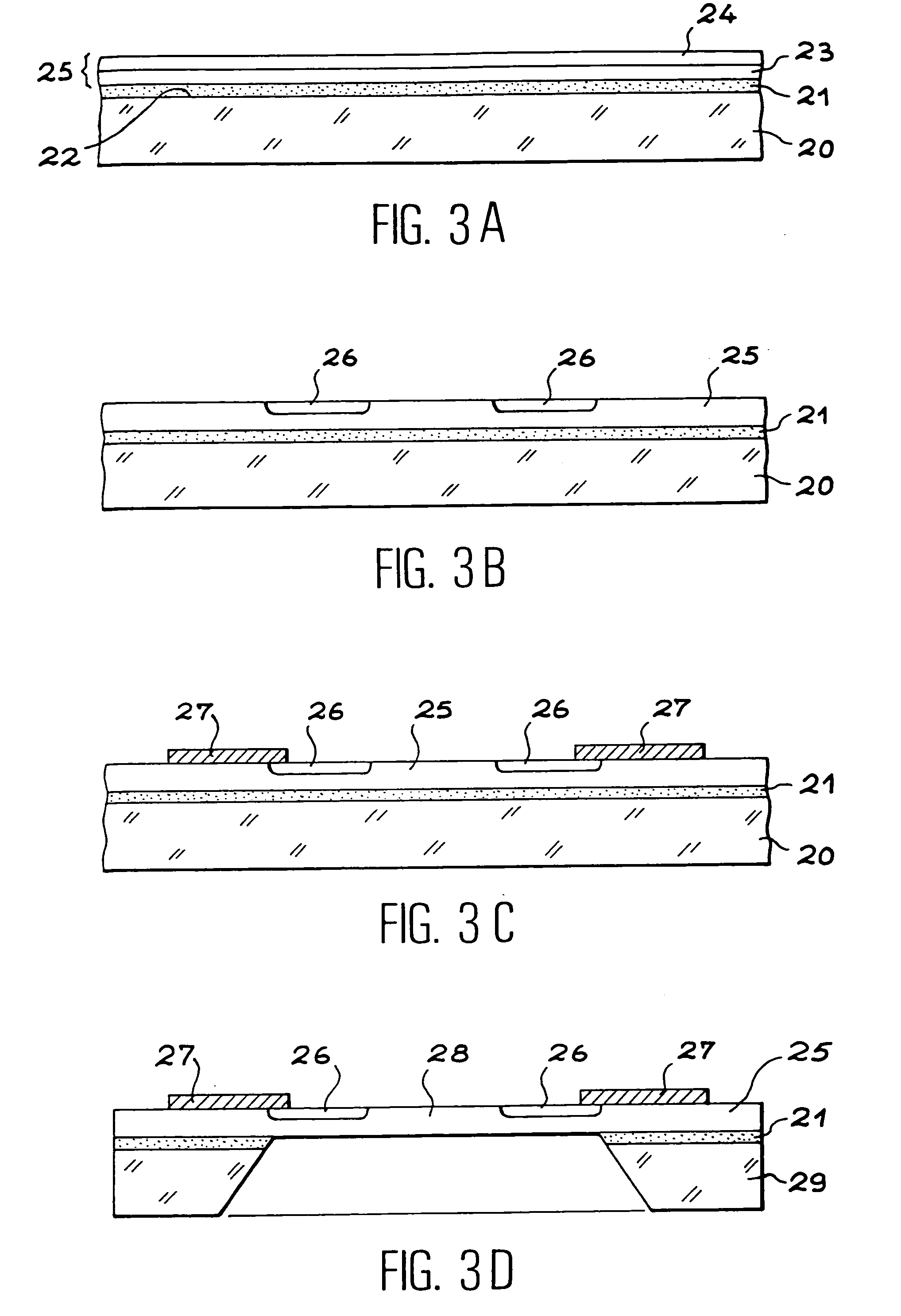

Membrane pressure sensor containing silicon carbide and method of manufacture

InactiveUS20040079163A1Line/current collector detailsElectrical transducersPolycrystalline silicon carbideMembrane deformation

The invention concerns a pressure sensor (1), able to operate at high temperature and measure the pressure of a hostile medium, comprising: a sensing element (4) integrating a membrane (8) in monocrystalline silicon carbide, made by micro-machining a substrate in polycrystalline silicon carbide, a first surface of membrane (8) intended to contact said medium, a second surface of membrane (8) comprising membrane deformation detection means (9) connected to electric contacts (10) to connect electric connection means (11), the surfaces of sensing element (4) contacting said medium being chemically inert to this medium; a carrier (5) to support sensing element (4) so that said first surface of membrane (8) may be contacted with said medium and the second surface of membrane (8) may be shielded from said medium, carrier (5) being in polycrystalline silicon carbide; a seal strip (6), in material containing silicon carbide, brazed between carrier (5) and sensing element (4) to protect the second surface of membrane (8) from any contact with said medium.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for preparing micropore ceramic separation film

InactiveCN101322919AUniform structureAperture controllableSemi-permeable membranesFiltration separationCross-linkMicroscopic observation

The invention relates to a preparation method for a millipore ceramic separation membrane which belongs to the technical fields of ceramics material preparing and processing. After ceramic powder with a grain diameter of 5 to 15Mu m is mixed with a dispersant, the mixture of organic monomer acrylamide and a cross-linking agent N,N'-methylene diacrylamide is added to manufacture suspended nitride with a solid volume fraction of 45 to 55 percent which is sintered into a porous ceramic supporter after drying and demoulding; then ceramic powder with a grain diameter of 2 to 6Mu m is manufactured into surface membrane suspended nitride with a solid volume fraction of 10 to 25 percent according to the method; the supporter is dipped into the surface membrane suspended nitride and is uniformly extracted to obtain the millipore ceramic separation membrane after being dried and sintered. Through microscopic observation, the supporter is firmly combined with the surface membrane; pores are uniformly distributed; the surface membrane is uniform without defects. The preparation method overcomes the problem that the normal ceramic separation membrane material is easy to form macropores and has asymmetric organizational structures, thus causing the surface membrane to be easy to have the defects of pinholes and cracks.

Owner:SUZHOU UNIV

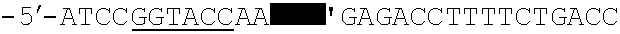

Methods for screening antibody-producing cells on heterogeneous antigen substrates

InactiveUS20060073095A1Reduce complexityShorten the timeAnimal cellsIn-vivo radioactive preparationsEpitopeMonoclonal antibody

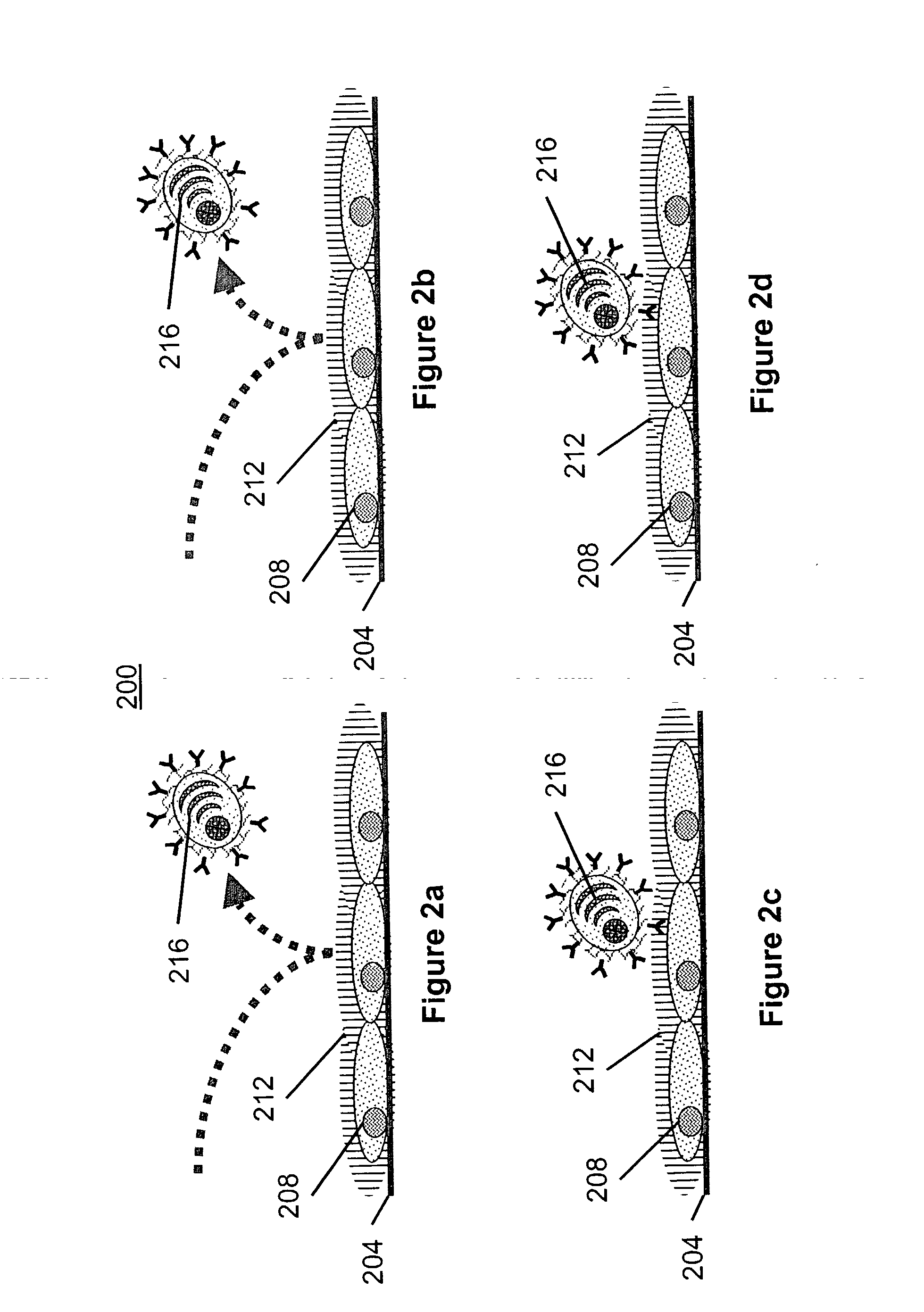

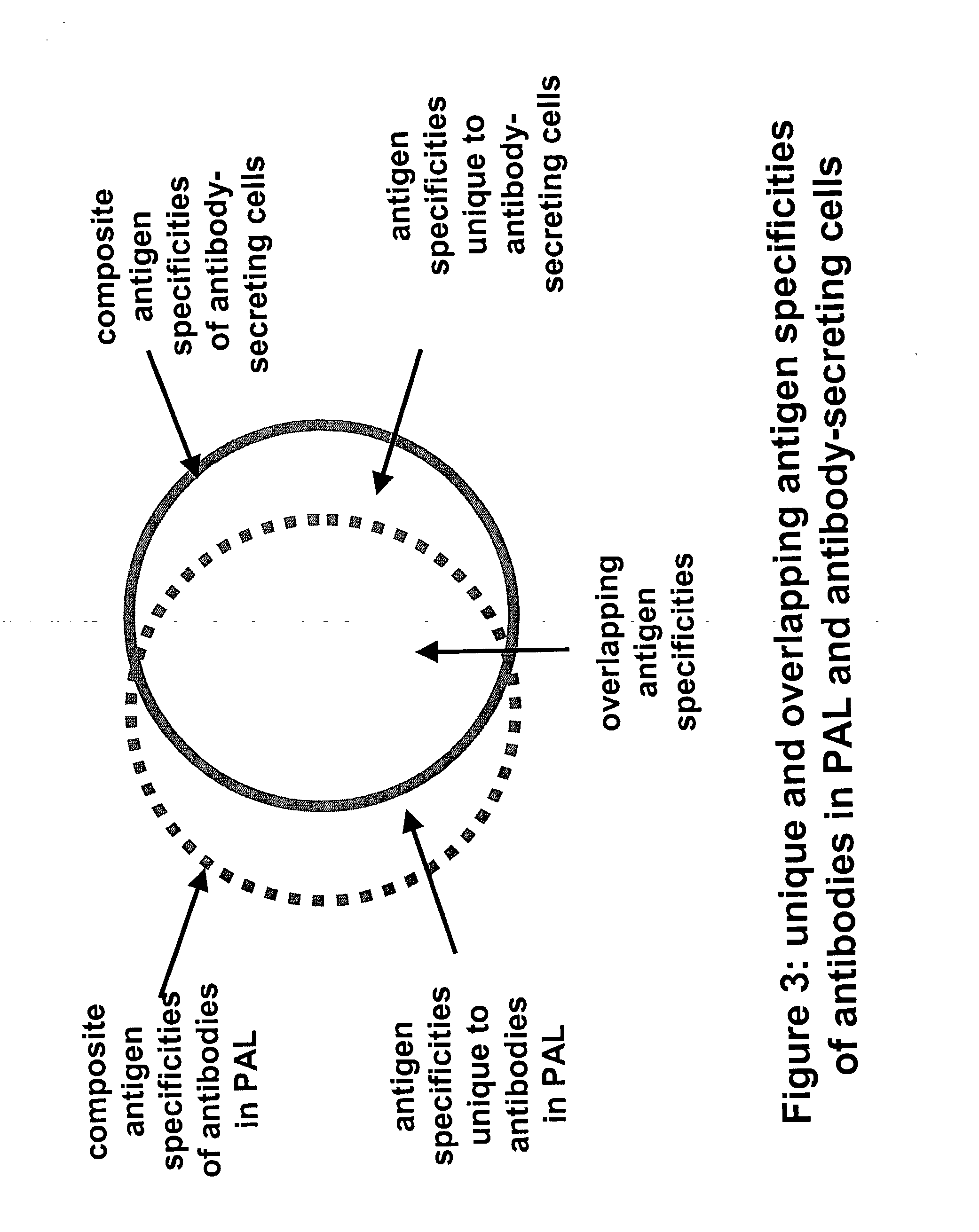

Methods and compounds are disclosed that relate to screening and selection of monoclonal antibodies specific for antigens in heterogeneous antigen mixtures. Antibody-secreting cells such as hybridomas are modified to make them capable of directly binding antigens by capturing their secreted antibody products onto their surface membranes in appropriate binding density and orientation. Selectivity of binding to novel or desired antigens is achieved by first reacting the antigen mixtures affixed to a solid substrate with a polyclonal antibody library that prevents access to the majority of antigens or epitopes other than those that are novel or desired.

Owner:KESSLER STEVEN

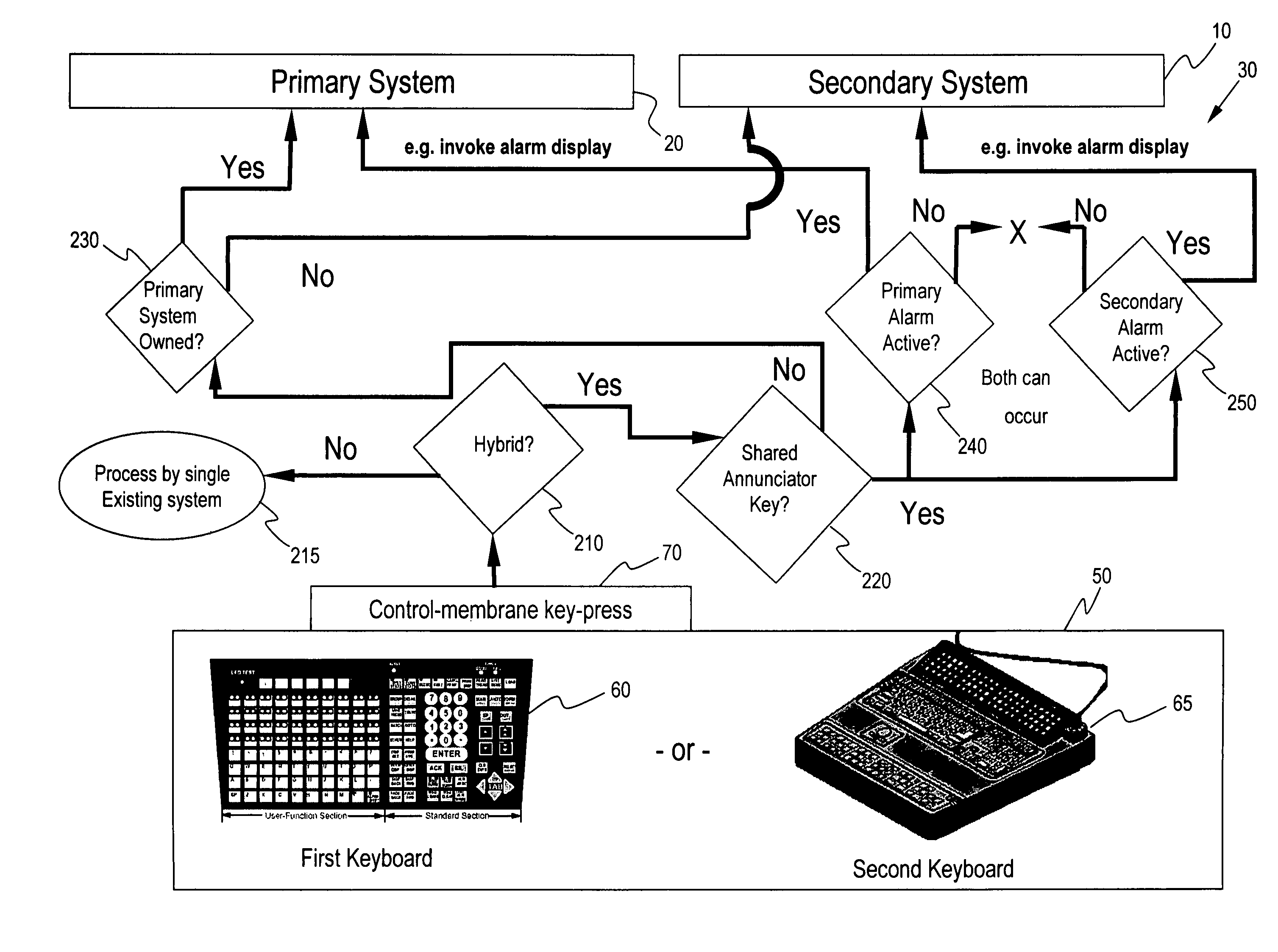

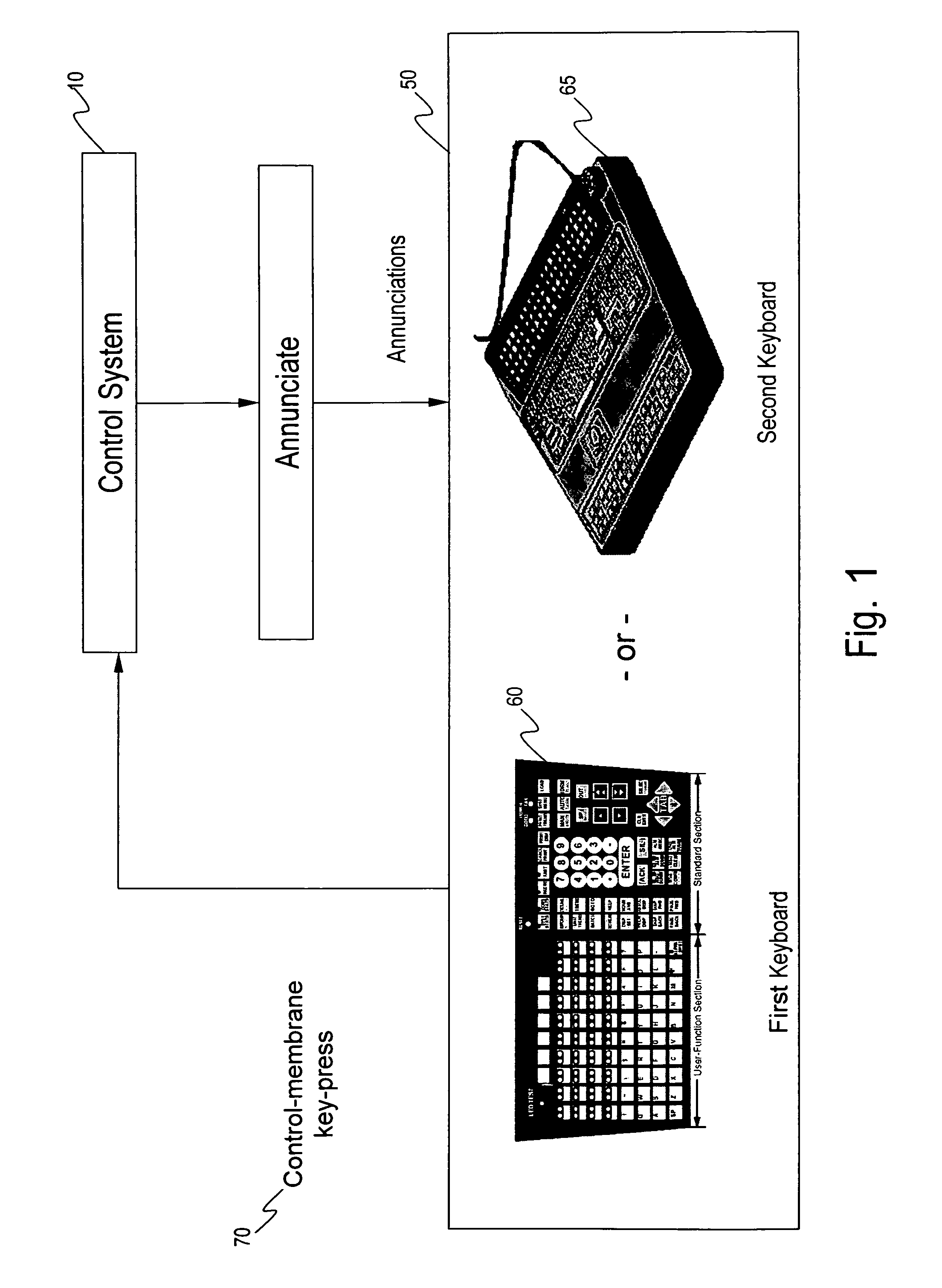

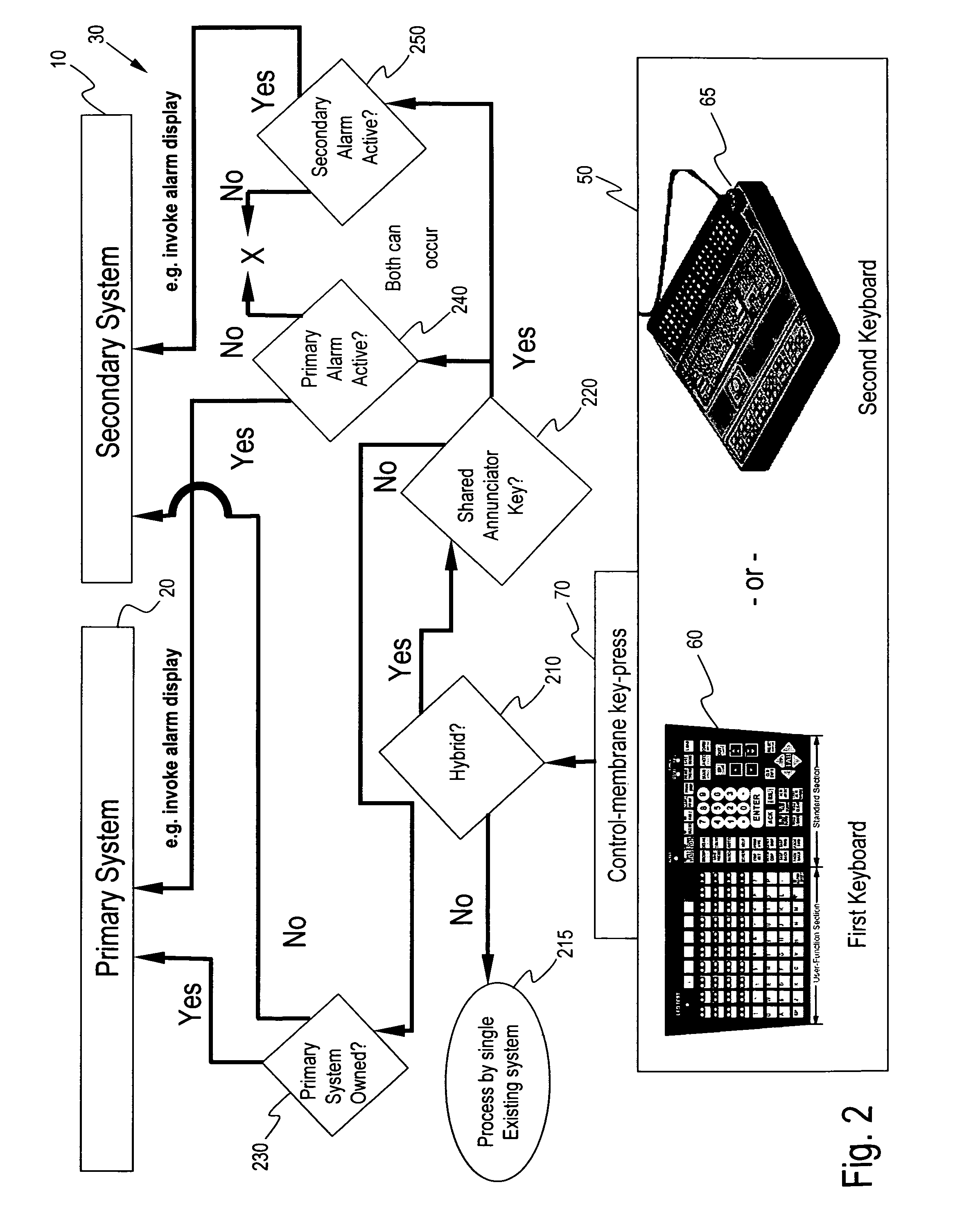

Method and apparatus for use of multiple control systems

A method and apparatus for simultaneously controlling multiple control systems is provided. The resulting hybrid control system provides for sharing of inputs and outputs on a control surface membrane between the multiple distinct control systems. A unified tactile / LED interface for both systems is achieved, allowing for a single hybrid control system experience for operators in industrial, manufacturing and control-room environments.

Owner:HONEYWELL INT INC

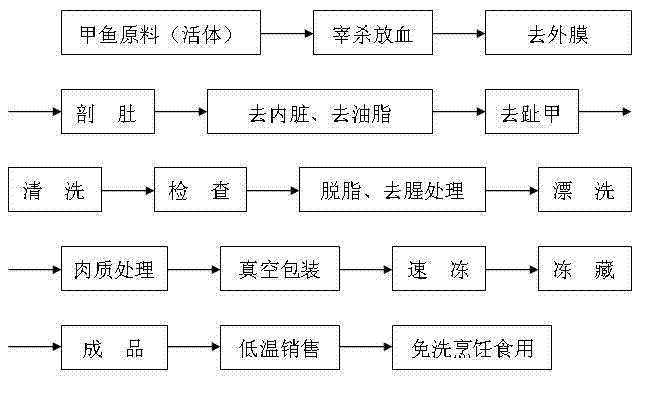

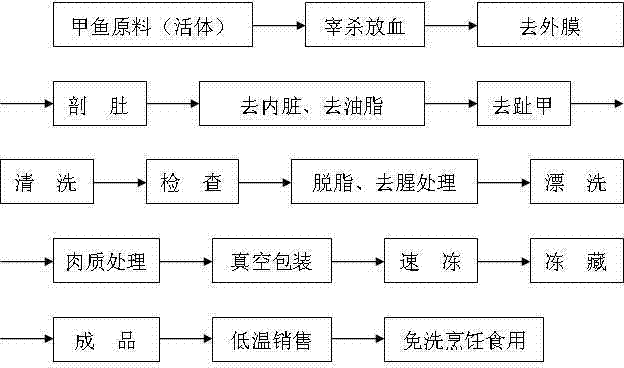

Processing technology for quick-frozen soft-shelled turtle

InactiveCN102370231AReduce freezing denaturationEasy to storeFood preservationQuick FreezeEngineering

The invention discloses a processing technology for a quick-frozen soft-shelled turtle, which comprises the following steps of: 1) using living soft-shelled turtles as raw materials; 2) cutting the necks of the soft-shelled turtles to slaughter the soft-shelled turtles to drain blood; 3) manually removing outer surface membranes; 4) crossly opening the bellies of the soft-shelled turtles or circularly opening the backs of the soft-shelled turtles; 5) clearing all internal organs and grease; 6) shearing off all nails of the soft-shelled turtles; 7) washing the soft-shelled turtles with tap water; 8) checking one by one; 9) degreasing and removing smell by using composite salt solution; 10) draining water and rinsing for 30min, 11) draining water after rinsing, and treating the meat of the soft-shelled turtles by using food antifreeze agent, water-retaining agent and antioxidant; 12) vacuum packaging; 13) enabling central temperature to rapidly reach a value below 18 DEG C below zero for quick freezing; and 14) conducting freezing storage under an environment below 18 DEG C below zero to obtain finished products. The processing technology for the quick-frozen soft-shelled turtle has the advantages that not only can the problem that the brought soft-shelled turtles are difficult to slaughter be solved, but also the soft-shelled turtles can be sold in the market all year round and the soft-shelled turtles are convenient to preserve.

Owner:SHAOXING ZHONGYA IND PARK

Ultrafiltration and microfiltration membrane assembly for tubular composite membrane

ActiveCN101785973ASolve the filtration accuracyEnhanced mechanical strength recoil availableUltrafiltrationPolyvinyl chlorideEngineering

The invention relates to an ultrafiltration and microfiltration membrane assembly for a tubular composite membrane, relating to the filtering element for water treatment. The ultrafiltration and microfiltration membrane assembly for the tubular composite membrane comprises a tubular machine shell with the ellipse heads which are symmetrically arranged at both ends and fastened by a strap. The centers of the two ellipse heads penetrate through a perforated central tube. A drain plug is arranged in the middle section of the perforated central tube and the ellipse heads are provided with a concentrated water outlet, an original water inlet and a purified water outlet, respectively. Multilayer membranous tubes with different inner and outer diameters are arranged areally on the circumference of the perforated central tube. The shell material of the tubular membrane assembly is polyvinyl chloride (PVC) or glass steel and the inner diameter of the membranous tubes is 5-20mm while the outer diameter thereof is 10-30mm. The membranous tubes consist of a basic membrane and a surface membrane, wherein the basic membrane material is sintered by using ultrahigh molecular weight polyethylene (UHMW-PE), and the material of the surface membrane filtering layer is polyvinylidene fluoride (PVDF), polyacrylonitrile (PAN) and polyvinyl acetate (PVA). The ultrafiltration and microfiltration membrane assembly can be matched with other pipelines, valves, instruments to form an ultrafiltration and microfiltration set for membrane engineering and has the characteristics of high strength, pollution resistance, fouling resisting property, short process flow, rapid online backwash-regeneration, long service life and the like.

Owner:金振忠 +1

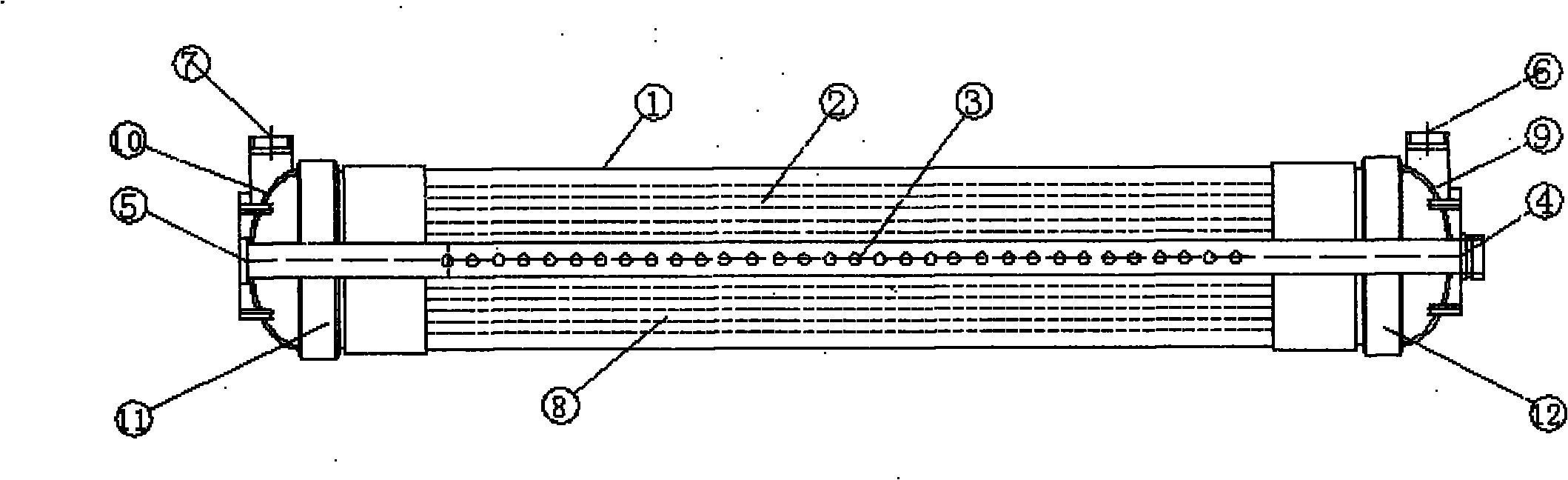

Rotating cross-flow flat ceramic membrane separation turntable

InactiveCN104841277AHigh strengthEasy to implement high pressure backwashUltrafiltrationSeparation technologyHigh pressure

The invention relates to a rotating cross-flow flat ceramic membrane separation turntable, which comprises a hollow central shaft, a support component fixedly arranged on the hollow central shaft, a plurality of flat ceramic membrane components supported by the support component and a driving mechanism for driving the hollow central shaft to rotate, wherein each flat ceramic membrane component comprises a hollow cavity type flat ceramic membrane; each hollow cavity type flat ceramic membrane comprises two separated surface membrane layers; a plurality of liquid collection accommodation cavities and liquid outlets are formed around the hollow cavity type flat ceramic membranes; a plurality of cavities are formed in the hollow cavity type flat ceramic membranes. According to the turntable, a flat ceramic membrane filtering technology is adopted, the characteristics of strong strength, convenience in high-pressure back washing and the like of the ceramic membranes are fully utilized, and the application fields of a rotating cross-flow membrane separation technology are well extended.

Owner:SUZHOU MOHAI SEPARATION TECH

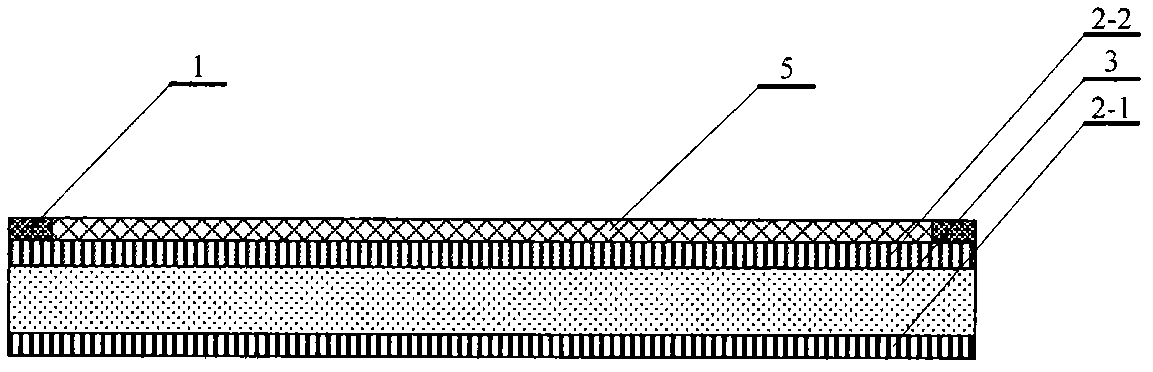

Long-lasting anti-fouling membranous-structure composite canopy material

ActiveCN106003931AIncreased static contact angleNot easy to penetrateSynthetic resin layered productsCoatingsPolyesterFiber

The invention relates to a long-lasting anti-fouling membranous-structure composite canopy material comprising a base membrane, base cloth and a surface membrane which are arranged sequentially from bottom to top, wherein a polyvinylidene fluoride coating is arranged on the surface membrane and is subjected to mirror face embossing treatment; the surface membrane as well as the base membrane is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 50 to 70 parts of a dioctyl terephthalate plasticizer, 5 to 25 parts of calcium carbonate powder, 1 to 5 parts of a flame retardant, 1 to 4 parts of a smoke suppressant, 1 to 6 parts of a barium-zinc stabilizer and 1 to 5 parts of a titanium pigment; the base cloth is 1000D*1000D polyester fiber woven cloth. Raw materials such as PVC resin powder, the plasticizer, calcium carbonate, the stabilizer and the flame retardant are mixed, plasticizing and calendaring are carried out to obtain soft membranes, then the soft membranes are compounded with the 1000D*1000D polyester fiber woven cloth, and embossing is carried out after surface treatment of polyvinylidene fluoride, so that the long-lasting anti-fouling membranous-structure composite canopy material is a membranous-structure composite canopy material being long-lasting in fouling resistance, efficient in fire retardancy, and high in strength.

Owner:浙江明士达股份有限公司

Preparation method of abrasion-resistant hydrolyzation-resistant polyurethane synthetic leather

ActiveCN102965965AIncreased durabilityGuaranteed permeabilityPolyureas/polyurethane adhesivesSynthetic resin layered productsSlurryWork in process

The invention discloses a preparation method of an abrasion-resistant hydrolyzation-resistant polyurethane synthetic leather, which comprises unit processes including wet-process synthetic leather semi-finished product preparation, transfer membrane preparation, veneering semi-finished product preparation and post processing, and particularly comprises the following steps of: firstly coating polyurethane slurry on the sueded face of a base cloth; then sequentially coagulating in a coagulating tank, washing and drying according to the conventional method to obtain a wet-process synthetic leather semi-finished product; uniformity coating polycarbonate slurry on the front surface of release paper, and drying to obtain a surface membrane; then uniformity coating two-component polycarbonate slurry on the surface membrane to obtain a bonding layer, and drying to obtain a transfer membrane; bonding the transfer membrane and the wet-process synthetic leather semi-finished product, drying, cooling for shaping, and then stripping off the release paper to obtain a veneering semi-finished product; and then conventionally immersing in water, diving in water, rubbing patterns and drying to obtain a finished product. The product prepared by the preparation method disclosed by the invention cannot be abraded by a H-18 mill working at the speed of 5000 rounds and has the 10 years durability.

Owner:ANHUI ANLI MATERIAL TECH

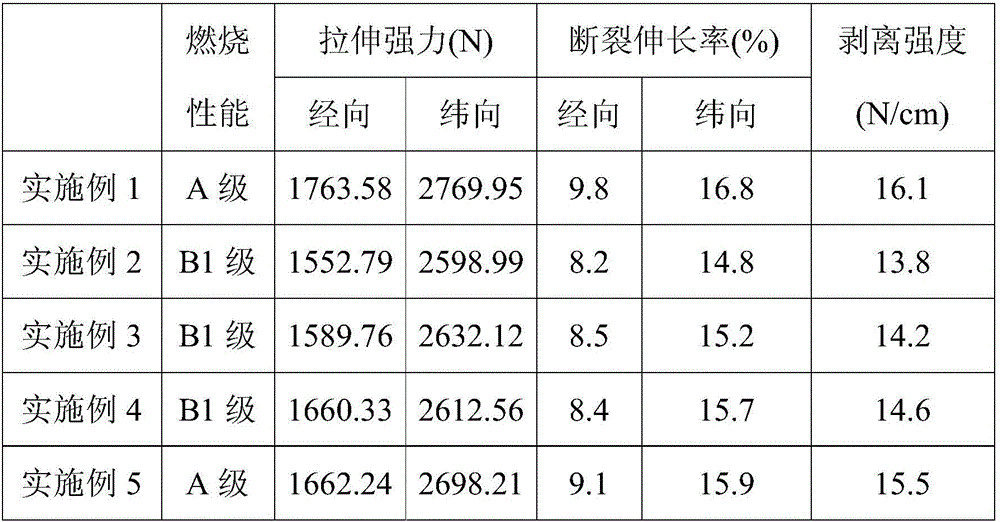

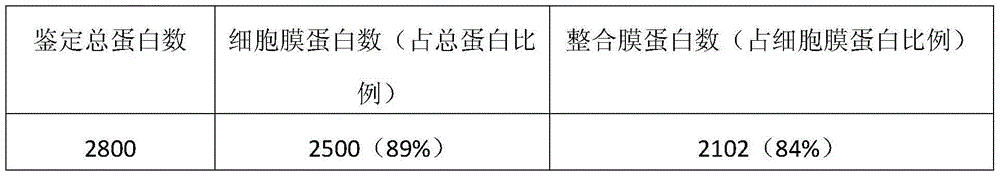

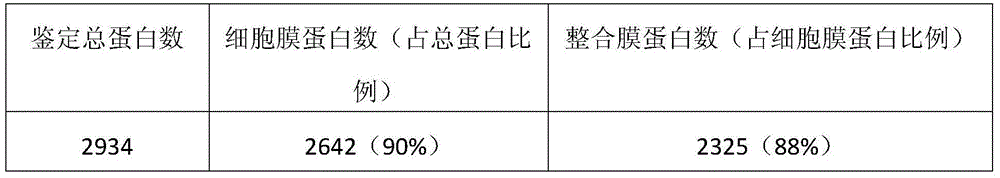

Cell membrane protein enrichment and purification method

ActiveCN104628810AEfficient separationAchieve separationPeptide preparation methodsPurification methodsMicrosphere

The invention relates to a cell membrane protein enrichment and purification method. The method utilizes the natural characteristics that cell membrane surface integrated membrane protein runs through a membrane bimolecular layer and galactosylated modification often occurs to the cell membrane surface membrane protein, and cell membrane surface galactosylated modification protein serving as the bait is capture by functional magnetic microspheres so as to realize separation of the cell membrane and organelles and efficient enrichment of cell membrane integrated membrane protein. The method has the advantages of high separation efficiency of cell membrane and organelles, and can achieve efficient analysis and characterization of cell membrane proteins. In addition, with the introduction of functional magnetic microspheres, the method has the advantages of simple operation, rapid separation and low sample loss.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Photo resist film removing agent

InactiveCN101071278AReduce COD contentImprove protectionPhotosensitive material processingResistCompound organic

A photoresist stripping of the membrane, which is composed of the percentage of weight: Composite organic base 10% - 30%; polyether active agent 1% to 5%; broken film of 1% to 5% copper Corrosion Inhibitor 0.1% -1%; deionized water 60 percent to 70 percent above base is a complex organic chemical-XR-NH2 organic amines in at least two, X is H, OH or NH2, R-n - base; polyether active agent for ethylene oxide and ethylene oxide to block copolymer or inorganic in at least one copolymer; broken film for the long carbon chain aliphatic amines, copper corrosion inhibitor for benzo triazole and its derivatives in at least one. The present invention retreat film properties, and its high rate of retreat membrane, the membrane of the retreat, the use of low-cost, Wuxi migration, copper corrosion, do not contaminate pure tin, gold, silver surface membrane retire at the metal layers with superior protection and particularly suitable for flexible lines and fine lines, and other high-end PCB manufacturing, production safety and environmental protection are used.

Owner:HUNAN SCI & TECH RES & DEV CENT

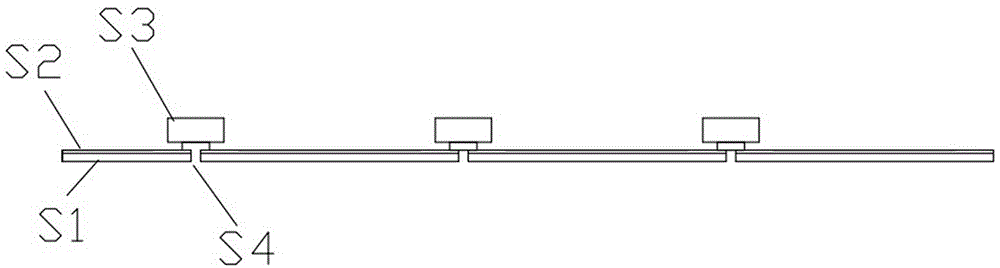

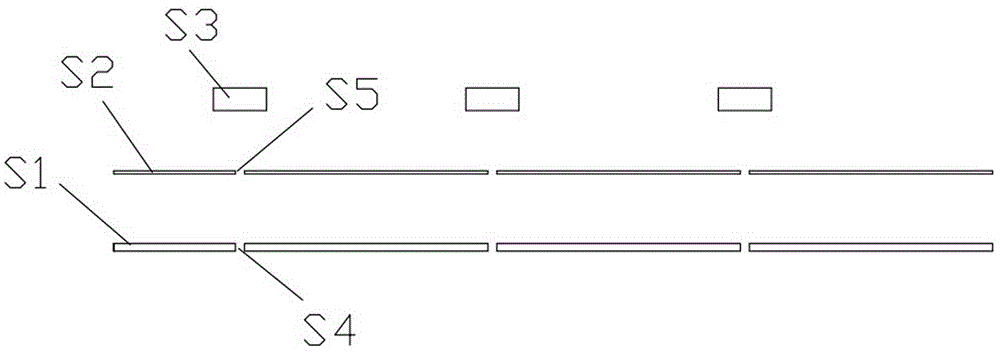

Smooth LED flexible light bar and device and method for manufacturing same

ActiveCN103822130ASimple structureReduce process stepsPrinted circuit assemblingPoint-like light sourceElectrical conductorEngineering

The invention discloses a smooth LED flexible light bar and a device and a method for manufacturing the same in the technical field of electronic lighting applications. The smooth LED flexible light bar is composed of a viscous material layer and a flat conductor adhesively bonded to the surface of the viscous material layer, a bonding layer used for bonding the flat conductor covers the surface of the viscous material layer, empty avoiding holes are punched in the surface of the viscous material layer, fracture surfaces used for disconnecting the flat conductor are punched in the surface of the flat conductor, the center of each fracture surface corresponds to the corresponding center of each empty avoiding hole, the fracture surfaces are located right above the empty avoiding holes, and electron components used for connecting the fracture surfaces are welded to the surface of the flat conductor. Compared with a conventional LED flexible light bar, the smooth LED flexible light bar has the advantages that a PI basement membrane and a PI surface membrane which are high in cost are omitted, the PI basement membrane is replaced through another low-cost viscous material layer such as a PET membrane, and the surface membrane can be omitted, so that the smooth LED flexible light bar is simple in integral structure, manufacturing cost can be saved, and wide promotion is facilitated.

Owner:广东田津电子技术有限公司

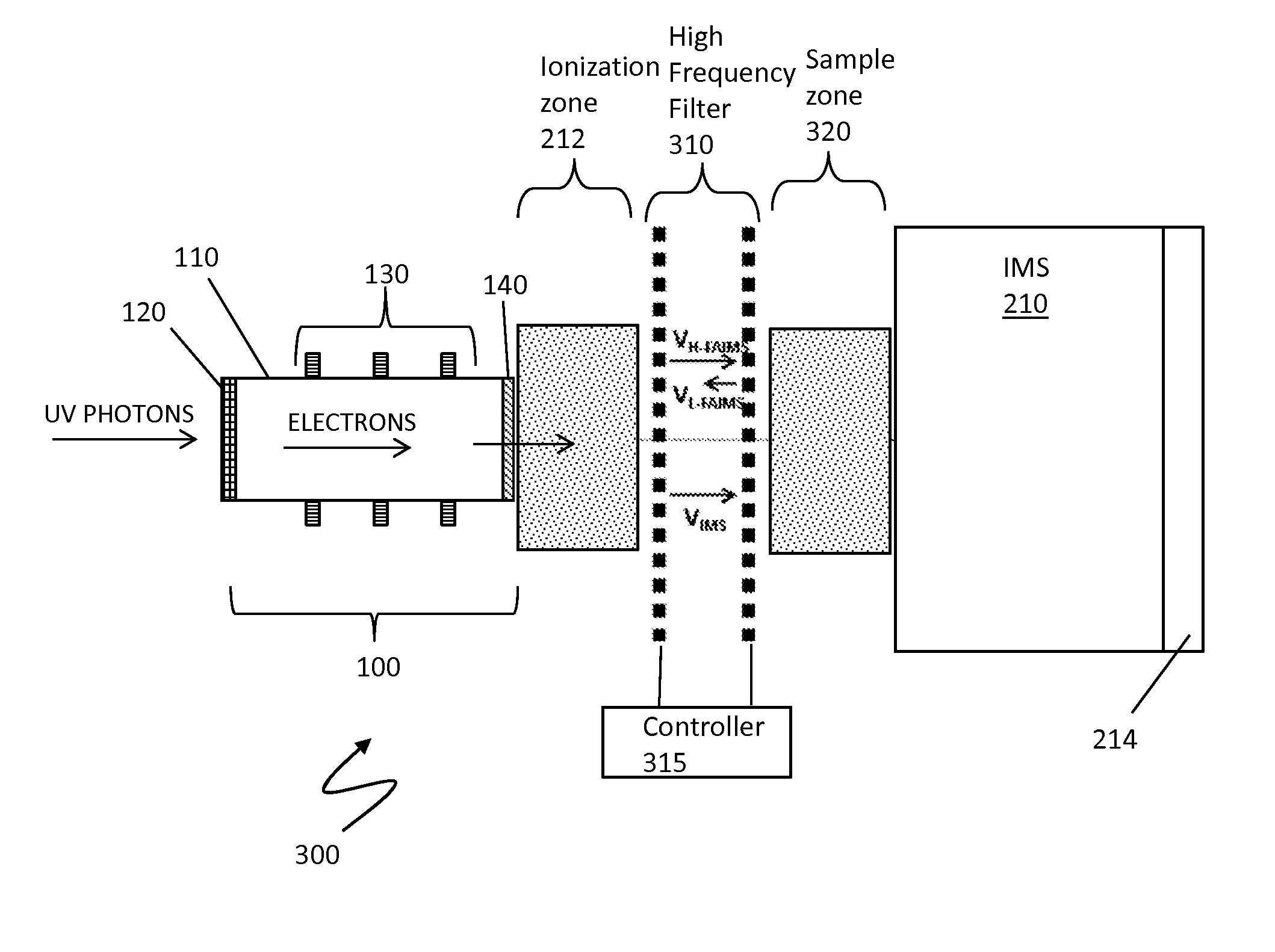

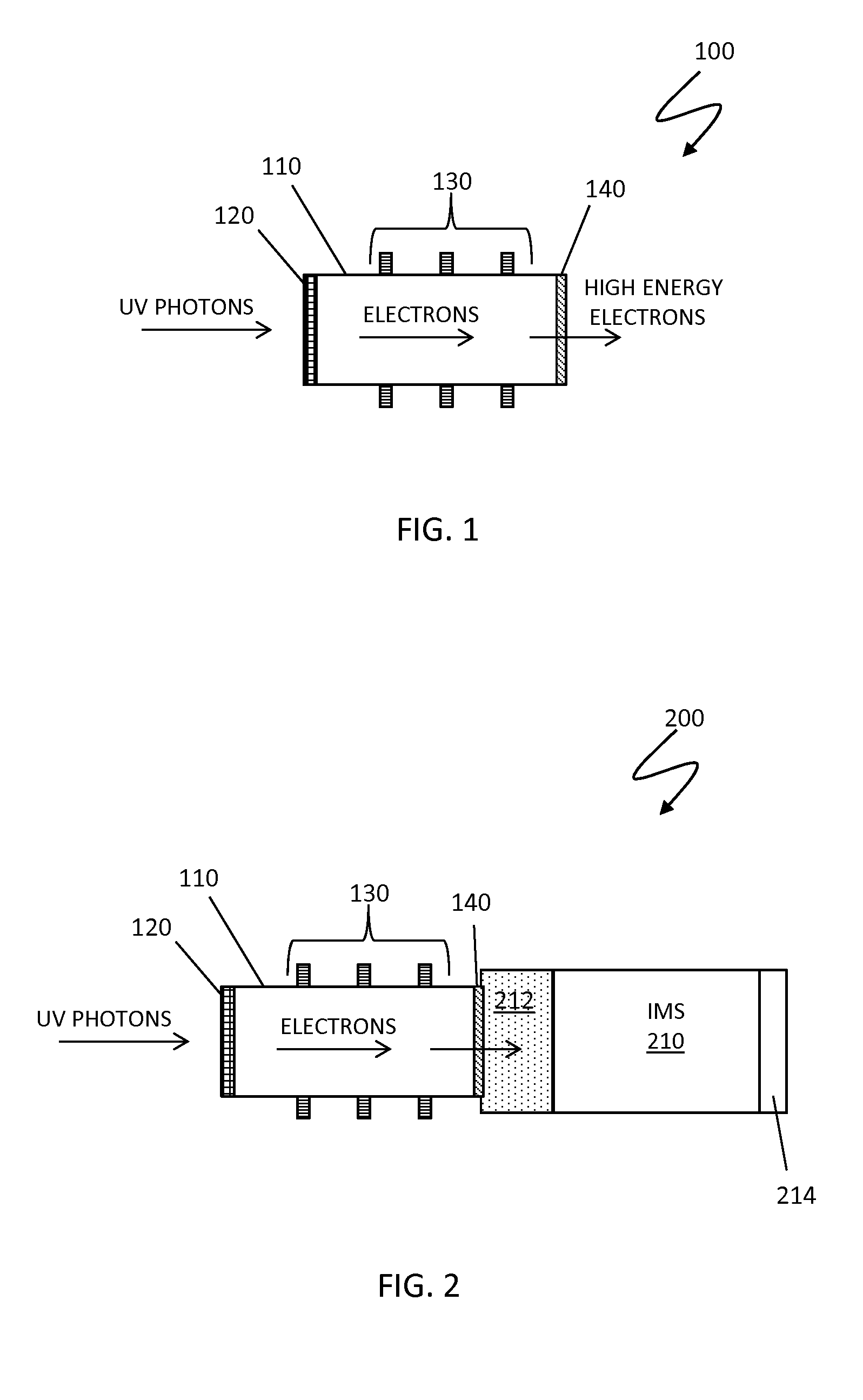

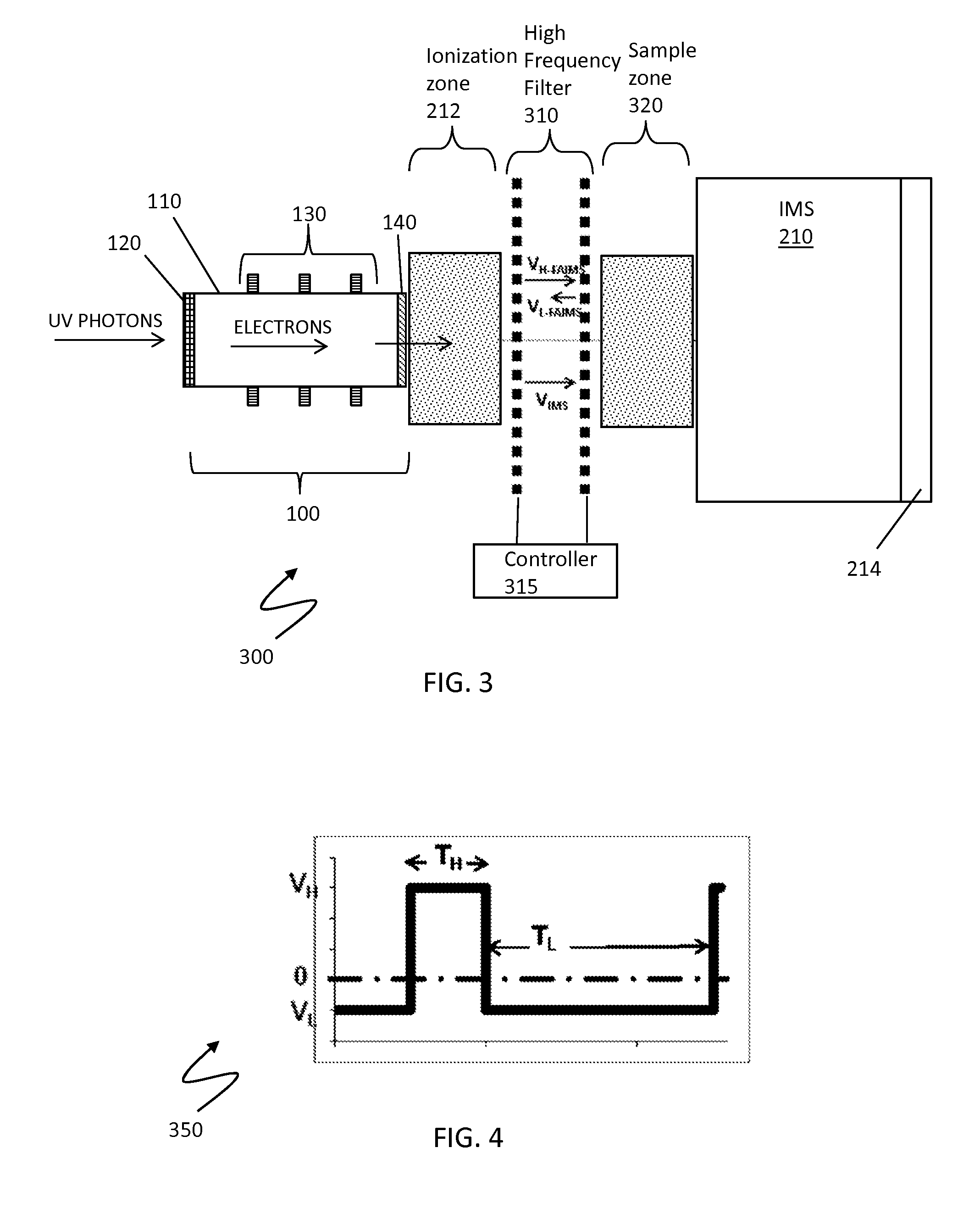

Non-radioactive ion source using high energy electrons

ActiveUS9006678B2Tubes with one/two output electrodesMaterial analysis by electric/magnetic meansPhotocathodeHigh energy

A system and method for producing a continuous or pulsed source of high energy electrons at or near atmospheric pressure is disclosed. High energy electrons are used to ionize analyte molecules in ambient air through collisions with reactant ions. The device includes an electron emitter, electron optics, and a thin membrane in an evacuated tube. The electron emitter may include a photocathode surface mounted on an optically transparent window and an external source of UV photons. The transparent window may include a UV transparent window mounted on an evacuated tube and / or the evacuated tube may be a transparent tube on which a photocathode surface film is deposited. The electron optics may include successive electrodes biased at increasing voltages. The membrane may include a material transparent or semi-transparent to energetic electrons. Upon impacting the membrane, continuous or pulsed electron packets are partially transmitted through to a high pressure ionization region.

Owner:LEIDOS SECURITY DETECTION & AUTOMATION INC

Self-bonding layer strip material with environmental protection and wide temperature change

InactiveCN101942279AAffect stickinessImprove product qualityLayered productsFilm/foil adhesivesProduction lineWeather resistance

The invention relates to a self-bonding layer strip material with environmental protection and wide temperature change. A first adhesive layer and a second adhesive layer are respectively coated on two surfaces of a basic layer; the other surface of the first adhesive layer or the second adhesive layer is provided with an isolating membrane; and the isolating membrane is a base membrane or a surface membrane and a side membrane, wherein the thicknesses of the first adhesive layer and the second adhesive layer are respectively 0.02-0.3mm. The self-bonding layer strip material has the advantages of aquosity, environmental protection, no toxicity or flavour, high bonding strength, high water resistance and weather resistance, stickiness being free from the influence of temperature change andcapability of long-time storage and use, can be widely applied to common waterproof coiled materials of rubber, macromolecule plastics, modified pitch, and the like and does not need other materials to be added into raw materials or heating reaction; the self-bonding type waterproof coiled material with the advantages of excellent performance and convenient construction can be produced as long asless reformation is performed on the production line of the traditional various common waterproof coiled materials; and the self-bonding layer strip material can be also applied to other objects and materials which are in different specifications and need self bonding.

Owner:北京立高科技股份有限公司 +1

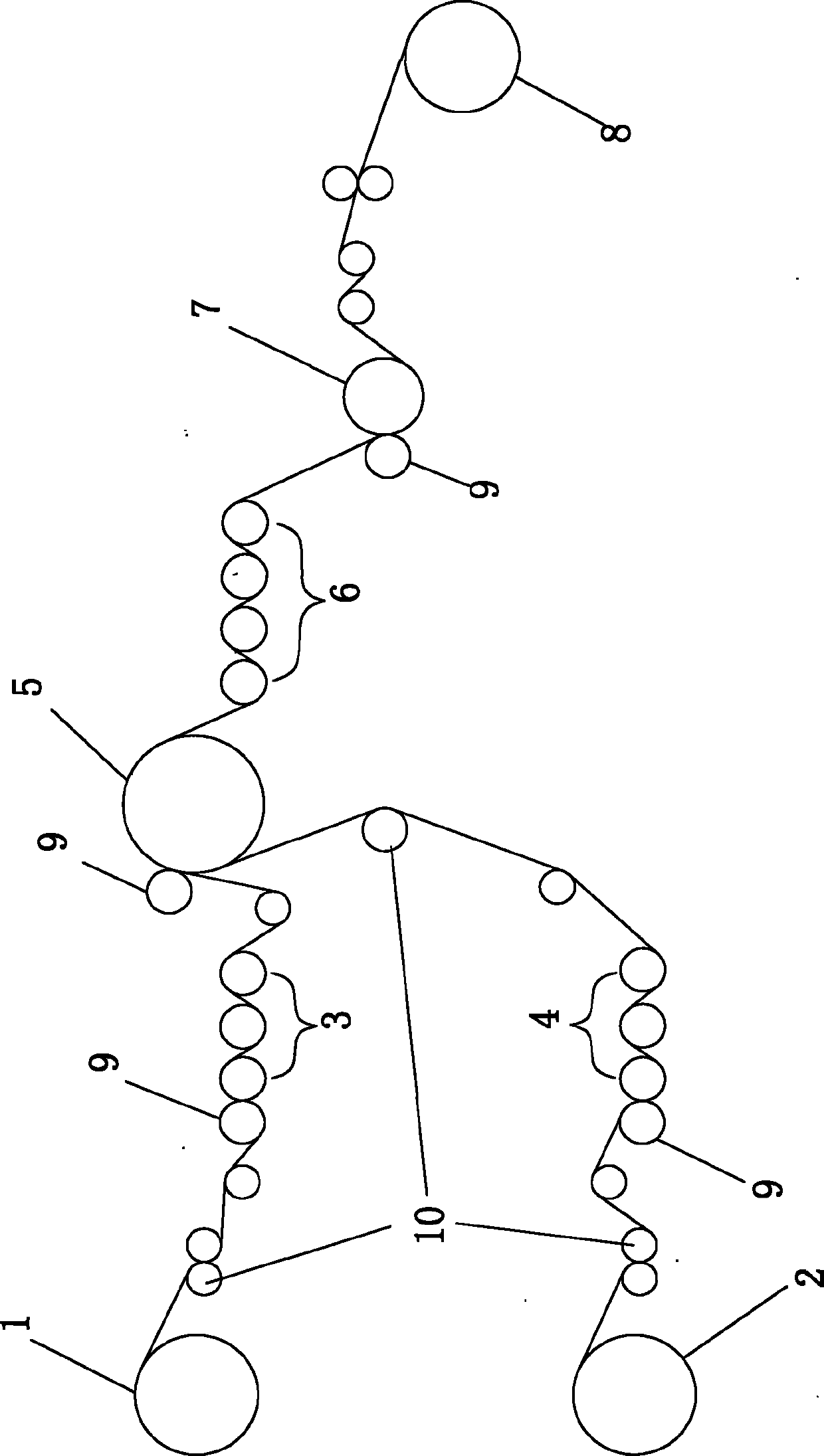

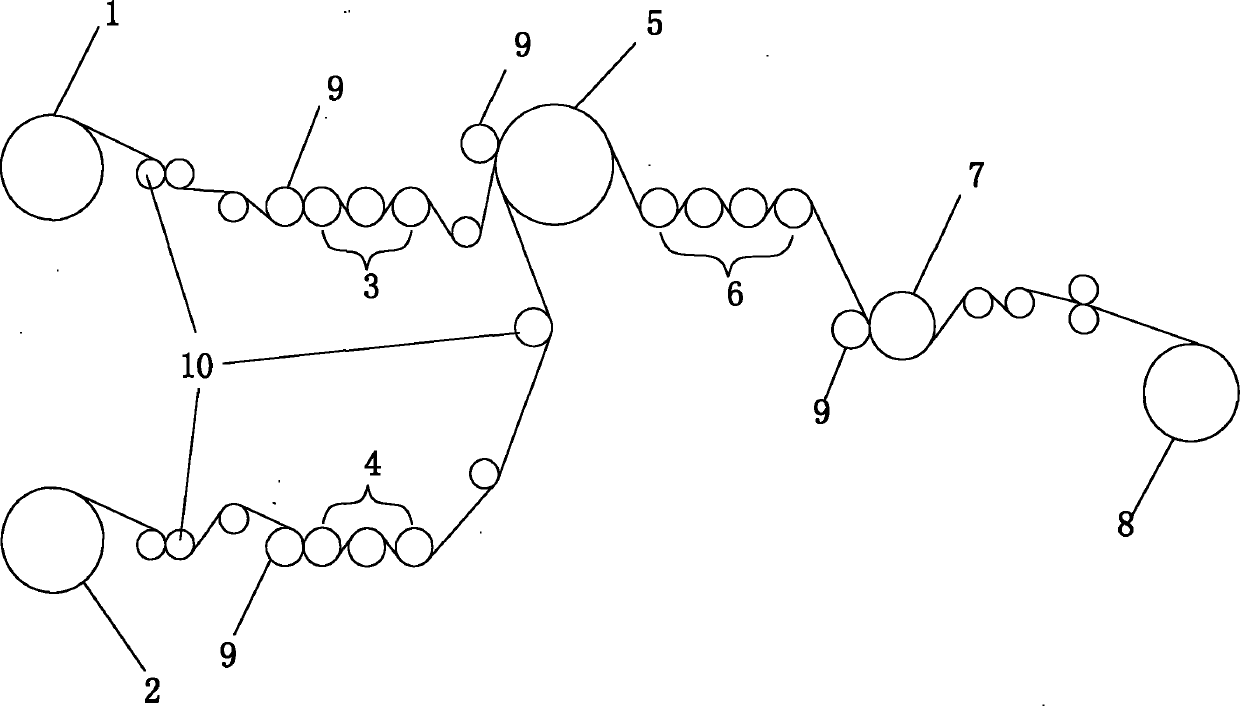

Combined embossing technology and equipment of polyvinyl chloride (PVC) sheet

The invention discloses combined embossing technology and equipment of a polyvinyl chloride (PVC) sheet. The compound embossing equipment comprises a surface membrane unwinding mechanism, a basement membrane unwinding mechanism and a winding mechanism, wherein a surface membrane preheating roller wheel is arranged in the rear of the rear surface of the surface membrane unwinding mechanism; a basement membrane preheating roller wheel is arranged in the rear of the rear surface of the basement membrane unwinding mechanism; first roller wheels of the surface membrane preheating roller wheel and the basement membrane preheating roller wheel are both provided with rubber rollers; a combined vat is arranged in the rear of the surface membrane preheating roller wheel and the basement membrane preheating roller wheel, and the rubber rollers are arranged with the combined vat together; a conveying roller is arranged in the rear of the combined vat; an embossing roller is arranged in the rear of the conveying roller, and the rubber rollers are arranged with the embossing roller together; and the winding mechanism is arranged in the rear of the embossing roller. Compared with the prior art, surface membrane unwinding and preheating is a path, basement membrane unwinding and preheating is an other path, the two paths are finally met together on the combined vat, combined by the combined vat and embossed by the embossing roller, and the whole production process is automatically carried out, thus the invention saves a large quantity of manpower, greatly enhances the production efficiency and the product quality and reduces the defective product ratio.

Owner:东莞市华富立装饰建材有限公司

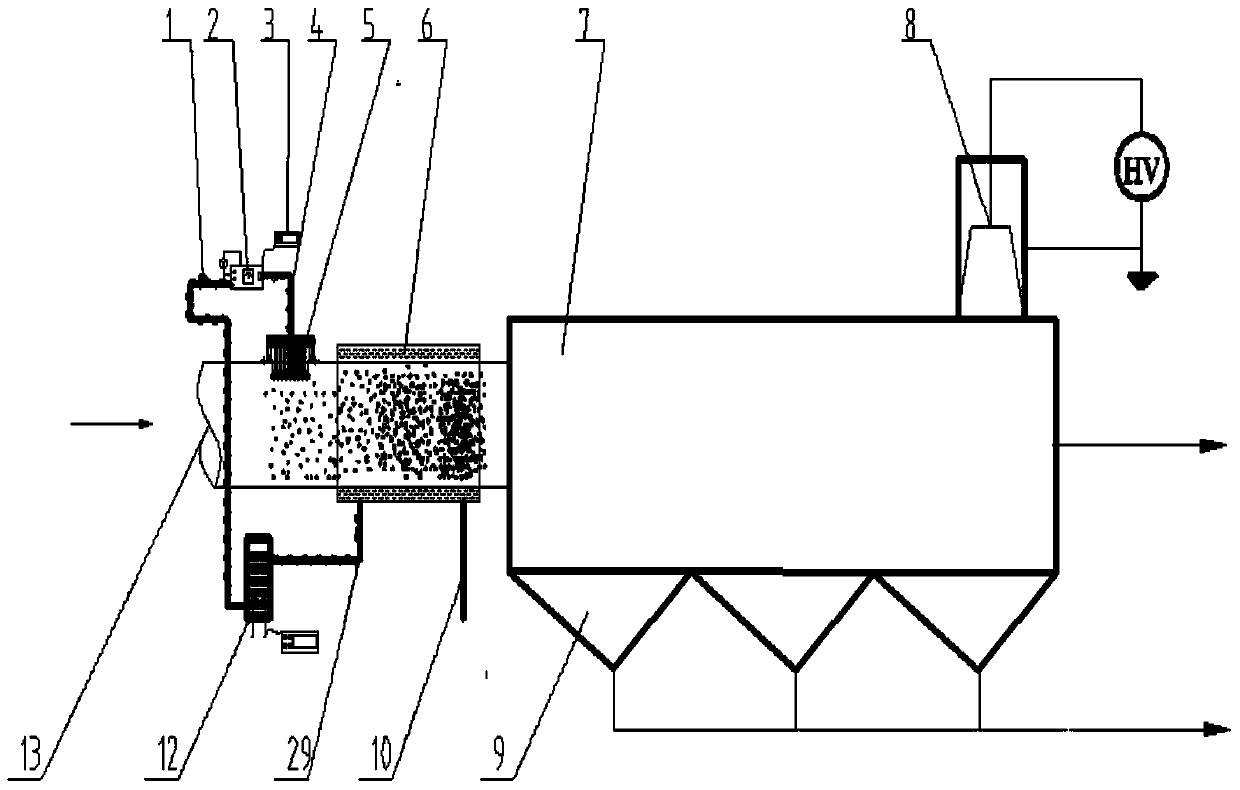

Surface membrane coagulation technology and device for efficiently removing fire coal flying ash microspheres

ActiveCN104043527ALower specific resistanceSmall particle sizeElectrostatic separationWater vaporWater storage tank

The invention relates to a surface membrane coagulation technology and a surface membrane coagulation device for removing fire coal flying ash microspheres. The device is composed of a pattern-plate-type atomizer, a flow rate meter, an ultrasonic wave driving power supply, an automatic temperature control device, a tracing heat pipeline, a condensing casing pipe, an electric heating water storage tank, a water pump and an electric deduster. According to the invention, high-temperature water is atomized into 10-20 micron single-diffusion liquid drop granules by utilizing ultrasonic waves; the saturation degree of flue gas is improved to in an ultra-saturated state, wherein the SR is greater than 1.3, and the temperature of the atomized liquid drop is controlled to be 80-90 DEG C; the temperature of liquid in the condensing casing pipe is controlled, so that the flue gas is cooled to 1-5 DEG C; steam in the flue gas is adsorbed to the outer surfaces of the microspheres by utilizing the high adsorption performance of the surfaces of the microspheres, and micro bulges on the surfaces of the microspheres are taken as cores, and 'sphere'-shaped coagulation is formed rapidly, so that the specific resistance of the microspheres is reduced by 1-2 dot products; the retention time of the atomized liquid drops in flue gas is controlled to be 300 milliseconds-1 second, and then the liquid drops are collected by an electrostatic deduster efficiently.

Owner:SHANDONG UNIV +1

Hexavalent-chromium appearance imitated anti-corrosion membrane plating method

InactiveCN102328471AImprove corrosion resistanceHigh weather resistanceVacuum evaporation coatingSputtering coatingUltravioletEvaporation

The invention discloses a hexavalent-chromium appearance imitated anti-corrosion membrane-plating method and relates to metallic and non-metallic surface membrane plating. The invention aims to provide a hexavalent-chromium appearance imitated anti-corrosion membrane-plating method which is characterized in that the function and quality of an obtained product are good, no water is required to be used in the whole process flow, and compared with the existing membrane plating by using a dry method, the method is more environmentally-friendly and more superior in performance. The method comprises the following steps: cleaning by using a dry method; carrying out ultraviolet curing on a prime coat; carrying out evaporation coating on a metal aluminum membrane; carrying out evaporation coating on a polymer membrane; and carrying out ultraviolet curing on a surface coat. The aluminum membrane is isolated from the outside by using a silica membrane so as to form a totally-closed structure, then through carrying out color-matching by using a finishing paint, a high-corrosion-resistant plated membrane with an imitated appearance of hexavalent chromium is obtained, so that the method disclosed by the invention replaces the traditional water electroplating process. A product prepared by using the method disclosed by the invention is high in corrosion resistance and weather resistance, andmore approximate to the appearance and high performances of the traditional water-electroplated hexavalent chromium.

Owner:XIAMEN RUNNER IND CORP

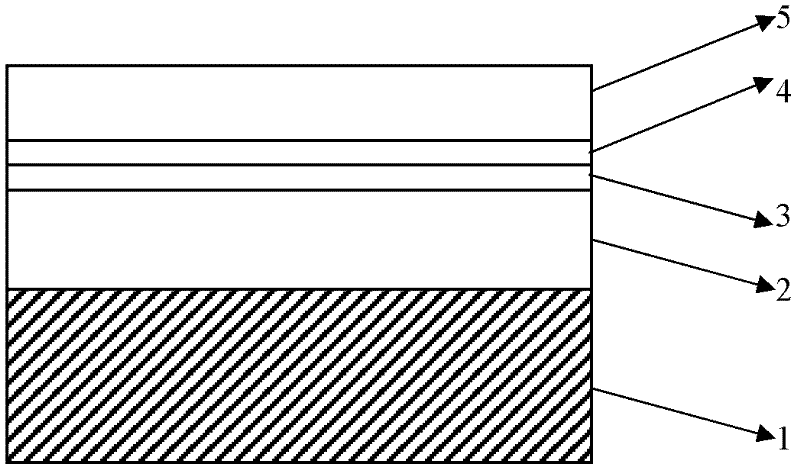

Method for making reverse ladder structure by using architecture-complementary micro-patterning technique

InactiveCN1877453AReduce pollutionSimple processing technologyElectroluminescent light sourcesSemiconductor/solid-state device manufacturingMicro structureMulti material

The invention relates to a method for processing complementary structure into pattern. The method comprises steps of: employing a capillary micro mould to make a micro structure with positive ladder type cross-section on the surface of the base, and taking the micro structure as a mount and coating a layer of membrane on the surface; selecting a solution that can solve the capillary micro mould, but can not solve its surface membrane to solve the micro structure, and driving the membrane fall away to keep the micro structure with negative ladder type on the base surface.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

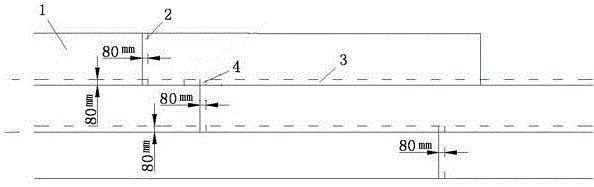

Wet placement method construction technique for macromolecule self-adhesive waterproof coiled materials

InactiveCN105064413AImprove reliabilityIncreased durabilityNon-macromolecular adhesive additivesBituminous material adhesivesStructural deformationWater leakage

The invention discloses a wet placement method construction technique for macromolecule self-adhesive waterproof coiled materials. The wet placement method construction technique for the macromolecule self-adhesive waterproof coiled materials comprises the following steps of S1 cardinal plane cleaning and wetting and S2 coiled materials placing. The S2 step further comprises the steps of laying a first coiled material, laying a second coiled material and laying the remaining materials. The overlap joint edges of the coil materials are adhered by the coiled material bodies, so that an integral flexible waterproof effect is achieved; the problems of cracking, water leakage and freeze-thaw damage in cold regions of the overlap edges of the coiled materials caused by structural deformation and splits due to the traditional method of complete rigid overlap are solved; the reliability and durability of a waterproof layer are improved and the risk of leakage is reduced. Material selection and the material ratio of an adhesion sizing agent are specified; the problems of low intensity of an adhesion agent, pulverization of the adhesion agent and bulging and falling off of the coiled materials are solved; an upper surface membrane tectoria treatment technique is adopted in the process of sizing mucosa overlapping of the short edges of the self-adhesive coiled materials, so that the adhesion strength and durability of the upper surface membrane tectoria of the coiled materials and a self-adhesion sizing material are improved.

Owner:SICHUAN WEIDUN JIANGXIN CONSTR CO LTD

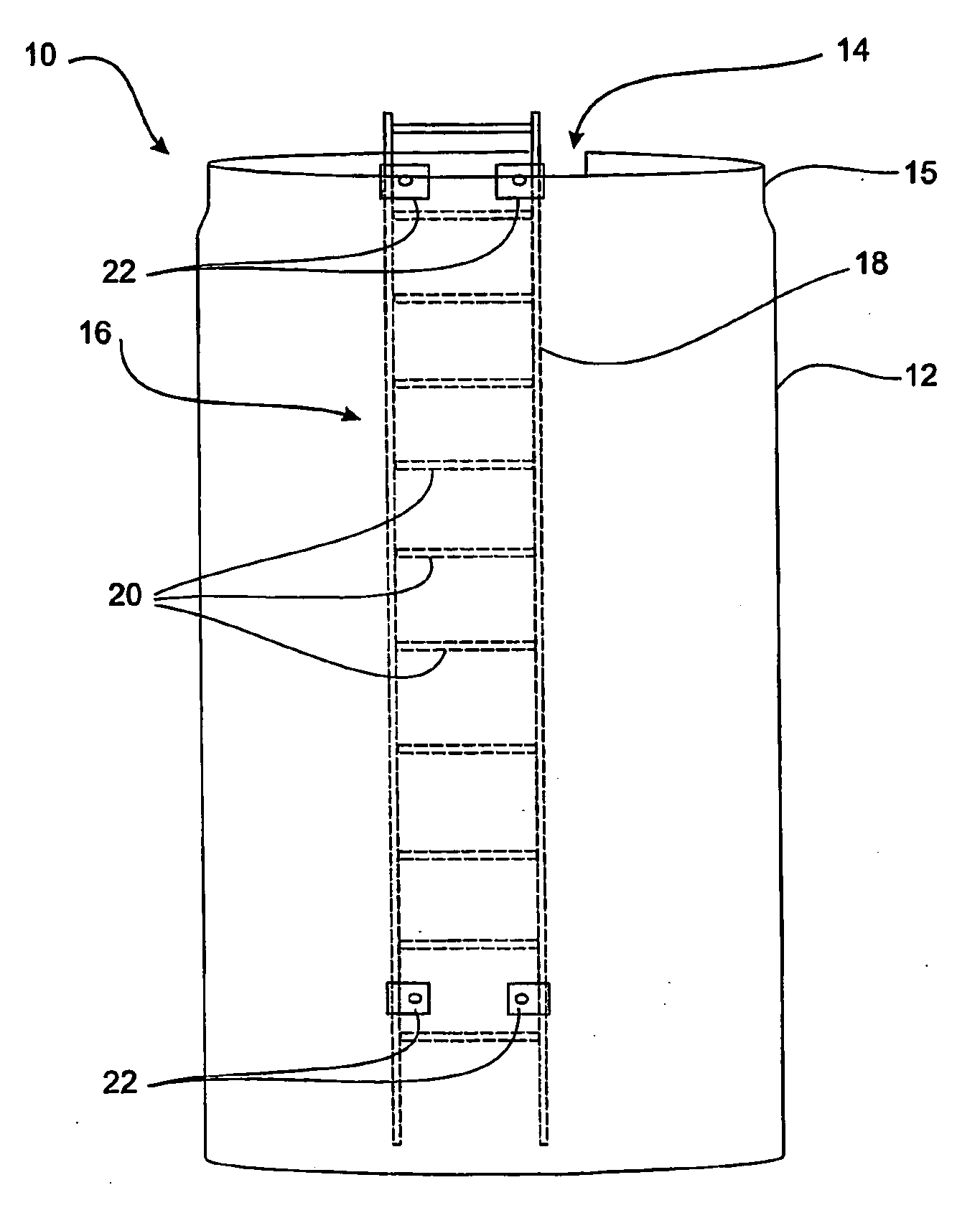

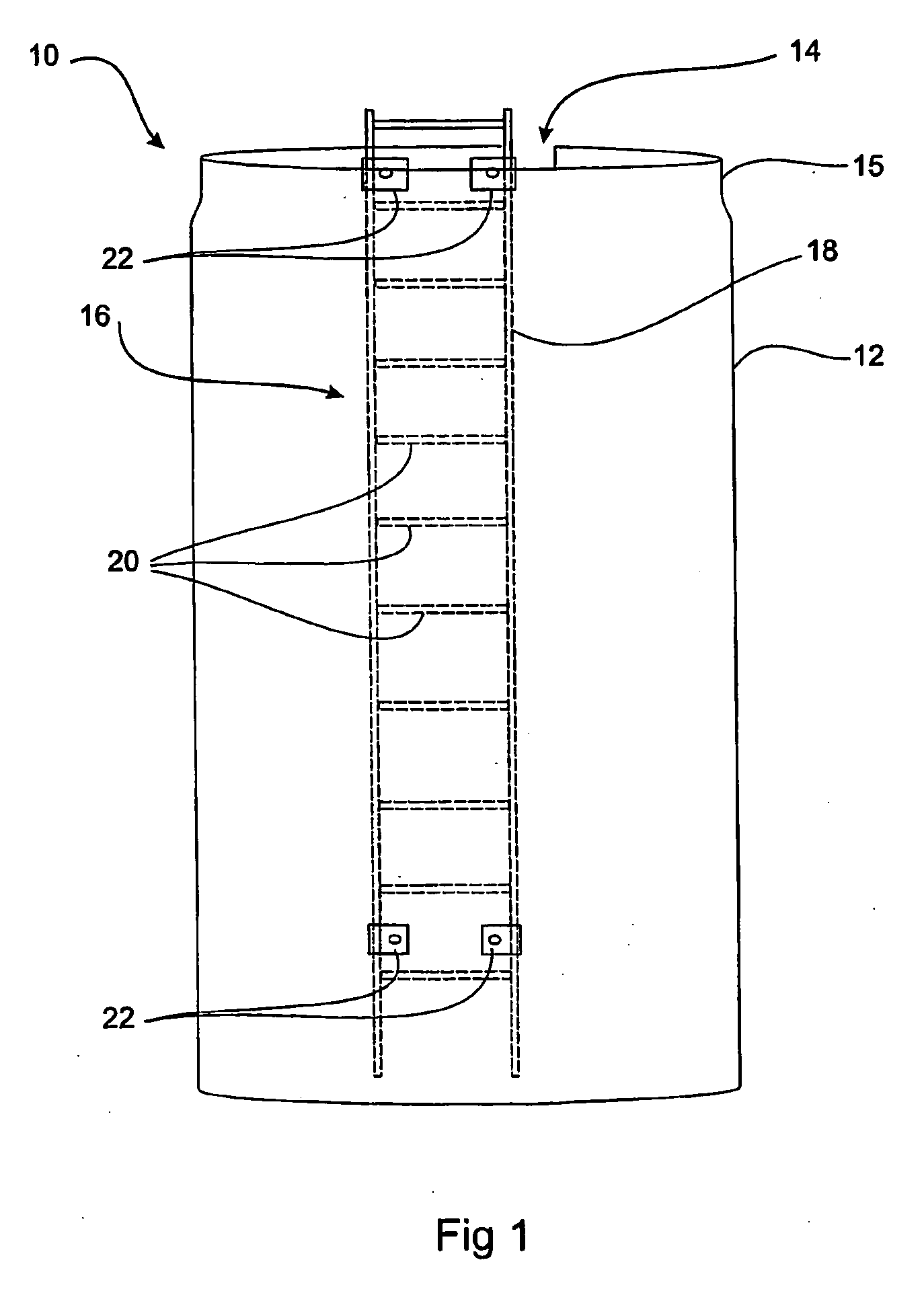

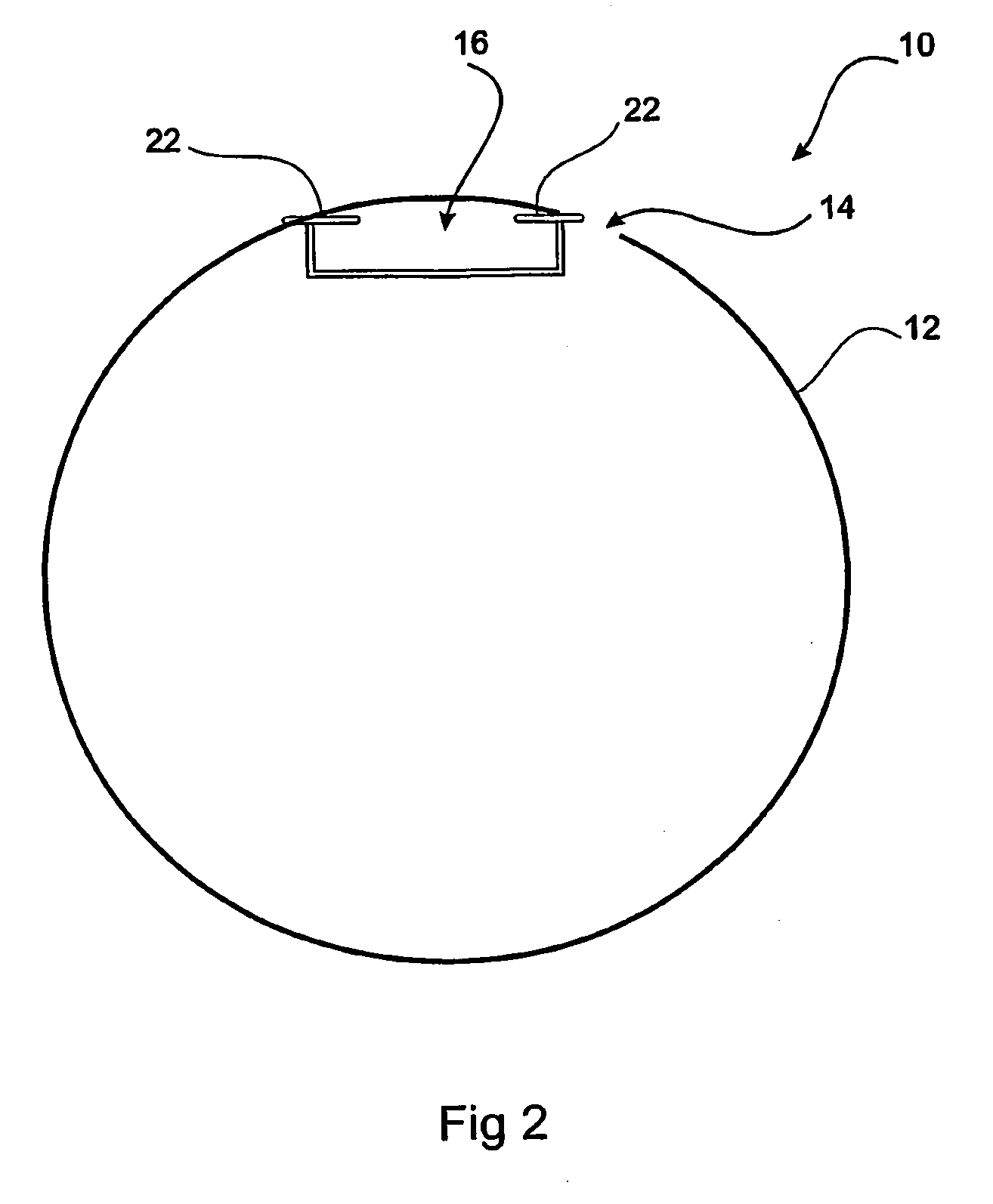

Ladderway system for underground raises

A ladderway system for an underground raise includes an elongate tube adapted to generally conform to the shape of the raise. The tube is of circular cross-section to generally conform to the shape of a round bored raise. The tube is formed with a longitudinal slit along its entire length, whereby the diameter of the tube can be adjusted to generally conform to the shape of the raise. The ladderway system further includes a ladder adapted to be mechanically coupled to an interior of the tube. The tube manufactured of a sufficiently rigid and strong plastics material, such as polyurethane, so that it acts as a surface membrane or liner within the raise.

Owner:BORTANA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com