Method for making reverse ladder structure by using architecture-complementary micro-patterning technique

A micro-patterning, inverted trapezoidal technology, applied in microlithography exposure equipment, photolithographic process exposure devices, semiconductor/solid-state device manufacturing, etc. For the peeling process and other problems, it can achieve the effect of simple processing technology, reduced pollution and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

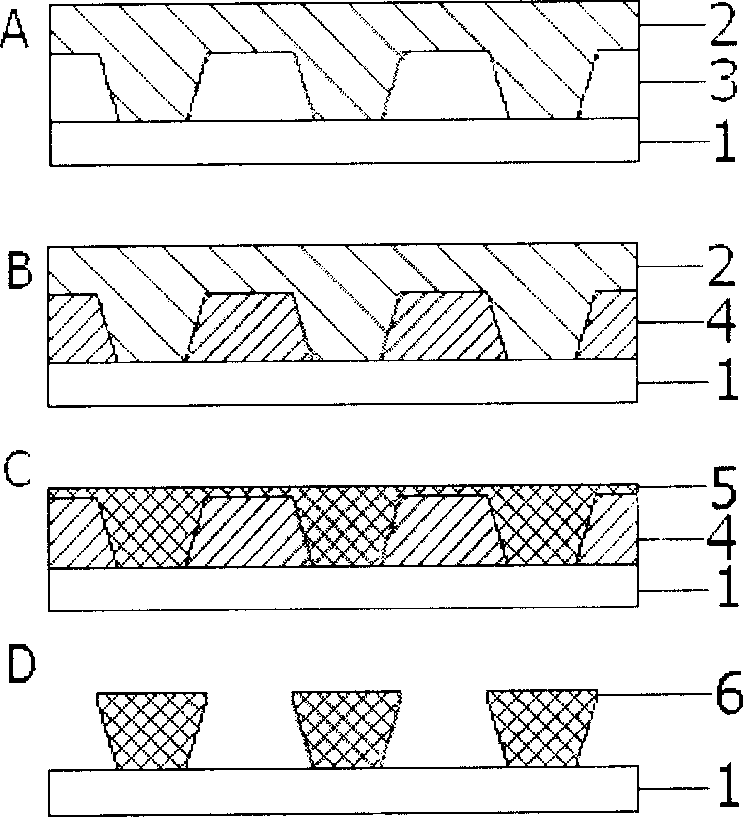

[0021] 1) Select a polydimethylsiloxane soft template 2 with a positive trapezoidal surface cross-section, place the polydimethylsiloxane soft template 2 on the glass substrate 1, and place the polydimethylsiloxane soft template 2 on the glass substrate 1. A capillary channel 3 is formed between the template 2 and the glass substrate 1 . Add an aqueous solution of polyvinylpyrrolidone with a concentration of 10% by weight to the capillary channel 3, and after the aqueous solution of polyvinylpyrrolidone flows into the capillary channel 3 under the action of capillary force, soften the polydimethylsiloxane The template 2 and the glass substrate 1 were placed together in a drying oven at 30 degrees Celsius to dry the polyvinylpyrrolidone aqueous solution.

[0022] 2), peel off the polydimethylsiloxane soft template 2 from the dried glass substrate 1, coat a photoresist film 5 on the glass substrate 1 with polyvinylpyrrolidone 4 patterns, and then apply the photoresist film 5 dr...

Embodiment 2

[0025] 1), select the polydimethylsiloxane soft template 2 whose surface pattern cross-section is a regular trapezoidal structure, and place the polydimethylsiloxane soft template 2 on the glass substrate with indium tin oxide deposited on the surface (hereinafter referred to as On the "ITO glass substrate") 1 , a capillary channel 3 is formed between the polydimethylsiloxane soft template 2 and the ITO glass substrate 1 . Add an aqueous solution of polyvinylpyrrolidone with a concentration of 20% by weight to the capillary channel 3, and after the aqueous solution of polyvinylpyrrolidone flows into the capillary channel 3 under the action of capillary force, soften the polydimethylsiloxane The template 2 and the ITO glass substrate 1 were placed together in a drying oven at 50 degrees Celsius to dry the polyvinylpyrrolidone aqueous solution.

[0026] 2), the polydimethylsiloxane soft template 2 is peeled off from the dried ITO glass substrate 1, and a photoresist film 5 is co...

Embodiment 3

[0029] 1) Select the polydimethylsiloxane soft template 2 whose surface pattern cross-section is a regular trapezoidal structure, place the polydimethylsiloxane soft template 2 on the glass substrate 1, and the polydimethylsiloxane soft template 2 and the glass substrate 1 form a capillary channel 3 . Add an aqueous solution of polyvinylpyrrolidone with a concentration of 30% by weight to the end of the capillary channel 3, and after the aqueous solution of polyvinylpyrrolidone flows into the capillary channel 3 under the action of capillary force, soften the polydimethylsiloxane The template 2 and the glass substrate 1 were placed together in a drying oven at 80 degrees Celsius to dry the polyvinylpyrrolidone aqueous solution.

[0030] 2) Peel off the polydimethylsiloxane soft template 2 from the dried glass substrate 1, apply a photoresist film 5 on the glass substrate 1 with polyvinylpyrrolidone 4 patterns, and then apply the photoresist film 5 drying.

[0031] 3) Place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com