Wet placement method construction technique for macromolecule self-adhesive waterproof coiled materials

A technology of self-adhesive waterproof membrane and construction technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the constraints on the application of polymer self-adhesive waterproof membrane, plain cement slurry There are no problems such as waterproof performance, freeze-thaw damage at overlapping edges, etc., to reduce the risk of leakage, prevent structural deformation, and increase bonding strength and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: The invention relates to a construction technique of wet laying of polymer self-adhesive waterproof membrane, which comprises the following steps:

[0045] S1. Base surface cleaning and wetting: clean the base surface to make the base surface flat, firm and clean, and fully wet the base surface with a sprayer, but there should be no clear water;

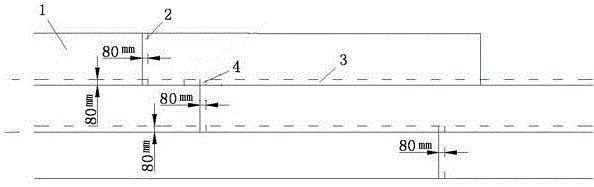

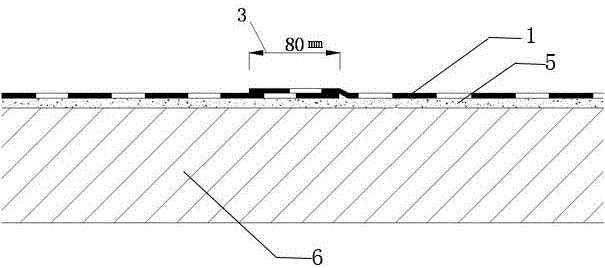

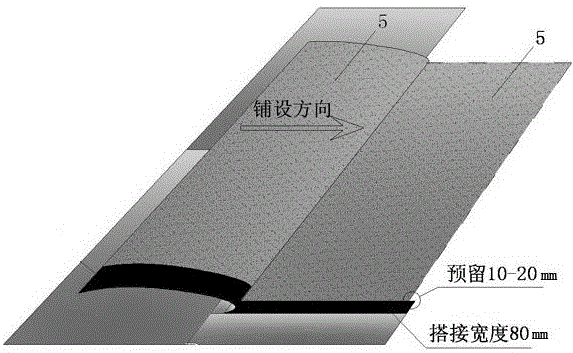

[0046] S2. Laying the coil:

[0047] S21. Laying the first coil:

[0048] Preparation of cement mortar: The cement mortar is prepared from 425R cement and redispersible instant adhesive powder. The weight ratio of 425R cement and redispersible instant adhesive powder is 1:0.005, and the water-cement ratio is 1:0.35.

[0049] The preparation method of the cement mortar is as follows: Weigh clean water according to the proportion, add the redispersible instant rubber powder into the clean water, stir while adding, and the stirring time is not less than 5 minutes, until the rubber powder is completely dissolved in t...

Embodiment 2

[0060] Example 2: The invention relates to a construction technique of wet laying of polymer self-adhesive waterproof membrane, which comprises the following steps:

[0061] S1. Base surface cleaning and wetting: clean the base surface to make the base surface flat, firm and clean, and fully wet the base surface with a sprayer, but there should be no clear water;

[0062] S2. Laying the coil:

[0063] S21. Laying the first coil:

[0064] Preparation of cement mortar: The cement mortar is prepared from 425R cement and redispersible instant adhesive powder. The weight ratio of 425R cement and redispersible instant adhesive powder is 1:0.005, and the water-cement ratio is 1:0.4.

[0065] The preparation method of the cement mortar is as follows: Weigh clean water according to the proportion, add the redispersible instant rubber powder into the clean water, stir while adding, and the stirring time is not less than 5 minutes, until the rubber powder is completely dissolved in th...

Embodiment 3

[0076] Example 3: The invention relates to a construction technique of wet laying of polymer self-adhesive waterproof membrane, which comprises the following steps:

[0077] S1. Base surface cleaning and wetting: clean the base surface to make the base surface flat, firm and clean, and fully wet the base surface with a sprayer, but there should be no clear water;

[0078] S2. Laying the coil:

[0079] S21. Laying the first coil:

[0080] Preparation of cement mortar: cement mortar is prepared from 425R cement and redispersible instant adhesive powder, the weight ratio of 425R cement and redispersible instant adhesive powder is 1:0.005, and the water-cement ratio is 1:0.36.

[0081] The preparation method of the cement mortar is as follows: Weigh clean water according to the proportion, add the redispersible instant rubber powder into the clean water, stir while adding, and the stirring time is not less than 5 minutes, until the rubber powder is completely dissolved in the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com