Combined embossing technology and equipment of polyvinyl chloride (PVC) sheet

A sheet and equipment technology, applied in the field of composite embossing of PVC sheets, can solve problems such as unguaranteed quality, complicated equipment, and increased production costs, and achieve the effects of saving manpower, reducing the rate of defective products, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

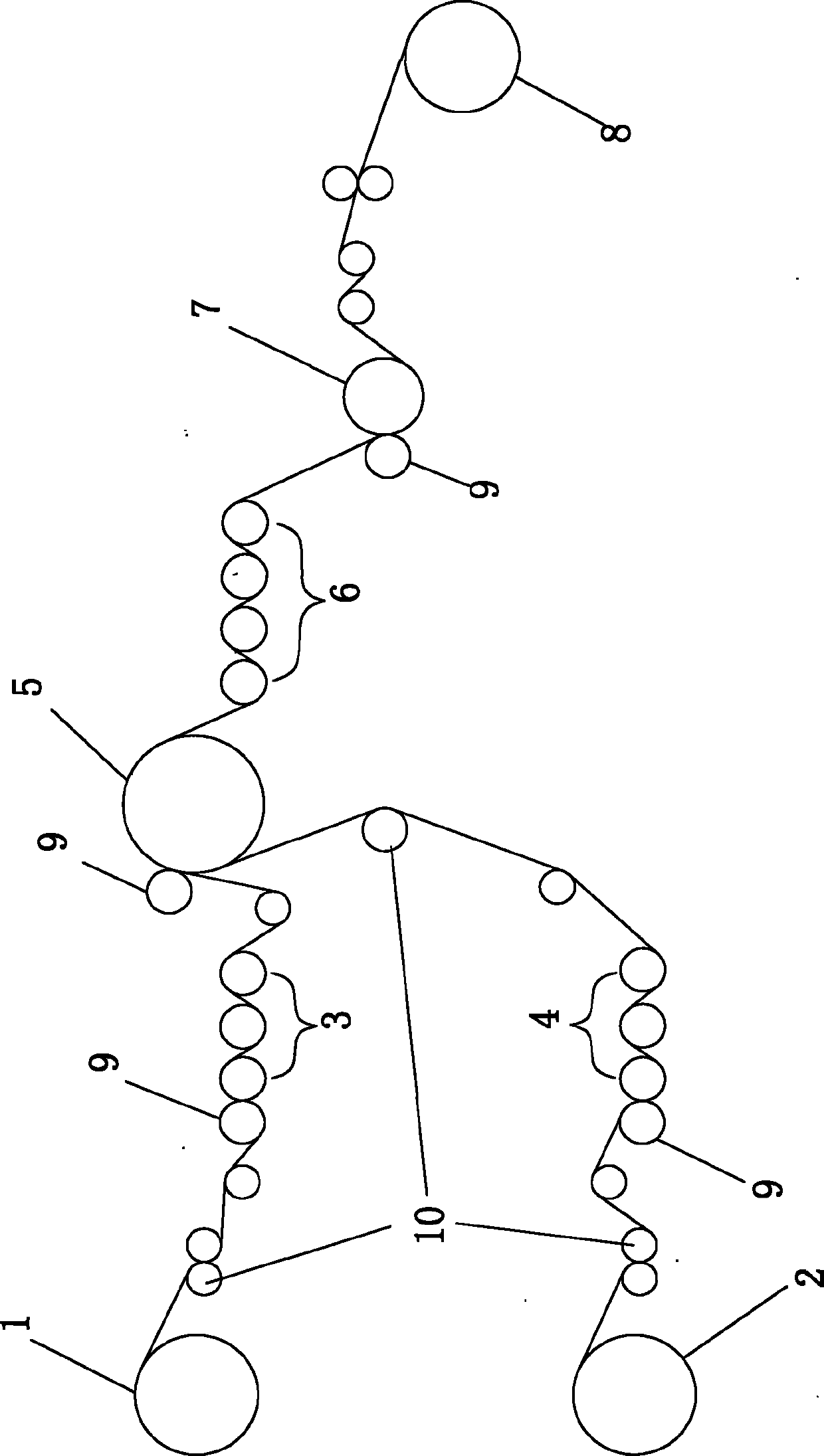

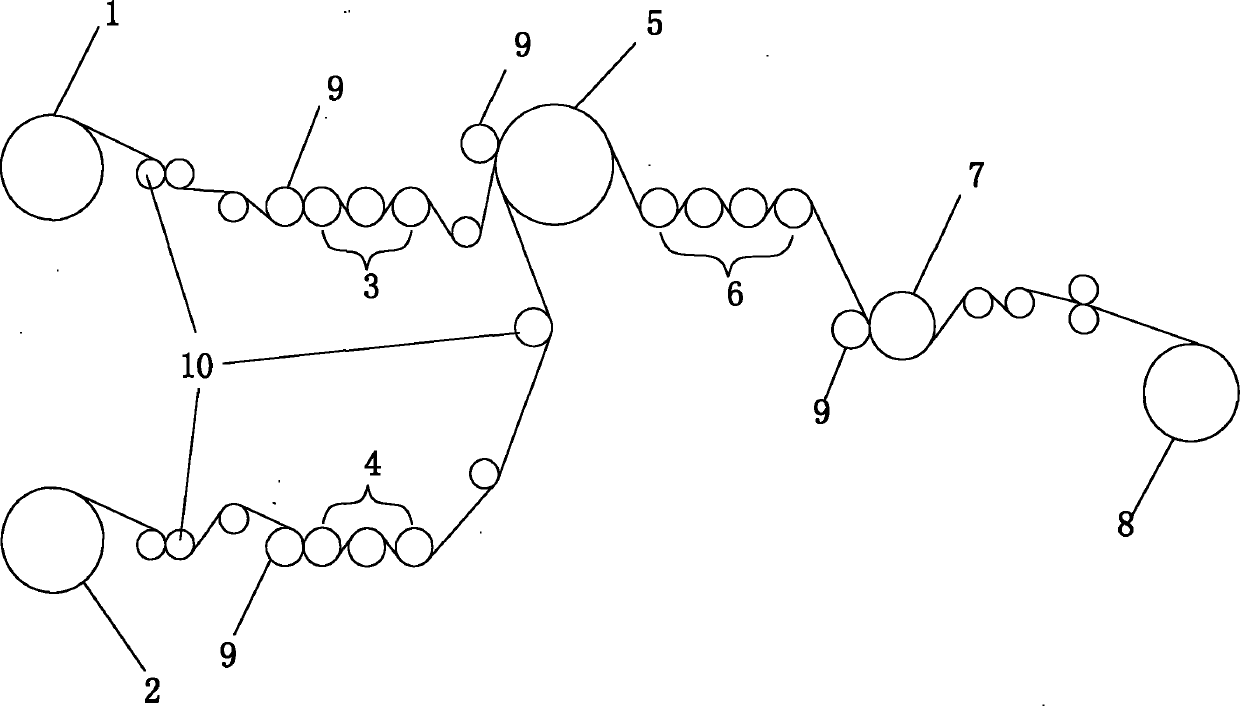

[0011] In this example, refer to figure 1 , the PVC sheet composite embossing equipment includes a facial mask unwinding mechanism 1, a base film unwinding mechanism 2 and a rewinding mechanism 8, the mask unwinding mechanism 1 is set as a facial mask preheating roller 3, and the base film unwinding mechanism 2. The bottom film preheating roller 4 is set at the back, and the first roller of the mask preheating roller 3 and the bottom film preheating roller 4 is provided with a rubber roller 9; the mask preheating roller 3 and the bottom film preheating roller The back of the hot roller wheel 4 is set as a compound vat 5, together with the compound vat 5, a rubber roller 9 is arranged, and the back of the compound vat 5 is provided with a delivery wheel 6; the back of the delivery wheel 6 is set as an embossing roller 7, and an embossing roller 7 is provided with rubber roller 9 together, and the back of embossing roller 7 is winding mechanism 8.

[0012] Among them, the prehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com