Ultrafiltration and microfiltration membrane assembly for tubular composite membrane

A composite membrane, microfiltration membrane technology, applied in ultrafiltration, membrane technology, semi-permeable membrane separation and other directions, can solve problems such as engineering blockage and failure, and achieve the effect of enhanced filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

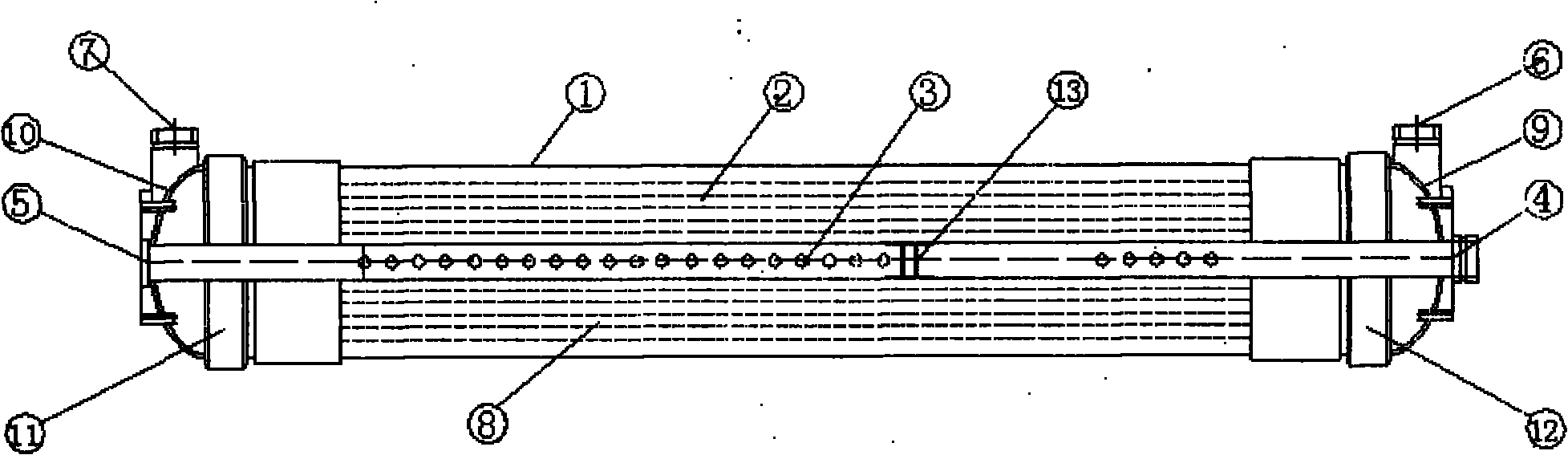

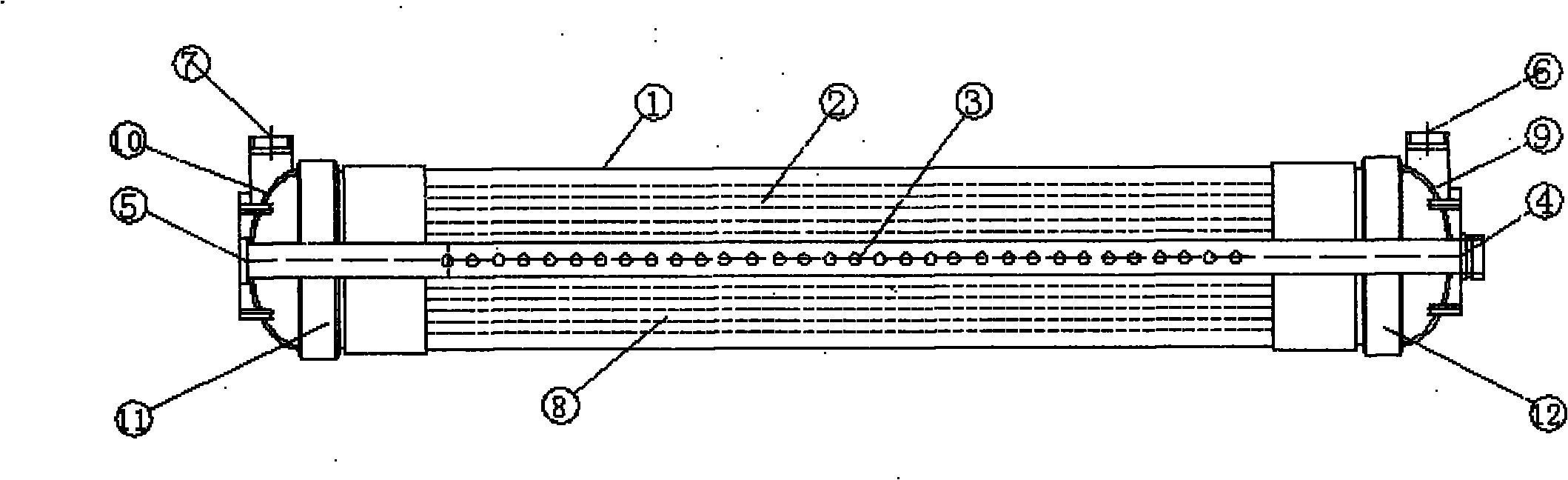

[0013] It comprises a tubular casing (1) that is symmetrically provided with elliptical heads (9), (10) fastened by cassettes (11), (12) at both ends; two elliptical heads (9), (10) The center runs through a center pipe with holes (3); the middle section of the center pipe with holes (3) is provided with a plug (8); the concentrated water outlet (4) and the raw water inlet ( 5), clean water outlets (6), (7); the circumference of the central tube with holes (3) is provided with multi-layer membrane tubes (2) with different inner and outer diameters. The tubular casing (1) is made of PVC or fiberglass. The inner diameter of the membrane tube (2) is Φ5-10mm; the outer diameter is Φ10-20mm. The membrane tube (2) is composed of a base membrane and a surface membrane; the base membrane material is sintered by ultra-high molecular weight polyethylene; the surface membrane filter layer material is PVDF, PAN, and PVA.

[0014] There are two different filtering methods, cross-flow fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com