Patents

Literature

422 results about "Coated membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A single or double lipid bilayer with any of several different proteinaceous coats that can associate with membranes. Membrane coats include those formed by clathrin plus an adaptor complex, the COPI and COPII complexes. [GOC:jid]

Timed pulsatile drug delivery systems

A pharmaceutical dosage form such as a capsule capable of delivering therapeutic agents into the body in a time-controlled or position-controlled pulsatile release fashion, is composed of a multitude of multicoated particulates (beads, pellets, granules, etc.) made of one or more populations of beads. Each of these beads except an immediate release bead has at least two coated membrane barriers. One of the membrane barriers is composed of an enteric polymer while the second membrane barrier is composed of a mixture of water insoluble polymer and an enteric polymer. The composition and the thickness of the polymeric membrane barriers determine the lag time and duration of drug release from each of the bead populations. Optionally, an organic acid containing intermediate membrane may be applied for further modifying the lag time and / or the duration of drug release. The pulsatile delivery may comprise one or more pulses to provide a plasma concentration-time profile for a therapeutic agent, predicted based on both its pharmaco-kinetic and pharmaco-dynamic considerations and in vitro / in vivo correlations.

Owner:ADARE PHARM INC

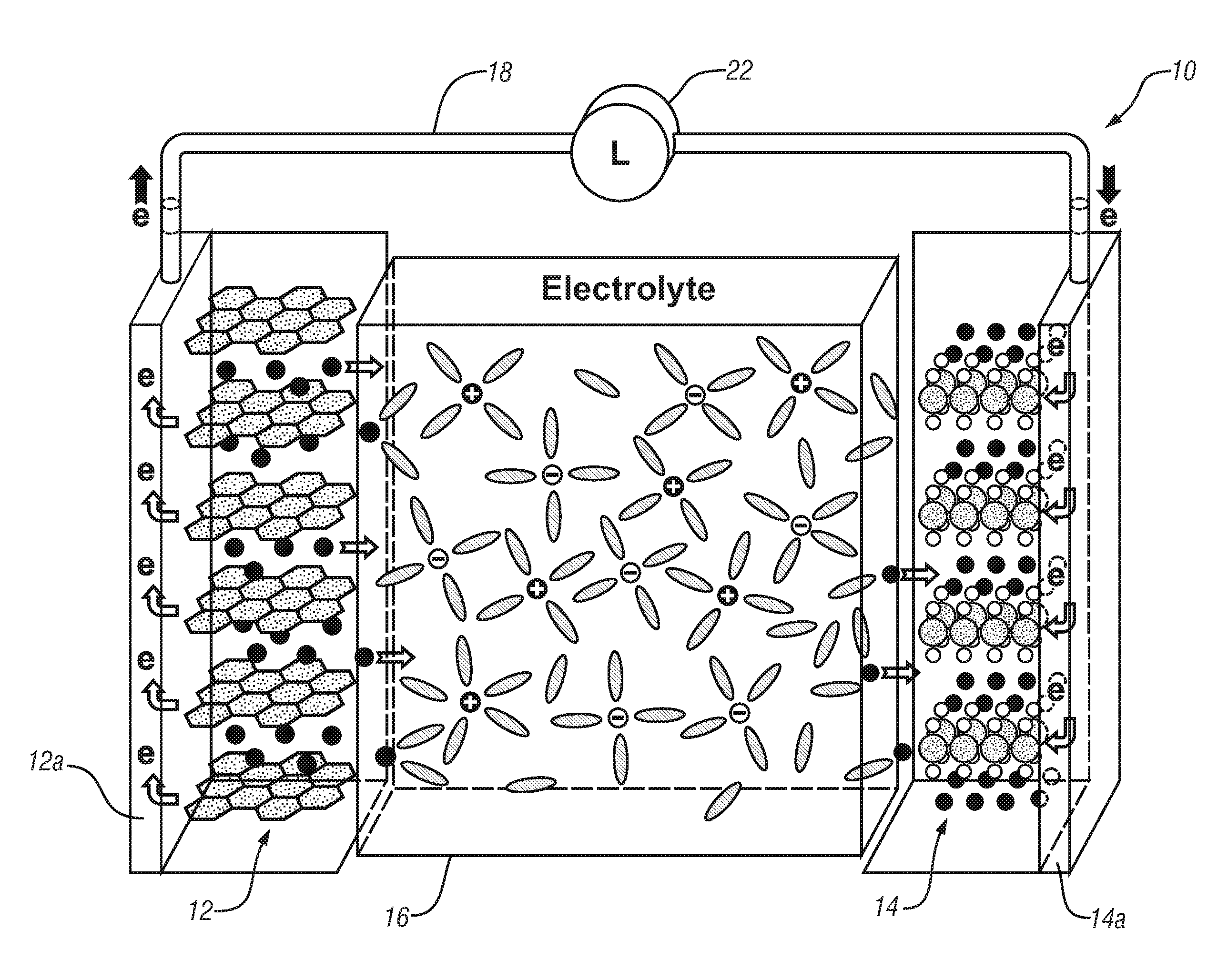

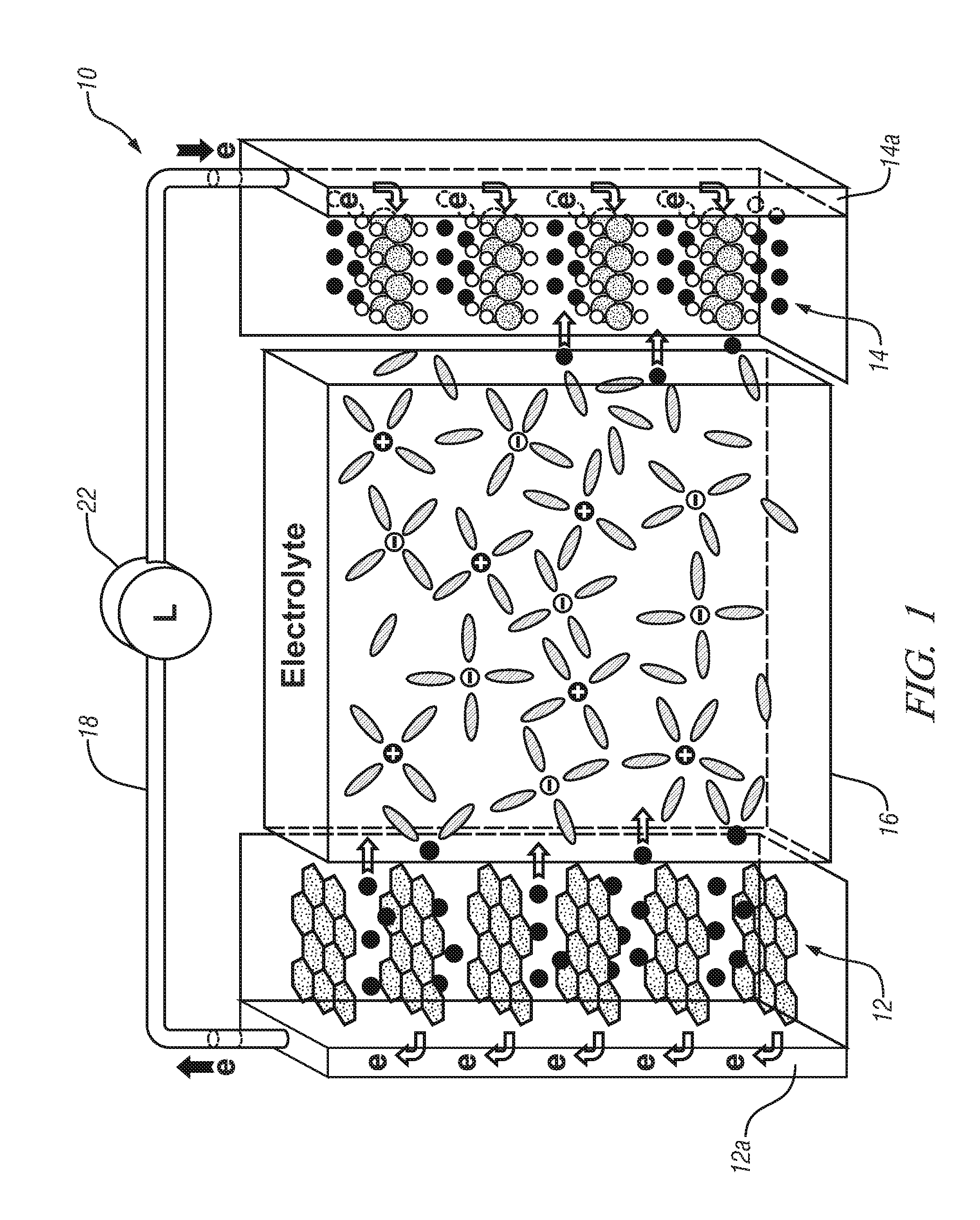

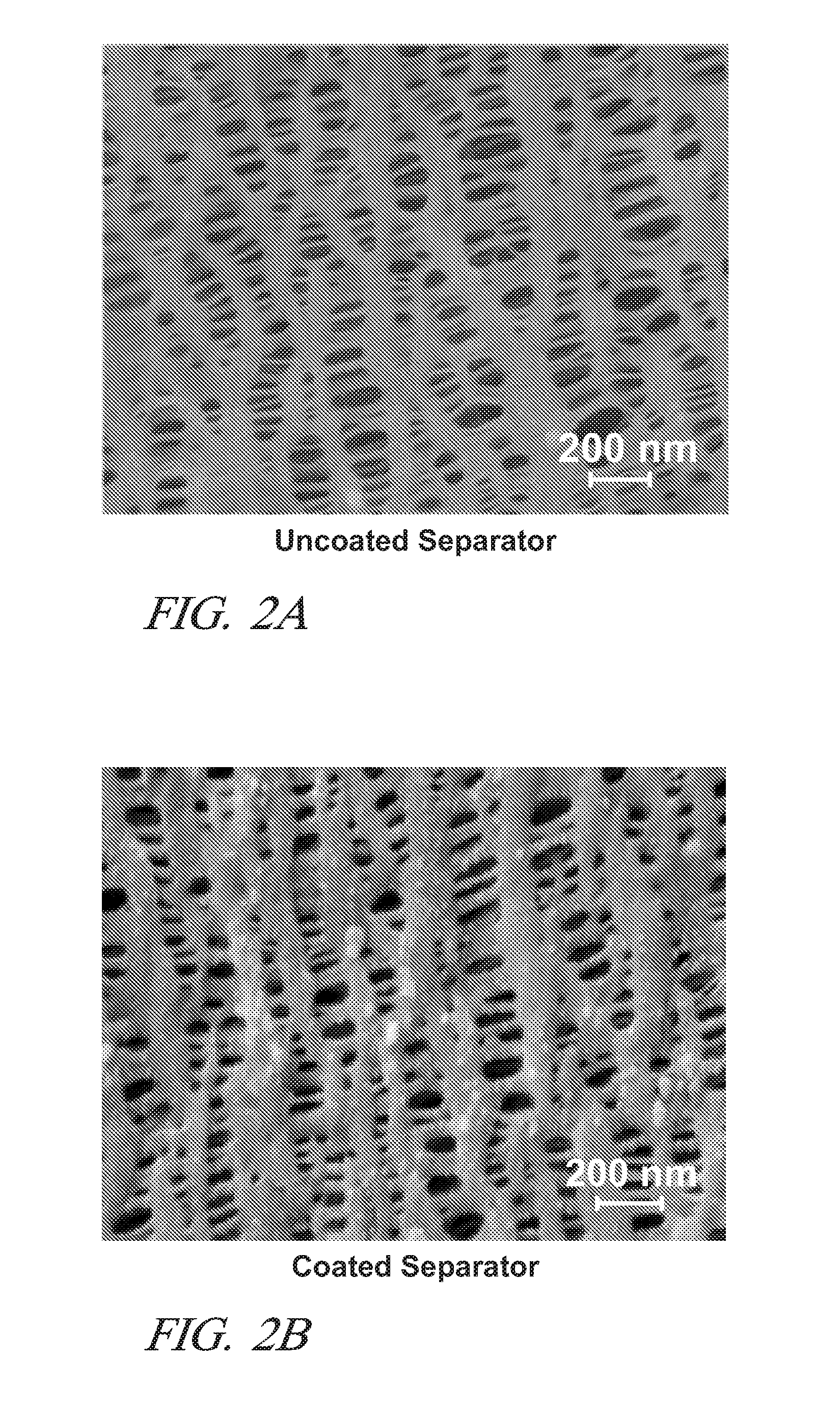

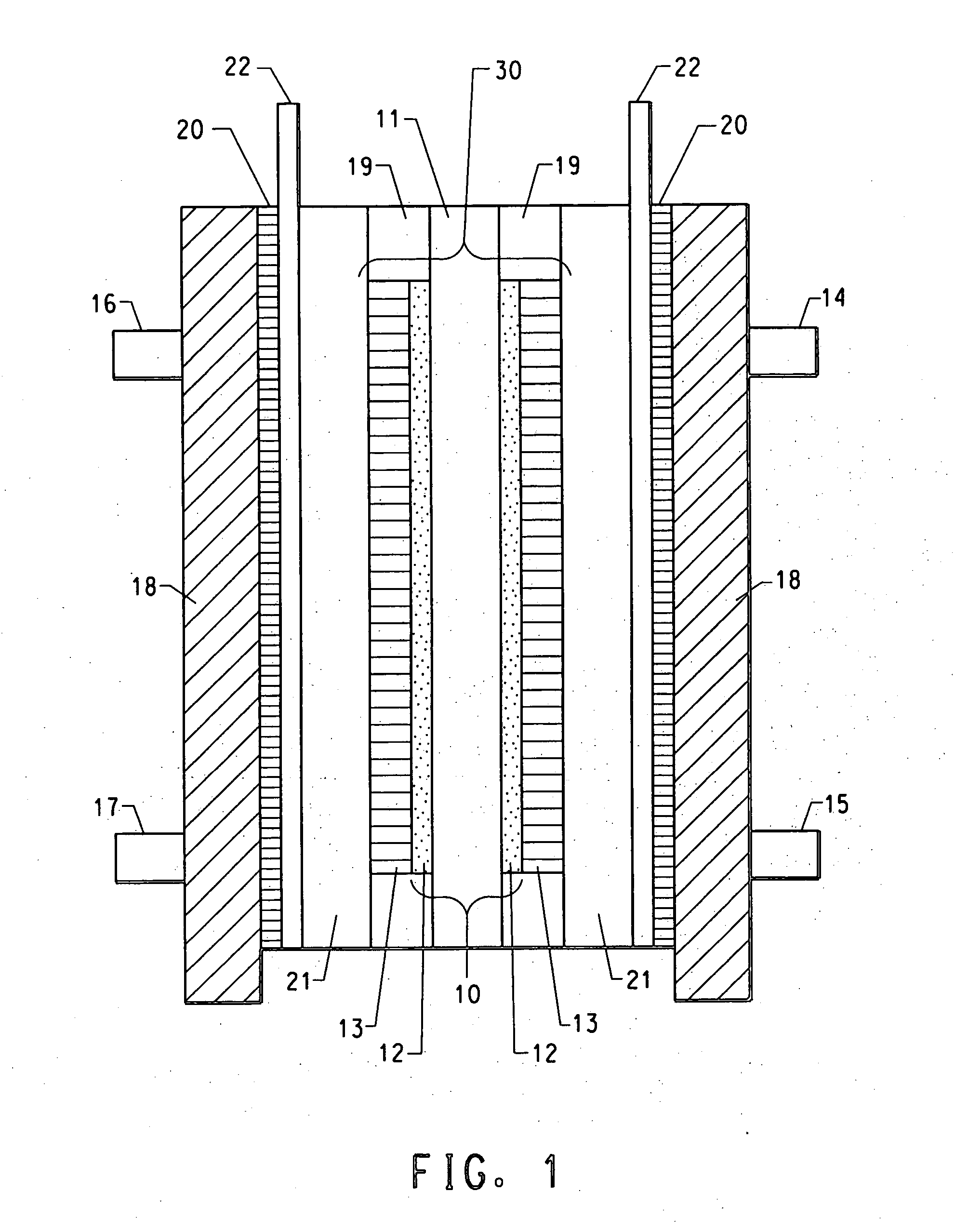

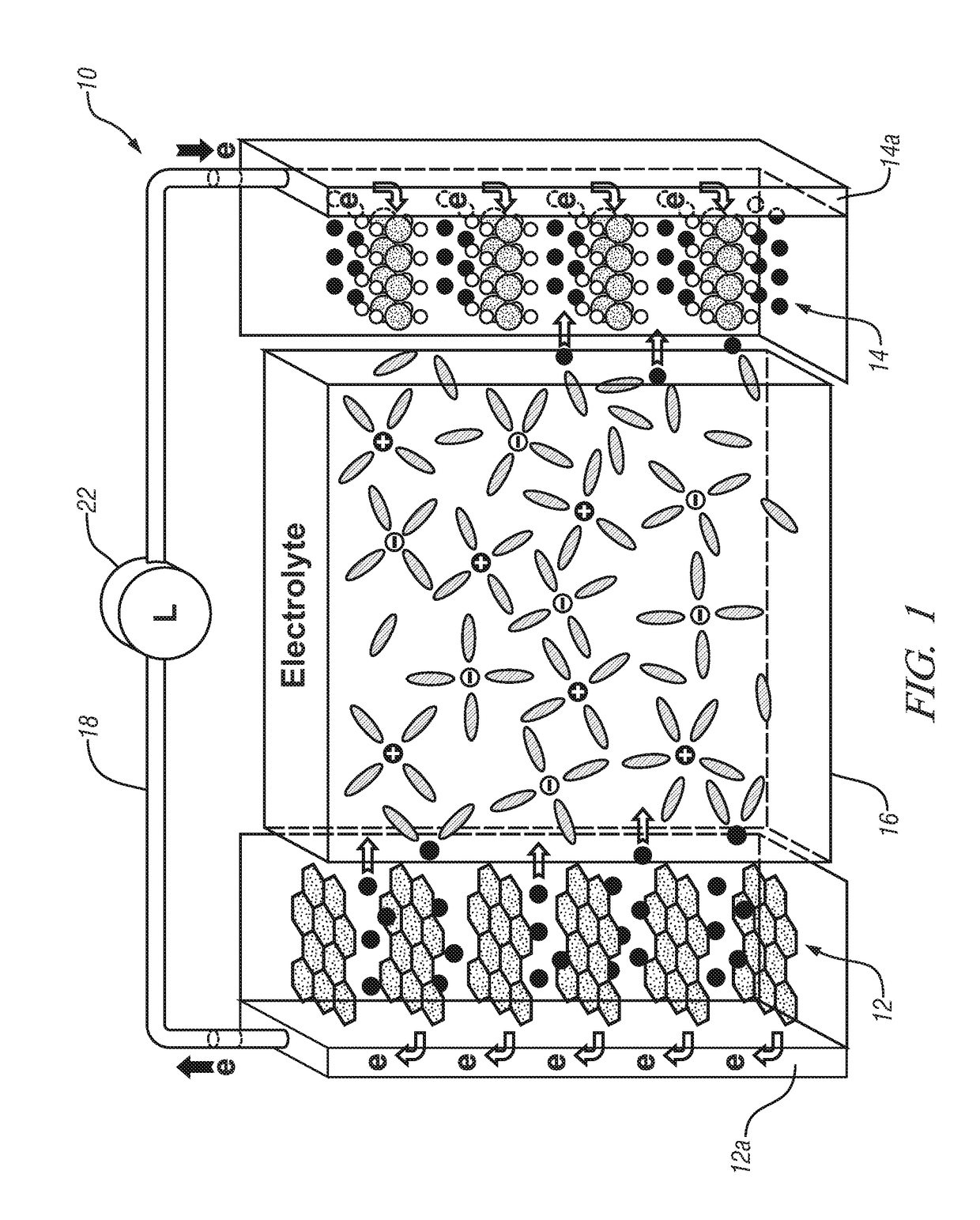

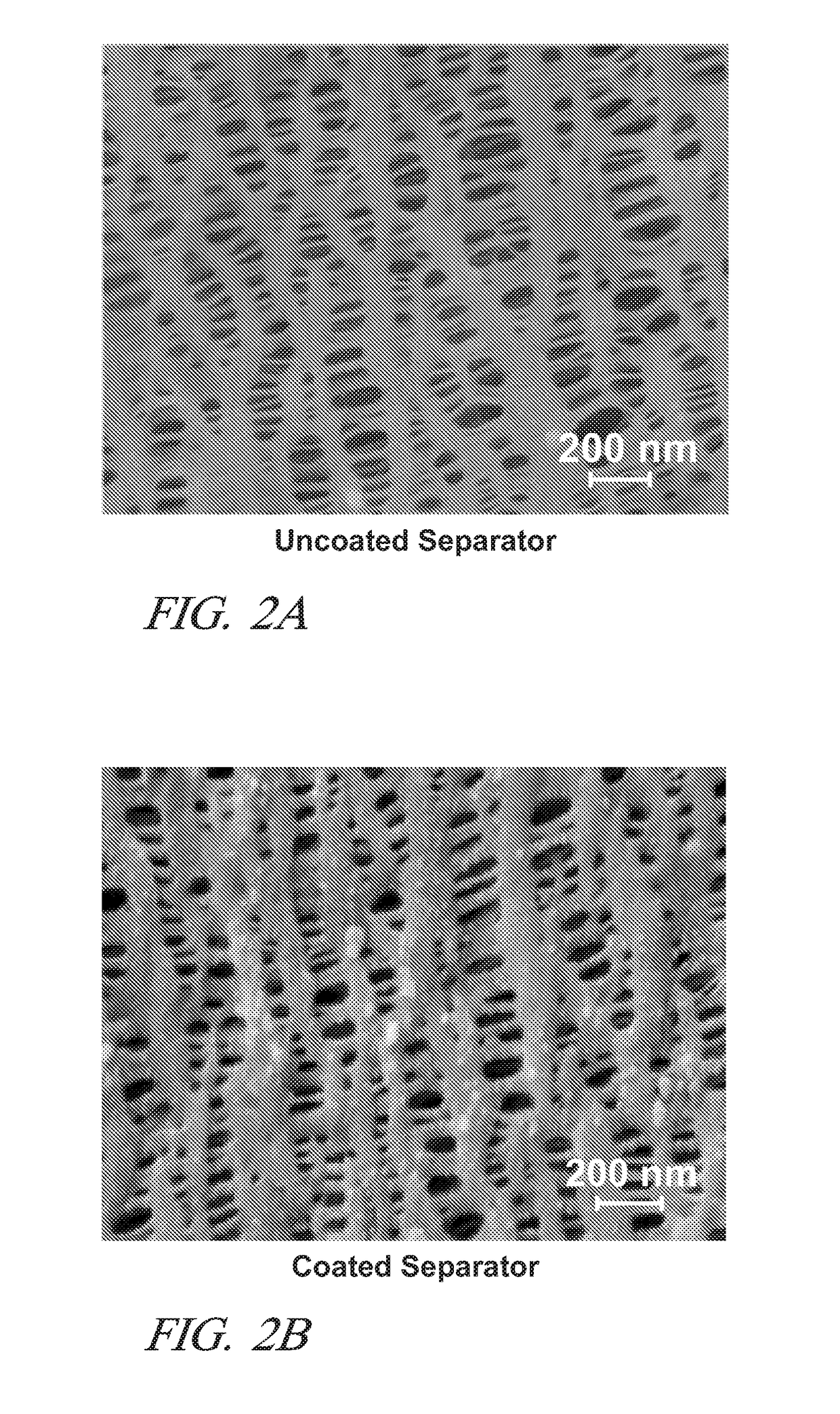

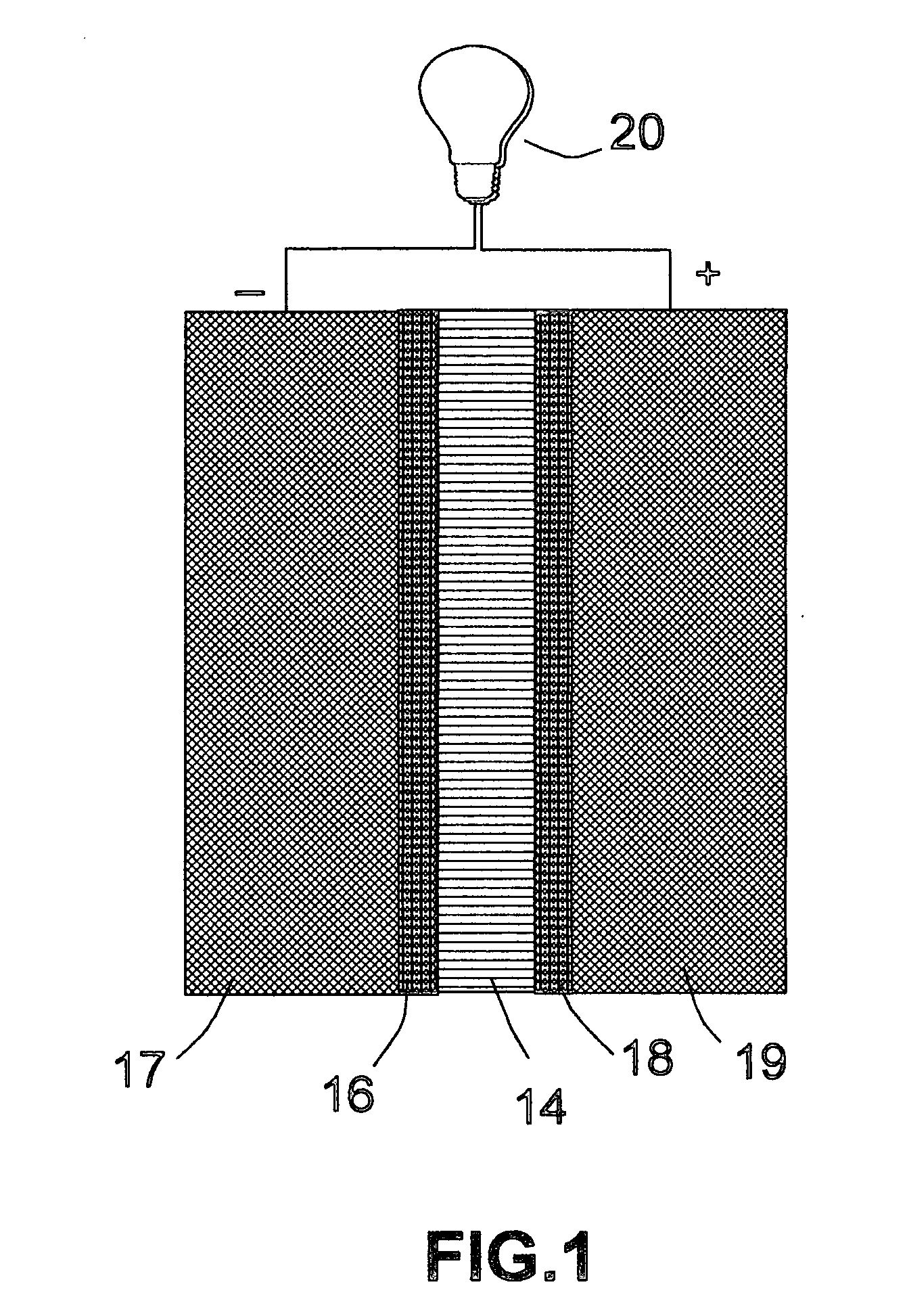

Lithium-ion batteries with coated separators

ActiveUS20110200863A1Low environmental impactThermal conductivityCell seperators/membranes/diaphragms/spacersLi-accumulatorsCoated membraneGas phase

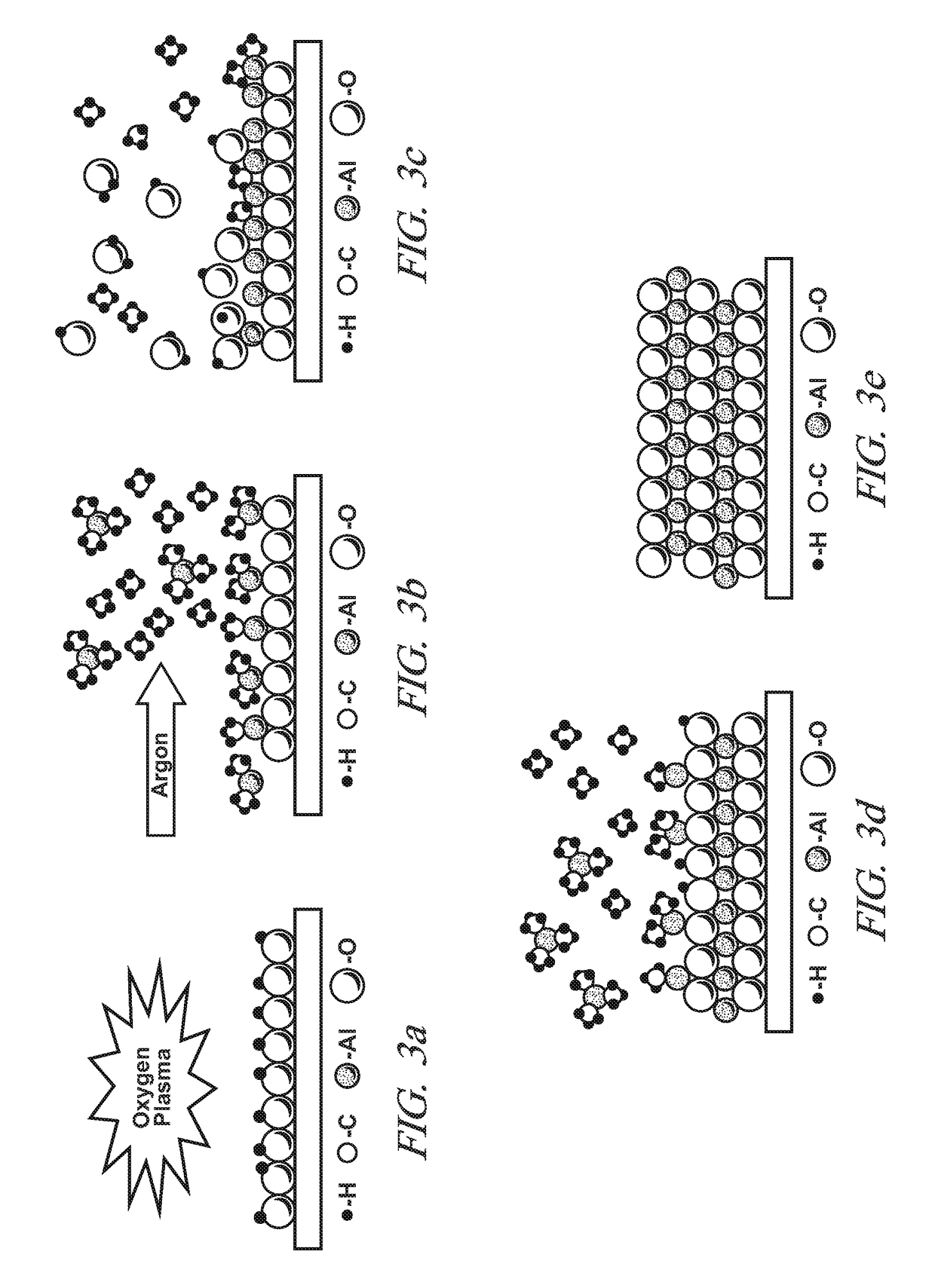

A porous polymer sheet or membrane is provided with a thin coating of an electrically non-conductive ceramic composition and the coating conforms to all surfaces, including the pore surfaces, of the membrane. Such a coated membrane serves well, for example, as an intra-cell separator in a lithium ion battery. The coating increases the mechanical properties and thermal stability of the separator in battery operation and retains electrolyte. The coating may be formed by a two-step vapor-phase process in which atoms of one or more metals such as aluminum, calcium, magnesium, titanium, silicon and / or zirconium are deposited in a conformal layer on a workpiece surface. The metal atoms may then be reacted with ammonia, carbon dioxide, and or water to form their respective non-conductive nitrides, carbides, and / or oxides on the surface. The two-step process is repeated as necessary to obtain a ceramic material coating of desired thickness.

Owner:GM GLOBAL TECH OPERATIONS LLC

Timed pulsatile drug delivery systems

A pharmaceutical dosage form such as a capsule capable of delivering therapeutic agents into the body in a time-controlled or position-controlled pulsatile release fashion, is composed of a multitude of multicoated particulates (beads, pellets, granules, etc.) made of one or more populations of beads. Each of these beads except an immediate release bead has at least two coated membrane barriers. One of the membrane barriers is composed of an enteric polymer while the second membrane barrier is composed of a mixture of water insoluble polymer and an enteric polymer. The composition and the thickness of the polymeric membrane barriers determine the lag time and duration of drug release from each of the bead populations. Optionally, an organic acid containing intermediate membrane may be applied for further modifying the lag time and / or the duration of drug release. The pulsatile delivery may comprise one or more pulses to provide a plasma concentration-time profile for a therapeutic agent, predicted based on both its pharmaco-kinetic and pharmaco-dynamic considerations and in vitro / in vivo correlations.

Owner:ADARE PHARM INC

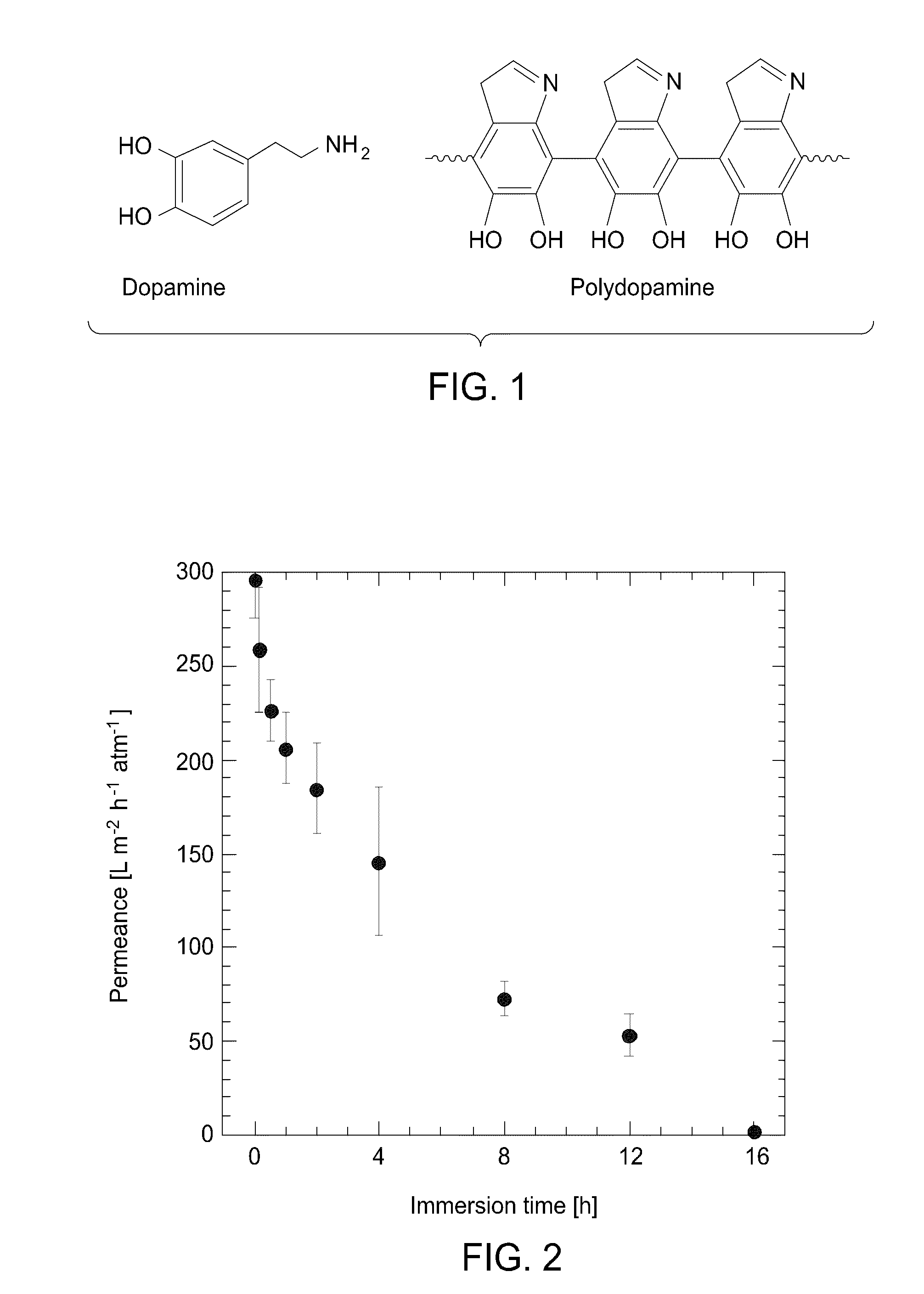

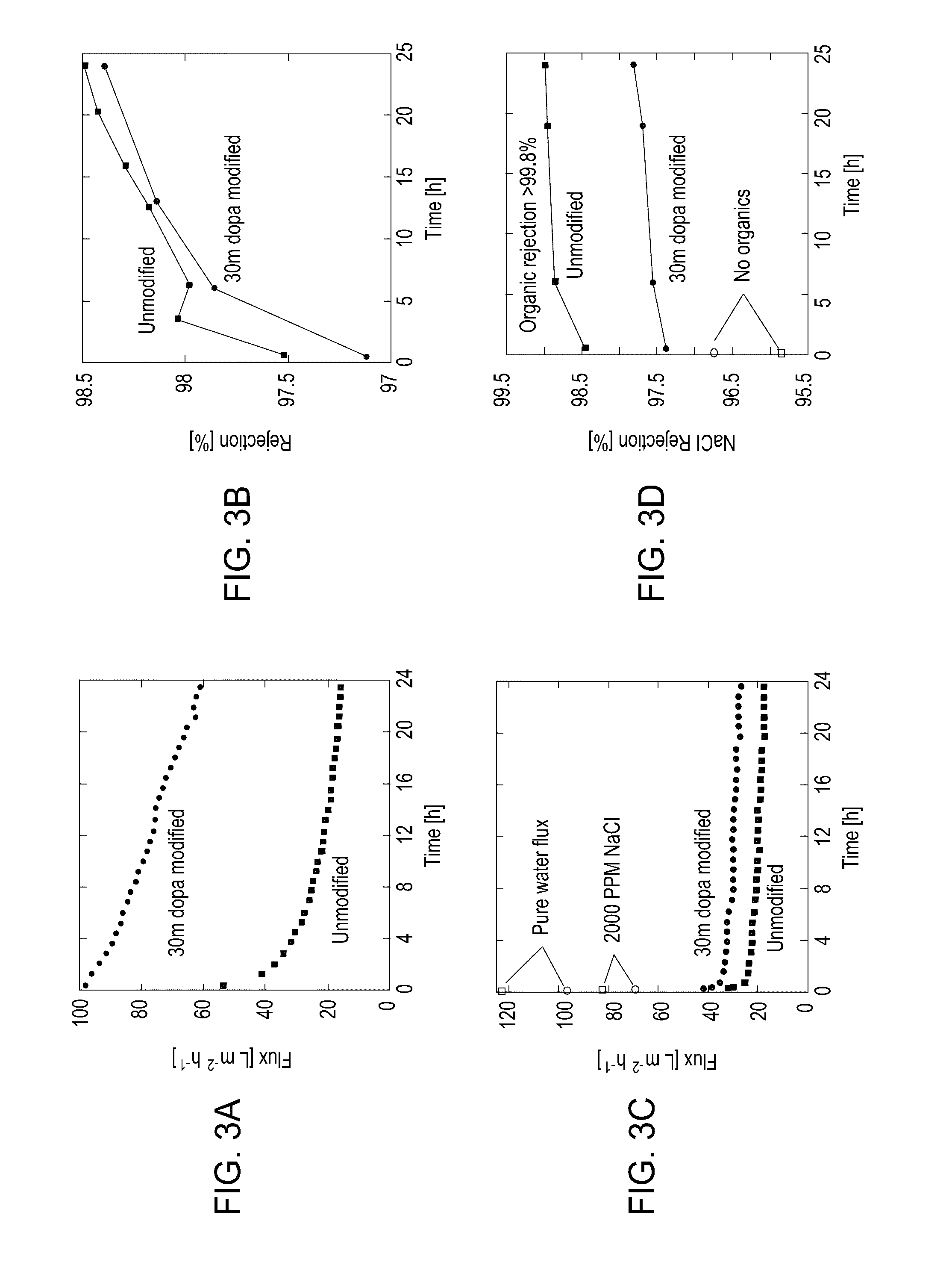

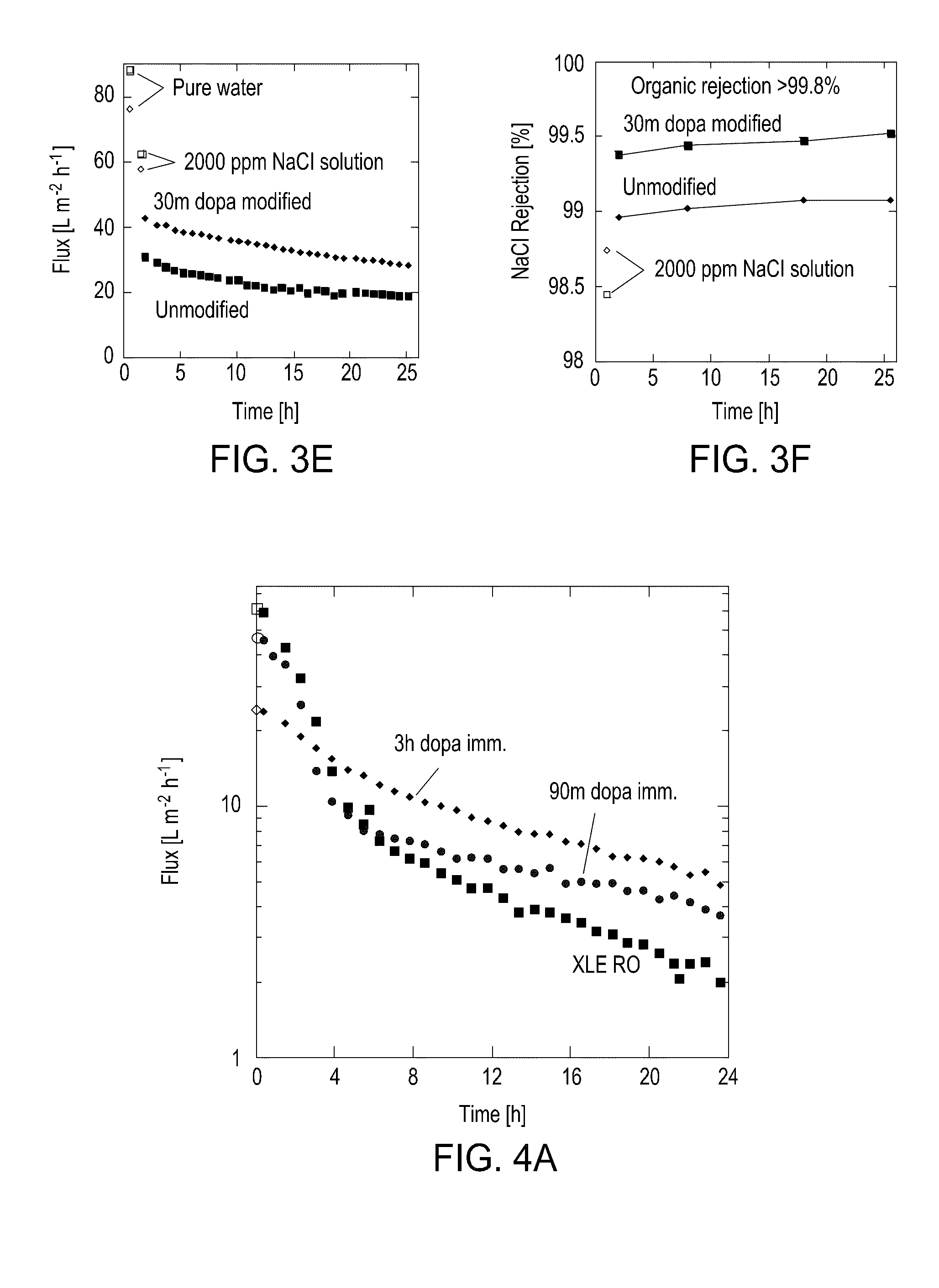

Water purification membranes with improved fouling resistance

ActiveUS20100051538A1Increase membrane hydrophilicityMitigation of membrane foulingMembranesSemi-permeable membranesCoated membraneAir purification

The present invention includes methods and compositions for liquid separation and water purification. The present invention includes a purification membrane having a polymer matrix purification membrane that has been treated with dopamine to form a polydopamine coated membrane with a high water flux and a high hydrophilicity.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

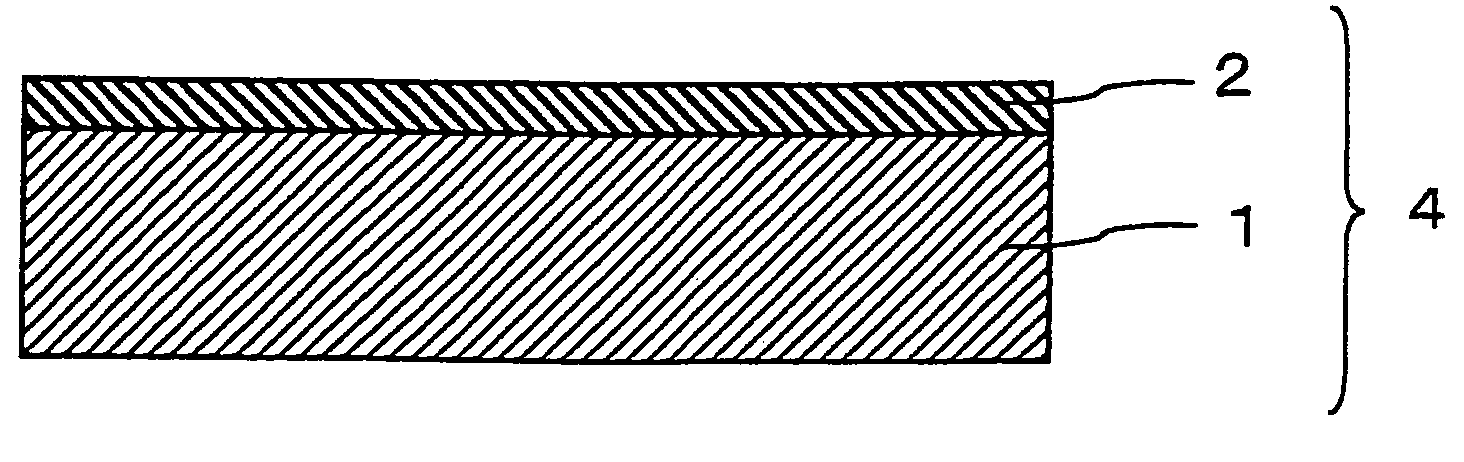

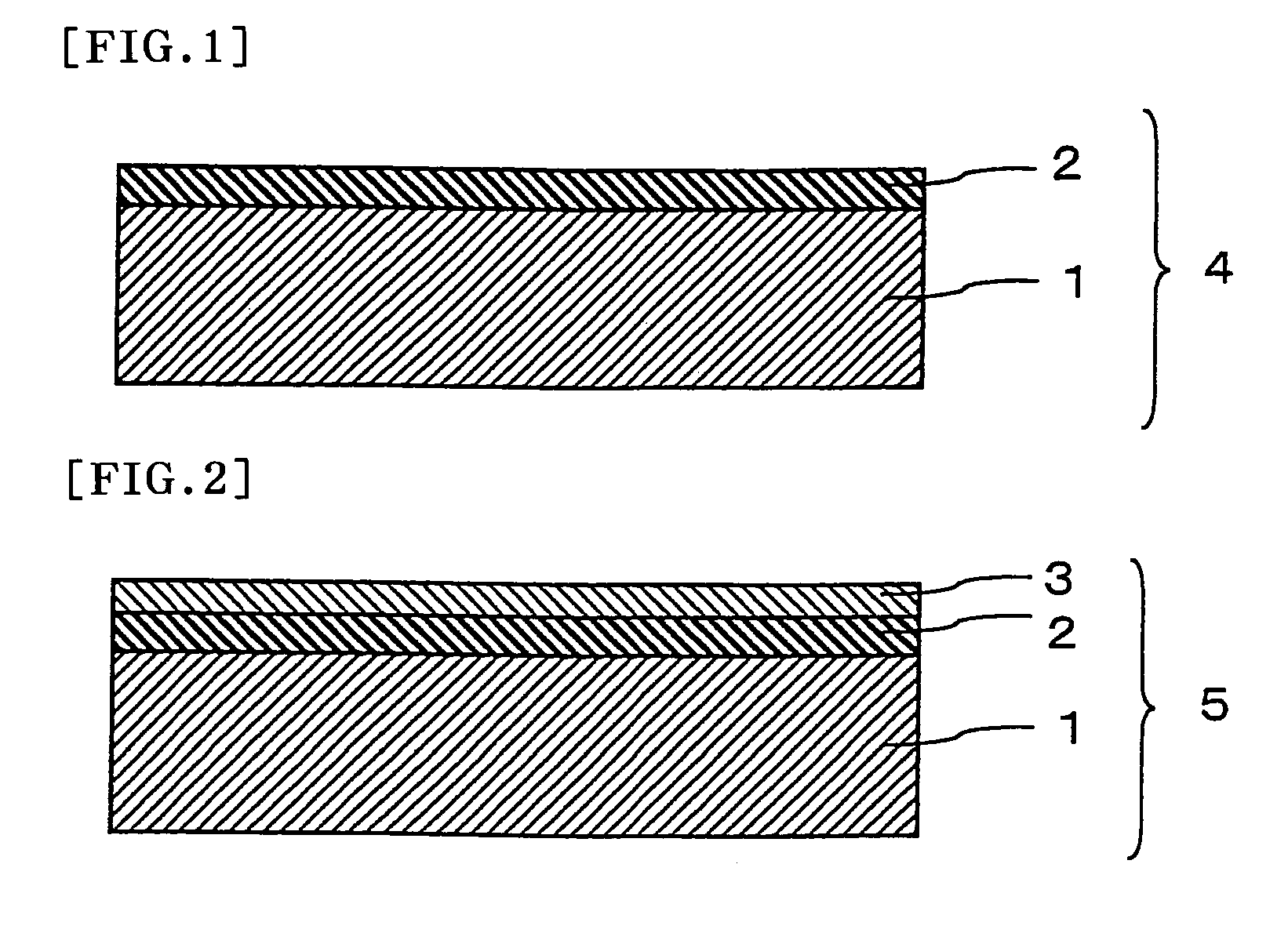

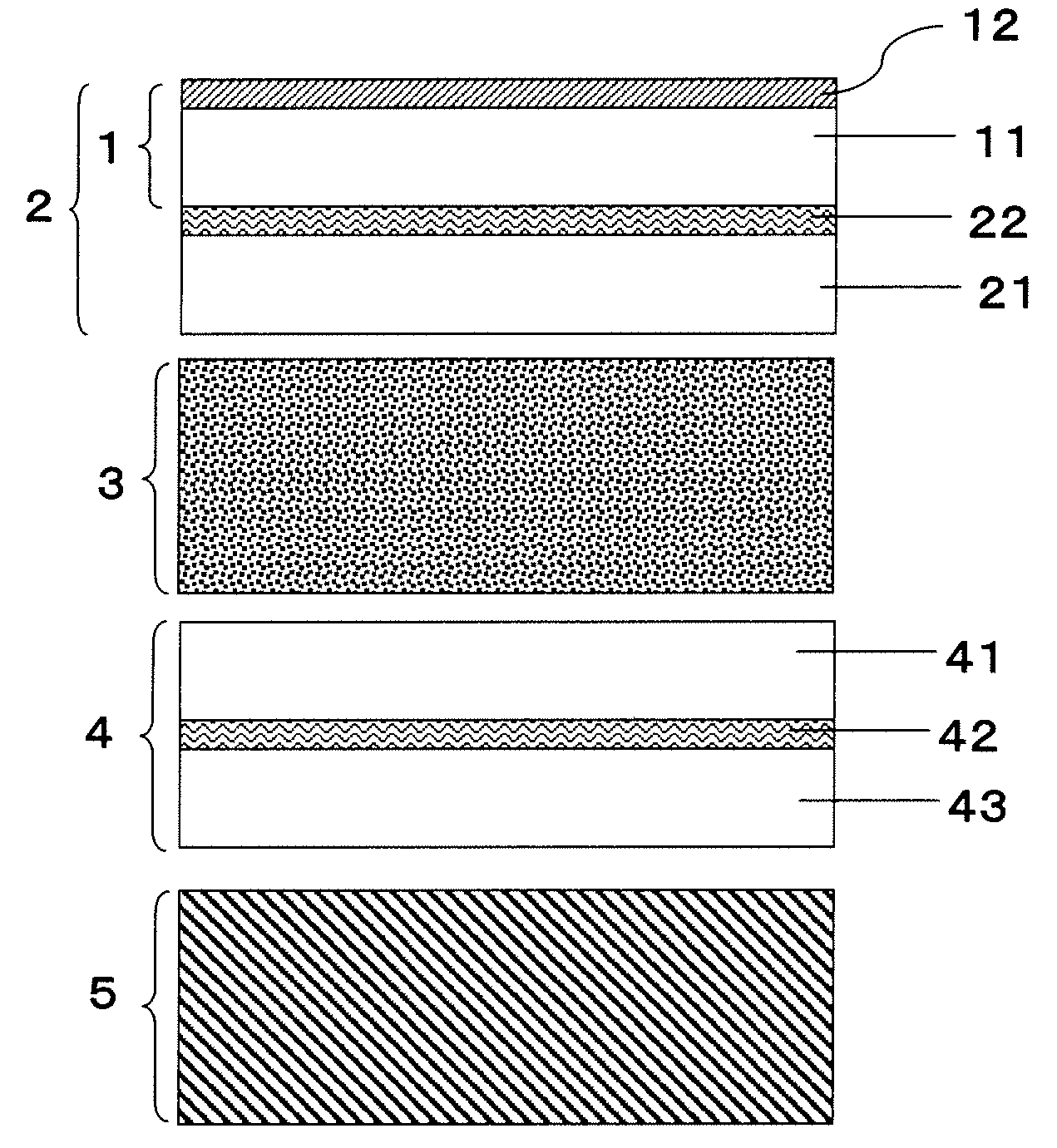

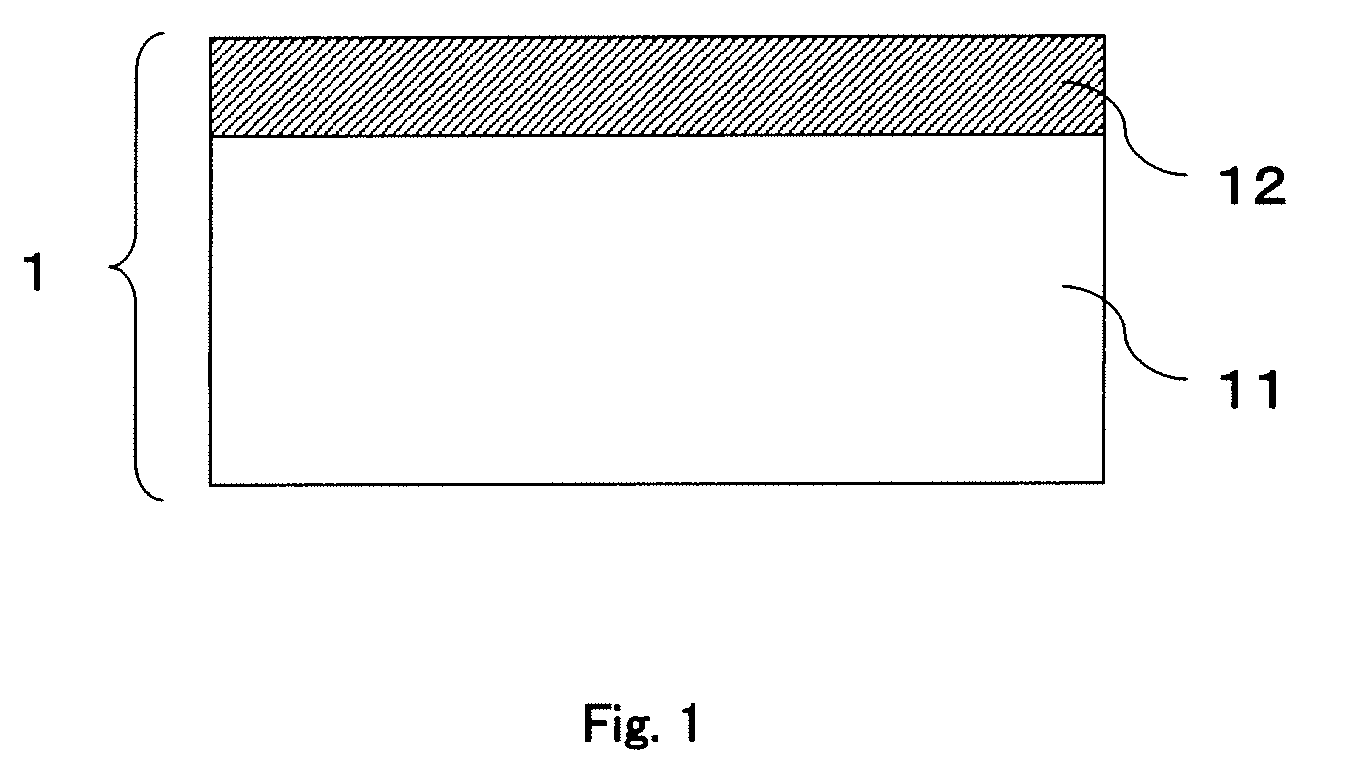

Hard coat film, antireflection hard coat film, optical element and image display

InactiveUS20070178297A1Suppress cracksCurl suppressionSynthetic resin layered productsCellulosic plastic layered productsOptoelectronicsHardness

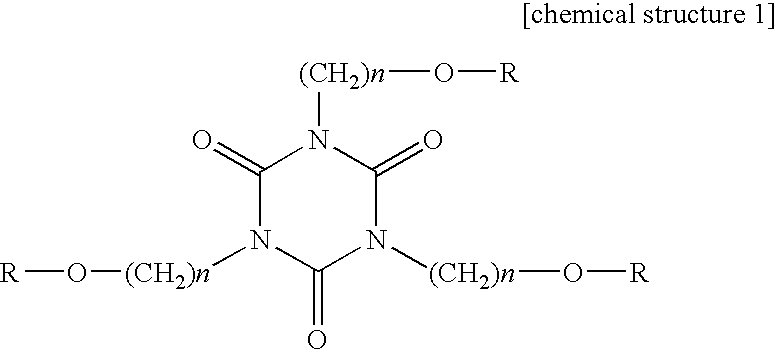

A hard coat film of the present invention comprises a hard coat layer, which is a cured coat layer, provided on at least one side of a transparent plastic film substrate, wherein a hard coat layer forming material comprises urethane acrylate (A); isocyanuric acid acrylate (B) and inorganic ultrafine particles (C), and has a high hardness and suppresses curling due to cracking and cure shrinkage.

Owner:NITTO DENKO CORP

Coated tool of cemented carbide

InactiveUS6187421B1Improve propertiesImprove tool lifePigmenting treatmentOther chemical processesCoated membraneCarbide coating

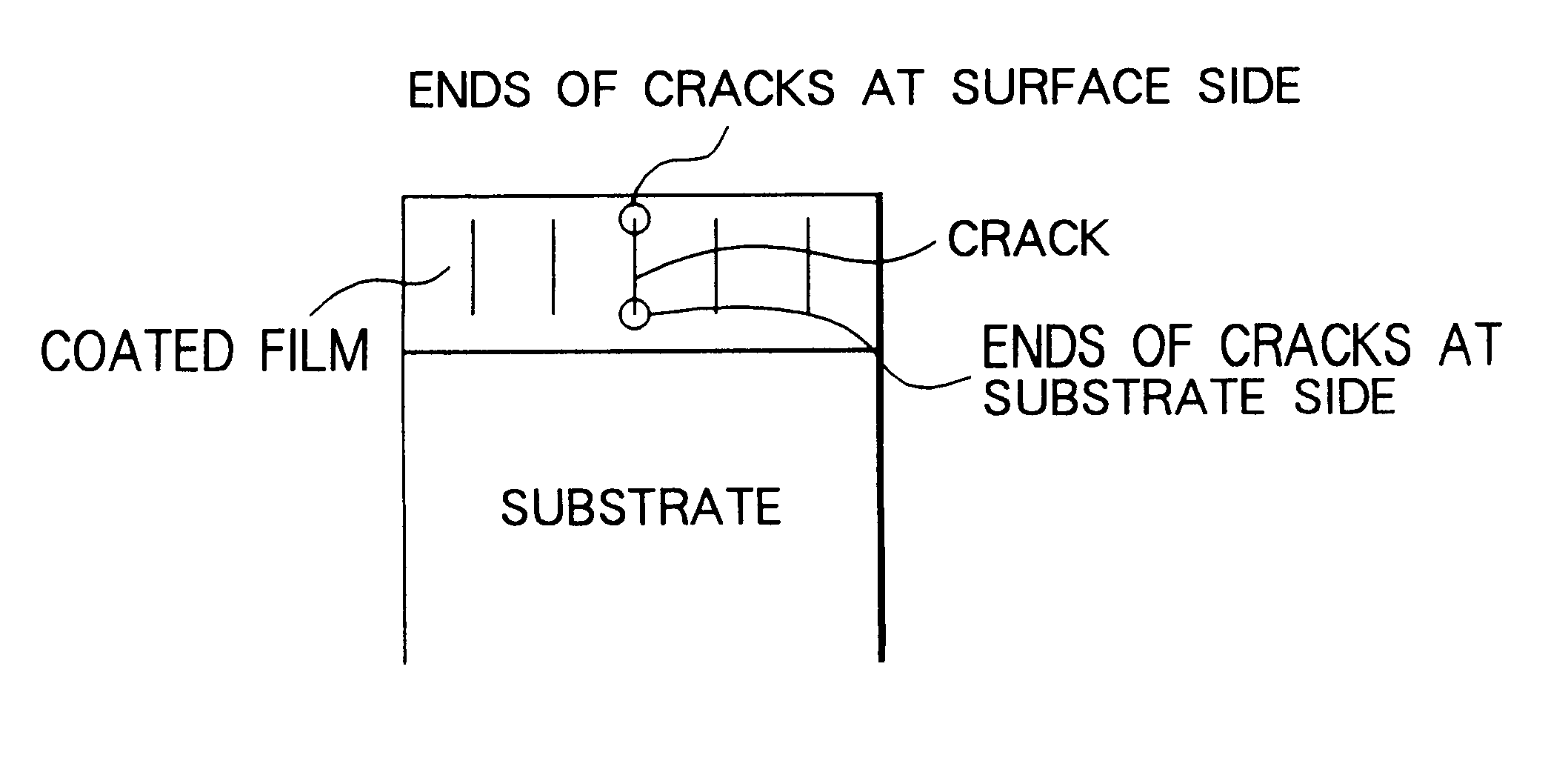

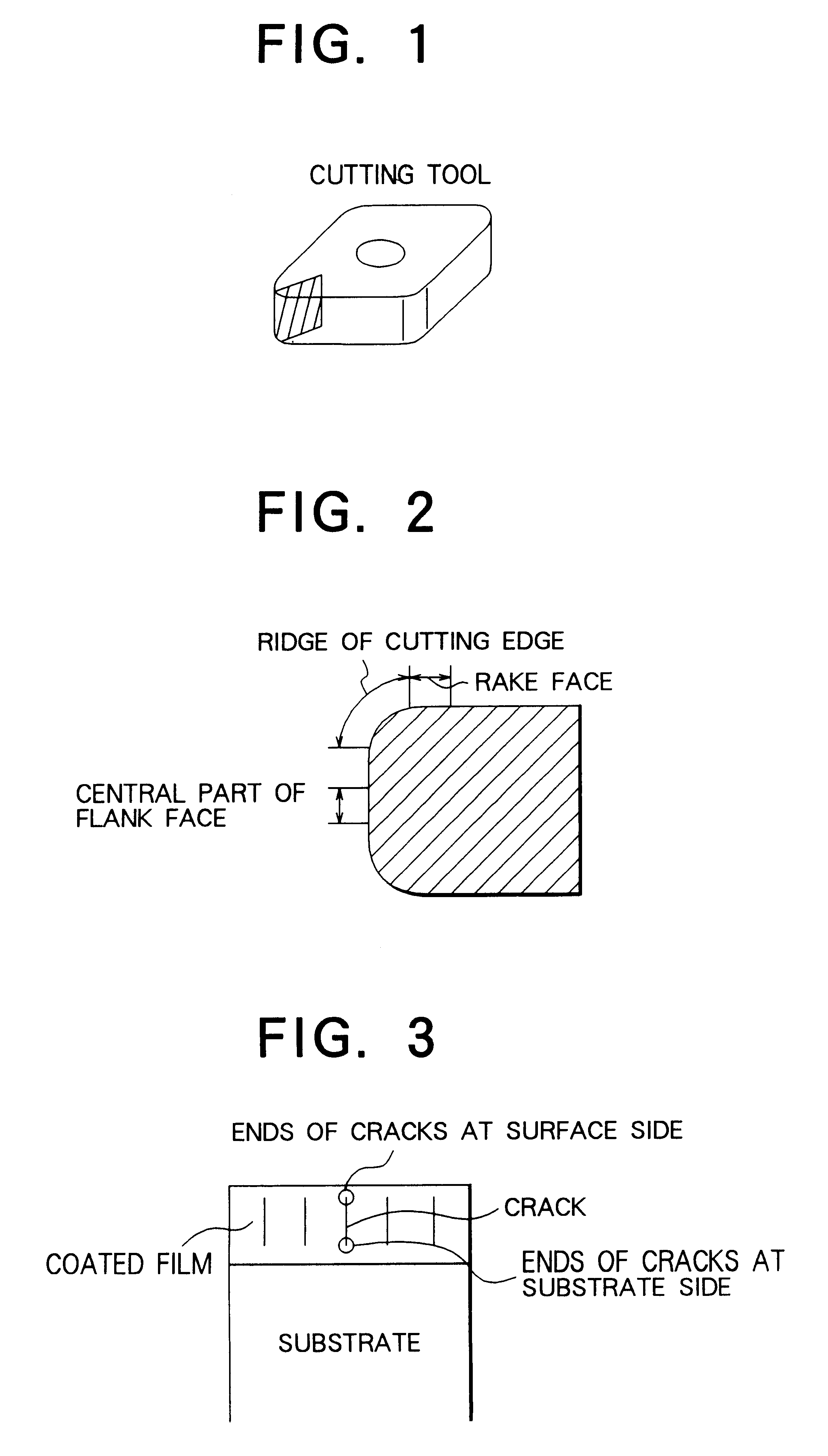

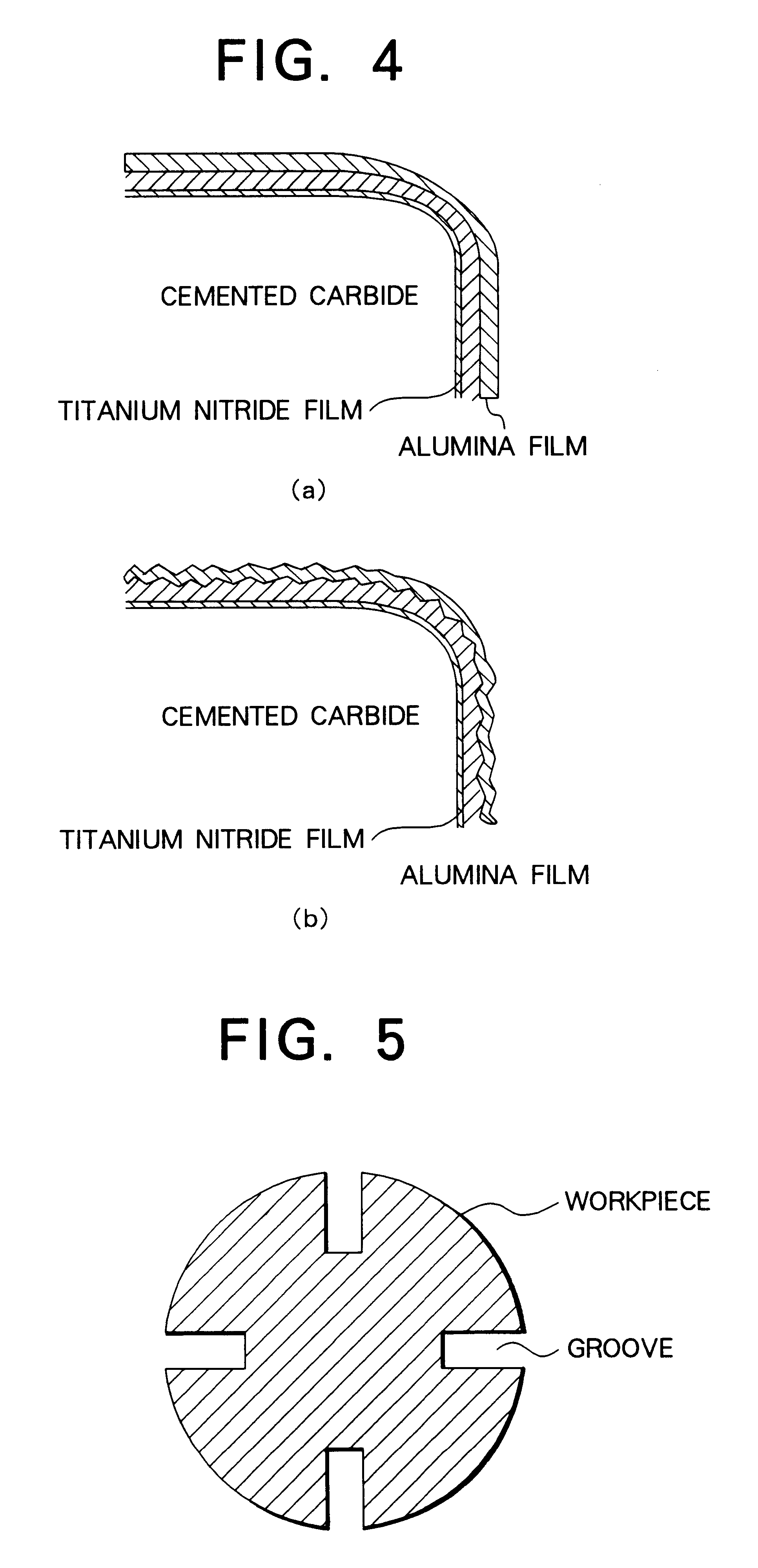

The principal object of the present invention is to provide a coated cemented carbide tool whose both properties of breakage resistance and wear resistance are improved and whose life is lengthened.The present invention has been made to achieve this object and is related with a coated cemented carbide cutting tool comprising a substrate consisting of a matrix of WC and a binder phase of an iron group metal and a plurality of coated layers provided on a surface of the substrate, in which (a) an innermost layer, adjacent to the substrate, of the coated layers consists essentially of titanium nitride having a thickness of 0.1 to 3 mum, (b) on a mirror-polished cross-sectional microstructure of the said tool, an average crack interval in the coated film on a ridge of a cutting edge and / or rake face is smaller than an average crack interval in the coated layer on a flank face, (c) at least 50% of the cracks in the coated film on the said ridge of the cutting edge and / or rake face have ends of the cracks in the said innermost titanium nitride layer, in a layer above the titanium nitride layer or in an interface between these layers and (d) an average crack length in the coated film on the said ridge of the cutting edge and / or rake face is shorter than an average film thickness on the flank face.According to the present invention, quantitatively specifying the crack intervals and positions of the ends of the cracks in the coated layer results in excellent breakage resistance as well as wear resistance.

Owner:SUMITOMO ELECTRIC IND LTD

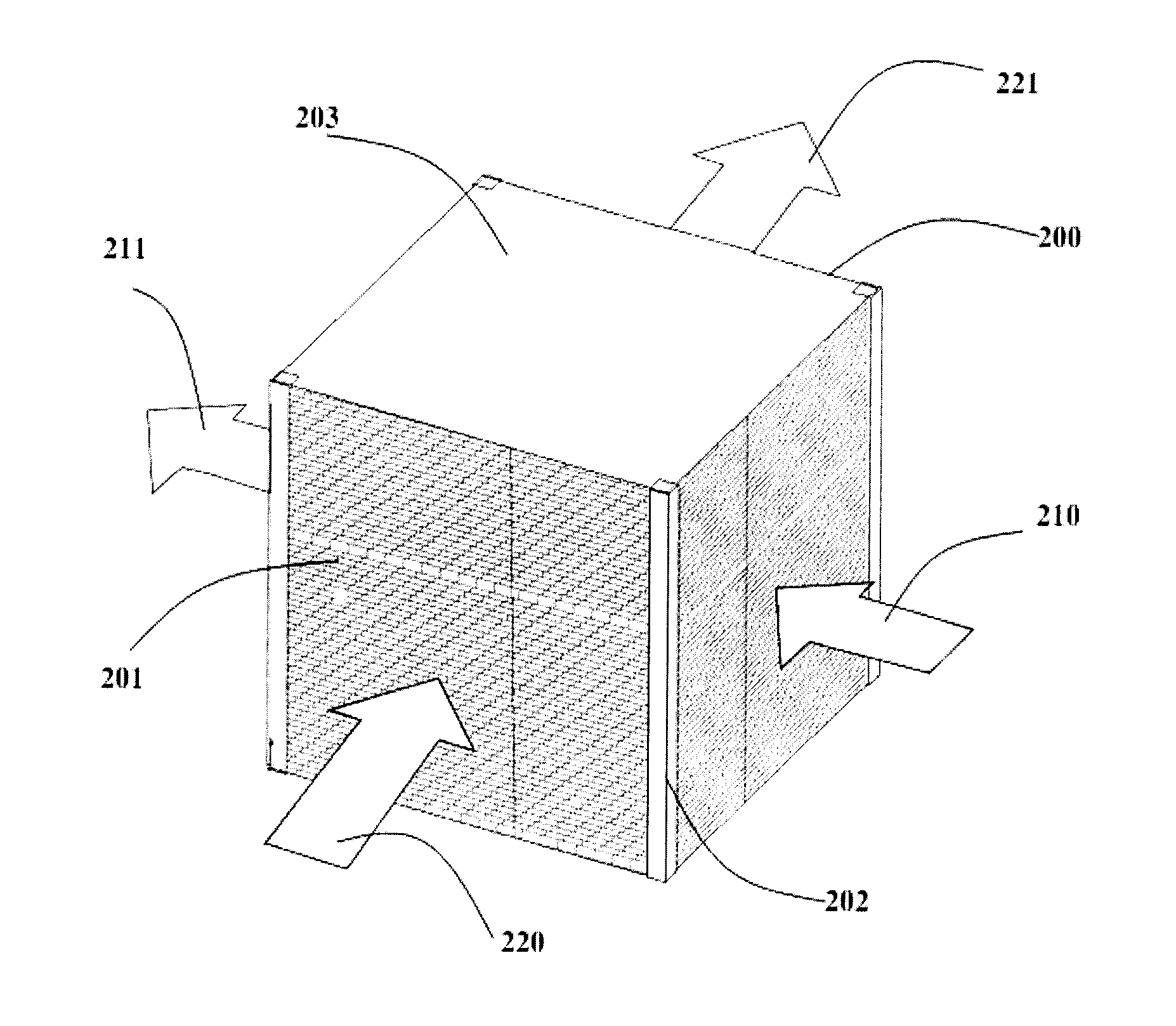

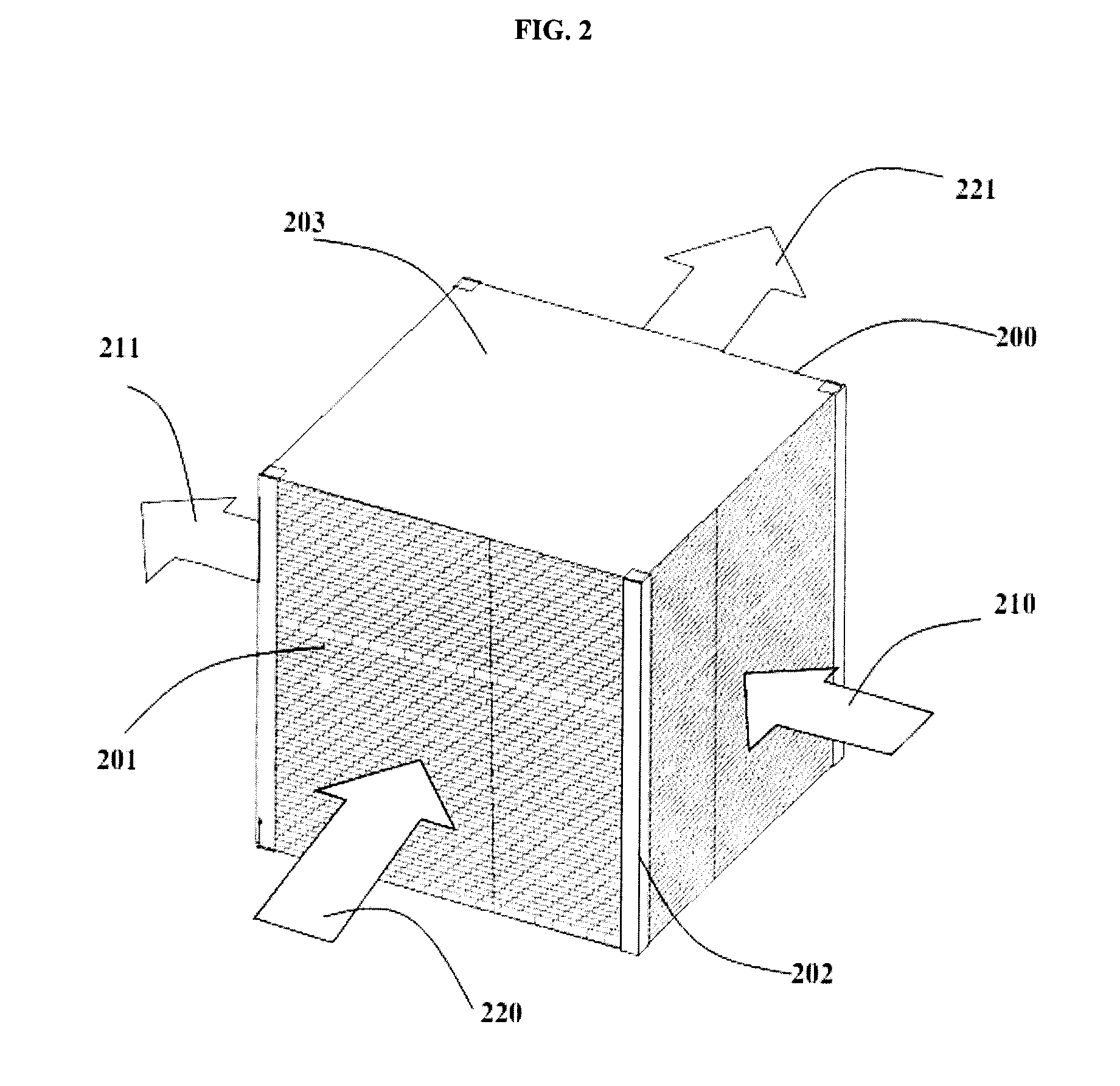

Coated membranes for enthalpy exchange and other applications

ActiveUS20120061045A1Energy recovery in ventilation and heatingSemi-permeable membranesCoated membranePolymer science

Coated membranes comprise a porous desiccant-loaded polymer substrate that is coated on one surface with a thin layer of water permeable polymer. Such membranes are particularly suitable for use in enthalpy exchangers and other applications involving exchange of moisture and optionally heat between gas streams with little or no mixing of the gas streams through the membrane. Such membranes have favorable heat and humidity transfer properties, have suitable mechanical properties, are resistant to the crossover of gases when the membranes are either wet or dry, and are generally low cost.

Owner:CORE ENERGY RECOVERY SOLUTIONS INC

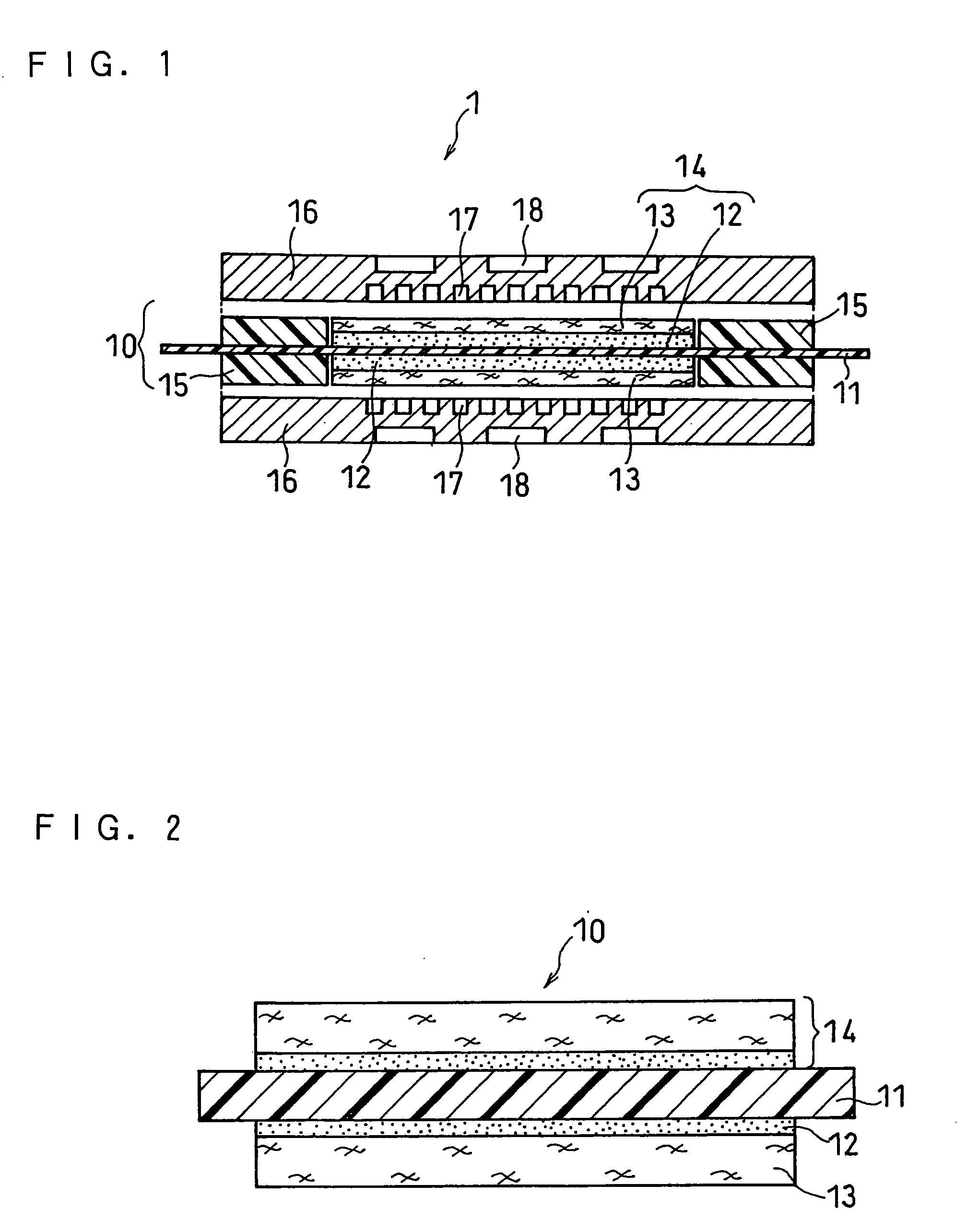

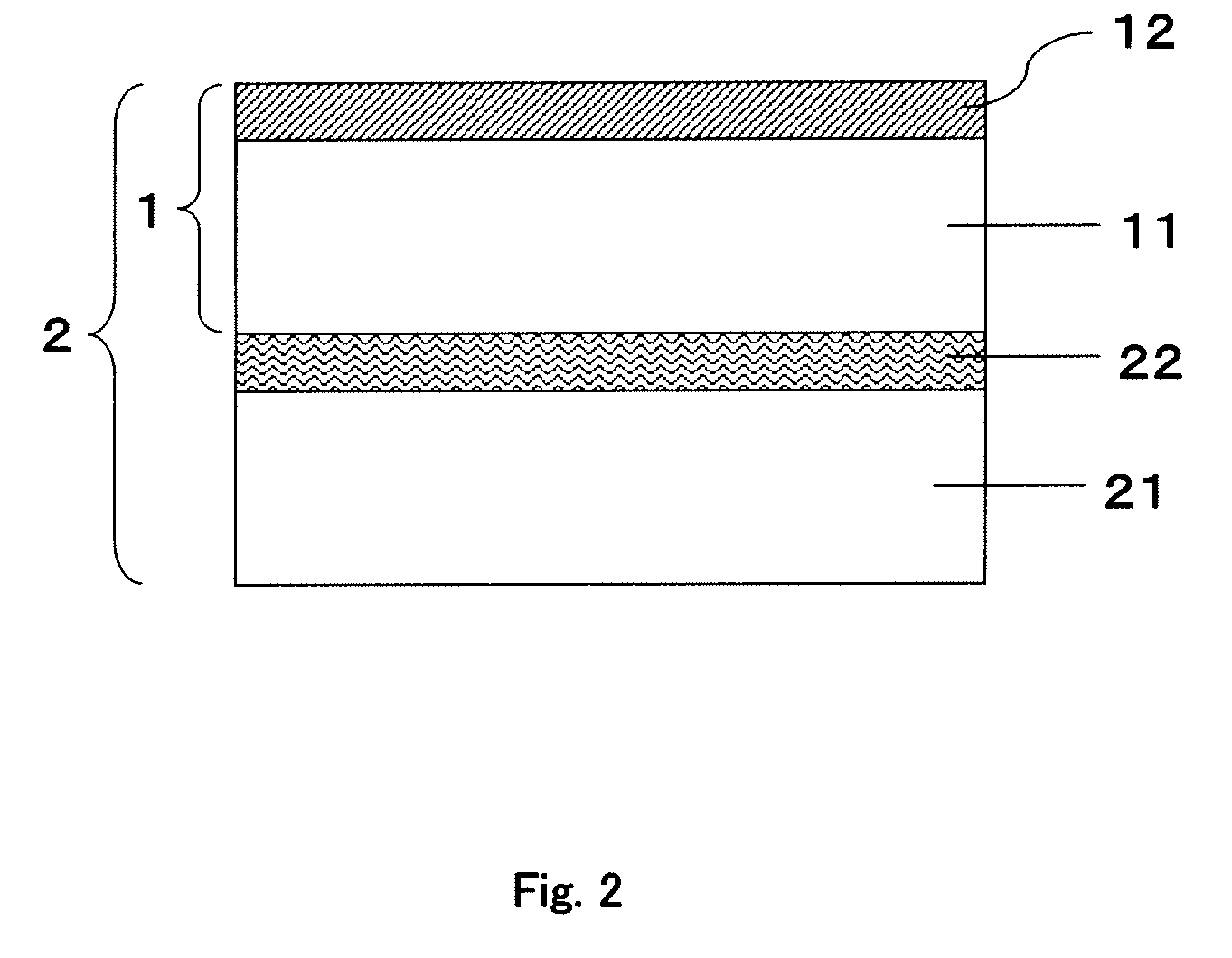

Composite electrolyte membrane, catalyst-coated membrane assembly, membrane-electrode assembly and polymer electrolyte fuel cell

InactiveUS20050227132A1High mechanical strengthAvoid size changeElectrolyte holding meansFuel cells groupingCoated membraneWrinkle skin

To provide a polymer electrolyte membrane having excellent size stability and excellent mechanical strength that can sufficiently prevent the size change due to the swelling condition, the displacement of the polymer electrolyte membrane and the formation of wrinkles during the production of the polymer electrolyte fuel cell, and can prevent damage during the production and operation of the polymer electrolyte fuel cell. In a composite electrolyte membrane including a porous reinforcement layer made of a resin and an electrolyte layer made of a polymer electrolyte and laminated at least one main surface of the reinforcement layer, the direction having a high tensile modulus of elasticity in the reinforcement layer is substantially corresponded with the direction having a high rate of size change in the electrolyte layer.

Owner:PANASONIC CORP

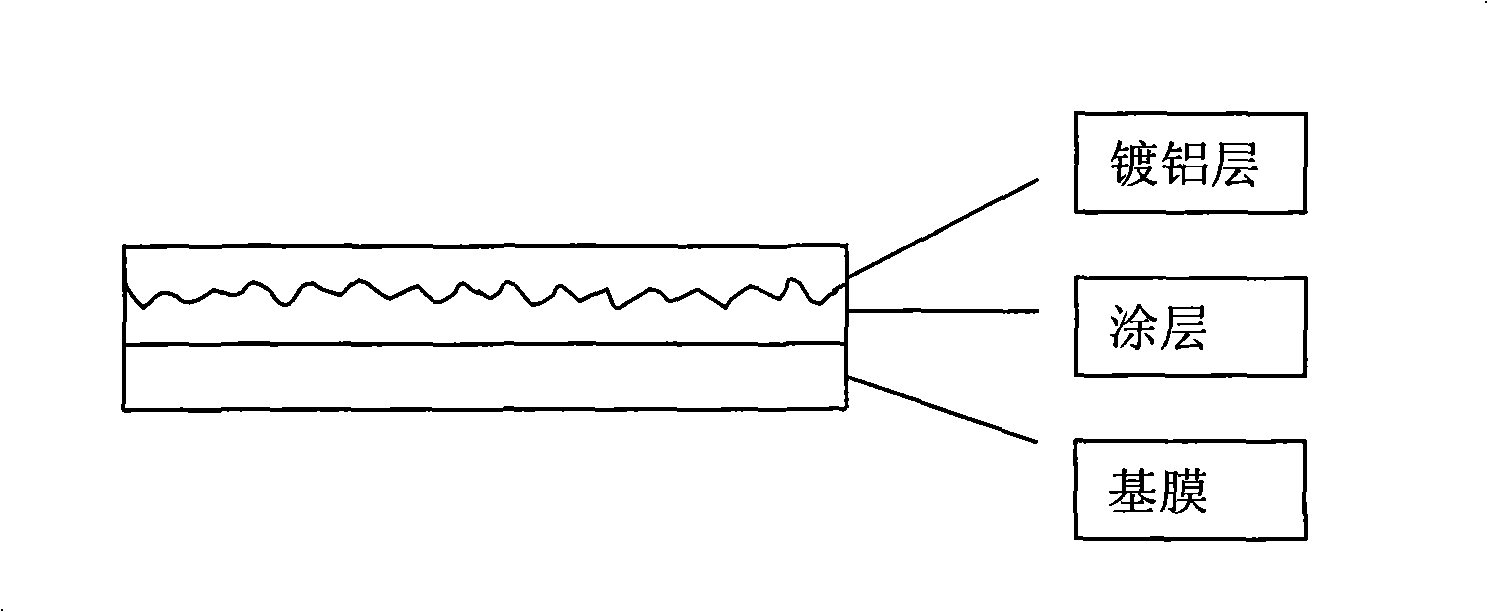

Process for producing PET laser transfer membrane

InactiveCN101537745ASimple processNovel processDecorative surface effectsPretreated surfacesBasementCoated membrane

The invention relates to a process for producing a PET laser transfer membrane. A PET membrane is used as a basement transfer membrane, and laser transfer pigment is coated and spread on the PET membrane. The method includes the following steps: a laser transfer pigment is coated and spread on the PET basement transfer membrane by an anilox roll at one step to form a coating layer, and a precoating membrane can be formed after the operation of drying is carried out; the precoating membrane is processed by the operation of laser mould pressing, and interference figures on a laser slab are printed on the coating layer of the precoating membrane by heat pressing so as to form a mould pressing membrane; and aluminum is coated on the mould pressing membrane, an aluminum layer is formed on an information layer, and the PET laser transfer membrane can be prepared, wherein the pigment includes thermoplastic acroid resin and cellulose acetate. The process has the advantages that the special singly coated laser transfer pigment and the unique manufacture process control are selected, and the entire process is simple, novel, stable and reliable. As the laser mould pressing transfer coating layer has the properties of easy mould pressing, favorable stripping, and the like, the operation of coating just needs to be carried out for one time, and therefore the production efficiency can be greatly improved. After being transferred and stripped, the aluminum coated membrane can be recycled to be repeatedly used for many times, and therefore cost can be greatly reduced; and the PET laser transfer membrane is the environmentally friendly anti-counterfeit laser material for packaging and printing.

Owner:上海宝绿包装材料科技有限公司

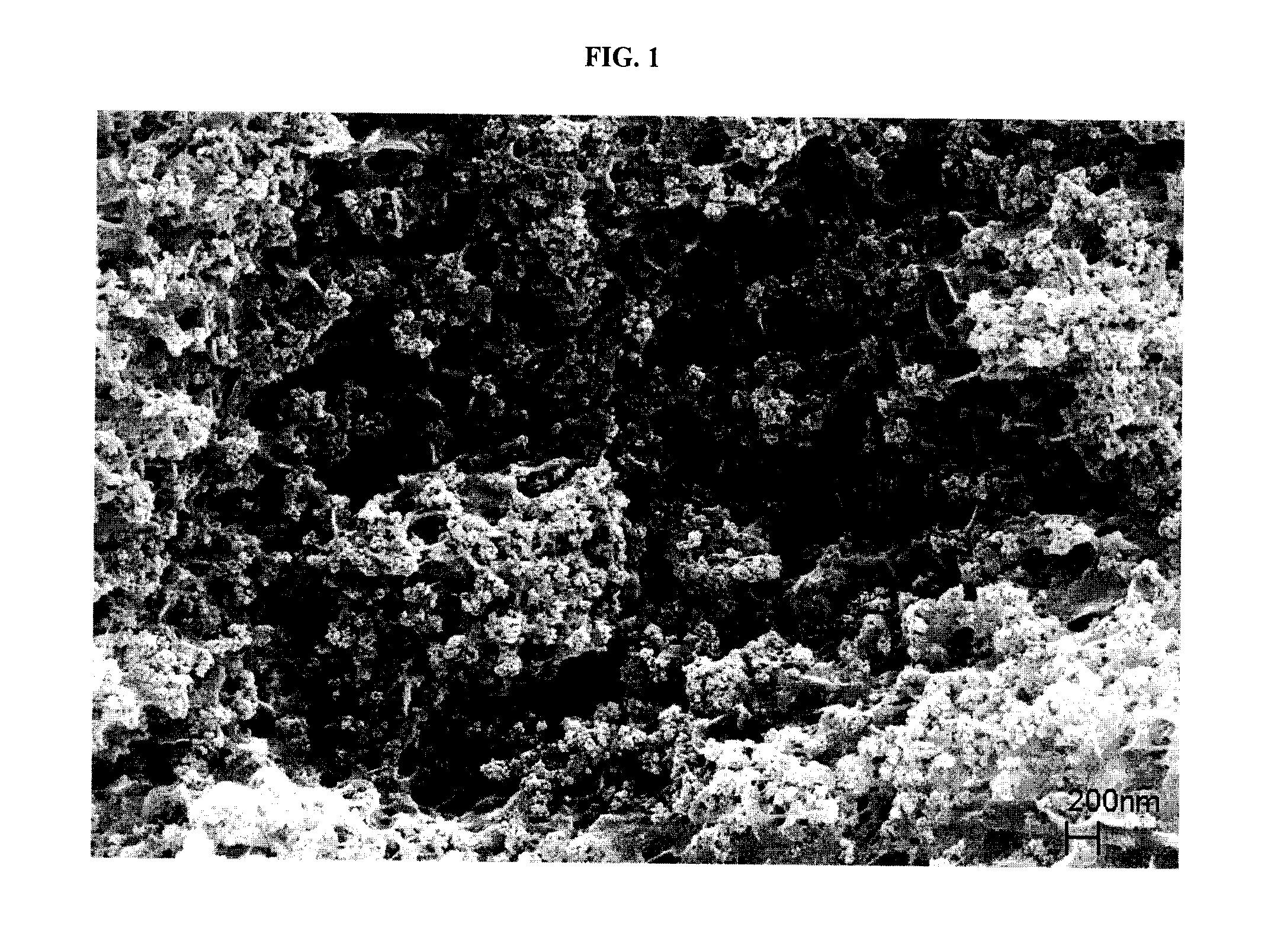

Nanoporous films and method for manufacturing the same

ActiveUS20120000845A1Small sizeEfficient removalMaterial nanotechnologySemi-permeable membranesCoated membraneNano size

Provided is a carbon nanostructure-metal composite nanoporous film in which a carbon nanostructure-metal composite is coated on one surface or both surfaces of a membrane support having micro- or nano-sized pores. A method for manufacturing a carbon nanostructure-metal composite nanoporous film, includes: dispersing a carbon nanostructure-metal composite in a solvent at the presence of a surfactant and coating the carbon nanostructure-metal composite on one surface or both surfaces of a membrane support; and fusing the metal on the membrane support by heating the coated membrane support. The metal in carbon nanostructure-metal composite nanoporous film melts at a low temperature since a size of a metal of the carbon nanostructure-metal composite is several nm to several-hundred nm.

Owner:BIONEER

Hard coat film

InactiveUS20050142362A1Increase resistanceEasy to wearInput/output for user-computer interactionSynthetic resin layered productsDisplay deviceSolvent

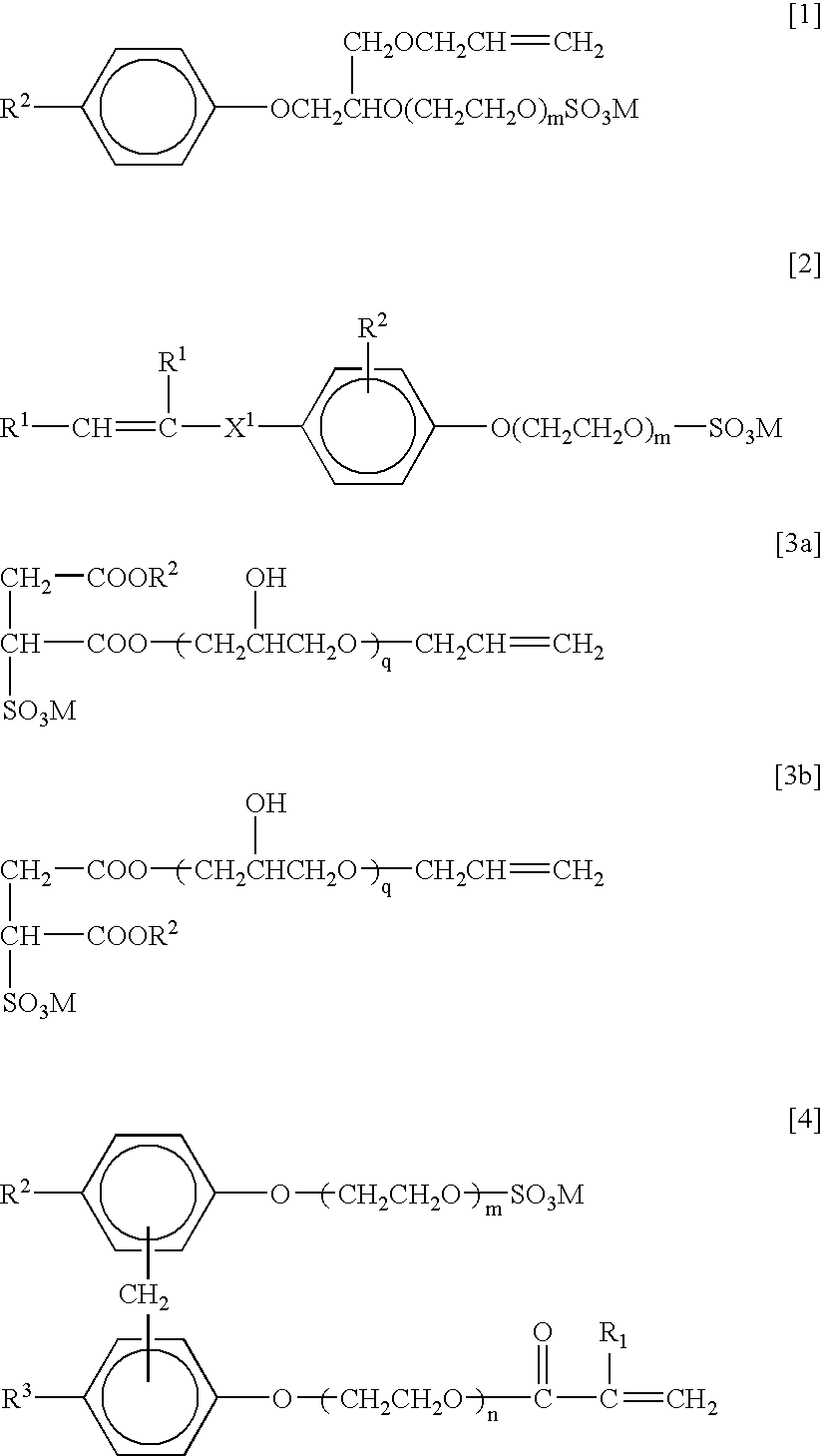

A hard coat film exhibits excellent scratch resistance and wear resistance, provides the property for preventing attachment of finger prints and the property for removal of finger prints by a simple operation, is excellent in retaining these properties, exhibits excellent solvent resistance and is advantageously used as the hard coat film for touch panels and the hard coat film for protecting various types of display. The hard coat film comprises a transparent substrate film and a hard coat layer disposed at least on one face of the substrate film, wherein the hard coat layer comprises a cured product of a resin composition sensitive to an ionizing radiation which comprises a polymerizable surfactant.

Owner:LINTEC CORP

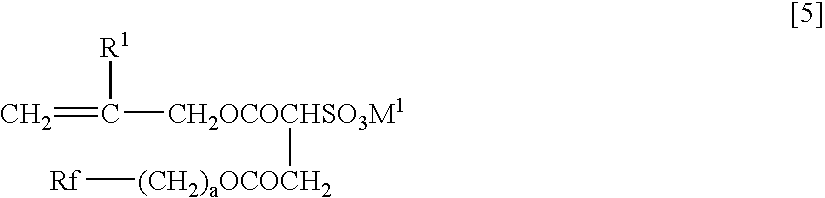

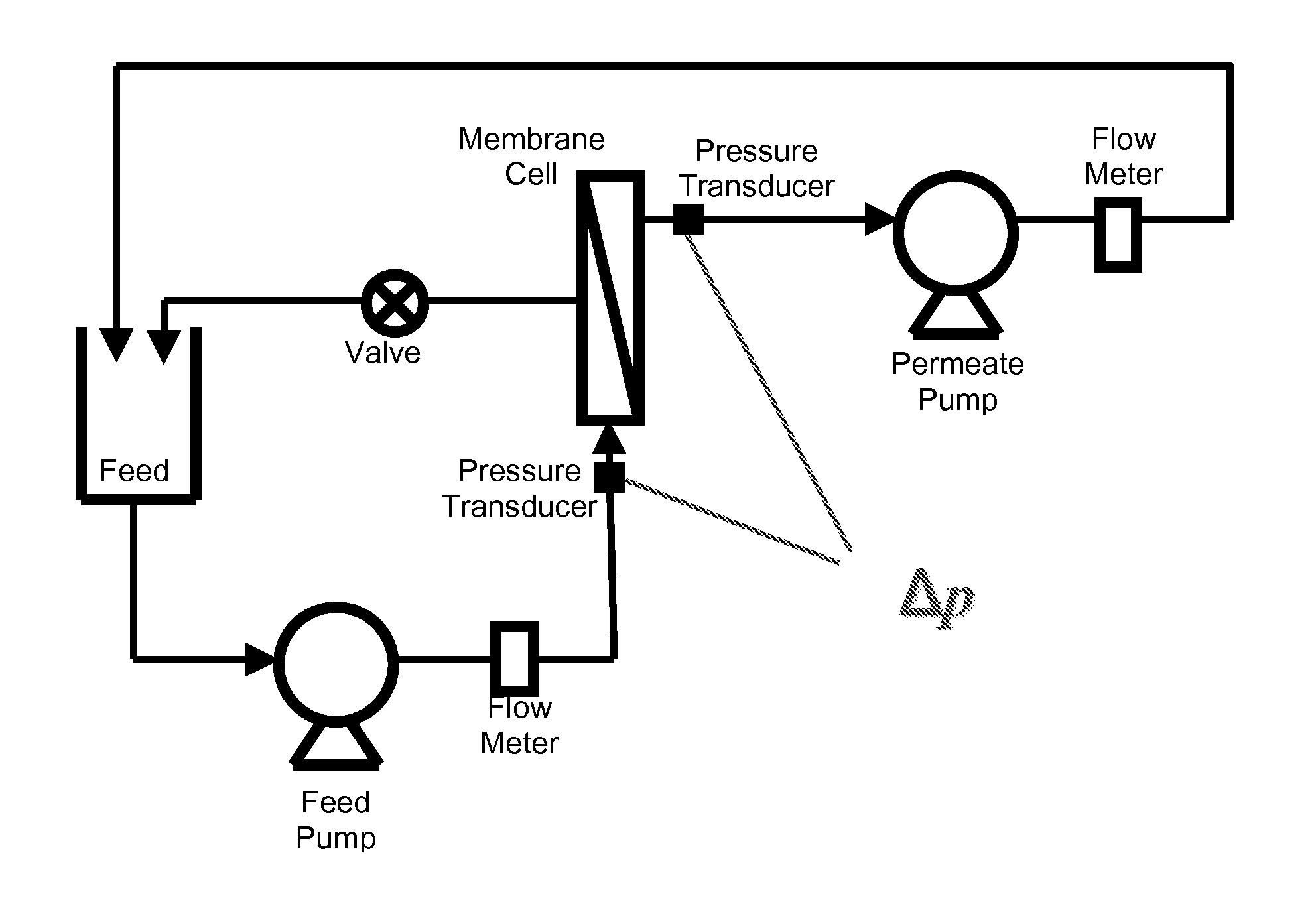

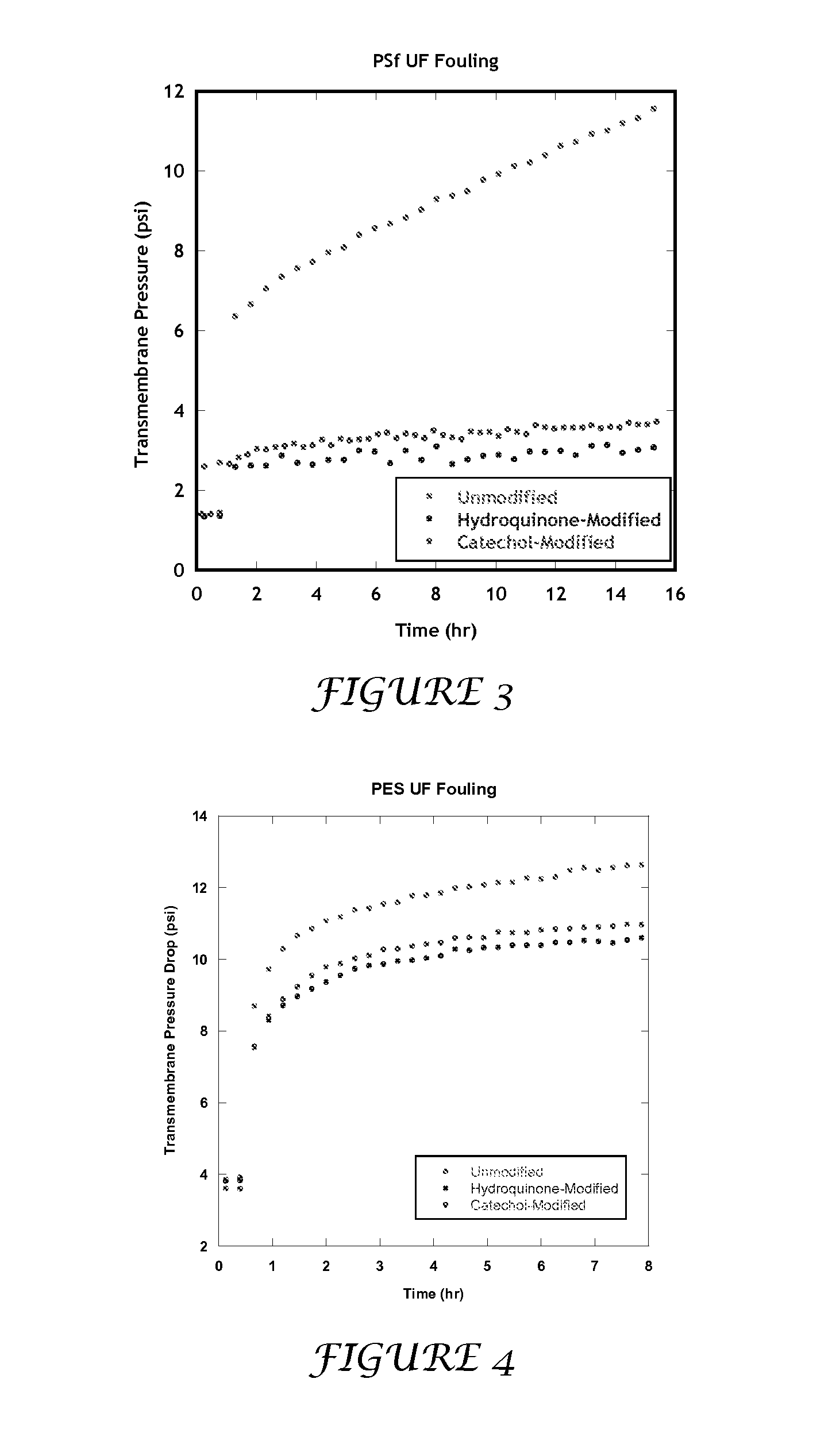

Surface Deposition of Small Molecules to Increase Water Purification Membrane Fouling Resistance

InactiveUS20120111791A1Efficient use ofEasy to retouchMembranesSemi-permeable membranesCoated membraneHydroquinone Compound

The present invention includes methods and compositions for liquid separation and water purification. The present invention includes a purification membrane having a polymer matrix purification membrane that has been treated with hydroquinone, catechol, and / or dopamine coated membrane with a high water flux.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Acrylic photovoltaic module backsheet

ActiveUS20110315189A1Easy to mergeEasy to stickPV power plantsSynthetic resin layered productsPolymer sciencePolyethylene terephthalate glycol

The invention relates to an acrylic layer (in the form of a coating, film or sheet) useful as part of a photovoltaic module backsheet. The acrylic layer contains at least 40 percent of one or more acrylic polymers, including an acrylic polymer matrix and optionally acrylic impact modifiers. The acrylic polymer is preferably a polymer, copolymer, or terpolymer containing at least 50 weight percent of methylmethacrylate monomer units. The acrylic layer is flexible and optionally contains high levels of white pigment. It may also contain fluoropolymers such as polyvinylidene fluoride to improve weathering, processibility and film formation. The acrylic layer adheres to a polymer support layer such as polyethylene terephthalate (PET). A preferred substrate is PET that is pre-treated to improve adhesion, but unprimed PET can also be used. The backsheet provides excellent weatherability, environmental stability and reflectivity as part of a photovoltaic module.

Owner:TRINSEO EURO GMBH

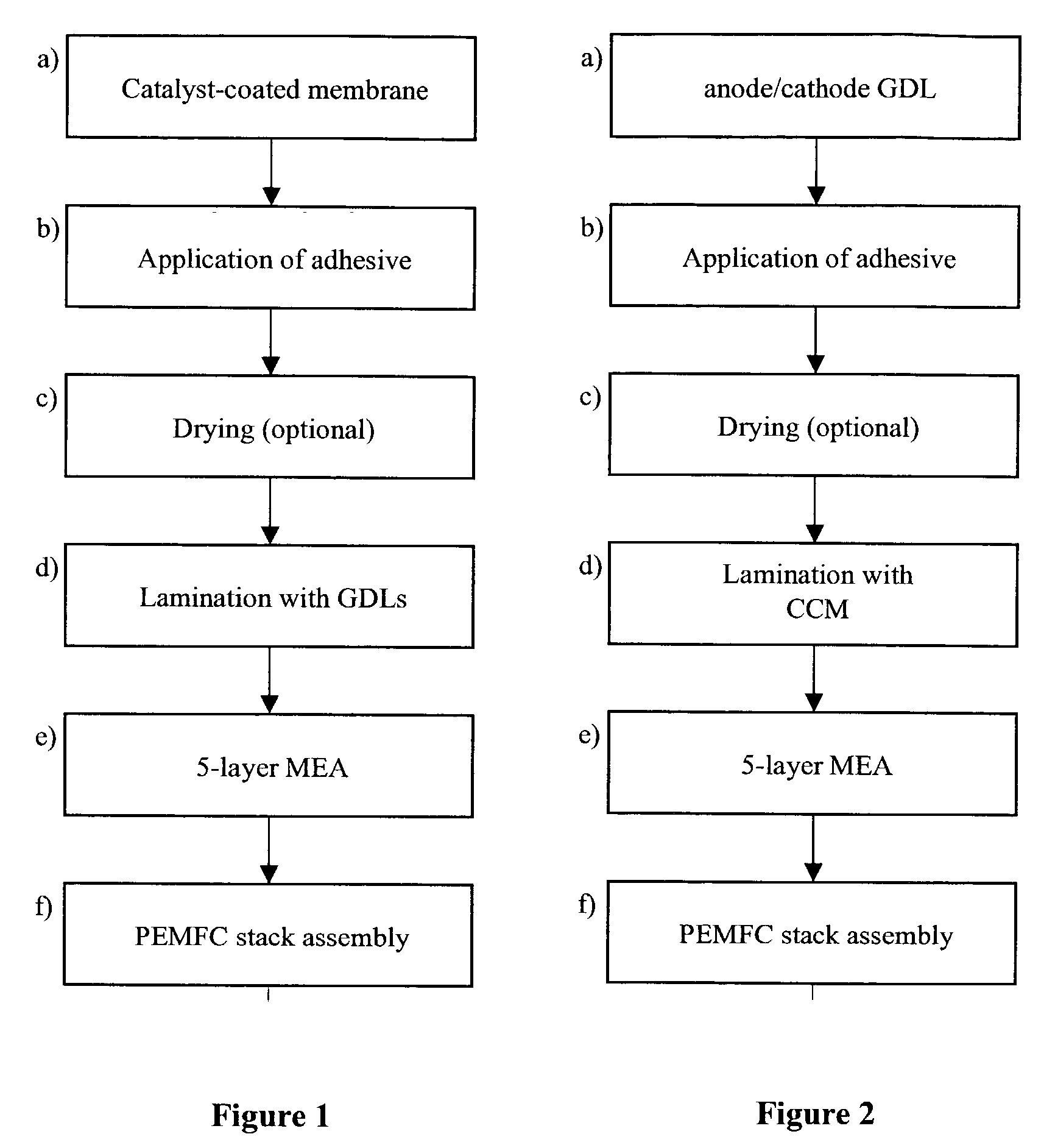

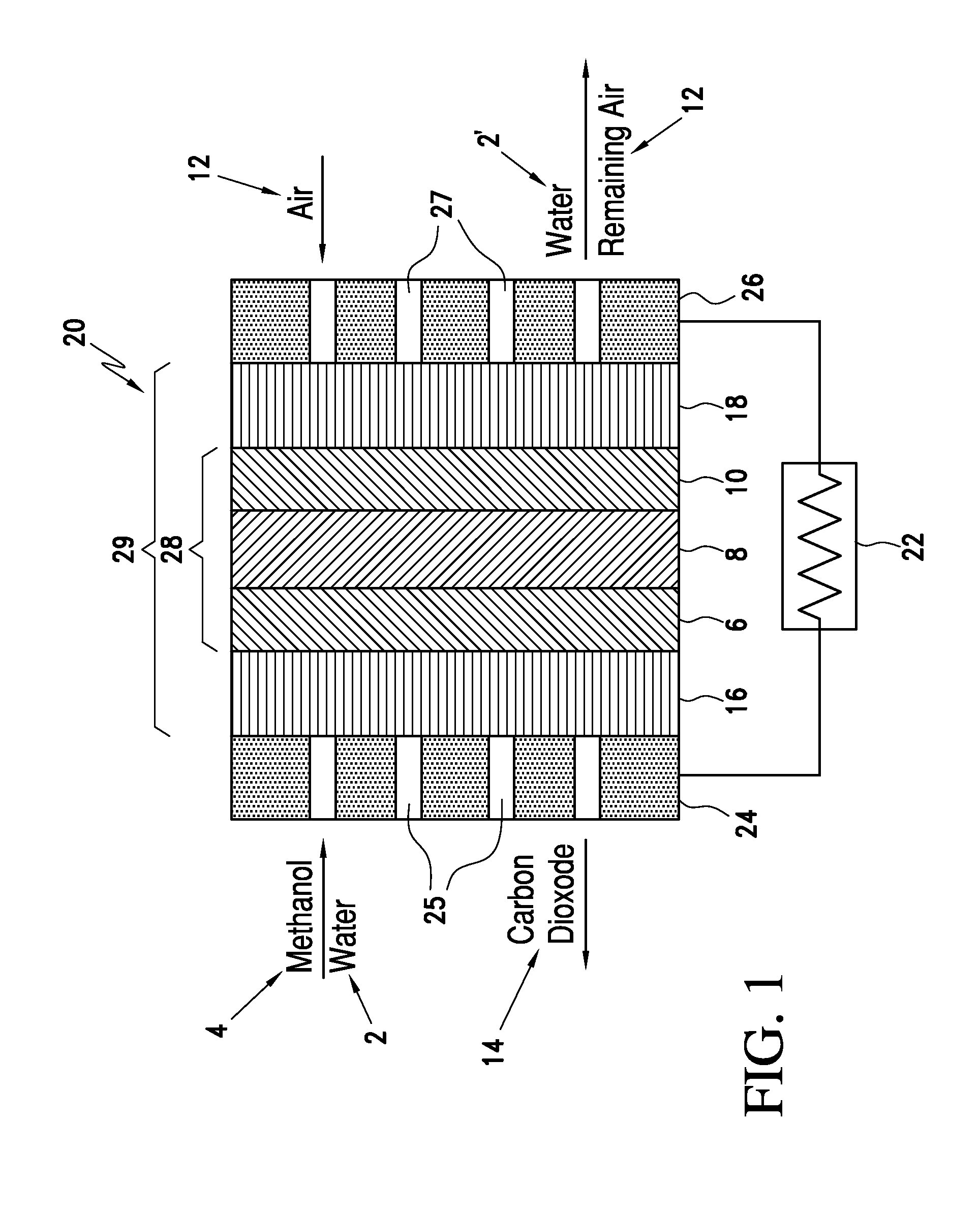

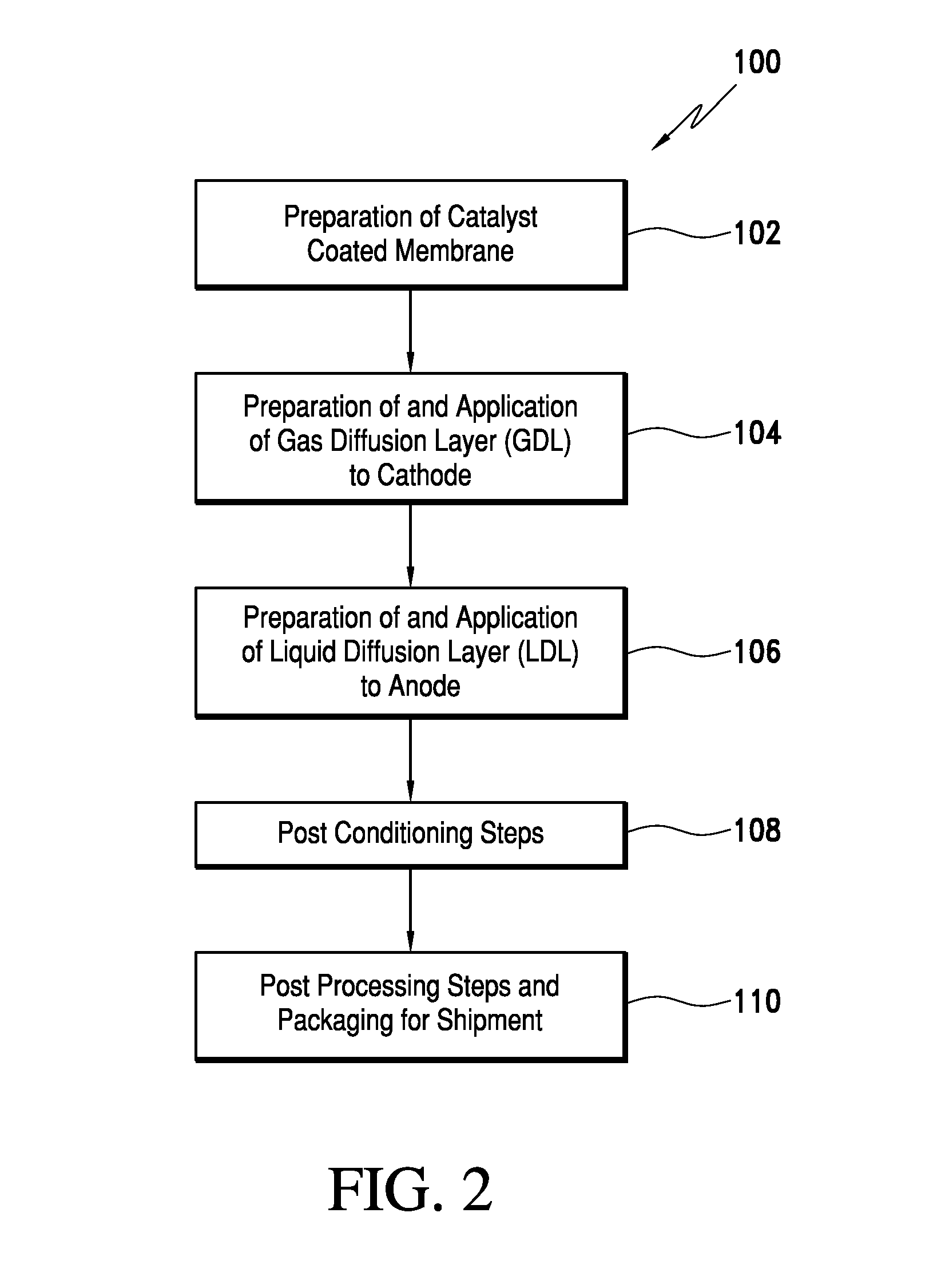

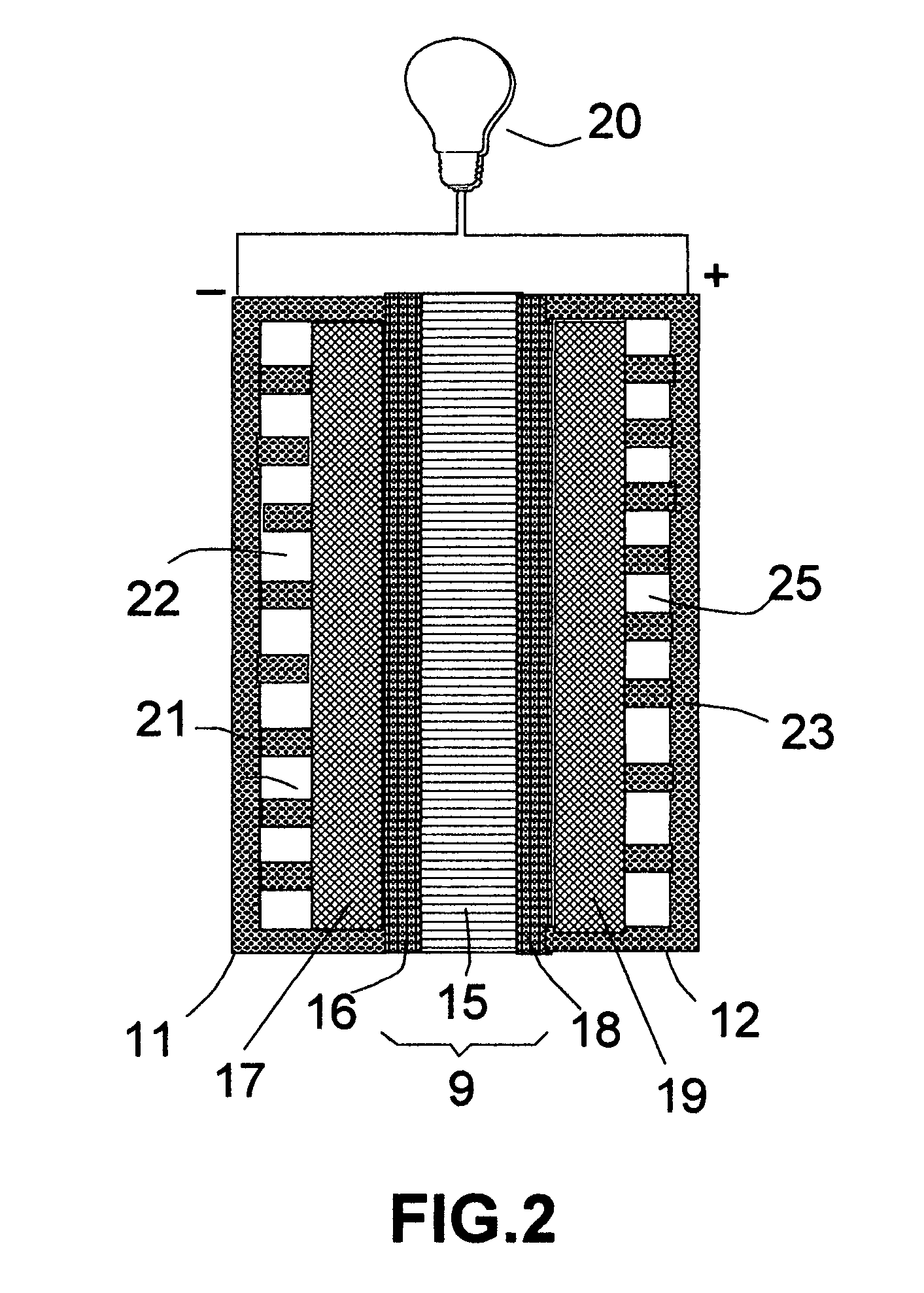

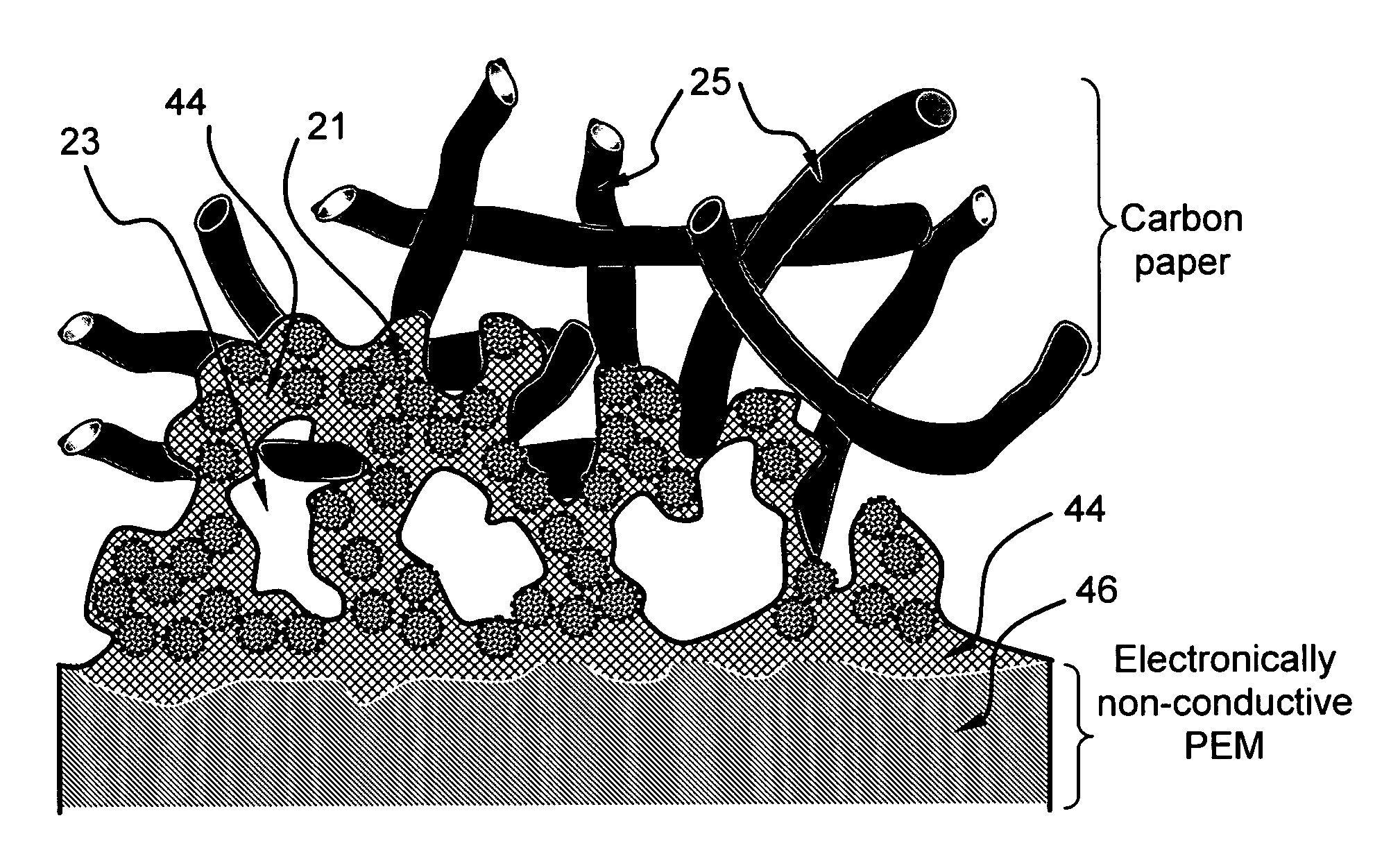

Process for the manufacture of membrane-electrode-assemblies using catalyst-coated membranes

ActiveUS20030224233A1Easy to assembleSimple handlingCellsSemi-permeable membranesCoated membranePolymer electrolytes

The present invention relates to the field of electrochemical cells and fuel cells, more specifically to polymer-electrolyte-membrane (PEM) fuel cells and describes a process for the manufacture of membrane-electrode-assemblies (MEAs) containing five layers. The five-layer MEA is assembled together by means of a lamination process involving an adhesive component. The anode gas diffusion layer, the catalyst-coated membrane and the cathode gas diffusion layer are combined together by a low temperature / low pressure lamination process. Handling of the MEAs and assembly of the products into PEMFC and DMFC stacks is simplified. Less damage and perforation of the catalyst-coated membrane occurs and thus the performance of the five-layer MEAs is significantly improved.

Owner:UMICORE AG & CO KG

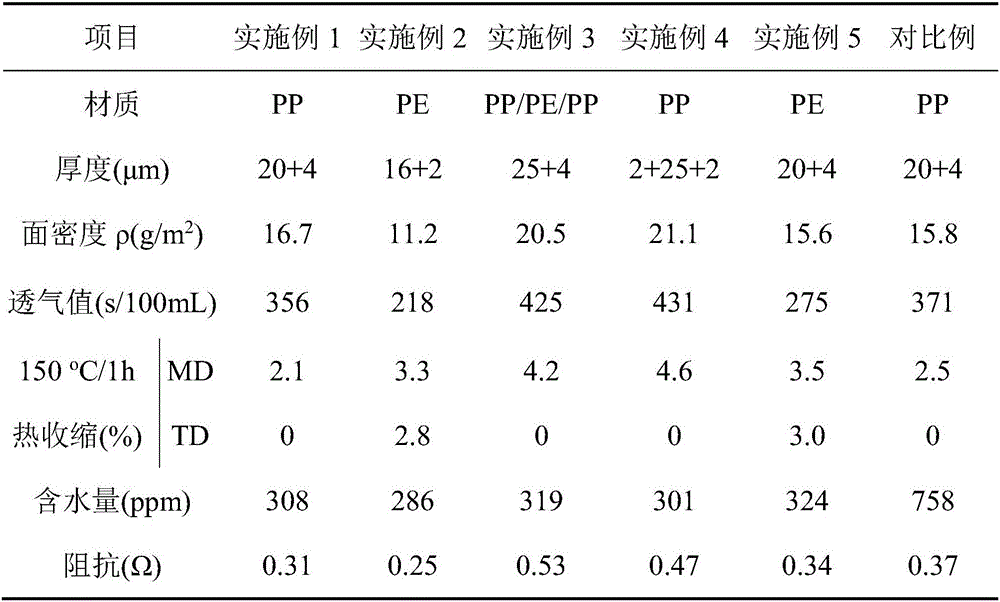

Waterborne ceramic coated membrane for lithium ion battery and preparation method thereof

InactiveCN105789539AHigh porosityImprove thermal stabilityCell component detailsCoatingsCoated membraneAdhesive

The invention discloses a waterborne ceramic coated membrane for a lithium ion battery and a preparation method thereof. The waterborne ceramic coated membrane comprises a microporous membrane and a ceramic coating, the ceramic coating is arranged on one side or two sides of the microporous membrane and prepared from, by weight, 40-70 wt% of water and 30-60 wt% of base materials, and the base materials include, by weight, 65-98 parts of boehmite powder, 1-15 parts of waterborne wetting agent, 1-15 parts of waterborne adhesive and 1-5 parts of waterborne dispersant. The waterborne ceramic coated membrane is good in conduction effect and high in thermostability and safety.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

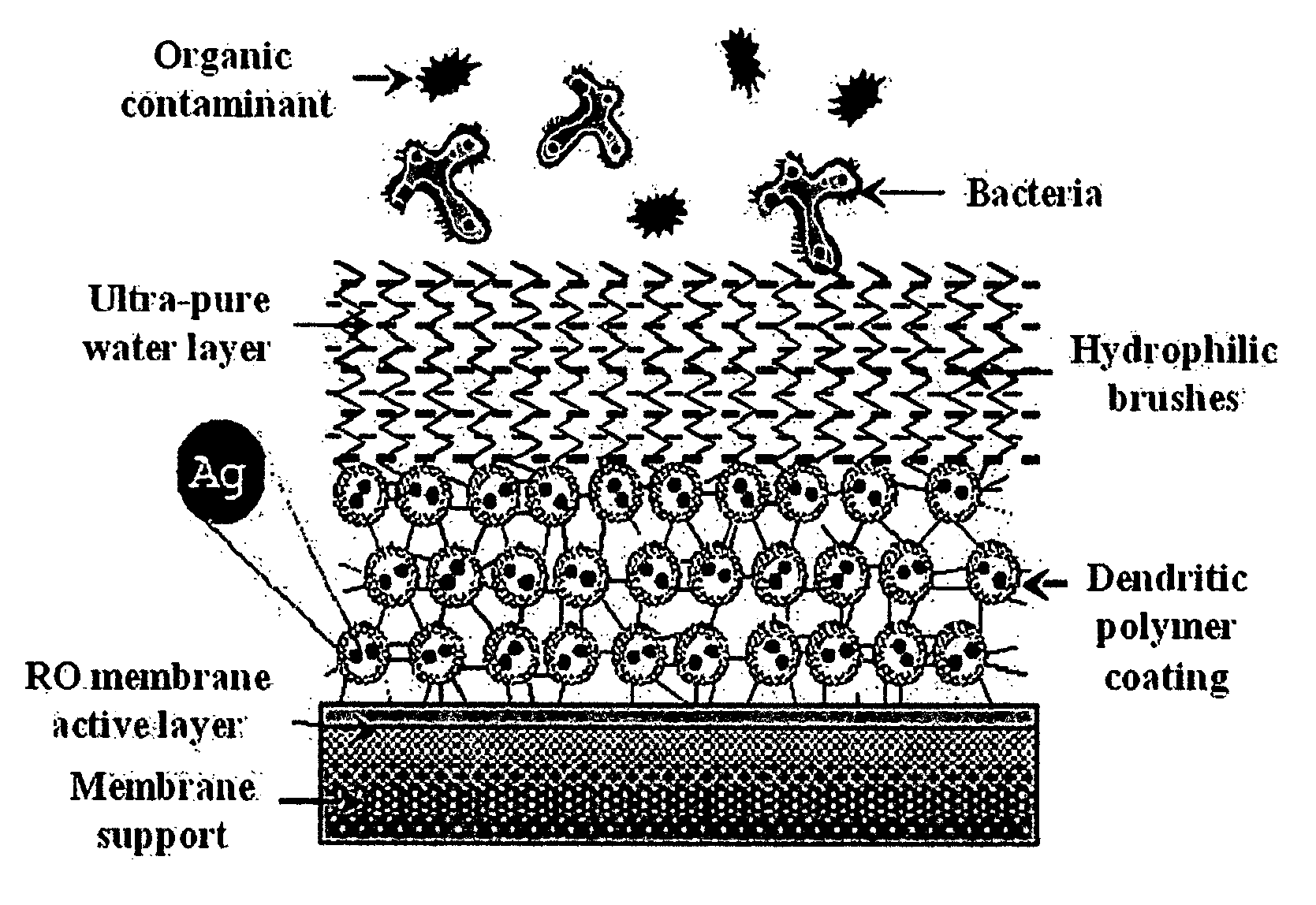

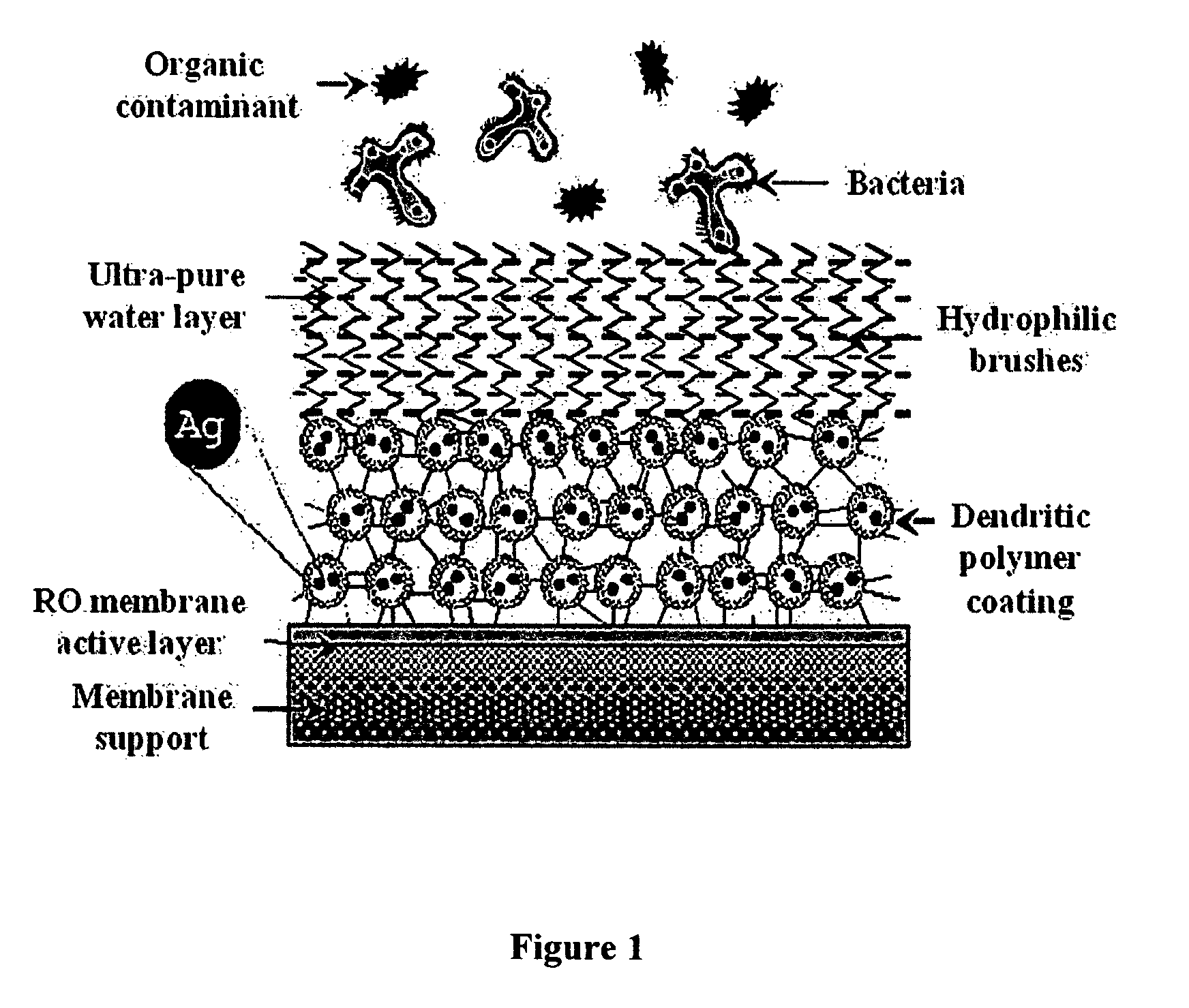

Surface modification of polyamide reverse osmosis membranes

InactiveUS8505743B2Improve hydrophilicityPrevent subsidenceMembranesSolid separationDendrimerCoated membrane

The present invention relates to surface modification of reverse osmosis membranes to introduce antifouling properties without compromising the separation properties of the original membranes. This approach utilizes: providing a coated membrane surface having enhanced hydrophilic characteristics that prevents the biofoulants from settling; have a surface that consists of hydrophilic brushes that unsettle any biofoulants that get through; and having antimicrobial ions present in the membrane coatings and able to remove or minimize any remaining biofoulants without leaching into the permeate. These coatings are made using dendritic polymers such as hyperbranched polymers or dendrimers.

Owner:MICHIGAN MOLECULAR INST

Process for making cation exchange membranes with reduced methanol permeability

The present invention provides for a process to prepare a solid polymer electrolyte membrane having an ionomer having imbibed therein a polymer is selected from the group consisting of a polyamine, a polyvinyl amine, and derivatives thereof, wherein the membrane is irradiated after the impregnation. The invention also provides a catalyst coated membrane and a fuel cell having this solid polymer electrolyte membrane.

Owner:EI DU PONT DE NEMOURS & CO

Polyvinylidene fluoride and metal-organic framework composite ultra-filtration membrane and preparation and application

ActiveCN105498553AImprove hydrophilicityEasy to separateMembranesUltrafiltrationCoated membraneFiltration membrane

The invention belongs to the technical field of composites, and discloses a polyvinylidene fluoride and metal-organic framework composite ultra-filtration membrane and preparation and application. The preparation method comprises the steps that MIL-100 (Fe) prepared through a hydrothermal method is ultrasonically dispersed in solvent, polyvinylidene fluoride and a pore-forming agent are sequentially added, stirring is conducted for 12-24 h to enable the added substances to be dissolved and blended to be uniform, and a membrane casting solution is formed; the membrane casting solution is defoamed and put on a support for membrane coating, staying of a coated membrane in the air is conducted for 30-60 s, the membrane is immersed into a coagulating bath for solvent exchange, and the polyvinylidene fluoride and metal-organic framework composite ultra-filtration membrane is obtained. The metal-organic framework material MIL-100 (Fe) is added to the composite ultra-filtration membrane, the hydrophily of the ultra-filtration membrane is improved, the separating capacity of the membrane is improved, the anti-pollution capacity of the ultra-filtration membrane is improved, the service life of the membrane is prolonged, and a good application prospect is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Lithium-ion batteries with coated separators

ActiveUS8470468B2Thermal conductivityLow environmental impactCell seperators/membranes/diaphragms/spacersLi-accumulatorsCoated membraneGas phase

A porous polymer sheet or membrane is provided with a thin coating of an electrically non-conductive ceramic composition and the coating conforms to all surfaces, including the pore surfaces, of the membrane. Such a coated membrane serves well, for example, as an intra-cell separator in a lithium ion battery. The coating increases the mechanical properties and thermal stability of the separator in battery operation and retains electrolyte. The coating may be formed by a two-step vapor-phase process in which atoms of one or more metals such as aluminum, calcium, magnesium, titanium, silicon and / or zirconium are deposited in a conformal layer on a workpiece surface. The metal atoms may then be reacted with ammonia, carbon dioxide, and or water to form their respective non-conductive nitrides, carbides, and / or oxides on the surface. The two-step process is repeated as necessary to obtain a ceramic material coating of desired thickness.

Owner:GM GLOBAL TECH OPERATIONS LLC

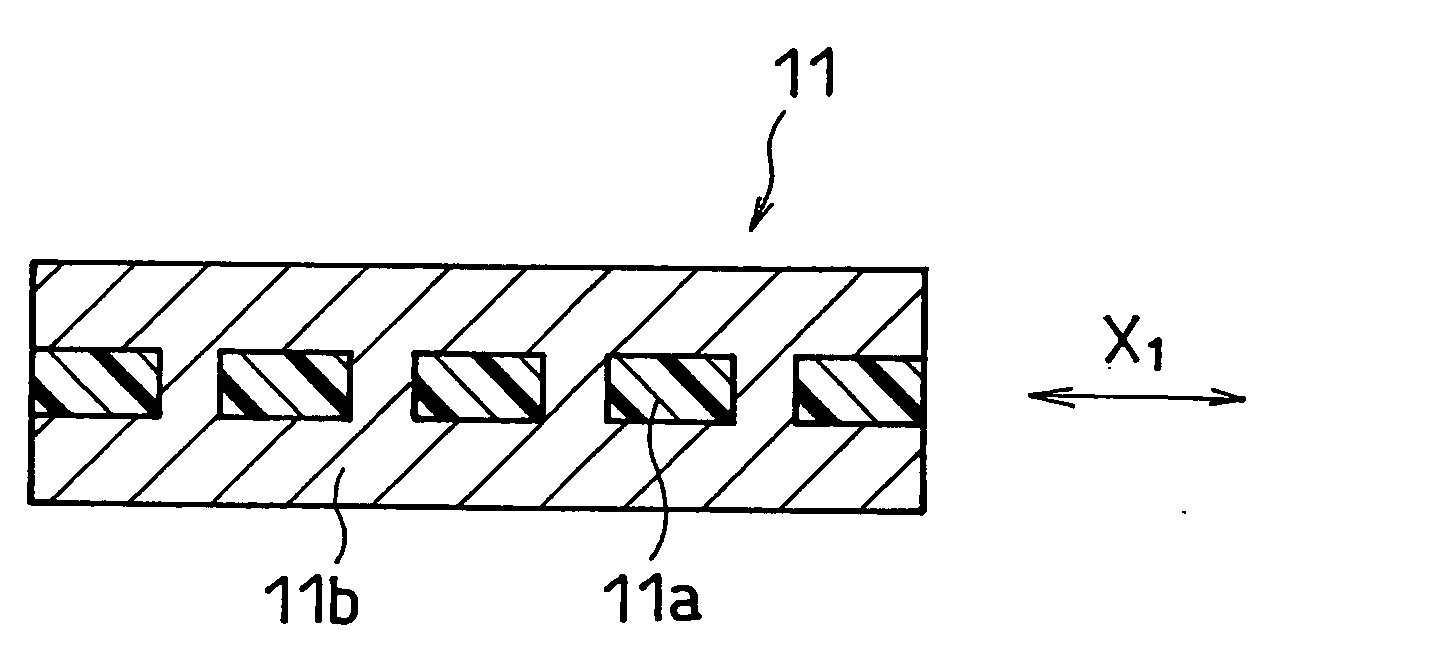

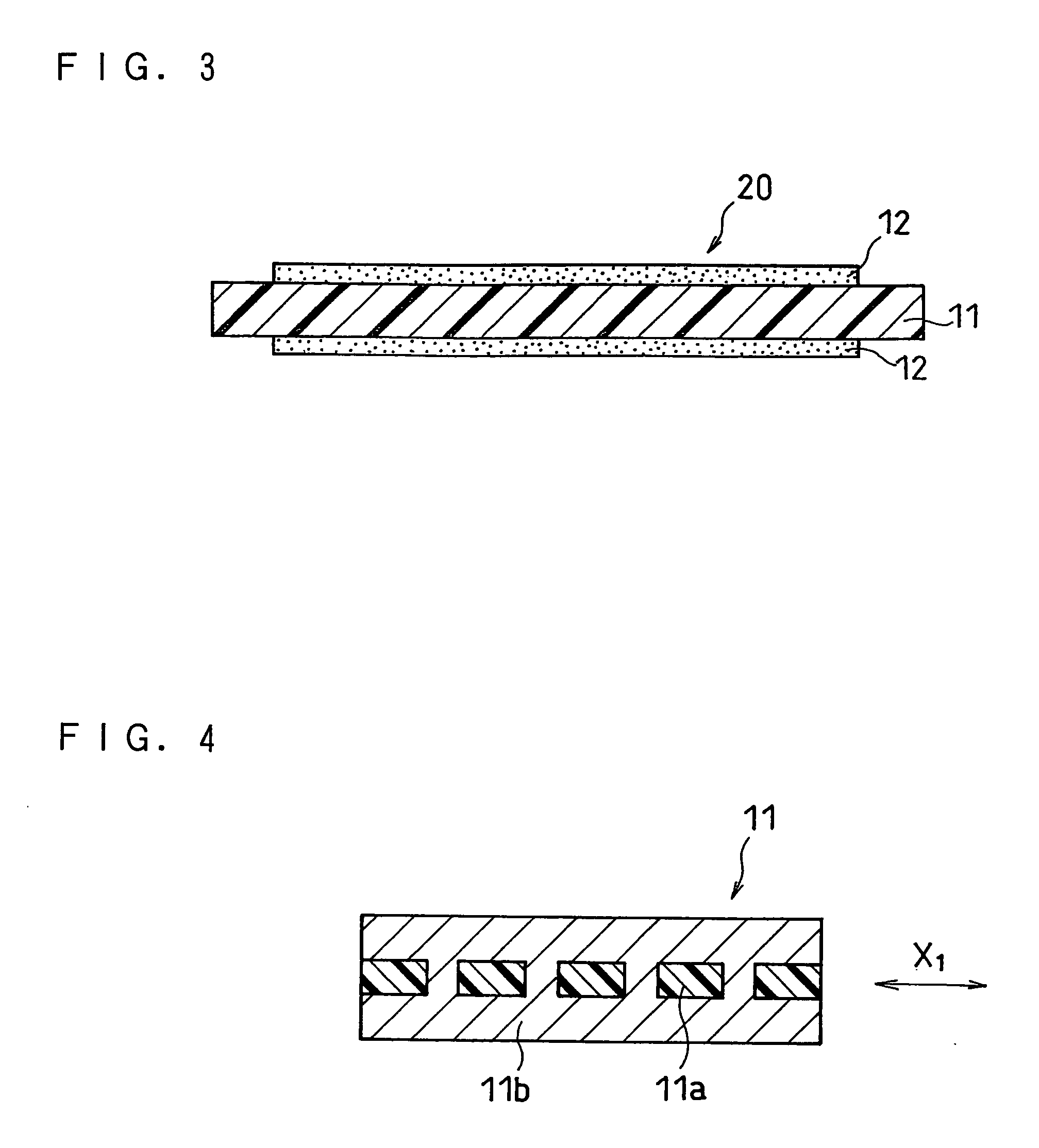

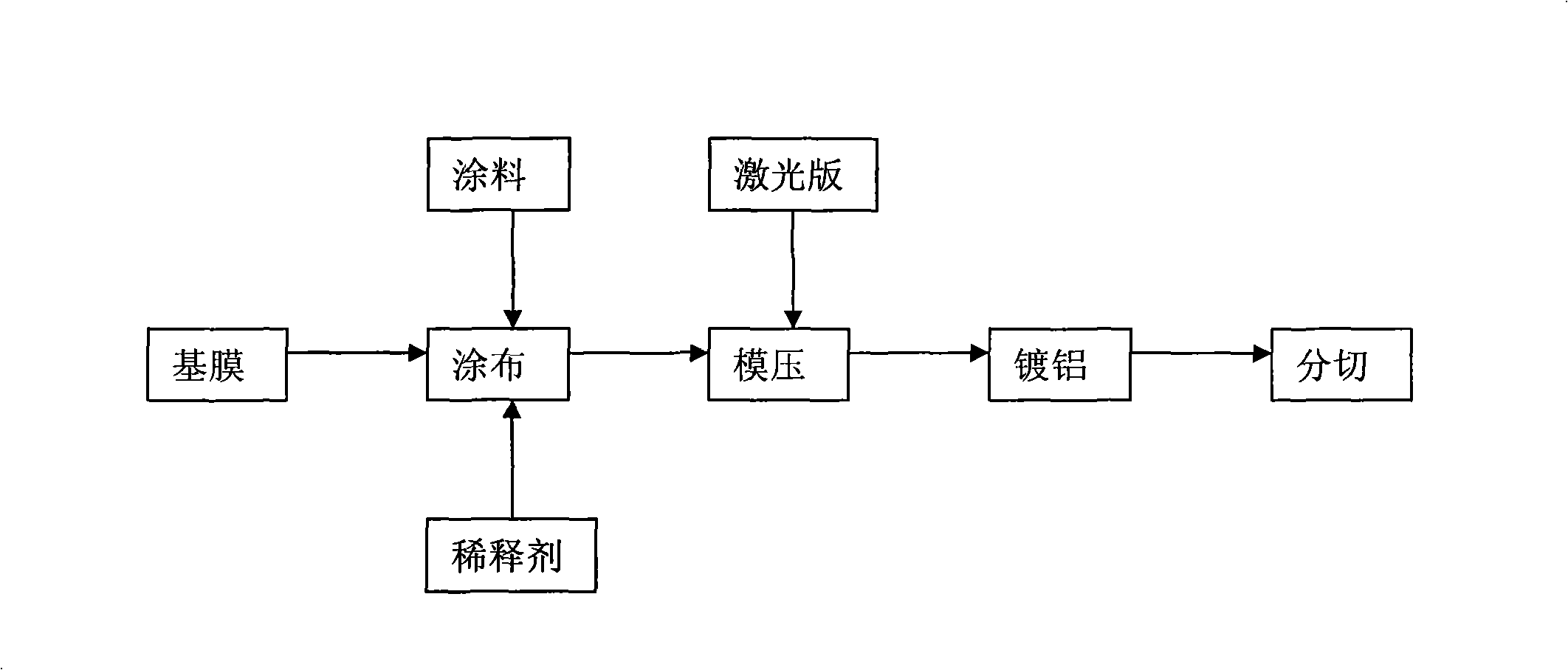

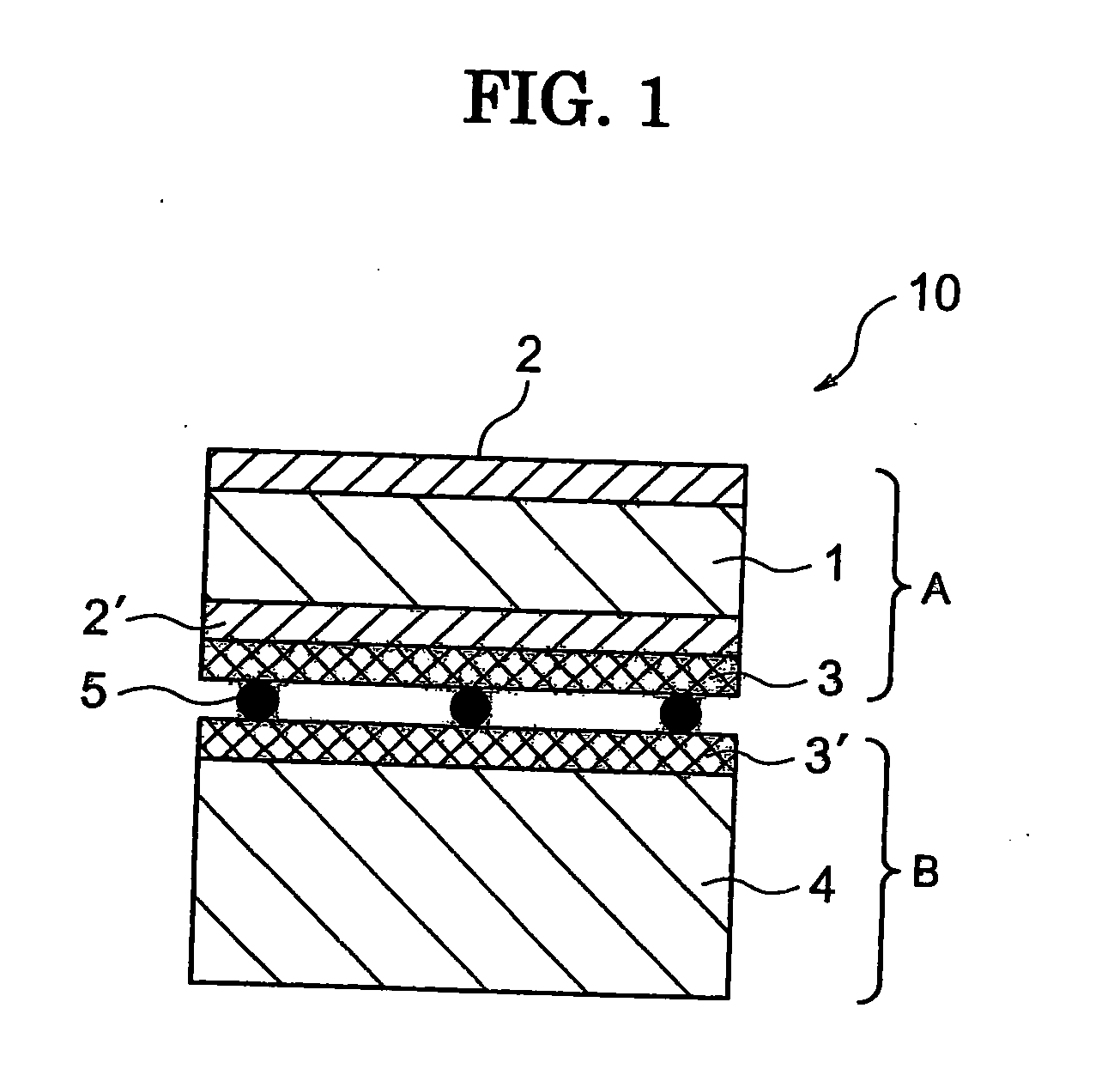

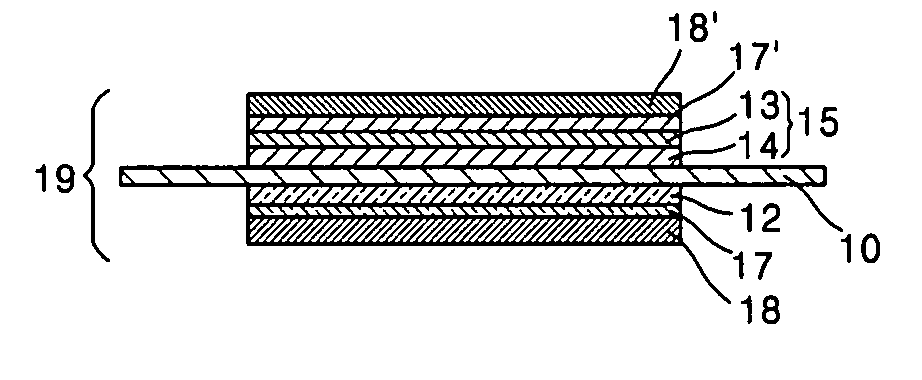

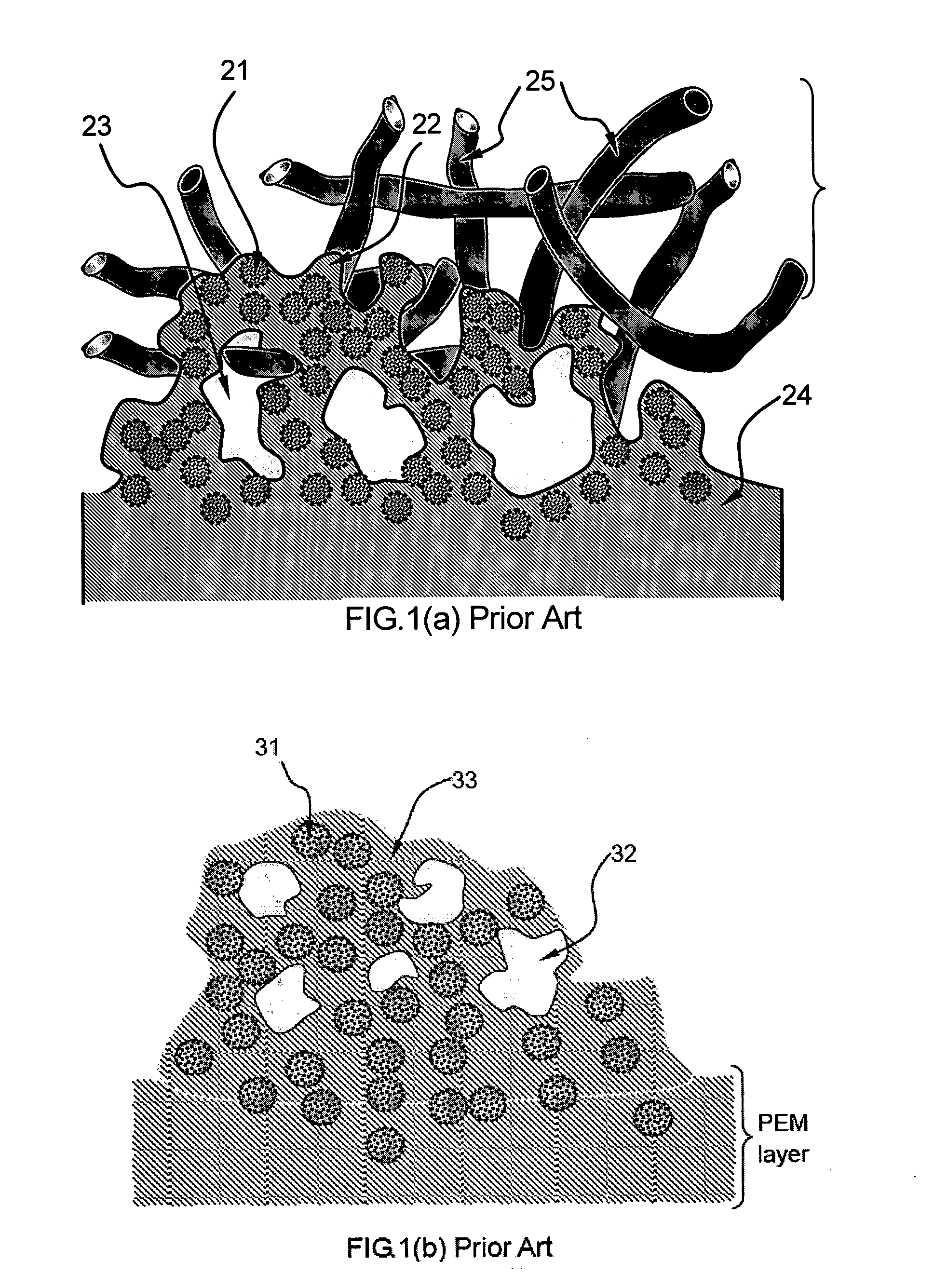

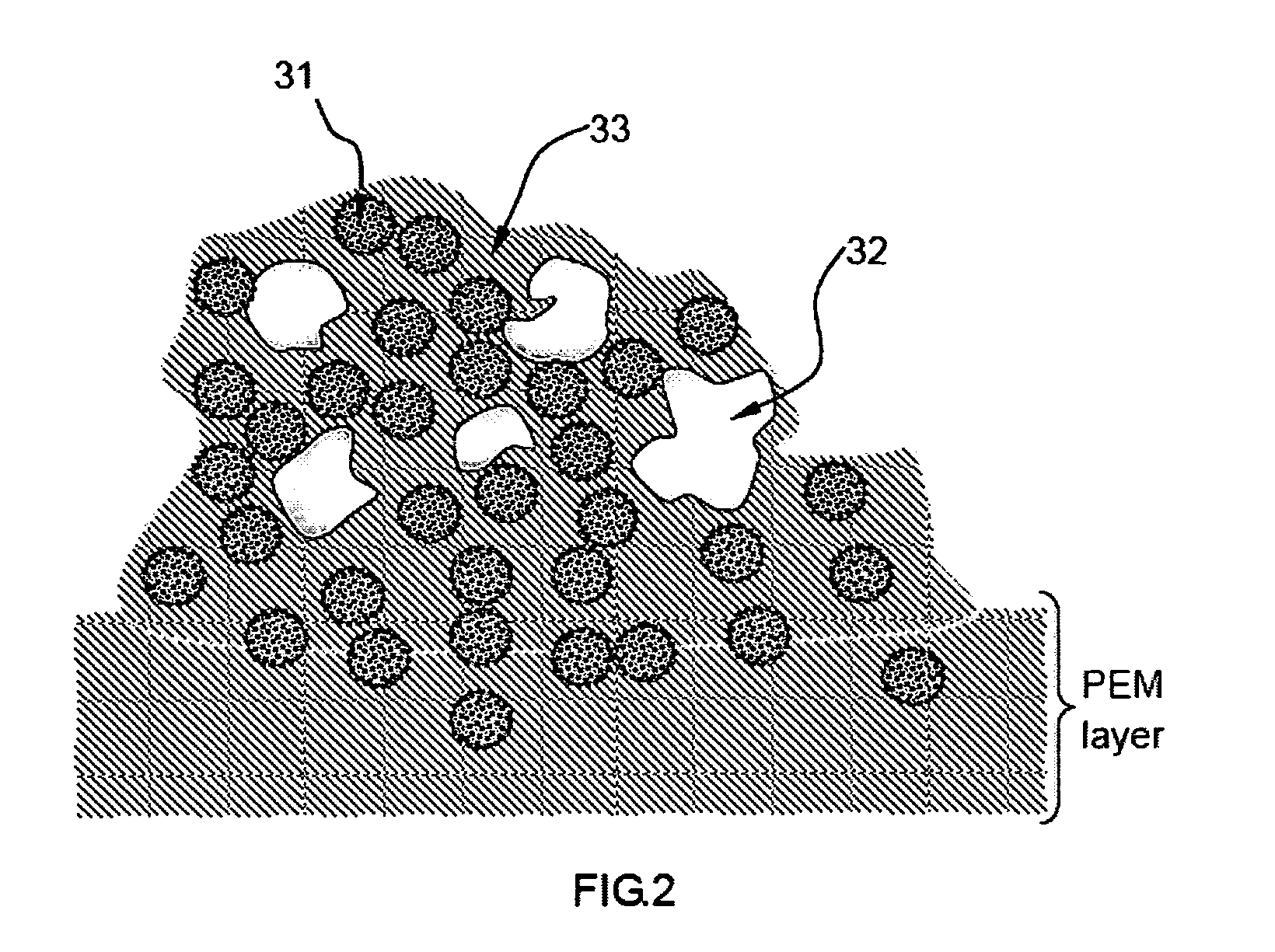

Catalyst coated membrane, membrane electrode assembly containing the same, method of producing the same, and fuel cell including the membrane electrode assembly

InactiveUS20070269699A1Improve unit performanceMaximum catalyst activityActive material electrodesNon-aqueous electrolyte accumulator electrodesCoated membraneFuel cells

A catalyst coated membrane (CCM) comprising an anode catalyst layer having a first catalyst layer composed of a non-supported catalyst and a second catalyst layer composed of a supported catalyst, a cathode catalyst layer composed of a supported catalyst, and an electrolyte membrane interposed between the anode catalyst layer and a cathode catalyst layer, the first catalyst layer of the anode catalyst layer being disposed adjacent to the electrolyte membrane; a membrane electrode assembly (MEA) comprising the catalyst coated membrane; a method of preparing the membrane electrode assembly; and a fuel cell comprising the membrane electrode assembly, are provided. The CCM, which comprises a bilayered anode catalyst layer including the first catalyst layer composed of a non-supported catalyst and the second catalyst layer composed of a supported catalyst, exhibits reduced electrical resistance and interfacial resistance, and has increased catalyst availability. The use of the CCM and an MEA having the same results in a decrease in the interfacial resistance between the electrodes and the electrolyte membrane, a decrease in the amount of the catalyst used in the electrode catalyst layer, and a decrease in the thickness deviation in the electrode layers. The fuel cell employing the MEA exhibits maximal activity of the supported catalyst, and has improved cell characteristics such as output voltage, output density, efficiency, and the like.

Owner:SAMSUNG SDI CO LTD

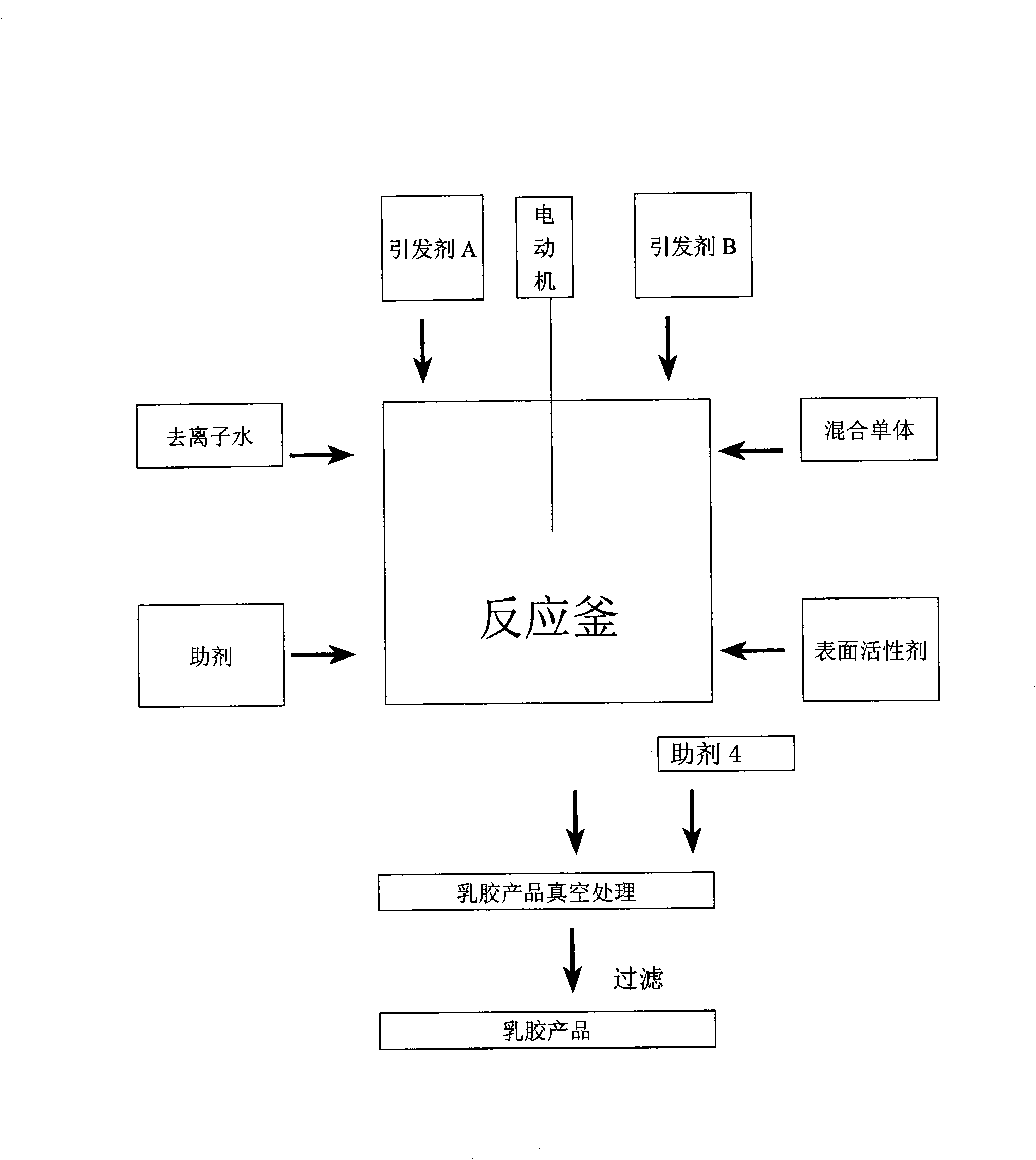

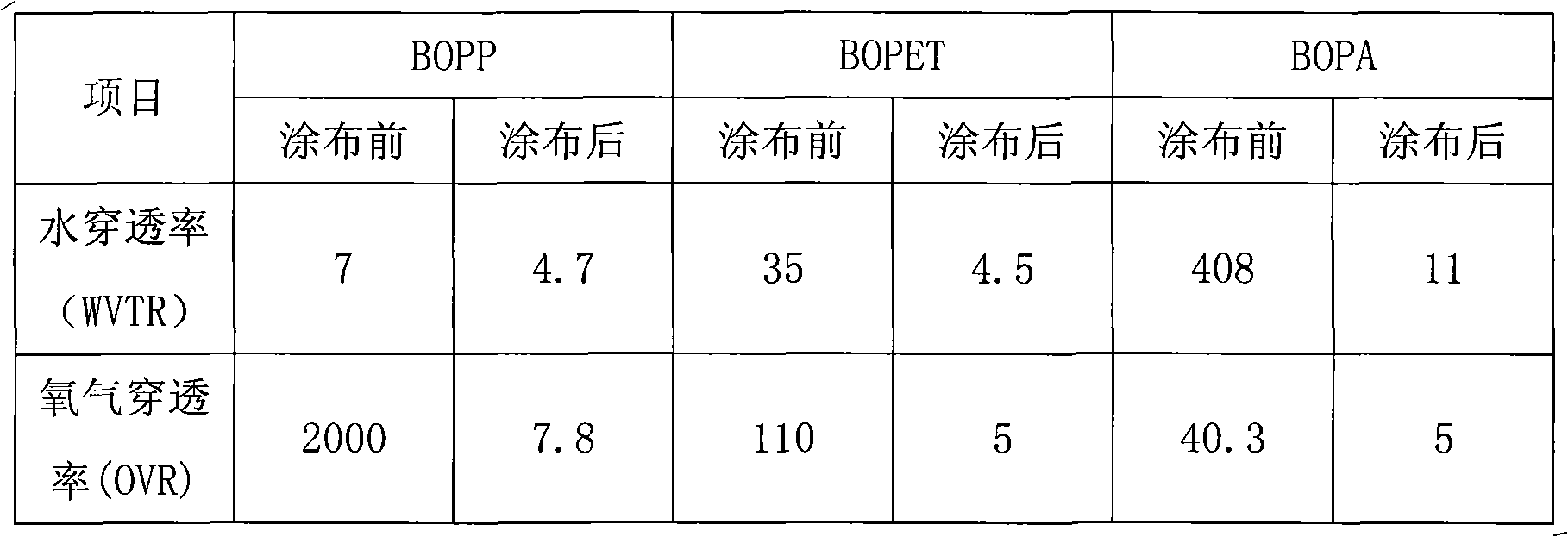

High barrier food package coated membrane latexes by thermal sealing at low temperature and preparation method

InactiveCN101358054AExtended shelf lifeHigh barrierFlexible coversWrappersCoated membraneVinylidine chloride

The invention relates to a low-temperature heat-sealing high-barrier food packaging film coating latex. The composition points of the mixed monomer of the latex is that vinylidene chloride accounts for 80 to 93 percent of the total amount of the mixed monomer; methyl acrylate, methyl ethyl oxalate, methyl methacrylate, butyl ester, acrylonitrile or methacrylonitrile account for 2 to 10 percent of the total amount of the mixed monomer; itaconic acid, acrylic acid, methacrylic acid account for 0.5 to 5 percent of the total amount of the mixed monomer; the surfactants added are 0.7 portion of SAS and 0.3 portion of sodium dodecyl sulfate; the additive 3 is 0.01 portion of metallic salt. The preparation method includes the following steps: deionized water, surfactant and additive are added in a reactor; the reactor is vacuumized and the gas is replaced by nitrogen gas; the mixed monomer is added. The product of the invention has the advantages of low temperature heat sealing and high barrier performance, and the food using the product has longer shelf life.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

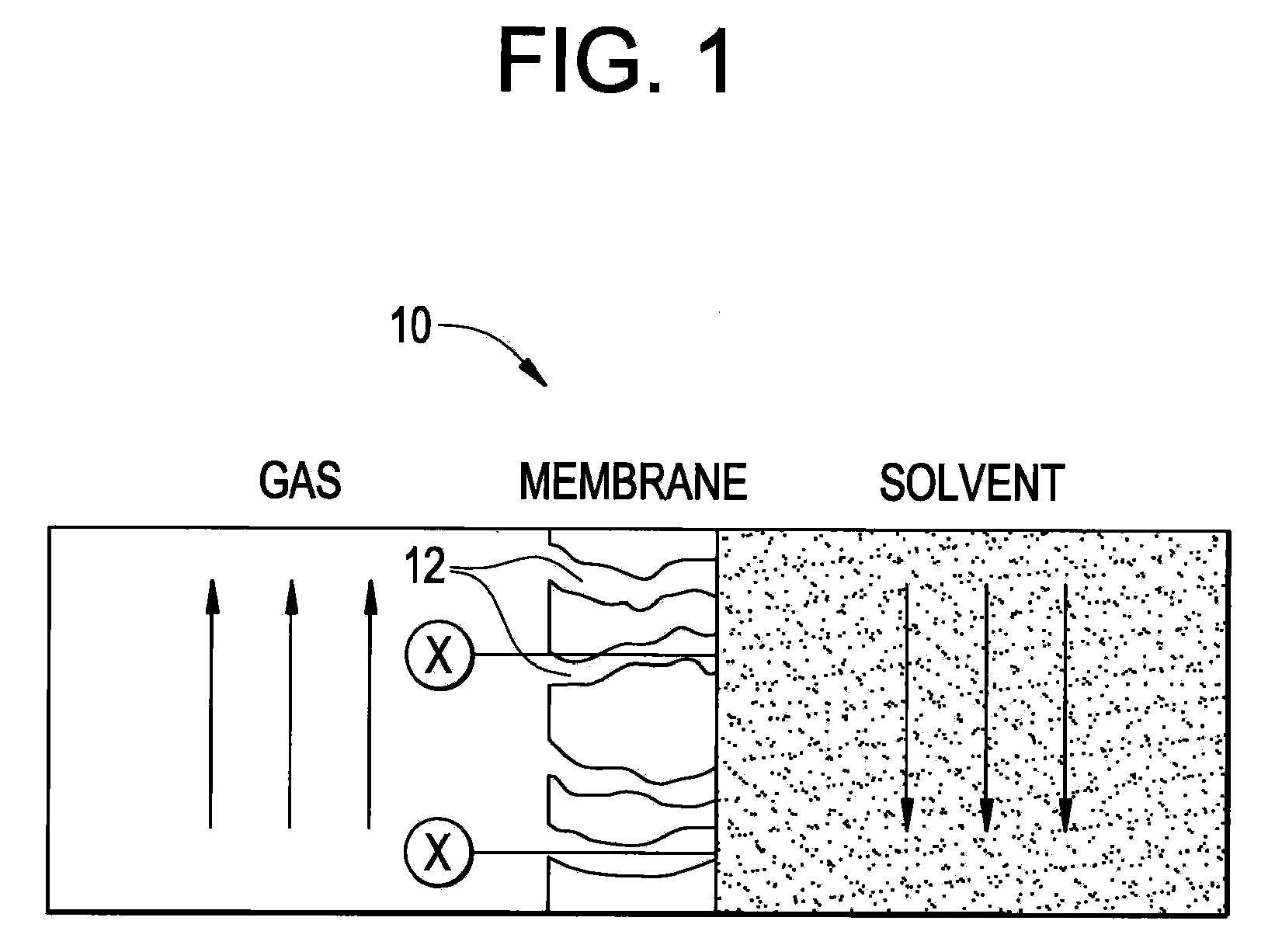

Membrane contactor systems for gas-liquid contact

A membrane contactor system for removing a component from a gas, comprising a housing defining a gas flow path; a microporous membrane positioned in the housing to allow the gas to flow across the membrane, wherein the membrane comprises a structure of nodes connected by fibrils in which surfaces of the structure of nodes and fibrils define a plurality of interconnecting pores extending through the microporous membrane, wherein the plurality of interconnecting pores are configured to allow the component to diffuse therethrough; and an oleophobic coating disposed on the microporous membrane to form a coated membrane and configured to provide oleophobicity to the coated membrane without blocking the plurality of interconnecting pores.

Owner:GENERAL ELECTRIC CO

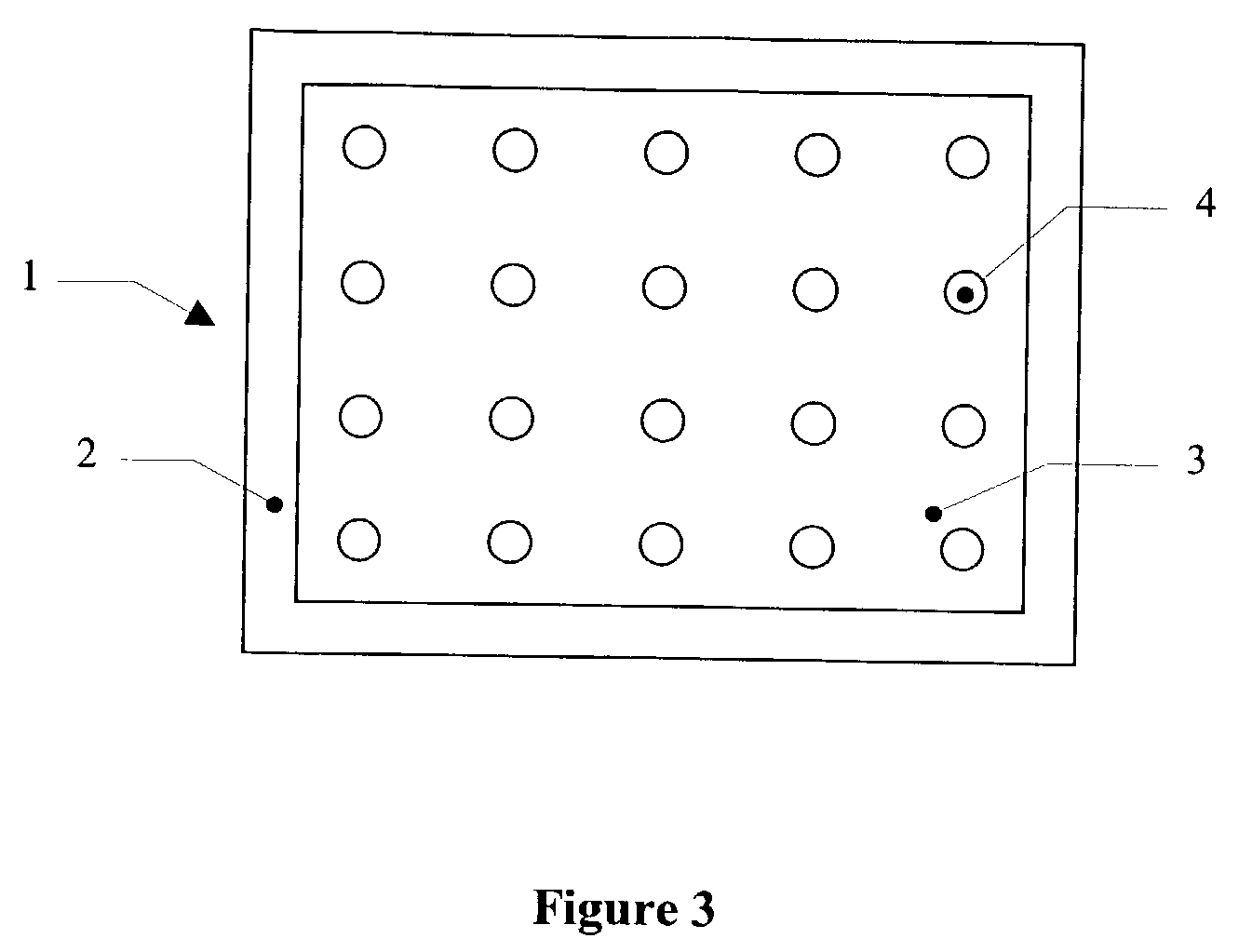

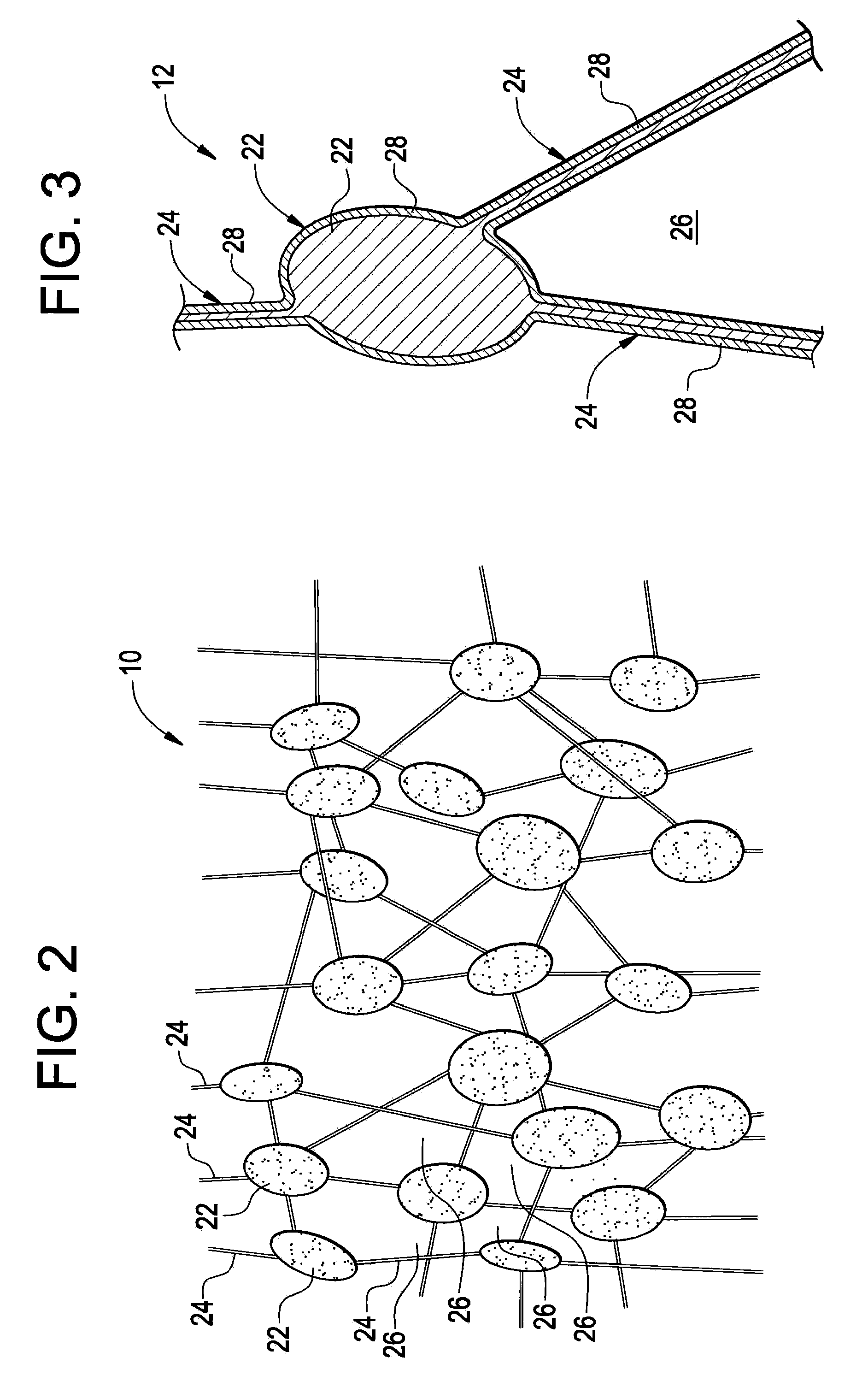

Processes, Framed Membranes and Masks for Forming Catalyst Coated Membranes and Membrane Electrode Assemblies

InactiveUS20080075842A1Easy and economical and efficient to manufactureImprove efficiencyIon-exchanger regenerationCell electrodesCoated membraneFuel cells

A process for preparing catalyst coated membranes and membrane electrode assemblies for use in direct methanol fuel cells is provided. Cathode and anode layers are formed by spraying catalyst-containing inks onto a novel framed electrolytic membrane to form a catalyst coated membrane. The spraying process optionally employs one or more masks, which carefully control where the catalyst-containing ink is deposited. Following application of the cathode and anode layers, diffusion layers are prepared and inserted onto the catalyst coated membranes, and pressed to form membrane electrode assemblies.

Owner:CABOT CORP

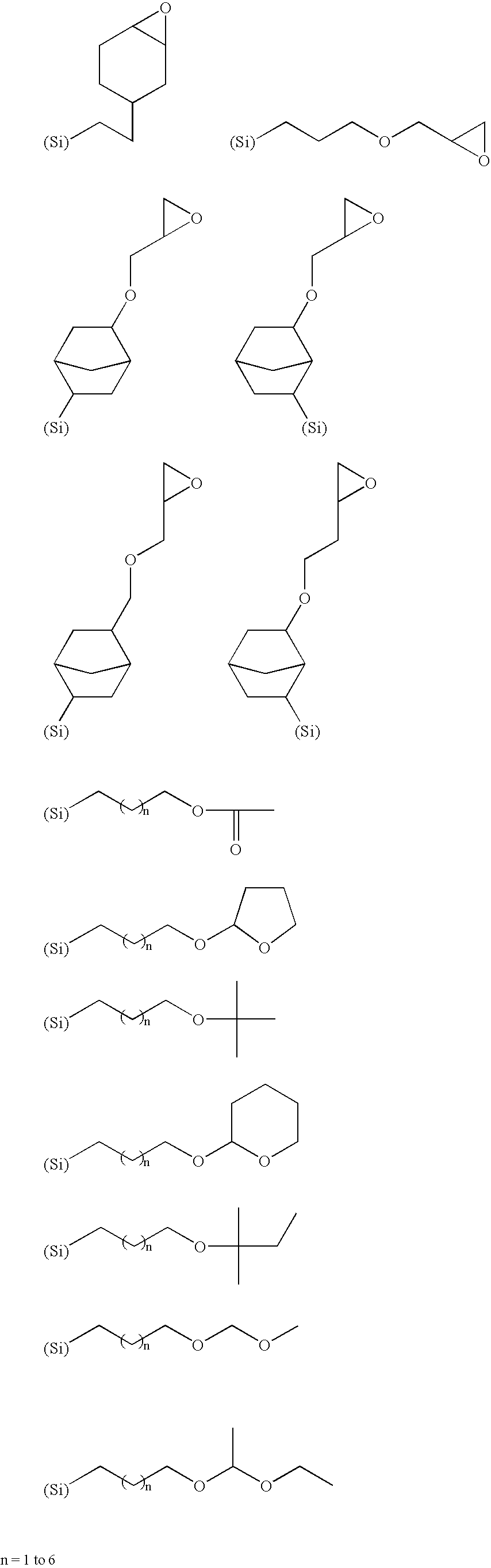

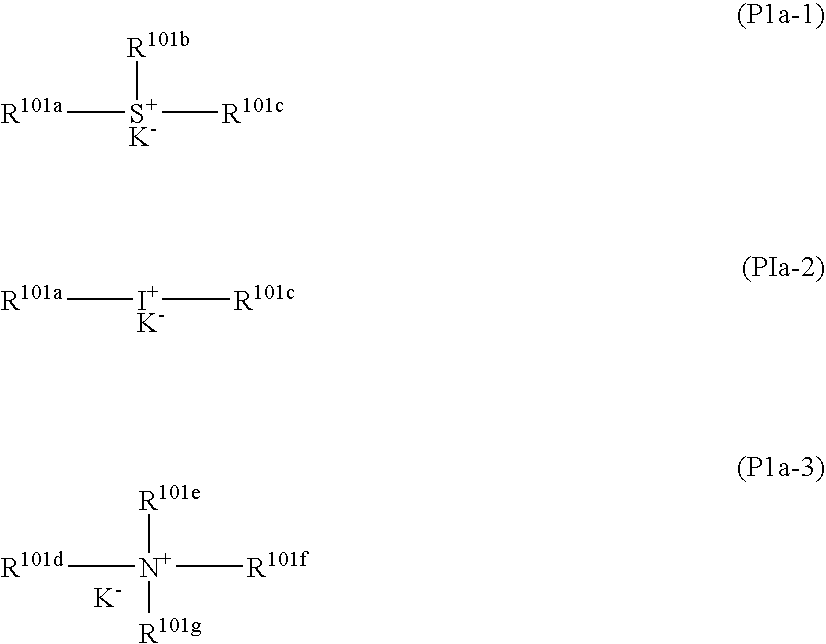

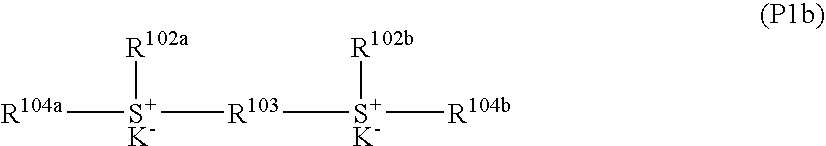

Silicon-containing film forming composition, silicon-containing film serving as etching mask, substrate processing intermediate, and substrate processing method

InactiveUS20070117044A1Photosensitive materialsRadiation applicationsCoated membraneSilane compounds

A multilayer resist process comprises forming in sequence an undercoat film, an intermediate film, and a photoresist film on a patternable substrate, and effecting etching in multiple stages. A silicon-containing film forming composition is useful in forming the intermediate film serving as an etching mask, comprising a silicon-containing polymer obtained through hydrolytic condensation of at least one Si—Si bond-containing silane compound having formula: R(6-m)Si2Xm wherein R is a monovalent hydrocarbon group, X is alkoxy, alkanoyloxy or halogen, and m is 3 to 6. The composition allows the overlying photoresist film to be patterned to a satisfactory profile and has a high etching selectivity relative to organic materials.

Owner:SHIN ETSU CHEM IND CO LTD

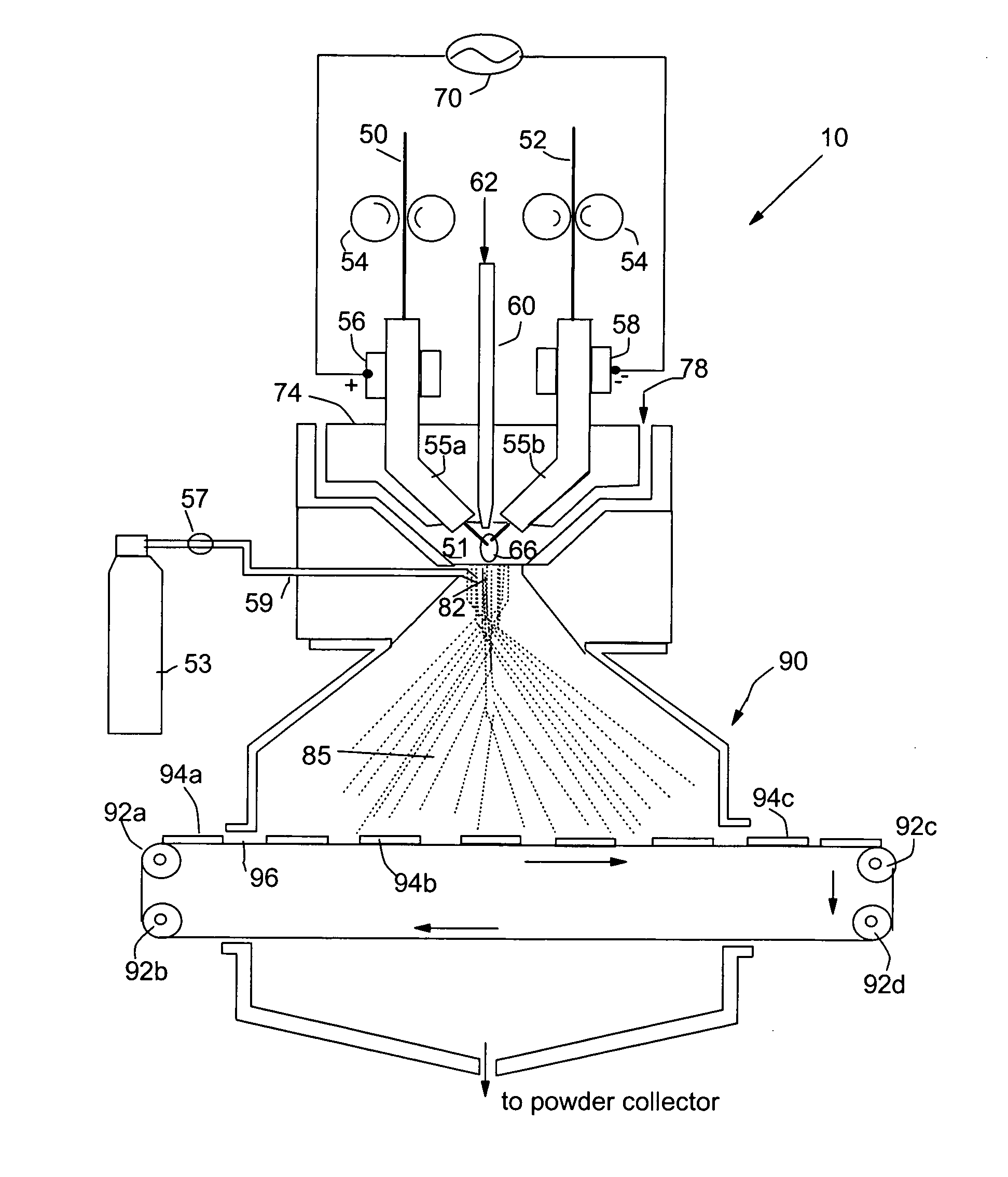

Twin-wire arc deposited electrode, solid electrolyte membrane, membrane electrode assembly and fuel cell

InactiveUS20050106435A1Easy to operateLow production costSolid electrolytesMolten spray coatingCoated membraneNanostructure

A twin-wire arc deposition method for depositing a nano-structured catalyst coating onto a solid electrolyte membrane or an electrode substrate from a precursor catalyst material selected from the group consisting of a metal, metal alloy, metal compound, and ceramic material. The method includes the steps of (a) providing an ionized arc nozzle comprising two consumable electrode and a working gas flow to form an ionized arc between the two electrodes, wherein the consumable electrodes provide the precursor catalyst material vaporizable therefrom by the ionized arc; (b) operating the arc nozzle to heat and at least partially vaporize the precursor catalyst material for providing a stream of nanometer-sized vapor clusters of the precursor catalyst material into a chamber in which the membrane or the electrode substrate has been placed; and (c) introducing a stream of a carrier gas into the chamber to impinge upon the stream of precursor vapor clusters to produce depositable nano clusters which are carried by the carrier gas to deposit onto a first side of the membrane or the electrode substrate for forming the nano-structured catalyst coating. Such a catalyst-coated membrane or electrode can be incorporated as a part of a fuel cell.

Owner:JANG BOR Z +2

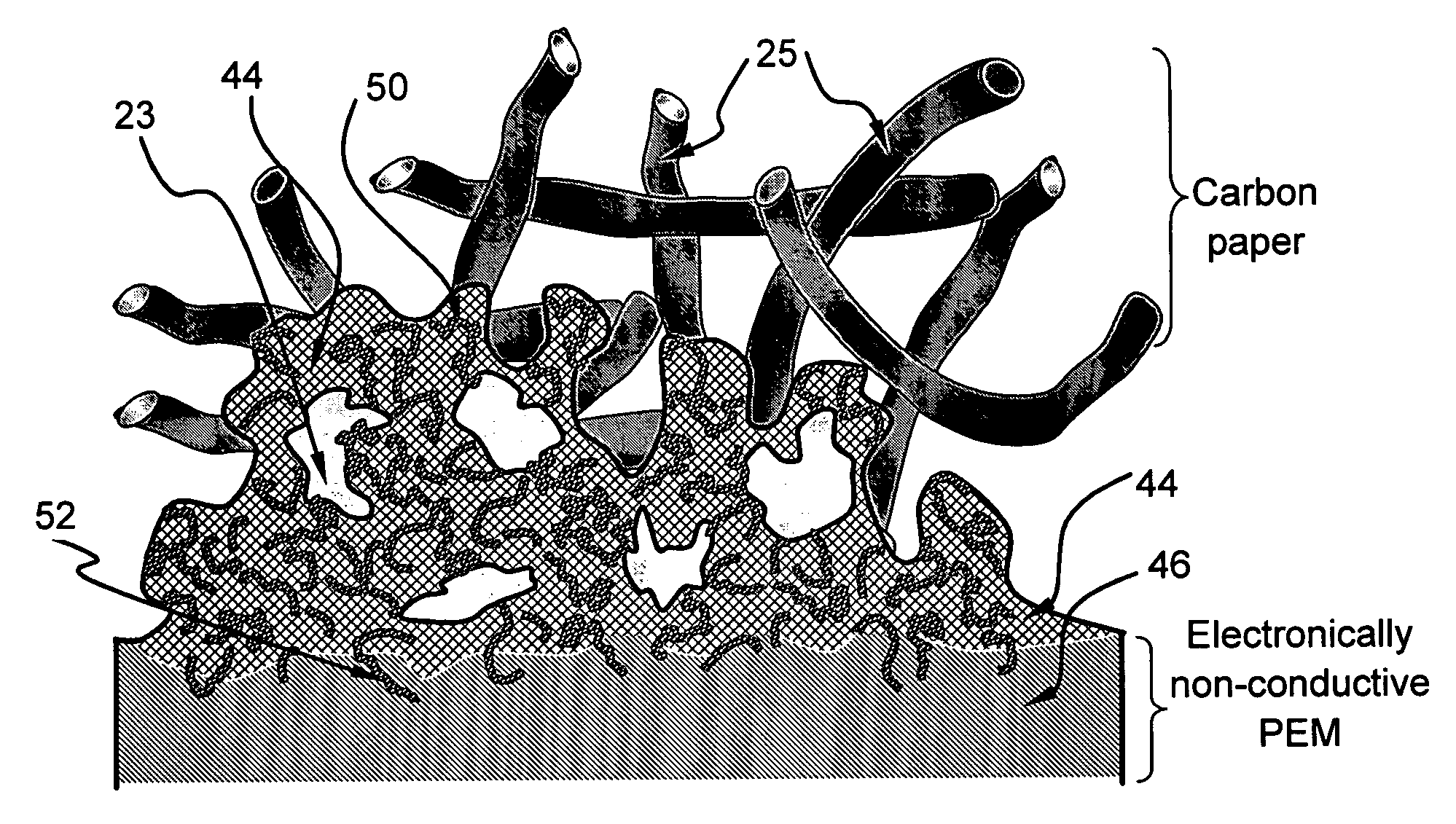

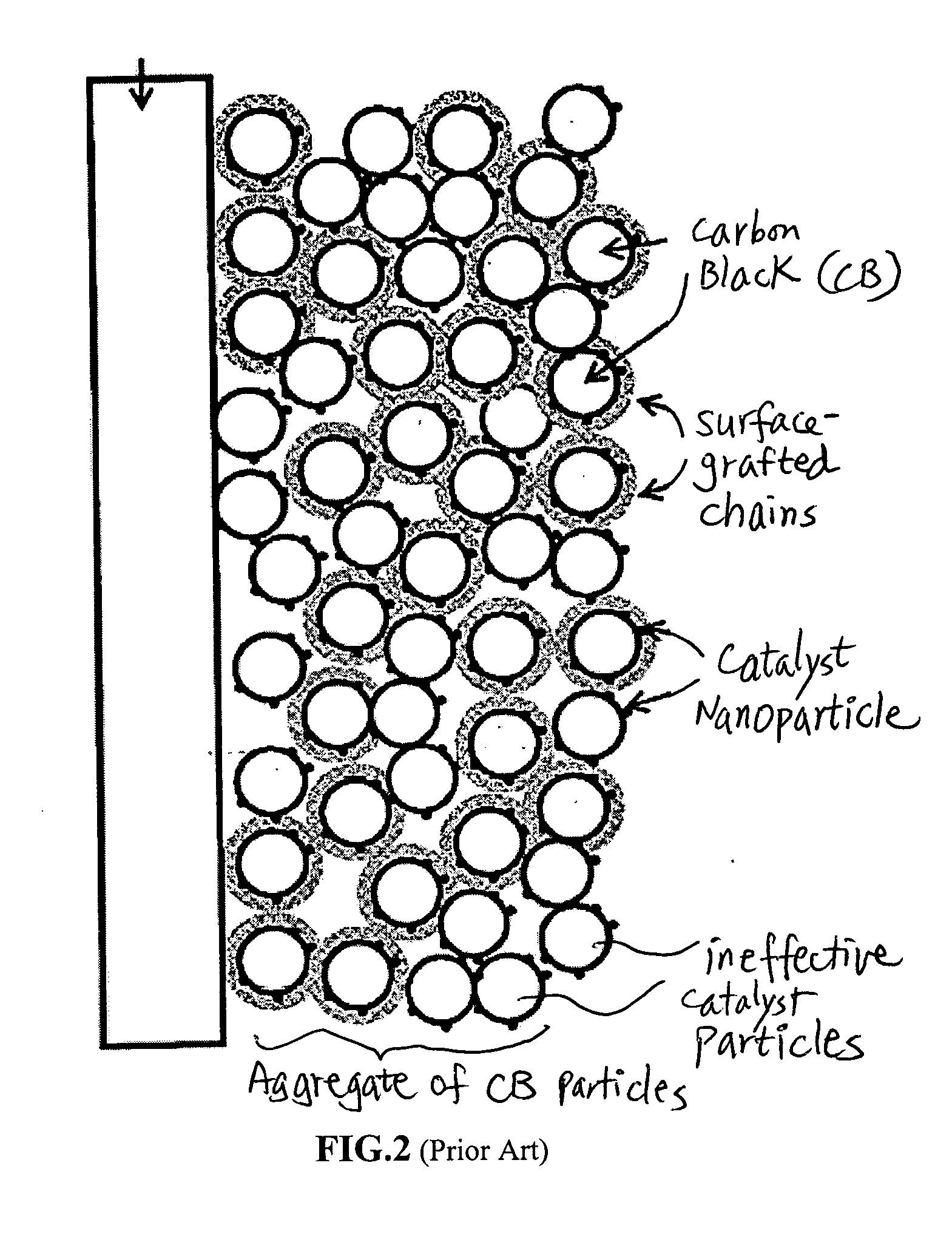

Fuel cell electro-catalyst composite composition, electrode, catalyst-coated membrane, and membrane-electrode assembly

InactiveUS20080182153A1Improve fuel cell performanceReduced Ohmic lossFuel cell auxillariesActive material electrodesCoated membraneFuel cells

Disclosed are an electro-catalyst composition and a precursor electro-catalyst composition (e.g., ink or suspension) for use in a fuel cell that exhibits improved power output. The electro-catalyst composition comprises: (a) a catalyst un-supported or supported on an electronically conducting carrier (e.g., carbon black particles); and (b) an ion-conducting and electron-conducting coating material in physical contact with the catalyst and / or coated on a surface of the carrier, wherein the coating material has an electronic conductivity no less than 10−4 S / cm (preferably no less than 10−2 S / cm) and an ion conductivity no less than 10−5 S / cm (preferably no less than 10−3 S / cm). Also disclosed are a fuel cell electrode comprising this composition, a membrane-electrode assembly (MEA) comprising this composition, and a fuel cell comprising this composition.

Owner:NANOTEK INSTR GRP LLC

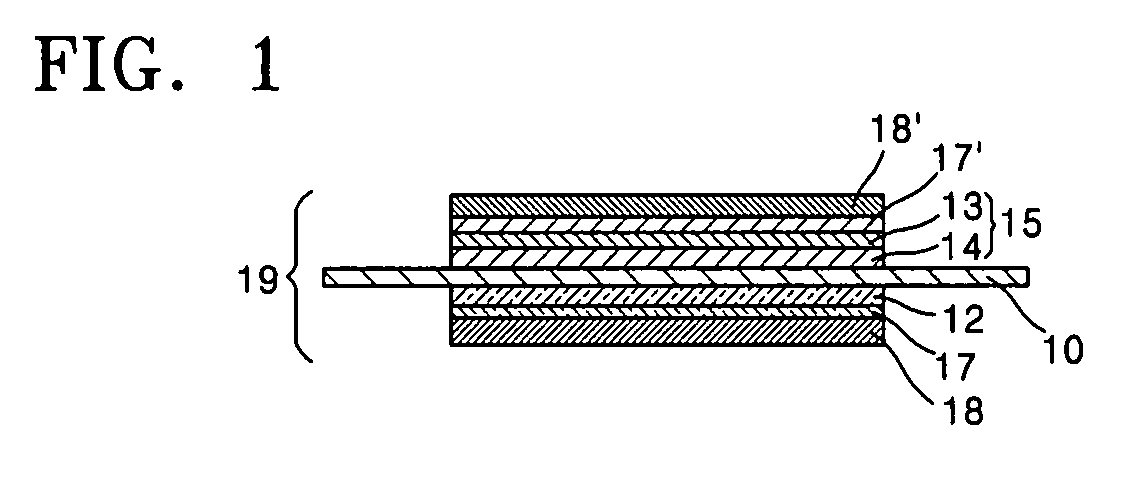

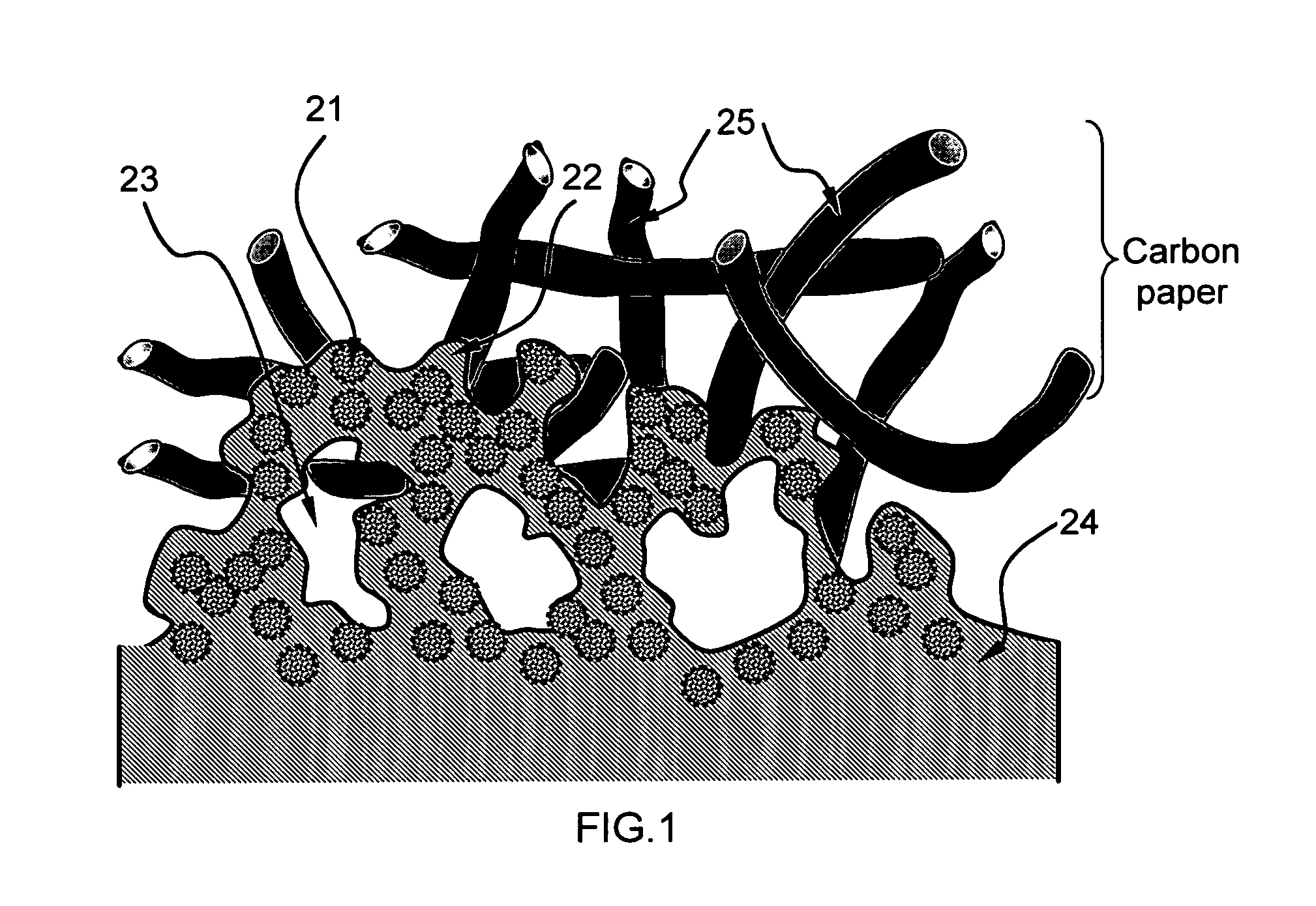

Process for producing fuel cell electrode, catalyst-coated membrane and membrane-electrode assembly

ActiveUS20080070777A1Improve fuel cell performanceReduced Ohmic lossActive material electrodesSolid electrolyte fuel cellsCoated membraneLiquid medium

Disclosed are processes for producing a fuel cell electrode and a membrane electrode assembly. In one preferred embodiment, the process comprises (a) preparing a suspension of catalyst particles dispersed in a liquid medium containing a polymer dissolved or dispersed therein; (b) dispensing the suspension onto a primary surface of a substrate selected from an electronically conductive catalyst-backing layer (gas diffuser plate) or a solid electrolyte membrane; and (c) removing the liquid medium to form the electrode that is connected to or integral with the substrate, wherein the polymer is both ion-conductive and electron-conductive with an electronic conductivity no less than 10−4 S / cm and ionic conductivity no less than 10−5 S / cm and the polymer forms a coating in physical contact with the catalyst particles or coated on the catalyst particles.

Owner:NANOTEK INSTR GRP LLC

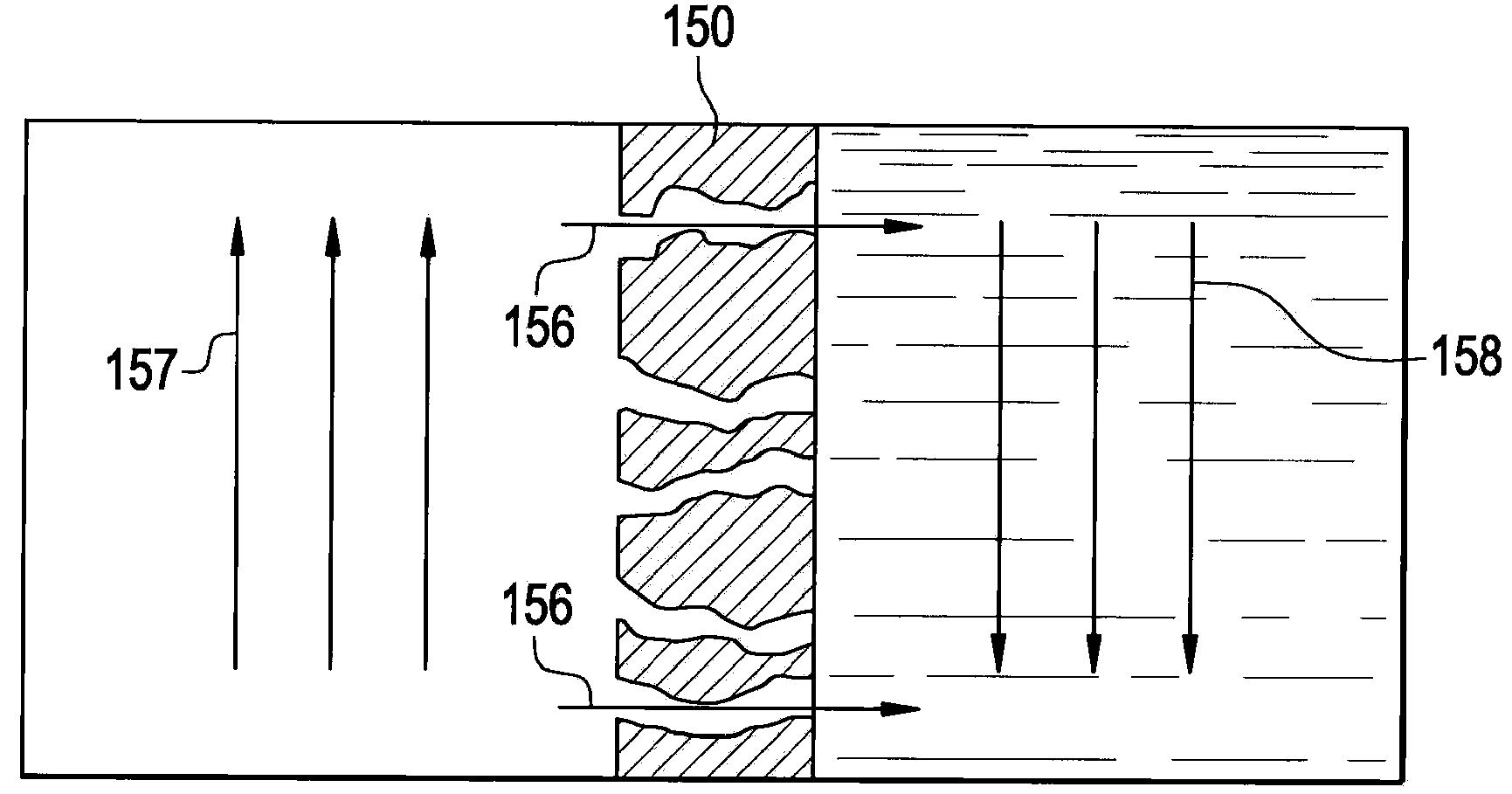

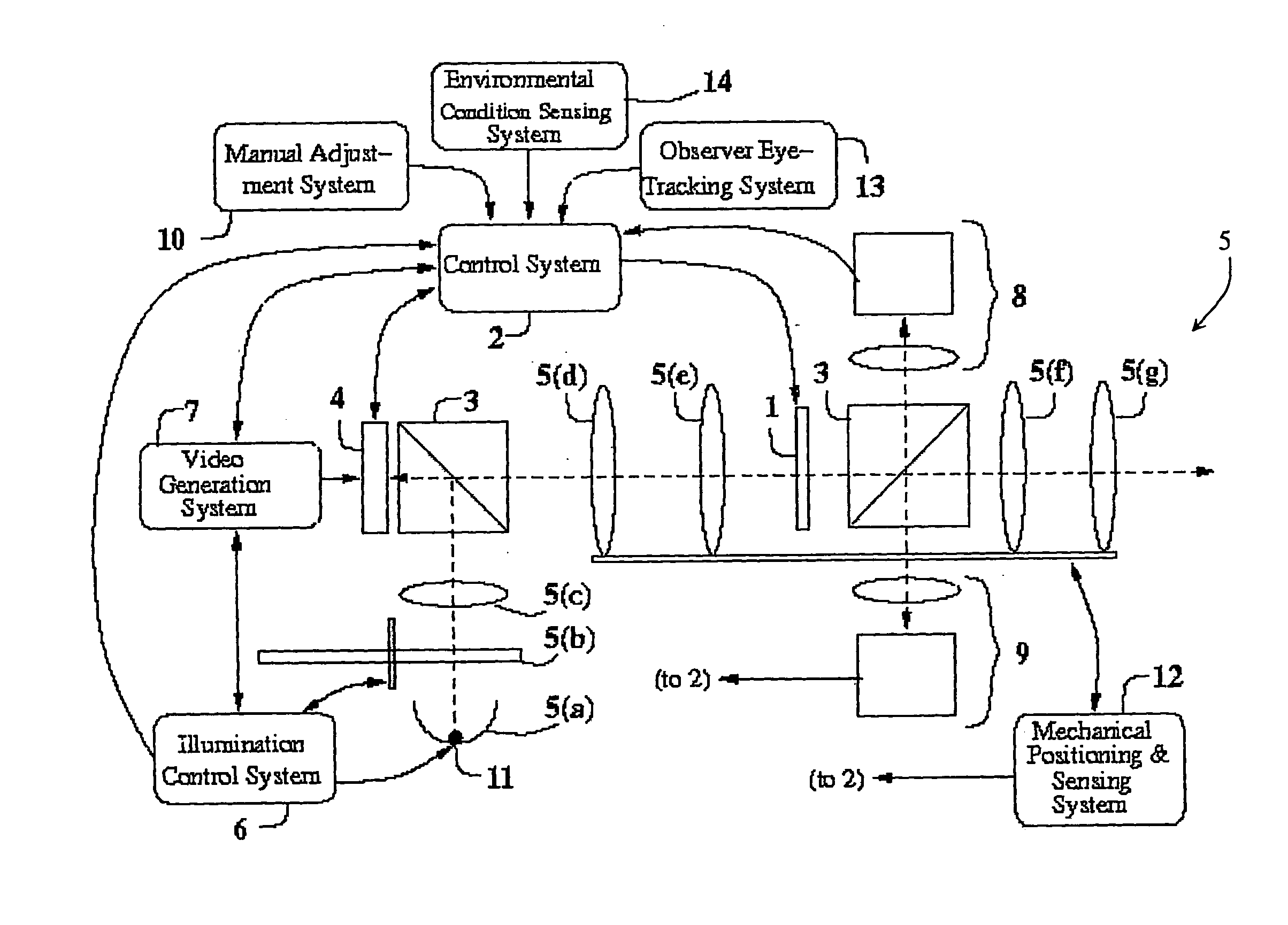

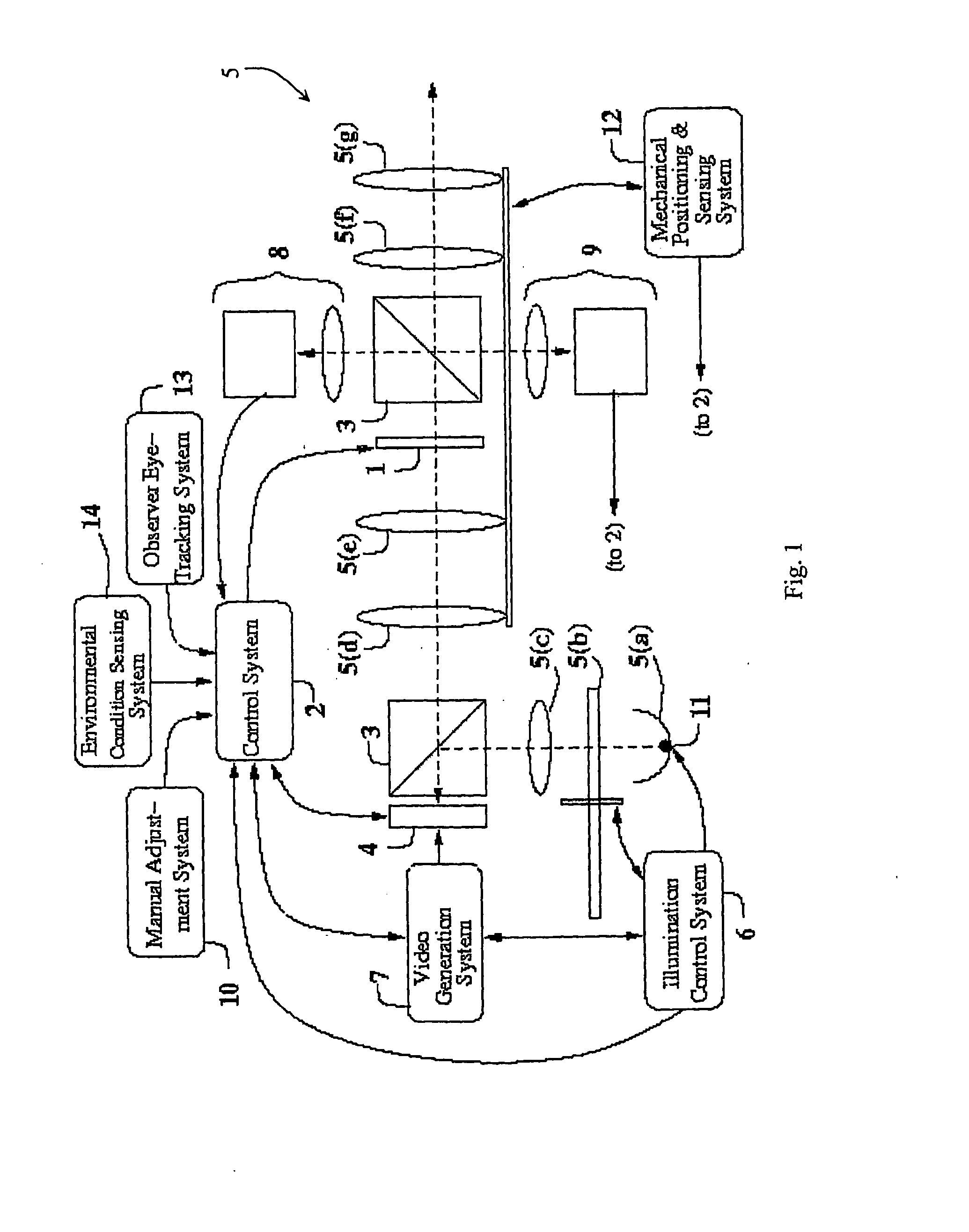

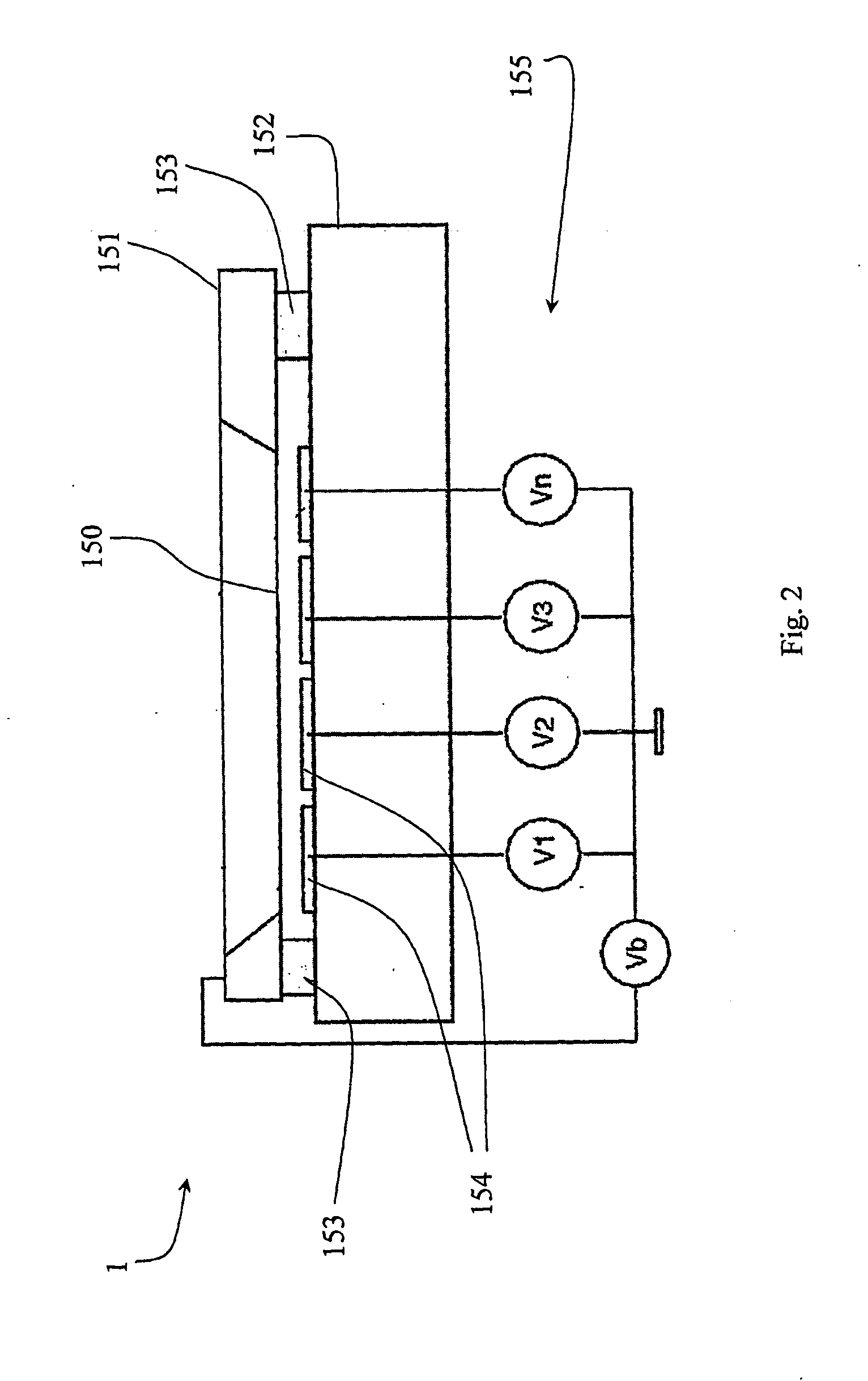

Image Projection Display System

InactiveUS20090290132A1Reduce the amount requiredTelevision system detailsProjectorsCoated membraneOptical property

An image projection display system comprises a variable optical property element (1). The element (1) is under direction of a control system (2) and is positioned within an optical system (5), comprising optical elements (5(a, b, c, d, e, f, g)). A source image electronic device (4) receives inputs from a video generation system (7) and is illuminated with light from a photon source (11) filtered by a wavelength-selecting colour wheel (5(b)), under direction of an illumination control system (6). The element 1 comprises a thin Al-coated membrane (150) etched from Sa3N4 (151) mounted via spacers (153) over a substrate (152) having actuator pads (154). Circuits (155) supply various control voltages Electrostatic attraction causes the membrane (150) to deform towards the actuator pads (154) when voltages V1, V2, . . . VN are applied to the actuation channels. The control system (2) receives inputs from the illumination control system (6), the video generation system (J), the source image formation device (4), the mechanical positioning and sensing system (12), and vice-versa.

Owner:OPTYKA

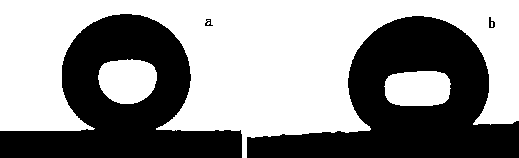

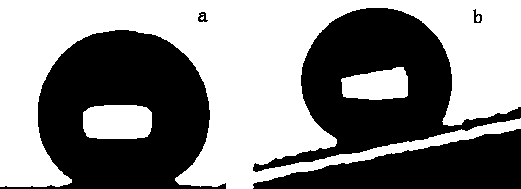

Preparation method of super-hydrophobic, super-oleophobic and high transparency triple-function coating film

InactiveCN103965673AExcellent superhydrophobic propertiesFrost resistantCoatingsCoated membraneSolar battery

The invention discloses a preparation method of a super-hydrophobic, super-oleophobic and high transparency triple-function coating film, belongs to the field of novel materials, and particularly belongs to the field of self-cleaning optical materials. The method comprises the steps of firstly assembling large-grained SiO2 nano particles on a glass substrate, so as to form the lower layer of the fine structure of a functional coating layer, simultaneously adding pore-foaming agent, so as to adjust and control space filling factors, then assembling upper layer fluoride SiO2 nano fine particles, and constructing a two-stage uneven surface coating layer with a suspension structure and super-hydrophobic, super-oleophobic high and transparency functions. The functional film has frost prevention, fog prevention, pollution prevention, bacteriostasis and self-cleaning properties, also has excellent translucency, can effectively prevent properties of optical elements, photoelectron elements, solar batteries and laser systems from being influenced by environment in severe environment, greatly expands the application range of the equipment, guarantees the operational reliability, and prolongs the service life, thereby greatly improving the practical values of the equipment.

Owner:JIANGNAN UNIV +1

Hard Coat Layer Composition and Hard Coat Film

InactiveUS20090274902A1Easy to disassembleImprove adhesionSynthetic resin layered productsPolarising elementsCoated membranePolymer science

The present invention provides a hard coat film and a hard coat layer forming composition which forms a hard coat layer adhering well to a substrate, which does not curl up easily and having antifouling properties, excellent abrasion resistance, surface hardness, and a high level of visibility. The present invention has a specific feature in that a hard coat layer forming composition which includes polyfunctional acrylic (or methacrylic) monomer (A), acrylic monomer having a hydroxyl group (B), radical photopolymerization initiator (C), and fluorocompound having a polymerizable group (D) is used. The hard coat film of the present invention has the hard coat layer which is formed by curing the hard coat layer forming composition on a transparent substrate and has a surface free energy less than 20 mN / m and the thickness in the range of 5-25 μm.

Owner:TOPPAN PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com