Membrane contactor systems for gas-liquid contact

a contactor system and membrane technology, applied in the field of membrane contactor systems, can solve the problems of increasing the cost of the system, affecting the utility of the system, and the amount of gas which has to be treated,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

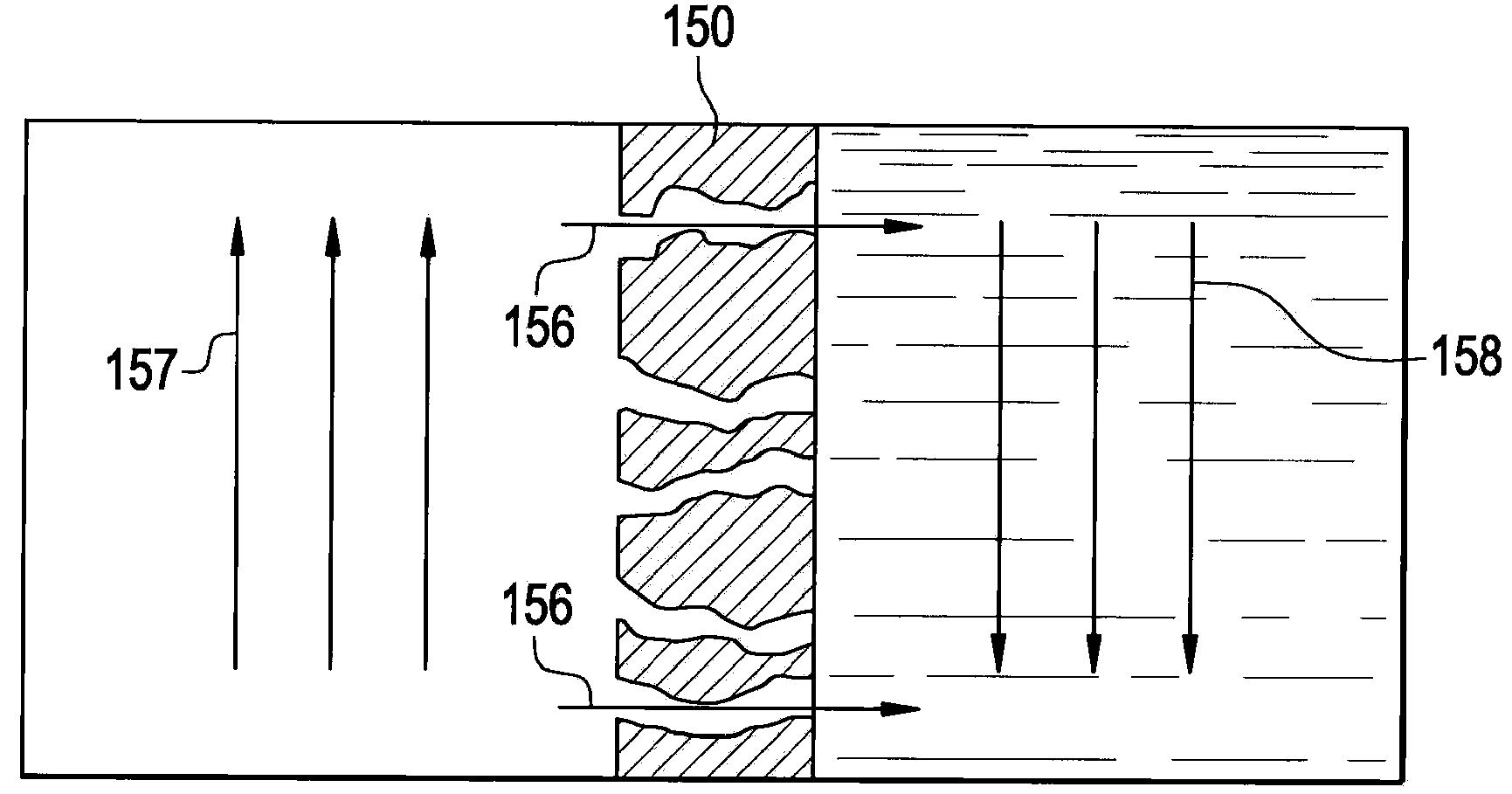

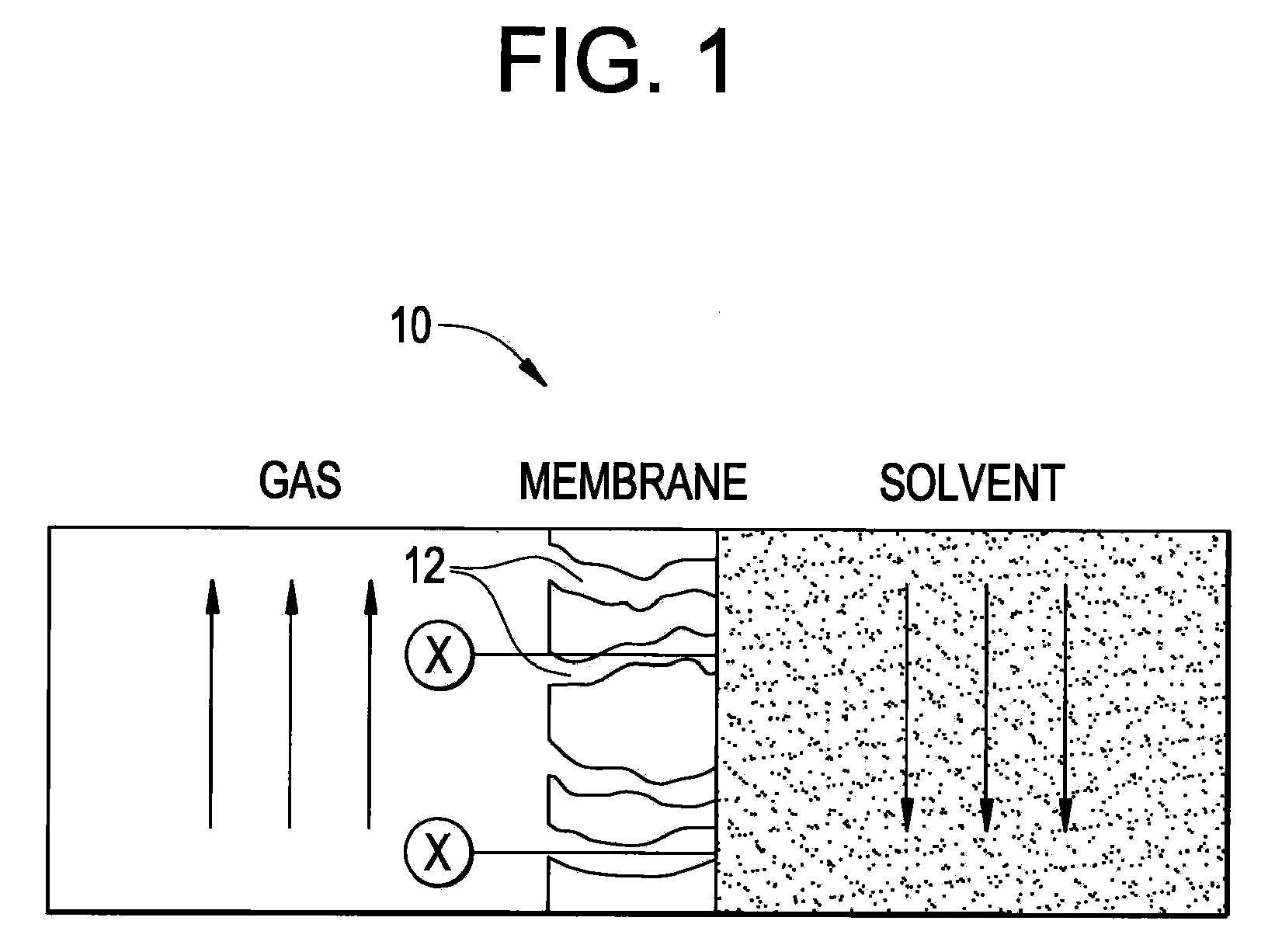

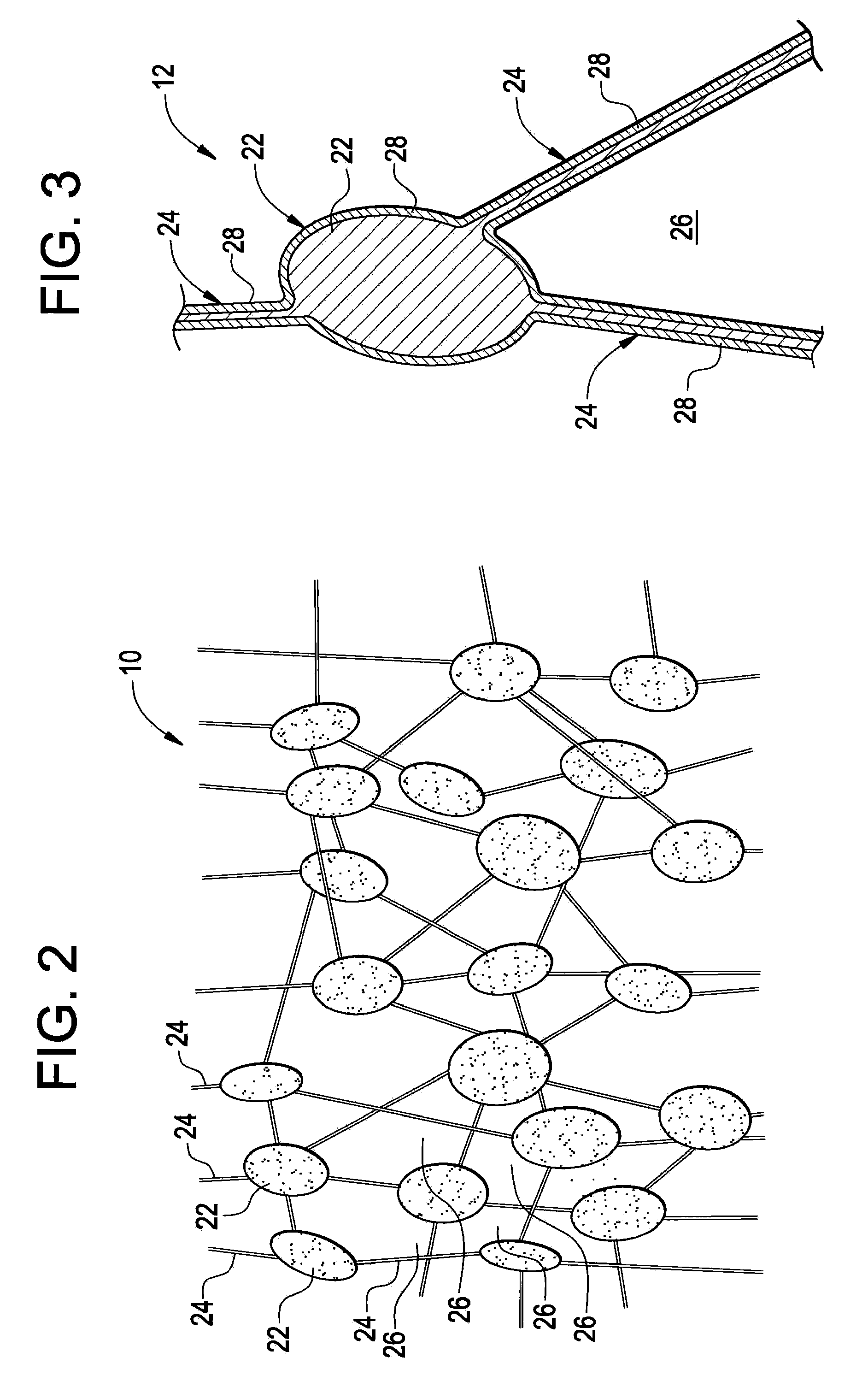

[0018]The membrane contactor systems described herein include an oleophobically-treated expanded polytetrafluoroethylene (PTFE) membrane. The oleophobic treatment on the expanded PTFE membrane can allow for the membrane contactor system to be effective in applications covering a wider range of liquids than current membrane contactors. The oleophobic treatment, moreover, can increase the operating life of the membrane in the contactor by reducing the amount of blockage of pores that can occur during use. The membrane contactor described herein can be disposed in any gas-liquid contacting application, such as, without limitation, carbon dioxide separation / removal, natural gas sweetening, oil degasification, and the like. In an exemplary embodiment, the membrane contactor system can replace current absorption units in a carbon dioxide (CO2) separation process. Employing the membrane contactor system instead of current separation technologies (e.g., packed bed scrubbers) for carbon diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oleophobicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com