Patents

Literature

369 results about "Degasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degassing, also known as degasification, is the removal of dissolved gases from liquids, especially water or aqueous solutions. There are numerous methods for removing gases from liquids. Gases are removed for various reasons. Chemists remove gases from solvents when the compounds they are working on are possibly air- or oxygen-sensitive (air-free technique), or when bubble formation at solid-liquid interfaces becomes a problem. The formation of gas bubbles when a liquid is frozen can also be undesirable, necessitating degassing beforehand.

Method for recycling sulfur from acid gases containing hydrogen sulfide

InactiveCN101791517AReduce consumptionHigh purityDispersed particle separationEnergy inputCatalytic oxidationEmission standard

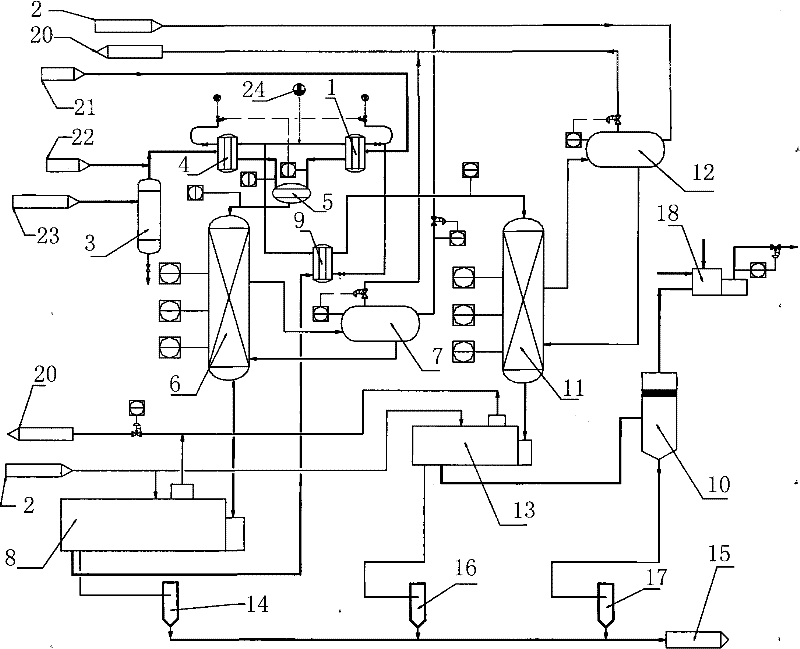

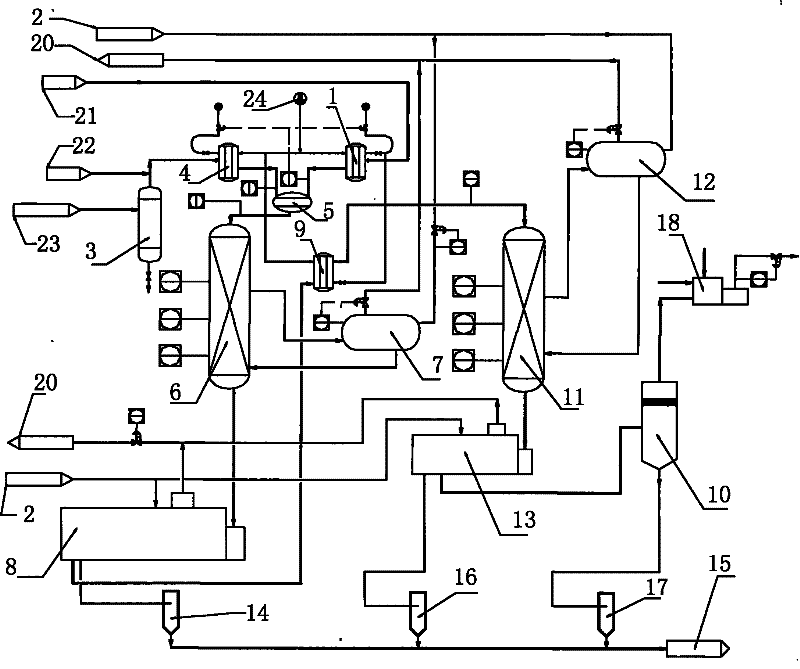

The invention relates to a method for recycling sulfur from acid gases containing hydrogen sulfide, comprising the following steps: (a) air supply; (b) acid gas pretreatment; (c) mixture; (d) primary direct catalytic oxidation; (e) primary sulfur condensation; (f) process gas reheating; (g) secondary direct catalytic oxidation; (h) secondary sulfur condensation; (i) sulfur re-separation; (j) degasification in a liquid sulfur tank; and (k) tail gas burning. When the volume concentration of H2S in the acid gases in the prior art is 1-15%, the recycle rate of sulfur can reach over 99% by the method of the invention, and the emission load of H2S in the acid gases processed by the method of the invention meets the emission requirement of Integrated Emission Standard of Air Pollutants (GB16297-1996).

Owner:北京至清时光环保工程技术有限公司

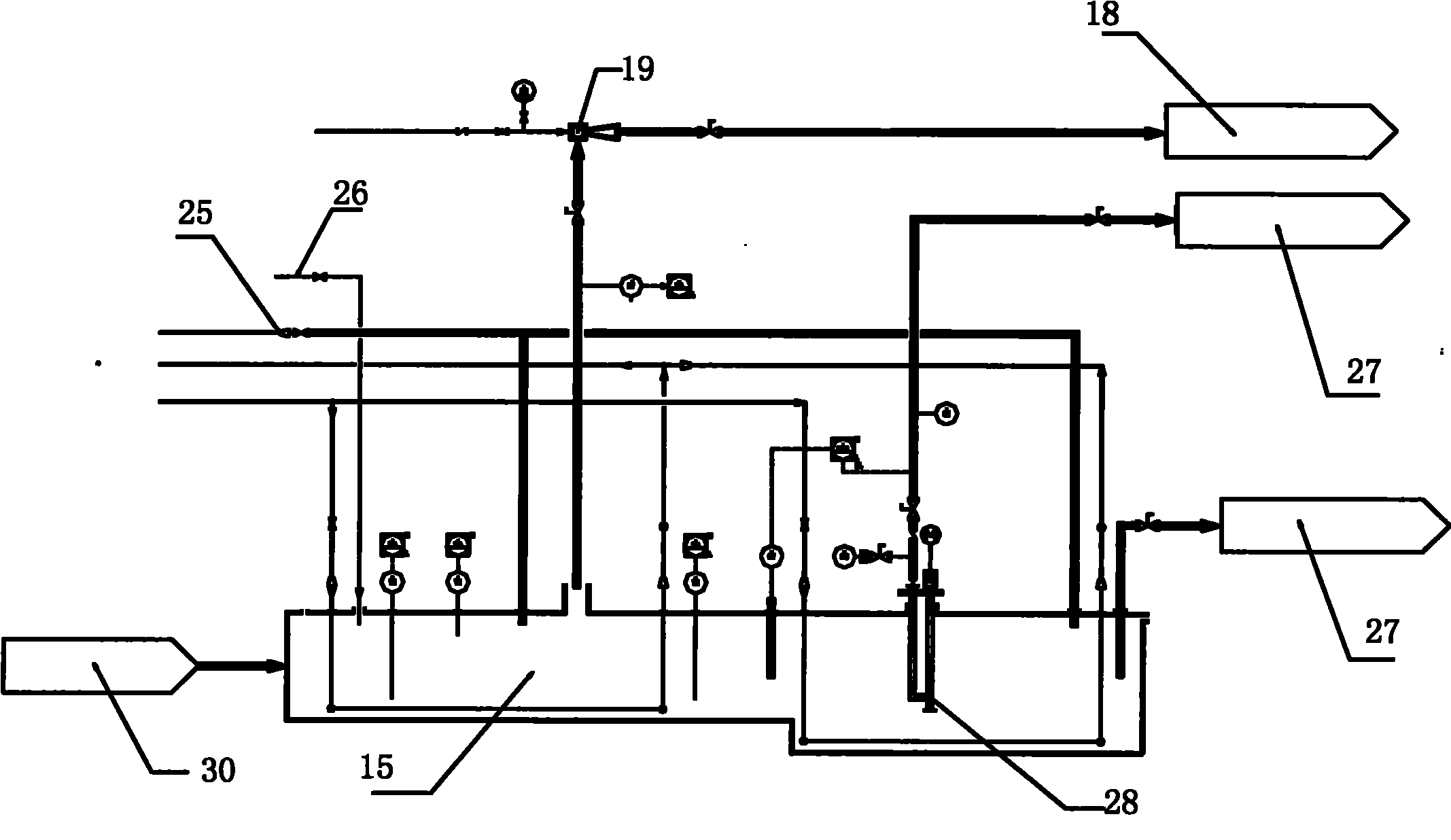

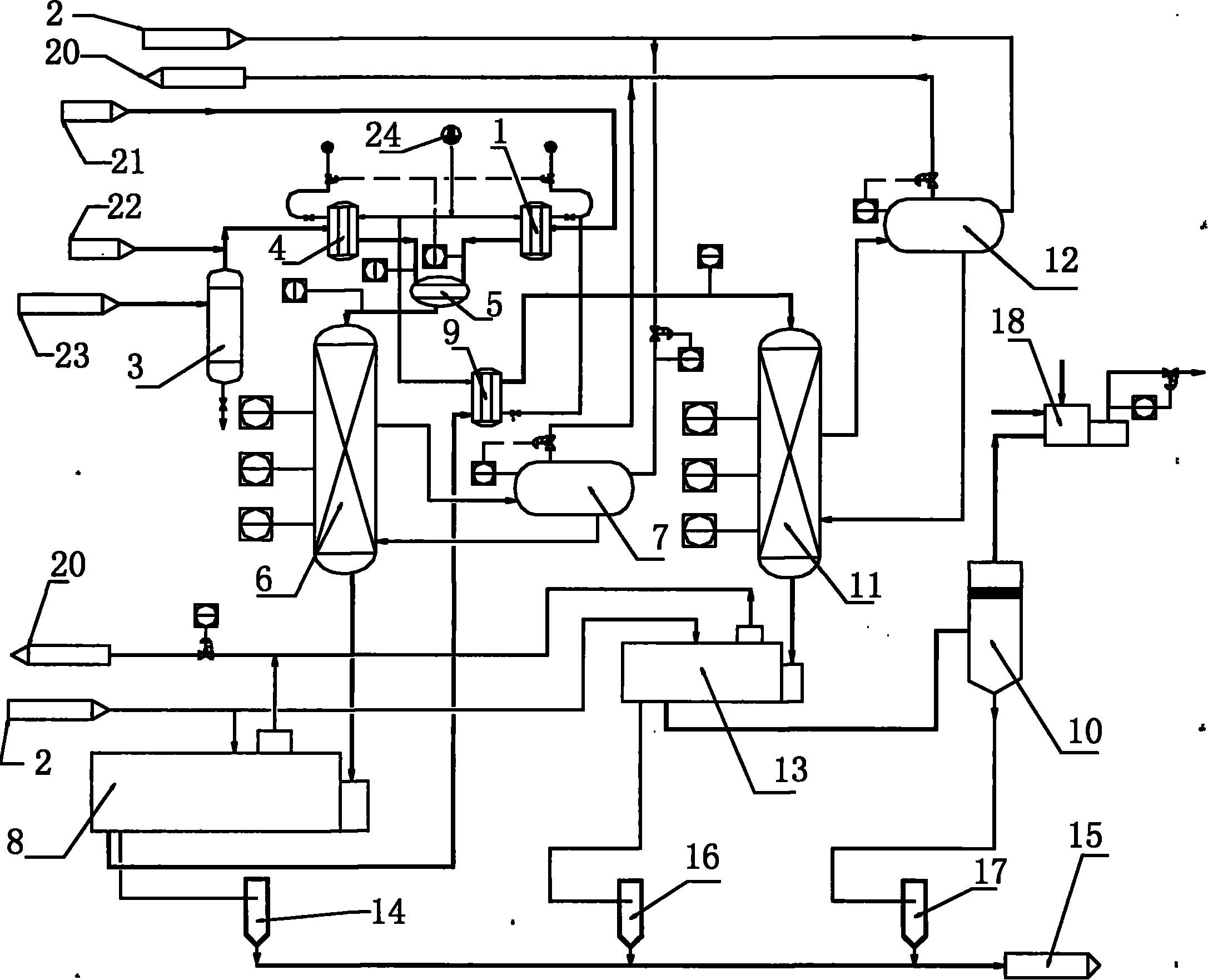

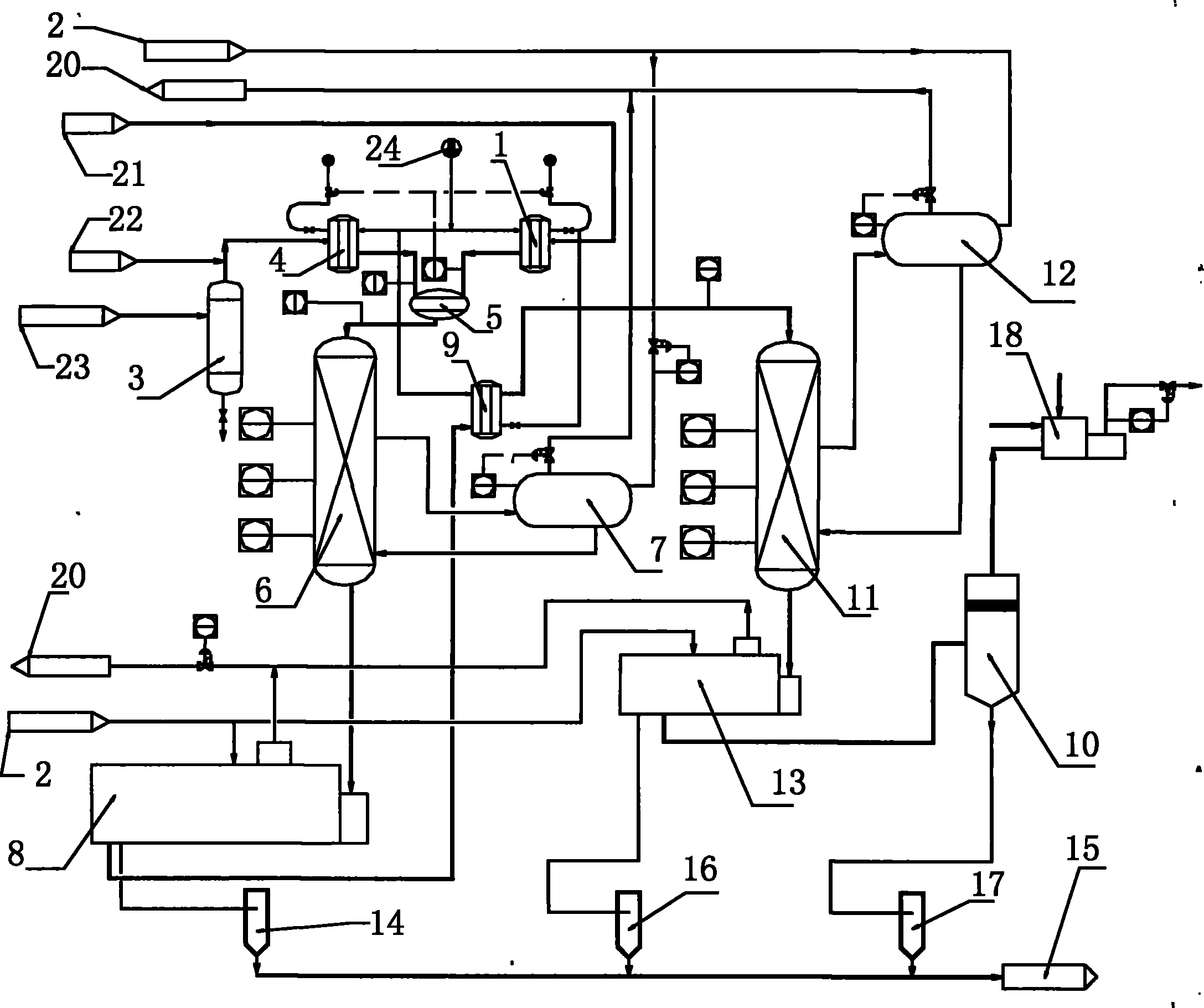

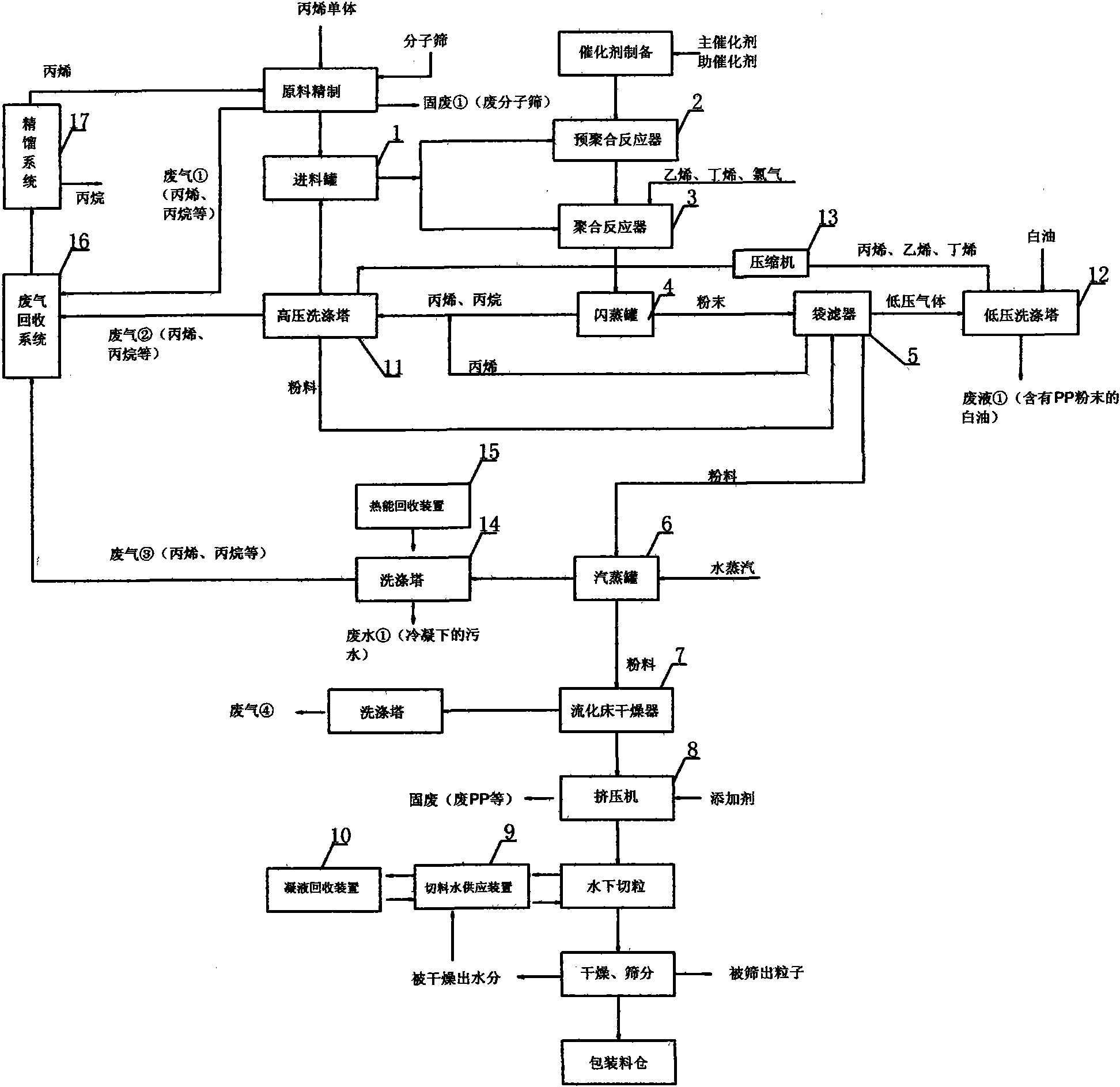

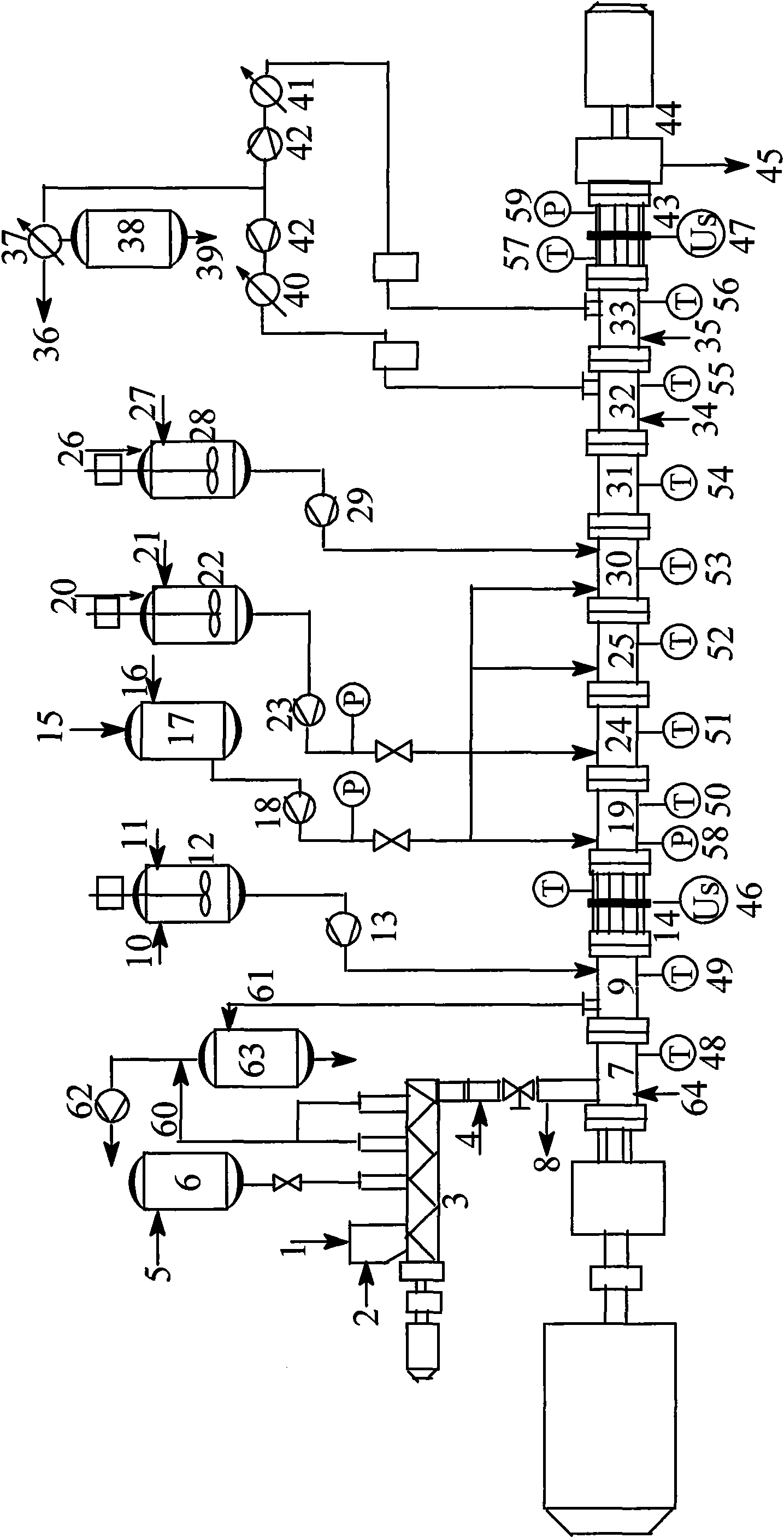

Production method of polypropylene and device thereof

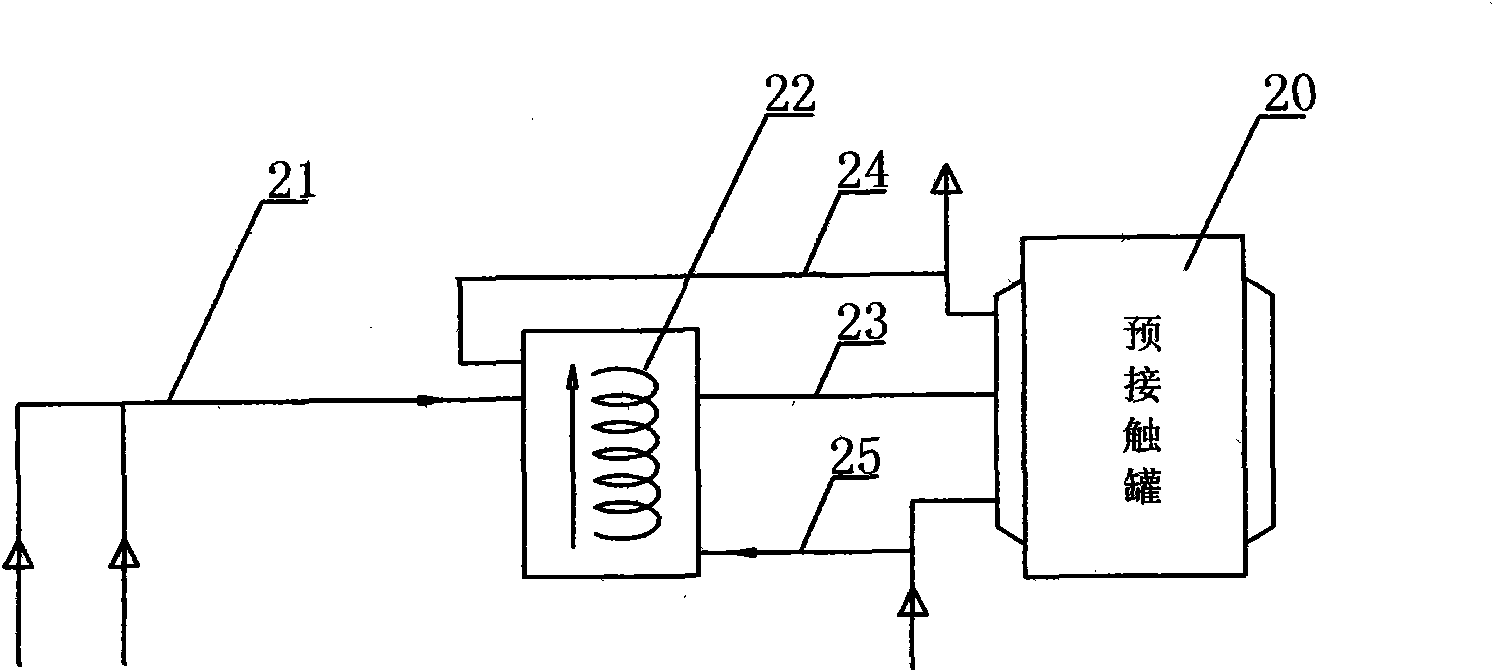

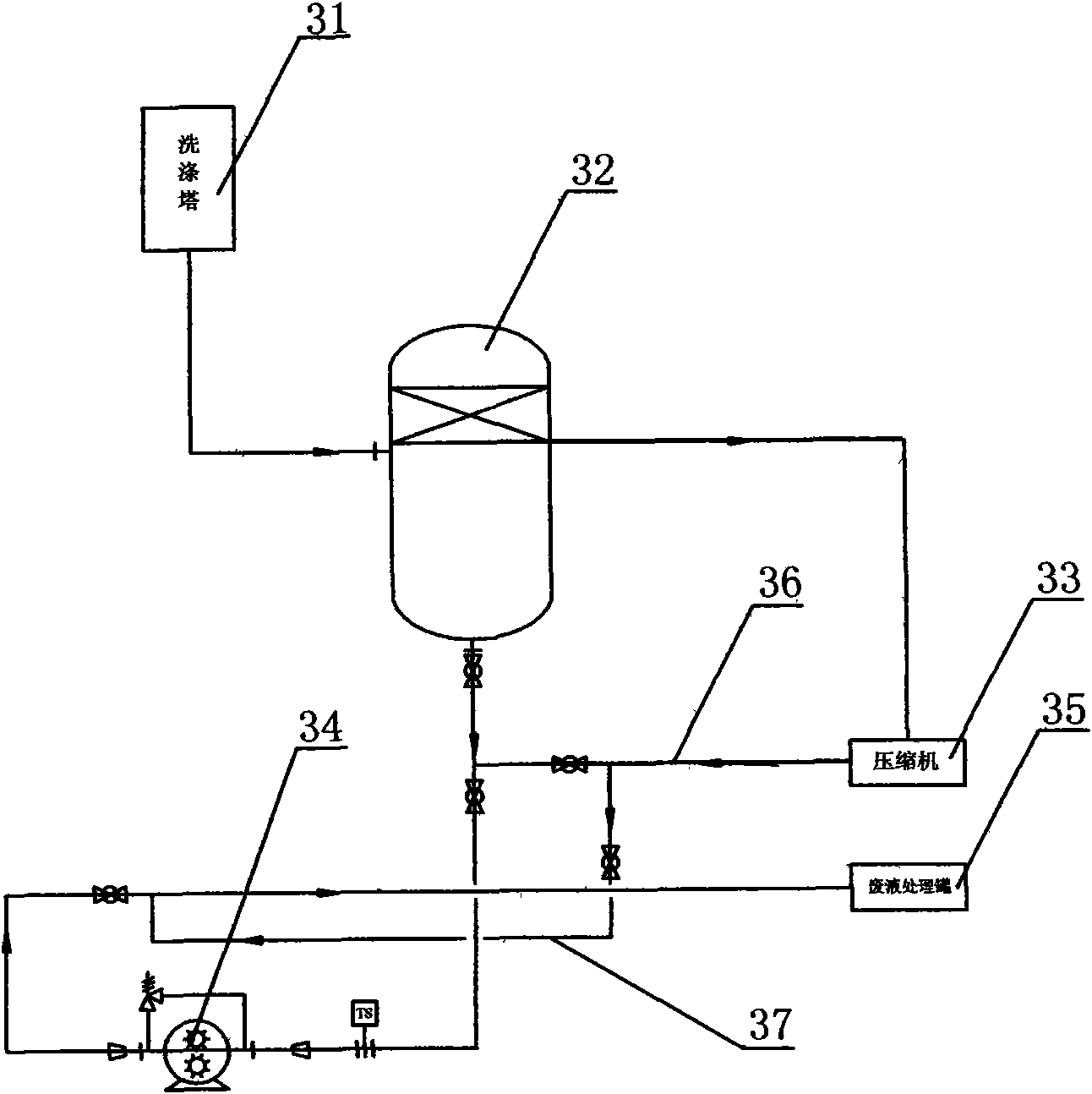

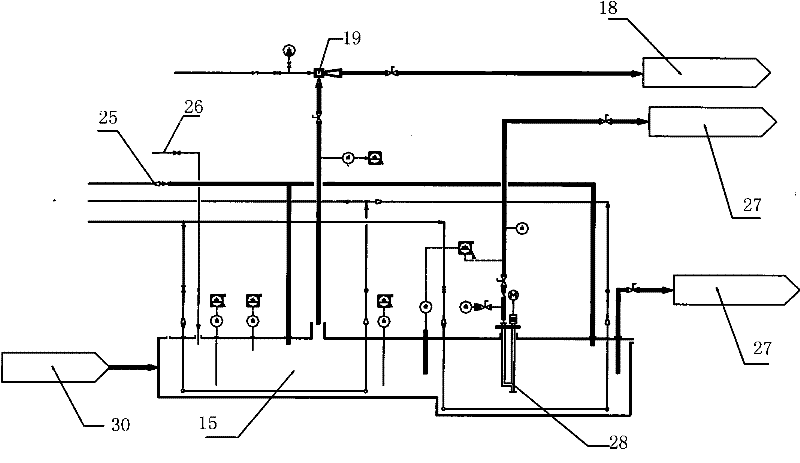

The invention discloses a production method of polypropylene with an English name of Polypropylene (short for PP) and a device thereof, belonging to the technical field of polymer synthesis. The production method comprises the steps of: prepolymerization, polymerization-flash vaporization, degasification-steaming, drying-extruding, granulating-product package and the like. By optimizing the technique steps and parameters of prepolymerization, polymerization, flash vaporization, degasification, steaming, drying, extruding, granulating and the like, the invention improves the utilization ratio of raw materials, simultaneously adds a waste gas and waste liquor recovery system creatively, adds a heat recovery system of a washing tower, uses recovered heat for heating grease, and improves heat utilization ratio; the setting of powder and condensate recovery device improves production efficiency and reduces production cost; a standby water tank is added for granulating and water supply, thus preventing machine stopping caused by fault of the water tank and improving production efficiency; and the improvement of gas-exiting pipelines and exhaust pipelines eliminates potential safety hazard, saves cost and has good environment protection.

Owner:ZHEJIANG SHAOXING SANJIN PETROCHEM

Method for manufacturing dendrobium officinale fresh juice stock solution

InactiveCN102008654ANot easy to clarifyNot easy to filterMetabolism disorderAlcoholic beverage preparationFlavorAdditive ingredient

The invention discloses a manufacturing method for extracting and processing fresh juice stock solution by using dendrobium officinale as a raw material. The method furthest protect the color, flavor, nutrition and effective ingredients of dendrobium officinale fresh juice by surface sterilization of the collected fresh dendrobium officinale and technology of juicing, enzymolysis, vacuum degasification, micro-filtration, ultra-filtration, sterile filling, high-temperature instantaneous sterilization and the like, and meanwhile, the product is favorable for storing and realizing industrialized production. The dendrobium officinale is processed into the dendrobium officinale fresh juice stock solution which is easy to store, convenient to carry, simple to administrate, good in mouthfeel and easy to absorb and has health-care nutritional components and medicinal functions; the fresh juice stock solution does not contain any additive; and the content of the fresh juice stock solution reaches over 99 percent. The dendrobium officinale fresh juice stock solution can be administrated separately, also can be added into mineral water to form health-care beverage, also can be dissolved into wine to form nourishing health-care wine, and can be added into high-grade dishes to form nourishing dishes for eating.

Owner:杨军

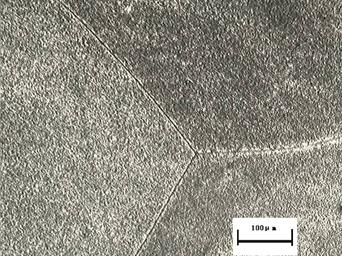

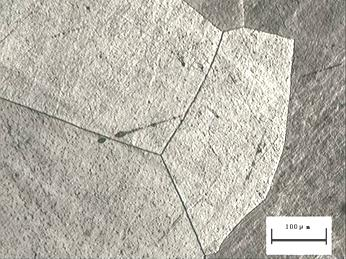

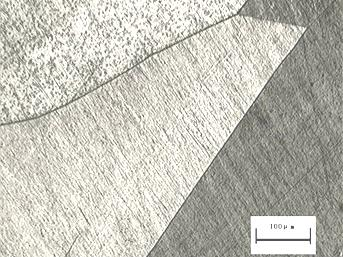

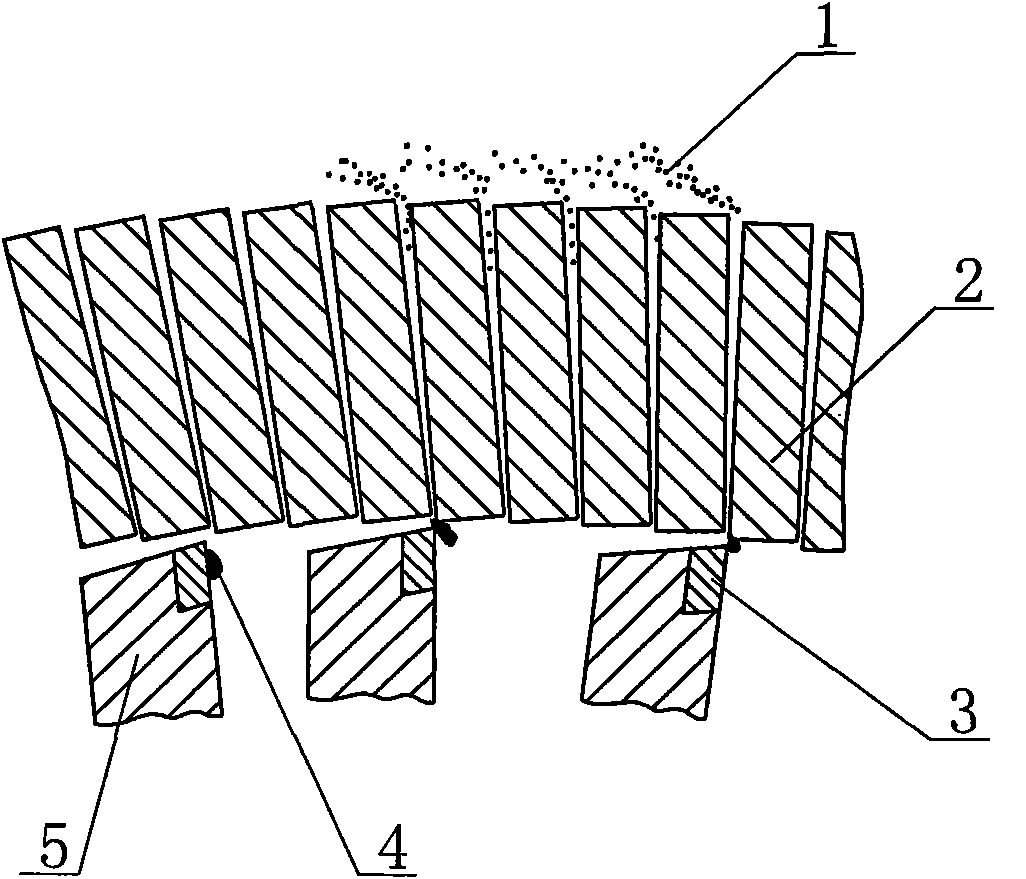

Production technology for bimetal coating copper strip

The invention discloses a production technology for a bimetal coating copper strip, which comprises the following steps: 1, smelting casting: preheating and drying electrolytic copper and placing in a smelting device for melting, adopting wood coal and graphite flakes to cover the surface of copper liquid, and after performing degasification and deoxidation on line by a degasification device, using a traction machine set to guide a copper rod upwards in a vacuum clutch type way to enable the copper rod to enter a wire taking-up device; 2, continuous extruding: enabling the oxygen-free copper rod obtained in step 1 to pass through a continuous extrusion machine set to produce a copper strip plate, and quickly using a cooling medium to cool to 20-30 DEG C to obtain the fine grain structured copper strip plate with the grain size of 0.005 mm to 0.010 mm; 3, rolling; 4, intermediate annealing; 5, fine rolling; 6, annealing; 7, cleaning and inactivating; 8, cutting; and 9, packaging and storing into a warehouse. According to the invention, the production technology has the advantages of excellent welding performance, high plastic processing performance, high electric conductivity, high surface quality and the like, and the technological process is short, and the technology is efficient and energy-saving.

Owner:NANTONG JIUWUBA TECH ENTERPRISE INCUBATOR CO LTD

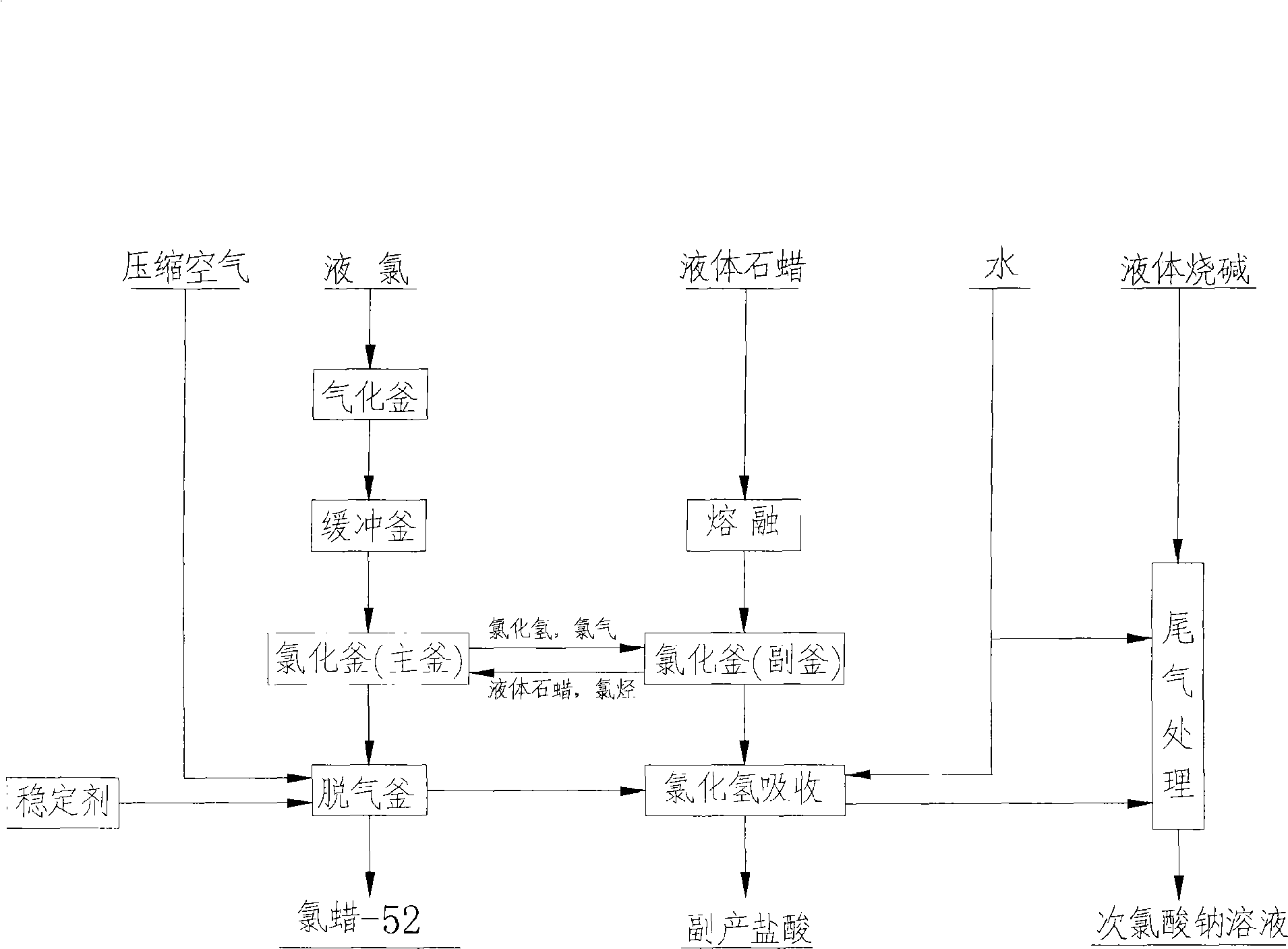

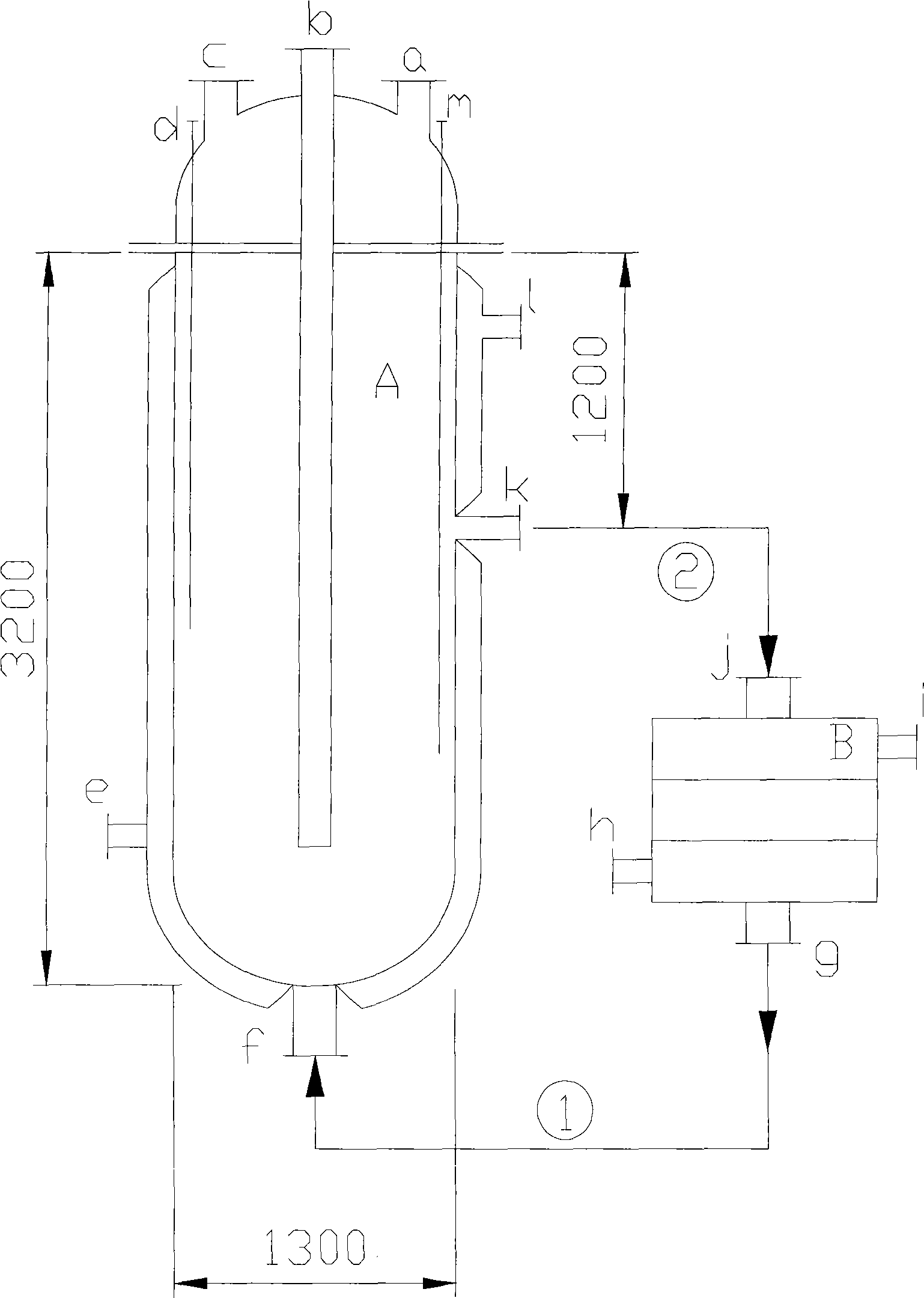

Self circulation heat exchange method for materials in production of chlorinating paraffin-52 and chlorination reaction device therefor

InactiveCN101544911AOrderly escapeNo reduction in mass transfer efficiencyPetroleum chemical modificationComing outParaffin wax

The invention provides a self circulation heat exchange method for materials in production of chlorinating paraffin-52 and a chlorination reaction device therefor. The method comprises the steps that: a, liquid paraffin is added into an automatic circulation main and auxiliary chlorination reaction kettle provided with a catalytic light source and a heat exchanger outside the kettle, and a catalytic light source lamp is turned on; b, liquid chlorine is introduced into a gasification kettle, stabilized by an accumulator still, and is introduced into a main kettle of the chlorination reaction kettle at a chlorine flowrate of between 200 and 230Kg / h, the chlorination temperature is controlled to be between 100 and 110 DEG C, the reaction is stopped when the chlorine content analyzed in a taken sample is between 50 and 54 percent to obtain a crude product of the chlorinating paraffin-52, dissolved chlorine and chlorine hydride in the crude product of the chlorinating paraffin-52 are removed by a degasification kettle, and then a stabilizing agent is added to obtain a finished product of the chlorinating paraffin-52; and c, gas coming out of the main kettle of the chlorination reaction kettle enters an auxiliary kettle of the chlorination reaction kettle, gas coming out of the auxiliary kettle of the chlorination reaction kettle passes through a graphitic absorber, a water falling film is used for absorbing the chlorine hydride in the gas to prepare hydrochloric acid, micro chlorine and chlorine hydride contained in tail gas which is discharged by the graphic absorber pass through a waste gas processor and are absorbed by water solution of sodium hydroxide to generate sodium hypochlorite and sodium chloride.

Owner:HENAN CHEM IND RES INST

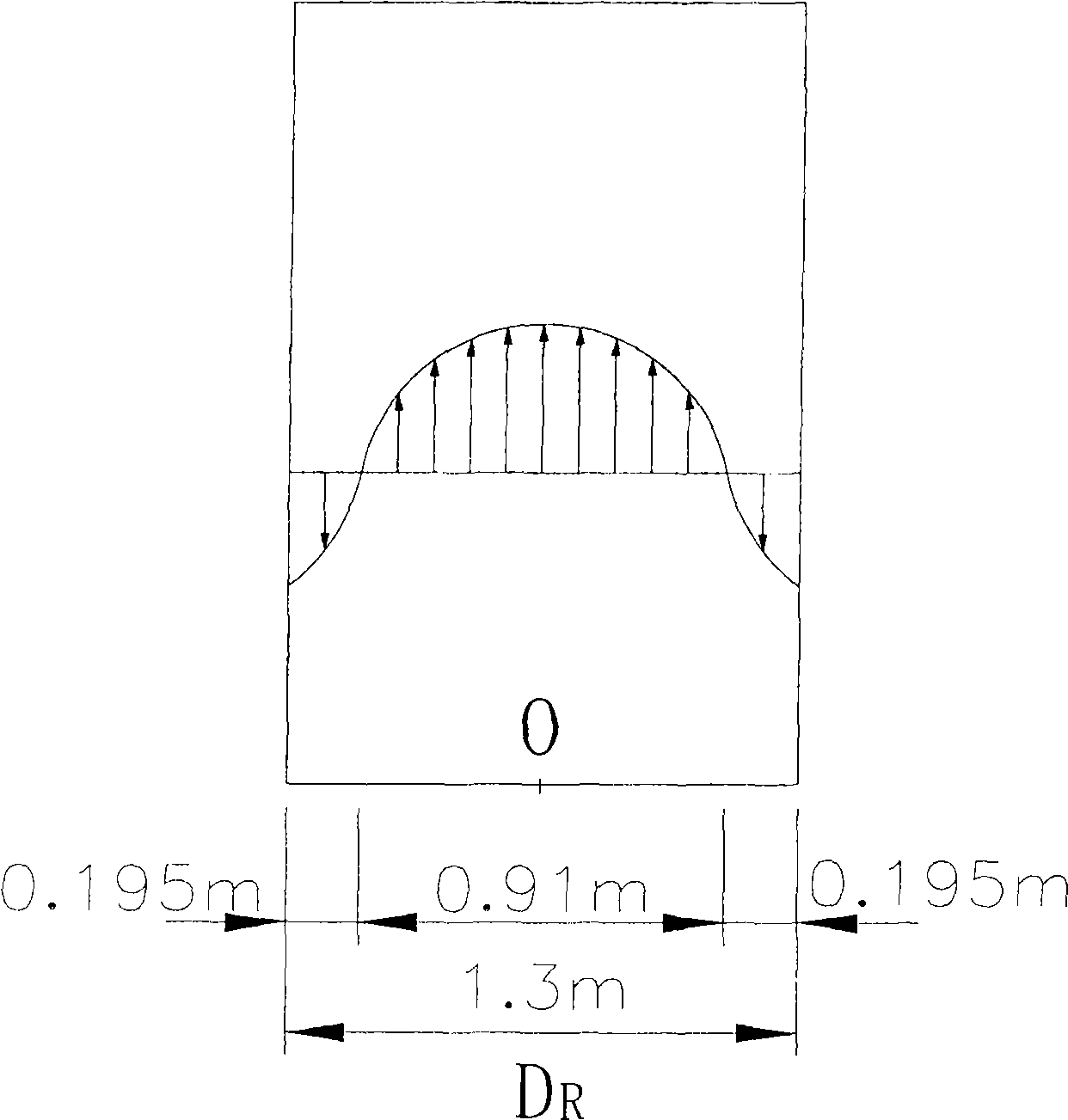

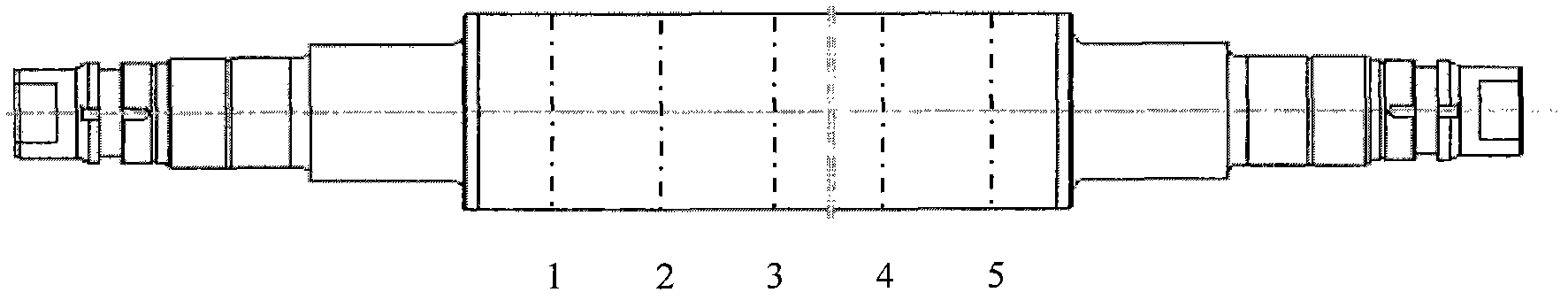

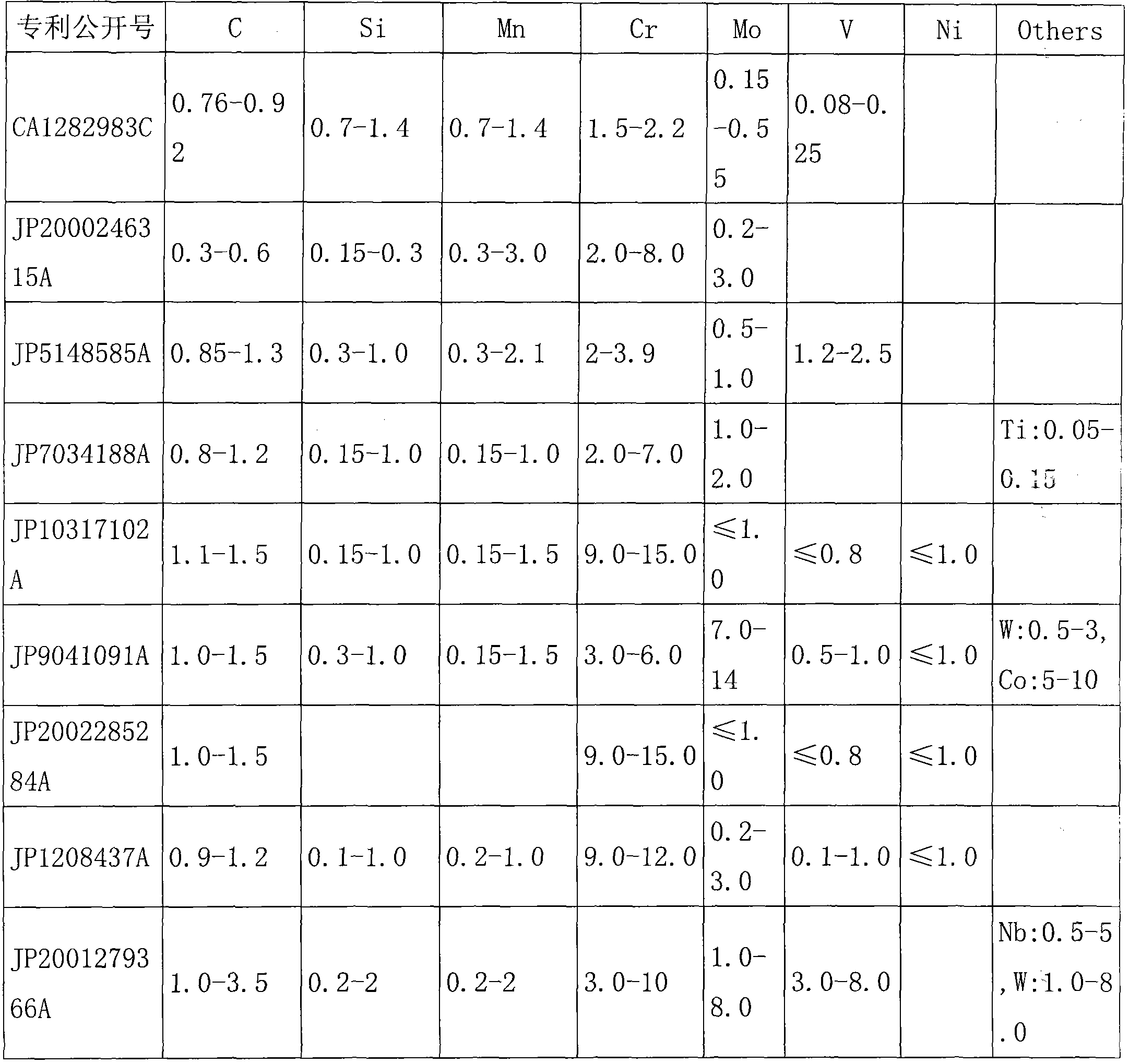

Cold work roll steel for high-strength steel rolling, cold work roll and its manufacturing method

The invention discloses cold work roll steel for high-strength steel rolling, a cold work roll and its manufacturing method. The material of cold work roll is composed of the following chemical components of: by weight, 0.6-0.8% of C; 0.6-1.5% of Si; 0.6-1.5% of Mn; 4.0-6.0% of Cr; 0.5-2.0% of Mo; 0.5-1.0% of V; P being less than or equal to 0.020%; S being less than or equal to 0.015%; and the balance being Fe and unavoidable impurities. The manufacturing process comprises steps of: electric furnace smelting; secondary refining; vacuum degasification; electric bar casting; electroslag refining; ingot casting; forging; preheat treatment; rough machining; quenching and tempering treatment; semi-finish machining; final heat treatment; finish machining; and finished product. According to thenovel cold work roll provided by the invention, the ratio of the alloy elements is optimized based on 5% of Cr. By the adoption of a short-time high-temperature solid solution quenched-tempered heat treatment technology, the roll strength and wear resistance of the cold work roll are improved, thus satisfying production requirements of high-strength cold rolled strips.

Owner:BAOSHAN IRON & STEEL CO LTD

Gas injection pressure-stabilizing drilling method

InactiveCN101139911AEfficient drilling processSafe drilling processSurveyFlushingComing outHigh pressure

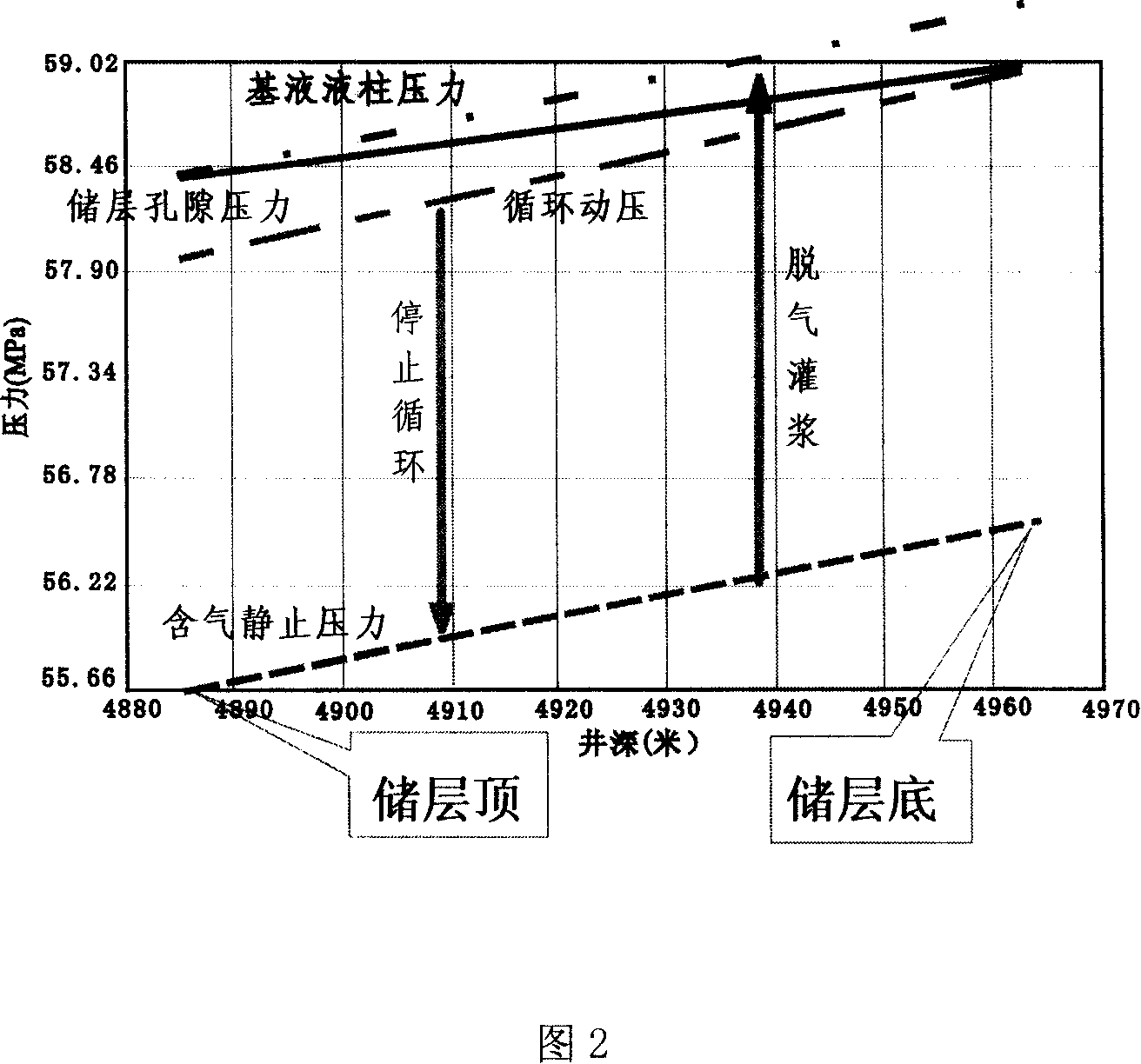

The invention discloses an air-injection stable-pressure well-drilling method and relates to a well-drilling method for petroleum and natural gas exploration and exploitation, in particular to a well-drilling method that can overcome the difficulties of fluid formation leakage, blowout and narrow safety window; the invention resolves the following difficult problems in prior well-drilling technologies: Not possible to adapt to leakage, blowout and narrow safety pressure window reservoirs, but easy to result in blowout, leakage or both during the well-drilling process; during the course of drilling fluid circulation, the invention adopts an air-injection method with suitable volume of air to eliminate the auxiliary friction resistance and dynamic pressure in drilling fluid circulation; before stopping the circulation, coming out of the hole or going into the hole, or in idling await status, repeatedly adopt pressure building, degasification, grouting amd release high-pressure gas to fulfill balanced killing; before the air-injection stable-pressure well-drilling is excuted, utilize a MWD method to test reservoir parameters, so as to determine whether utilizes the method and how to utilize the method. The invention discloses the well-drilling method to decrease the downhole pressure variation window into a narrow line, so that the window can be completely included in the leakage and blowout safety pressure window; therefore, the invention adapts to well-drilling in exploration and development of oil and natural gas.

Owner:SOUTHWEST PETROLEUM UNIV

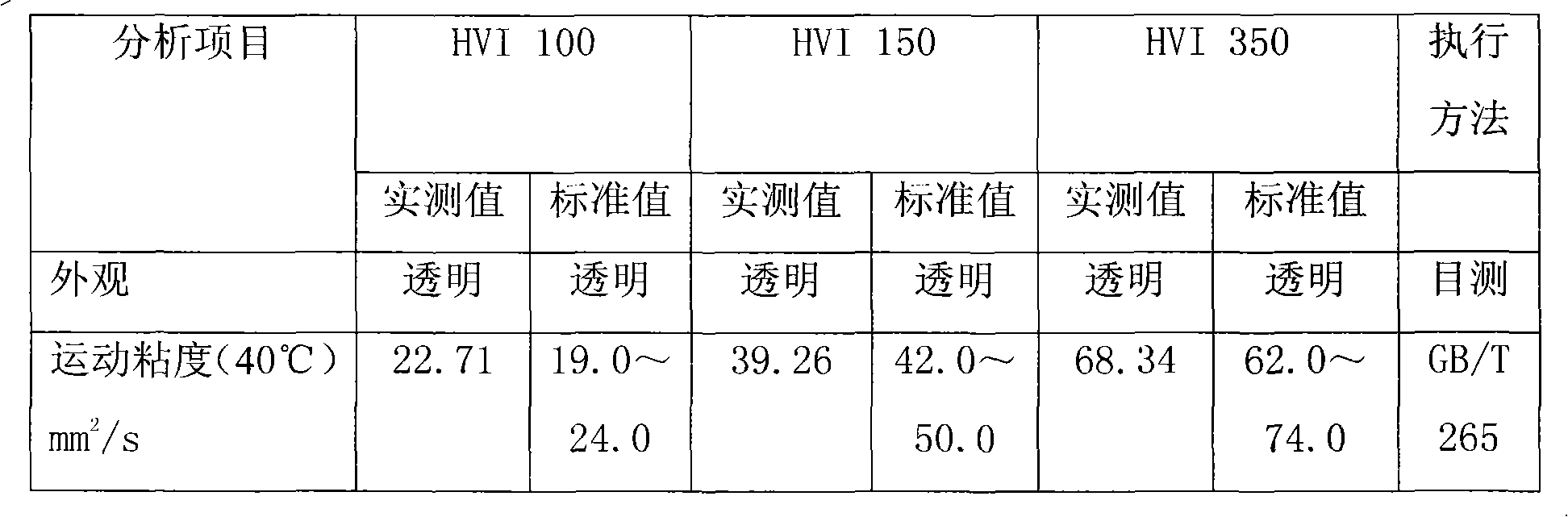

Process method for producing base oil by regenerating waste lubricating oil

ActiveCN102373108AShort stayImprove qualityTreatment with plural serial refining stagesLubricant compositionDistillationEconomic benefits

The invention discloses a process method for producing base oil by regenerating waste lubricating oil, realized by the steps of pretreatment of waste lubricating oil, thin film evaporation, molecular distillation, clay refining and degasification with flash evaporation. The use of the process can regenerate any waste lubricating oil collected from markets. According to different quality of the waste lubricating oil, the base oil yield is 50-90 %. The process can be flexibly adjusted, particularly, the process can be used for producing base oil with single specification of low and medium viscosity in parallel to maximize the production and processing capacity of devices, and can be used for producing base oil with three specifications of low, medium and high viscosity in series to separatethe base oil fraction from the waste lubricating oil completely according to different quality and values, so that the maximum economic benefit is achieved.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH

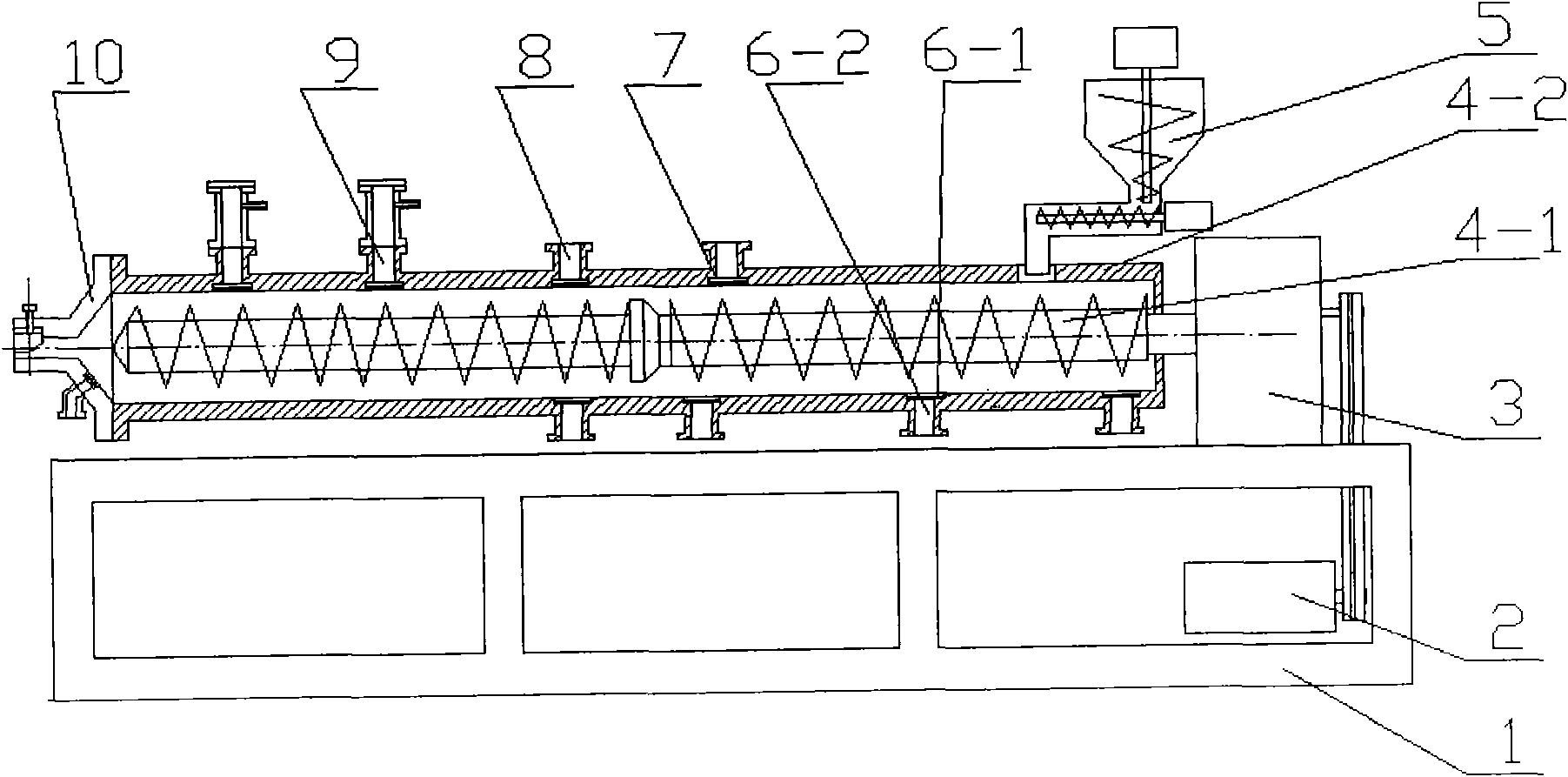

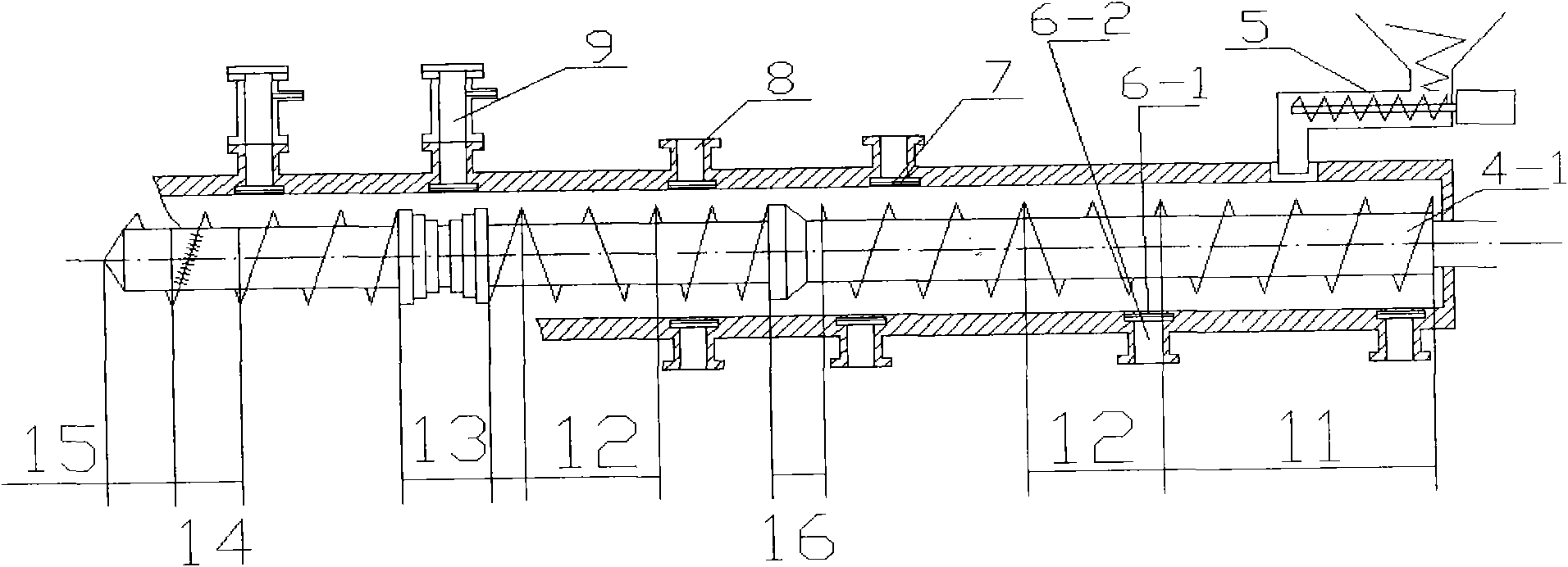

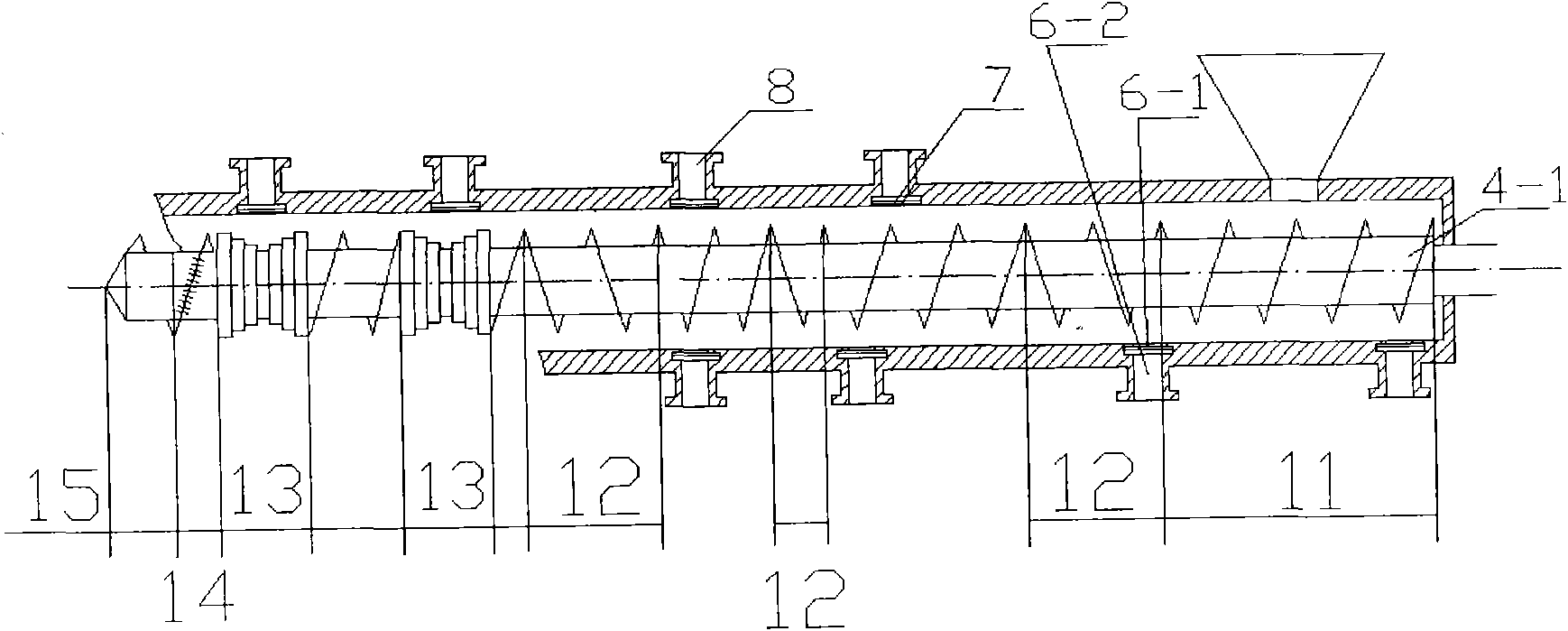

Double screw dehydrating equipment capable of realizing dehydrating, drying and puffing processes

InactiveCN102059017ARealize the continuous production of extrusion dehydrationRealize continuous productionPressesStationary filtering element filtersAutomatic controlEngineering

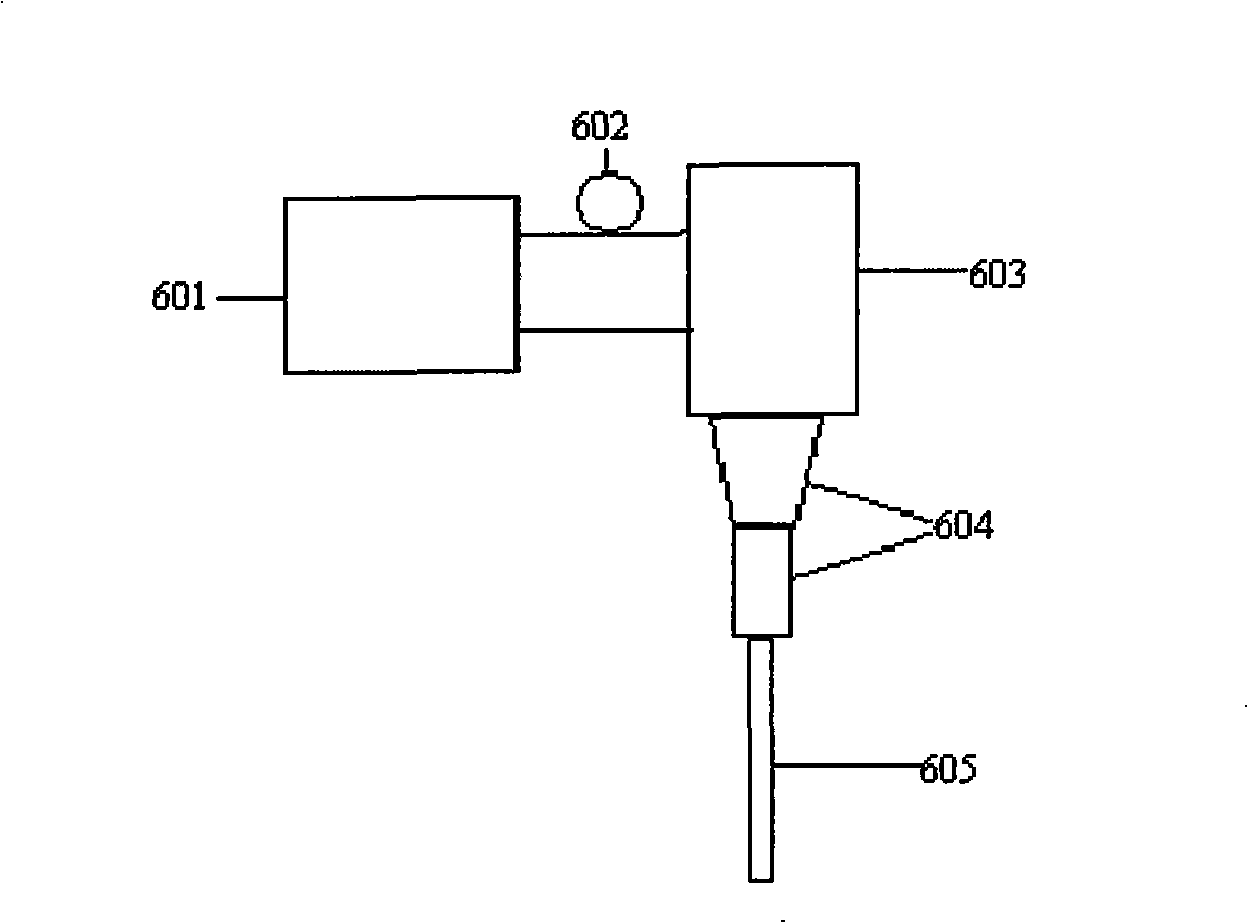

The invention relates to double screw dehydrating equipment capable of realizing dehydrating, drying and puffing processes, comprising a power source, a reduction gear mechanism, a screw machine barrel pair, a rack, a forced volume control feeding device, a dehydrating and filtering device, a degassing device, a nose pressure control device and an automatic control system. The power source is connected with two screws in the screw machine barrel pair by virtue of the reduction gear mechanism, the forced feeding device is connected with a machine barrel in the screw machine barrel pair, and the two screws are arranged in the machine barrel; the machine barrel is of a sectional type and is divided into a feeding machine barrel, a dehydrating machine barrel and an exhaust machine barrel; each machine barrel section is externally provided with a heating device, and each machine barrel is internally provided with a cooling water runner used for cooling; the dehydrating and filtering device is connected with the dehydrating machine barrel and is provided with a rapid filter screen replacing device; the degassing device is connected with the exhaust machine barrel, a water ring vacuum pump is utilized to realize negative pressure degasification, and a filter screen and the rapid filter screen replacing device are arranged to prevent materials from flowing out along with the negative pressure; and the nose pressure control device is connected with the outlet of the machine barrel and controls the pressure of the materials at the outlet by adjusting the position of a damping plate.

Owner:BEIJING UNIV OF CHEM TECH

Refining agent for copper and copper alloy smelting

A refining agent for copper and copper alloy smelting is characterized in that the components of the refining agent are 5 to 15 percent by weight of calcium fluoride, 1 to 5 percent by weight of silicon dioxide, 1 to 5 percent by weight of titanium dioxide, 2 to 10 percent by weight of sodium fluosilicate, 40 to 60 percent by weight of sodium carbonate and the balance sodium tetraborate; the refining agent materials are weighed according to a formula, uniformly mixed, placed into a drying box and dried under 120 DEG C for an hour, and a metallographic inlaying machine is used for manually pressing the refining agent into the shape of a sheet. The refining agent has the advantages that the refining agent is integrated with the functions of deoxidization, degasification, impurity removal and the like, and has strong adsorbing, dissolving and combination slagging capabilities; the surface tension between the refining agent and metal melt is high, the refining agent can promote molten slag to float up, so that the molten slag can be better separated from molten metal, and thereby the effects of refining, impurity removal and melt purification are achieved; the refining agent has high chemical stability and thermal stability, does not have the corrosion effect on metal and the furnace lining, and cannot chemically react with the molten metal, the refining agent and the molten metal cannot be melted into each other as well, and thereby the original composition and properties of alloy are guaranteed; and the refining agent does not have public hazard, is safe and environment-friendly, is convenient to use, and is cheap.

Owner:NANCHANG UNIV

Berry can and processing method thereof

The invention relates to a new can processing method which is applicable to a berry raw material and a berry can processed through the method, and the can processing method is characterized in that the tissue improvement method in line with the characteristics of berry is adopted, a calcium preparation and the sugar impregnation are combined for treatment so as to increase the strength of the skin part and pulp part of the berry, and the complete and due taste of fruit granules can be maintained during the follow-up heat treatment process; a formula with special flavor and nutritional attributes is utilized for the preparation of canned soup, thereby greatly improving the health-care and beautifying effects of the product; according to the actual nutritional requirement of the berry raw material, a safe thermal sterilization way is adopted, the thermal degasification temperature and sterilization temperature in the traditional process are reduced by about 10 DEG C, the nutritional value and sensory quality of the product are better protected, the natural taste of the berry raw material is maintained, energy is saved, and the can processing method can be maturely applied to berry can products and is applicable to actual situations of the majority of can food production enterprises.

Owner:丹东美比食品有限公司

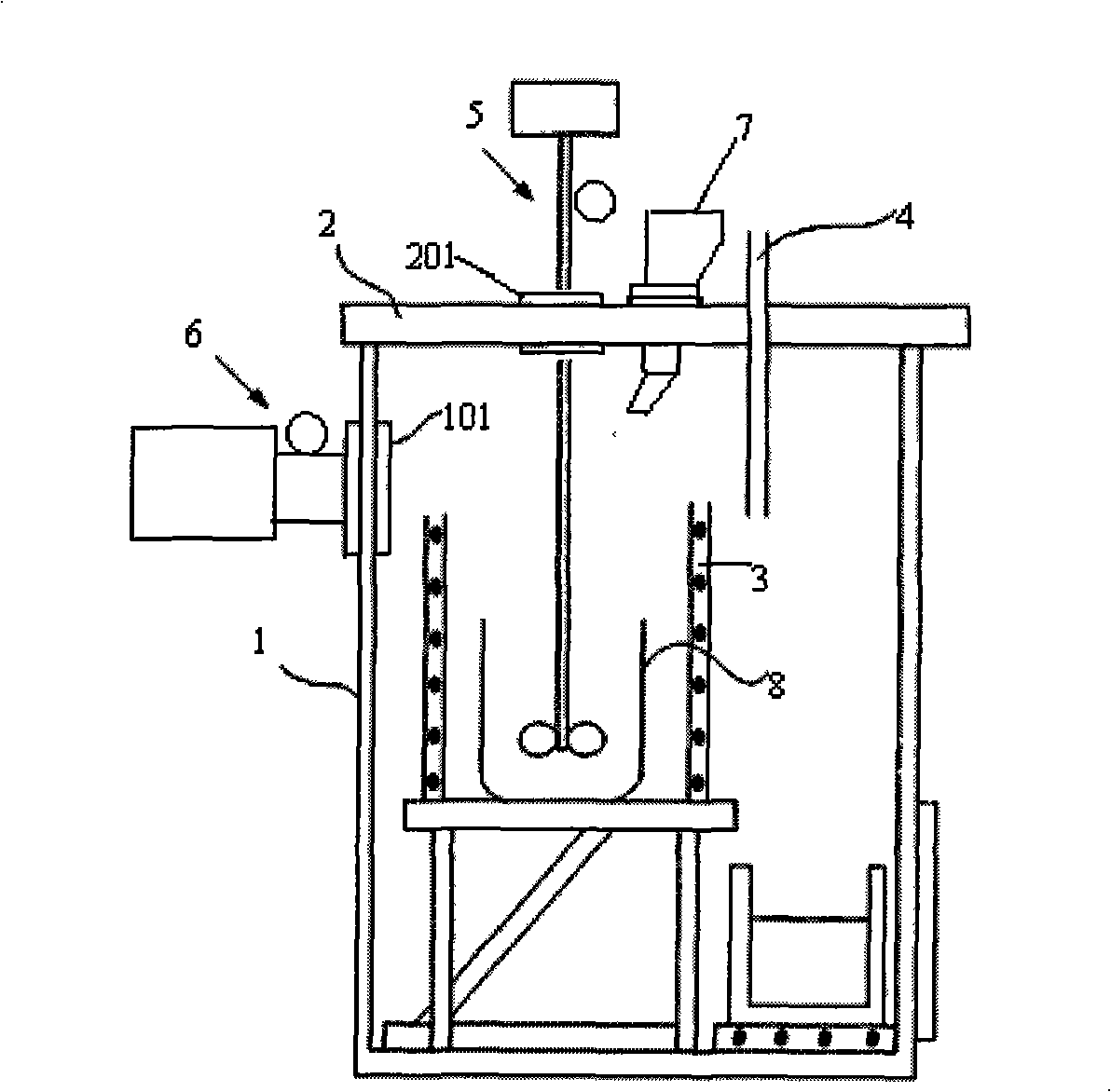

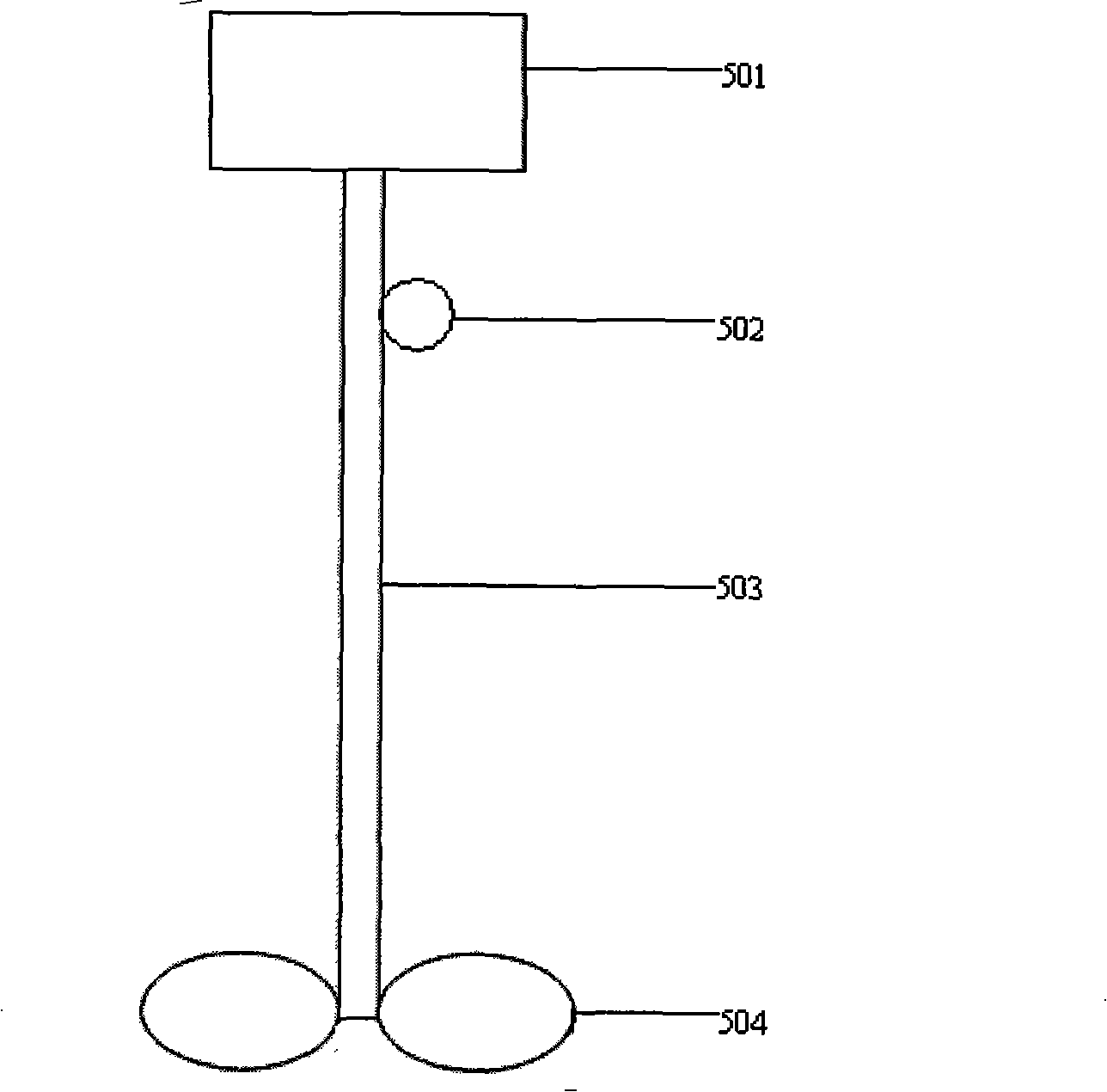

Smelting furnace with mechanical agitation and high-energy ultrasonic processing and smelting method thereof

The invention discloses a smelting furnace with mechanical agitation and high-energy ultrasonic processing and a smelting method thereof. The smelting furnace mainly comprises a furnace body, a furnace cover, a heating device, a protective gas input device, a mechanical agitation device and a high-energy ultrasonic processing device; wherein, the upper part of the furnace body is provided with an interface of the high-energy ultrasonic processing device, so that the furnace body can be connected with the high-energy ultrasonic processing device in a sealing way; the furnace cover is provided with an interface of the mechanical agitation device, so as to be connected with the mechanical agitation device in a sealing way. As the mechanical agitation device, the high-energy ultrasonic processing device and the protective gas input device are arranged on one smelting furnace, the molt can be stirred and fusion casted under the gas protection. The high-energy ultrasonic processing device is introduced into the smelting furnace, so that the problems of agglomeration and wetting property of reinforcement body grain, especially ultrafine grain in the composite material can be improved, and the smelting furnace has the effects of degasification, deslagging and refining grain; finally, the structural homogeneity and the mechanical property the composite material prepared by the smelting furnace can be enhanced.

Owner:BEIHANG UNIV

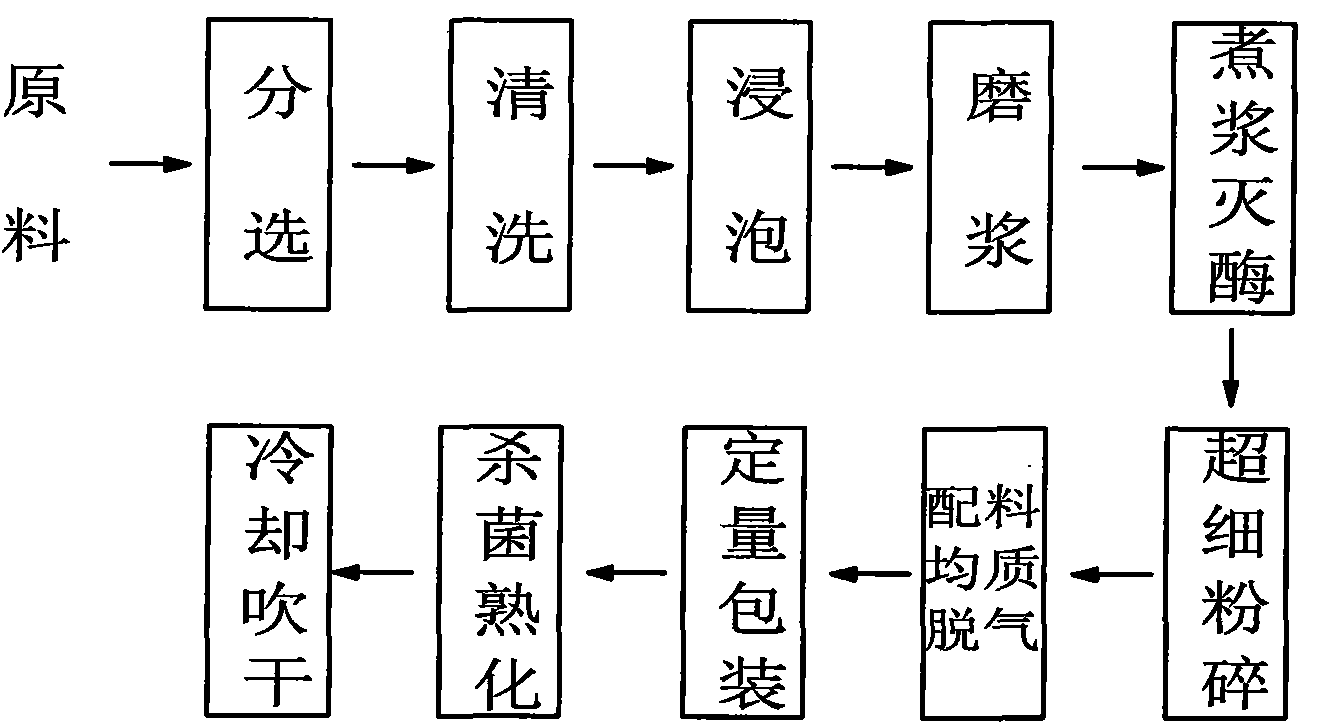

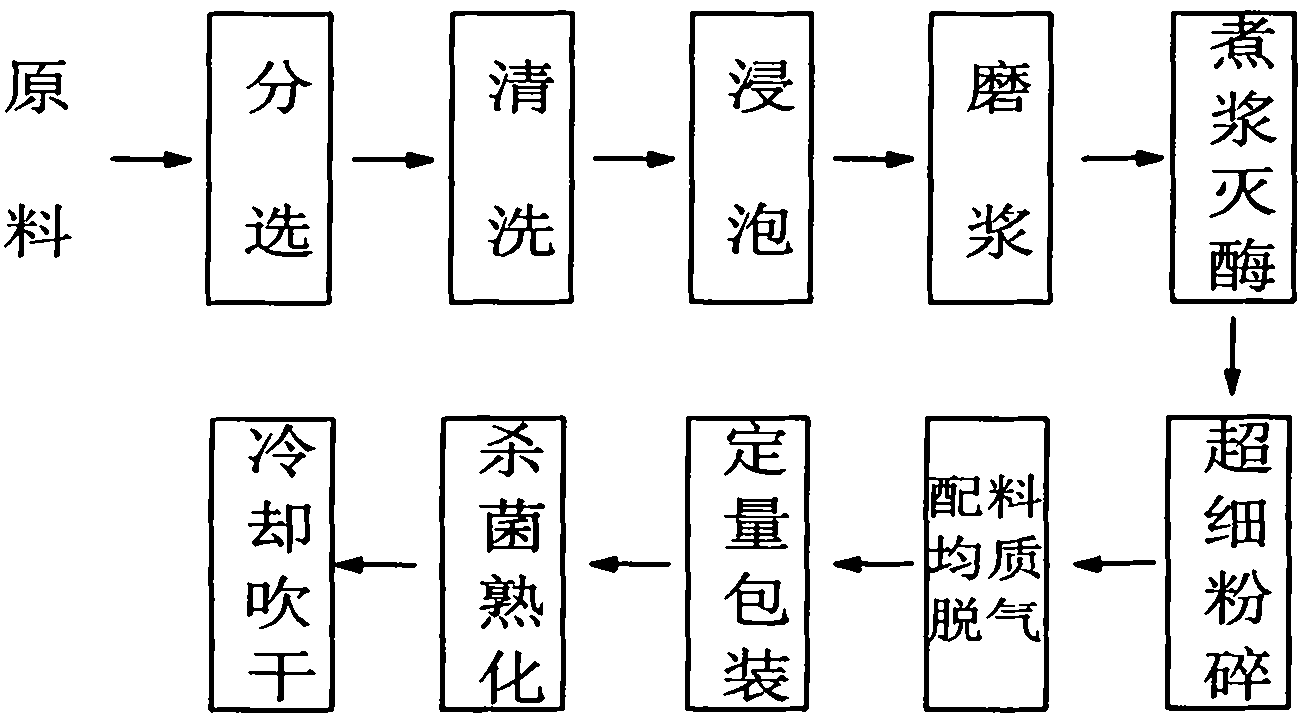

Method for preparing whole bean high-fiber high-concentration preserved soya-bean milk

InactiveCN101878816AAchieving zero-emission productionHigh nutritional valueMilk substitutesFood scienceNutritive valuesFiber

The invention discloses a method for preparing whole bean high-fiber high-concentration preserved soya-bean milk, and belongs to the field of soybean processing. In the method, the whole bean high-fiber high-concentration preserved soya-bean milk is prepared from soybeans through sorting, immersing, defibrination, pulp boiling and enzyme killing, superfine grinding, mixing, degasification, homogenizing, quantitative filling and packaging, sterilization, cooling and drying. The method has the advantages that bean dregs can be utilized completely to ensure that the products have smooth mouthfeel and high nutritive value; the soya-bean milk can be infused by cold water or hot water for drinking, and has the advantages of convenient use and long storage time; and the zero emission production of the soya-bean milk is realized, and the environment is protected.

Owner:JIANGNAN UNIV

1-polyolefin halogenation production method

InactiveCN101671412AMeet the needs of halogenation reactionIncreased macroscopic reaction ratePolyolefinProcess equipment

The invention relates to a 1-polyolefin halogenation production method which is characterized in that continuous plastication (mixing), degasification, ultrasonic wave visbreaking, softening, multistage halogenation, neutralization and stabilization, devolatilization, ultrasonic wave temperature reduction and stripping and slicing measurement are realized in a sealing drying system in a double-screw extruder reactor to produce the halogenated polyolefin. Compared with the traditional process, the process flow is shortened by three fourth, which saves investment and energy power consumption; the halogen content of the halogenated polyolefin can be controlled, and does not contain corrosive acid gas, so that the equipment can not be corroded severely, is the modern green engineering, and canwidely replace the process equipment of the current halogenated polyolefin.

Owner:江苏圣杰实业有限公司

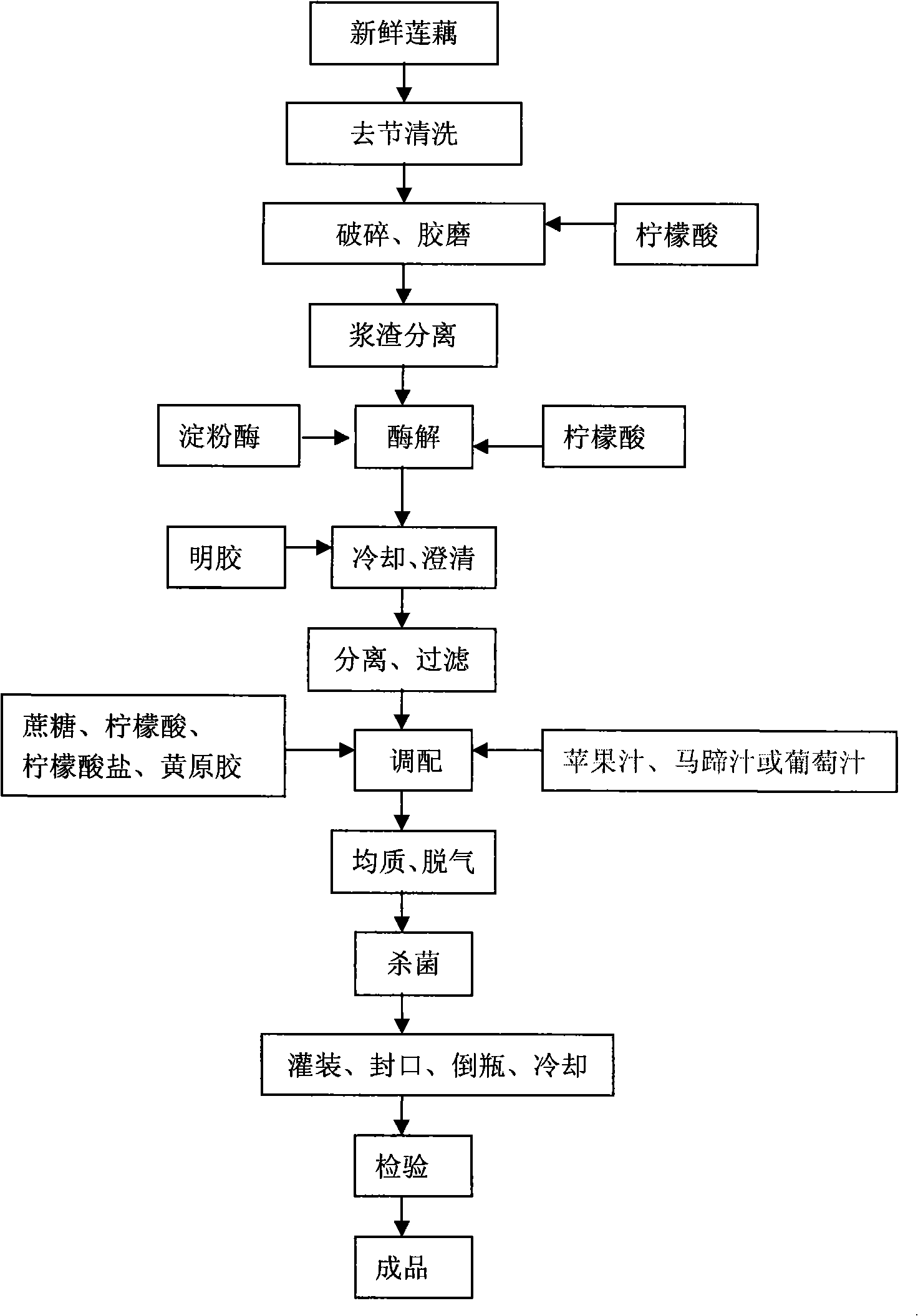

Method for processing clear type lotus rhizome juice series drink in PET bottles

InactiveCN101297709ASolve precipitationIncrease the juice yieldFood preparationFiltrationAdditive ingredient

The invention relates to a processing method for a PET bottling clarifying lotus root juice series drink, belonging to the technical field of food processing. The method takes fresh lotus root as raw material and produces the novel PET bottling clarifying lotus root juice series drink by carrying out the steps of nodus removal and washing, crushing, glue-grinding, slurry and dreg separation, zymohydrolysis, clarification, separation, filtration, preparation, homogenization, degasification, sterilization, hot filling, sealing, bottle falling, cooling and inspection, and utilizing modern biotechnology, color protecting technology and conserving technology. The lotus root juice drink produced by the method of the invention has full-bodied lotus root flavor due to clarification, can be conserved at normal temperature, is convenient to be drunk and adopts one-time sterilizing hot filling with low sterilization strength, thus having less damages to the nutrient content of the products.

Owner:JIANGNAN UNIV

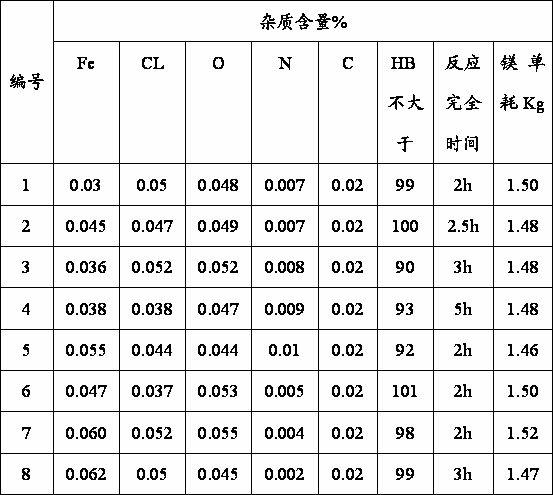

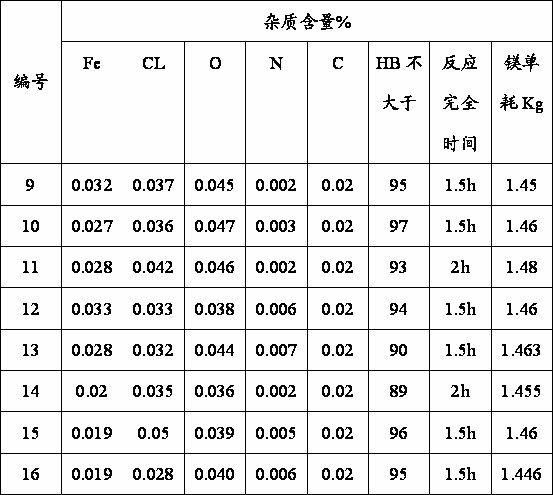

Method for preparing titanium sponge

The invention discloses a method for preparing a titanium sponge, comprising the following steps of: placing metallic magnesium in a reactor; adding magnesium chloride blocks to the metallic magnesium according to the weight ratio (4:1) of metallic magnesium to magnesium chloride; using a Roots pump for vacuum pumping for 30 minutes, and inputting argon; achieving the following temperature variation after being put into a furnace: respectively carrying out constant temperature degasification at 150 DEG C for two hours, at 200 DEG C for two hours, and at 300 DEG C for two hours; raising the temperature to 800 to 880 DEG C, and adding titanium tetrachloride liquid for reduction reaction; adding titanium tetrachloride for ten times; and adding the magnesium chloride by ten times. The invention reduces the impurity content of the product, changes the surface color thereof, increases the rate of finished products and improves the product quality.

Owner:朝阳金达钛业股份有限公司

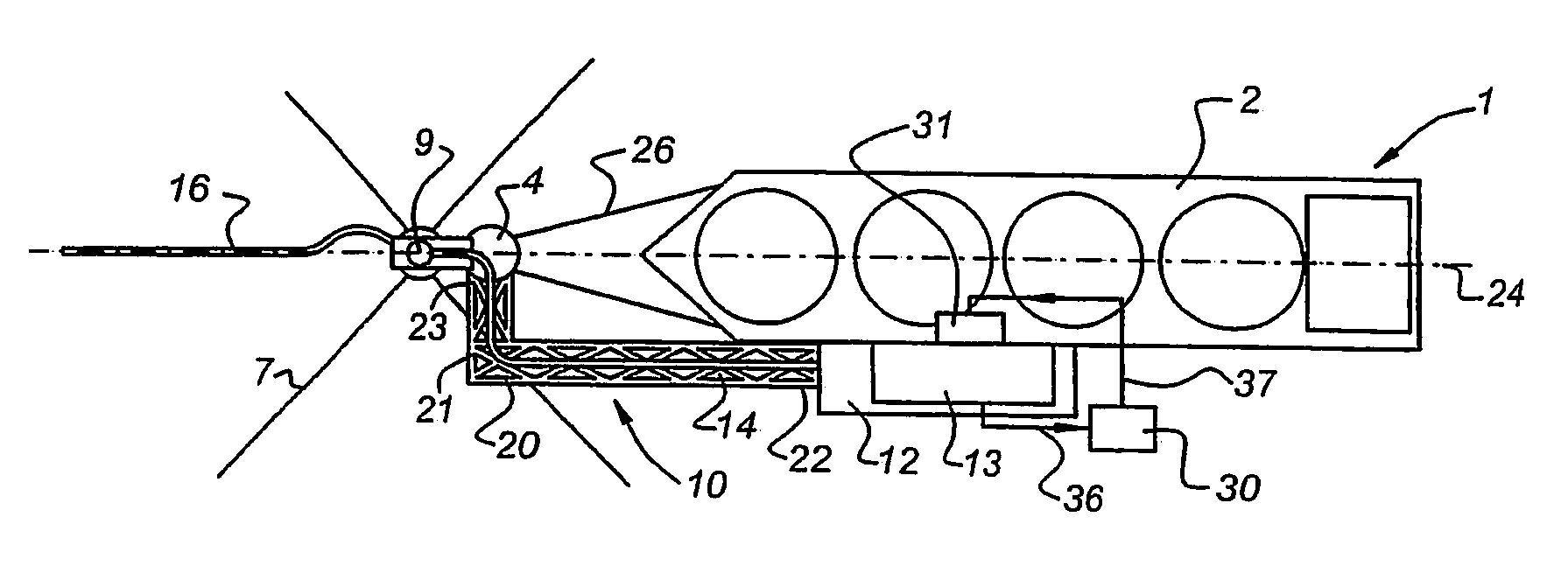

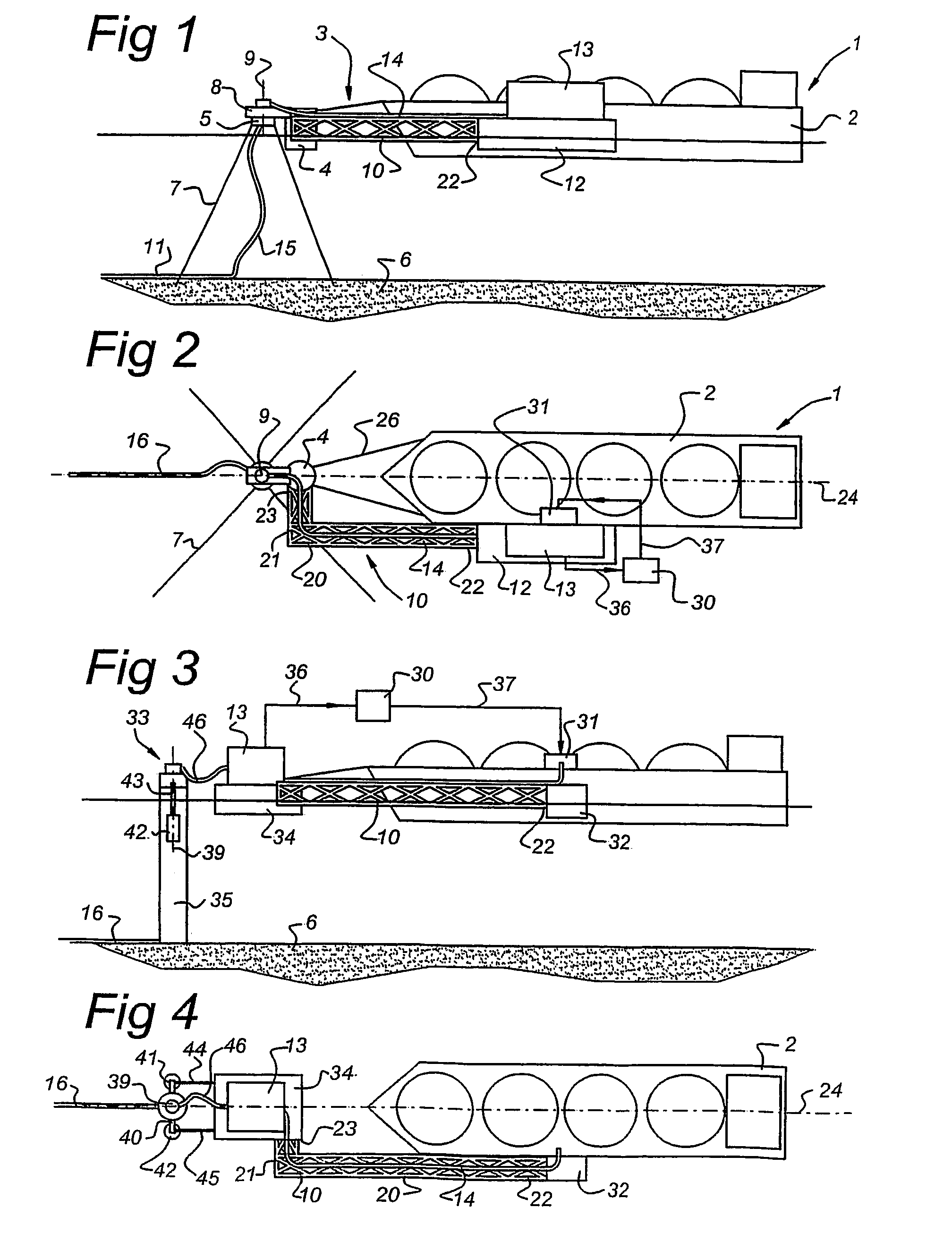

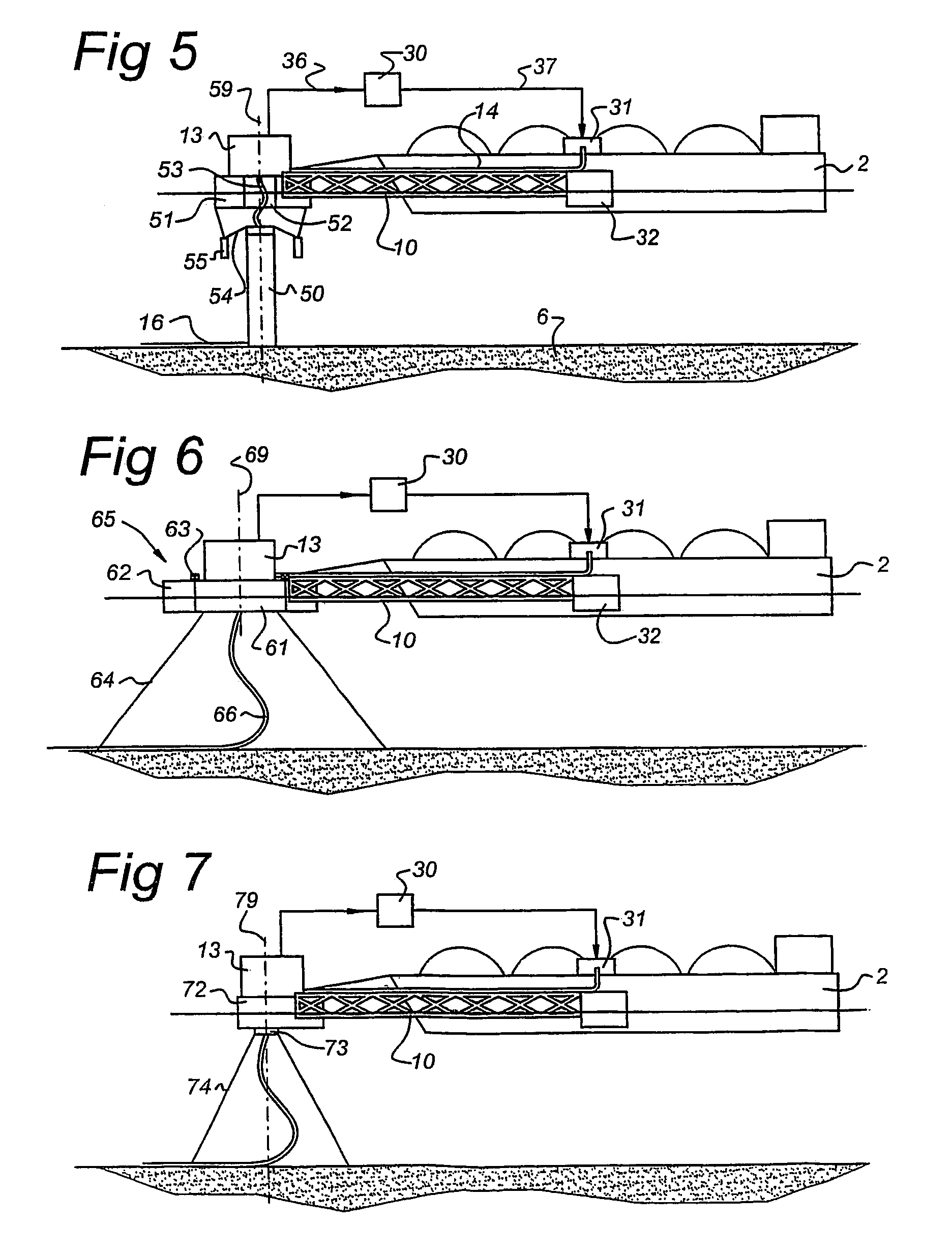

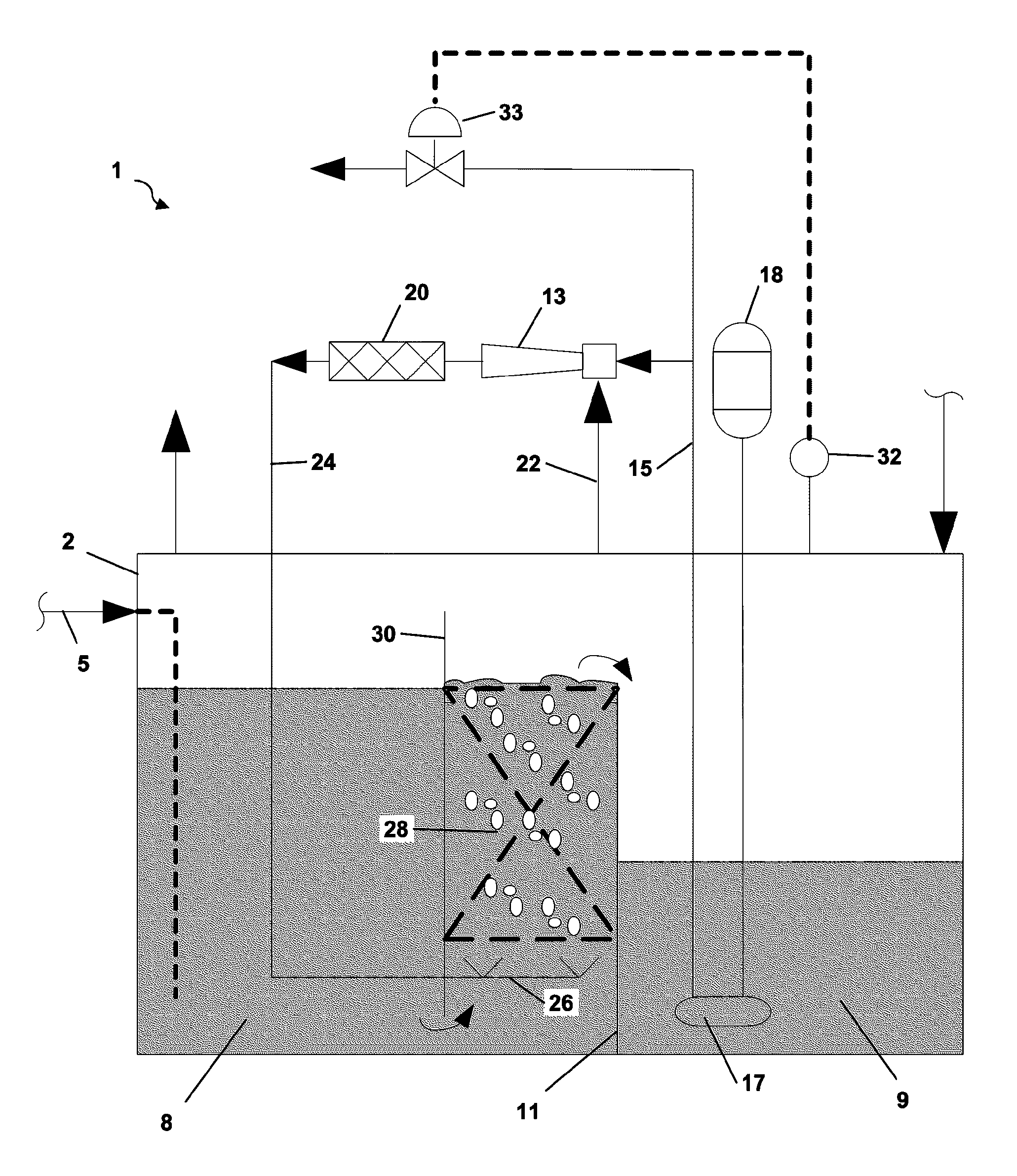

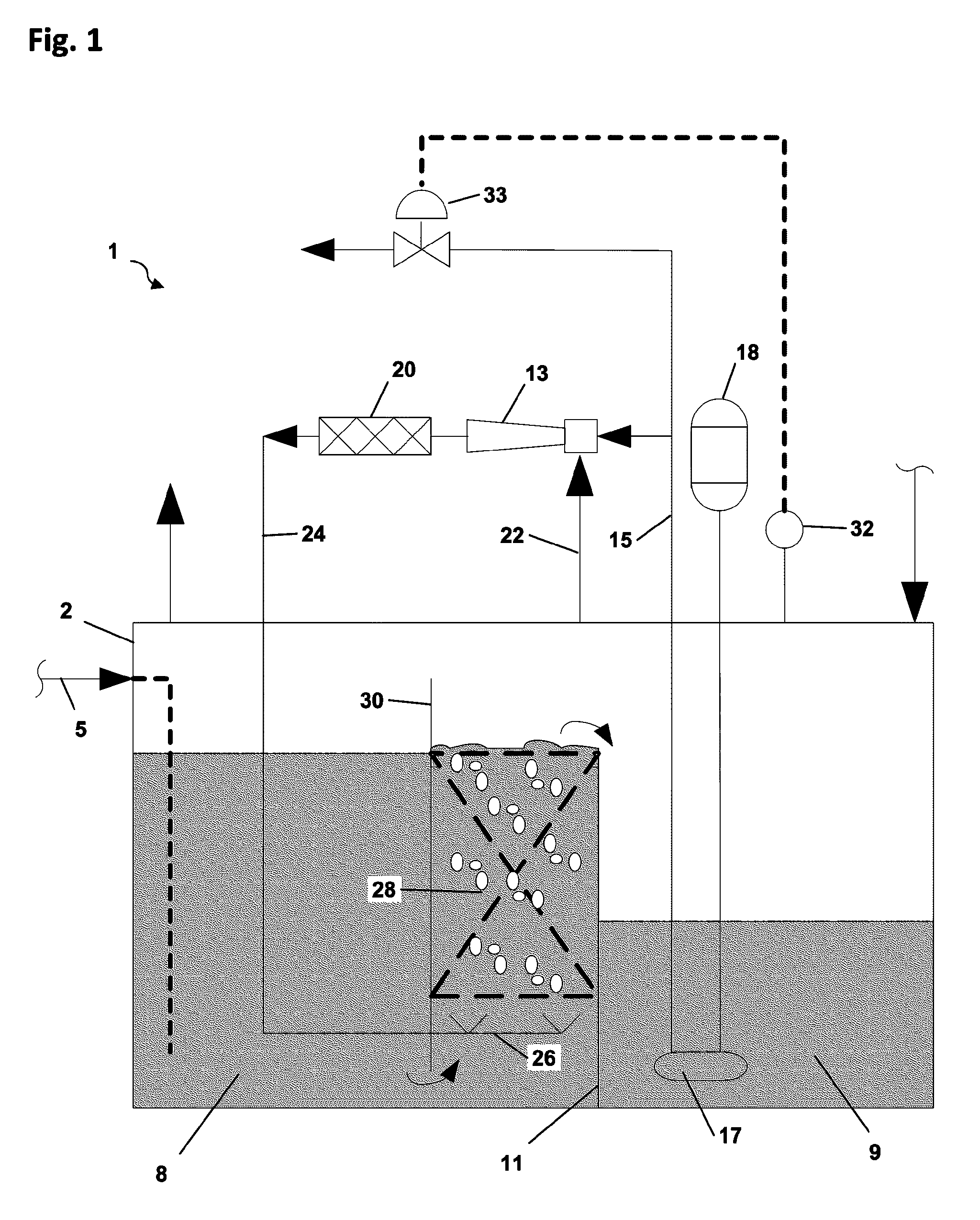

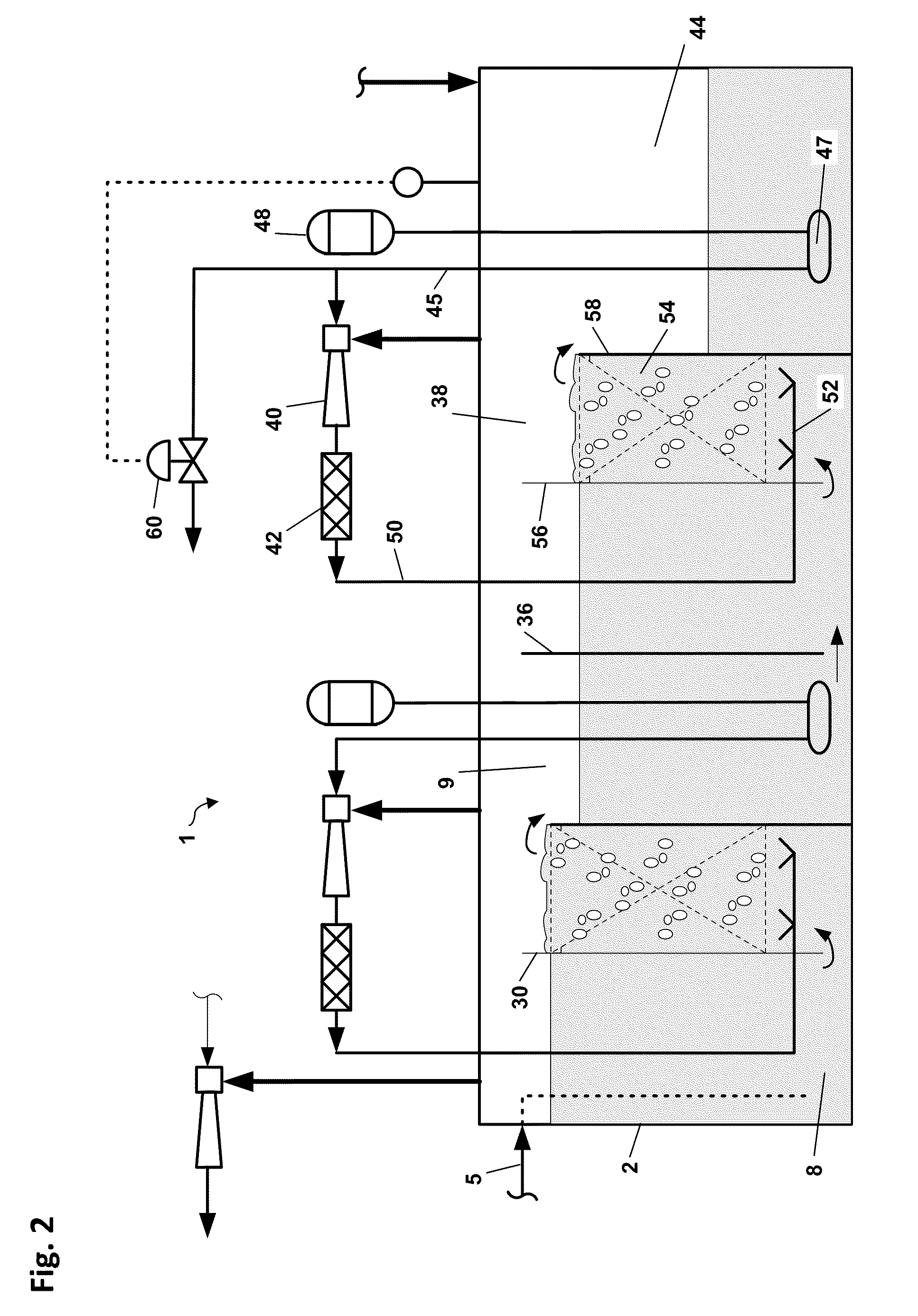

Weathervaning LNG offloading system

InactiveUS7107925B2Small sizeCargo handling apparatusBarrels/casks fillingTreatment unitDegasification

A cryogenic fluid offloading system, having a tanker vessel (2) moored in line with an offshore mooring construction (4, 8) and connected to a processing unit, such as regasification plant (13). The degasification plant (13) has no large storage facilities, the tanker (2) being unloaded in dependence on onshore demand for gas.

Owner:SINGLE BUOY MOORINGS INC

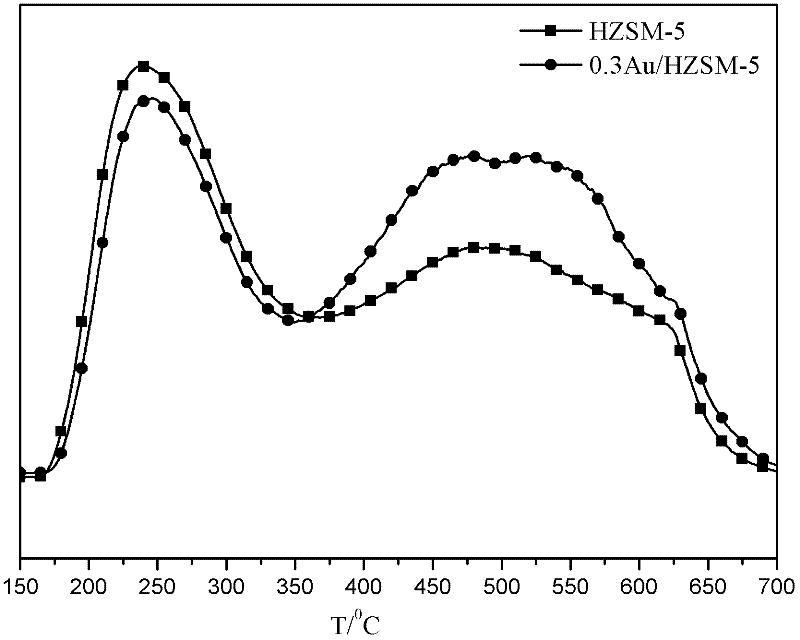

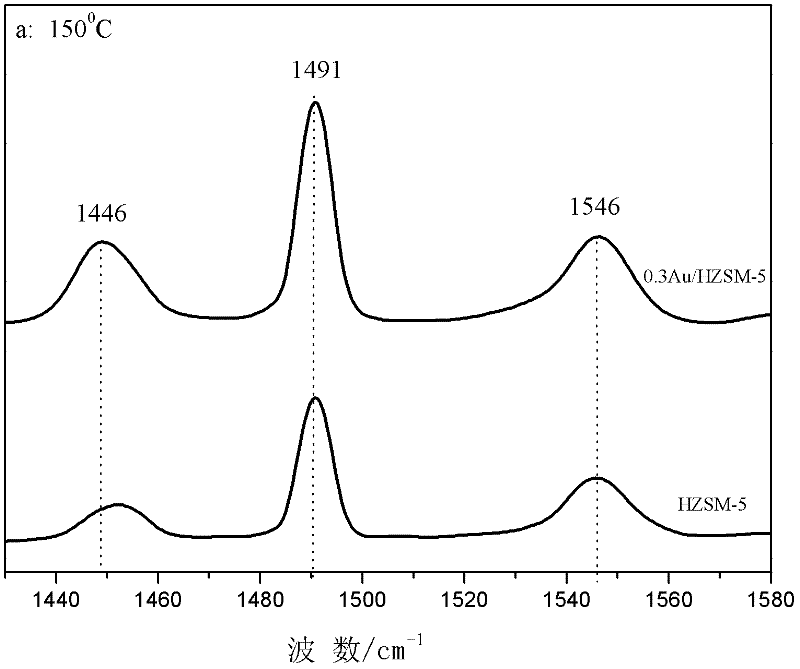

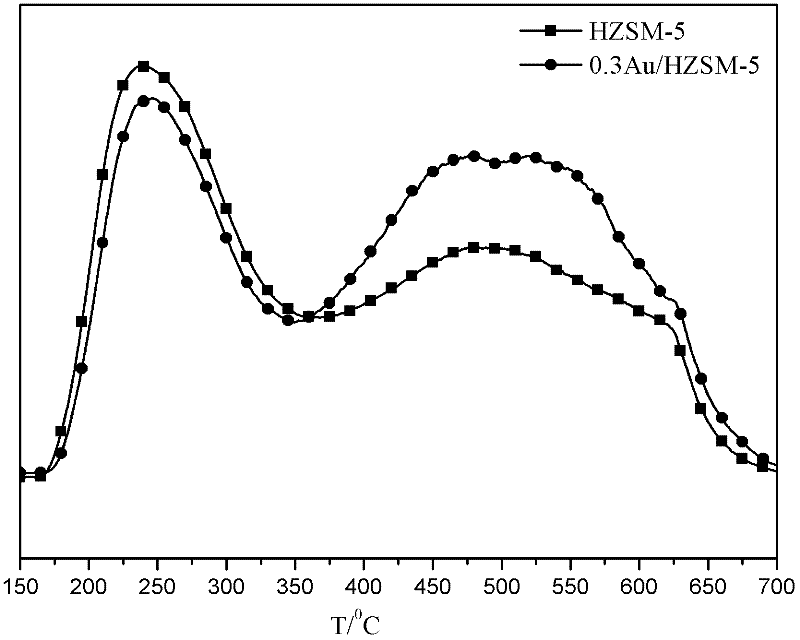

Method for converting n-alkane into isoalkane by gold-loaded molecular sieve catalyst

InactiveCN102416341AEasy to prepareIncrease acidityHydrocarbon by isomerisationMolecular sieve catalystsAlkaneIsomerization

A method for converting n-alkane into isoalkane by a gold-loaded molecular sieve catalyst belongs to the technical field of catalysts. After a molecular sieve is treated by completely negative pressure degasification and purification, a gold precursor is loaded on the molecular sieve carrier by a negative pressure deposition precipitation method so as to form a Si-O(H)-Au structure. The molecular sieve is a high-silica zeolite molecular sieve; the preparation of gold-loaded catalyst under a negative pressure condition by the deposition precipitation method facilitates the purification of the internal and external surfaces and pore channels of the molecular sieve; and Au is easy to enter the pore channels of the molecular sieve to reach high dispersion, and can be combined with silicon hydroxyls on the internal and external surfaces to form the Si-O(H)-Au structure. The method can dehydrogenize n-alkanes to generate alkenes under the difunctional action of metal and the carrier; the alkenes obtain protons at the acid sites to form carbonium ions; and isoalkanes are generated by skeletal isomerization and hydrogenation desorption of the carbonium ions.

Owner:DALIAN UNIV OF TECH

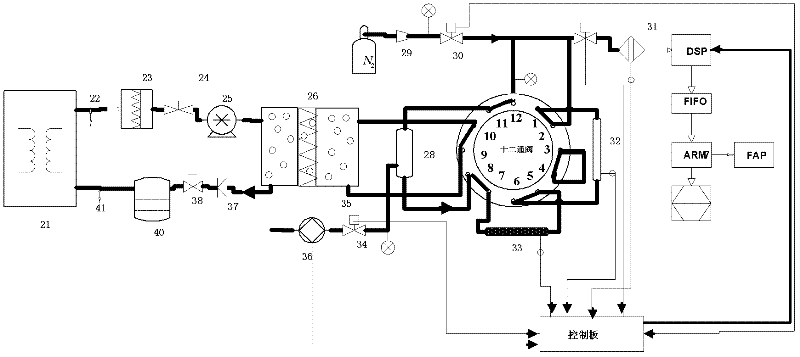

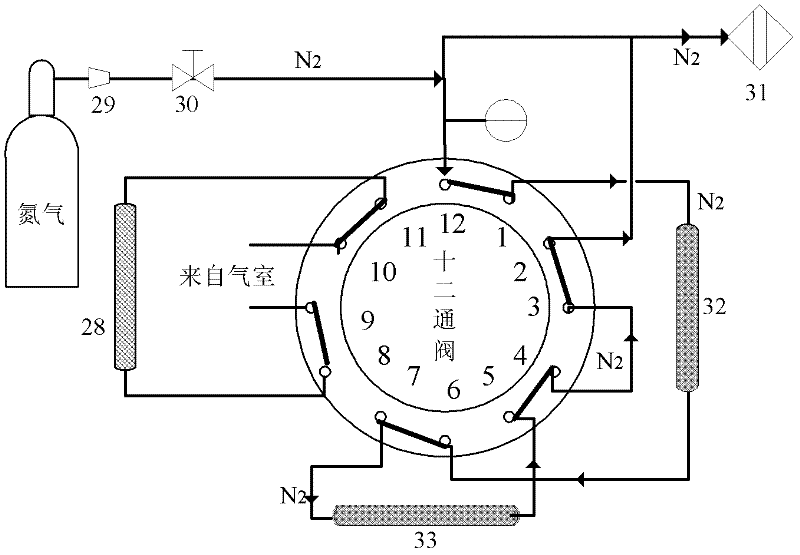

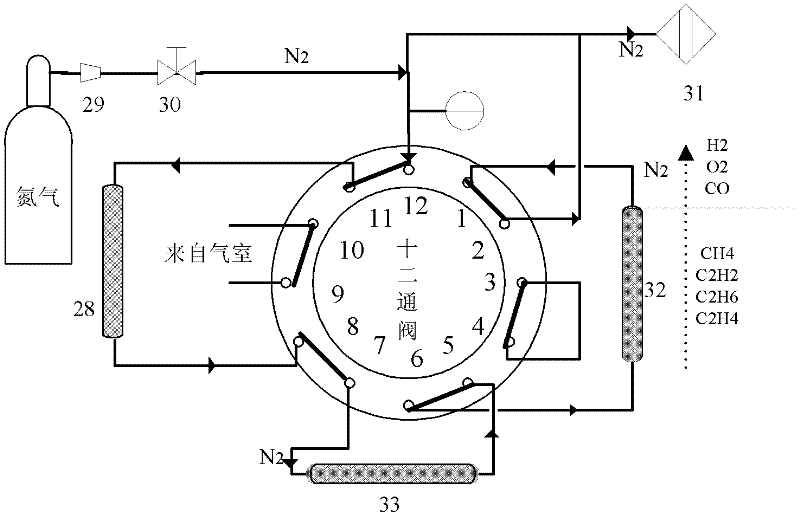

On-line detection system and method of trace dissolved gas in organic oil

InactiveCN102353724ASeparation EquilibriumEasy and quick passProgramme controlComponent separationRefluxFuel cells

The invention discloses an on-line detection system and method of trace dissolved gas in organic oil, characterized in that: a polymer degassing film with short oil-gas balance time is used, thus the structure is simple, and degasification speed is fast; the trace dissolved gas in organic oil is separated through the dual column chromatography, thus the number of channels of traditional chromatograph is simplified; the unique twelve-way valve structure is used, and double chromatographic columns are arranged, thus the system works respectively alternately in states of reflux and sample injection, and the problem of difficult separation of O2 and CO gas existing in the traditional chromatographic system is effectively solved; a trace flammable gas detection sensor produced by using a solidoxide fuel cell technique can simultaneously detect 7 kinds of dissolved gases in organic oil with high detection accuracy and good separating degree of different component gases, and the number of gas sensor in the system is reduced. According to the invention, an oil-gas separation, a gas separation detection unit and a control unit are combined together, thus the volume of the system device isreduced, the stability of the system is increased, and the system is convenient for installation and maintenance.

Owner:CENT SOUTH UNIV

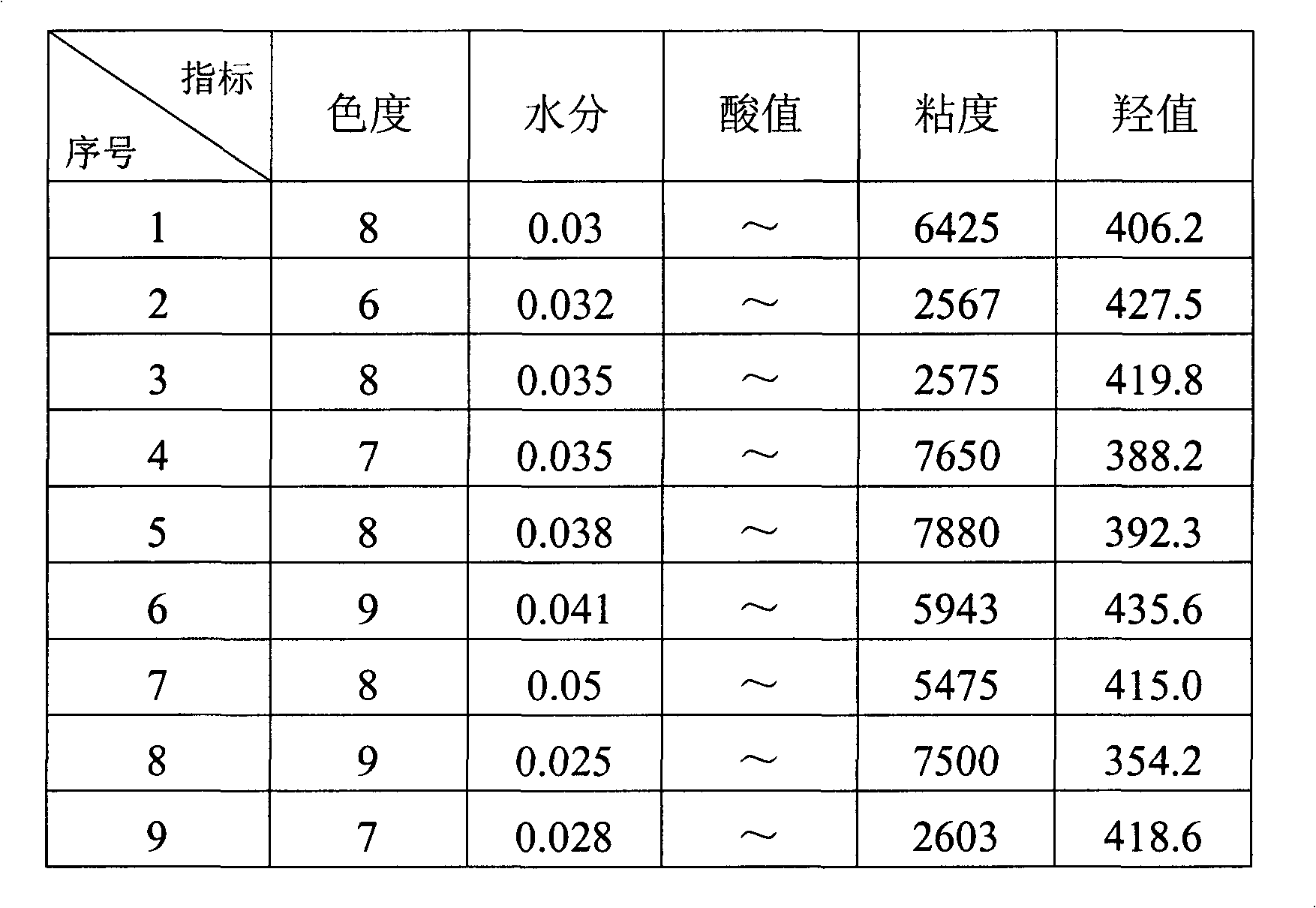

Synthetic method of polyether polyatomic alcohol

The invention discloses a synthetic method of a polyether glycol which belongs to the manufacture technical field of chemical products. The synthetic method of the invention comprises the following steps: sucrose, a compound partly containing active hydrogen, and propylene oxide are taken as raw materials and the polyether glycol is prepared under the effect of a catalyst by the processes of ring opening polymerization, curing, neutralized degasification and dehydrating, etc.; and the synthetic method of the invention is characterized in that: the raw materials also comprise seed oil, and the inventory rating of each component is as follows according to weight percent: 20-25 percent of the sucrose, 2-15 percent of the compound partly containing the active hydrogen, 45-60 percent of the propylene oxide and 5-25 percent of the seed oil, and the total sum of the weight percent of each component is 100 percent; the seed oil can be any one or a mixture of more than one of castor oil, palm oil, soybean oil, cotton seed oil, peanut oil, coconut oil, linseed oil, rapeseed oil, corn, olive oil and sunflower oil, etc. The synthetic method of the invention reasonably chooses the seed oil as raw materials, thus being capable of effectively reducing the usage of the propylene oxide, improving the service performance of the products and reducing the production cost.

Owner:绍兴广佳庄鑫建材制造有限公司

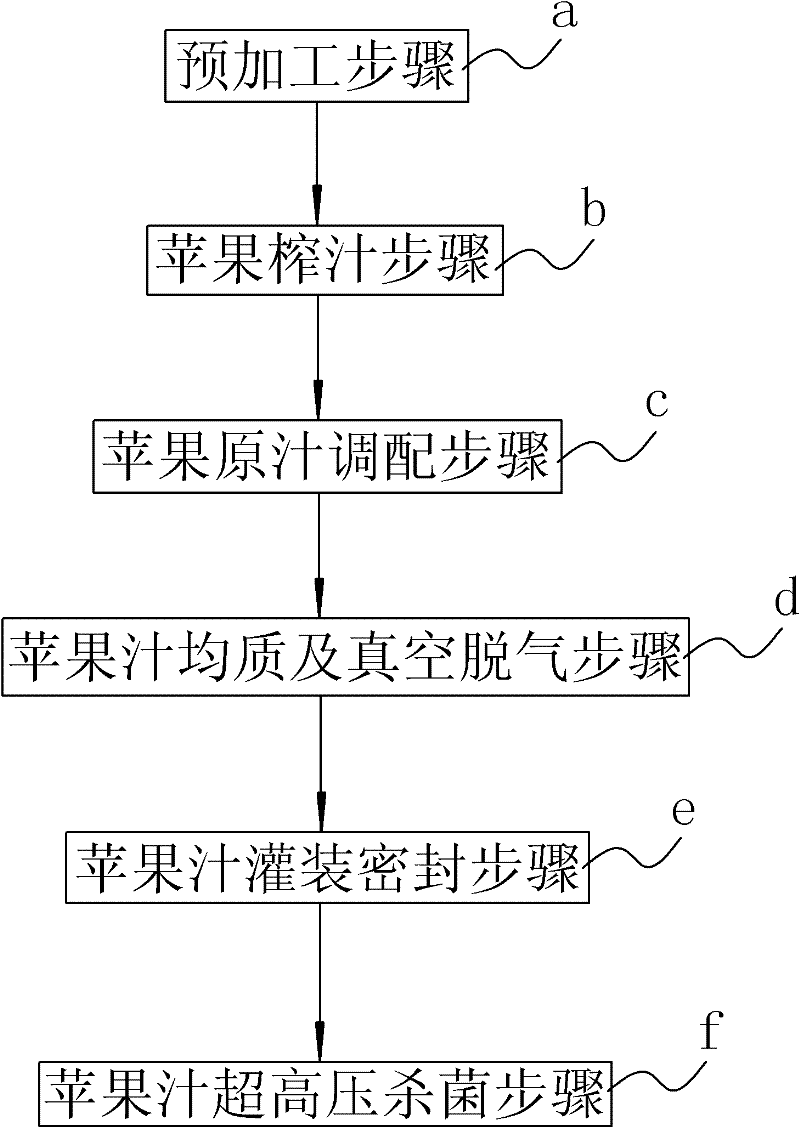

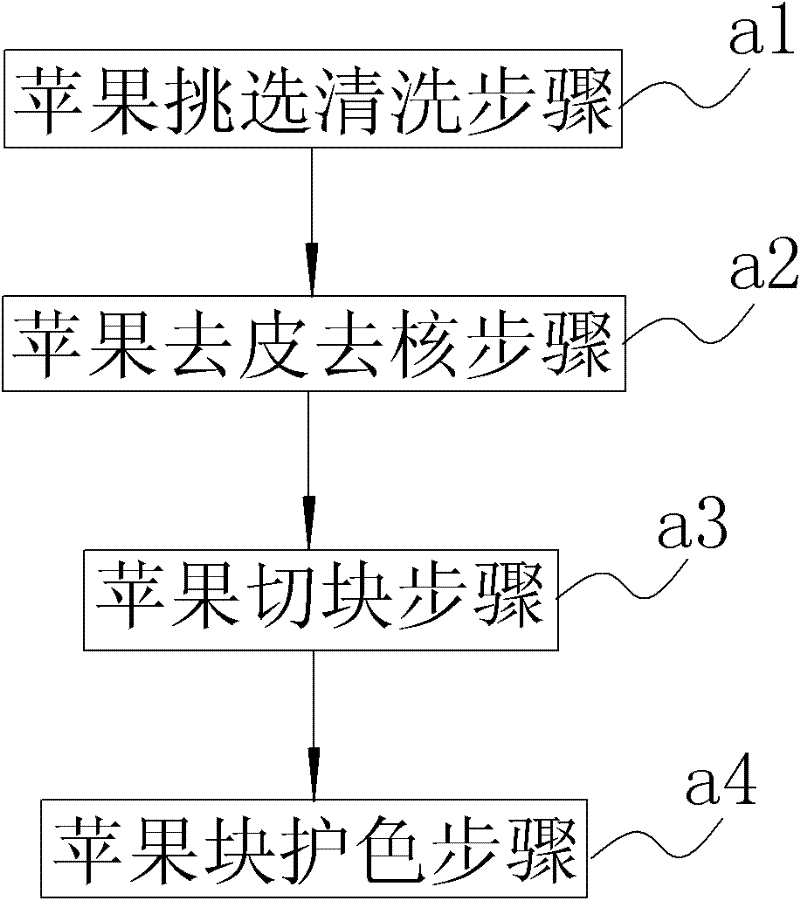

Apple juice and preparation method thereof

The invention relates to an apple juice and a preparation method thereof. The preparation method comprises the following steps: preprocessing; juicing apples; blending raw apple juice; homogenizing the apple juice, and carrying out vacuum degasification; filling the apple juice, and sealing; and carrying out extra-high-pressure sterilization on the apple juice. The apple juice is the product processed by the preparation method. By carrying out extra-high-pressure sterilization at normal temperature, the invention can effectively reduce enzymatic change and browning caused by thermal reaction in the processing course of the apple juice, solve the problems of mouthfeel and flavor degradation and nutrient loss of the product caused by high-temperature heating sterilization during the traditional thermal sterilization processing, and favorably keep the natural flavor and nutrient of the product.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

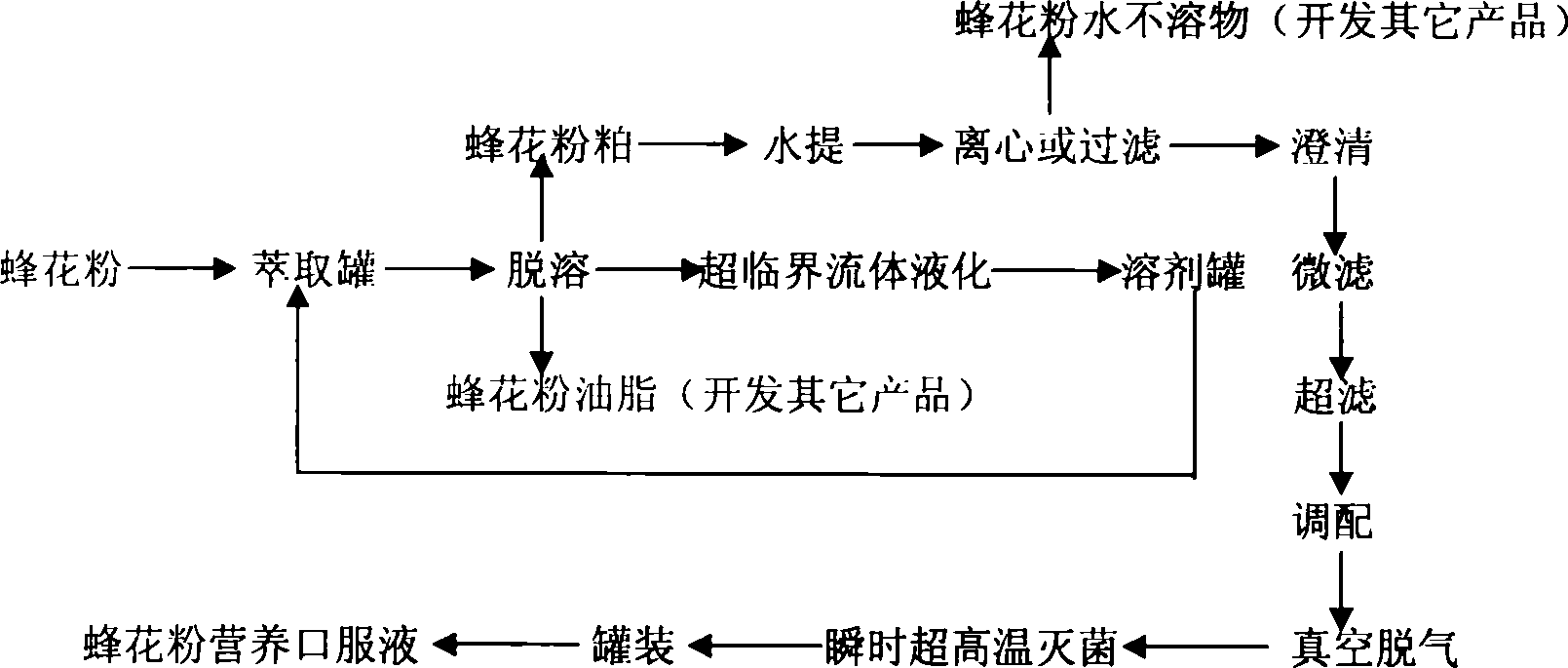

Bee pollen nutrition oral liquid and preparation method thereof

InactiveCN1883514AGood clarificationProduct appearance is clear and translucentAnthropod material medical ingredientsMetabolism disorderUltrafiltrationSolvent

The invention relates to a nourishing oral liquid of bee pollen and process for preparation, which comprises extracting bee pollen grease through hypercritical fluids, reclaiming solvent to obtain bee pollen cakes, carrying out centrifugal filtration and film separation, allocating bee pollen penetrated liquid and auxiliary materials including water, fructose syrup, bee honey, cane sugar, citric acid and perfume compound, finally carrying out vacuum degasification, high temperature instantaneous sterilizing, and asepsis canning.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

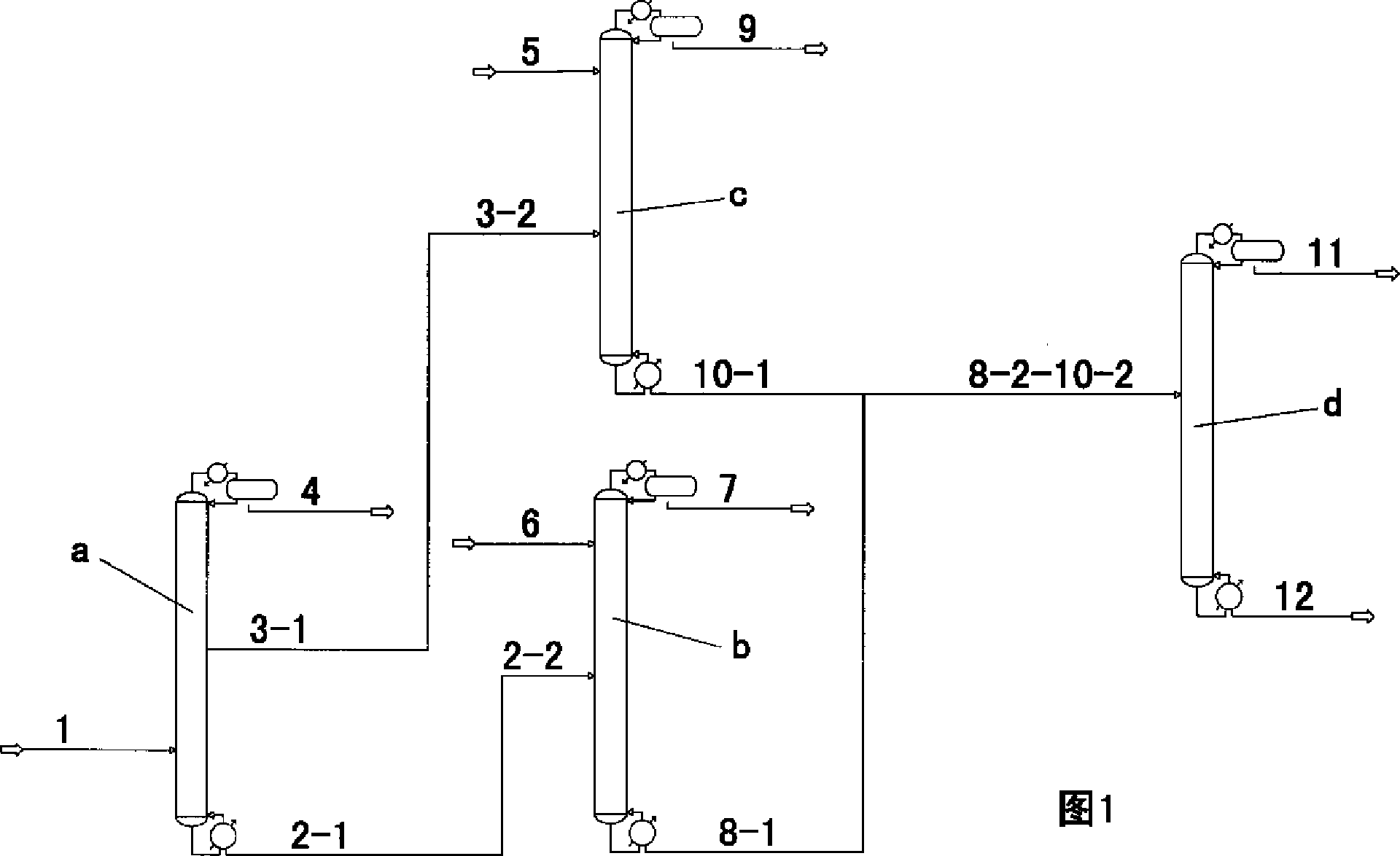

Method for separating butane and butylenes, and dedicated installation

This invention discloses method and apparatus for separating butane and butylene. The method comprises: (1) pretreating the raw materials; (2) extraction-rectifying the heavy fractions separated from step 1; (3) extraction-rectifying the light-heavy fractions separated from step 1; (4) separating the heavy fractions and the extractant in a degasification column. The apparatus comprises a raw material pretreatment rectification column, a heavy fraction extraction rectification column, a light-heavy fraction extraction rectification column, and a degasification column. The method can effectively increase the yields and purities of the fractions separated from C4 raw materials, lower the consumption of the extractant, and effectively reduce the foaming in the extraction rectification columns. Besides, the operation is stable. When used to separate butane and butylene from C4 raw materials in oil refinery plant, the method can realize high yield and purity of butylene product, low consumption of the extractant, and high purity of butane product.

Owner:CHINA PETROLEUM ENG CORP LTD

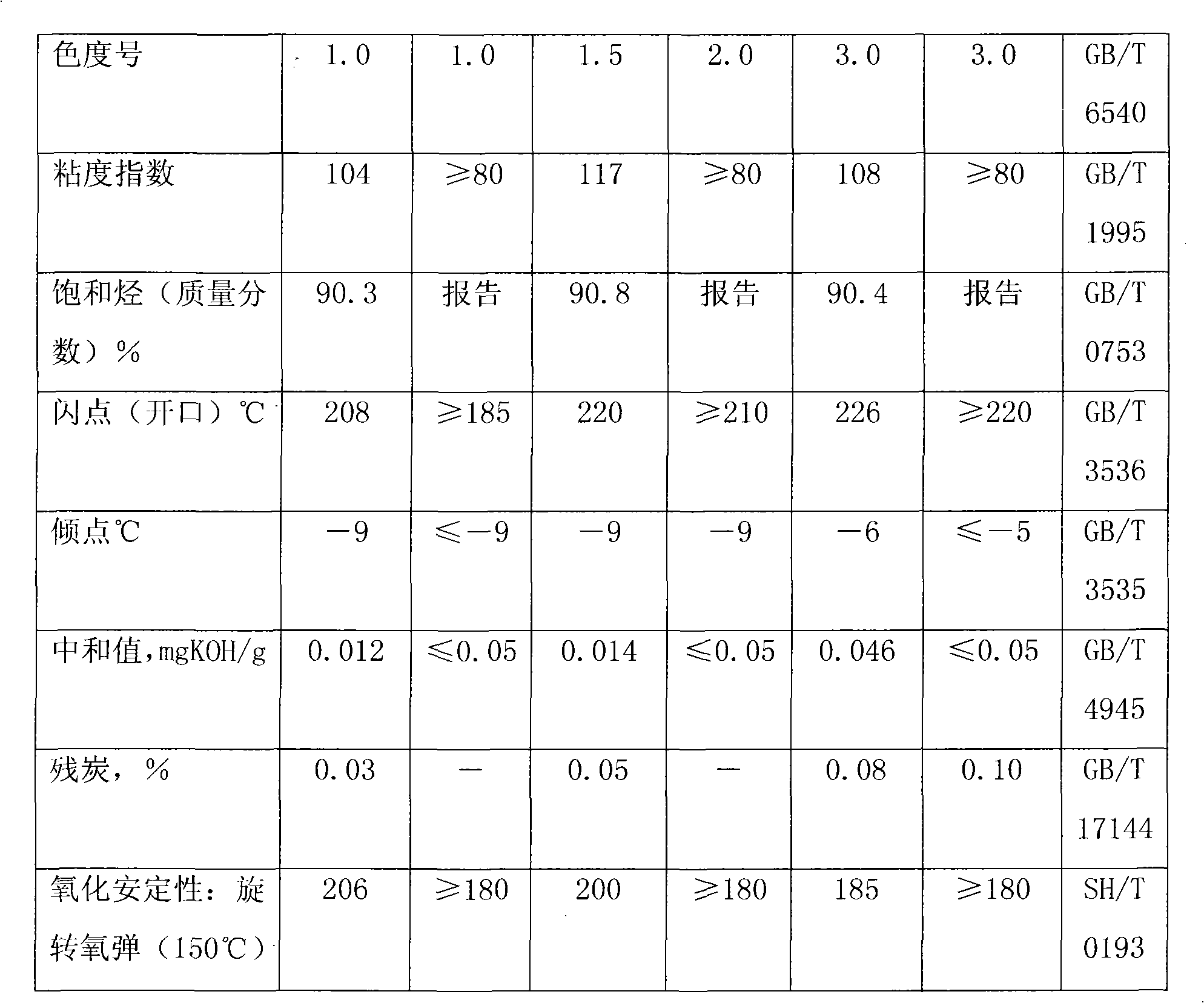

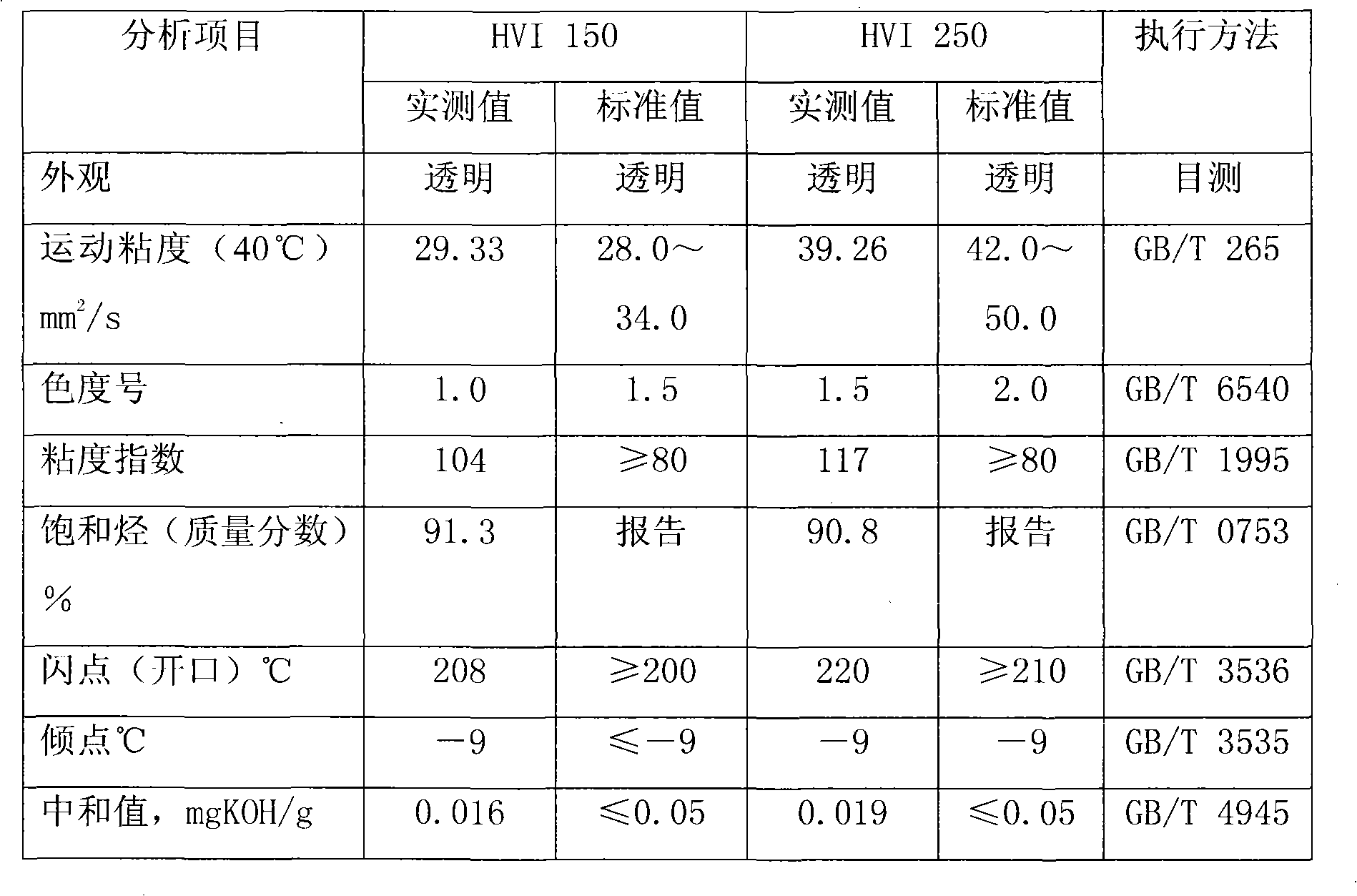

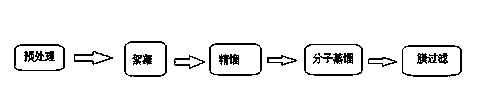

Regeneration technology for molecular distillation treatment of spent lubrication oil

The invention relates to a regeneration technology for the molecular distillation treatment of spent lubrication oil. The regeneration technology is characterized in that the regeneration technology comprises the following steps: preprocessing: after the spent lubrication oil is placed in a sedimentation tank for sedimentation, an upper oily mixture is obtained and placed in a plate and frame filter for filtering, so as to obtain a treatment fluid; flocculation: the treatment fluid is heated up to 120-170 DEG C, and during the heating, one fifth of an organic flocculant is added for every temperature rise of 20 DEG C until the organic flocculant is used up; rectification: the flocculated treatment fluid sequentially goes through degasification and drying, and is then transferred into a rectifying tower for rectification; molecular distillation: the rectified lubrication oil further goes through multistage molecular distillation; membrane filtration: the lubrication oil after the molecular distillation goes through membrane filtration to obtain base oil. The invention has the advantages of small investment scale, low operation costs, high quality of regenerated base oil products, high yield, energy conservation, environmental friendliness, high regeneration efficiency and safety, and prevents 'secondary pollution'.

Owner:四川省德阳昌盛至轩石油化工厂

Method for recycling sulfur from acid gases containing hydrogen sulfide

InactiveCN101791517BReduce consumptionHigh purityDispersed particle separationEnergy inputCatalytic oxidationEmission standard

The invention relates to a method for recycling sulfur from acid gases containing hydrogen sulfide, comprising the following steps: (a) air supply; (b) acid gas pretreatment; (c) mixture; (d) primary direct catalytic oxidation; (e) primary sulfur condensation; (f) process gas reheating; (g) secondary direct catalytic oxidation; (h) secondary sulfur condensation; (i) sulfur re-separation; (j) degasification in a liquid sulfur tank; and (k) tail gas burning. When the volume concentration of H2S in the acid gases in the prior art is 1-15%, the recycle rate of sulfur can reach over 99% by the method of the invention, and the emission load of H2S in the acid gases processed by the method of the invention meets the emission requirement of Integrated Emission Standard of Air Pollutants (GB16297-1996).

Owner:北京至清时光环保工程技术有限公司

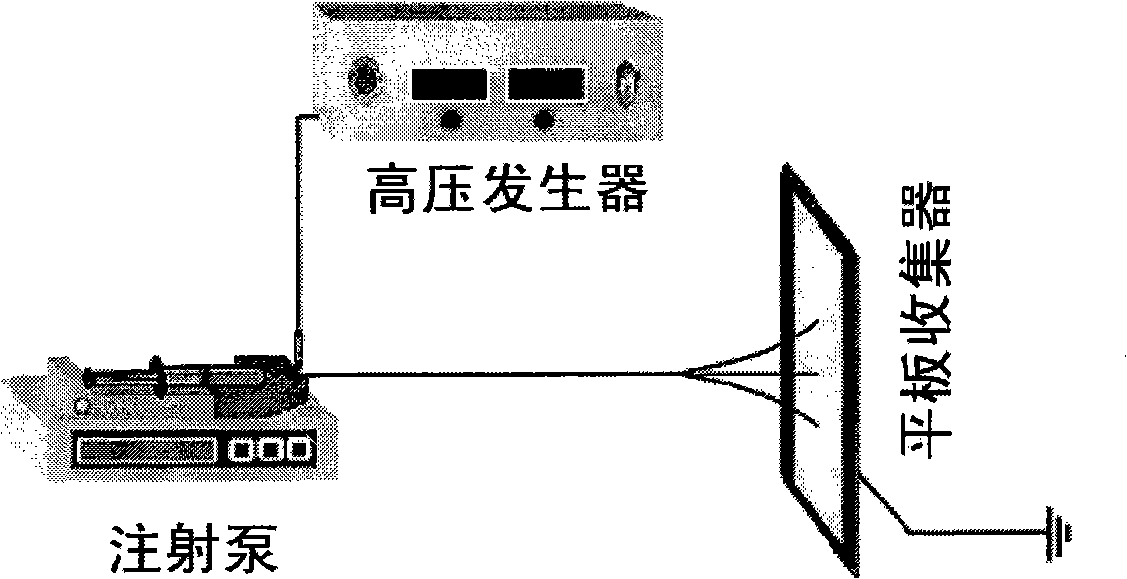

Preparation of nano crystal fibre felt of water-insoluble medicament

InactiveCN101327182AControlled drug administrationEasy to preparePharmaceutical delivery mechanismPharmaceutical non-active ingredientsSolubilityWater insoluble

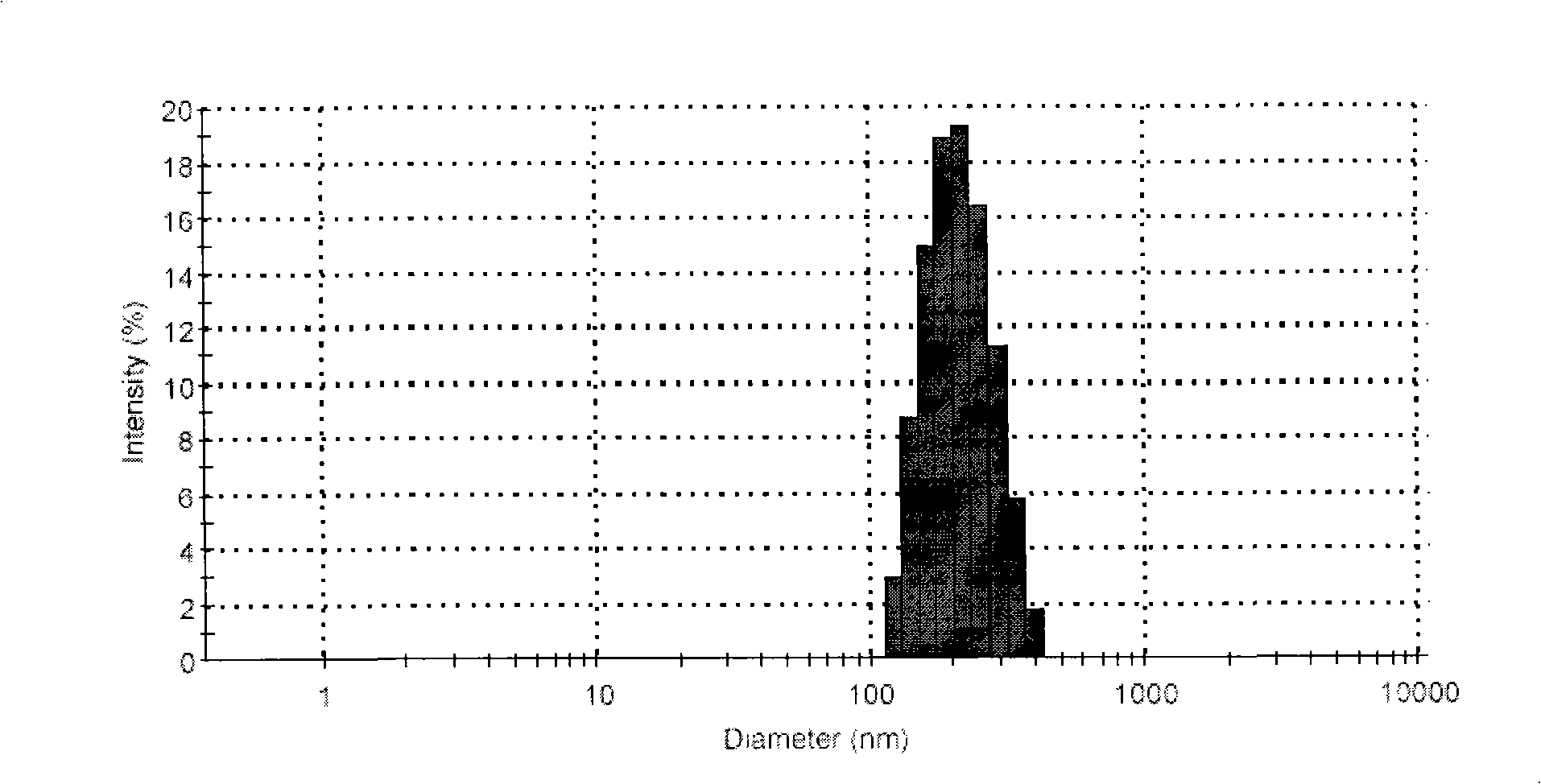

The invention relates to a preparation of a water-insoluble medicine nanocrystal fibrofelt, which comprises that: water-insoluble medicine is dissolved in organic solvent, then polymeric material is added under the stir condition, the stir is continued and ultrasonic degasification is carried out; the prepared solution is poured into a solution storing tank, a flattened injection needle is used as a capillary tube for injecting thin flow, the positive pole of high voltage source is connected, an aluminum foil receiving flat plate is used to connecte with the negative pole, a microinjection pump is used for controlling the solution injection amount, the spinning condition is adjusted, electrostatic spinning is carried out so that nanocrystal fibrofelt is obtained. The method of the invention is simple, the loading action of polymer material can effectively control the administration in a proper releasing rate and a proper amount, the prepared water-insoluble medicine nanocrystal has favorable solubility, the medicine oral administration bioavailability is improved, multiple ways of administration of water-insoluble medicine is realized, and the application range is widened.

Owner:DONGHUA UNIV

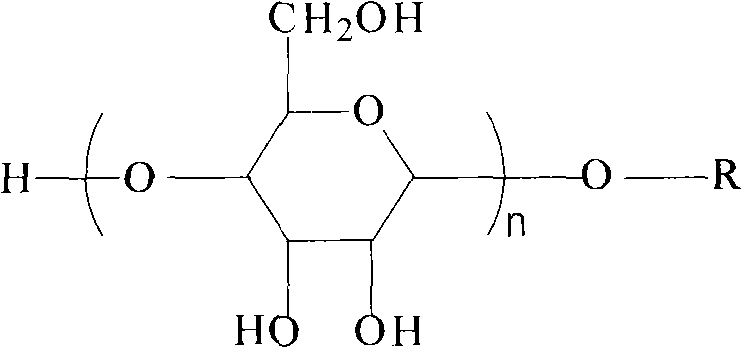

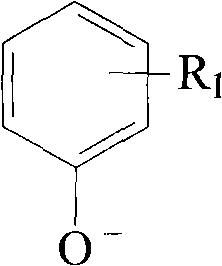

Natural high class fatty alcohol emulsion and preparation method thereof

A natural high class fatty alcohol emulsion and a preparation method thereof belong to the technical field of fine chemical preparation. The natural high class fatty alcohol emulsion is characterized by comprising natural high class fatty alcohol, paraffin, polyether, alkyl polyglucoside (APG for short), thickening agent and water. The preparation method comprises the following steps: A. mixing natural high class fatty alcohol and paraffin in proportion, heating to 70-90 DEG C to obtain mixture (1); B. dissolving polyether and APG in hot water of 70 DEG C to obtain mixture (2); C. adding mixture (1) slowly into mixture (2), and then using an exorbitant shearing device to further emulsify to obtain a crude emulsion; D. supplementing corresponding water quantity to dilute into the required concentration; and E. using the thickening agent to adjust the viscosity of the product to 250-400mPa.s to obtain the natural high class fatty alcohol emulsion. The prepared natural high class fatty alcohol emulsion has good degasification performance in paper-dipping procedure of paper-making and excellent usage in paper-making industry.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Corrosion-resistant easy cutting plastic mold steel

InactiveCN1920085AImprove corrosion resistanceEasy to processHeat treatment process controlStructure propertyMachinability

The invention relates the plastic mold steel. The weight percents of the components are as follows: C0.25-0.35, Mn0.50-1.00, Si0.30-0.60, S0.04-0.10, P<=0.025, Cr15.00-18.00, Mo0.05-0.03, V0.06-0.35, Ni0.60-1.00, N0.03-0.07, and the left are steel furnace burden. The method comprises the following steps: using electric furnace, vacuum degasification and electroslag remelting smelting. The invention also adopts the electric furnace and vacuum degasification smelting technology. The plastic mold steel has plastic mold steel, free-cutting machinability, homogeneous structure property and good deformability. The plastic mold steel is used to make large-scale plastic mold.

Owner:WUXI CHICHENG SPECIAL STEEL VENDITION

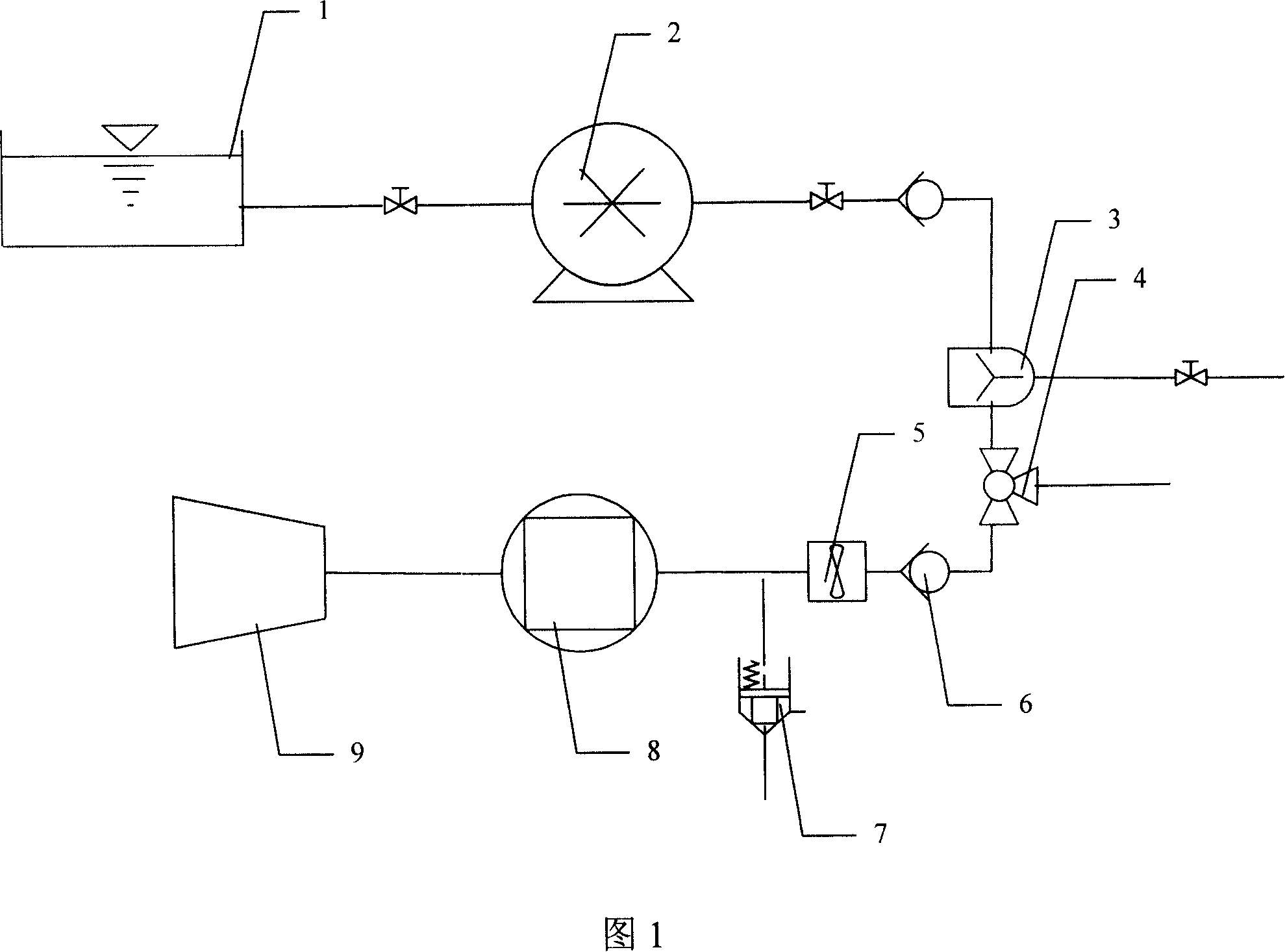

Method and apparatus for degasification of claus-derived sulfur

ActiveUS8084013B2Complete efficientlySulfur preparation/purificationLiquid solutions solvent extractionSulfurStatic mixer

A method and apparatus for degasification of Claus-derived sulfur by the use of gas-liquid eductor using the liquid sulfur as the ejector motive force and ambient sweep air as the active degassing agent combined with a static mixer and packed bed for promoting the intimate contact of the air and the sulfur.

Owner:KNM INT SDN BHD

Technology for producing degradable and edible film by utilizing corn composite modified starch

ActiveCN102311554AGood viscosity stabilityImprove strength propertiesFlexible coversWrappersCarrageenanPhosphate

The invention provides technology for producing a degradable and edible film by utilizing corn composite modified starch, belonging to the technical field of food processing. The technology comprises the following main production processes: firstly gelatinizing the corn hydroxypropyl-phosphate monoester composite modified starch; then adding glycerin, sorbitol, sodium alginate, carrageenan and other components which improve the film performance; carrying out tape casting on the film solution on a copper plate after homogenization and degasification; adopting a copper plate film forming conveyer belt to firstly pass through steam drying pipeline equipment and then pass through cooling pipeline equipment with relative humidity being about 50% to form a film; and finally adopting mechanical film rolling equipment to roll the film, thus producing a degradable and edible film with high strength. The film material has good mechanical performance and oil, moisture and oxygen resistance. The film can be applied to packaging of various materials such as food, health products, drugs, feed and the like.

Owner:活泼

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com