Method for recycling sulfur from acid gases containing hydrogen sulfide

A technology of acid gas and hydrogen sulfide, applied in chemical instruments and methods, separation methods, preparation/purification of sulfur, etc., can solve the problems of low conversion rate of sulfur, achieve high purity, convenient daily maintenance, and less equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

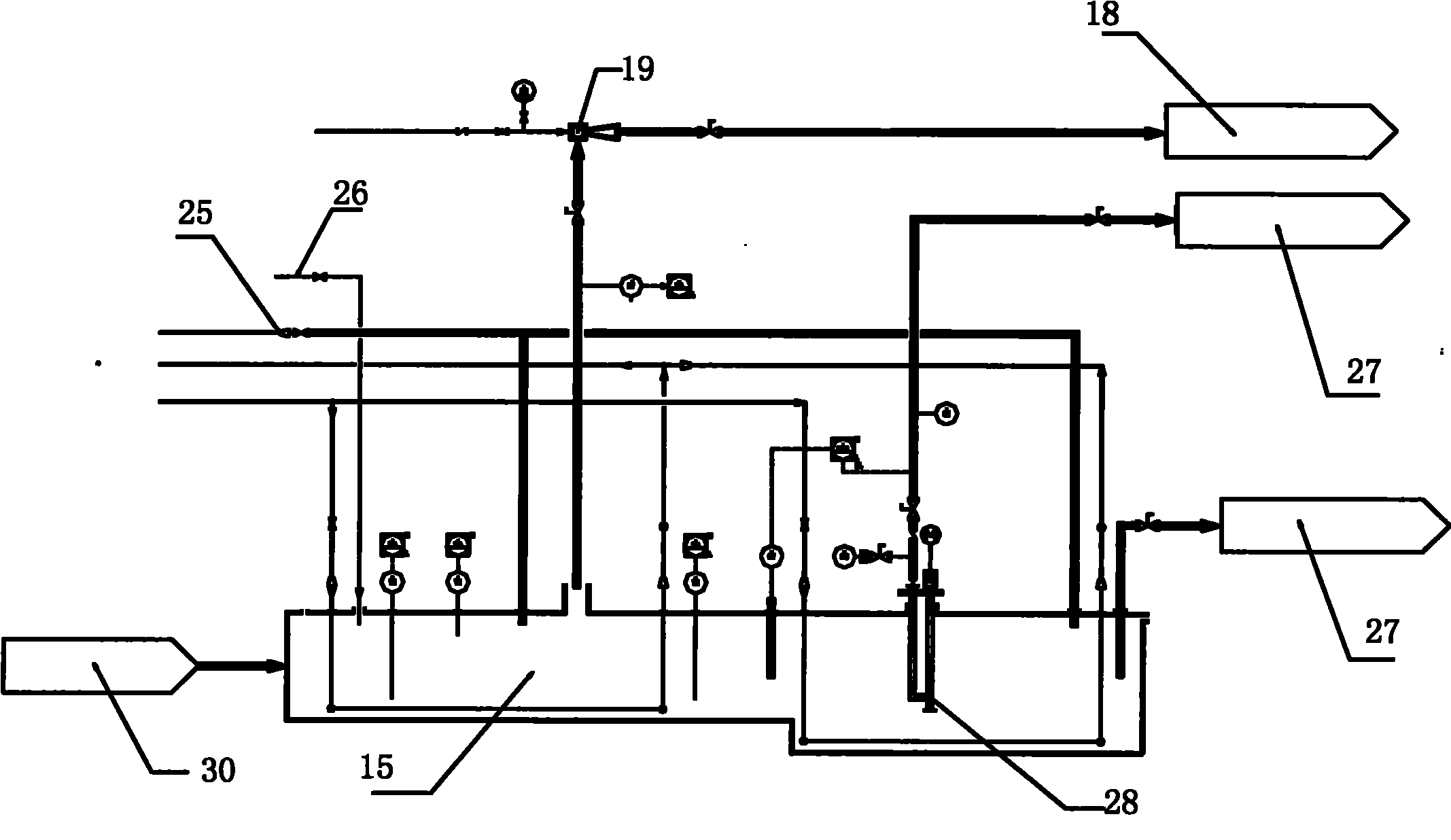

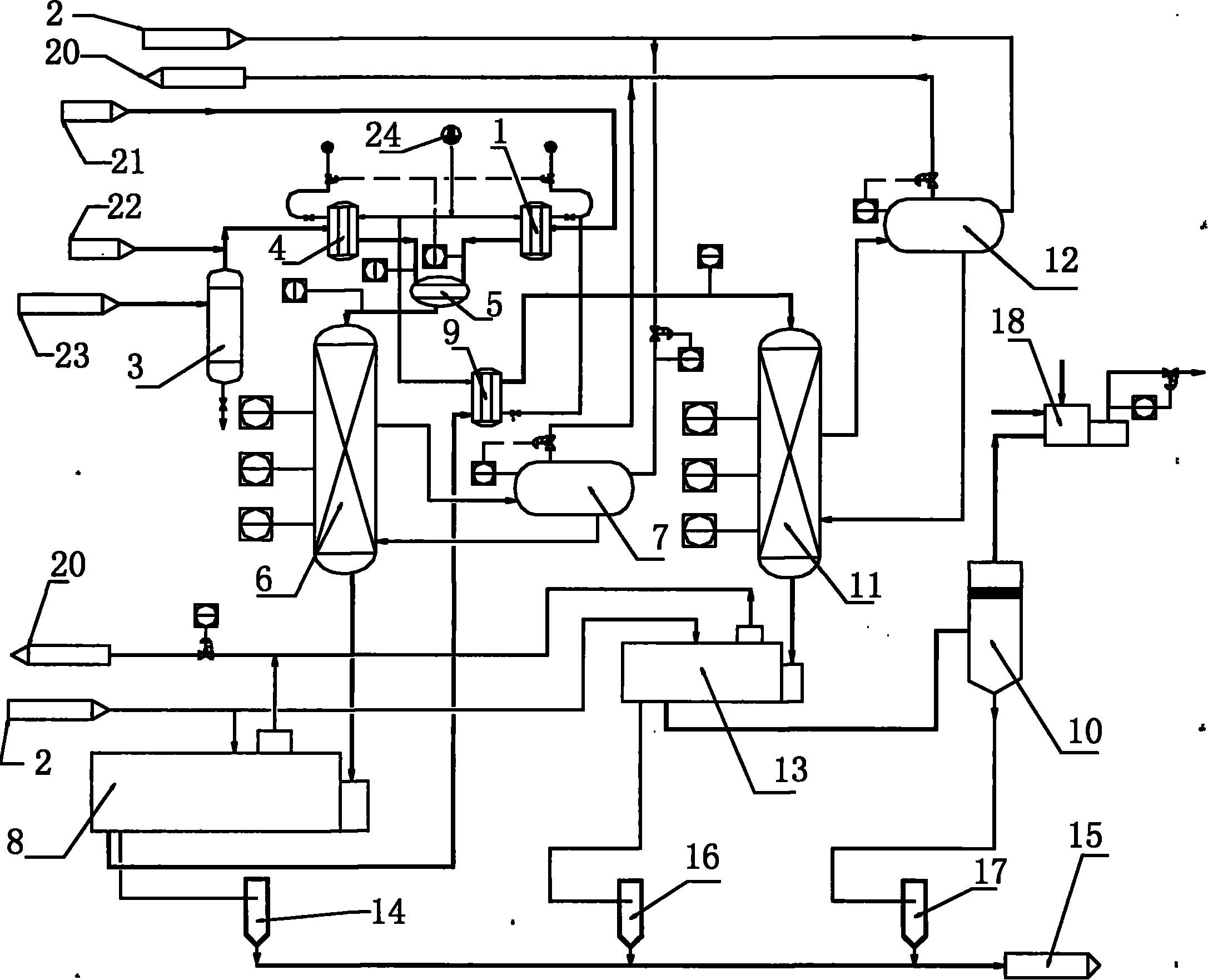

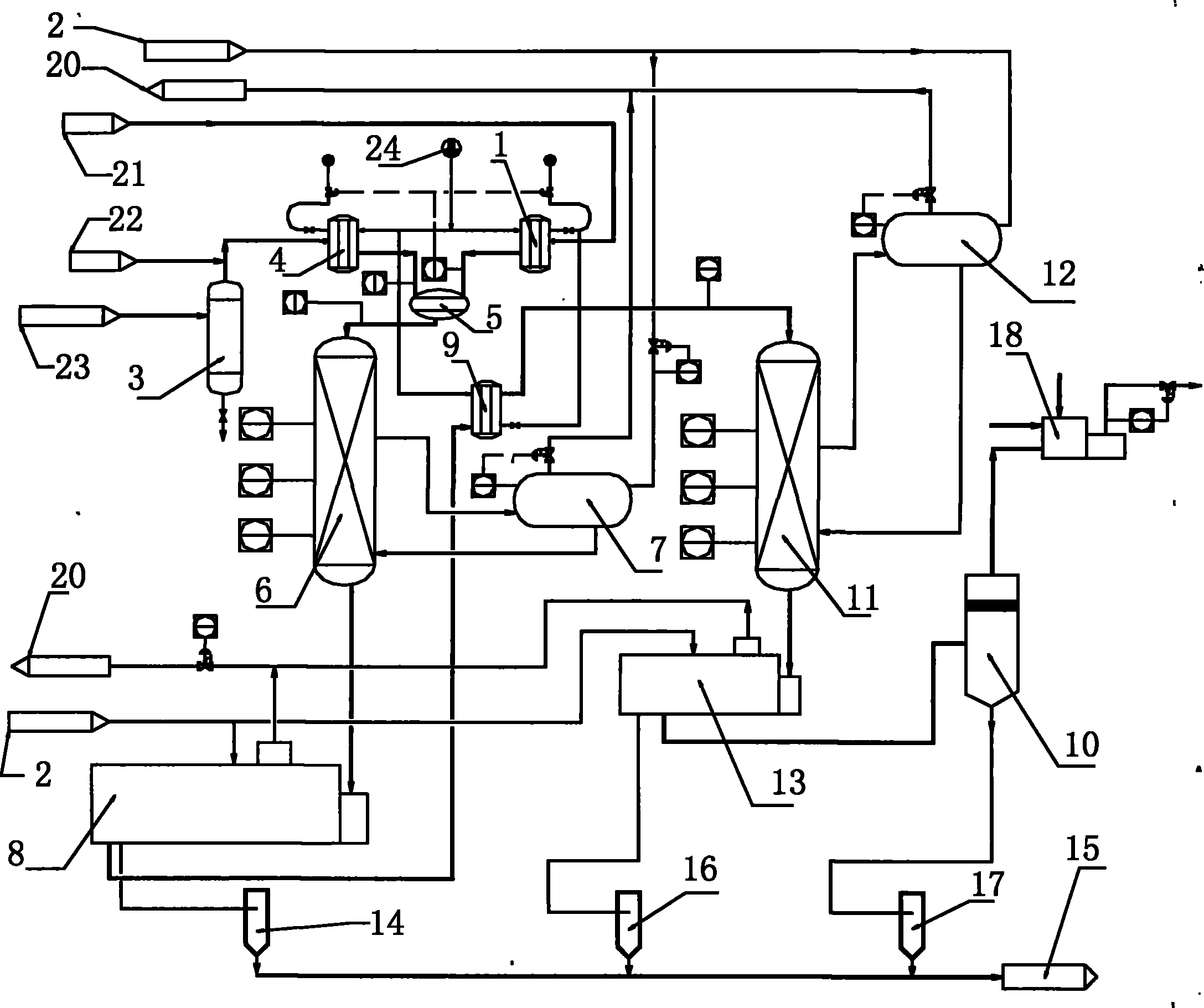

[0025] The method for recovering sulfur from acidic gas containing hydrogen sulfide of the present embodiment comprises the following steps: (a) Air supply: Utilize an air blower to introduce air from the outside into the air preheater 1, and preheat the air through the air preheater 1 Heat to 240°C to form preheated air; (b) acid gas pretreatment: acid gas is introduced into acid gas separator 3, and the liquid droplets carried by acid gas are separated, and the separated acid gas separator 3 comes out The acid gas enters the acid gas preheater 4 and is heated to 240° C. by medium-pressure steam; (c) mixing: the ratio of the amount of hydrogen sulfide to the amount of oxygen is calculated according to the ratio of 2: 1, and the The preheated air in the air preheater 1 and the acid gas preheated to 240°C in the acid gas preheater 4 are passed into the static mixer 5 to be fully mixed to form process gas; the flow rate of the air is determined by the acid gas The flow rate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com