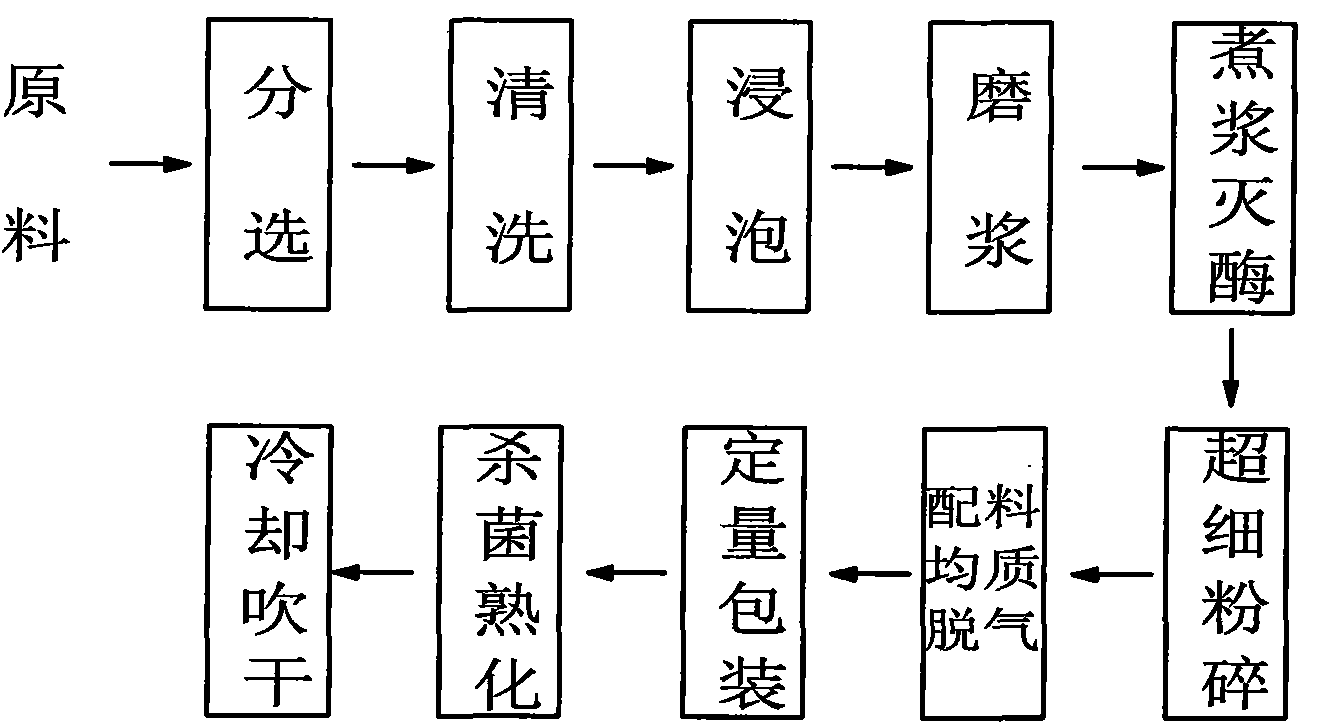

Method for preparing whole bean high-fiber high-concentration preserved soya-bean milk

A manufacturing method and high-concentration technology, applied in dairy products, milk substitutes, applications, etc., can solve the problems of product nutrition loss, nutrition loss, waste of resources, etc., and achieve the effects of long storage time, high nutritional value, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

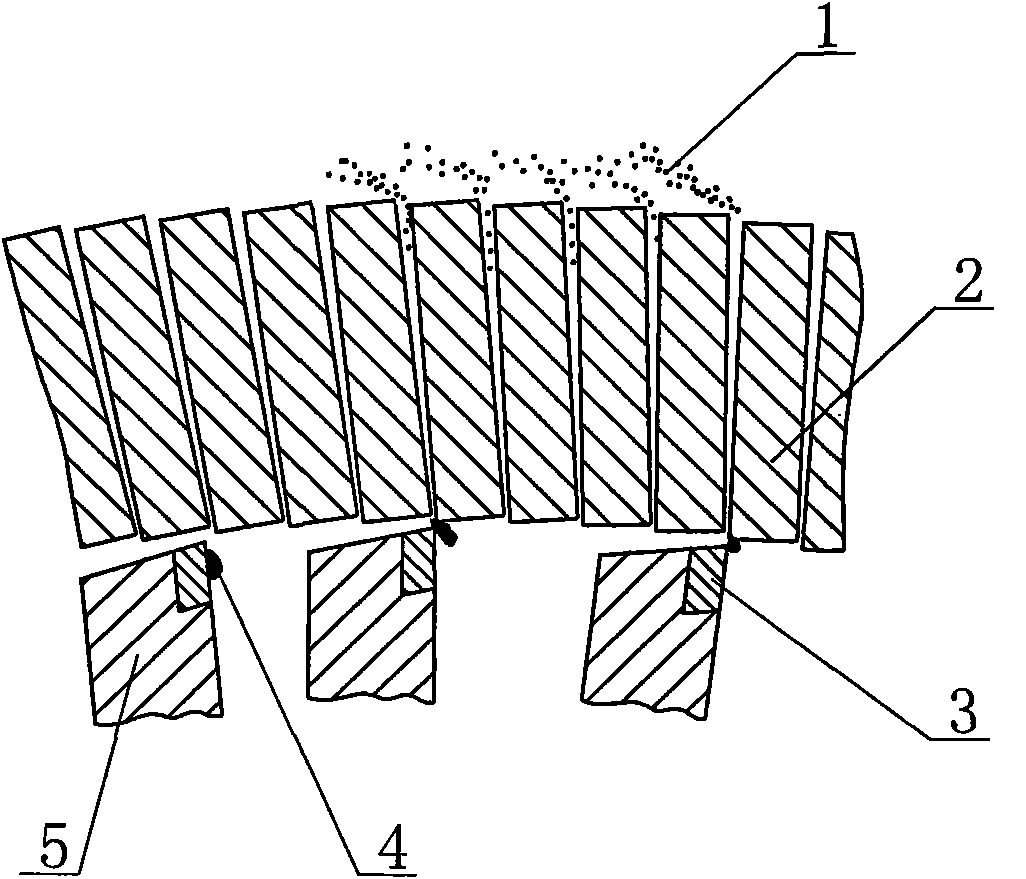

[0032] The tooth gap is 0.20mm, the gap is 0.15mm, the rotation speed is 9000r / min, the slurry and slag mixture, the average output is 3 tons / hour, and the average particle size of the obtained high-concentration soybean milk 1 is 240μm.

Embodiment ( 2

[0034] The tooth gap is 0.025mm, the gap is 0.15mm, the rotation speed is 9000r / min, the slurry and slag mixture, the average output is 1.5 tons / hour, and the average particle size of the obtained high-concentration soybean milk 1 is 70μm.

Embodiment ( 3

[0036] The tooth gap is 0.20mm, the gap is 0.15mm, the rotation speed is 2900r / min, the slurry and slag mixture, the average output is 1 ton / hour, and the average particle size of the obtained high-concentration soybean milk 1 is 280μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com