Crystallization method of ammonium fluoride or ammonium bifluoride

A technology of ammonium bifluoride and ammonium fluoride, which is applied in the direction of ammonium fluoride and ammonium halide, can solve the problems of uneven particle size of crystal particles, strong corrosion of ammonium bifluoride, open air pollution, etc., and achieve high yield of finished products, The effect of stable product quality and no waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

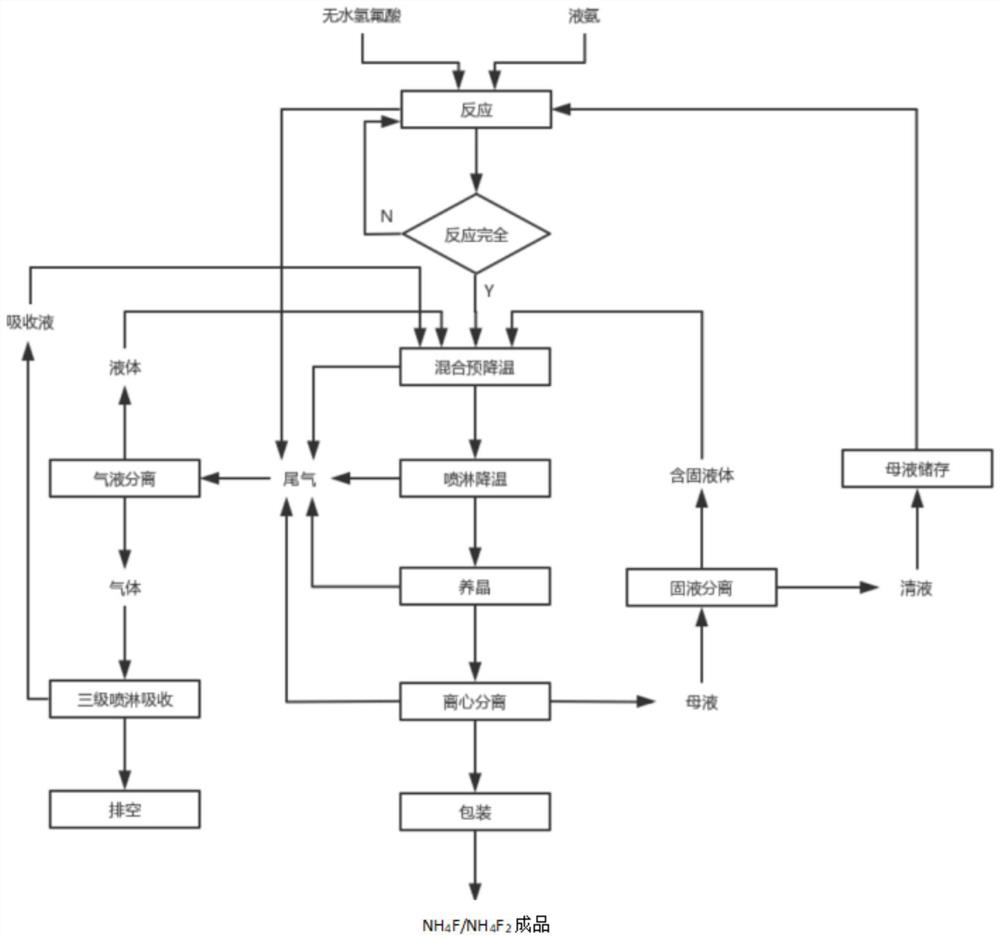

[0075] A kind of crystallization method of ammonium fluoride adopts air-cooled spray cooling tower to carry out crystallization, specifically comprises the following steps:

[0076] S1. Pump 1t of ammonium fluoride mother liquor into the reaction kettle with graphite tube cooling tower, and divide the amount of anhydrous hydrogen fluoride and liquid ammonia into 2 batches according to the theoretical feeding amount;

[0077] S2. In the water-cooled state, feed the anhydrous hydrogen fluoride 270kg of the first batch of feed into the reactor, then slowly feed the liquid ammonia 233kg of the first batch of feed into the reactor, by controlling the liquid ammonia flow, Make the temperature of the reaction system not exceed 85°C;

[0078] S3. After the completion of the ammonia passage in S2, 270kg of anhydrous hydrogen fluoride of the second batch of feeding amount is passed into the reactor, and the temperature of the reaction system is kept not exceeding 85°C, and the liquid of...

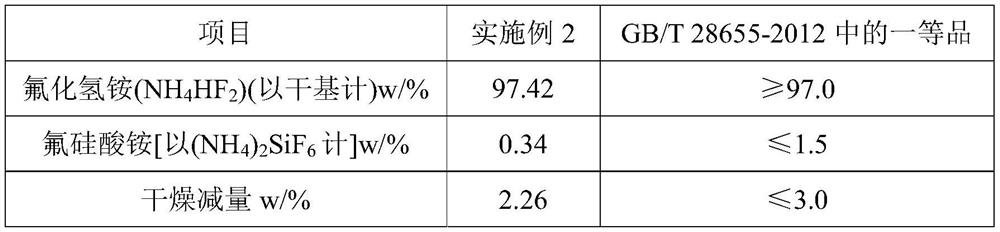

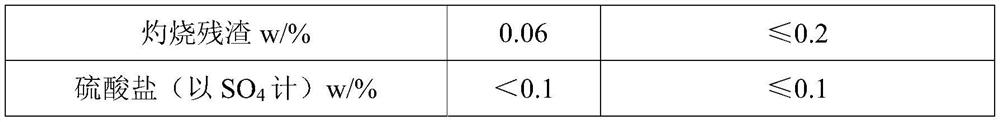

Embodiment 2

[0087] A kind of crystallization method of ammonium bifluoride adopts air-cooled spray cooling tower to carry out crystallization, specifically comprises the following steps:

[0088] S1. Pump 2t of ammonium bifluoride mother liquor into the reaction kettle with graphite tube cooling tower, and divide the amount of anhydrous hydrogen fluoride and liquid ammonia into 3 batches according to the theoretical feeding amount;

[0089] S2. In the water-cooled state, feed the anhydrous hydrogen fluoride 700kg of the first batch of feed into the reactor, then slowly feed the liquid ammonia 299kg of the first batch of feed into the reactor, by controlling the liquid ammonia flow, Make the temperature of the reaction system not exceed 93°C;

[0090] S3. After the completion of the ammonia passage in S2, 700kg of anhydrous hydrogen fluoride of the second batch of feeding amount is passed into the reactor, and the temperature of the reaction system is kept not exceeding 93°C, and the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com