Patents

Literature

158results about How to "Not easy to take away" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double hot-rolling composite friction material and its production

A bi-hot pressing composite friction material and its production are disclosed. The process is carried out by the first hot-press forming, crushing for composite friction material, sifting, mixing composite friction material 40-70 wt% and high-temperature-resisting modified resin 15-35 wt% with reinforced fiber 5-15 wt%, rubber powder 5-15 wt% and residual lubrication material, putting them into mould, hot-press forming at 140-165 degree and 12-20 Mpa and keeping temperature to obtain final product. It has stable friction coefficient, less wear rate and friction noise, better surface toughness and higher gas-pocket coefficient.

Owner:SOUTH CHINA UNIV OF TECH

Anti-slide fog seal material and its construction method

ActiveCN102815892AImprove skid resistanceAvoid the problem of insufficient skid resistanceIn situ pavingsKaolin clayRoad surface

The invention relates to an anti-slide fog seal material and its construction method. The anti-slide fog seal material is obtained by the following steps of: mixing 15-30 parts by weight of composite kaolin, 35-70 parts by weight of water and 1.2-2.0 parts by weight of an asphalt emulsifier, adjusting the pH value into a range required by the corresponding asphalt emulsifier with a pH value conditioning agent, then emulsifying 25-40 parts by weight of hot melt asphalt so as to obtain a stable mixed emulsion, and finally mixing the emulsion with 50-80 parts by weight of sand and conducting stirring. When the anti-slide fog seal material is sprayed on a road surface uniformly by a spraying vehicle, it can bond well with the road surface. Thus, the material not only seals original road surface micro-cracks and voids, plays a strong waterproof role, but also prolongs the road service life. And the sand in the anti-slide fog seal material can substantially improve the anti-slide performance of the road surface.

Owner:GAOYUAN HIGHWAY MAINTENANCE TECH HENAN PROV

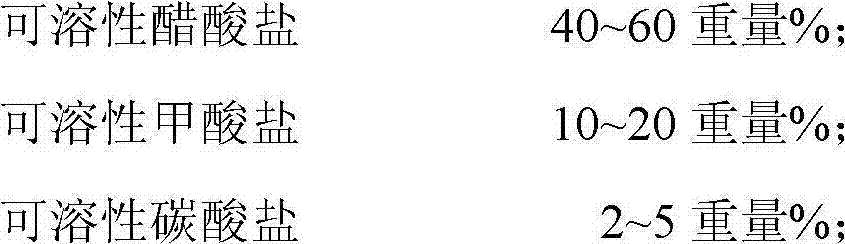

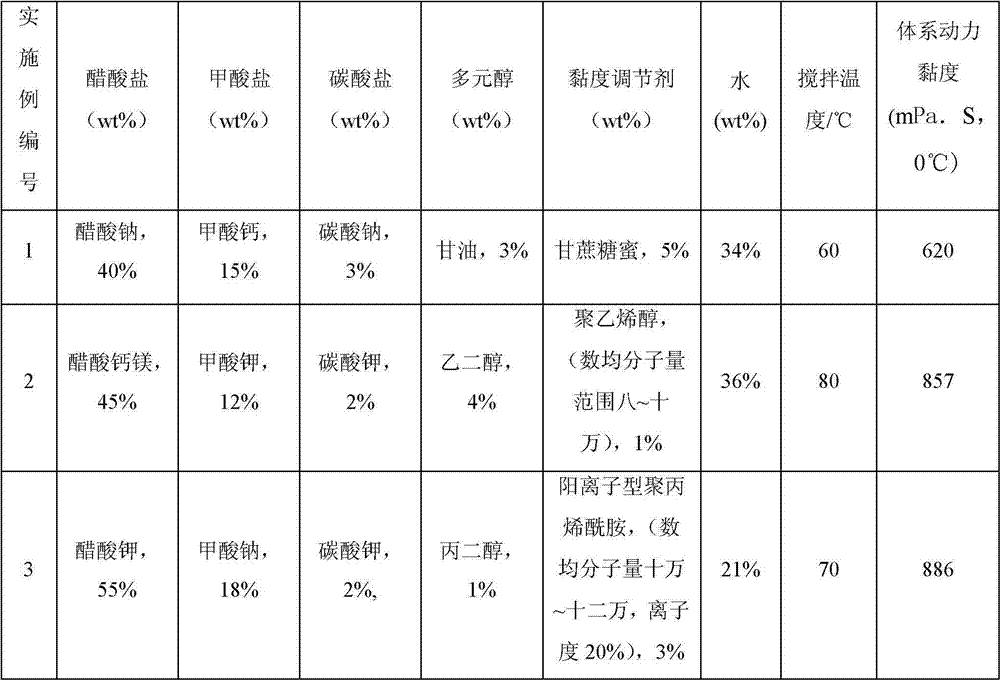

Green environment-friendly snow-melting liquid and preparation method thereof

InactiveCN102899004AFast melting rateNo pollution in the processOther chemical processesFormateMetallic materials

The invention relates to a green environment-friendly snow-melting liquid and a preparation method thereof. The liquid contains the following components: 40-60 wt% of a soluble acetate; 10-20 wt% of a soluble formate; 2-5 wt% of a soluble carbonate; 1-5 wt% of a polyol; 1-5 wt% of a viscosity modifier; and 20-40 wt% of water. The green environment-friendly snow-melting liquid provided in the invention is free of chloride ions, has a fast snow-melting rate, has no corrosion on metal materials such as steel bars, and has no pollution on soil and water bodies, thus being green and environment-friendly. The snow-melting liquid is convenient for storage and transportation, and has wide application. Compared with most of existing solid snow-melting materials, the snow-melting liquid has the characteristics of fully mechanized spreading way, uniform spreading, labor cost reduction, and spreading time reduction, etc.

Owner:HUBEI PROVINCE FREEWAY IND DEV +1

Flowability improver for crude oil and its preparing process

An improver for the flowability of crude oil in oil well or pipeline is prepared from polyoxyacrylic polyoxyvinyl propane diol ether, polyoxyacrylic polyoxyethene polyvinylpolyamine ether, sodium dodecylphenylsulfonate, poluoxyacrylic polyoxyvinyl resinether, polyoxyacrylic polyoxyvinyl emtrolether, methanol and water through proportional mixing, heating to 50-100 deg.C, stirring for 2 hrs and cooling to 30-40 deg.C.

Owner:大庆油田九龙实业公司

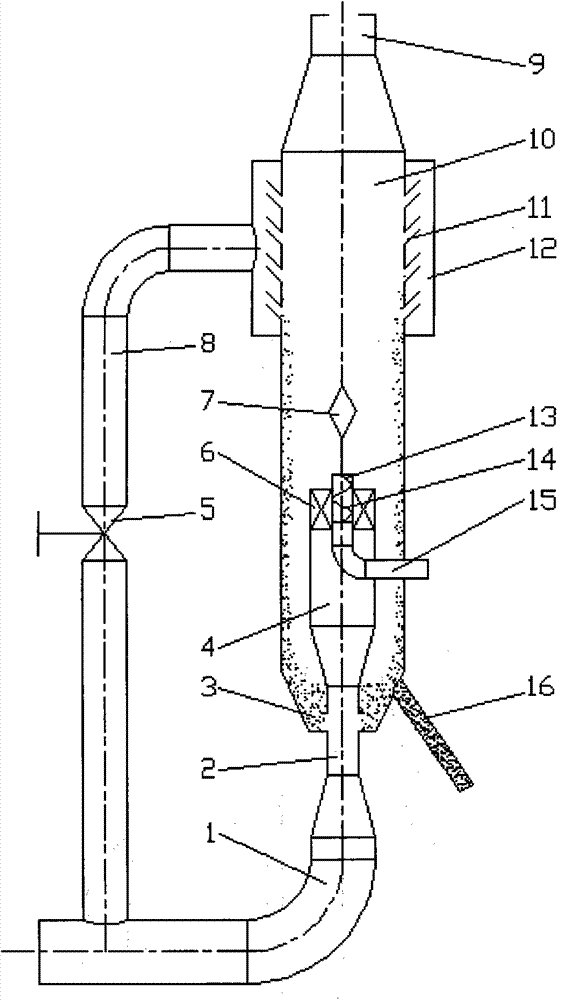

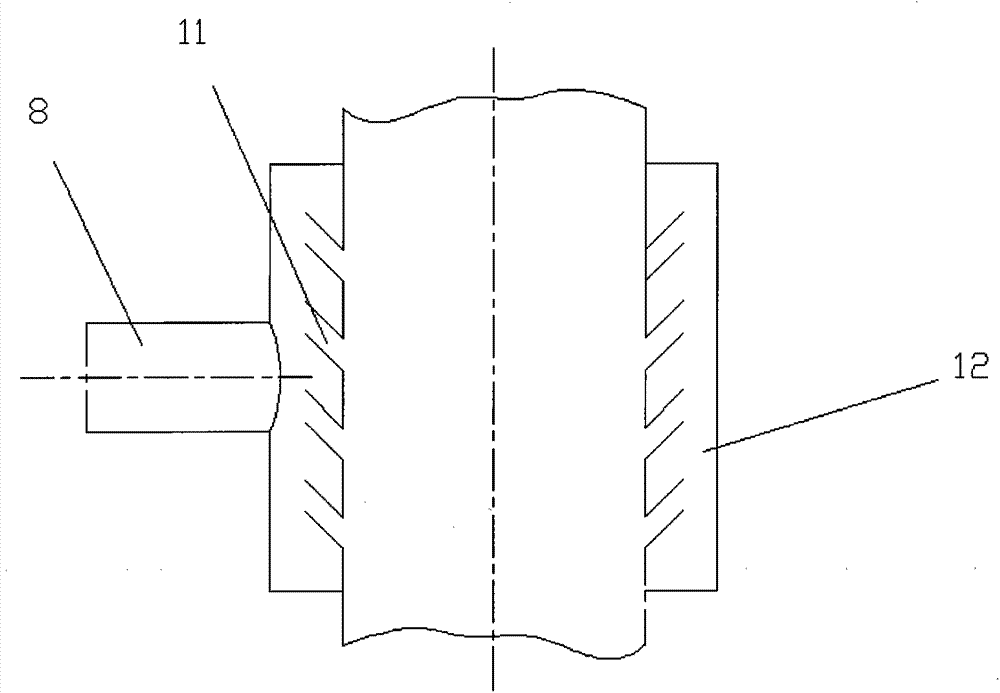

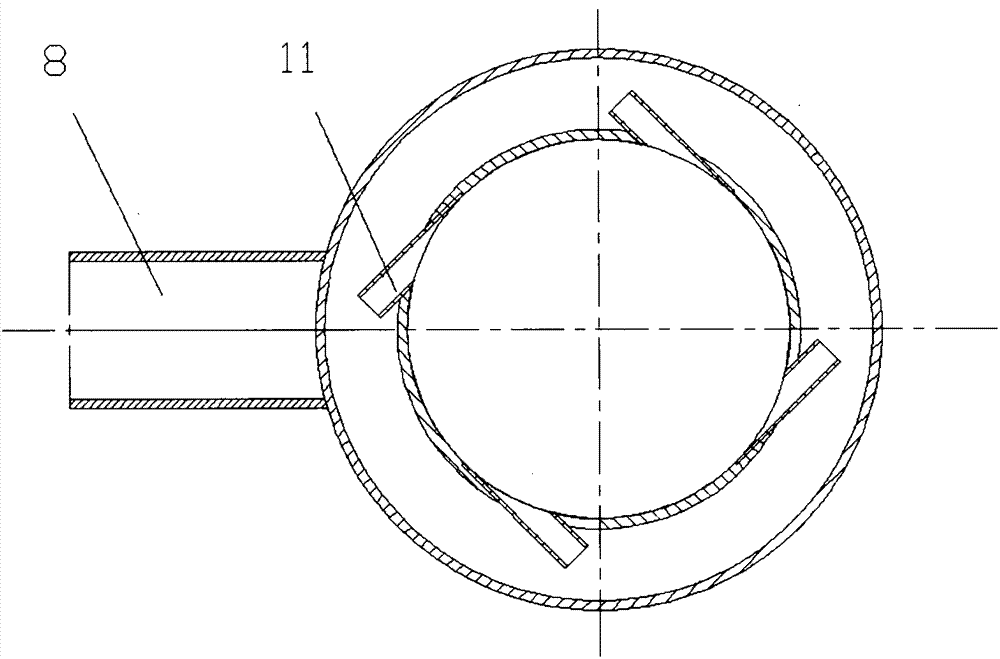

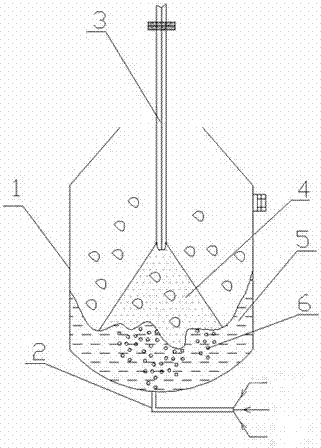

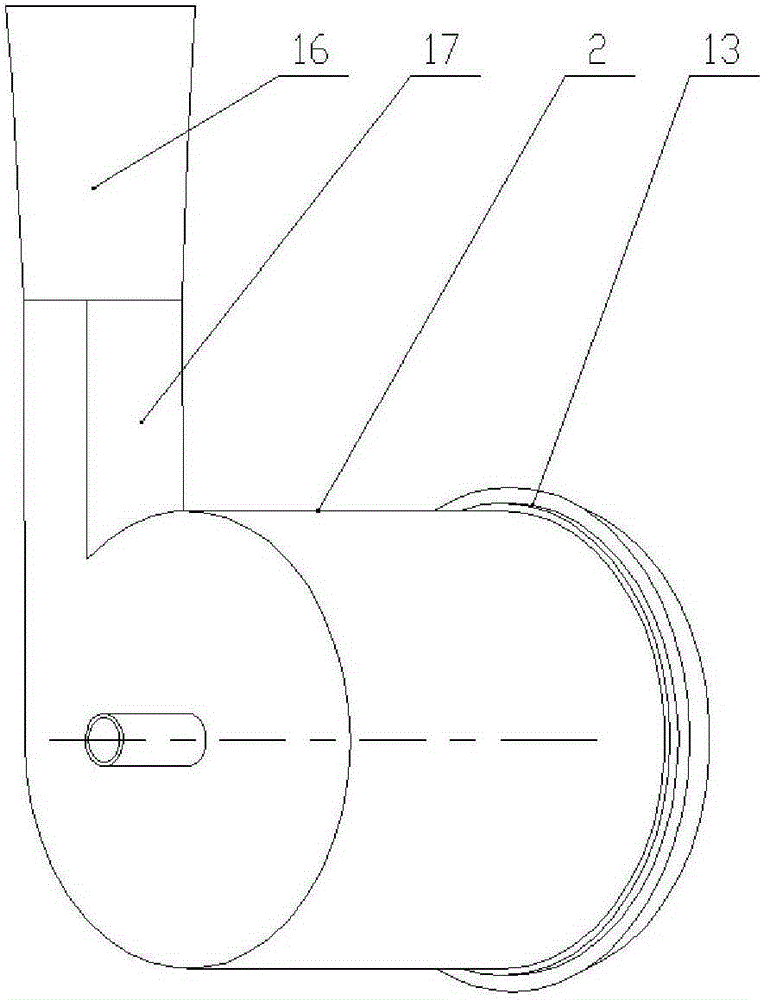

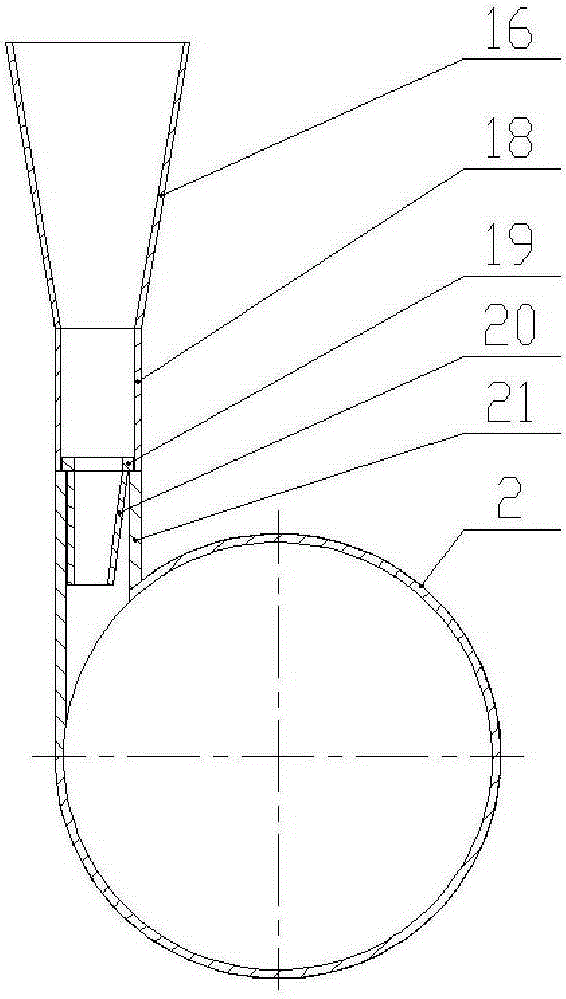

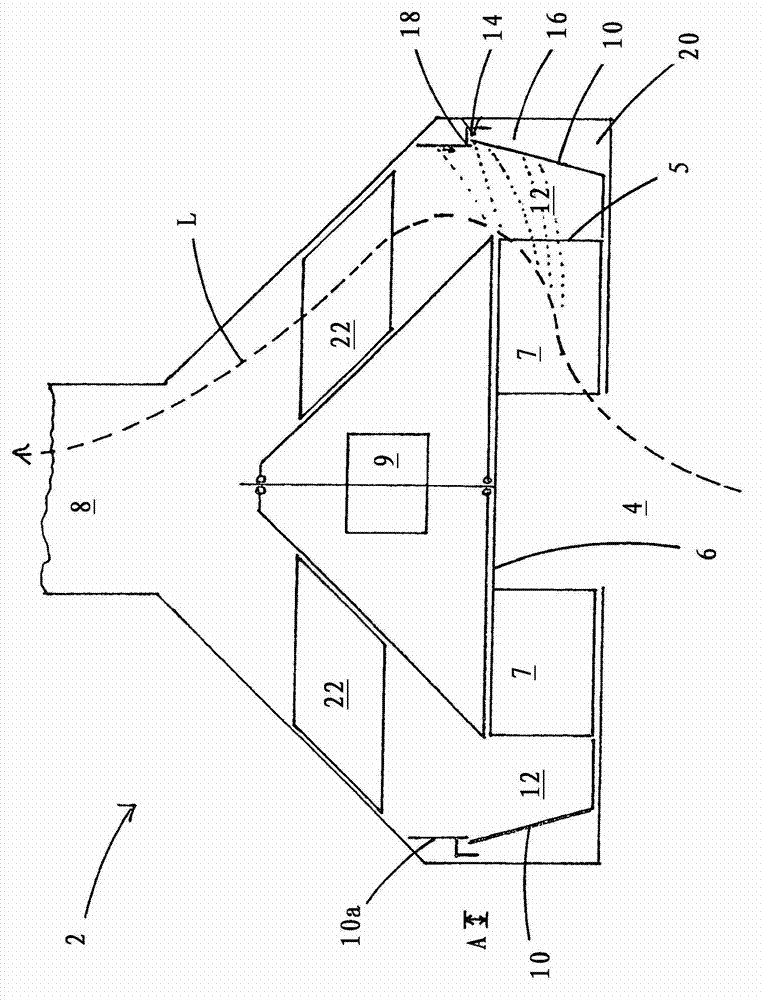

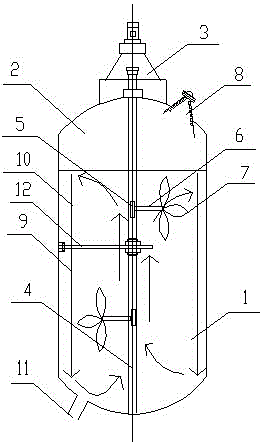

Semi-dry circulating cyclone bed desulfurizing tower

InactiveCN103480268AIncrease shear forceIncrease profitDispersed particle separationCycloneFluidized bed

The invention discloses a semi-dry circulating cyclone bed desulfurizing tower. By providing a tangential exhaust gas inlet structure of the desulfurizing tower, a rotating flow field is established inside the desulfurizing tower so as to sufficient mixing and contact of exhaust gas, so that the desulfurizing reaction process inside the desulfurizing tower is intensified, a desulfurizing agent is sufficiently utilized, the desulfurizing efficiency is improved; and secondary air is arranged to intensify the intensity of a rotating flow, so that separation of gas from solid is achieved inside the desulfurizing tower. By adopting the structure, an external cyclone separator in a conventional circulating fluidized bed desulfurizing process is omitted, so that the semi-dry circulating cyclone bed desulfurizing tower is compact in structure and easy to install and maintain.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

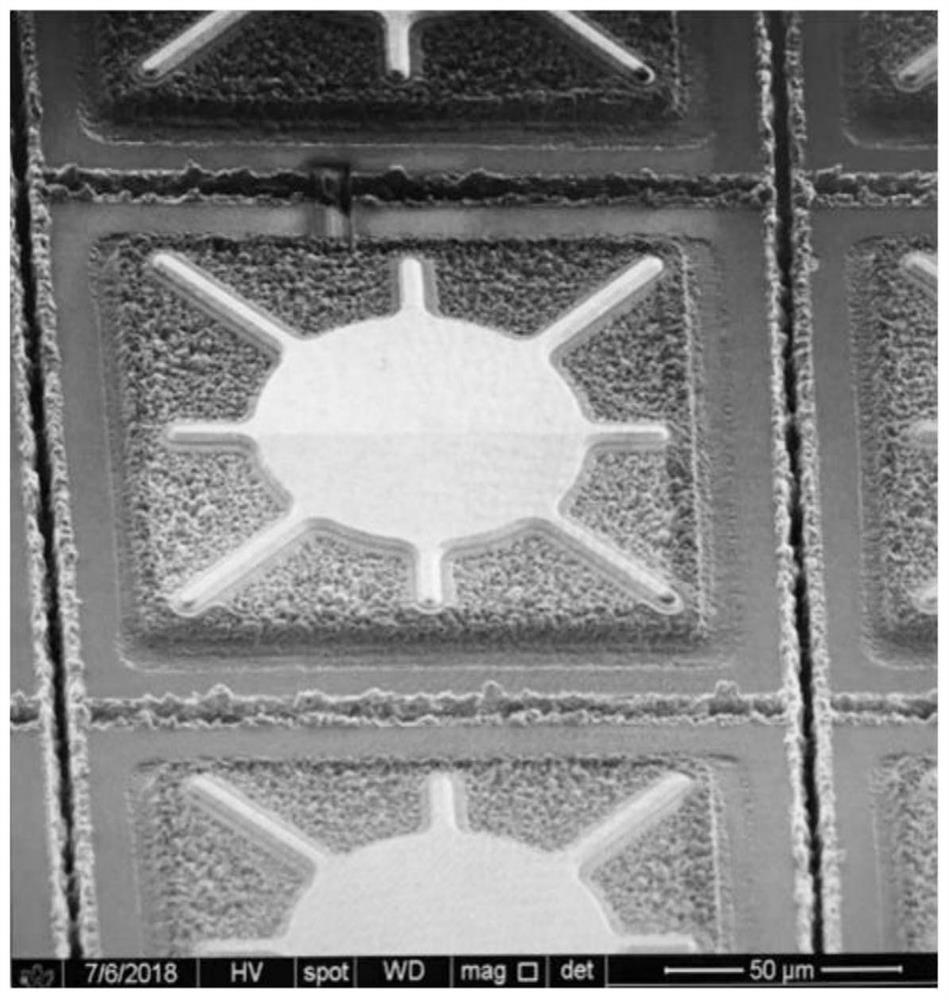

Inorganic metal compound, composition comprising inorganic metal compound, device, apparatuses, and manufacturing method for device

ActiveCN106876599AImprove stabilityReduce fluorescence quenchingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorChelation

The invention provides an inorganic metal compound, a composition comprising the inorganic metal compound, a device, apparatuses, and a manufacturing method for the device. The inorganic metal compound is used for a first current carrier transport layer of a photoelectric device; the inorganic metal compound is a chelate which is obtained from inorganic semiconductor nanocrystals and a chelating agent through a chelating reaction; and first current carriers comprise electrons or holes. By adoption of the inorganic metal compound, material stability can be improved; the chelate with a stable structure is formed by virtue of matching of the chelating agent and active sites of the inorganic semiconductor nanocrystals in the chelating reaction; therefore, by lowering or inactivating the activity of the active sites on the surfaces of the inorganic semiconductor nanocrystals, the capability of accepting external electrons or holes of the active sites is lowered; the electrons or holes of a quantum dot light emitting layer cannot be extracted by the active sites easily; fluorescence quenching of the quantum dots is reduced; the problem of fluorescence quenching of a quantum dot light emitting screen easily caused by the existing inorganic current carrier transport material can be solved; and the light emitting efficiency of the photoelectric device is improved.

Owner:NANJING TECH CORP LTD

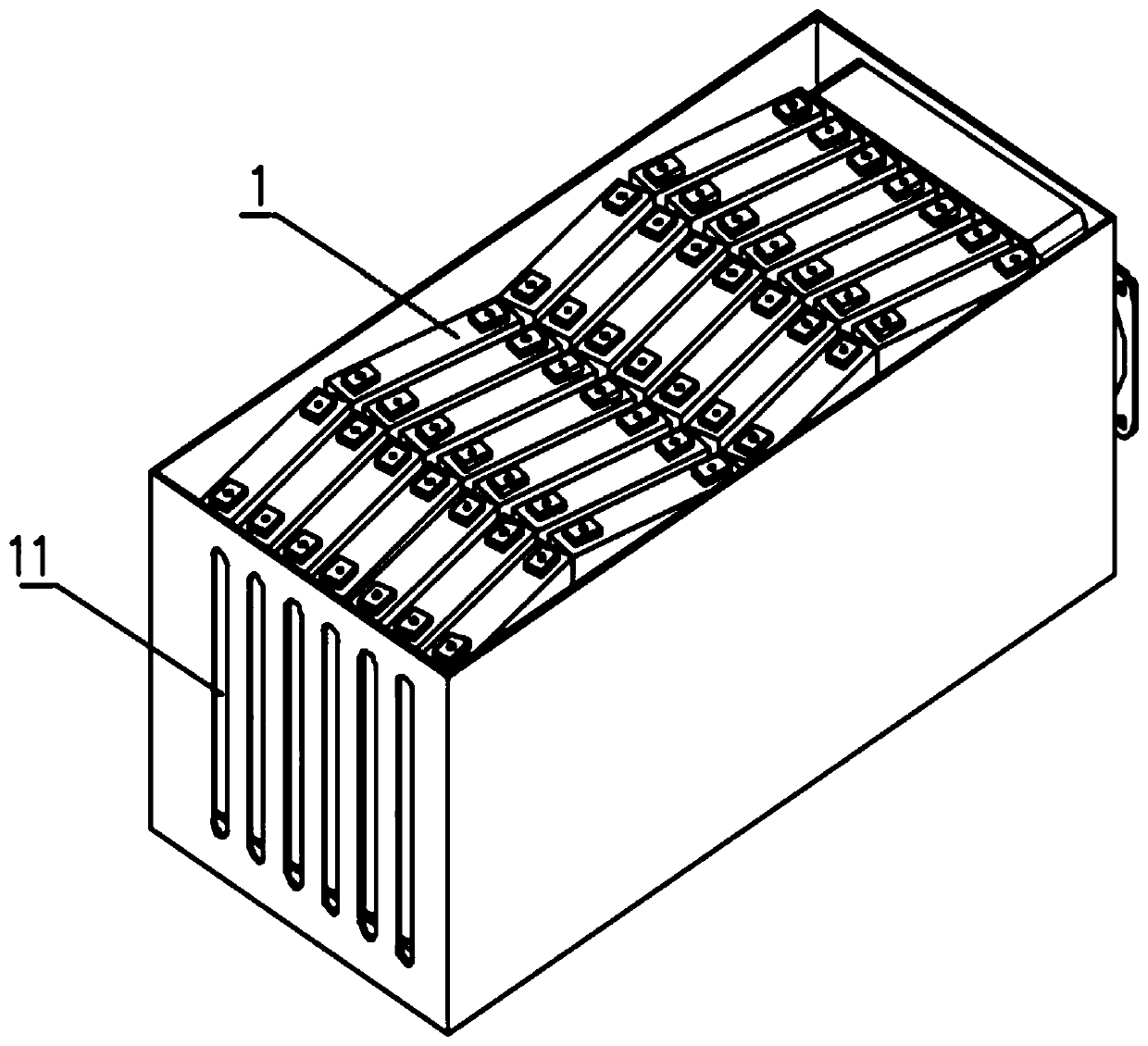

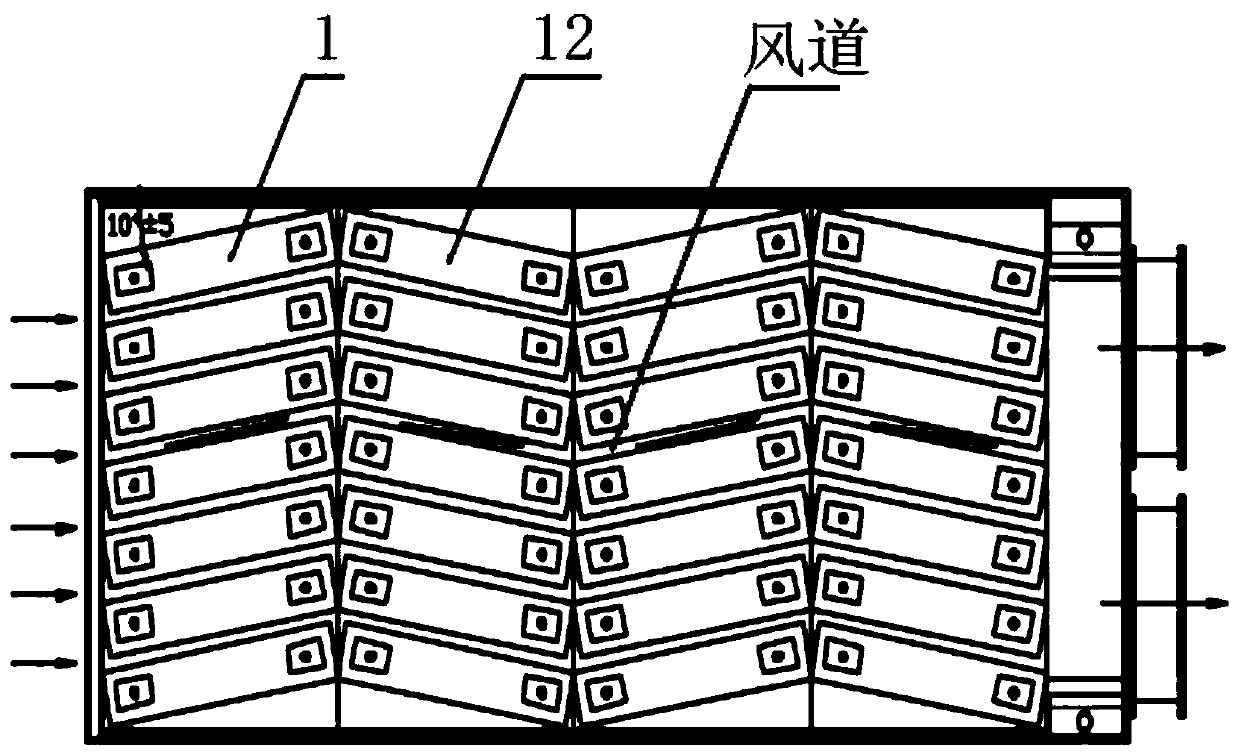

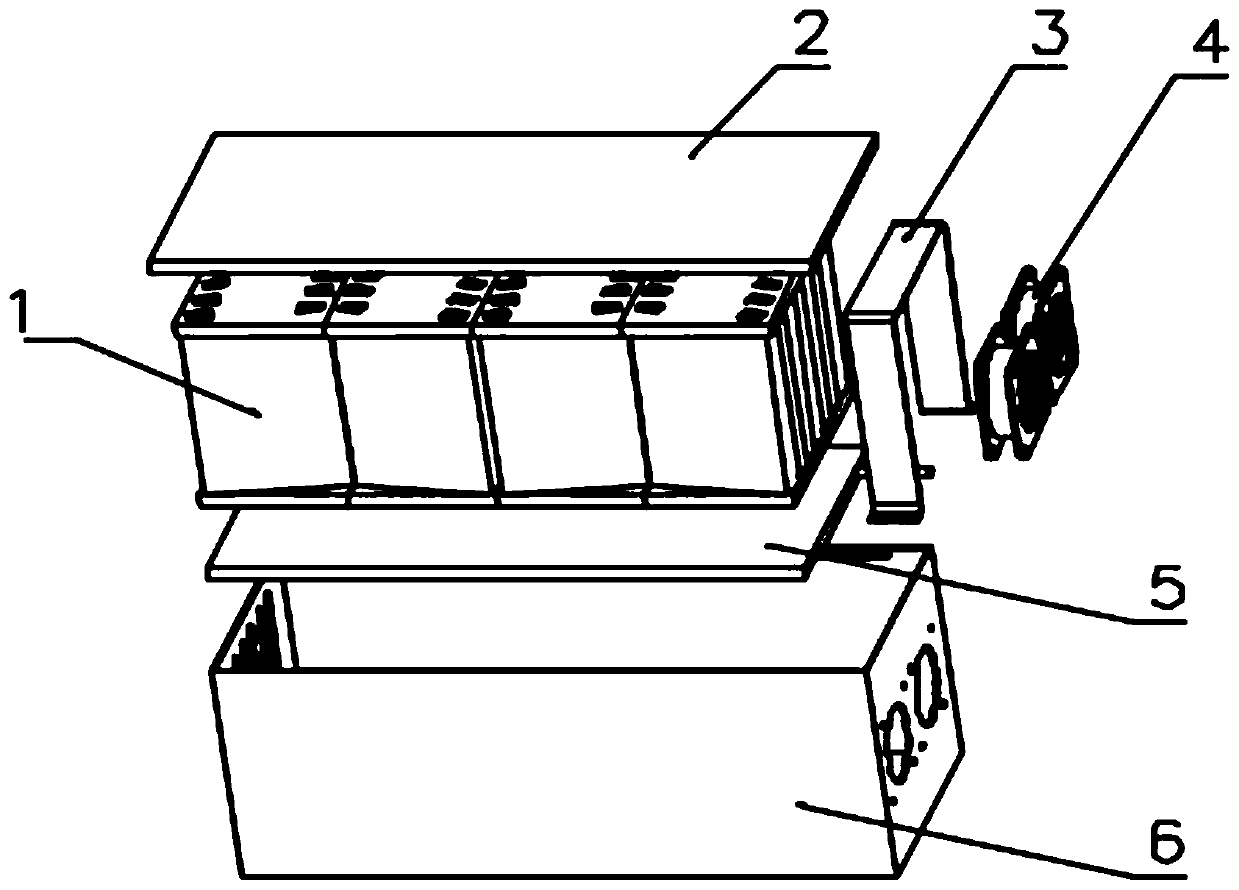

Mixed heat dissipation device for lithium battery pack

ActiveCN110911779AHeat dissipation fastEven heat dissipationSecondary cellsThermodynamicsBattery thermal management

The invention discloses a mixed heat dissipation device for a lithium battery pack, and relates to the technical field of battery thermal management. The device comprises a box body, an air cooling assembly, a phase change energy storage heat conduction plate, a liquid cooling assembly, a plastic box cover and a plastic bottom plate. A plurality of groups of placing holes for placing battery cellsare formed in the plastic bottom plate. Each group of placing holes consists of a plurality of placing holes which are arranged in parallel and obliquely. Two adjacent groups of placing holes are symmetrically arranged to form an air duct for airflow to pass through. An included angle between the placing hole and the front surface of the box body is 10 + / -5 degrees. The bottom of the battery cellis positioned at the upper part of the placing hole. The phase change energy storage heat conduction plate is mounted at the lower part of the placement hole, and the upper and lower ends of the phase change energy storage heat conduction plate are contacted with the battery cell and the liquid-cooling assembly. The mode of combining air cooling, the phase change composite board and liquid cooling is adopted, rapid heat dissipation of the lithium battery can be achieved, the heat dissipation efficiency of the lithium battery is improved, the defect that the heat dissipation efficiency is lowin a pure liquid cooling or pure air cooling mode is overcome, and heat dissipation of the battery pack is more uniform and more efficient.

Owner:西安电子科技大学芜湖研究院

Mixed cotton seed oil refining process

InactiveCN1931982AReduce needLow specific gravityFatty-oils/fats refiningEngineeringChemical property

The mixed cotton seed oil refining process treats leached mixed cotton seed oil directly with the evaporating unit in the leaching plant. Leached mixed cotton seed oil is refined based on its special physical and chemical properties through treatment in vacuum condition and pressurized condition successively. The technological process is simple, low in power consumption, convenient in niger and high product quality.

Owner:白长军

Method for improving gasifying dephosphorization effect through bottom-blowing powder spraying of converter

InactiveCN107419061AShorten the protection cycleShort cycleManufacturing convertersProcess efficiency improvementSlagPowder Spray

The invention provides a method for improving the gasifying dephosphorization effect through bottom-blowing powder spraying of a converter. The method for improving the gasifying dephosphorization effect through bottom-blowing powder spraying of the converter specifically comprises the steps that after steel is discharged out of the converter, the basic state of converter slag is observed and judged, slag-splashing converter protection operation is started, and gasifying dephosphorization powder is sprayed into the converter through a carrier gas nozzle at the bottom of the converter at the same time; the bottom-blown carrier gas pressure and the powder-gas ratio of the converter are controlled, so that the gasifying dephosphorization powder efficiently reacts with hot slag in the converter under the surging and stirring effect achieved when the carrier gas penetrates through the converter slag; and phosphorus in the slag is removed in a gasifying mode, the slag is converted into gasified and dephosphorized high-quality slag after the reaction and is used for the next round of converter smelting. The gasifying dephosphorization rate of the converter is 50%-60%, the penetration ratio of the dephosphorization powder is 80%-90%, and lime consumption is reduced by 2.5-3.5 kg / t. According to the method for improving the gasifying dephosphorization effect through bottom-blowing powder spraying of the converter, the strong surging and stirring function and other functions of the gasifying dephosphorization powder and the carrier gas are brought into full play, the gasifying dephosphorization rate is increased, the slag-splashing converter protection cycle is shortened, and the utilization rate of left converter slag is increased. The bottom-blowing dephosphorization powder is not prone to being carried away, the operating condition and distribution of the powder in the hot slag are improved, and the utilization rate of the powder is increased.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

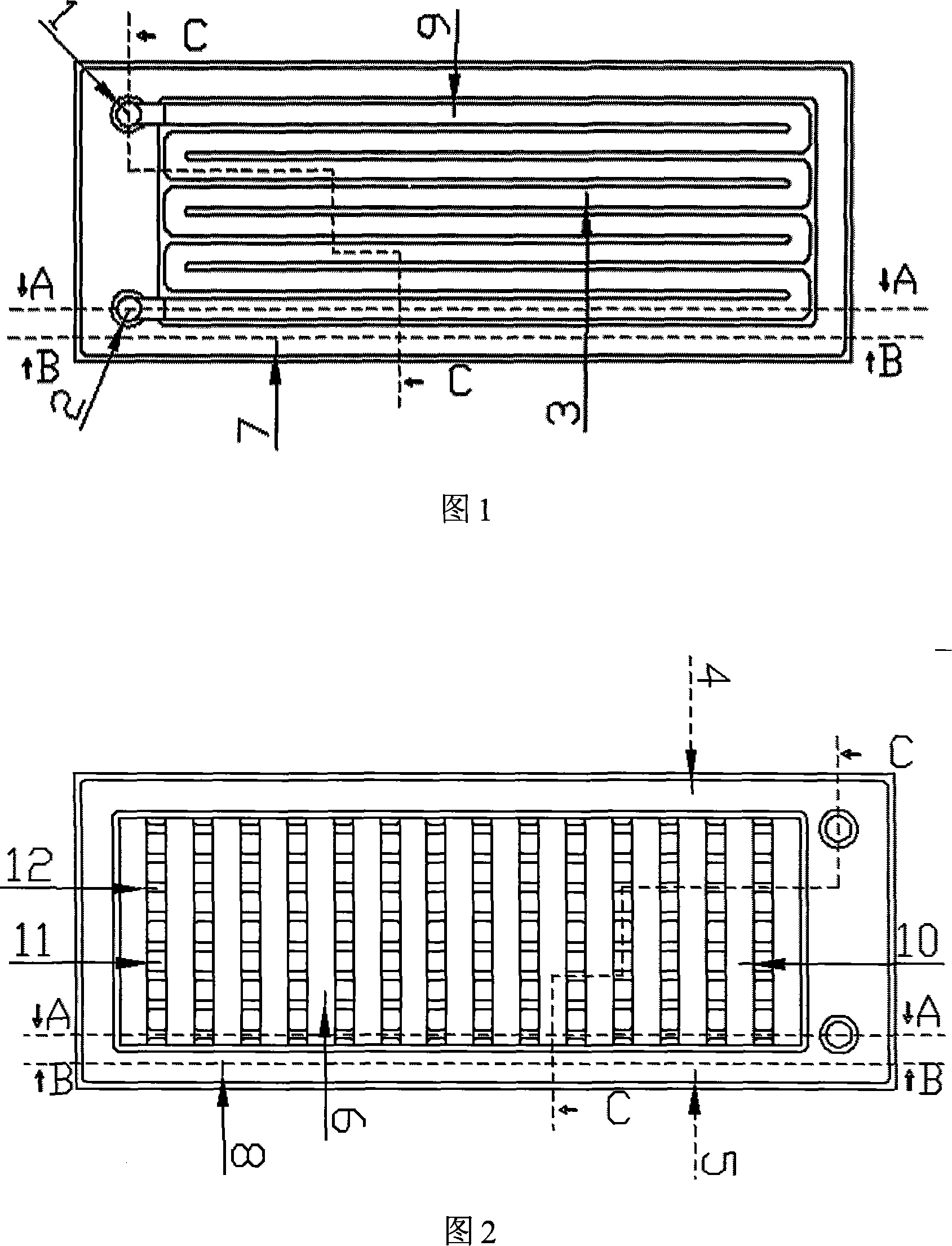

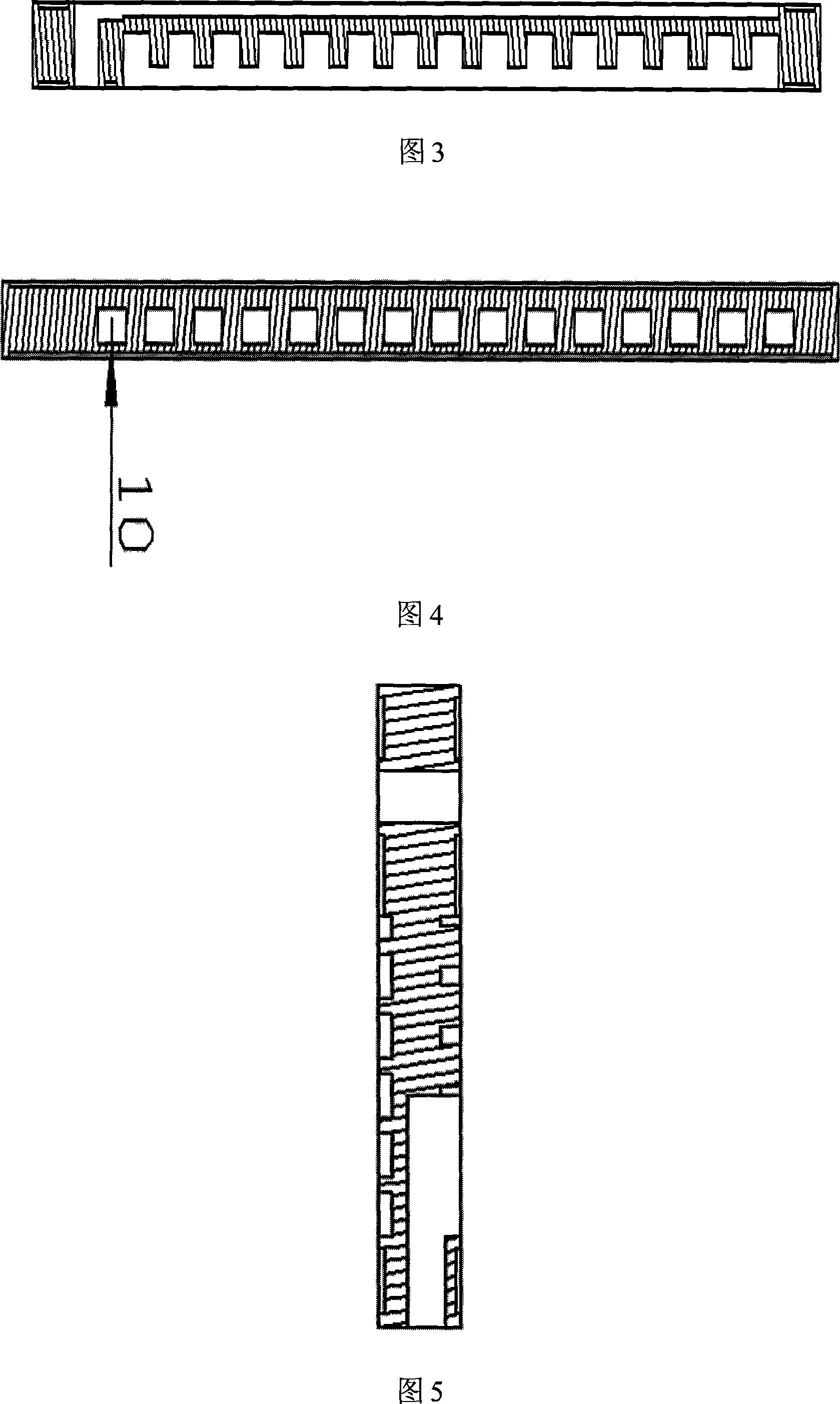

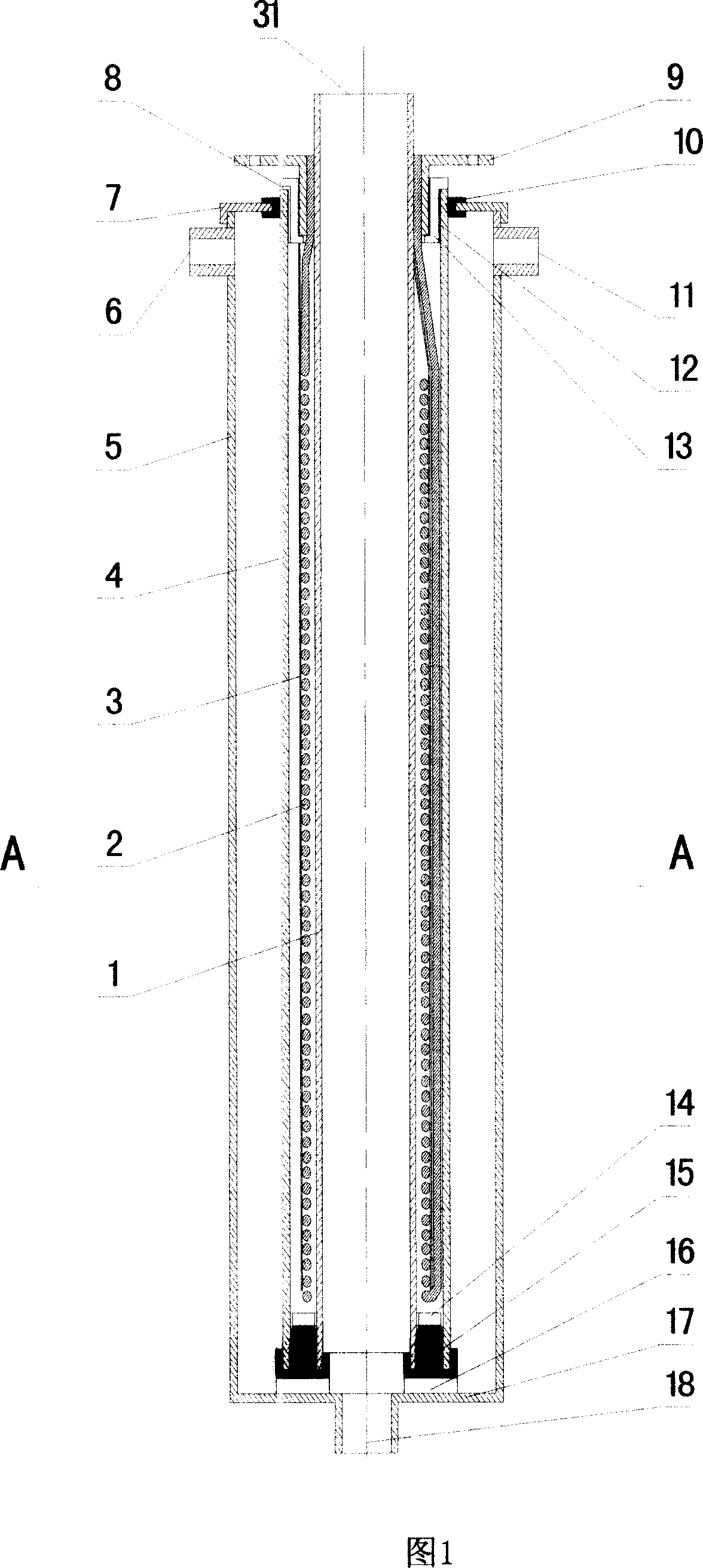

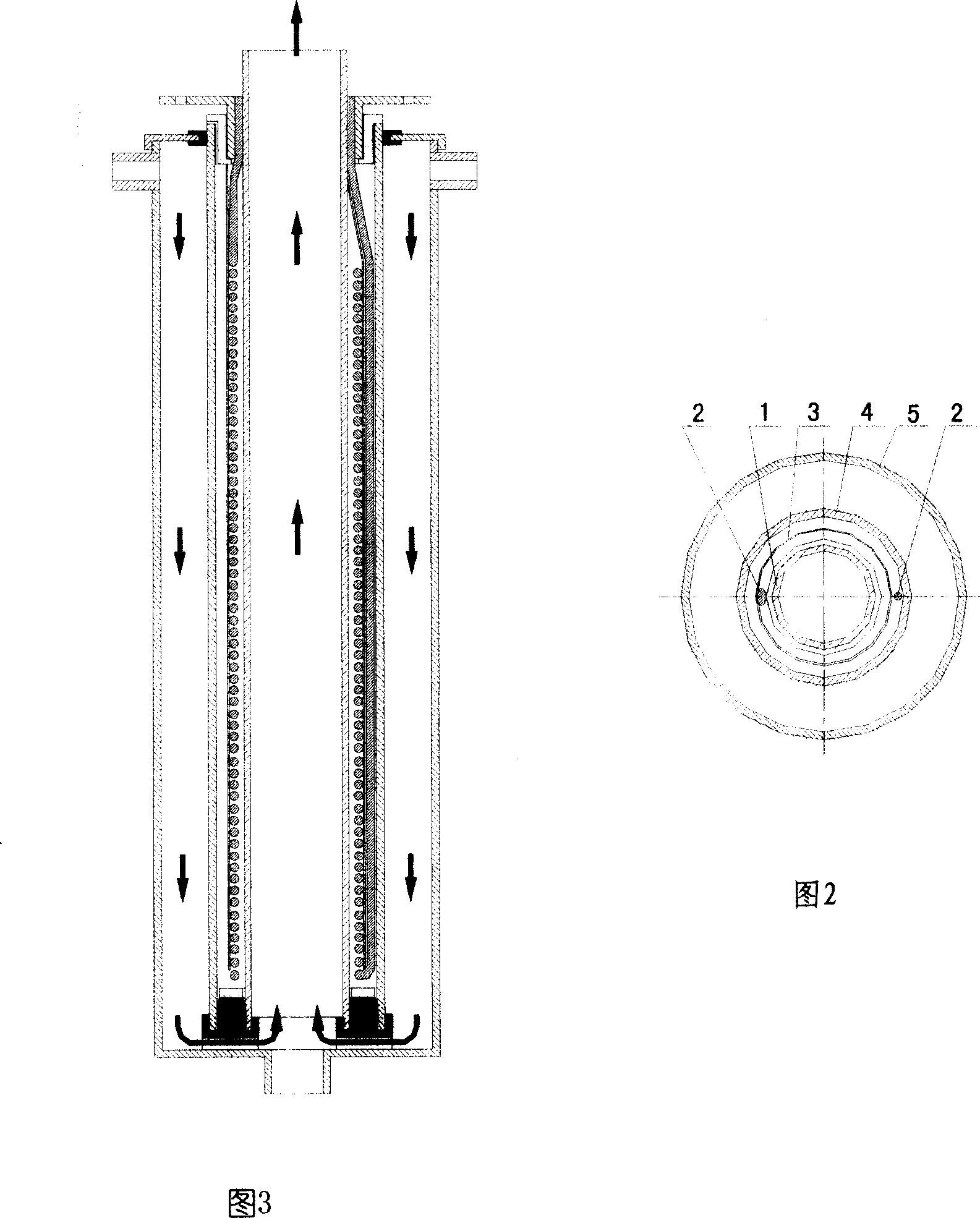

Ion exchange film fuel cell dipole plate and application thereof

InactiveCN101022171AEasy to take awayAdequate responseFuel cells groupingCell electrodesFuel cellsEngineering

This invention provides a dual-pole plate of an ionic exchange film fuel cell and its application, in which, two ends of fuel flow channel set at the fuel reaction region are connected with the inlet and outlet of fuels, one side of the dual-pole plate is opened with a raw of oxidant inlets and the other side has a raw of outlets connected to each other by the oxidant flow channel passing through the dual-pole plate from a side, sealing grooves are set around the fuel reaction region and the oxidant reaction region and applied by spring sealing pieces, th dual-pole plate can be molded at one run carrying an insulation board, a collection board, a plate of the fuel end, membrane electrodes, dual-pole plates, film electrode, an end board, collector, and insulation board of the oxidant end to be sealed layer by layer to be connected and fastened to form a fuel cell stack.

Owner:SUN YAT SEN UNIV

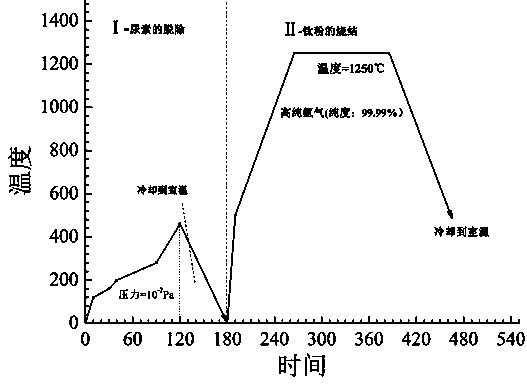

Method for preparing open-cell foam titanium

The invention relates to a method for preparing open-cell foam titanium. The method includes 1) selecting high-purity titanium powder and needle-like urea to be mixed in a grinded body evenly to obtain initial mixture, wherein average grain diameter of the needle-like urea is 225-420 micrometers; 2) forming a cylindrical raw compact by the initial mixture; 3) performing two steps of hot processing on the raw compact, firstly, preheating the raw compact in a carbon tube furnace in a rough vacuum state of 10-1Pa to 10-2Pa, blowing out and cooling when heating temperature reaches above 460 DEG C, secondly, sintering the raw compact for 2 hours under a high-purity argon protective atmosphere at the temperature of 1250 DEG C, and finally, cooling the raw compact in the furnace to the room temperature to obtain the foam titanium. Two heating processes enable collapse not easy to occur during melting of the urea, and the titanium powder is not easy to carry away by melted urea liquid, so that output rate of the foam titanium is greatly increased when content of the urea serving as a pore forming agent is larger than 60% (volume fraction); in addition, two-time heating rate and temperature rate are properly selected to enable the urea to fully volatilize, and the titanium powder is free of contamination.

Owner:CHONGQING UNIV

Fluorine gas purifying filler and preparation method and application thereof

ActiveCN107337180AHigh porosityWidely used valueDispersed particle separationFluorineHydrofluoric acidPorosity

Owner:洛阳森蓝化工材料科技有限公司

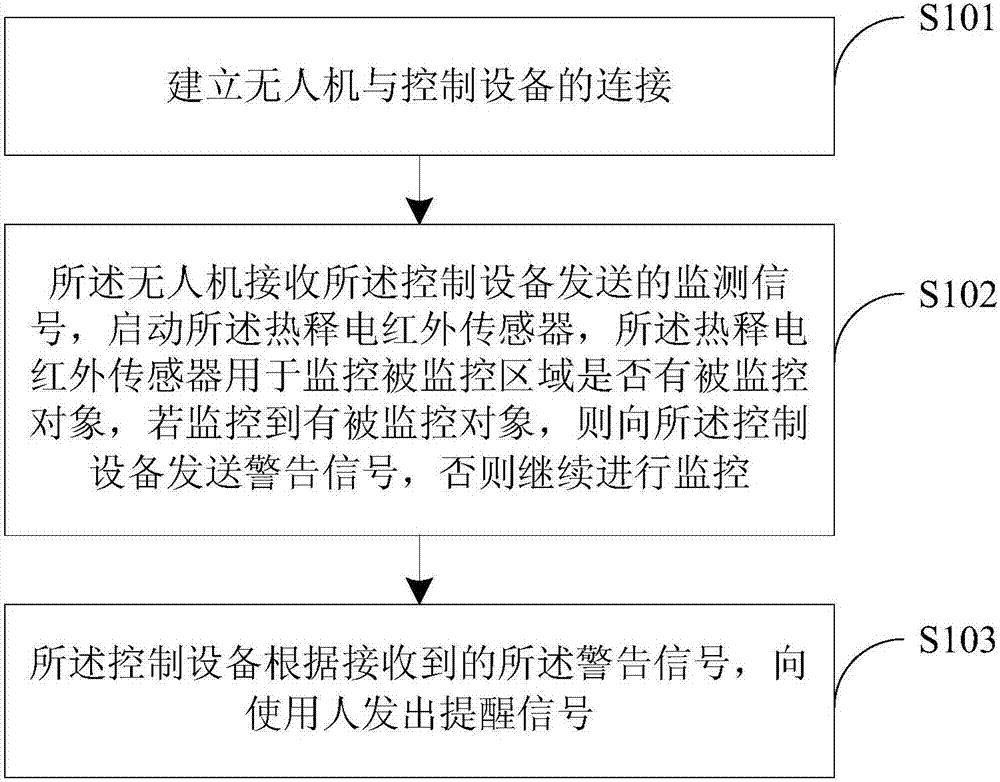

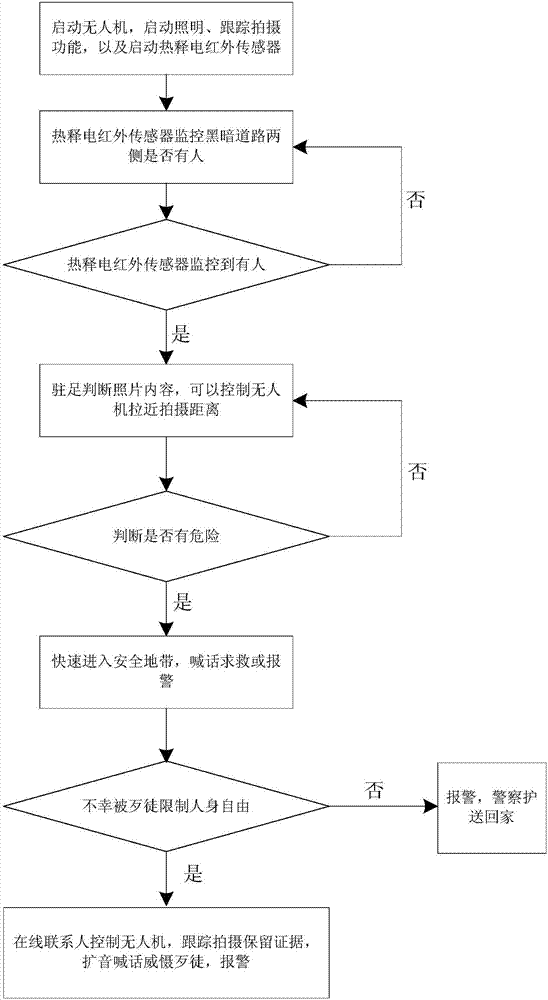

Safety monitoring method and safety monitoring system based on flying drone

InactiveCN107067617ANot easy to take awaySolve the problems of being robbed, being restricted, and unable to ask for helpBurglar alarmUncrewed vehicleSafety monitoring

The invention discloses a safety monitoring method and a safety monitoring system based on a flying drone to solve the problem that in the evenings, when a person is assaulted alone with his or her phone grabbed or safety restricted, he or she could not seek for help. The safety monitoring method based on the flying drone comprises: establishing the connection between the flying drone and a control device; receiving by the flying drone the monitoring signal transmitted from the control device; starting a pyroelectric infrared sensor to monitor whether there exists an object under supervision or not in a monitored area; and if there exists such an object, then, transmitting an alarm signal to the control device; and otherwise, continuing the monitoring; and according to the received alarm signal, sending by the control device a prompting signal to the user.

Owner:BOE TECH GRP CO LTD

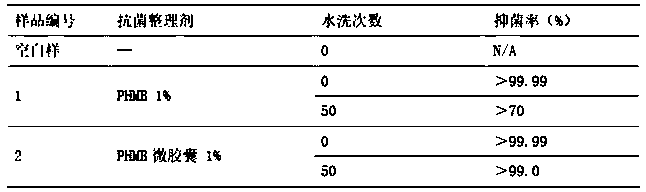

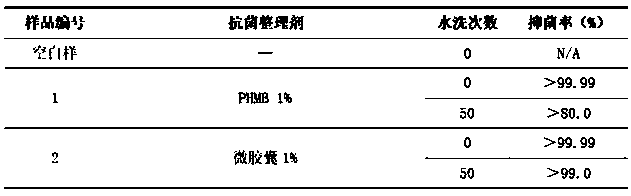

Preparation and application of antibacterial agent slowly released by microcapsule

InactiveCN110093785AImprove washing resistanceMaintain long-term antibacterial effectBiochemical treatment with enzymes/microorganismsMicroballoon preparationActive matterAntibacterial agent

The invention discloses preparation and application of an antibacterial agent slowly released by a microcapsule. The antibacterial agent is prepared from, by weight, 1-2,000 parts of the antibacterialagent, 1-1,000 parts of an emulgator, 1-3,000 parts of an enzyme and 1-10,000 parts of water. The preparation method comprises the following steps that S1, antibacterial agent active matter is addedinto water at the constant temperature, the temperature is kept at 20-30 DEG C, uniform stirring is conducted, the revolving speed is controlled at 80-200 revolutions / minute, and the mixture is sufficiently mixed and dissolved; S2, the long-chain organosilicone emulgator is added, the mixture is uniformly stirred, and the revolving speed is controlled to determine that the layering phenomenon doesnot occur; S3, the enzyme is added into the prepared solution, and the revolving speed is controlled to avoid demulsification; S4, essence is added, uniform stirring is conducted, the revolving speedis controlled at 80-100 revolutions / minute, and sufficient stirring is conducted for 30 minutes. The antibacterial agent solves the problems in the prior art that PHMP of the medium and high molecular weight remains in a fabric and has a continuous antibacterial effect, sterilization components and electrostatic adsorption of the fabric have poor effects, washing with water cannot be conducted frequently, and an existing antibacterial agent does not have an ideal effect when applied to fabrics.

Owner:南京天诗蓝盾生物科技有限公司

Papermaking process of heavy basic weight paper for daily use

InactiveCN105507056AAdhesion is smoothNot easy to take awayDryer sectionChemical/chemomechanical pulpFiberSlag

The invention relates to the field of papermaking, and in particular relates to a papermaking process of heavy basic weight paper for daily use. The papermaking process comprises the following steps: pulp selection, pulp dispersing, slag removal, pulp grinding, pulp mixing, diluting, screening, shaping on a screen, dehydrating and squeezing, drying, wrinkling and rolling primarily. The papermaking process has the beneficial effects that by virtue of a high-viscosity water-resistance coating, namley polyamide-epichlorohydrin resin, paper can be adhered to a dryer smoothly when contacting the dryer, and the problems of paper break and the hidden hazard of halt, caused by the lack of paper web, can be avoided; by virtue of a low-degree wrinkling scraper of 5-12 degrees, the uniformity and the completeness of the coating can be kept, the probability of paper break, caused during a wrinkling process, is lowered, and the ratio of long fibers is increased; and with free beating and with addition of chemi-mechanical pulping, the breathability of paper can be enhanced.

Owner:SHANDONG SUN HOUSEHOLD PAPER LTD

Contamination resistant acrylic ester emulsion

Owner:江苏日出化工有限公司

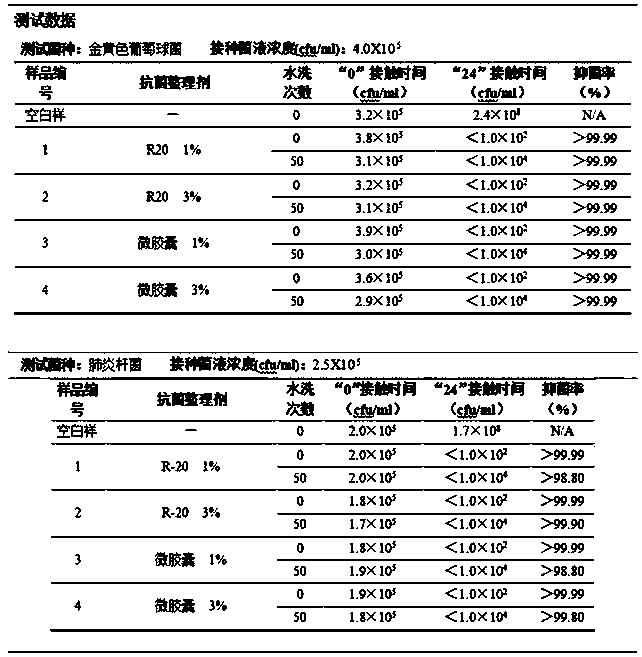

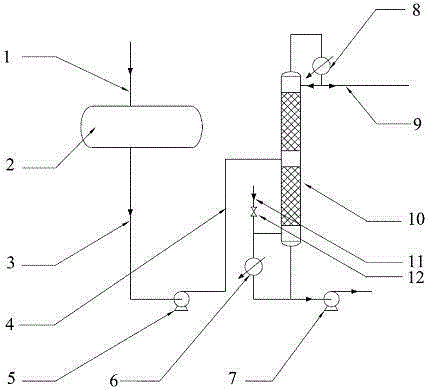

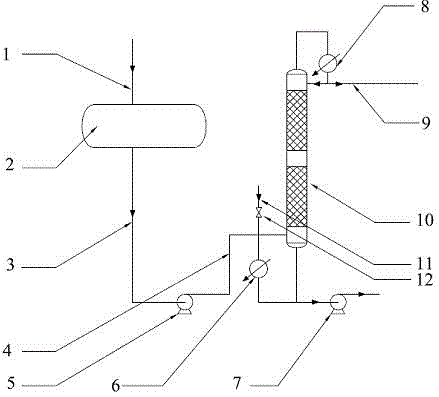

Centrifugal pump of front-mounted cyclone type gas-liquid separator

ActiveCN105201870AEasy to separateNot easy to take awayLiquid degasificationPump componentsCycloneVapor–liquid separator

The invention provides a centrifugal pump of a front-mounted cyclone type gas-liquid separator. The centrifugal pump comprises a cyclone cylinder, a feeding pipe, an exhaust pipe and a centrifugal pump body, wherein the cyclone cylinder comprises a cylinder wall enclosed into a cylindrical shape and an end cover with a closed end; the other end of the cyclone cylinder is open; the feeding pipe is tangentially connected with the cylinder wall, close to the end cover, of the cyclone cylinder; the exhaust pipe is arranged on the end cover of the cyclone cylinder; the centrifugal pump body comprises a volute with an axial inlet and a tangential outlet, an impeller arranged in the volute and a driving shaft of the impeller; the axial inlet is connected with the open end of the cyclone cylinder. According to the centrifugal pump provided by the invention, gas-liquid cyclone separation is combined with the centrifugal pump, so that two functions of gas-liquid separation and fluid delivery are integrally realized; gas is separated out before entering into an impeller area, so the blockage of a pump inlet is not easily caused, the gas is not easily taken away by the impeller, and the degassing capability is higher; a low-pressure area is formed at the center of the cyclone cylinder, so that the separation of the gas dissolved in liquid is facilitated, and further the gas-liquid separating effect is improved.

Owner:ZHEJIANG UNIV

Production method of dichlorosilane for preparing silane

The invention relates to a production method of dichlorosilane for preparing silane; the method comprises the steps of in a tower kettle of a reaction rectification tower, carrying out disproportionation on a raw material trichlorosilane, carrying out rectification separation and extracting the prepared dichlorosilane through the tower top; the production method is characterized in that reaction and separation are coupled, and catalytic disproportionation is carried out to obtain the dichlorosilane product with the content of more than or equal to 90%, wherein a catalyst is an ionic liquid catalyst. By using the method, dichlorosilane can be prepared simply and efficiently, whole-process materials are in closed cyclic utilization, and the method has no pollution emission and is environmentally friendly.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

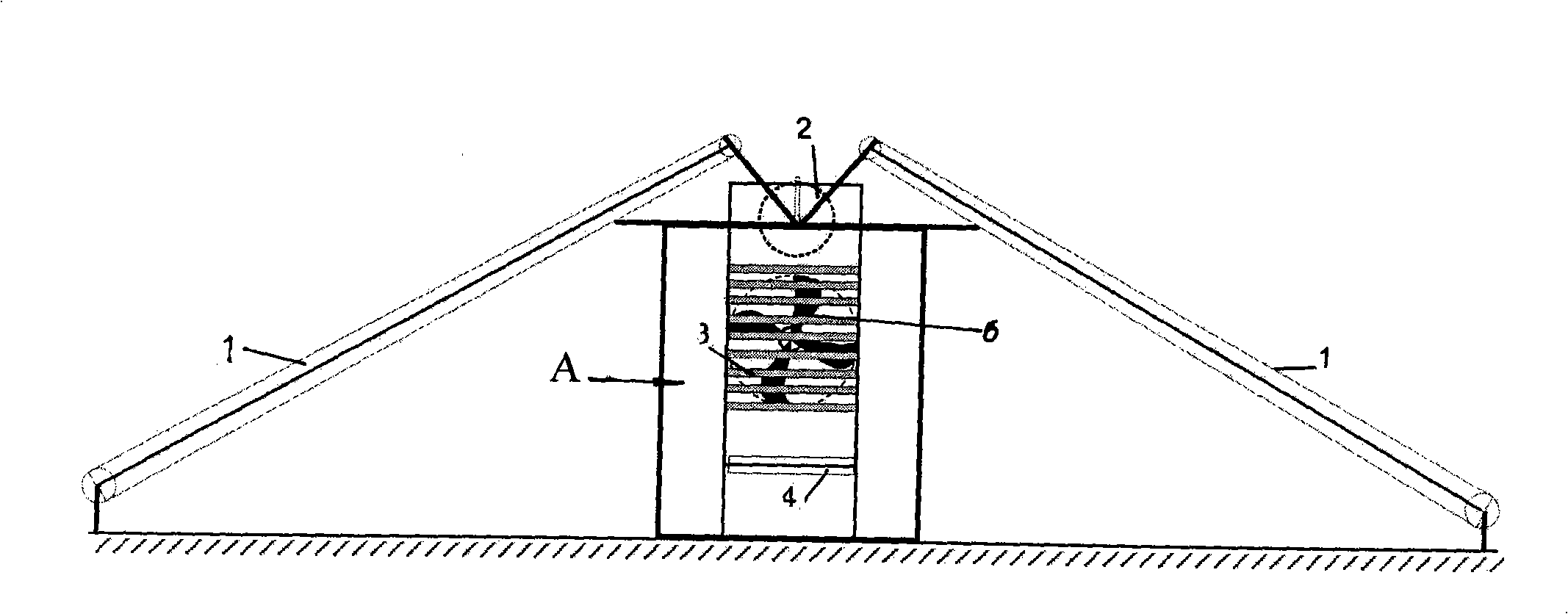

High-efficiency method for removing leaves from sweet sorghum straws and device thereof

ActiveCN101524684AImplemented separatelyWill not affect the overall situation of productionGas current separationDistillationEngineering

The invention provides a high-efficiency method for removing leaves from sweet sorghum straws and a device thereof. The high-efficiency method for removing leaves from sweet sorghum straws comprises the following four procedures: a conveying procedure, a sawing up procedure, a procedure of separating stem and leaf mixture, and a procedure of conveying stems. New process methods 'sawing up' and 'blowing method' are used in the method. Compared with device used in the traditional 'straight leaf removal method' of the sweet sorghum straws, the device has the following advantages: 1. simple operation, good effect, high efficiency, being free from influence of thickness of the straws or aerial roots of the straws, being capable of processing bunches of sweet sorghum straws in a short time; 2. simple structure, low cost, convenient and simple operation, easy maintenance, and being fit for popularized generalization; and 3. demultiplied energy consumption, and multiplied production efficiency as stems of the processed sweet sorghum straws are good for following conveying, heating, fermentation and the like links in the process of making fuel ethanol from the sweet sorghum straws. The device also solves the problem that the leaves contain no sugar but water, and a large quantity of leaves are mixed to reduce sugar in fermentation materials, which increases following distillation cost. The device also solves the problem that the leaves contain miscellaneous fungi which increases sterilization difficulty and causes fermentation failure. Therefore, the device is crucial to enhance finished product quality and production efficiency of producing the fuel ethanol from the sweet sorghum straws.

Owner:张永北 +1

Method for inhibiting powder bed electron beam 3D printing powder from splashing

ActiveCN111570792AImprove conductivityImprove thermal conductivityAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgySurface roughness

The invention relates to a method for inhibiting powder bed electron beam 3D printing powder from splashing. The method comprises the following steps that first-round electron beam scanning preheatingis carried out on powder in a forming section of a powder bed; second-round electron beam scanning preheating is conducted on powder in a preset area of the powder bed, wherein the preheating currentof each time of second-round electron beam scanning preheating ranges from 5 mA to 40 mA, and the scanning speed ranges from 2 m / s to 20 m / s; and the powder on the preset area after second-round electron beam scanning preheating is melted, and third-round of electron beam scanning preheating is carried out on the powder on the forming section of the powder bed. By the adoption of the method, splashing of the powder is basically avoided in the 3D printing process, and a component obtained after 3D printing is high in density and small in surface roughness.

Owner:广州赛隆增材制造有限责任公司

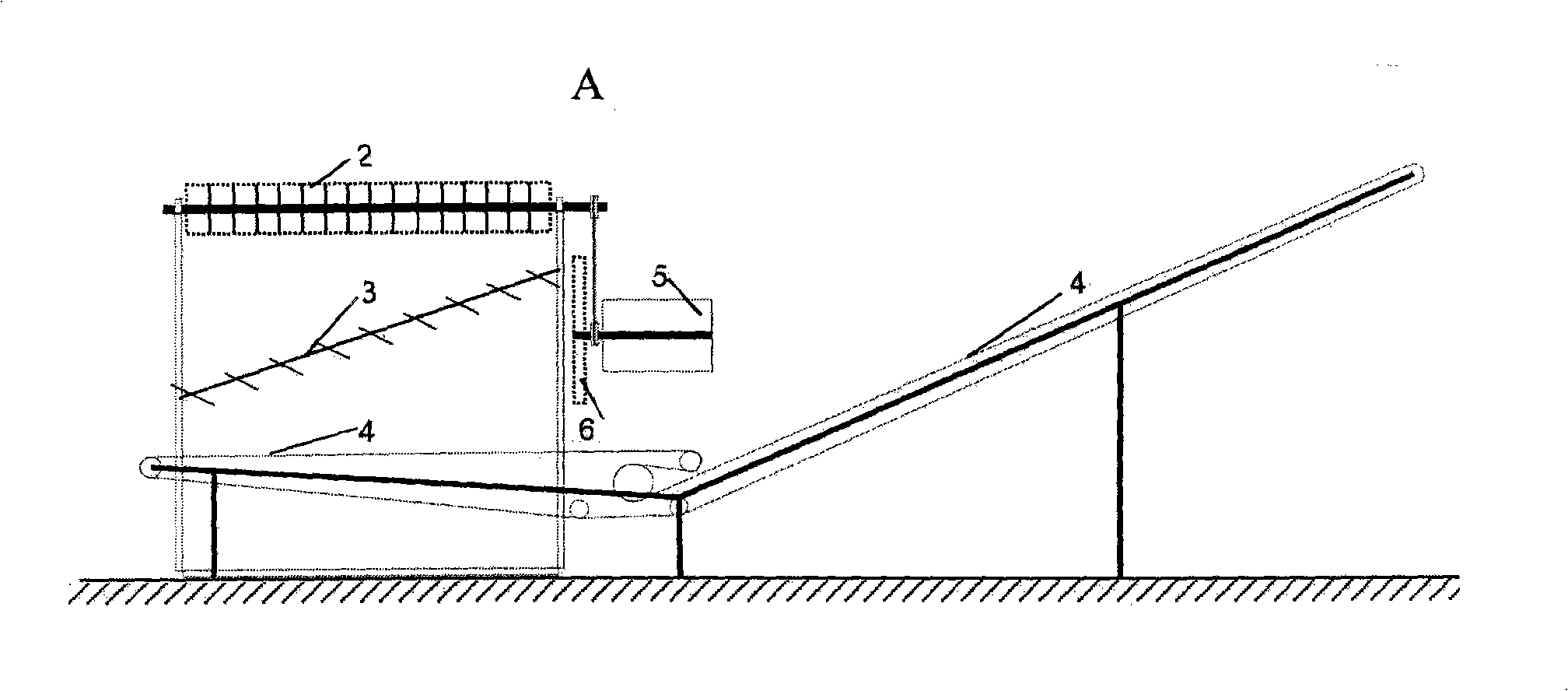

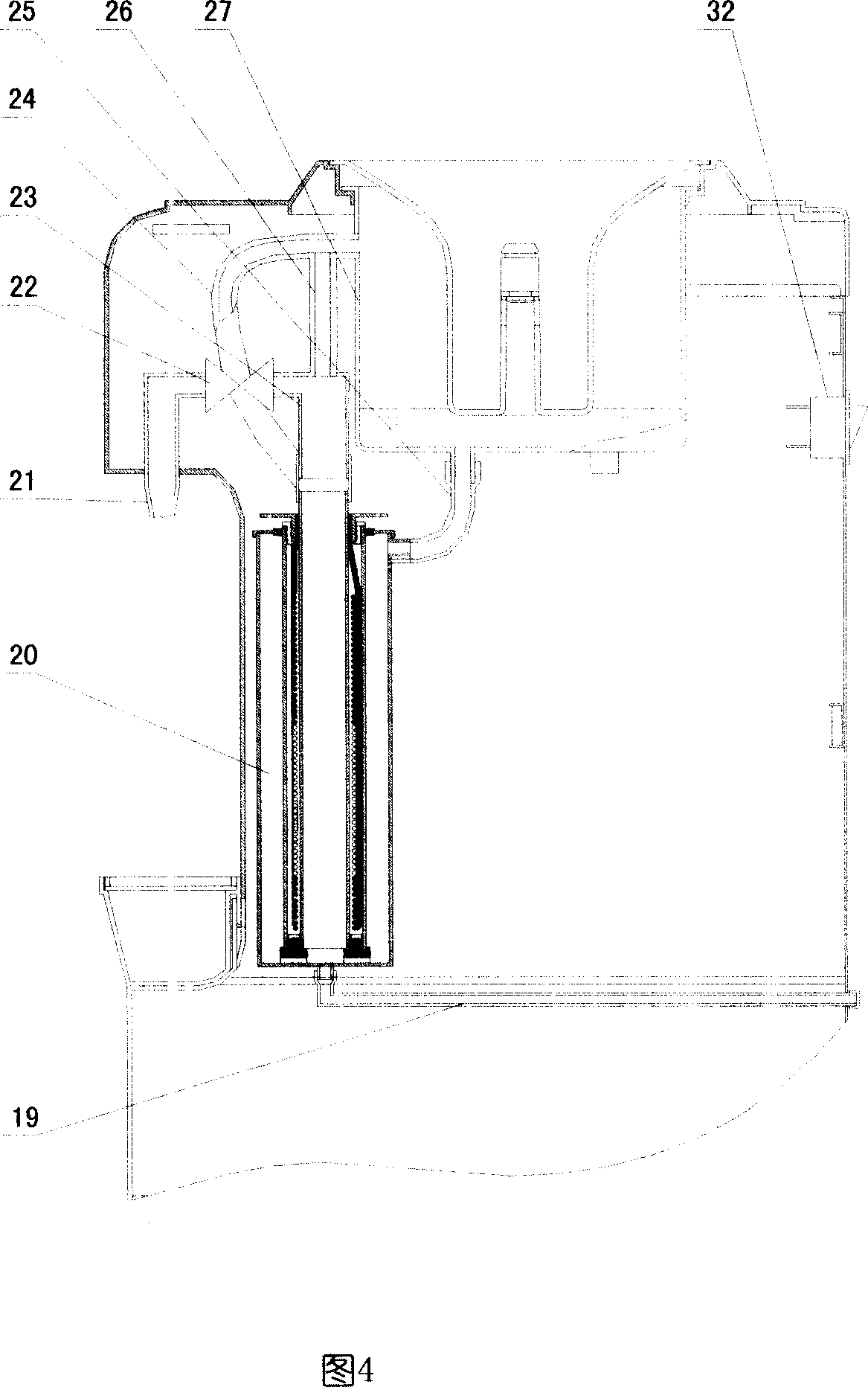

AA-MBBR sewage treatment system and sewage treatment method

ActiveCN107055784ARelieve swellingEasy to handleTreatment with aerobic and anaerobic processesSustainable biological treatmentWater treatment systemSludge

The invention discloses an AA-MBBR sewage treatment system. The AA-MBBR sewage treatment system comprises a water inlet pond, a water inlet pump, an anoxic MBBR pond, a main reaction pond, a sludge refluxing pump and a secondary sedimentation tank. The water inlet pond is connected to the anoxic MBBR pond via a water inlet tube through the water inlet pump; the main reaction pond is divided into an aerobic MBBR pond positioned in the outer ring and an anaerobic pond positioned in the inner ring; a water outlet tube of the anoxic MBBR pond is connected into the anaerobic pond in the inner ring of the main reaction pond through a pipeline; an aerator tube is arranged at the bottom in the aerobic MBBR pond and is provided with an aerator; a refluxing hole is formed in the bottom of the anaerobic pond; a water inlet hole which communicates to the inside of the aerobic MBBR pond is formed in a position, which is close to the bottom, of the anaerobic pond; a water outlet is formed in the upper part of the outer side of the main reaction pond and is connected into the secondary sedimentation tank via a pipeline; the bottom of the secondary sedimentation tank is connected with a refluxing tube; and the secondary sedimentation tank is connected to the refluxing hole of the anaerobic pond via the refluxing tube through the sludge refluxing pump. The AA-MBBR sewage treatment system is high in nitrogen and phosphorus removal ability and good in effect.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

Heat quantity reclaiming type electric heater

An electric heater of heat recovery comprises a nonmetallic water pump, a heating element arranged outside the nonmetallic water pump, a water jacket arranged outside the heating element, the inner drum of the water jacket is sealed and connected with the water pump at lower end, the lower end of the outer drum of the water jacket is equipped with an end plate, a water inlet of a heater is arranged on the upper part of the water jacket, and the water outlet of the heater is the upper end open of the nonmetallic water pump. The electric heater is mainly matched with a water-drinking machine of no hot penetration for heating flowing drinking water, the invention is characterized by high water temperature, low temperature of the outer surface of the heater (about 50 DEG C), non fire threat, energy conservation, scale uneasily producing. The electric heater can be matched with other similar products for heating flowing sanitation liquor.

Owner:黄樟焱

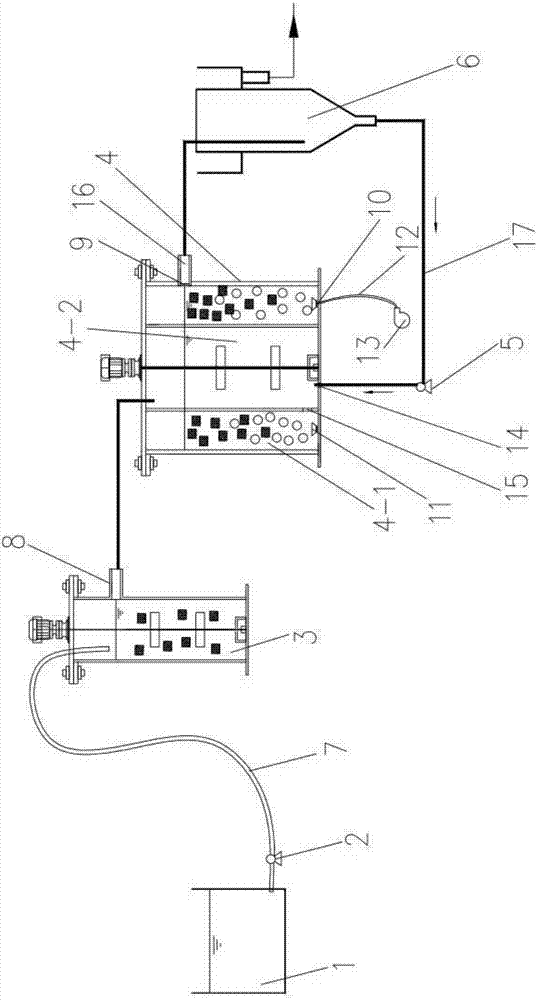

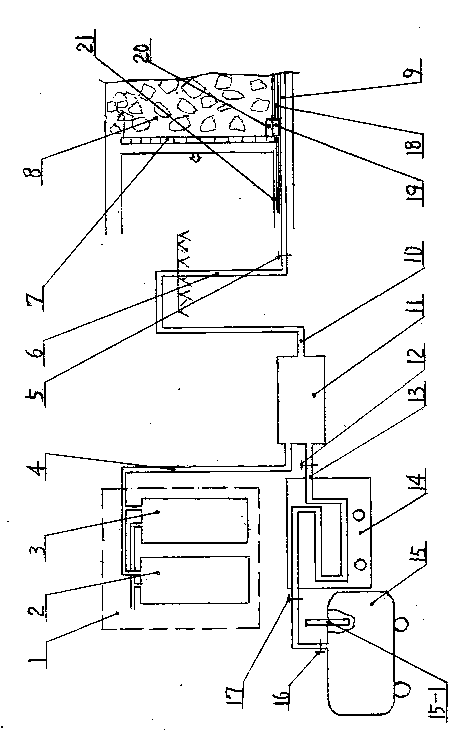

Coupled inert gas fire prevention and extinguishing technology in coal mine

InactiveCN108979705AImprove the effectSimple equipmentMining devicesDust removalSpecific gravityCarbon dioxide sensor

The invention belongs to the field of safety equipment for coal mine production and particularly relates to a coupled inert gas fire prevention and extinguishing technology in a coal mine. The technology includes the following steps of: (1) calculating coupled inert gas injection flow by using the formula Qn=60KeQ0 (C1-C2) / (Cn+C2-1); (2) burying pipes in a goaf; (3) connecting a low temperature stainless steel hose of a liquid carbon dioxide tanker (15) to a carbon dioxide vaporizer (14); (4) delivering nitrogen to an inert gas coupler (11); (5) coupling gaseous carbon dioxide and nitrogen inthe inert gas coupler (11) to be then continuously transported to a working face the goaf (8) to prevent and extinguish fire; (6) detecting gas in the goaf (8). The coupled inert gas fire preventionand extinguishing technology in the coal mine has the advantages that due to the fact that when the specific gravity of the coupled inert gas is increased to a greater proportion than that of the air,flow in the goaf is slow and not easy to be carried away by air leakage in the goaf; injecting appropriate amount under the control of a carbon dioxide sensor does not endanger the health of workers;when the oxygen concentration in the goaf is reduced below 7%, spontaneous combustion does not occur.

Owner:阜新新纪煤矿科技所 +1

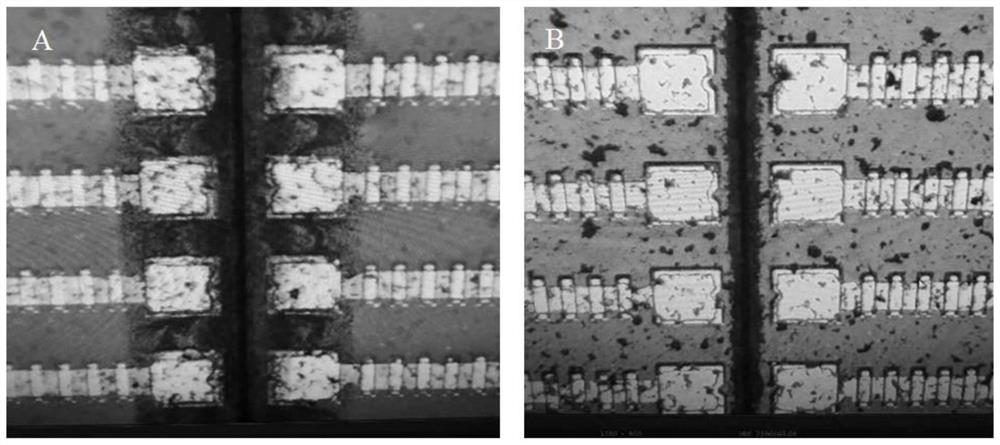

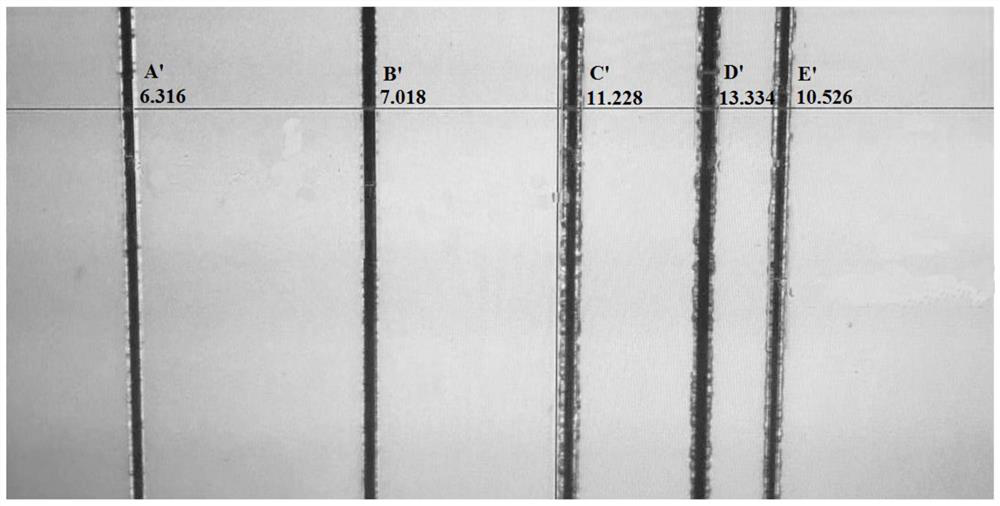

Protective liquid film composition for laser-induced supercritical liquid ablation processing, and laser cutting process

ActiveCN112831261AEasy to carryEasy to take awaySemiconductor/solid-state device manufacturingPolyether coatingsLaser cuttingDefoaming Agents

The invention discloses a protective liquid film composition for laser-induced supercritical liquid ablation processing, and a laser cutting process, belonging to the technical field of chemical reagents for semiconductor processing and processing processes. The composition mainly comprises a matrix mixture capable of generating supercritical liquid through laser induction, a coolant, a wetting agent, a defoaming agent and water. During use, the protective liquid film composition is spin-coated on a processed surface of a material, and laser permeates a liquid film, then irradiates the material surface and induces the composition to generate the supercritical liquid which can effectively remove chippings generated by laser ablation, melts accumulated around an action area and a crater height.

Owner:科纳瑞雅(昆山)新材料科技有限公司

Air extraction device and method for removing particles carried by an air flow

ActiveCN102859201AEasy to separateReduce current consumptionDomestic stoves or rangesPump componentsImpeller

Owner:BERLING

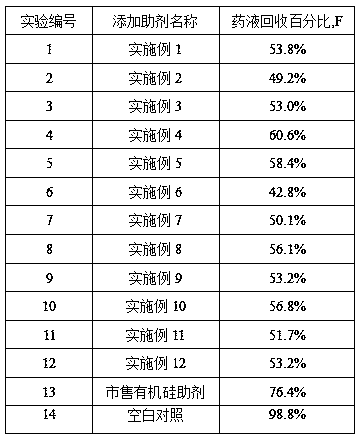

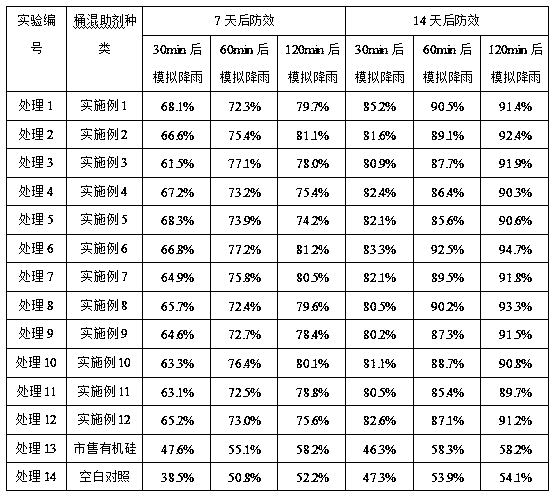

Rainwash resistant pesticide adjuvant composition and application thereof

The invention discloses a rainwash resistant pesticide adjuvant composition and application thereof. The rainwash resistant pesticide adjuvant composition comprises, by weight, 1-10% of polysaccharide, 5-20% of polyquaternium, 10-40% of alkyl-polyoxyethylene ester, 10-20% of emulsifier and the balance being solvents. The pesticide adjuvant can be used as a spray additive of herbicides, has excellent hydrophilcity, and has good rainwash resistance function to the herbicides, especially the water-soluble herbicides.

Owner:四川省乐山市华莱利科技有限公司

Efficient and practical evaporator

ActiveCN104096369AAchieve hybridEvenly distributedRotary stirring mixersEvaporator accessoriesEngineeringScrew thread

An efficient and practical evaporator comprises a heating chamber and an evaporating chamber, wherein the evaporating chamber is located above the heating chamber; a stirring device is arranged in the heating chamber and comprises a motor and a rotating shaft, a turning block is arranged at each of the upper half part and the lower half part of the rotating shaft and connected with a cross bar, three blades are fixed at the tail end of each cross bar, the tail end of one blade is linearly connected with the cross bar, and the other two blades are vertically and symmetrically arranged and perpendicularly connected with the cross bar, so that a liquid is sufficiently and uniformly mixed, solute is uniformly distributed, and a feed liquid is not easy to escape; and an steam outlet of the evaporating chamber is in a circular truncated cone shape, and zigzag threads are formed in the steam outlet, so that crystal can be effectively prevented from being taken away by steam, the crystal interception effect is good, and the product yield is improved.

Owner:JIANGSU HUATAI HEAVY IND EQUIP

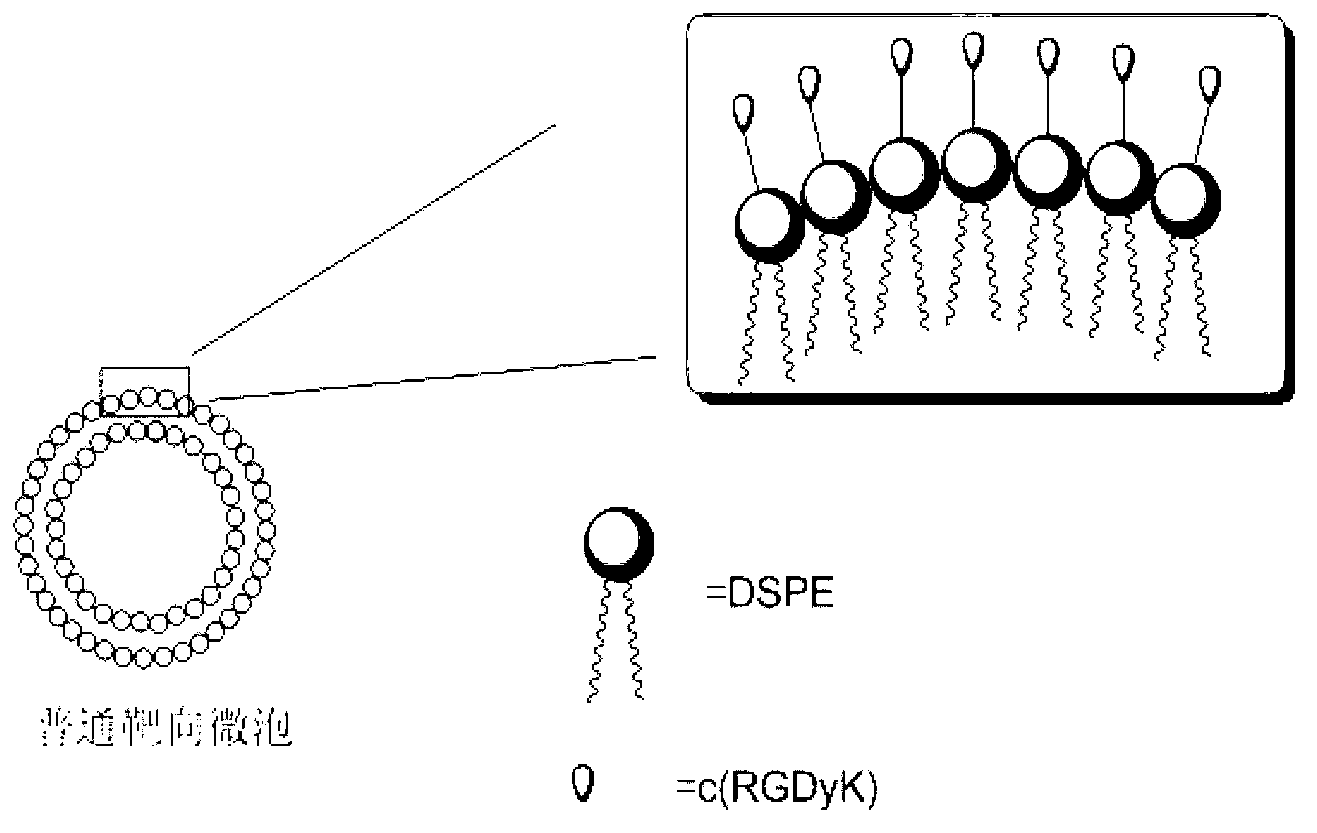

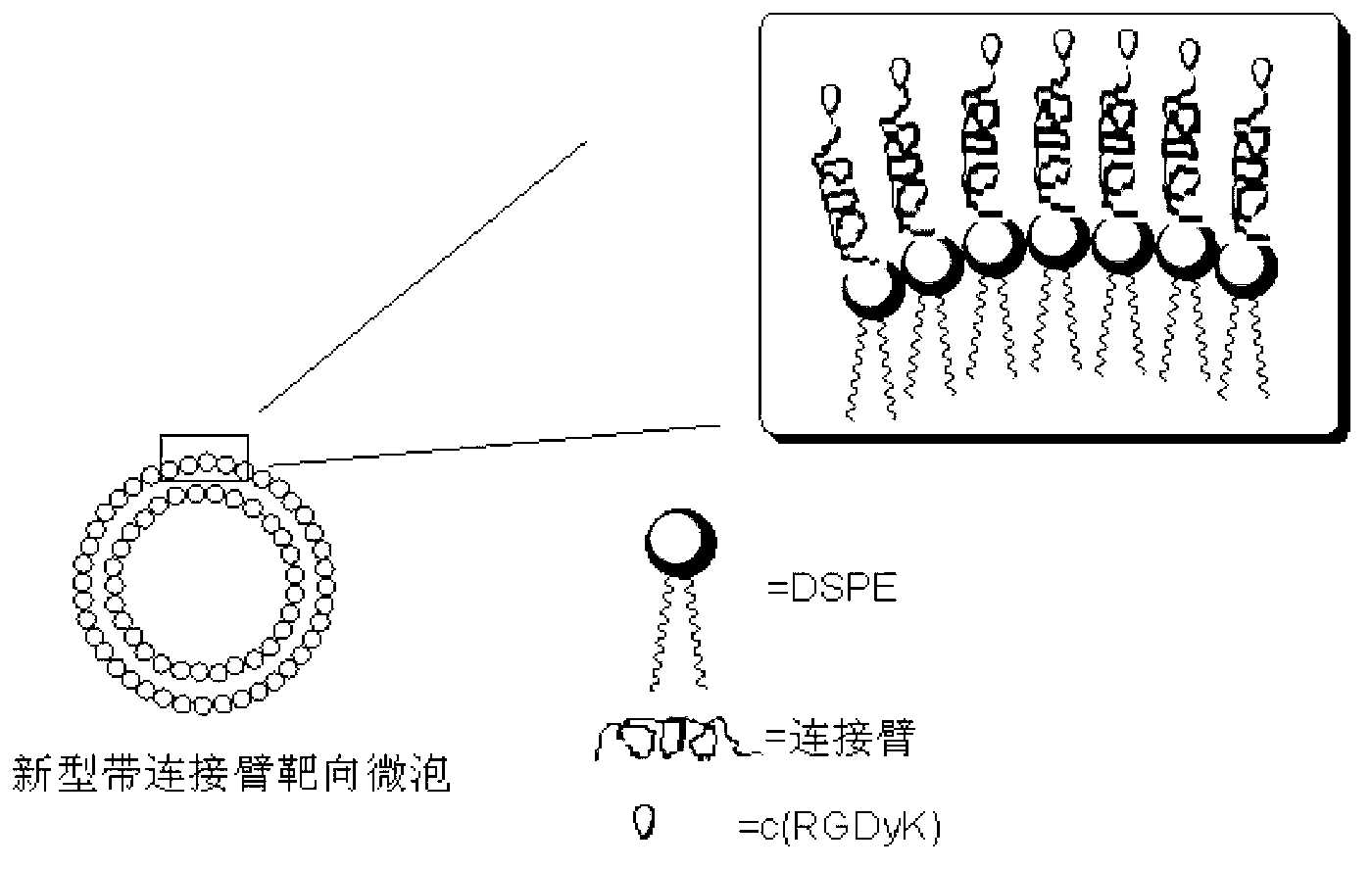

Targeted micro-bubble contrast agent and preparation method thereof

InactiveCN103230605AMolecular fragments are smallIncreased activityGenetic material ingredientsEchographic/ultrasound-imaging preparationsTarget organDspe peg

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV +1

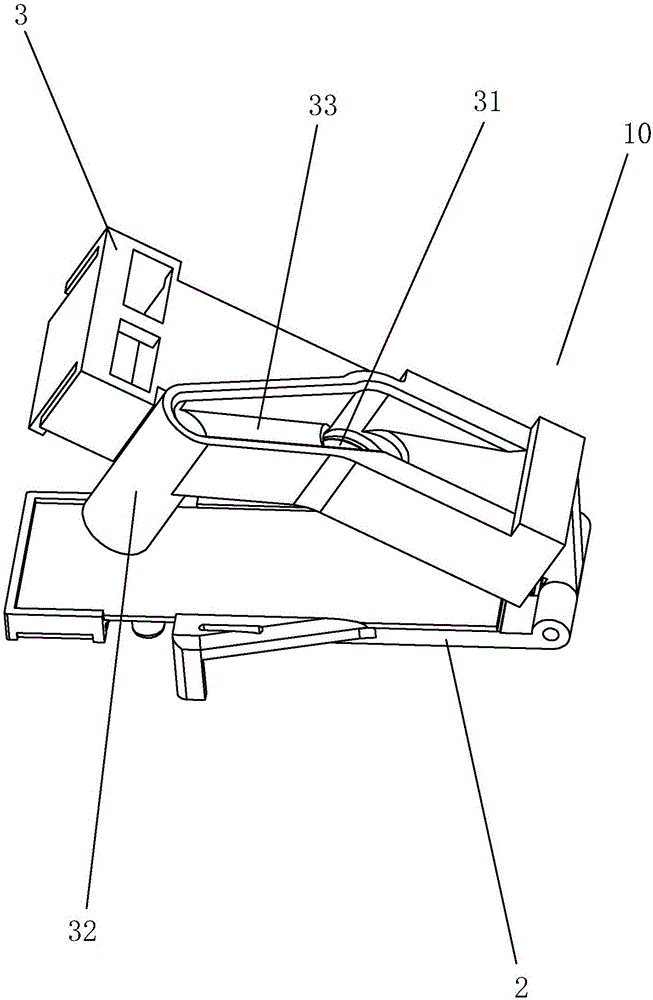

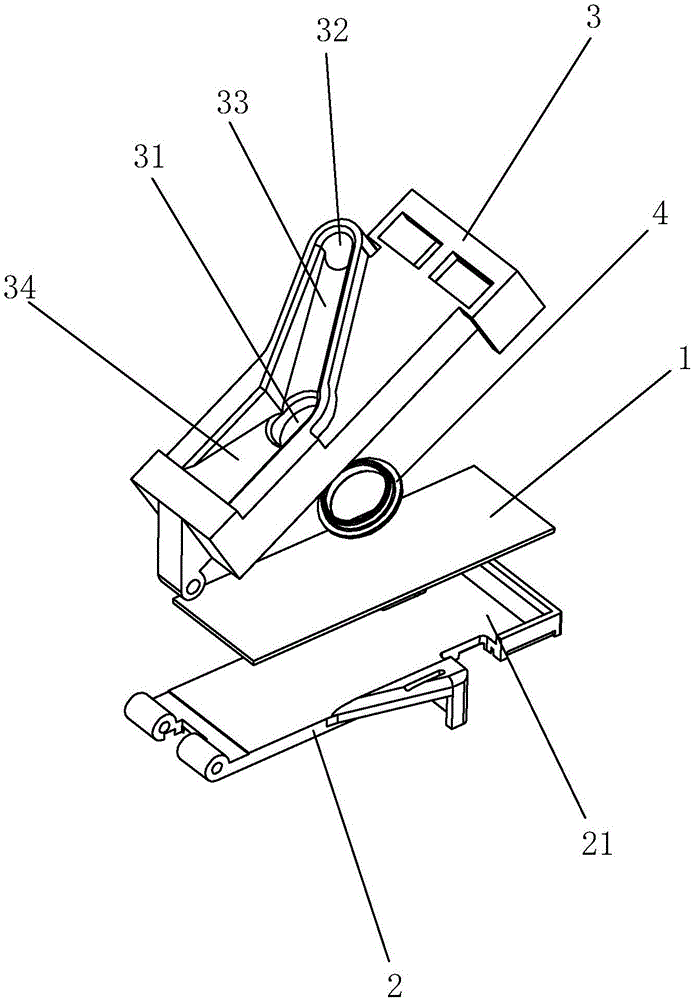

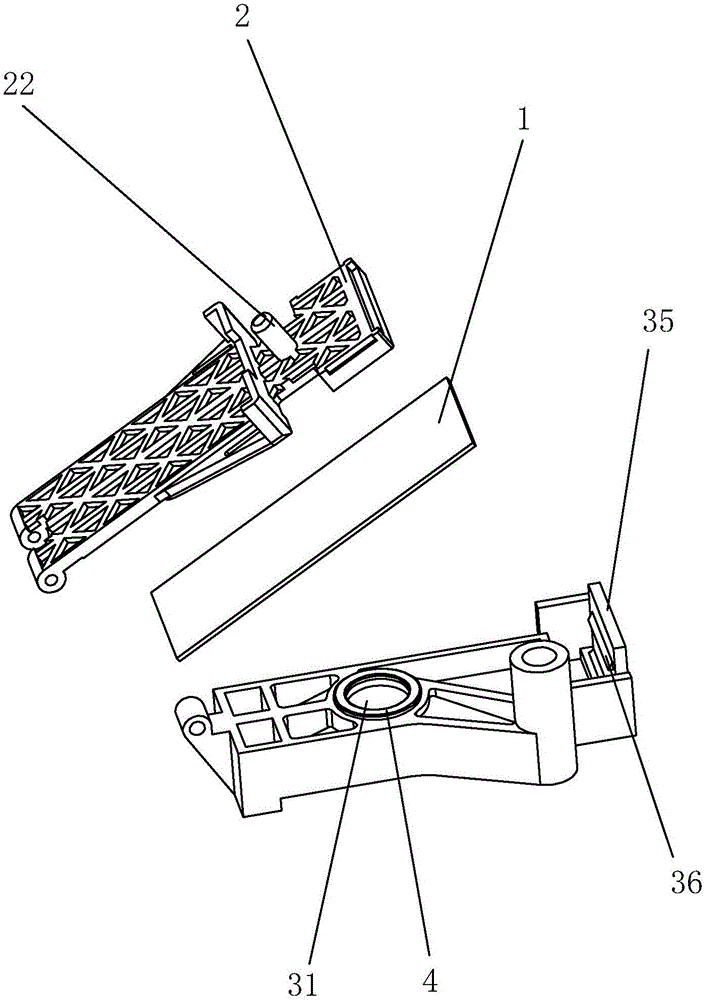

Clamp for dyeing of cell glass slide

PendingCN106769352AAvoid damageAchieve separationPreparing sample for investigationGlass slideContamination

The invention discloses a clamp for the dyeing of a cell glass slide. The clamp comprises a bearing member for bearing a cell glass slide; and a pressing member, which is arranged above the bearing member and is used to tightly press the cell glass slide onto the bearing member; wherein the pressing member is provided with a liquid injection cell, a liquid discharge channel, and a liquid guiding groove, which is arranged between the liquid injection cell and the liquid discharge channel and is upward obliquely arranged. The clamp can quickly separate a dyeing reagent and cells, the production period is shortened, the using amount of dyeing reagent is reduced, and the cross contamination caused by a next reagent for soaking the cells is avoided. The structure of the clamp is simple and the performance is reliable.

Owner:GUANGZHOU JIANGYUAN MEDICAL SCI & TECH CO LTD

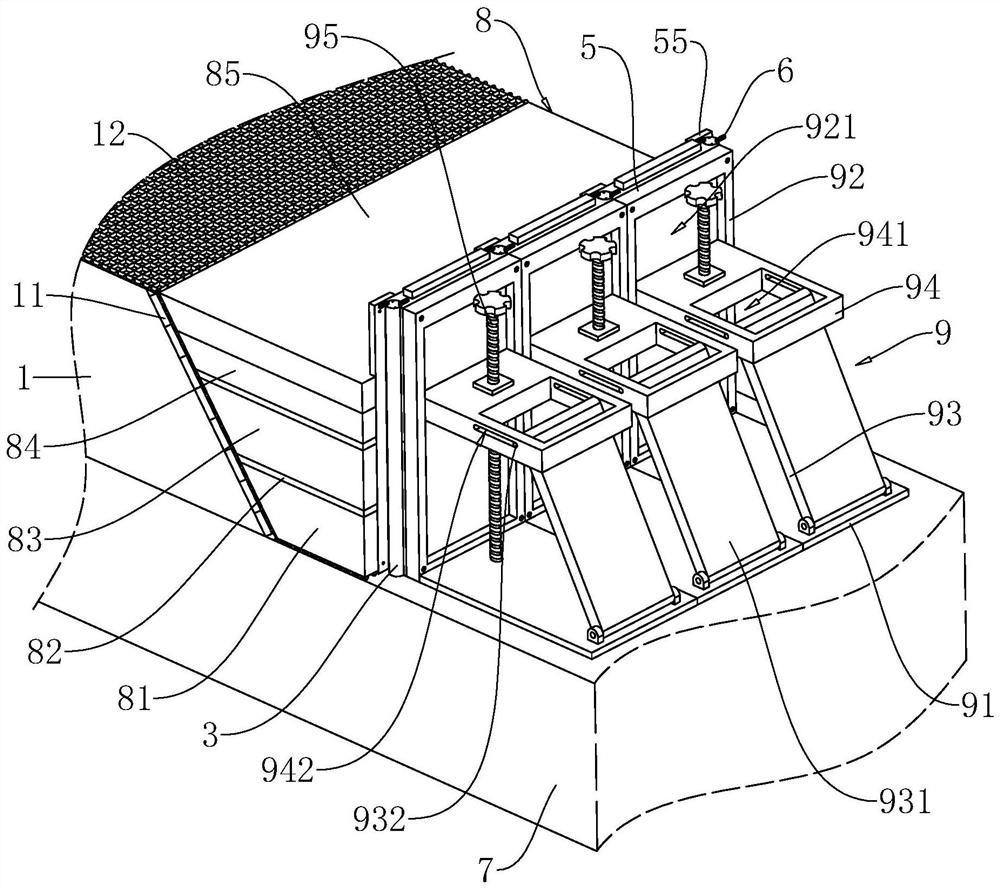

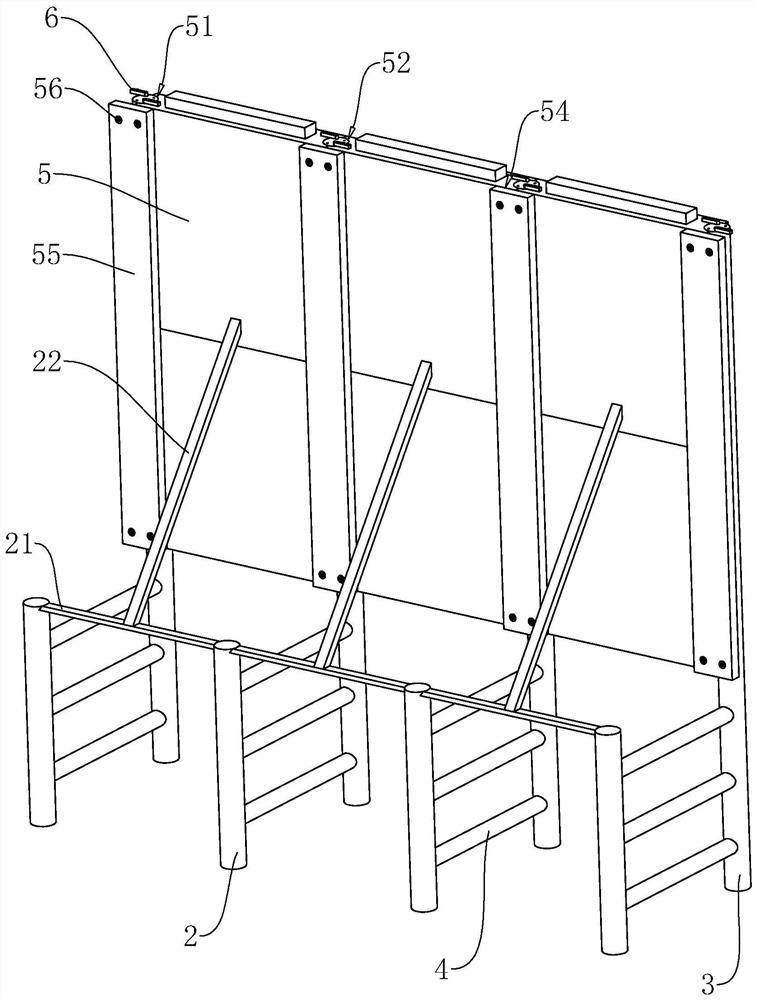

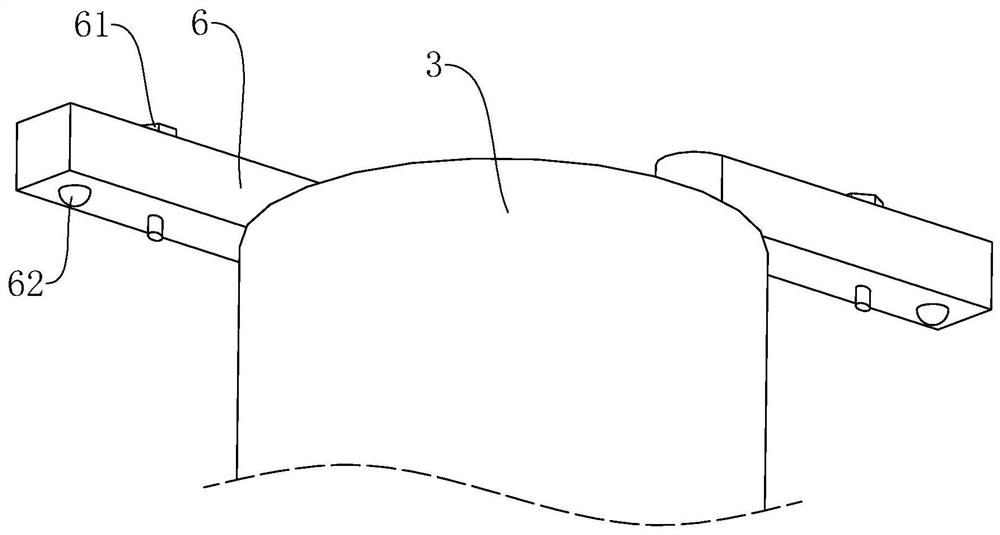

Revetment reinforcing facility and construction method thereof

ActiveCN113417252ABlock positive impactExtended service lifeBreakwatersQuaysStructural engineeringRevetment

The invention relates to a revetment reinforcing facility and a construction method thereof. The revetment reinforcing facility comprises reinforcing piles and fixing piles which are arranged on the side, facing a river channel, of a revetment, wherein the reinforcing piles are located between the revetment and the fixing piles, and the height of the revetment and the height of the reinforcing piles are both lower than the height of the fixing piles; the multiple reinforcing piles and the multiple fixing piles are arranged in the extending direction of the revetment, connecting columns are fixed between the reinforcing piles and the fixing piles close to the reinforcing piles, a positioning plate is detachably connected between any two adjacent fixing piles correspondingly, a buffering frame is connected to the side, away from the revetment, of each positioning plate, and the buffering frame is provided with a buffering inclined surface facing the river channel. The revetment reinforcing facility has the effect of prolonging the service life of the revetment.

Owner:乐清市大禹水利水电工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com