Preparation and application of antibacterial agent slowly released by microcapsule

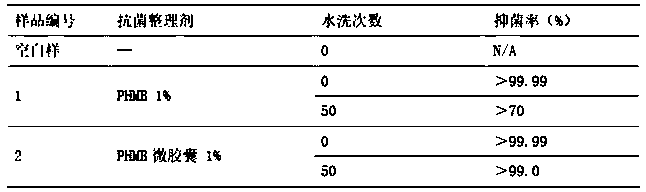

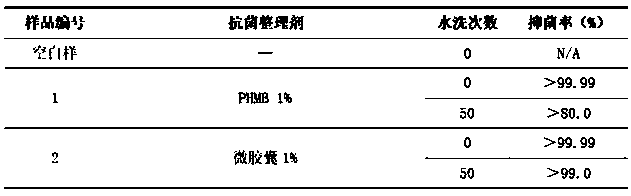

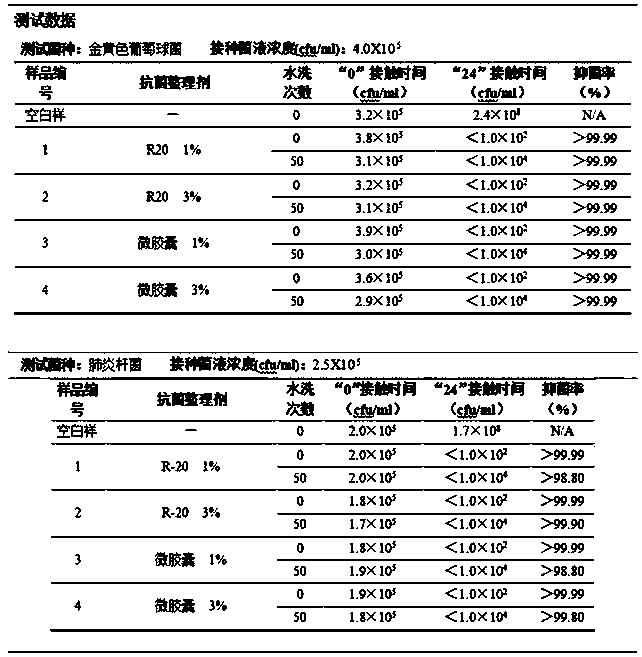

An antibacterial agent and microcapsule technology, which is applied in the field of preparation and application of antibacterial agents, can solve the problems of electrostatic adsorption of bactericidal components and fabrics, unsatisfactory application effect, and can not withstand washing, so as to maintain long-term antibacterial effect and improve washing resistance. The number of times, the effect of increasing the antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An embodiment provided by the invention: preparation and application of a microcapsule slow-release antibacterial agent, the parts by weight of each raw material are:

[0027] 30 parts of polyhexamethylene biguanide hydrochloride (PHMB), 13 parts of octadecyl silicone emulsifier, 2 parts of enzyme and 100 parts of water.

[0028] A preparation method, comprising the steps of:

[0029] S1. Add a certain concentration of polyhexamethylene biguanide hydrochloride (PHMB) into the water at high temperature, keep the temperature at 20-30 degrees, and stir evenly, control the speed at 60-80 rpm, fully mix and dissolve;

[0030] S2. Add octadecyl silicone emulsifier to the solution prepared in S1, stir evenly, control the rotation speed, and confirm that there is no stratification;

[0031] S3, adding enzyme to the emulsion prepared in S2, controlling the rotation speed, and avoiding demulsification;

[0032] S4. Add essence to the emulsion prepared in S3, stir evenly, contro...

Embodiment 2

[0034] An embodiment provided by the invention: preparation and application of a microcapsule slow-release antibacterial agent, the parts by weight of each raw material are:

[0035] 20 parts of polyhexamethylene biguanide hydrochloride (PHMB), 15 parts of octadecyl silicone emulsifier, 1 part of enzyme and 100 parts of water.

[0036] A preparation method, comprising the steps of:

[0037] S1. Add a certain concentration of polyhexamethylene biguanide hydrochloride (PHMB) into the water at a constant temperature, keep the temperature at 20-30 degrees, stir evenly, control the speed at 60-80 rpm, and fully mix and dissolve;

[0038] S2. Add octadecyl silicone emulsifier to the solution prepared in S1, stir evenly, control the rotation speed, and confirm that there is no stratification;

[0039] S3, adding enzyme to the emulsion prepared in S2, controlling the rotation speed, and avoiding demulsification;

[0040] S4. Add essence to the emulsion prepared in S3, stir evenly, c...

Embodiment 3

[0042] An embodiment provided by the invention: preparation and application of a microcapsule slow-release antibacterial agent, the parts by weight of each raw material are:

[0043] 20 parts of polyhexamethylene biguanide hydrochloride (PHMG), 15 parts of octadecyl silicone emulsifier, 1.5 parts of enzyme and 65 parts of water.

[0044] A preparation method, comprising the steps of:

[0045] S1. Add a certain concentration of polyhexamethylene biguanide hydrochloride (PHMG) into the water at constant temperature, keep the temperature at 20-30 degrees, and stir evenly, control the speed at 60-80 rpm, fully mix and dissolve;

[0046] S2. Add octadecyl silicone emulsifier to the solution prepared in S1, stir evenly, control the rotation speed, and confirm that there is no stratification;

[0047] S3, adding enzyme to the emulsion prepared in S2, controlling the rotation speed, and avoiding demulsification;

[0048] S4. Add essence to the emulsion prepared in S3, stir evenly, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com