Antibacterial active carbon fiber coated by chitosan porous membrane and process for preparing same

The technology of activated carbon fiber and activated carbon fiber felt is applied in the field of antibacterial activated carbon fiber coated with chitosan porous film and its preparation field, and achieves the effects of lasting antibacterial effect, promoting wound healing, and excellent adsorption and flocculation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Preparation of Antibacterial Activated Carbon Fibers

[0018] Weigh 0.5g of chitosan with a molecular weight of 550kD, dissolve it in 50mL of acetic acid solution with a volume fraction of 1%, and prepare a chitosan-acetic acid solution with a concentration of 10g / L, then add 0.1mL of 30% H 2 o 2 solution. Take 1.02g specific surface area as 968m 2 The polyvinyl alcohol-based activated carbon fibers per gram were soaked in the above-mentioned chitosan solution at 60°C for 0.5 hours, the activated carbon fibers were taken out and dried by centrifugation, then soaked in a dilute alkali solution with a mass fraction of 1% and washed until neutral, and centrifuged again After drying, vacuum-dry at 60° C. to constant weight to obtain 1.12 g of antibacterial activated carbon fibers coated with chitosan film.

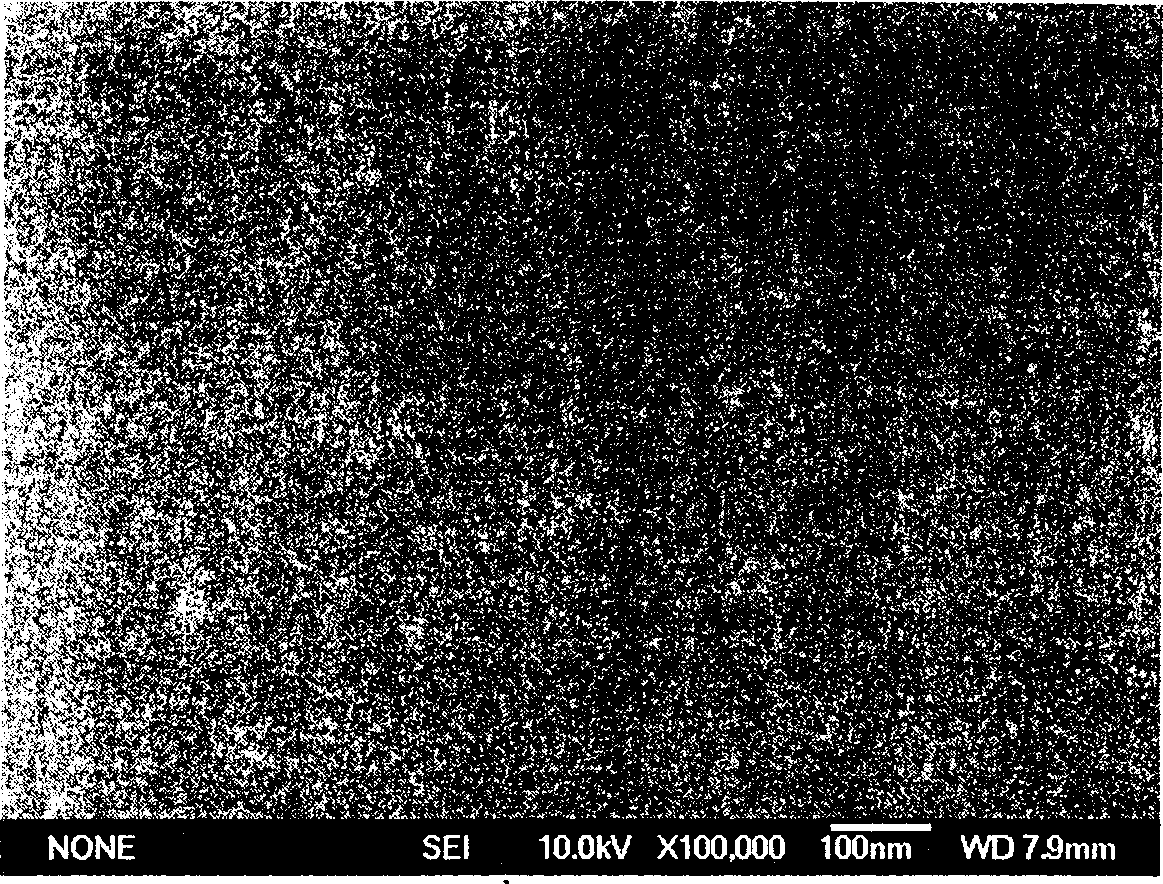

[0019] According to the mass calculation of activated carbon fibers before and after treatment, the weight fraction of chitosan in the obtained chitosan porous me...

Embodiment 2

[0036] Weigh 1.5g of chitosan with a molecular weight of 100kD, dissolve it in 50mL of 1% acetic acid solution by volume fraction, and prepare a chitosan-acetic acid solution with a concentration of 30g / L. Take the specific surface area as 968m 2 The polyvinyl alcohol-based activated carbon fiber of / g is soaked in the above-mentioned chitosan solution according to the same method as in Example 1, to obtain the antibacterial activated carbon fiber coated with chitosan film.

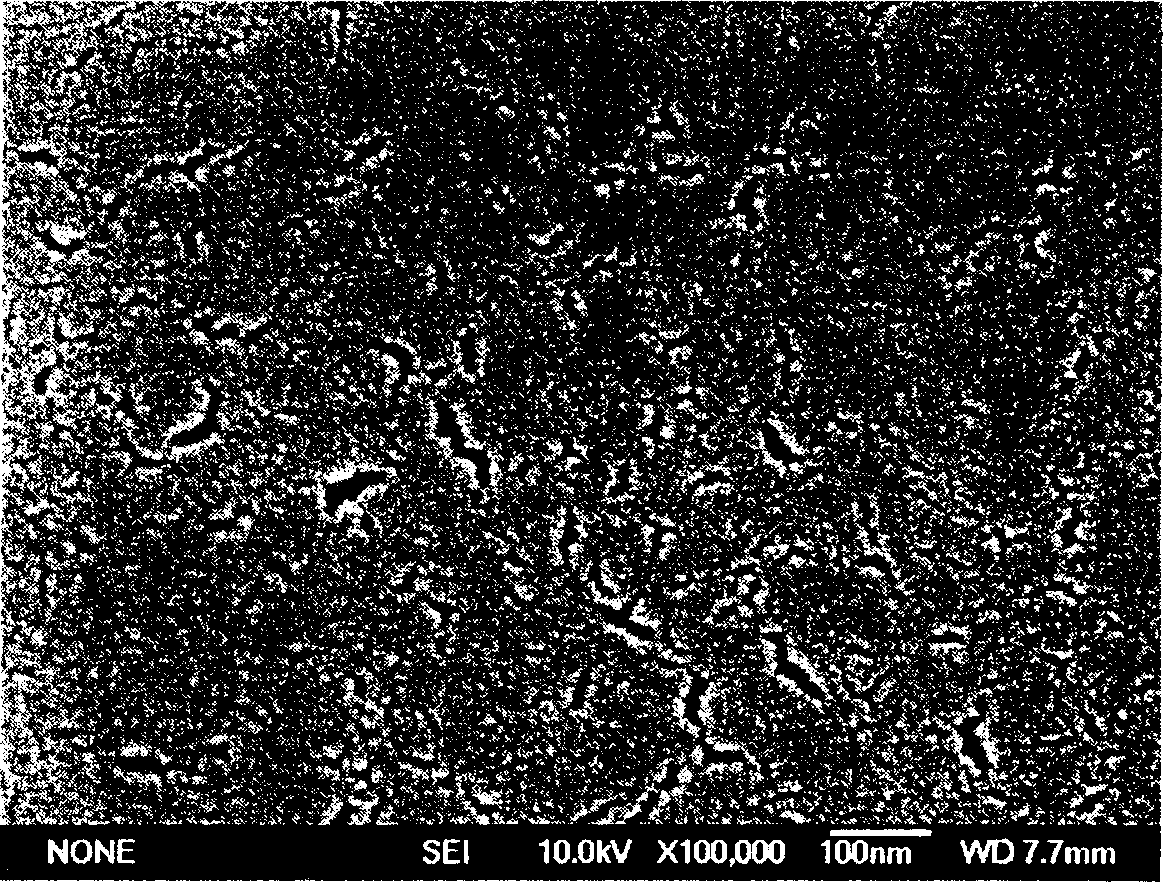

[0037] The weight fraction of chitosan in the obtained antibacterial activated carbon fiber is 5%; By carrying out field emission scanning electron microscopy to the activated carbon fiber surface topography before and after the chitosan porous membrane coating, it can be known that the thickness of the chitosan porous membrane on the fiber is The membrane is covered with slit-shaped holes about 10-50nm in length and 10nm in width.

[0038] According to the antibacterial performance test, when the concen...

Embodiment 3

[0040] Weigh 1.0g of chitosan with a molecular weight of 550kD, dissolve it in 50mL of acetic acid solution with a volume fraction of 1%, and prepare a chitosan-acetic acid solution with a concentration of 20g / L, then add 0.1mL of 30% H 2 o 2 solution. With a specific surface area of 400m 2 The pitch-based activated carbon fiber felt of / g is base material, prepares antibacterial activated carbon fiber felt according to the method identical with embodiment 1.

[0041] The weight fraction of chitosan in the antibacterial activated carbon fiber felt coated with chitosan porous membrane obtained is 29%; by field emission scanning electron microscope observation of the activated carbon fiber felt surface morphology before and after chitosan porous membrane coating, it can be seen that The thickness of the chitosan porous membrane on the antibacterial activated carbon fiber felt is about 2 μm, and the membrane is covered with slit-shaped holes with a length of about 10-30 nm an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com