Graphene microcapsules, intelligent thermoregulation fibers and preparation methods thereof

An ene microcapsule, intelligent temperature regulation technology, applied in the field of materials, can solve the problems of unstable fiber quality, fiber agglomeration, complex process flow, etc., to improve thermal conductivity and heat storage performance, improve dispersion and compatibility, improve smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

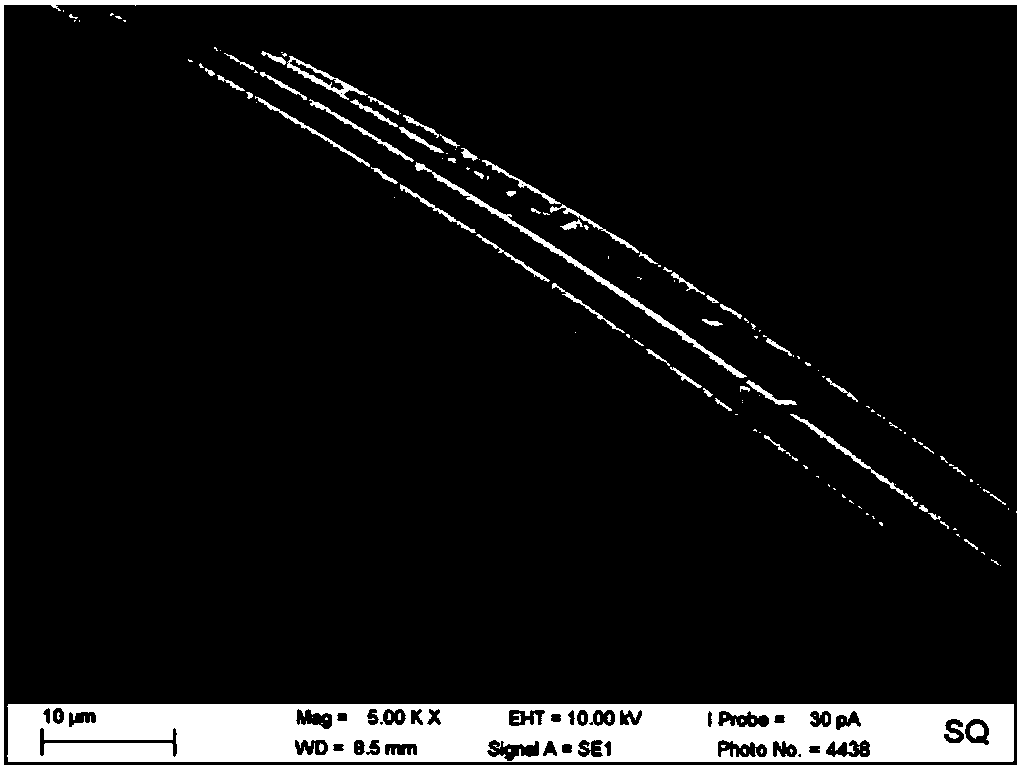

[0064] Preparation of graphene microcapsules: the core material is graphene A, and the shell material is melamine resin.

[0065] The first step is the preparation of melamine prepolymerized aqueous solution: place urea, formaldehyde solution (37wt%) and deionized water in a three-necked flask equipped with a stirrer, thermometer and reflux condenser, stir until the urea is dissolved, and then use triethanolamine The stock solution is adjusted to pH=8-9, melamine is added, and the reaction is kept at 60°C-80°C for 1 hour with stirring at a stirring rate of 450r / min. After dilution, a colorless and transparent aqueous solution of 10wt% melamine prepolymer is obtained.

[0066] The second step is the preparation of graphene aqueous dispersion: ultrasonically disperse graphene A in an aqueous solution (mixing ratio: the mass ratio of graphene material to melamine prepolymer 15:85), and obtain uniformity after centrifugation or standing. The graphene dispersion solution; and then add t...

Embodiment 2

[0071] The difference from Example 1 is only the type of shell material, which is nylon.

[0072] The preparation process is as follows:

[0073] The first step is to prepare the nylon prepolymerization aqueous solution: mix adipoyl chloride and lysine in a mass ratio of 50:8, add 8 times the amount of water to it, adjust the pH of the system between 8-9, and increase the temperature to 25 ~30℃, reaction for 2h; aqueous solution of nylon prepolymer.

[0074] The second step is the preparation of graphene aqueous dispersion: ultrasonically disperse graphene A in an aqueous solution, centrifuge or stand to obtain a uniform graphene dispersion solution; then add a dispersant-Tween 80 (quality graphene 0.5% of A), a stable graphene dispersion is obtained, and the concentration of graphene A is 0.6 wt%.

[0075] In the third step, add the graphene dispersion of the second step to the nylon prepolymer aqueous solution of the first step (the mixing ratio is: the ratio of graphene material t...

Embodiment 3

[0079] The only difference from Example 1 is that the shell material is phenolic resin.

[0080] The preparation process is as follows:

[0081] In the first step, the preparation of the aqueous solution of phenolic prepolymer: take the Resol type phenolic resin prepolymer, add 8 times the amount of water to it, raise the temperature to 70-80°C, and react for 2h; obtain the aqueous solution of the phenolic prepolymer.

[0082] The second step is the preparation of graphene aqueous dispersion: ultrasonically disperse graphene A in an aqueous solution, centrifuge or stand to obtain a uniform graphene dispersion solution; then add a dispersant-Tween 80 (quality graphene 0.5% of A), a stable graphene dispersion is obtained, and the concentration of graphene A is 0.6 wt%.

[0083] In the third step, add the graphene dispersion of the second step to the phenolic prepolymer aqueous solution of the first step (the mixing ratio is: the ratio of graphene material to the phenolic resin prepolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com