Protective liquid film composition for laser-induced supercritical liquid ablation processing, and laser cutting process

A laser-induced, supercritical technology, applied in semiconductor/solid-state device manufacturing, coating, electrical components, etc., can solve the problem that the protective film has no obvious improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

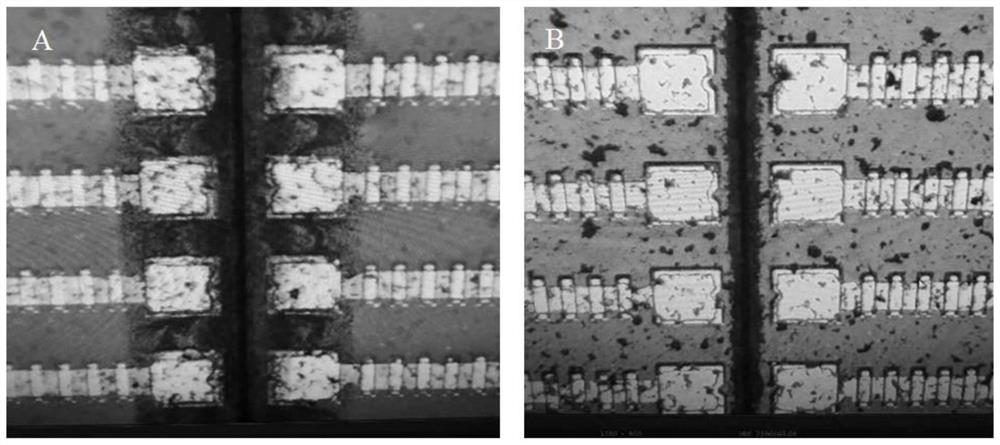

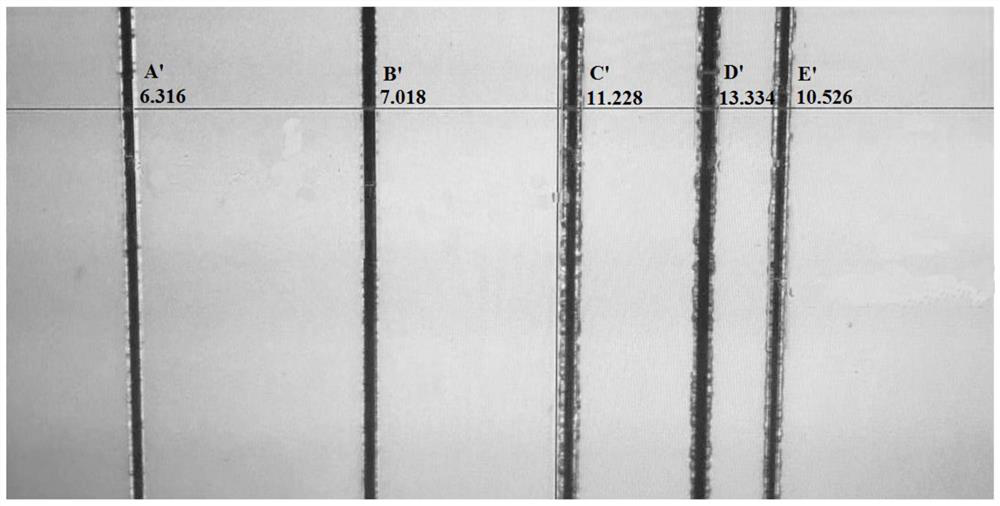

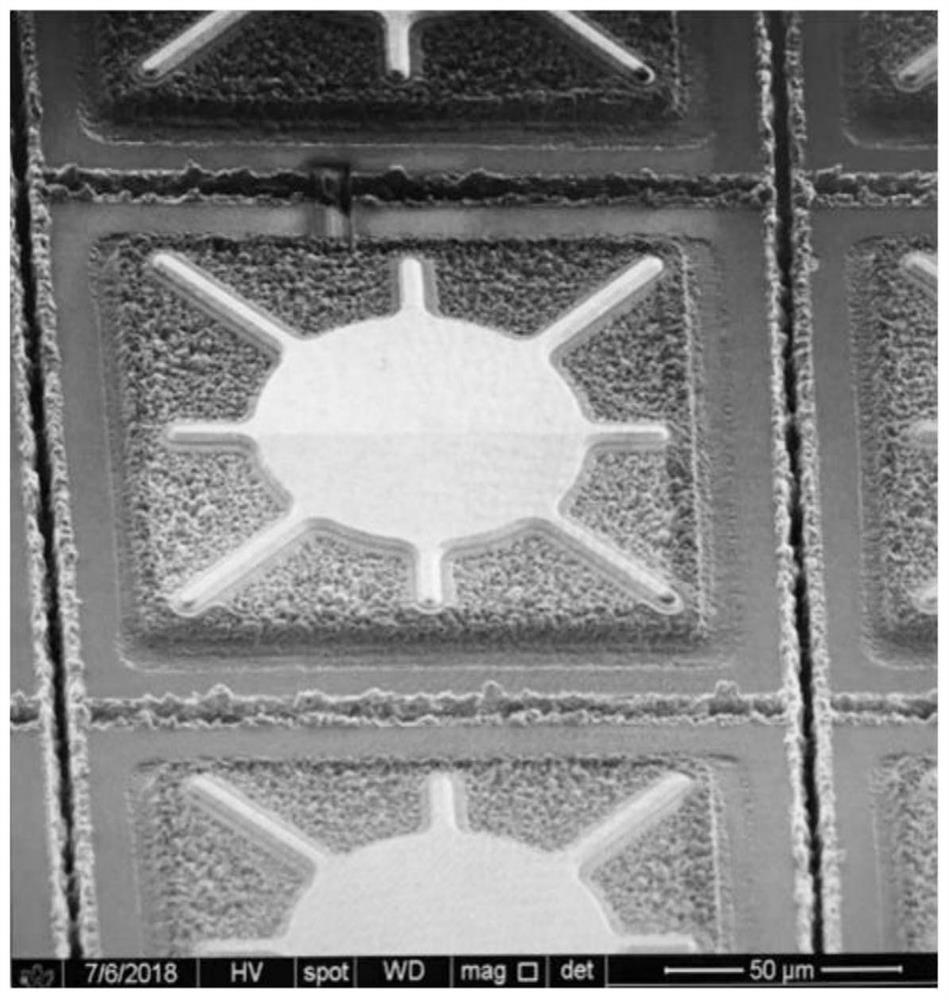

Image

Examples

Embodiment Construction

[0032] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0033] According to the formula composition of each specific embodiment and comparative example recorded in the following table 1, the matrix mixture, coolant, wetting agent, and defoamer capable of laser-induced generation of supercritical liquid are dropped into a mixing device provided with a stirrer After mixing with water, stir at room temperature at a speed of 500 rpm for 1 hour to manufacture a wafer protective film or protective liquid film composition for laser dicing.

[0034] Table 1 specific embodiment and comparative example compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com