Method for improving gasifying dephosphorization effect through bottom-blowing powder spraying of converter

A converter bottom blowing and powder spraying technology is used in the improvement of process efficiency, manufacturing converters, lime production, etc. It can solve problems such as unachieved, and achieve the effect of improving operating conditions, making full use of thermal energy, and promoting kinetic conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

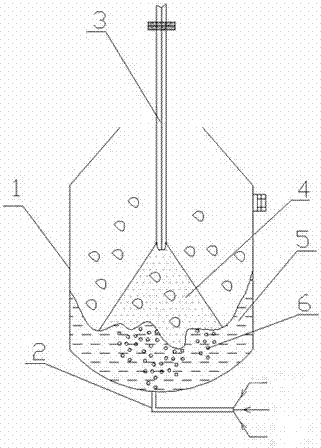

[0030] See figure 1 After the tapping of 65t converter 1 in a steel plant, the basic state of converter slag was observed and judged, and the slag splashing operation was started. At the same time, the gasification dephosphorization powder 6 was injected into the converter through the carrier gas nozzle and bottom blow pipe 2 at the bottom of the converter , The gasification dephosphorization powder 6 has a particle size of 600 mesh, the main component is a carbonaceous agent, and the carbonaceous agent is a carbon powder. At the same time, lime powder is added. The weight ratio of carbon powder: lime powder is 17:3. The mass accounts for 85% of the total mass of gasification dephosphorization powder.

[0031] The carrier gas pressure at the bottom of the converter is controlled to 1.8MPa, and the powder-to-gas ratio of the gasification dephosphorization powder 6 to the nitrogen gas 4 is 1.3, so that the gasification dephosphorization powder 6 will be heated by the carrier gas pa...

Embodiment 2

[0034] See figure 1 After the tapping of 65t converter 1 in a steel plant, the basic status of converter slag was observed and judged, and the slag splashing operation was started. At the same time, gasification dephosphorization powder 6 was sprayed into converter 2 through the carrier gas nozzle at the bottom of converter 1 Phosphorus powder 6 has a particle size of 500 mesh, the main component is carbonaceous, the carbonaceous composition is carbon powder and coke powder, and lime powder is added. The quality of carbonaceous agent accounts for 90% of the total mass of gasification dephosphorization agent. The weight ratio of carbon powder: coke powder: lime powder is 5:4:1. The carrier gas pressure at the bottom of the converter is controlled to 2.4 MPa, and the powder-to-gas ratio of the gasification dephosphorization powder 6 to the nitrogen gas 4 is 1.0, so that the gasification dephosphorization powder will be heated by the carrier gas passing through the converter slag ...

Embodiment 3

[0037] See figure 1 After tapping from a 65t converter in a steel plant, observe and judge the basic state of converter slag, start the slag splashing operation, and at the same time spray gasification dephosphorization powder into the converter through the carrier gas nozzle at the bottom of the converter, with a particle size of 450 mesh. The main component is carbonaceous agent, which is coke powder and anthracite, and lime powder and magnesium oxide powder are added. The quality of carbonaceous agent accounts for 80% of the total mass of gasification dephosphorization agent. Coke powder: anthracite: The weight ratio of lime powder: magnesium oxide powder is 4:4:1:1. Control the bottom blowing carrier gas pressure of the converter to 3.2MPa, and the powder-to-gas ratio of gasification dephosphorization powder 6 to nitrogen 4 to 0.7, so that the gasification dephosphorization powder will interact with the hot molten slag in the converter under the effect of the carrier gas pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com